Fly ash-based inorganic polymer composite cementitious material and preparation method thereof

A technology of composite cementitious materials and inorganic polymers, applied in solid waste management, sustainable waste treatment, cement production, etc., can solve problems such as low compressive strength and poor flexural strength, and achieve the effect of improving pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Accurately weigh 1350 grams of fly ash, 150 grams of silicon fume, and 225 grams of activator sodium silicate (Na 2 SiO 2 9H 2 O) dissolved in 307 grams of water (water+Na 2 SiO 2 9H 2 Water of crystallization in O: fly ash and silicon powder=0.29, and this water yield is to deduct 128 grams of water of crystallization contained in sodium silicate in 435 grams of total water consumption). At room temperature, pour the activator aqueous solution into a double-rotation and double-speed slurry mixer, and then add the well-mixed fly ash and silicon powder for mixing to form a well-mixed slurry; put the slurry into a 40mm×40mm ×160mm iron triple mold. Vibrate on a mortar vibrating table, and scrape it flat with a scraper to obtain a formed fly ash-based inorganic polymer gelling material.

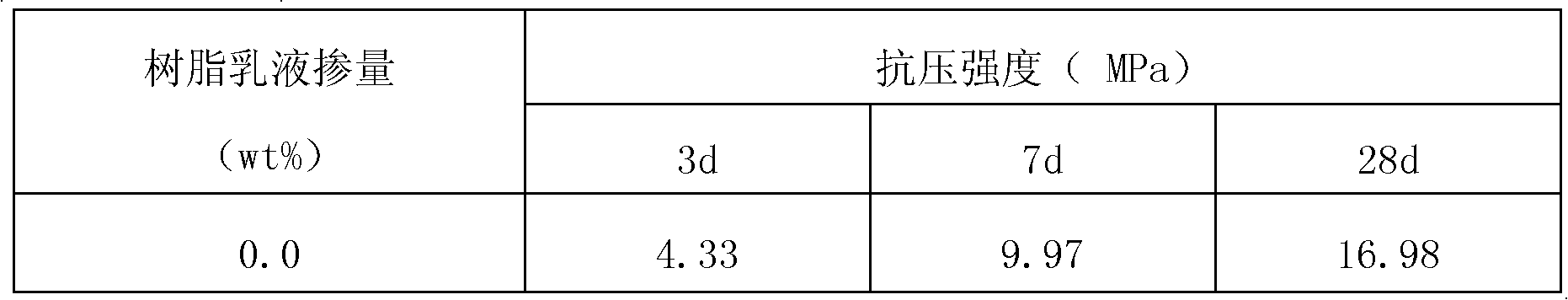

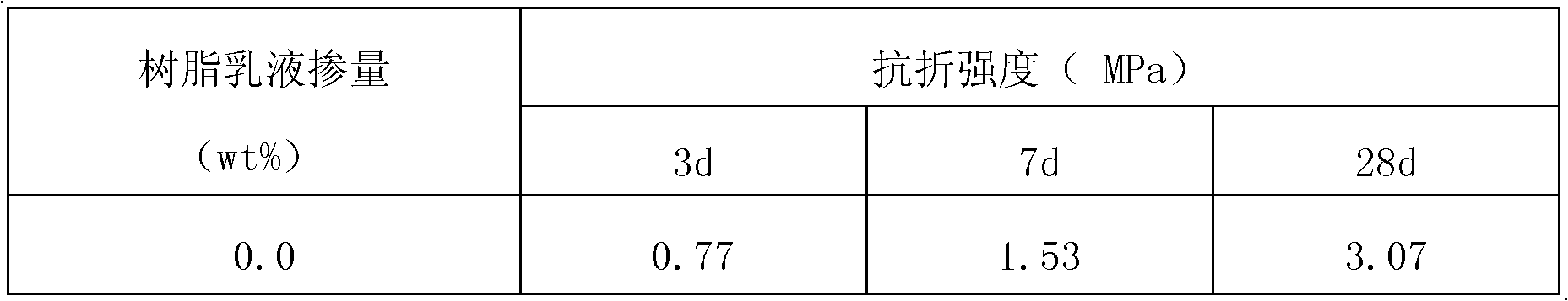

[0089] The molded specimens were cured at room temperature for 24 hours, and after demoulding, they were cured at room temperature for 3 days (3d), 7 days (7d), 28 days (28d) and ot...

