Patents

Literature

35results about How to "Good heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

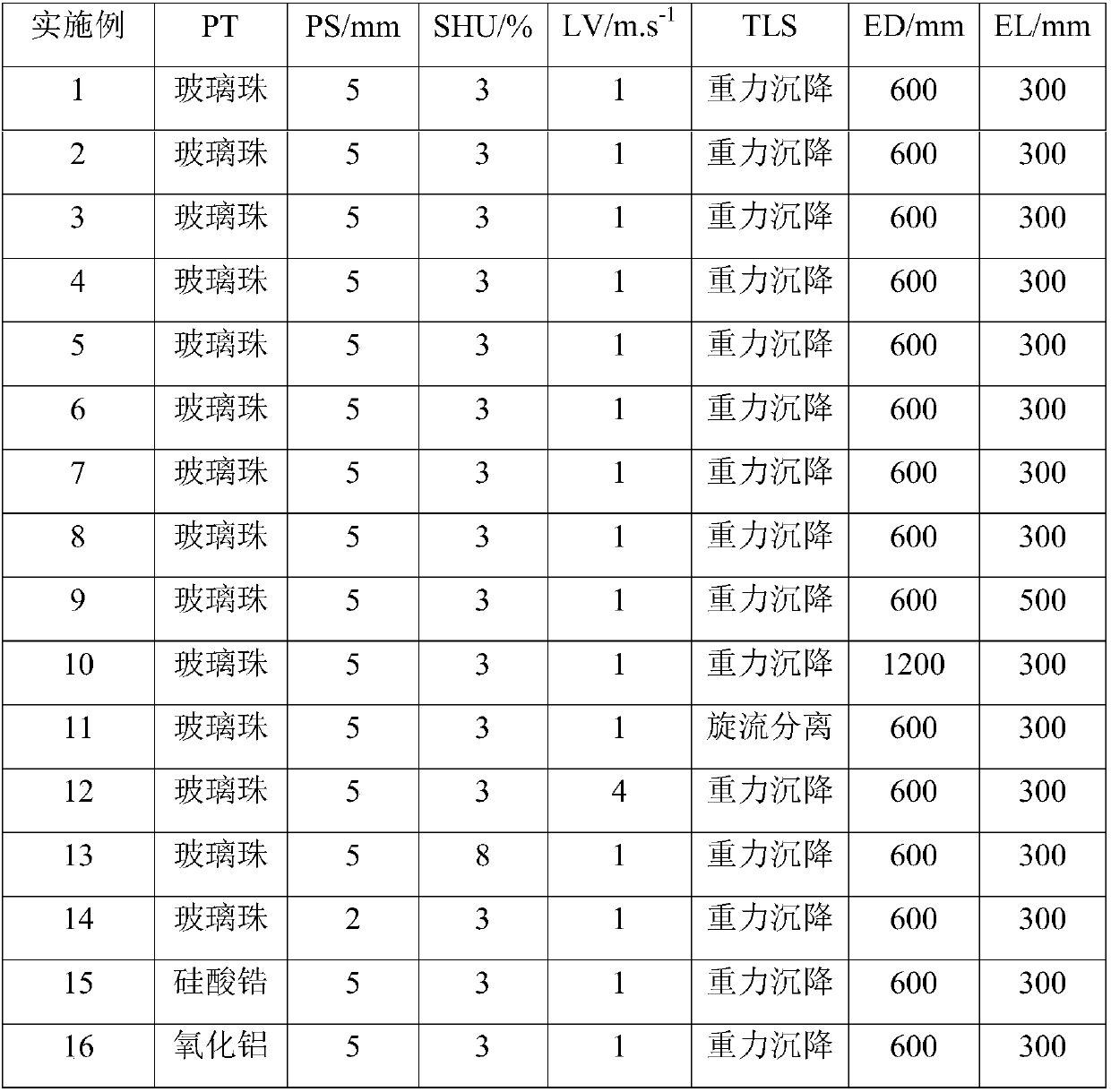

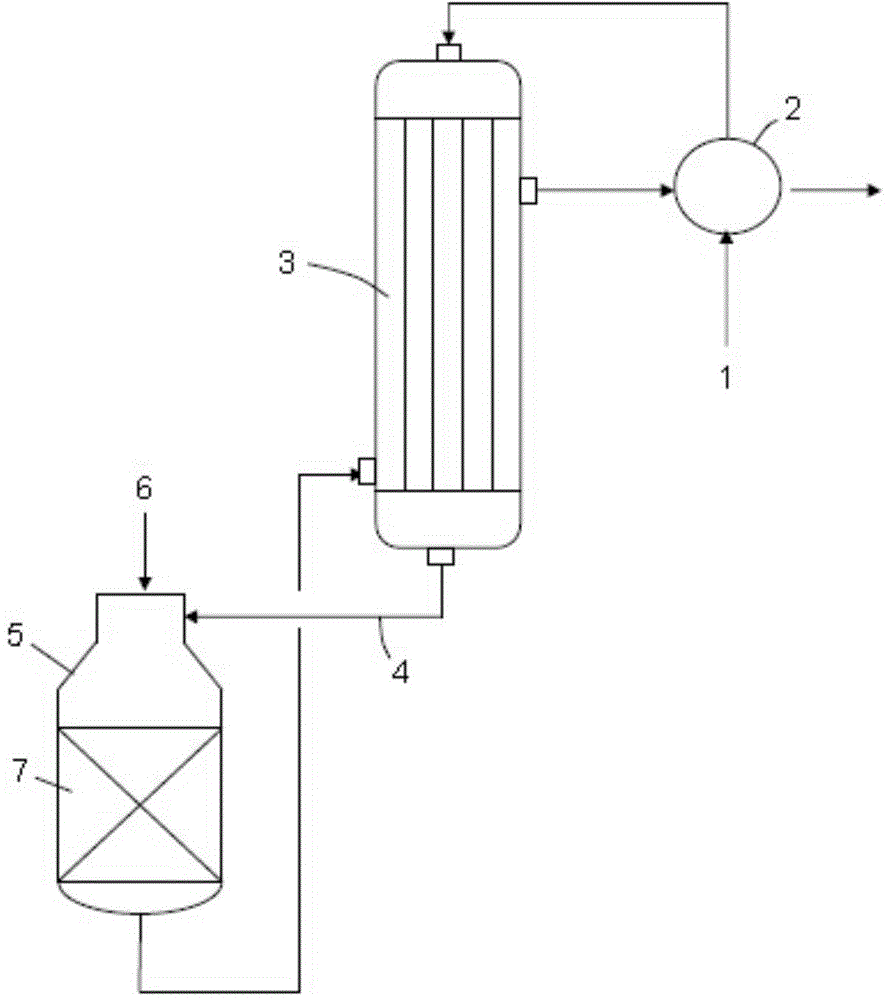

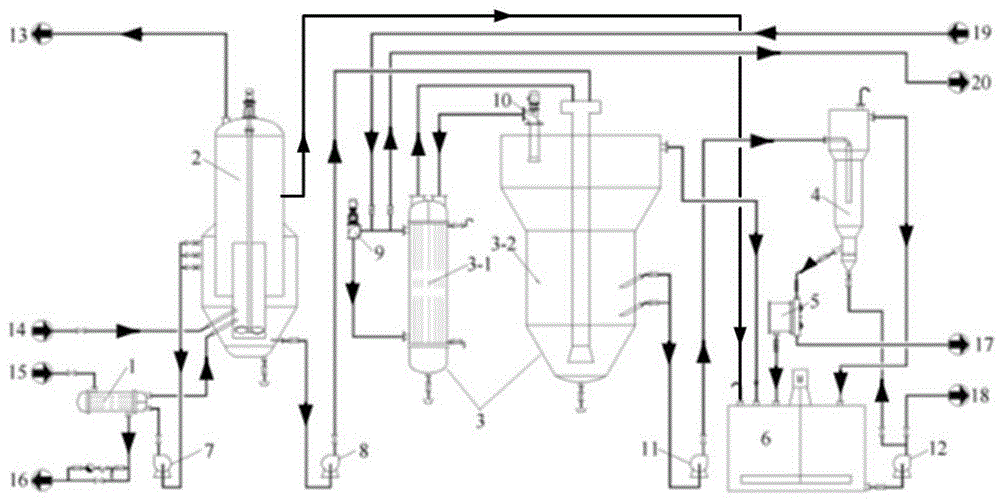

Continuous crystallization process for monopotassium phosphate

InactiveCN103159194AReduce manufacturing costEasy to operatePhosphorus compoundsSmall footprintMonopotassium phosphate

The invention discloses a continuous crystallization process for monopotassium phosphate. The continuous crystallization process comprises the following specific steps of: introducing a feed liquid to be crystallized into a first-stage continuous flash crystallizer so as to be separated into a primary clear liquid, primary crystal mush and secondary steam; discharging the primary crystal mush from the first-stage continuous flash crystallizer and feeding the primary crystal mush into a second-stage continuous cooling crystallizer, wherein the second-stage continuous cooling crystallizer is composed of an Oslo crystallizer and an external cooler; separating the primary crystal mush into secondary crystal mush and a secondary clear liquid in the Oslo crystallizer; discharging the secondary crystal mush from the Oslo crystallizer, feeding the secondary crystal mush into a thickener and separating the secondary crystal mush into triple clear liquid and triple crystal mush; discharging the triple crystal mush from the thickener, feeding the triple crystal mush into a centrifugal machine, and separating the triple crystal mush into solid monopotassium phosphate and a centrifugal liquid; and discharging the solid monopotassium phosphate from the centrifugal machine. The continuous crystallization process is stable in operation, low in energy consumption and low in labor intensity; and by using the continuous crystallization process, the operation stability and the product quality are greatly improved, the on-site operation environment is improved, and the production cost of the monopotassium phosphate is reduced. A mating device for the process is small in floor area and high in capacity.

