Energy-saving, low-carbon and heat-insulation composite wallboard, and production method and equipment thereof

A thermal insulation composite and wall panel technology, applied in the direction of thermal insulation, building components, etc., can solve the problems of uneconomical, small promotion area, etc., and achieve the effect of light weight, improved compactness, and good compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

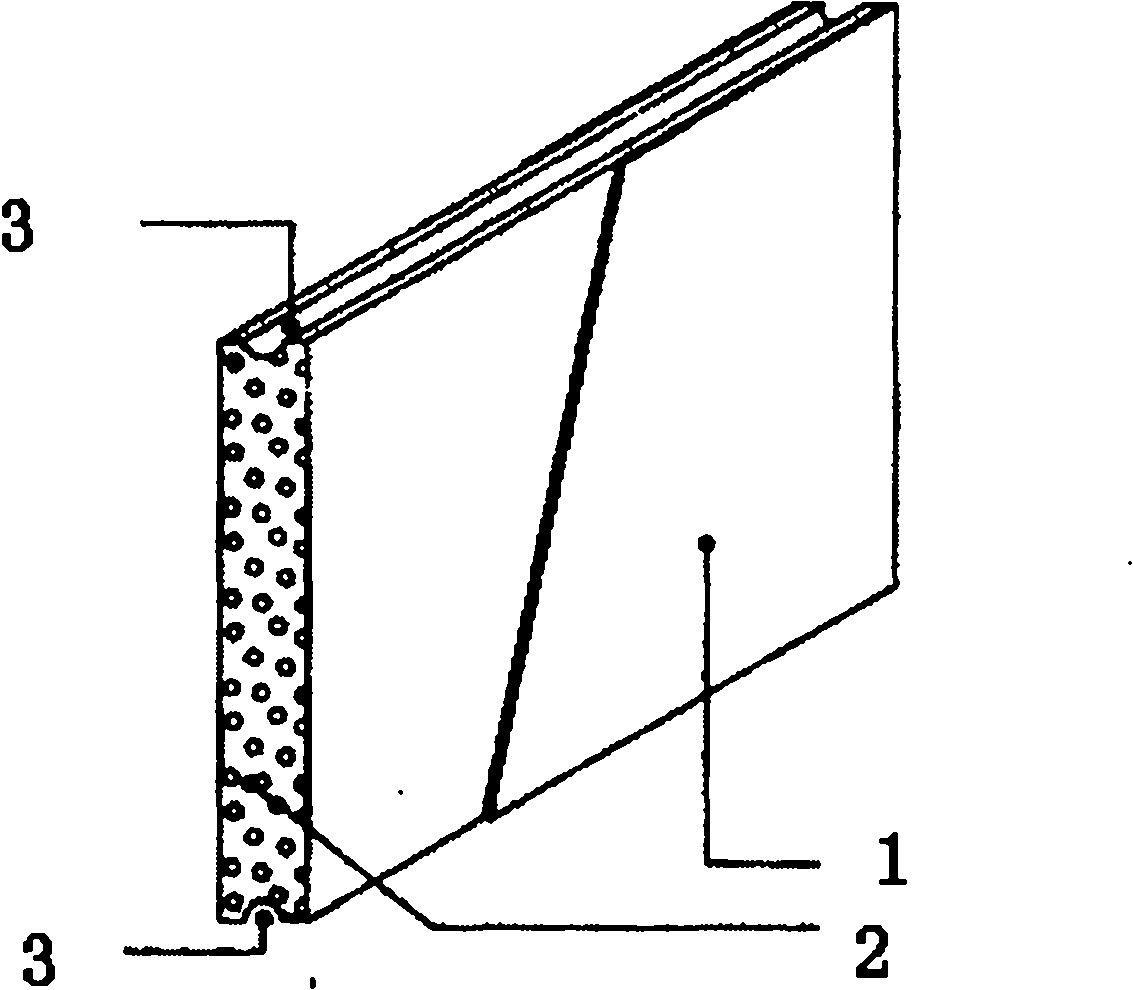

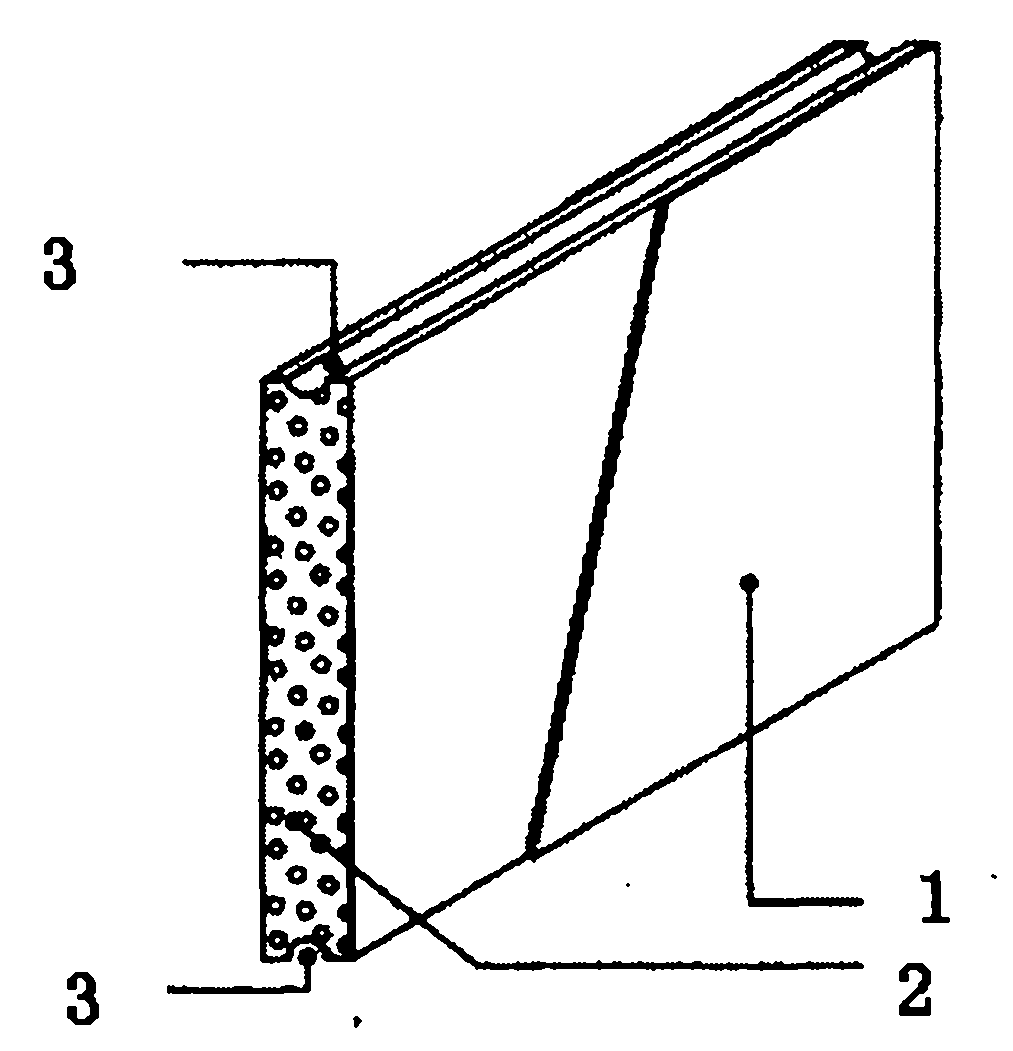

[0023] Such as figure 1 As shown, it is a schematic structural diagram of an energy-saving low-carbon thermal insulation composite wallboard. The energy-saving low-carbon thermal insulation composite wallboard consists of two panels 1 with a thickness of 4-8 mm and a thickness of 50-50 mm between the two panels 1. 150mm core plate 2, the panel 1 is a commercially available lignocellulose calcium silicate plate, which can be the NALC type plate produced by Aifuxi Company. The core board 2 is made of polystyrene foam plastic particles, fly ash, cement (>42.5 grade), sand (particle size<2mm), additives and water. The admixture is a mixture of Keny-J water reducer, Keny-F foaming agent and Keny-G adhesive. Keny-J water reducing agent, Keny-F foaming agent and Keny-G adhesive are produced by Guangzhou Hanhong Chemical Co., Ltd. and are available in the market.

[0024] The upper and lower ends of the core board 2 are provided with tongue and groove 3 . The double concave tenon a...

Embodiment 2

[0030] Similar to Example 1, the difference is that: Panel 1 uses a magnesia cement board with a thickness of 4-8 mm. The consumption of each raw material during production is: 6 parts by weight of polystyrene foam plastics, 60 parts by weight of fly ash, 250 parts by weight of cement, 60 parts by weight of sand, 0.3 parts by weight of Keny-J water reducing agent, and 0.3 parts by weight of Keny-F foaming agent 0.1 parts by weight, 6 parts by weight of Keny-G adhesive and 200-250 parts by weight of water.

[0031] The density of the obtained wallboard is ≤700kg / m 3 , Compression ≥ 3.5MPa, fire ≥ 3h, sound insulation ≥ 45DB. Thermal conductivity W / m k0.0969, hanging force ≥ 1000N, weather resistance, weather resistance 80 heat-rain cycle cycles, 5 heat-cold cycle cycles, no foaming, no peeling, impact strength of insulation system 3J .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com