Agricultural microbial agent microcapsule based on cell membrane mimicking and preparation method thereof

A technology of agricultural microorganisms and cell membranes, applied in the field of microorganisms, can solve problems such as unfavorable industrialization and application of microcapsule products, poor uniformity of microcapsule size, and destruction of microbial agents, so as to enhance the antioxidant capacity of plants, alleviate damage, and prolong the lifespan of plants. The effect of validity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A, the preparation of the core material (microbial cells) and the wall material mixture, that is, the continuous phase: Pseudomonas stutzeri (Pseudomonas stutzeri) CCTCC NO.M209107, sterilized γ-polyglutamic acid, xanthan gum and Tris / HCl buffer solution (pH 7.4), mix thoroughly; the total number of bacterial colonies of Pseudomonas stutzeri in Tris / HCl buffer solution is 10 10 cfu / mL, the mass volume ratio of γ-polyglutamic acid and Tris / HCl buffer solution is 0.5g / 100mL; the mass volume ratio of xanthan gum and Tris / HCl buffer solution is 0.1g / 100mL;

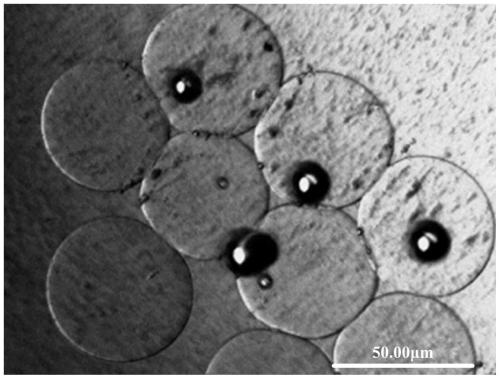

[0041] B. Add a certain amount of dopamine into the above mixed solution (the mass volume ratio of dopamine to Tris / HCl buffer solution is 0.02g / 100mL), stir evenly, adjust the pH of the mixed solution to 8.5, and stir at 500rpm for 12h at room temperature. Dopamine is polymerized under alkaline conditions to obtain microspheres, which are dispersed in the continuous phase solution; the collected microspheres are washe...