Owner:HEBEI NUODA CHEM EQUIP

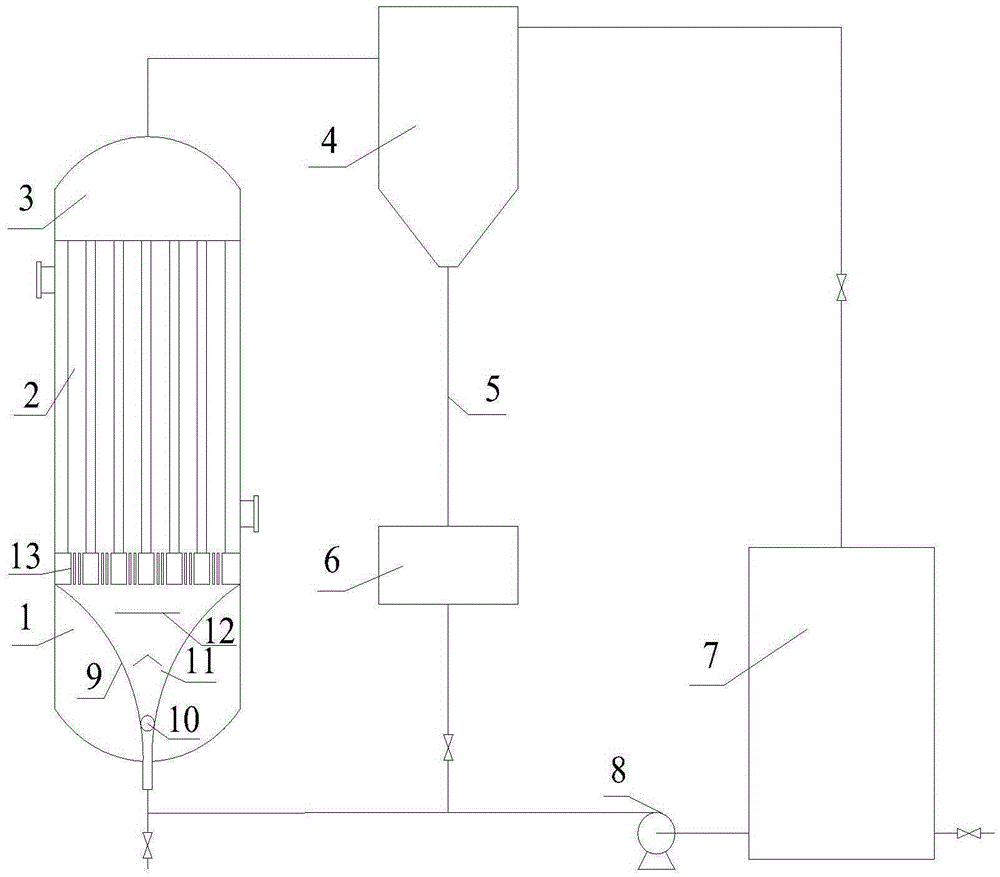

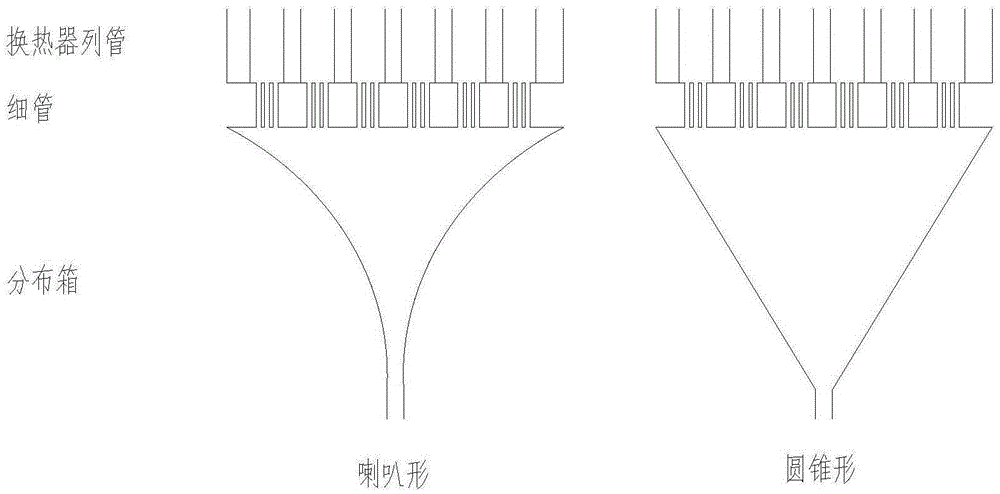

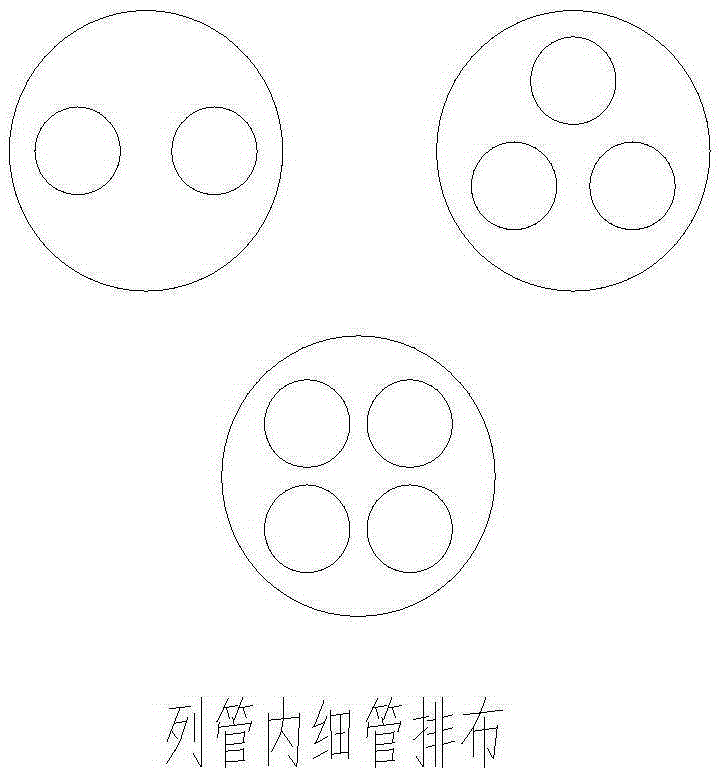

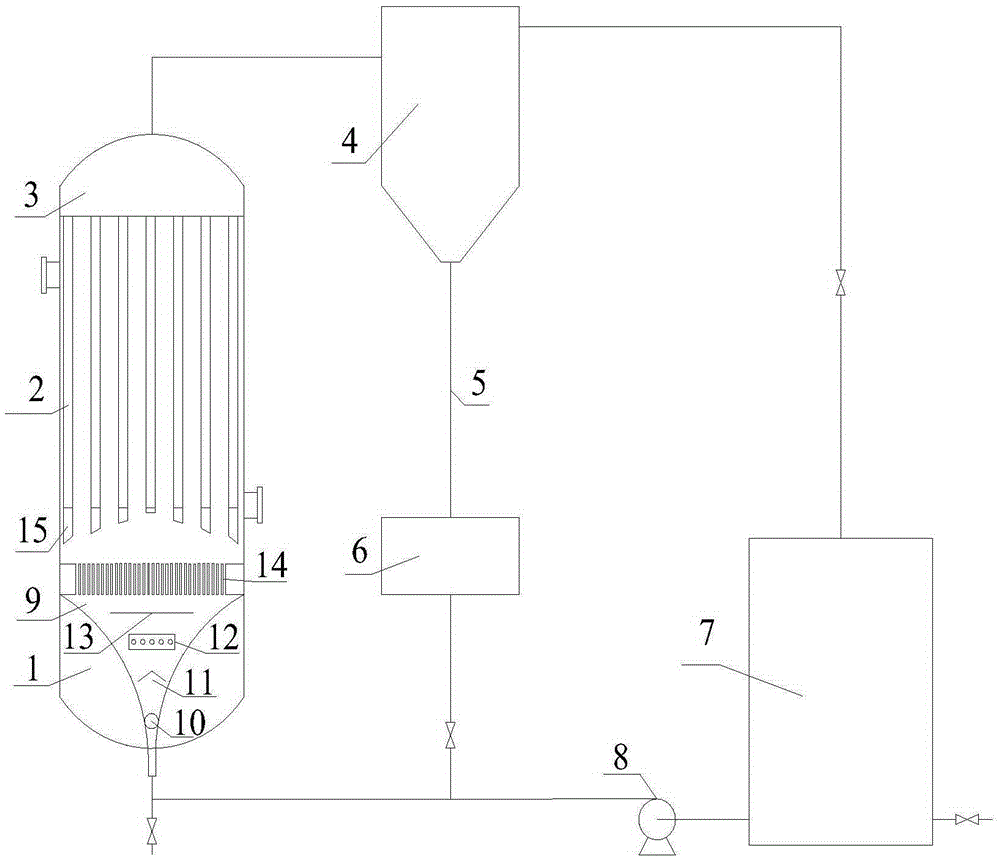

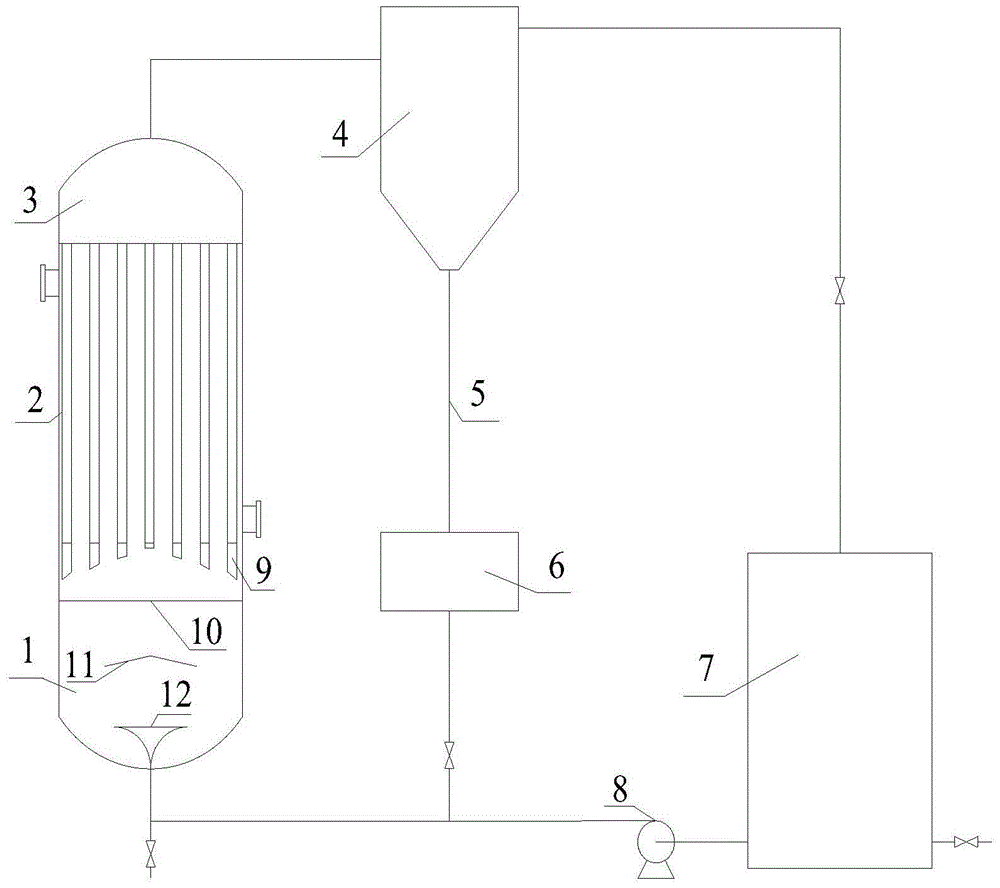

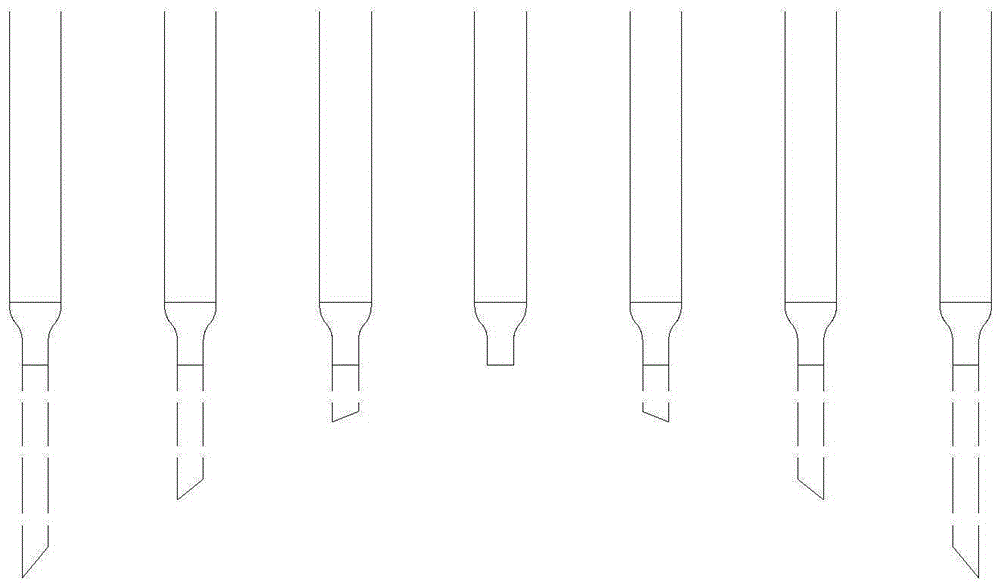

