Preparation method of intra-fibrous biomimetic mineralized collagen membrane capable of promoting osteogenic differentiation of cells

A biomimetic mineralization and osteogenic differentiation technology, applied in tissue regeneration, medical science, prostheses, etc., can solve problems such as bionics, achieve good cell adhesion, good biocompatibility, and promote cell osteogenic differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

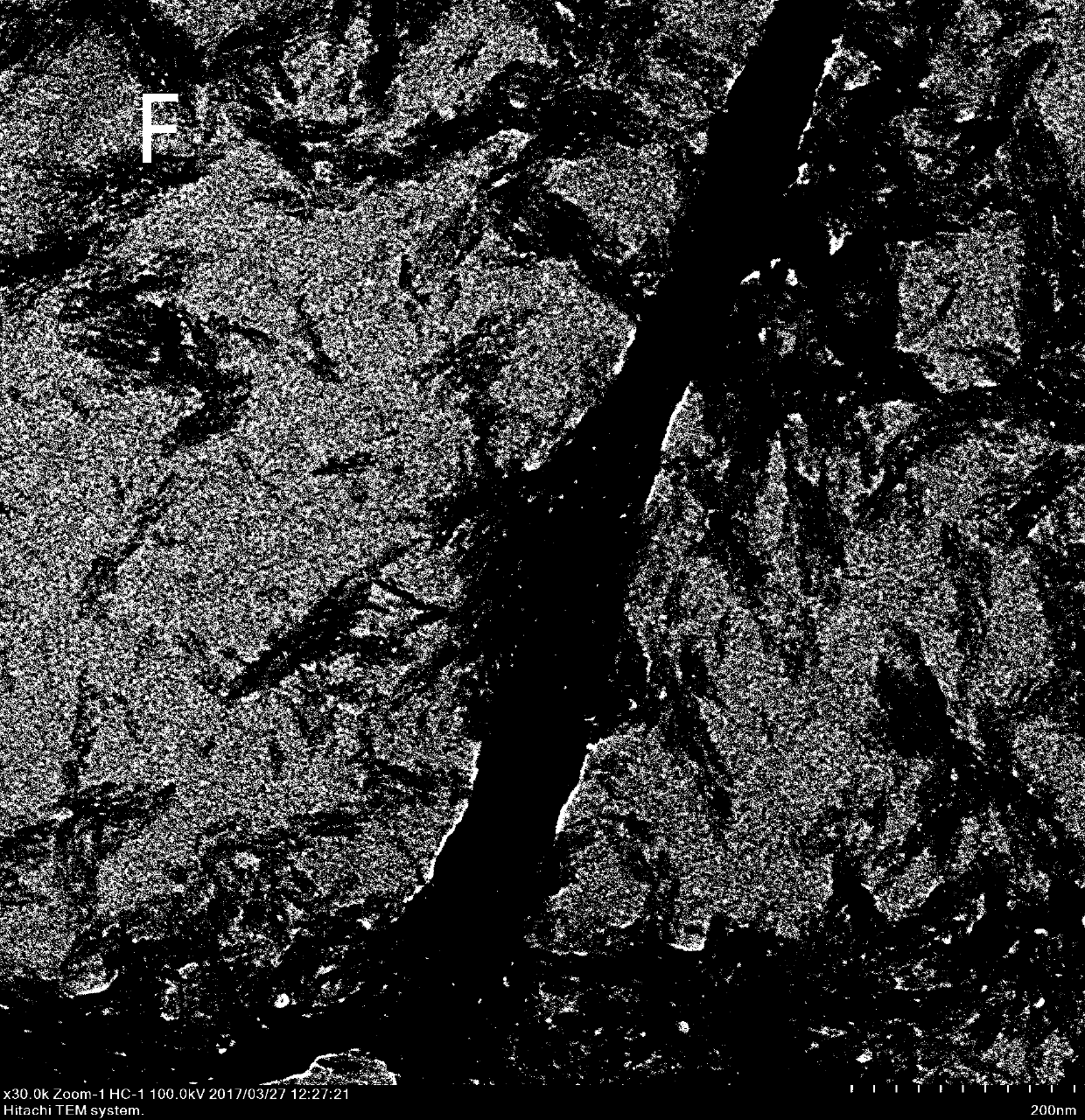

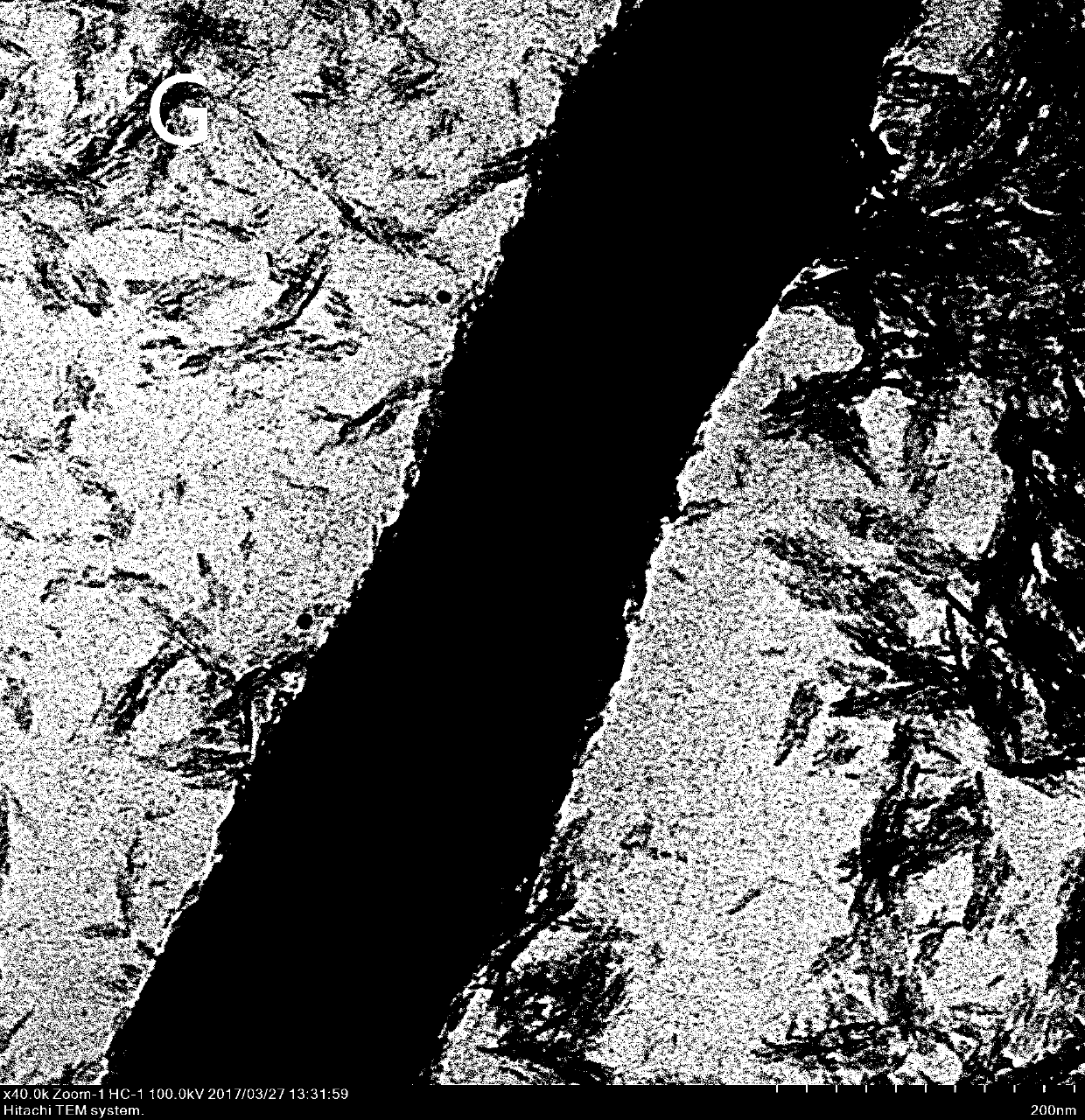

[0037] The specific method for preparing the type I collagen film of biomimetic mineralization is:

[0038] Dissolve the lyophilized powder of calf epidermis in 0.1mol / L acetic acid solution (pH=2.5) to prepare a 3-5g / L collagen solution, store it at 4°C for 24 hours and use it within three months. Pour the collagen solution into a prefabricated mold and put it into a closed container containing 1% ammonia water. After neutralizing for 4 hours, remove it and put it in a 36-38°C incubator to continue culturing for 20 hours. During this process, the collagen completes self-assembly and becomes Gel-like. In order to stabilize the collagen structure, 0.025% glutaraldehyde was used for cross-linking for 1 h. At this point, the pure collagen gel was prepared. Put the pure collagen gel in the biomimetic mineralization solution and culture it at 37°C for 2 days to 4 days respectively to prepare collagen gels with different degrees of biomimetic mineralization, cool down the collagen ...

Embodiment 1

[0040] (1) The concrete method of synthesizing the biomimetic mineralization liquid containing amorphous calcium phosphate is:

[0041] 8g / L polyacrylic acid was used as a stabilizer for amorphous calcium phosphate, and 400mM glutamic acid solution was used as a remineralization accelerator. At 36°C, use 0.1M disodium hydrogen phosphate aqueous solution with a pH of 9.5±0.1 and 0.2M calcium chloride aqueous solution to make mother liquor; use a 50ml syringe to add calcium chloride aqueous solution at a volume ratio of 1:1 within 30 minutes In the disodium hydrogen phosphate aqueous solution, stir with a magnetic stirrer during the reaction process, and use 0.1M sodium hydroxide solution to control the pH to maintain the interval of 9.5±0.5; so that the final concentration of calcium ions in the prepared biomimetic mineralization solution is 9.0mM , the final concentration of phosphorus ions was 5.0 mM, and the final concentration of glutamic acid was 10 mM. The final concentr...

Embodiment 2

[0045] (1) The concrete method of synthesizing the biomimetic mineralization liquid containing amorphous calcium phosphate is:

[0046] 9g / L polyacrylic acid was used as a stabilizer for amorphous calcium phosphate, and 400mM glutamic acid solution was used as a remineralization accelerator. At 37.5°C, use 0.17M disodium hydrogen phosphate aqueous solution with a pH of 9.5±0.1 and 0.28M calcium chloride aqueous solution to make mother liquor; use a 50ml syringe to add calcium chloride aqueous solution at a volume ratio of 1:1 within 37 minutes In the disodium hydrogen phosphate aqueous solution, a magnetic stirrer is used to stir during the reaction, and a 0.1M sodium hydroxide solution is used to control the pH to maintain the interval of 9.5±0.5; so that the final concentration of calcium ions in the prepared biomimetic mineralization solution is 10.0mM , the final concentration of phosphorus ions was 6.3 mM, and the final concentration of glutamic acid was 75 mM. The final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com