Spinneret plate

A spinneret and the other end face technology is applied in the field of round-hole spinnerets, which can solve the problems of high production cost and complicated spinning process, and achieve the effects of reasonable distribution, enhanced penetration rate, and guaranteed cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

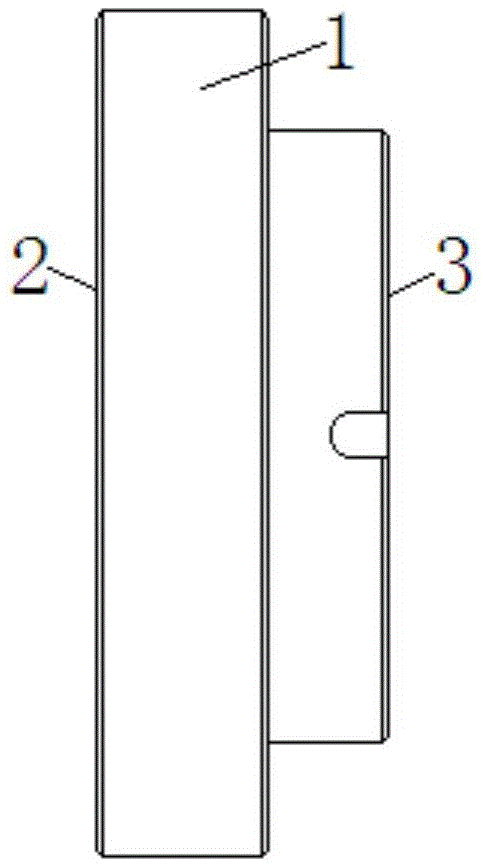

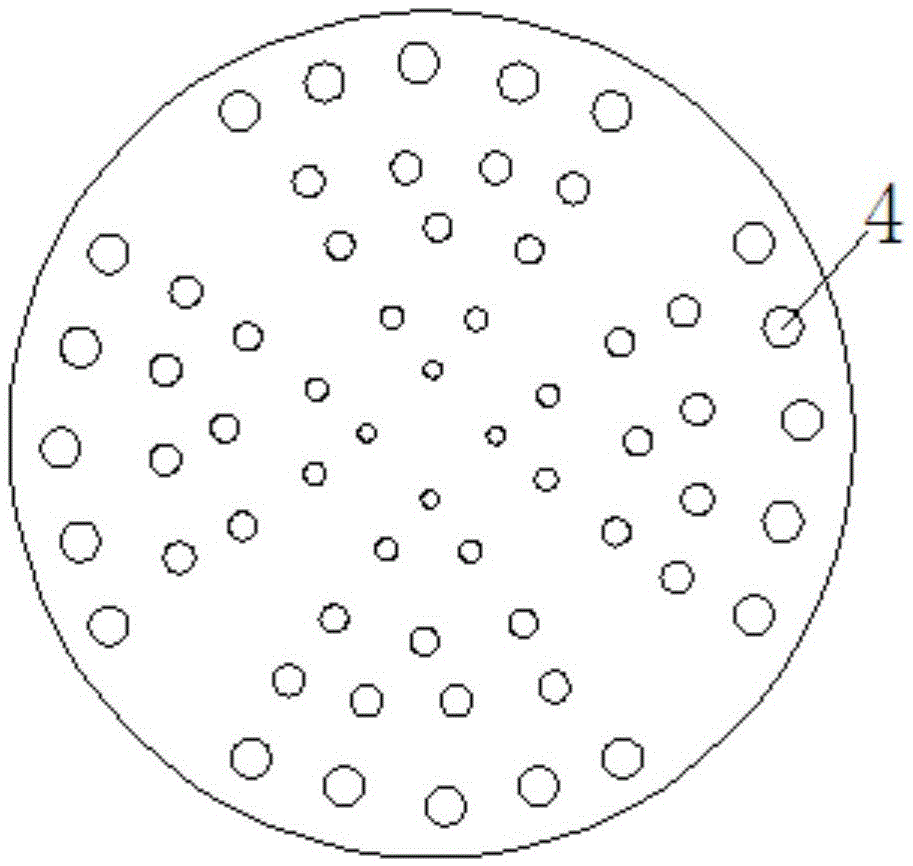

[0011] like figure 1 and figure 2 Shown, a kind of spinneret of the present invention, it comprises spinneret body 1, and described spinneret body 1 is circular, and the diameter of described spinneret body 1 is 180mm, and described spinneret One end surface of the body 1 is the feed surface 2, and the other end surface is the discharge surface 3, and the spinneret microhole 4 is provided on the spinneret body 1, and the spinneret microhole 4 is circular, and the spinneret microhole 4 is circular. The length-to-diameter ratio is 1.2-2.2. There are 60 spinneret microholes 4 on the spinneret body 1. They are divided into four groups of "V"-shaped structures, and each group of "V"-shaped structures is from the inner ring to the outer ring. The number of 4 spinneret microholes in the ring is 1, 2, 3, 4 and 5 respectively, and the diameters of the 4 spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com