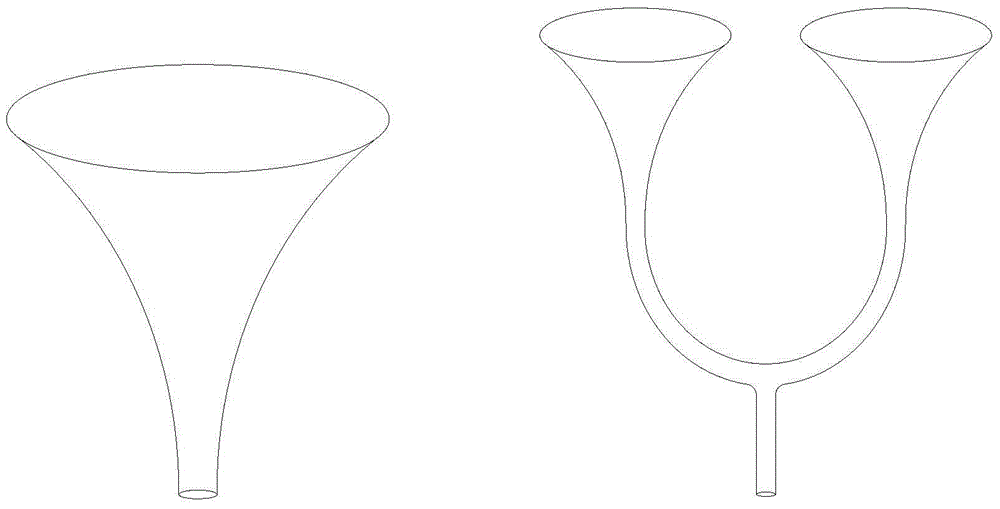

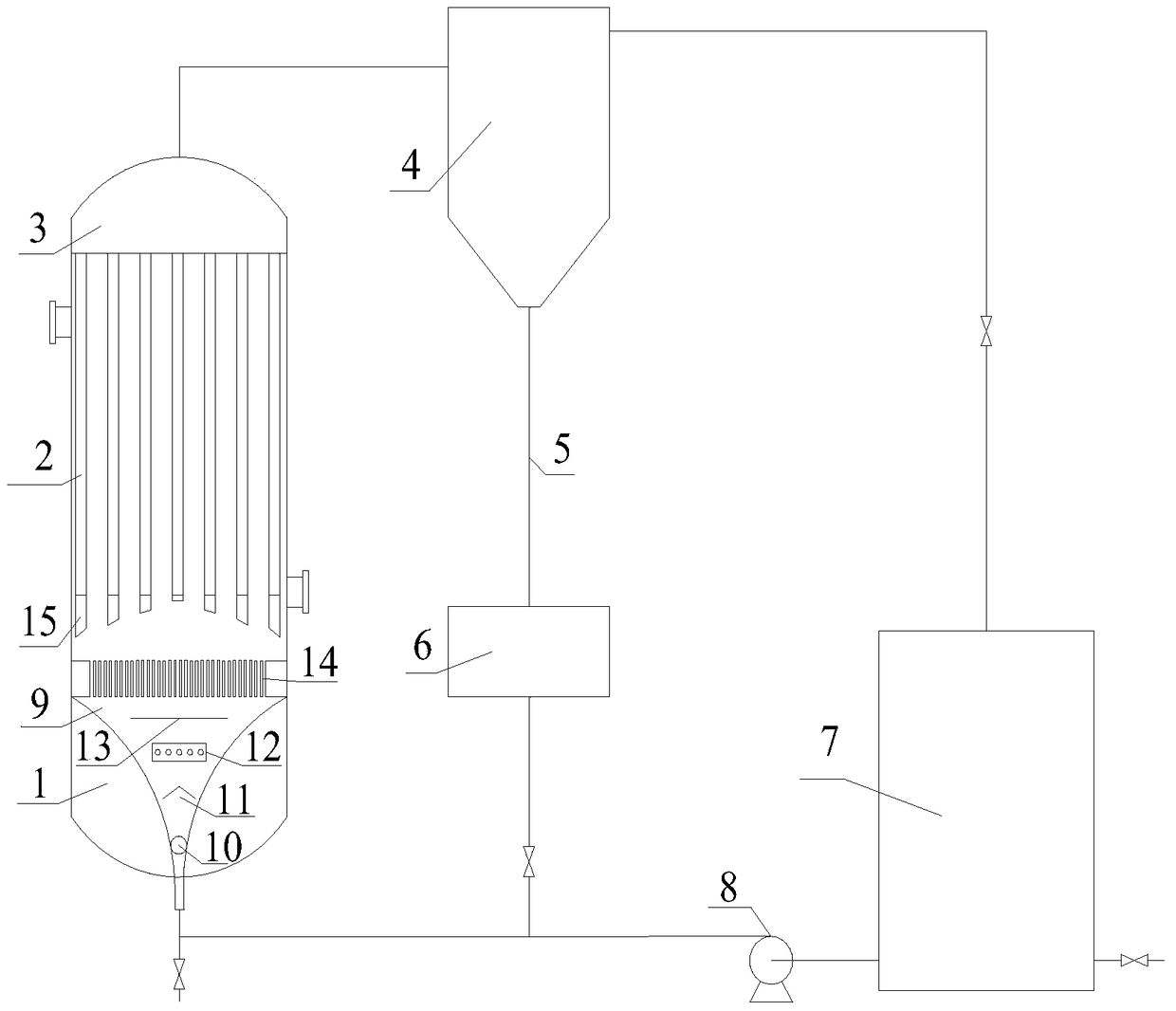

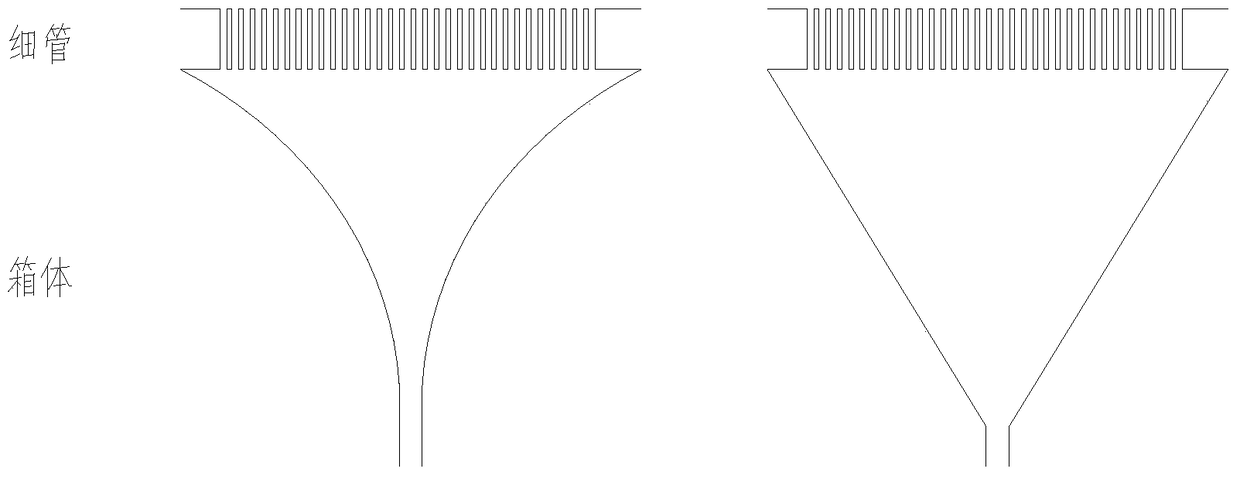

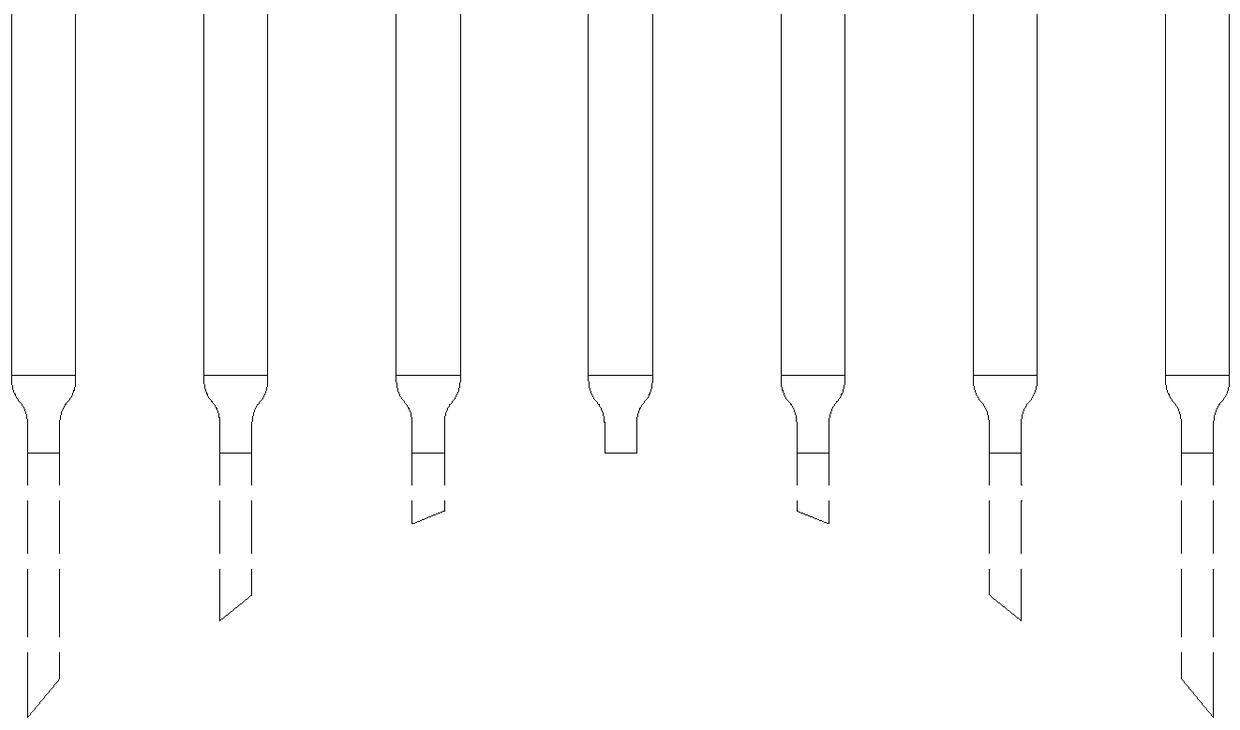

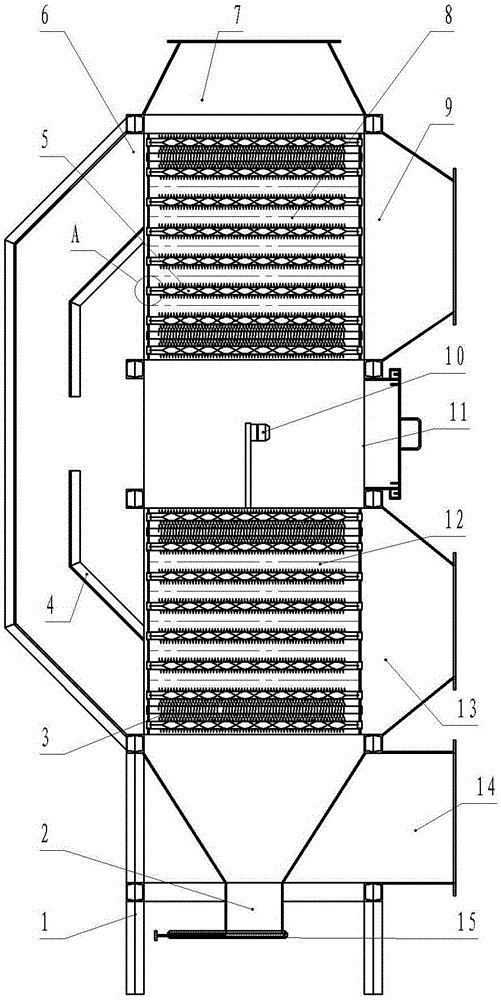

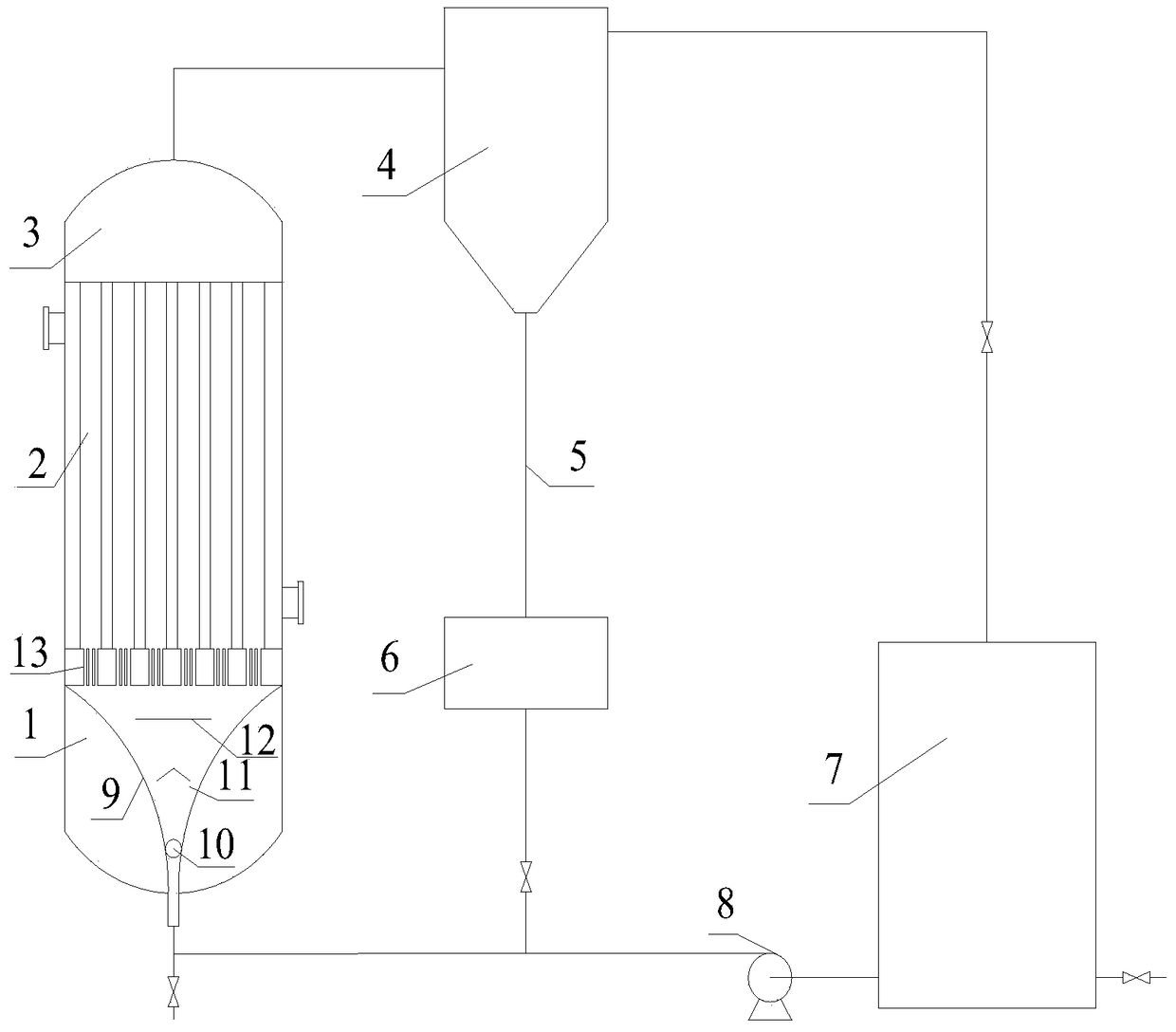

