Concrete accelerator and preparation method thereof

A technology of quick-setting agent and concrete, applied in the field of concrete, can solve the problems of a large amount of waste gas, waste water and waste smoke, can not effectively improve the performance of concrete quick-setting agent, can not use waste aluminum ash, etc., to improve performance, kiln temperature The effect of easy control and good compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

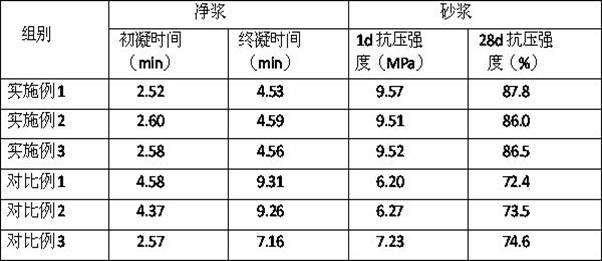

Examples

Embodiment 1

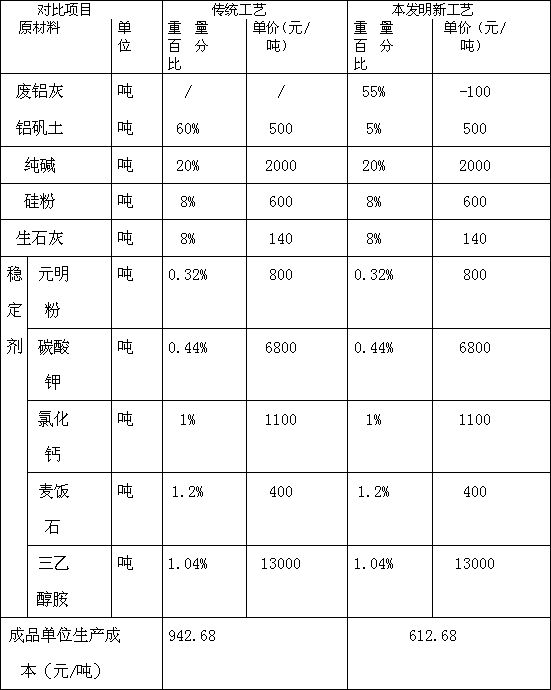

[0037] Concrete accelerator, concrete accelerator includes by weight:

[0038] 50-60 parts by weight of waste aluminum ash;

[0039] 3-8 parts by weight of bauxite;

[0040] 15-25 parts by weight of soda ash;

[0041] 6-10 parts by weight of silicon powder;

[0042] 6-10 parts by weight of quicklime;

[0043] The stabilizer is 2-6 parts by weight.

[0044] The stabilizer includes in parts by weight:

[0045] 5-10 parts by weight of sodium sulfate;

[0046] 8-14 parts by weight of potassium carbonate;

[0047] 21-29 parts by weight of calcium chloride;

[0048] Medical stone 24-36 parts by weight;

[0049] 22-30 parts by weight of triethanolamine.

[0050] Preparation of concrete accelerator:

[0051] A1: The raw material components of waste aluminum ash, bauxite, soda ash, silicon powder, quicklime, sodium sulfate, potassium carbonate, calcium chloride, medical stone, and triethanolamine are accurately weighed in proportion, and then the mixture is transported The system is transported to the r...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is:

[0060] The concrete accelerator includes in parts by weight:

[0061] 55 parts by weight of waste aluminum ash;

[0062] 5 parts by weight of bauxite;

[0063] 20 parts by weight of soda ash;

[0064] 8 parts by weight of silicon powder;

[0065] 8 parts by weight of quicklime;

[0066] The stabilizer is 4 parts by weight; the stabilizer includes 8 parts by weight of sodium sulfate, 11 parts by weight of potassium carbonate, 25 parts by weight of calcium chloride, 30 parts by weight of medical stone, and 26 parts by weight of triethanolamine.

[0067] Preparation of concrete accelerator:

[0068] The raw material components are accurately weighed in proportion, and then the mixture is transported to the rotary kiln through the conveying system for roasting. Among them, roasting specifically includes the steps: heating the mixture to 200°C at a heating rate of 1.5°C / min, holding it for 30 minutes, then heating it to 850°C ...

Embodiment 3

[0070] The difference between this embodiment and embodiment 1 is that the concrete accelerator includes, in parts by weight:

[0071] 50 parts by weight of waste aluminum ash;

[0072] 3 parts by weight of bauxite;

[0073] 15 parts by weight of soda ash;

[0074] 6 parts by weight of silicon powder;

[0075] 6 parts by weight of quicklime;

[0076] The stabilizer is 2 parts by weight; the stabilizer includes 5 parts by weight of sodium sulfate, 8 parts by weight of potassium carbonate, 21 parts by weight of calcium chloride, 24 parts by weight of medical stone, and 22 parts by weight of triethanolamine.

[0077] Preparation of concrete accelerator:

[0078] The raw material components are accurately weighed in proportion, and then the mixture is transported to the rotary kiln through the conveying system for roasting. Among them, roasting specifically includes the steps: heating the mixture to 150°C at a heating rate of 1°C / min, holding it for 20 minutes, then heating it to 800°C at a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com