Recycling treatment method of lignin production wastewater

A lignin and waste water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost, waste of resources, waste of sulfuric acid, etc., and increase the product The effect of high income and utilization efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

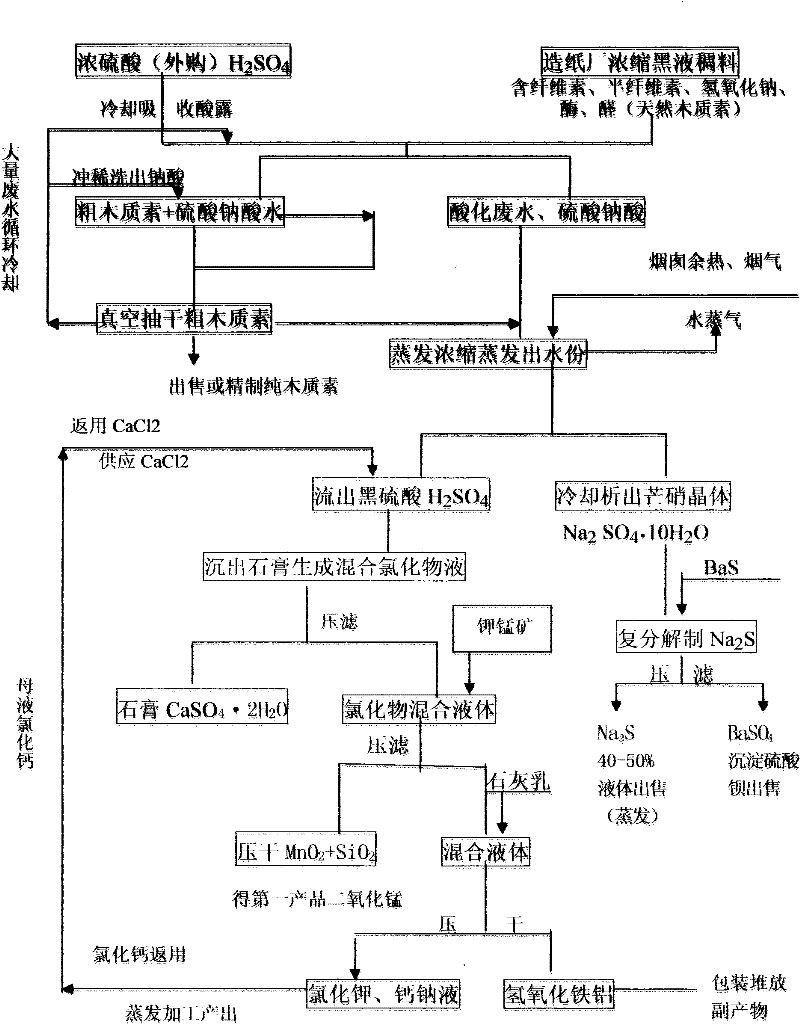

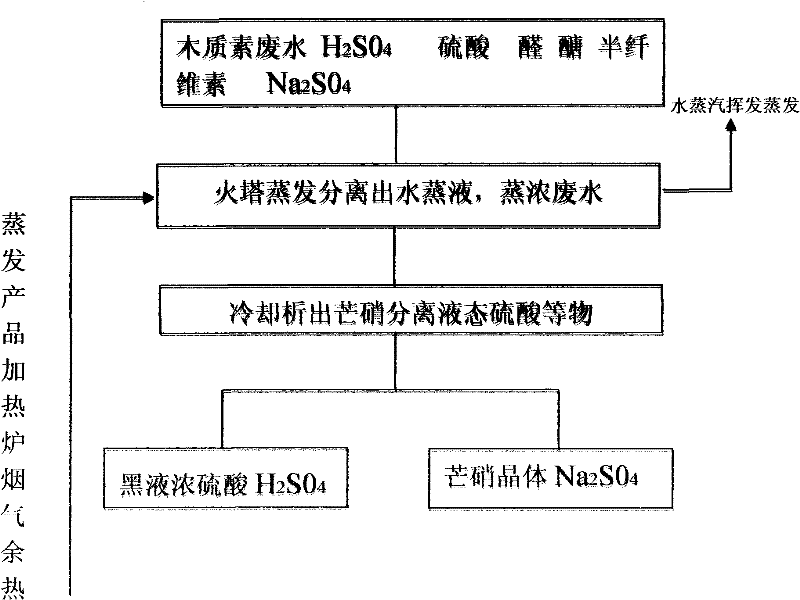

[0041] After lignin production, waste water is heated----evaporated, and the evaporated waste liquid is cooled and circulated, then crystallized to separate mirabilite and black liquor containing sulfuric acid, and the crystallized mirabilite is dissolved and reacted with barium sulfide to produce insoluble in water Barium sulfate and sodium