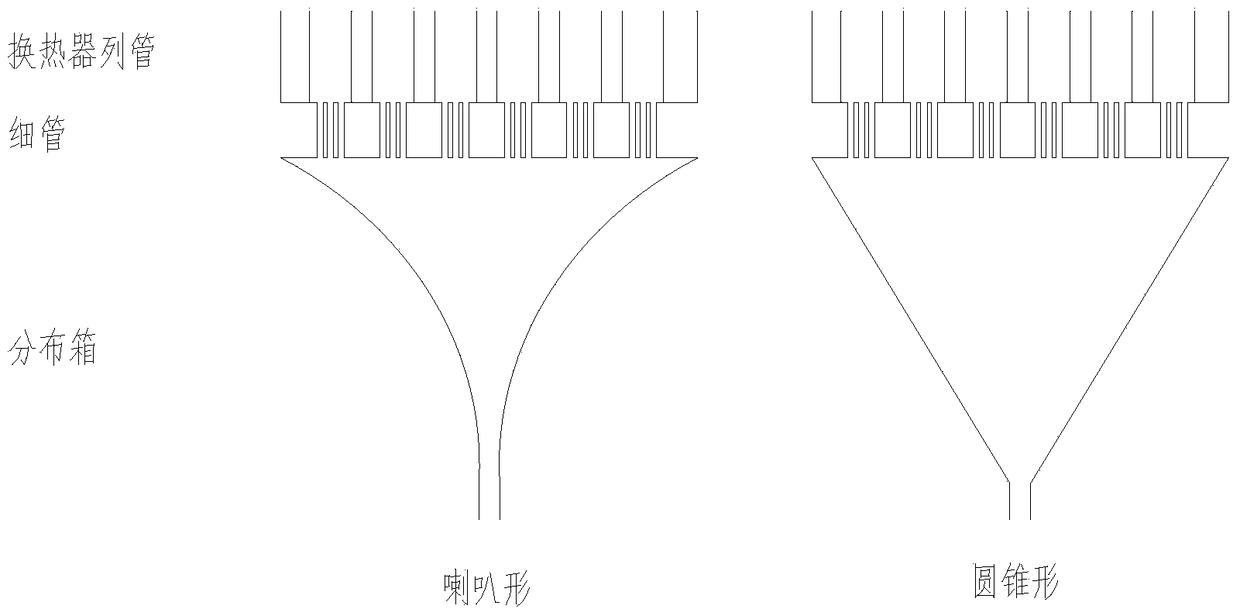

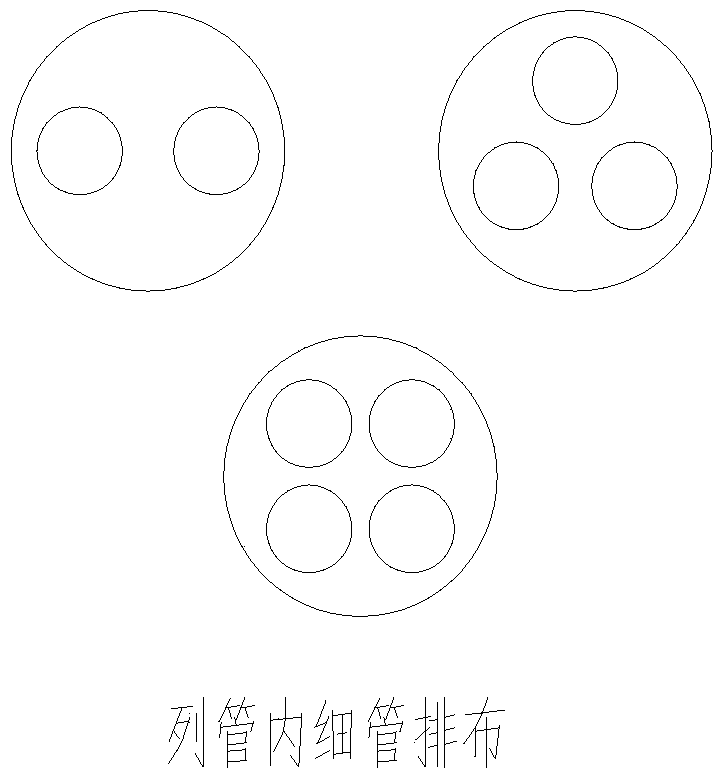

No-scaling fluidized bed heat exchanger

ActiveCN106595348AGood heat transfer coefficientCorrosion preventionStationary tubular conduit assembliesFluidized bedCirculator pump