Embodiment 2

[0095] Accurately weigh 1350 grams of fly ash, 150 grams of silicon fume, and 300 grams of activator sodium silicate (Na 2 SiO 2 9H 2 O) dissolved in 264 grams of water (water+Na 2 SiO 2 9H 2 Water of crystallization in O: fly ash and silicon powder=0.29, this water yield is to deduct sodium silicate contained crystal water 171 grams in total water consumption 435 grams). At room temperature, pour the activator aqueous solution into a double-rotation and double-speed slurry mixer, and then add the well-mixed fly ash and silicon powder for mixing to form a well-mixed slurry; put the slurry into a 40mm×40mm ×160mm iron triple mold. Vibrate on a mortar vibrating table, and scrape it flat with a scraper to obtain a formed fly ash-based inorganic polymer gelling material.

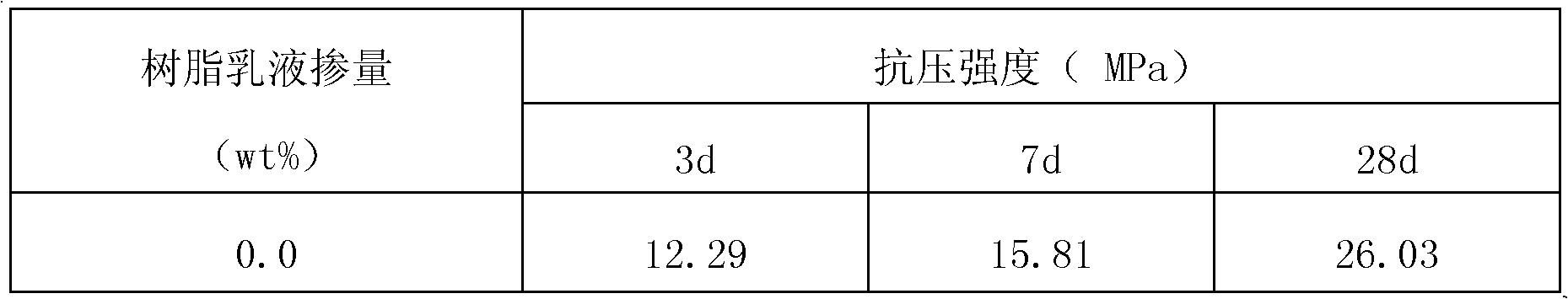

[0096] The molded specimens were cured at room temperature for 24 hours, and after demoulding, they were cured at room temperature for 3 days (3d), 7 days (7d), 28 days (28d) and other different ages, and ...

Embodiment 3

[0103] Accurately weigh 1350 grams of fly ash, 150 grams of silicon fume, and 300 grams of activator sodium silicate (Na 2 SiO 2 9H 2 O) dissolved in 264 grams of water (water+Na 2 SiO 2 9H 2 Water of crystallization in O: fly ash and silica fume, this water yield deducts 171 grams of crystal water contained in sodium silicate in 435 grams of total water consumption), and the butyl acrylate-acrylic resin emulsion dosage is 7.5 grams (for 0.5% of the weight of fly ash silica fume). At room temperature, pour the activator aqueous solution into a double-rotation double-speed slurry mixer, then add the well-mixed fly ash and silicon powder for mixing, and slowly add butyl acrylate-acrylic resin emulsion during the mixing process to form a uniform mixture The slurry; put the slurry into a 40mm × 40mm × 160mm iron triple mold. Vibrate on a mortar vibrating table, and scrape it flat with a scraper to obtain a formed fly ash-based inorganic polymer gelling material.

[0104]The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com