Insulation board and manufacturing method thereof

A technology for thermal insulation boards and wood chips, applied in the field of thermal insulation board preparation technology, can solve the problems of flammability, high water absorption, low compressive strength, etc., and achieve superior toughness and rigidity, good thermal insulation performance, and good compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

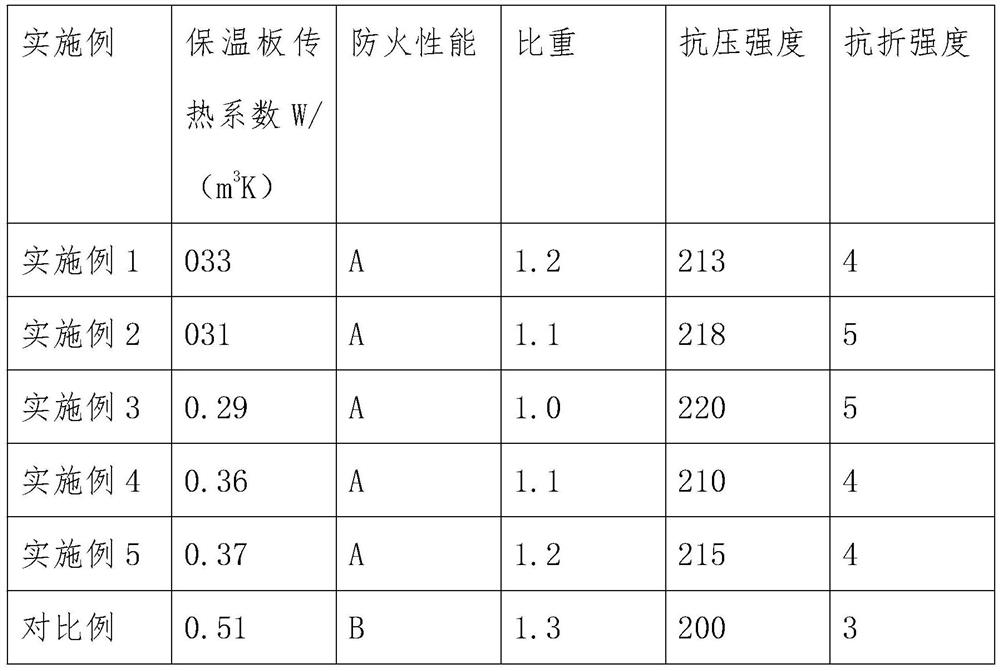

Examples

Embodiment 1

[0021]The method of making a thermal insulation plate proposed by the present invention includes the following steps:

[0022]S1, the mine powder slag, wood chips and straw fibers are placed in the mixer, and the stirred speed is 50 r / s, stirred for 20-28 minutes to obtain the first mixture;

[0023]S2, in the first mixture in S1, an adhesive was added in weight, continued, and the mixer was adjusted to 100 R / S, stirred for 30-40 minutes, and the second mixture was obtained;

[0024]S3, according to the weight of the polystyrene resin and the blowing agent, in place in the generator, heating mixing, the heating temperature is 60-70 ° C, the rotation speed is 30 r / s, then the catalyst is added, and stirring, stirring, stirring for 20 minutes, A third mixture is obtained;

[0025]S4, adding an antioxidant, stabilizer, and fire agent to the third mixture obtained in S3, continuing the stirring, a rotational speed of 30 r / s, and then poured the stirred mixture into the second mixture to con...

Embodiment 2

[0029]The method of making a thermal insulation plate proposed by the present invention includes the following steps:

[0030]S1, the mine powder slag, wood chips and straw fibers are placed in the mixer, and the stirred speed is 50 r / s, stirred for 20-28 minutes to obtain the first mixture;

[0031]S2, in the first mixture in S1, an adhesive was added in weight, continued, and the mixer was adjusted to 100 R / S, stirred for 30-40 minutes, and the second mixture was obtained;

[0032]S3, according to the weight of the polystyrene resin and the blowing agent, in place in the generator, heating mixing, the heating temperature is 60-70 ° C, the rotation speed is 30 r / s, then the catalyst is added, and stirring, stirring, stirring for 20 minutes, A third mixture is obtained;

[0033]S4, adding an antioxidant, stabilizer, and fire agent to the third mixture obtained in S3, continuing the stirring, a rotational speed of 30 r / s, and then poured the stirred mixture into the second mixture to con...

Embodiment 3

[0037]The method of making a thermal insulation plate proposed by the present invention includes the following steps:

[0038]S1, the mine powder slag, wood chips and straw fibers are placed in the mixer, and the stirred speed is 50 r / s, stirred for 20-28 minutes to obtain the first mixture;

[0039]S2, in the first mixture in S1, an adhesive was added in weight, continued, and the mixer was adjusted to 100 R / S, stirred for 30-40 minutes, and the second mixture was obtained;

[0040]S3, according to the weight of the polystyrene resin and the blowing agent, in place in the generator, heating mixing, the heating temperature is 60-70 ° C, the rotation speed is 30 r / s, then the catalyst is added, and stirring, stirring, stirring for 20 minutes, A third mixture is obtained;

[0041]S4, adding an antioxidant, stabilizer, and fire agent to the third mixture obtained in S3, continuing the stirring, a rotational speed of 30 r / s, and then poured the stirred mixture into the second mixture to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com