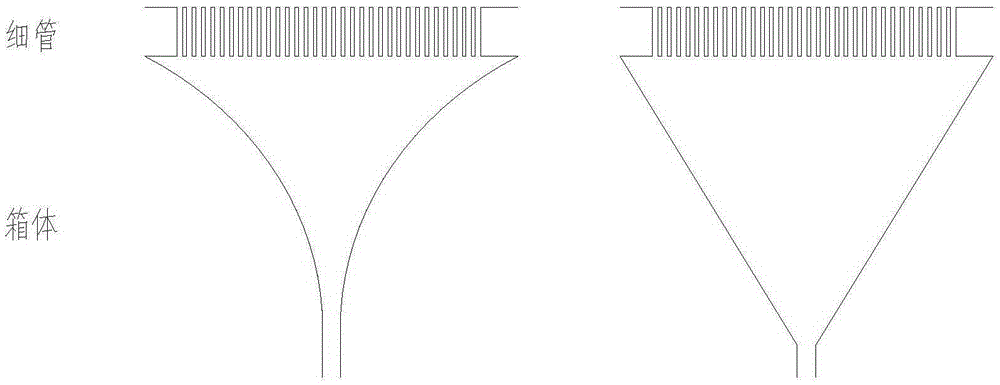

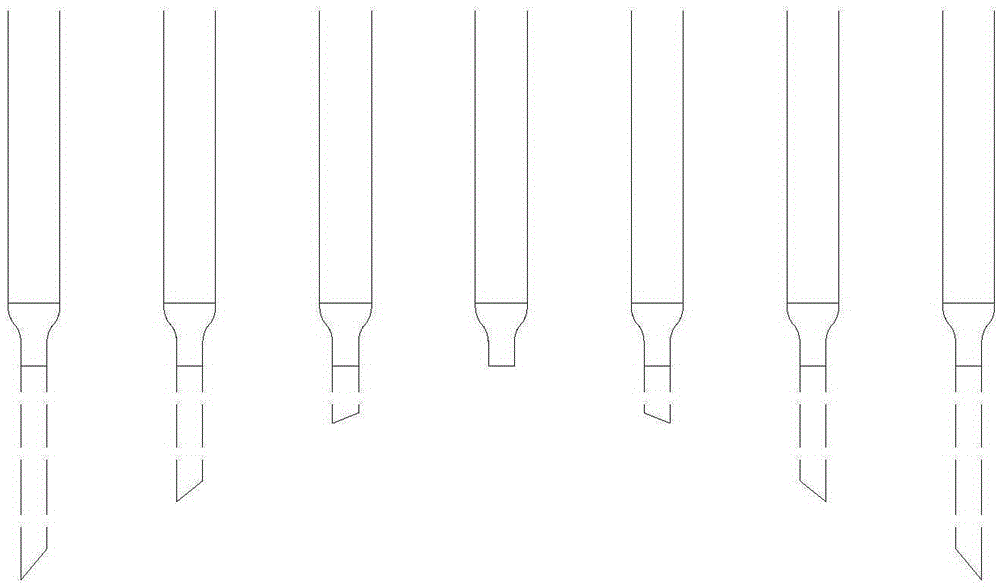

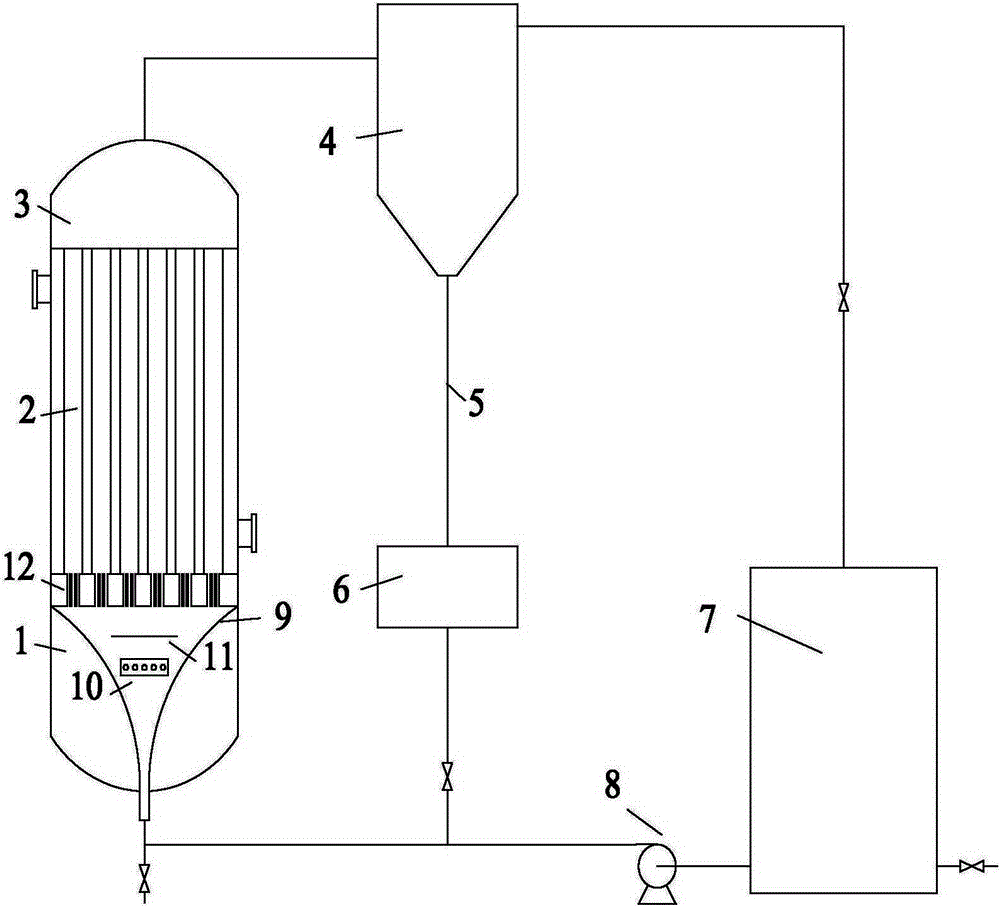

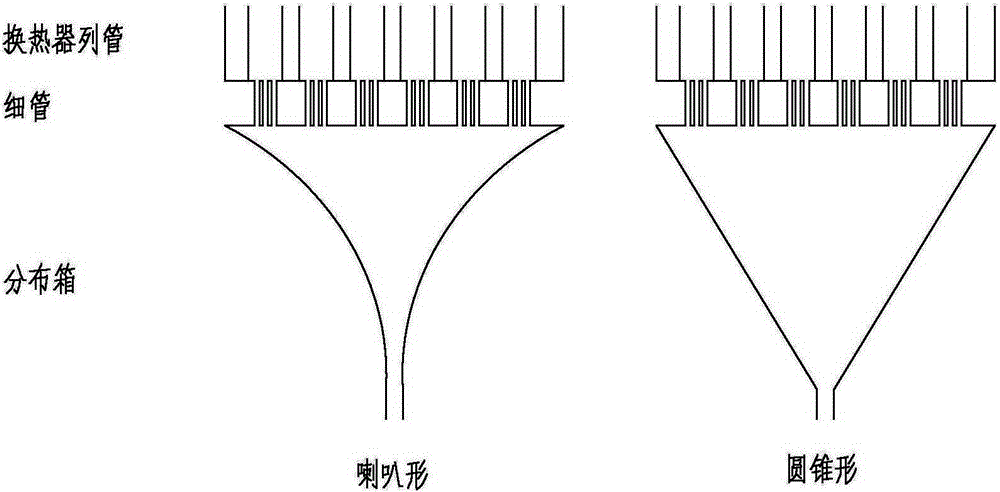

The invention relates to a no-scaling fluidized bed heat exchanger. The no-scaling fluidized bed heat exchanger is mainly used for solving the technical problems that in the traditional technology, a methyl tertiary butyl ether device refining tower condenser tube pass is liable to scale, and the heat exchange effect is lowered significantly after a long period of usage. According to the adopted technical scheme of the no-scaling fluidized bed heat exchanger, a lower pipe box 1, a heat exchanger tube 2, an upper pipe box 3, a liquid-solid separator 4, a downtake 5, a solid particle trough 6, a liquid storage trough 7, a liquid circulation pump 8, a distribution box 9, a ball plug 10, a baffle 11 and a distribution plate 12 are included; the distribution box 9 is connected with the heat exchanger tube 2 through a thin tube 13; the heat exchanger tube 2 is connected with the upper pipe box 3; the upper pipe box 3 is connected with the liquid-solid separator 4; solid particles enter the solid particle trough 6 through the downtake 5 and then return to the lower pipe box 1; liquid enters the liquid storage trough 7 and is conveyed to the lower pipe box 1 through the liquid circulation pump 8, through the technical scheme, the technical problems are solved well, and the no-scaling fluidized bed heat exchanger can be used for prolonging the operation cycle of a methyl tertiary butyl ether device refining tower condenser.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heat-dissipation graphite powder mixed plastic material