Embodiment 2

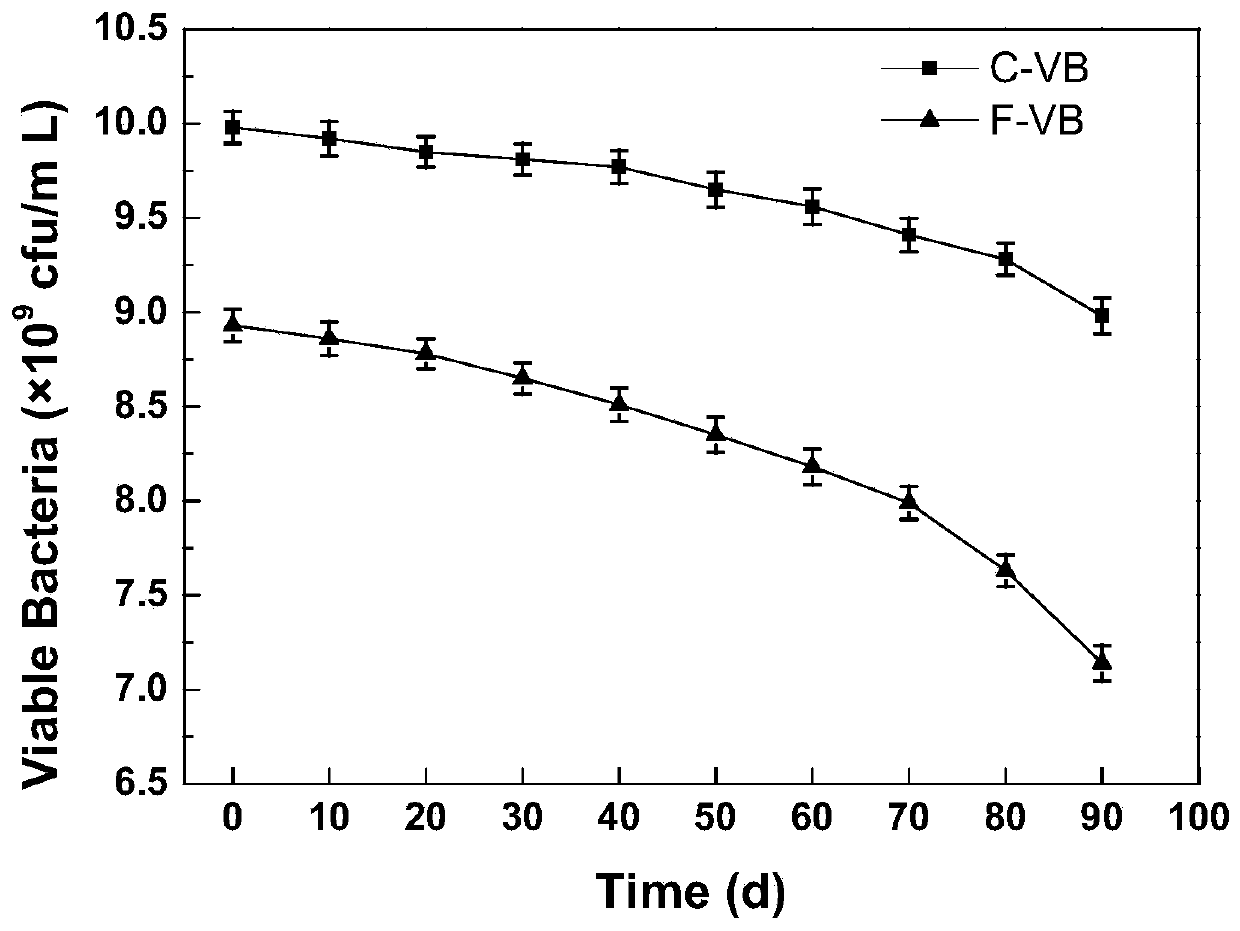

[0045] A, the preparation of the core material (microbial cells) and wall material mixture, i.e. the continuous phase: Streptomyces lydicus (Streptomyces lydicus) CGMCC No.16840, sterilized γ-polyglutamic acid, seaweed polysaccharide and Tris / HCl buffer solution (pH 7.4), fully mixed; the total number of bacterial colonies of Streptomyces lydidi in Tris / HCl buffer solution is 9 × 10 9 cfu / mL, the mass volume ratio of γ-polyglutamic acid to Tris / HCl buffer solution is 1.0g / 100mL; the mass volume ratio of seaweed polysaccharide to Tris / HCl buffer solution is 0.5g / 100mL;

[0046] B. Add a certain amount of dopamine into the mixed solution (the mass volume ratio of dopamine to Tris / HCl buffer solution is 0.04g / 100mL), stir evenly, adjust the pH of the mixed solution to 8.5, and stir at 500rpm for 12h at room temperature. Dopamine is polymerized under alkaline conditions to obtain microspheres, which are dispersed in the continuous phase solution; the collected microspheres are was...

