Polyurethane rigid foam

A rigid foam and polyurethane technology, applied in the field of polyurethane rigid foam, can solve the problems of falling off the foam and the shell, lack of active hydrogen, and reducing the thermal insulation effect of the water tank, and achieve the effect of avoiding deformation of the water tank and excellent compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

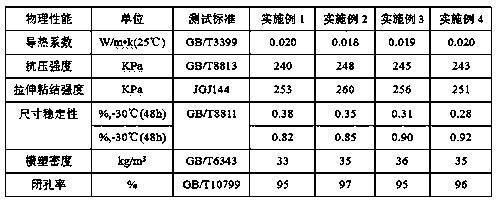

Examples

Embodiment 1

[0033] First prepare polyether polyol I, the process is as follows:

[0034] (1) Weigh 80g of lignin, 40g of water, 5g of lignin peroxidase, 1g of catalase, 1g of furfural acetaldehyde and 5g of furfuryl alcohol in a reactor, the reaction temperature is 80°C, and the reaction is stirred for 5 hours to obtain Enzymatic modification of lignin;

[0035] (2) Mix 100g of enzymatically modified lignin, 300g of glycerol, 200g of diethylene glycol and 0.03g of Pd-Fe catalyst in the reactor, control the reaction temperature at 120°C, and bubble the reaction with nitrogen from the bottom of the reactor , and then vacuumized, 8 g of propylene oxide was added, and the reaction was sealed under normal pressure for 2 hours to obtain the polyether polyol I with a functionality of 4.6 and a hydroxyl value of 400 mgKOH / g.

[0036] Then prepare polyether polyol II, the process is as follows:

[0037](1) Weigh 40g of ethylene glycol and 3g of magnesium chloride into 200g of palm oil, control t...

Embodiment 2

[0041] First prepare polyether polyol I, the process is as follows:

[0042] (1) Weigh 50g of lignin, 30g of water, 3g of lignin peroxidase, 2g of catalase, 3g of furfural acetaldehyde and 10g of furfuryl alcohol in a reactor, the reaction temperature is 80°C, and the reaction is stirred for 5 hours to obtain Enzymatic modification of lignin;

[0043] (2) Mix 100g of enzymatically modified lignin, 250g of glycerol, 100g of diethylene glycol and 0.01g of Pd-Fe catalyst in the reactor, control the reaction temperature at 120°C, and bubble the reaction with nitrogen from the bottom of the reactor , and then vacuumized, adding 4 g of propylene oxide, and reacting under normal pressure for 2 hours to obtain the polyether polyol I with a functionality of 5.0 and a hydroxyl value of 400 mgKOH / g.

[0044] Then prepare polyether polyol II, the process is as follows:

[0045] (1) Weigh 20g of ethylene glycol and 1g of magnesium chloride into 100g of palm oil, control the reaction temp...

Embodiment 3

[0049] First prepare polyether polyol I, the process is as follows:

[0050] (1) Weigh 100g of lignin, 50g of water, 2g of lignin peroxidase, 3g of catalase, 8g of furfural acetaldehyde and 6g of furfuryl alcohol in a reactor, the reaction temperature is 80°C, and the reaction is stirred for 5 hours to obtain Enzymatic modification of lignin;

[0051] (2) Mix 100g of enzymatically modified lignin, 350g of glycerol, 250g of diethylene glycol and 0.05g of Pd-Fe catalyst in the reactor, control the reaction temperature at 120°C, and bubble the reaction with nitrogen from the bottom of the reactor , and then vacuumized, 10 g of propylene oxide was added, and the reaction was sealed under normal pressure for 2 hours to obtain the polyether polyol I with a functionality of 4.7 and a hydroxyl value of 410 mgKOH / g.

[0052] Then prepare polyether polyol II, the process is as follows:

[0053] (1) Weigh 50g of ethylene glycol and 5g of magnesium chloride into 300g of palm oil, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com