InactiveCN102093691AGood cooling performanceGood heat transfer coefficientHeat-exchange elementsThermoplasticPlastic materials

The invention discloses a heat-dissipation graphite powder mixed plastic material which comprises thermoplastic or thermosetting plastics. Heat-dissipation graphite powder, which accounts for 20-60 wt%, is uniformly mixed in the thermoplastic or thermosetting plastics. Since the heat-dissipation graphite powder is added into the plastic material disclosed by the invention, the particles of the graphite powder are orderly arranged to some extent to form microchannel carbon tubes, and each heat-dissipation channel is composed of a plurality of microchannels, thereby generating the chimney effect. When being installed on the surface of a heat source, the plastic material has favorable heat-dissipation performance. When being mixed in the plastic material, the graphite powder can modify the plastic material, so that the plastic material has favorable coefficient of heat transfer, and has the effects of shielding electromagnetic waves, blocking secondary radiation and the like.

Owner:黄柱联

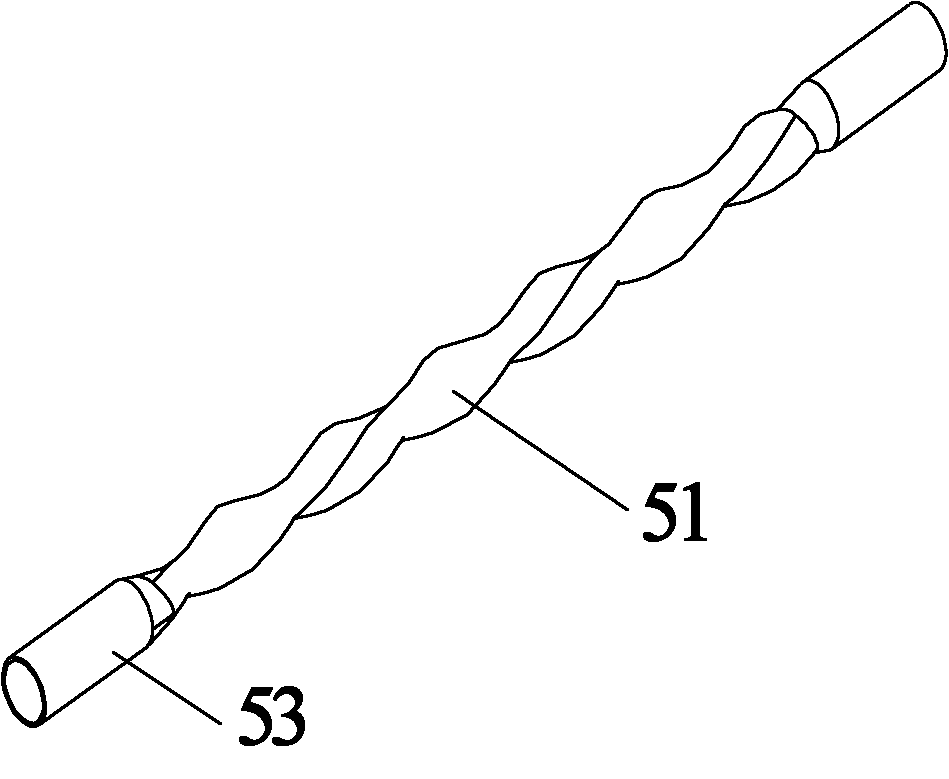

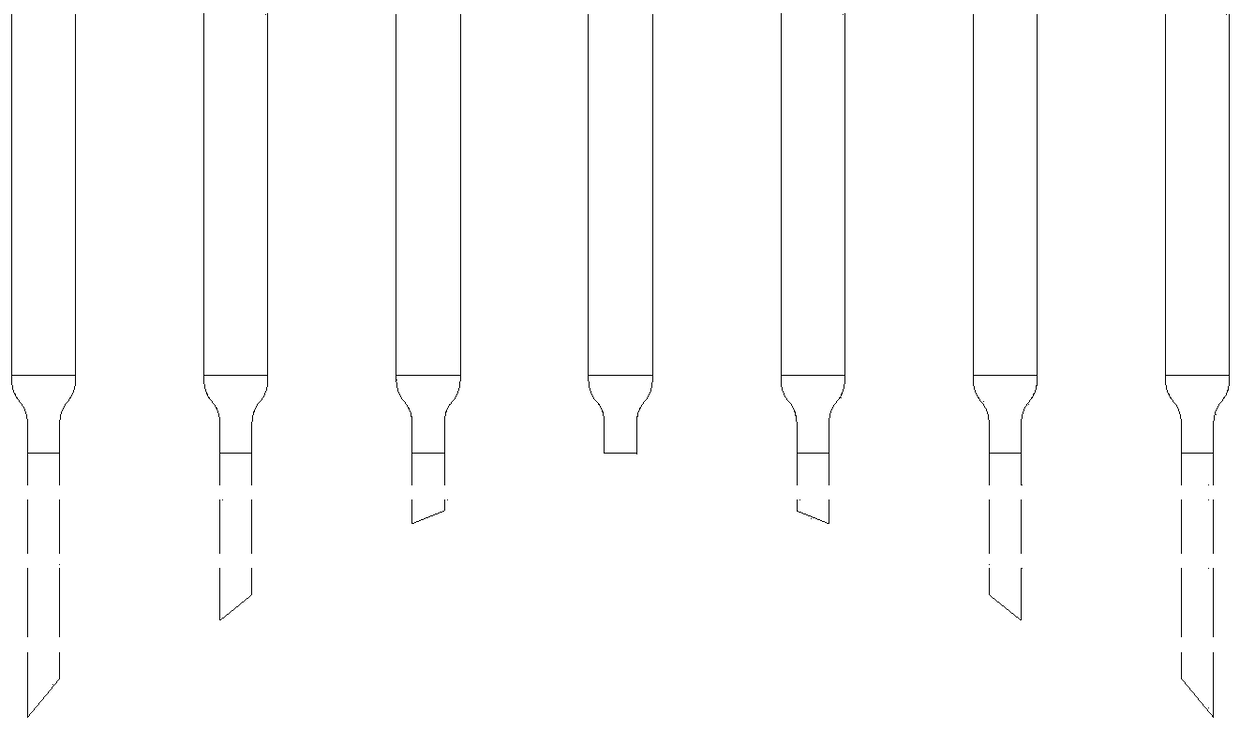

Heat exchange tube and burner with spiral flat tube self-preheating device

InactiveCN102183165AOvercome the problem of uneven heat transfer and poor heat transfer effectIncrease the outer surface areaIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringSmoke

The invention provides a heat exchange tube and a burner with a spiral flat tube self-preheating device. The heat exchange tube is a twisted spiral flat tube; the spiral flat tube comprises a spiral flat tube main body with a flatly tubular section and a spiral flat tube end connected with the spiral flat tube main body; and the section of the spiral flat tube end is round. The burner at least comprises a smoke chamber, and a heat exchange tube which is used for accommodating a gas to be preheated and arranged in the smoke chamber; and the heat exchange tube is the heat exchange tube provided by the invention. The invention is simple in operation, reliable and stable in running, and higher in heat exchange efficiency.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

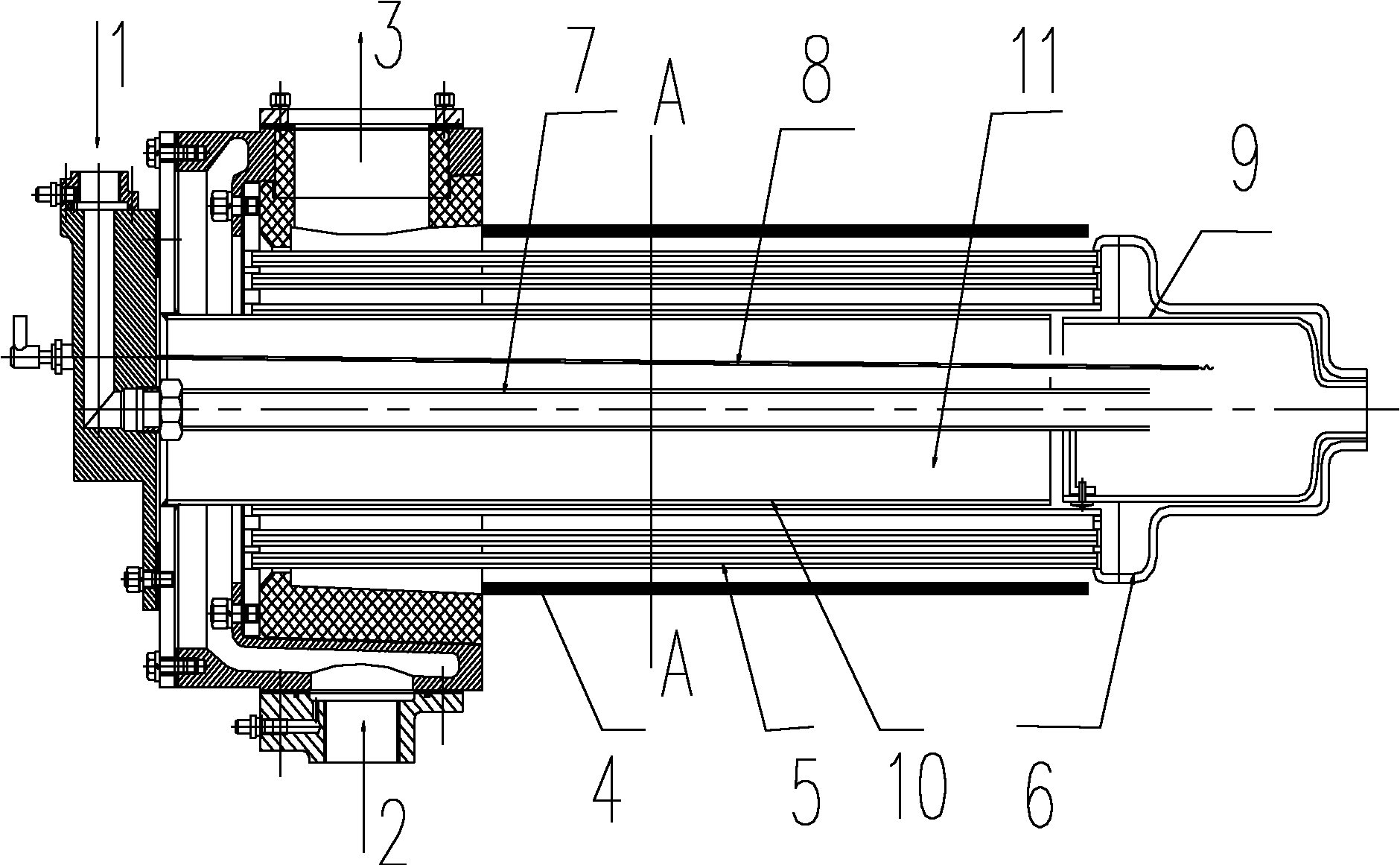

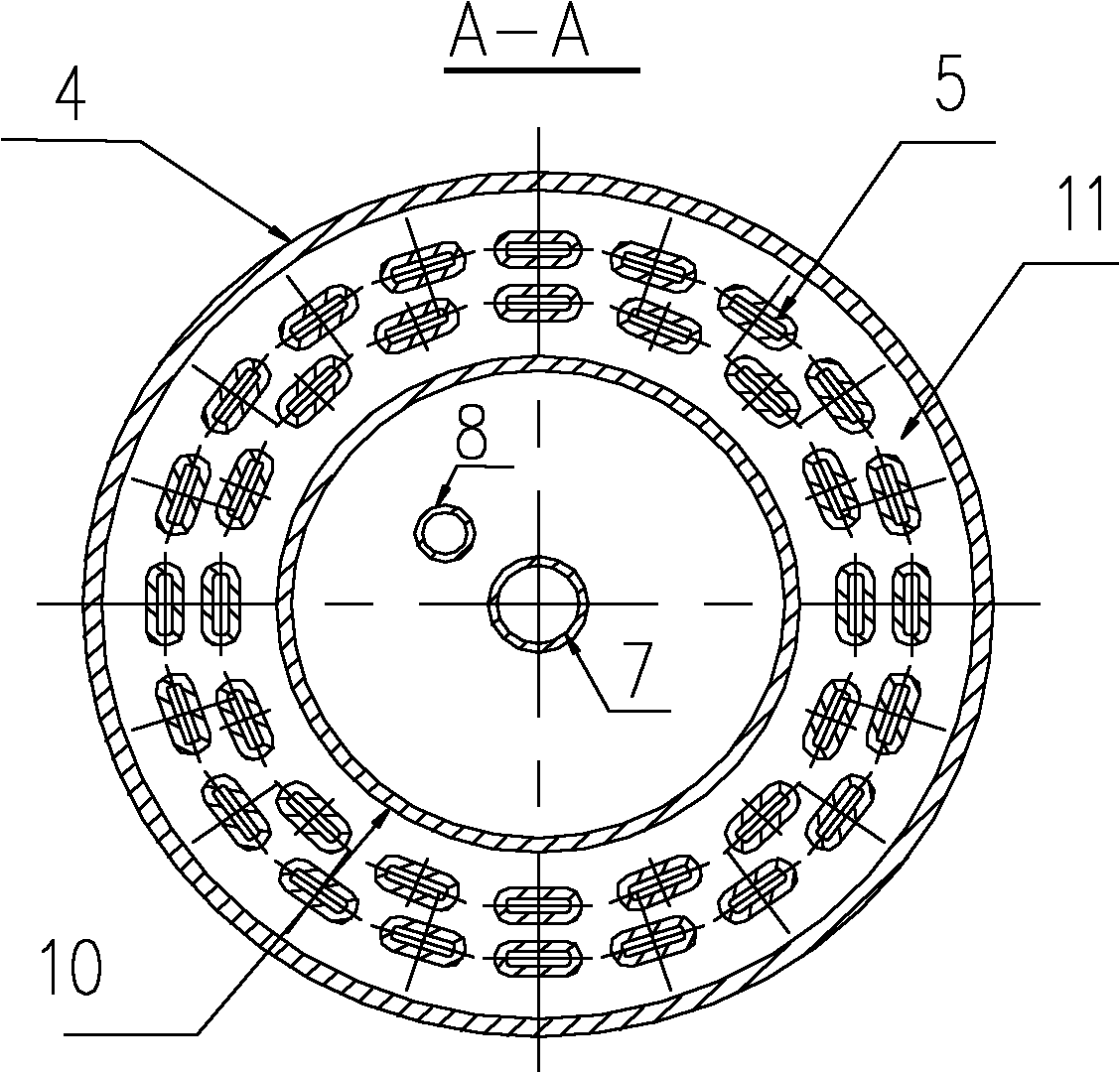

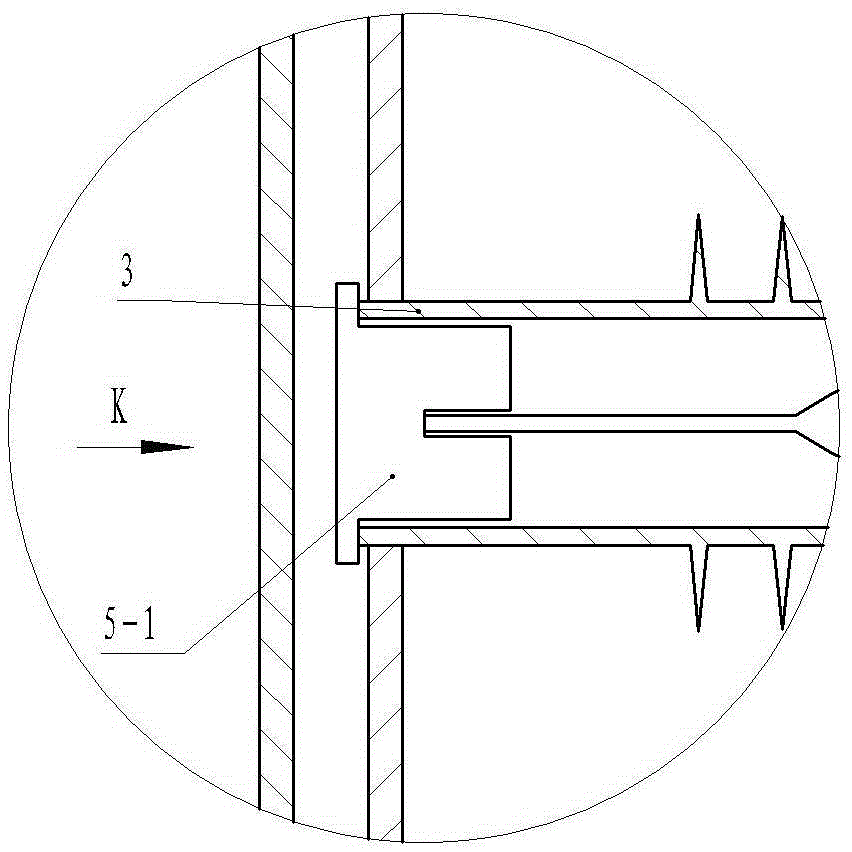

Anti-scaling and de-scaling heat exchanger for fluidized bed

ActiveCN106595351AGood heat transfer coefficientThe heat transfer coefficient is still maintained at the original 95% better technical effect is goodCorrosion preventionStationary tubular conduit assembliesFluidized bedLiquid storage tank

The invention relates to an anti-scaling and de-scaling heat exchanger for a fluidized bed. The anti-scaling and de-scaling heat exchanger is aimed at solving the technical problem in the prior art. Therefore, tube passes of a decarburized