Embodiment 3

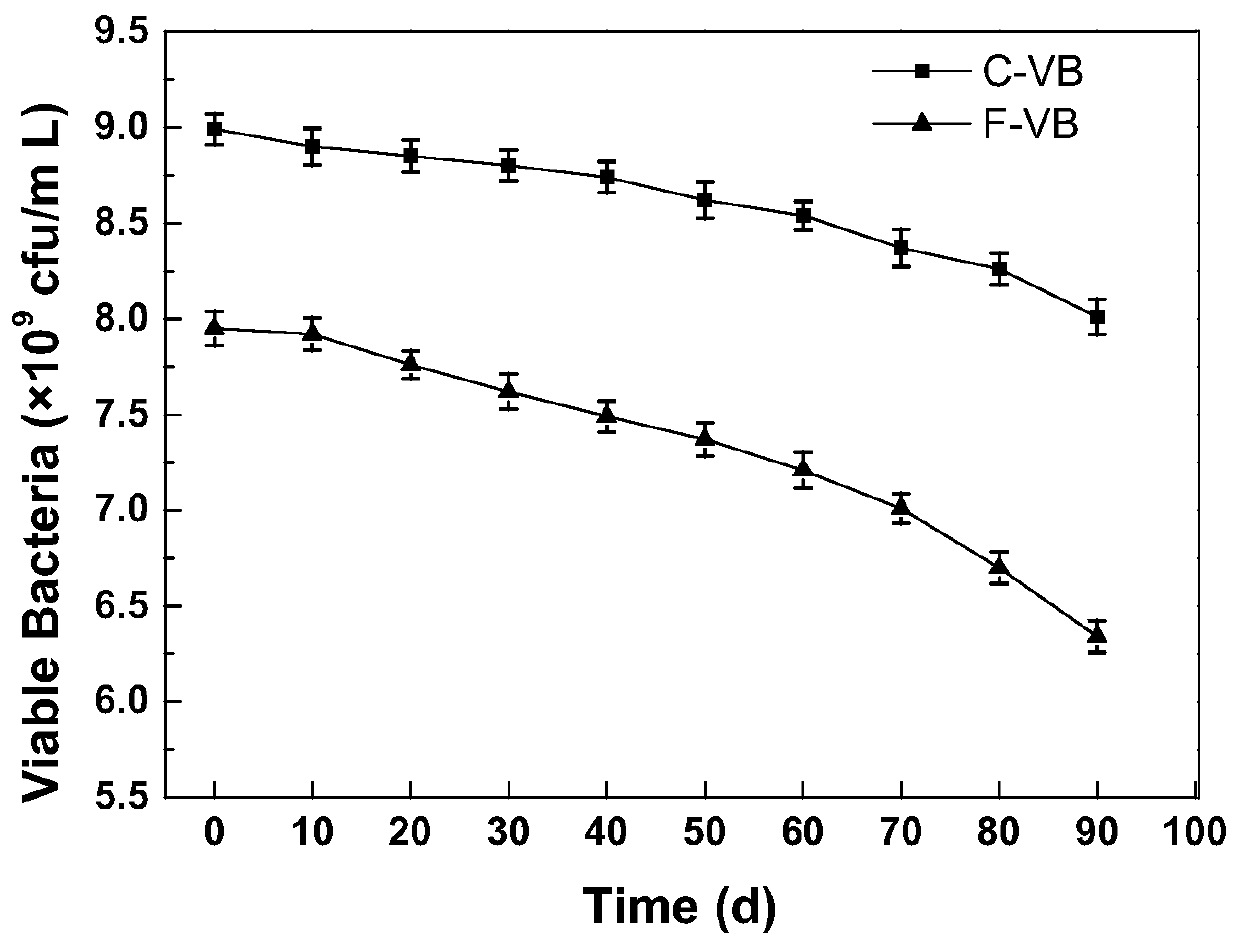

[0049] A, the preparation of the core material (microbial cell) and wall material mixture, that is, the continuous phase: Penicillium aspenicillium (P.asturianum) CGMCC No.17198, sterilized γ-polyglutamic acid, chitosan and Tris / HCl Buffer solution (pH 7.4), mix thoroughly; the total number of bacterial colonies of Penicillium aspenicillium in Tris / HCl buffer solution is 8×10 9 cfu / mL, the mass volume ratio of γ-polyglutamic acid and Tris / HCl buffer solution is 1.5g / 100mL; the mass volume ratio of chitosan and Tris / HCl buffer solution is 1g / 100mL;

[0050] B. Add a certain amount of dopamine into the mixed solution (the mass volume ratio of dopamine to Tris / HCl buffer solution is 0.05g / 100mL), stir evenly, adjust the pH of the mixed solution to 8.5, and stir at 500rpm for 12h at room temperature. Dopamine is polymerized under alkaline conditions to obtain microspheres, which are dispersed in the continuous phase solution; the collected microspheres are washed 5 times with Tris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com