Fiber reinforced concrete and preparation method thereof

A fiber-reinforced concrete technology, applied in the field of concrete, to achieve the effects of increasing compressive strength and flexural strength, excellent compressive strength, increasing crack resistance and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

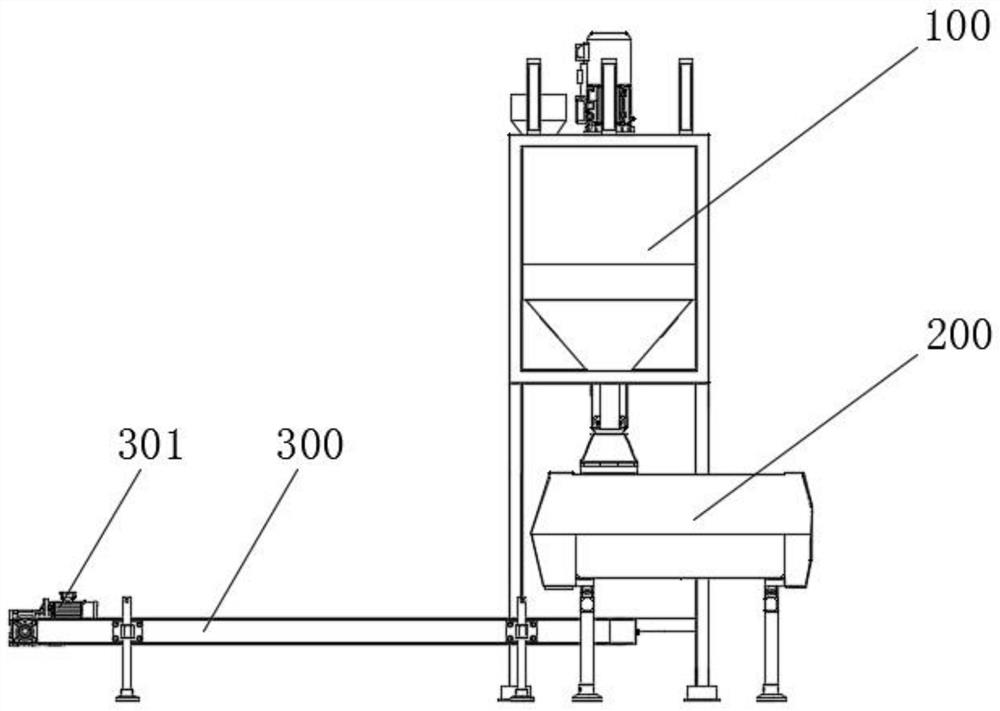

[0045] see Figure 1-9 As shown, the present embodiment is a kind of fiber reinforced concrete, comprising the following components in parts by weight:

[0046] A fiber-reinforced concrete comprising the following components in parts by weight:

[0047] 50 parts of cement, 30 parts of fly ash, 18 parts of mineral powder, 30 parts of water, 140 parts of gravel, 120 parts of river sand, 1 part of water reducing agent, 5 parts of carbon fiber, 1 part of brucite fiber, 1.5 parts of glass fiber , 10 parts of epoxy resin, 5 parts of acrylate emulsion, 0.7 parts of dispersant, 1.8 parts of diatomaceous earth, 0.3 parts of rubber powder;

[0048] The dispersant is methyl cellulose; the water reducer is aliphatic water reducer.

[0049] A method for preparing fiber-reinforced concrete, comprising the steps of:

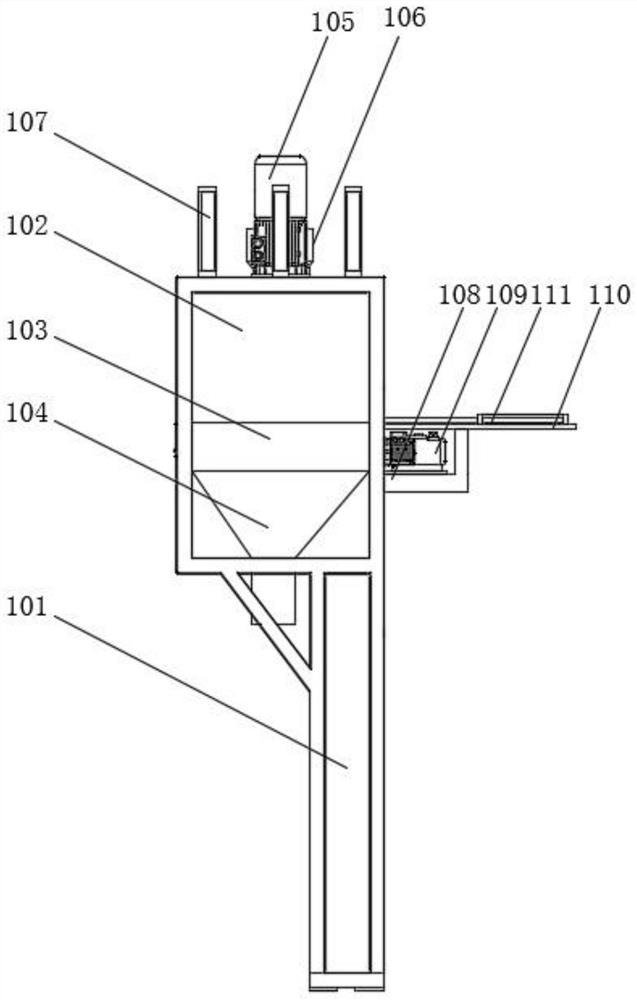

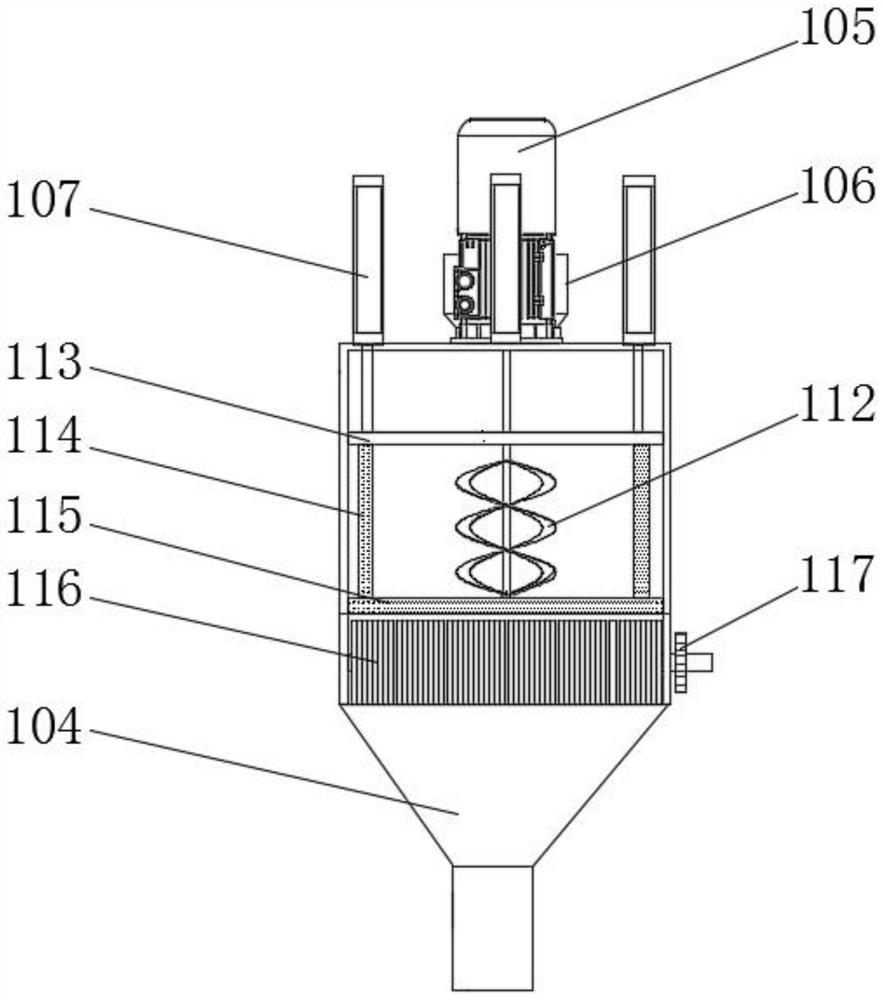

[0050] Step 1: Add the acrylate emulsion to the curing box 102 from the hopper 106 of the reinforced fiber production equipment, then add diatomaceous earth and rubber powde...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that: a fiber-reinforced concrete comprises the following components in parts by weight:

[0059] 55 parts of cement, 35 parts of fly ash, 20 parts of mineral powder, 33 parts of water, 150 parts of gravel, 130 parts of river sand, 2 parts of water reducing agent, 7 parts of carbon fiber, 3 parts of brucite fiber, 2.3 parts of glass fiber , 13 parts of epoxy resin, 8 parts of acrylate emulsion, 1.0 part of dispersant, 2.2 parts of diatomaceous earth, 0.4 part of rubber powder;

[0060] The dispersant is sodium lauryl sulfate; the water reducer is a naphthalene-based water reducer.

[0061]The performance of the fiber-reinforced concrete of Example 2 is detected, and the test results: 7d compressive strength 34.3MPa, 14d compressive strength 48.6MPa, 28d compressive strength 63.7MPa; 7d flexural strength 7.01MPa, 28d flexural strength 11.11 MPa.

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that: a fiber-reinforced concrete comprises the following components in parts by weight:

[0064] 60 parts of cement, 40 parts of fly ash, 22 parts of mineral powder, 36 parts of water, 160 parts of gravel, 140 parts of river sand, 3 parts of water reducing agent, 10 parts of carbon fiber, 5 parts of brucite fiber, 3 parts of glass fiber , 25 parts of epoxy resin, 10 parts of acrylate emulsion, 1.4 parts of dispersant, 2.6 parts of diatomaceous earth, 0.5 part of rubber powder;

[0065] The dispersant is sodium carboxymethyl cellulose; the water reducer is polycarboxylate water reducer.

[0066] The performance of the fiber-reinforced concrete of Example 3 is detected, and the test results: 7d compressive strength 35.6MPa, 14d compressive strength 49.3MPa, 28d compressive strength 65.1MPa; 7d flexural strength 7.16MPa, 28d flexural strength 11.28 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com