Concrete and preparation method thereof

A technology for concrete and construction waste, applied in the field of concrete, can solve the problems of low compressive strength of foam concrete, affecting application and promotion, etc., and achieve the effects of enhancing crack resistance and impermeability, improving waterproof protection period, and enhancing bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

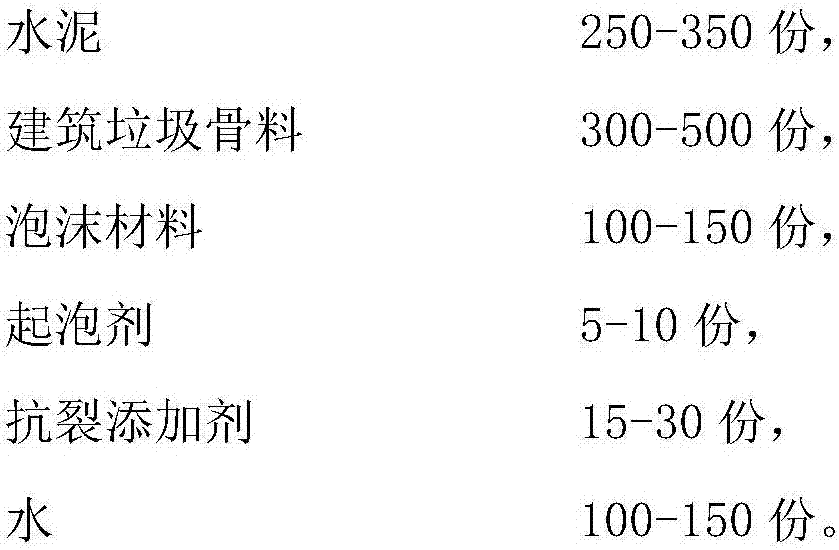

[0022] A kind of concrete is characterized in that, comprises following raw material by weight:

[0023]

[0024] The construction waste includes red bricks, blue bricks, tiles, broken glass, fly ash, asphalt concrete mines and scrap metal.

[0025] The construction waste aggregate is obtained by crushing construction waste to particles with a particle diameter of 1 mm.

[0026] The fly ash is solidified after being blended with calcium salts.

[0027] The foam material is one or a mixture of graphite, ceramic material, and sintered foam metal.

[0028] The foaming agent is a mixture of alkylsulfonate and alkylbenzenesulfate in any proportion.

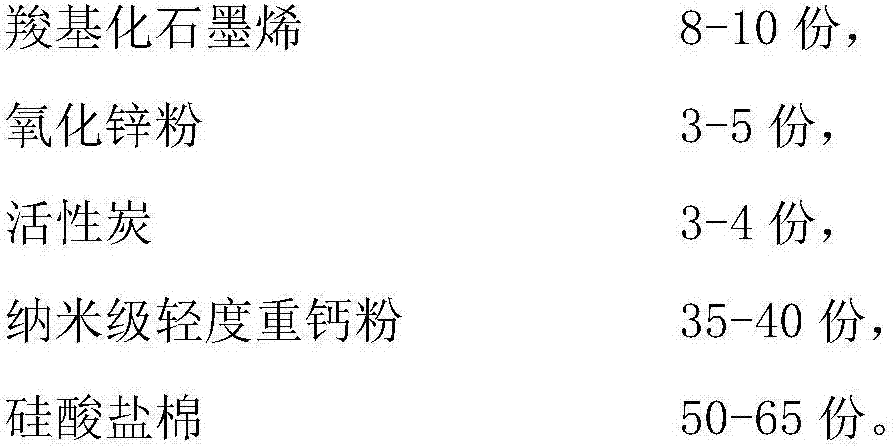

[0029] Described anti-cracking additive comprises following raw material by weight:

[0030]

[0031] The preparation method of described concrete comprises the following steps:

[0032] Step 1: Add a dispersant to the foam material and stir evenly, and obtain product 1 after drying;

[0033] Step 2: Mix cement, construction...

Embodiment 2

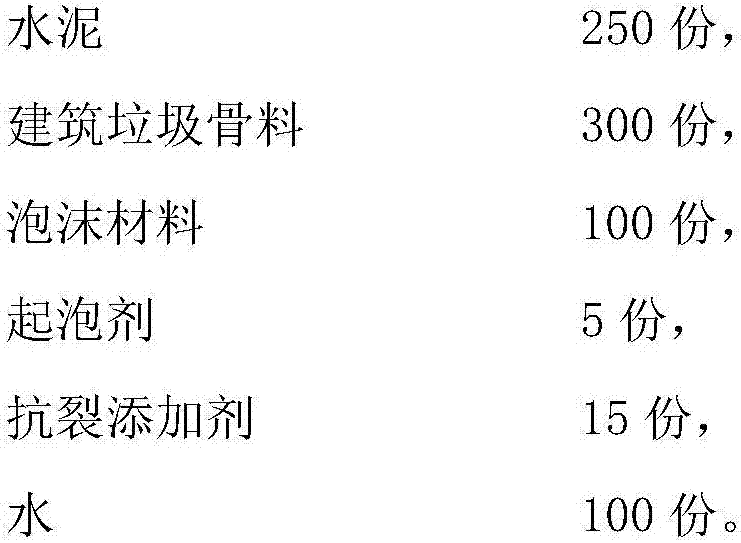

[0035] A kind of concrete is characterized in that, comprises following raw material by weight:

[0036]

[0037]

[0038] The construction waste includes red bricks, blue bricks, tiles, broken glass, fly ash, asphalt concrete mines and scrap metal.

[0039] The construction waste aggregate is obtained by crushing construction waste to particles with a particle diameter of 10 mm.

[0040] The fly ash is solidified after being blended with calcium salts.

[0041] The foam material is one or a mixture of graphite, ceramic material, and sintered foam metal.

[0042] The foaming agent is a mixture of alkylsulfonate and alkylbenzenesulfate in any proportion.

[0043] Described anti-cracking additive comprises following raw material by weight:

[0044]

[0045] The preparation method of described concrete comprises the following steps:

[0046] Step 1: Add a dispersant to the foam material and stir evenly, and obtain product 1 after drying;

[0047] Step 2: Mix cement,...

Embodiment 3

[0049] A kind of concrete is characterized in that, comprises following raw material by weight:

[0050]

[0051] The construction waste includes red bricks, blue bricks, tiles, broken glass, fly ash, asphalt concrete mines and scrap metal.

[0052] The construction waste aggregate is obtained by crushing construction waste to particles with a particle diameter of 5 mm.

[0053] The fly ash is solidified after being blended with calcium salts.

[0054] The foam material is one or a mixture of graphite, ceramic material, and sintered foam metal.

[0055] The foaming agent is a mixture of alkylsulfonate and alkylbenzenesulfate in any proportion.

[0056] Described anti-cracking additive comprises following raw material by weight:

[0057]

[0058] The preparation method of described concrete comprises the following steps:

[0059] Step 1: Add a dispersant to the foam material and stir evenly, and obtain product 1 after drying;

[0060] Step 2: Mix cement, construction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com