sulfide, a large amount of sodium sulfide is produced and concentrated into a 40%-50% solution by evaporation.

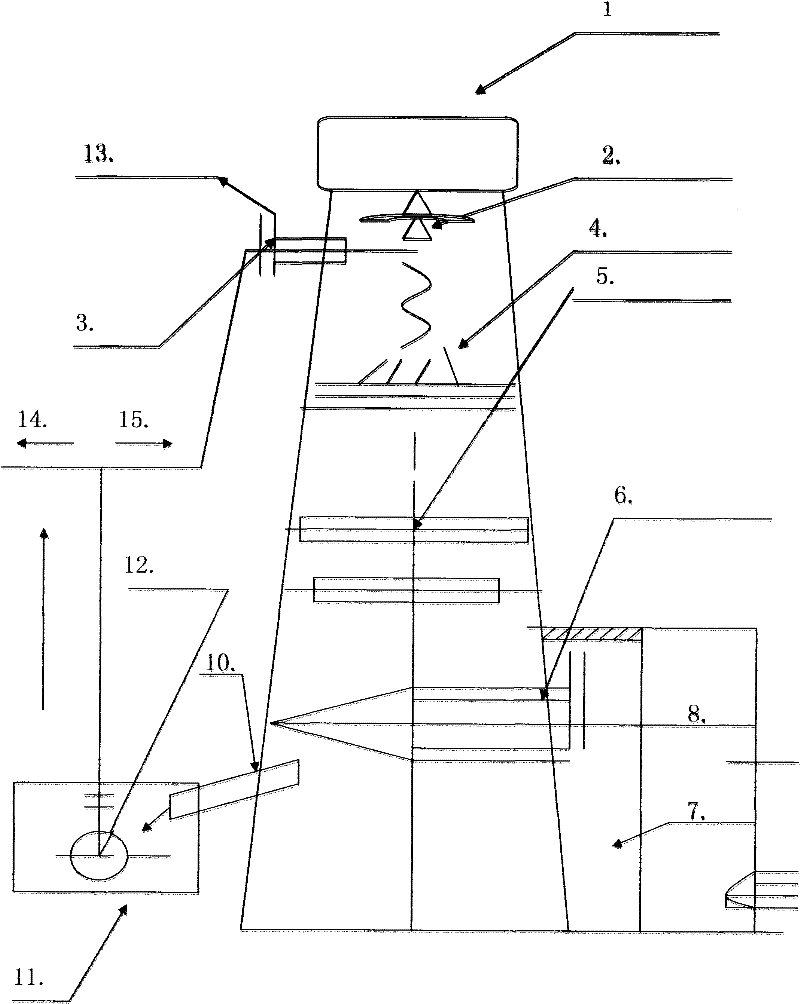

[0042]The waste water enters the tower through the pump feeding pipe 3 through the feeding screw nozzle 13, and falls freely in the form of mist. The feeding screw nozzle 13 is made of acid-proof stainless steel material. The high-pressure flue gas enters the Yanlong gas cabinet, enters the tower through the Yanlong air slot 7 and the air inlet 6 of the induced draft fan, and sends the waste heat flue gas of the evaporator to about 170°C-270°C, and directly heats the liquid mist to evaporate, and the superheated steam rises with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com