lye cooler of a synthetic ammonia device are not easily scaled. After long-term use, the heat exchange effect is still good. The anti-scaling and de-scaling heat exchanger is composed of a lower tube box 1, a heat exchanger tube array 2, an upper tube box 3, a liquid-solid separator 4, a descending tube 5, a solid particle groove 6, a liquid storage tank 7, a liquid circulating pump 8, a distribution box 9, a spherical plug 10, a baffle plate 11, a distribution disc 12, a distribution plate 13, slim tubes 14 and a lower-edge sleeve tube 15. An outlet of the distribution box 9 is connected with the slim tubes 14. The heat exchanger tube array 2 is connected with the upper tube box 3 connected with the liquid-solid separator 4. Solid phase enters the solid particle groove 6 through the descending tube 5. Liquid phase enters the liquid storage tank 7. The solid phase and liquid phase circulate to return the lower tube box 1. The anti-scaling and de-scaling heat exchanger for the fluidized bed has following beneficial effects: by adoption of the technical scheme, the above technical problem is solved; and the anti-scaling and de-scaling heat exchanger can be used for prolonging running cycle of the decarburized lye cooler of the synthetic ammonia device.

Owner:CHINA PETROLEUM & CHEM CORP +1

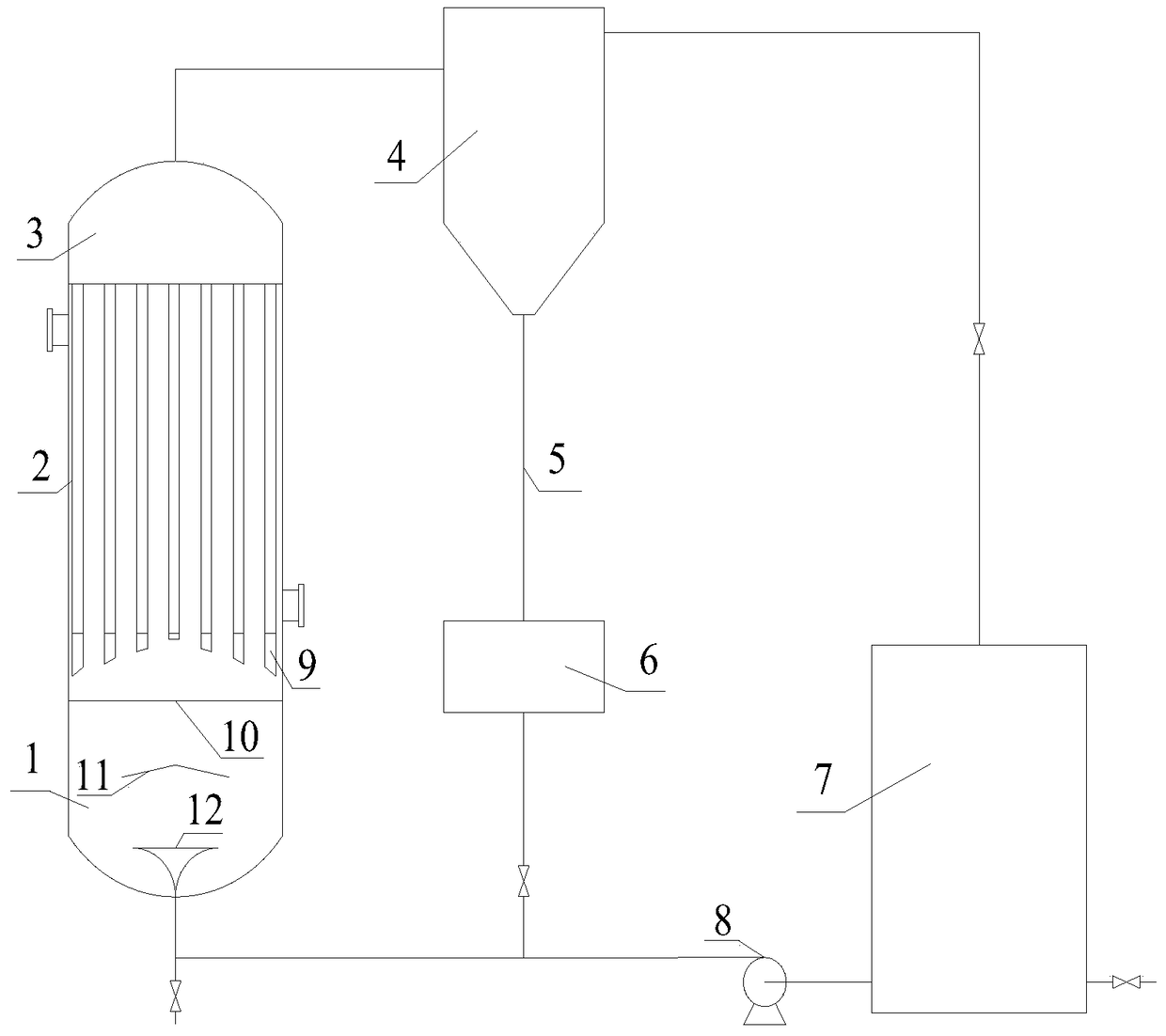

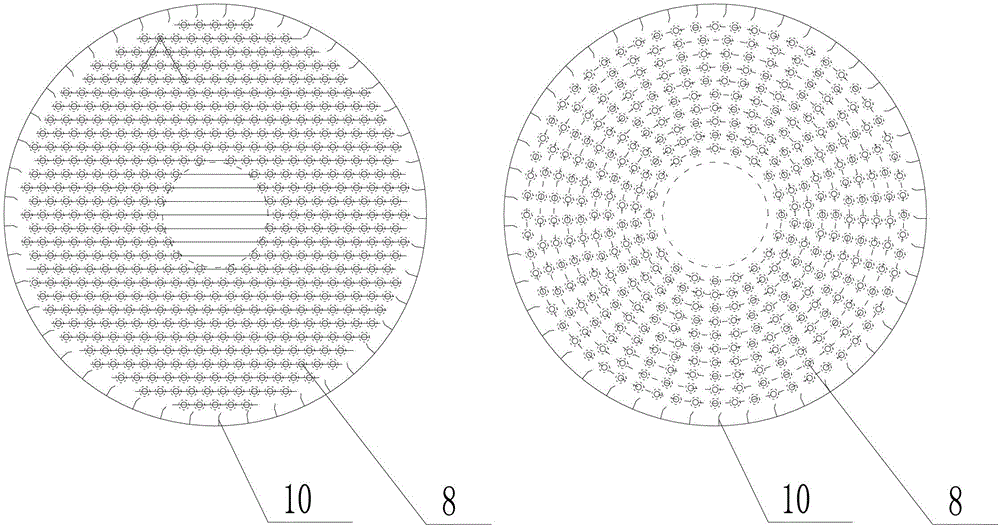

Liquid-solid circulating fluidized bed heat exchanger

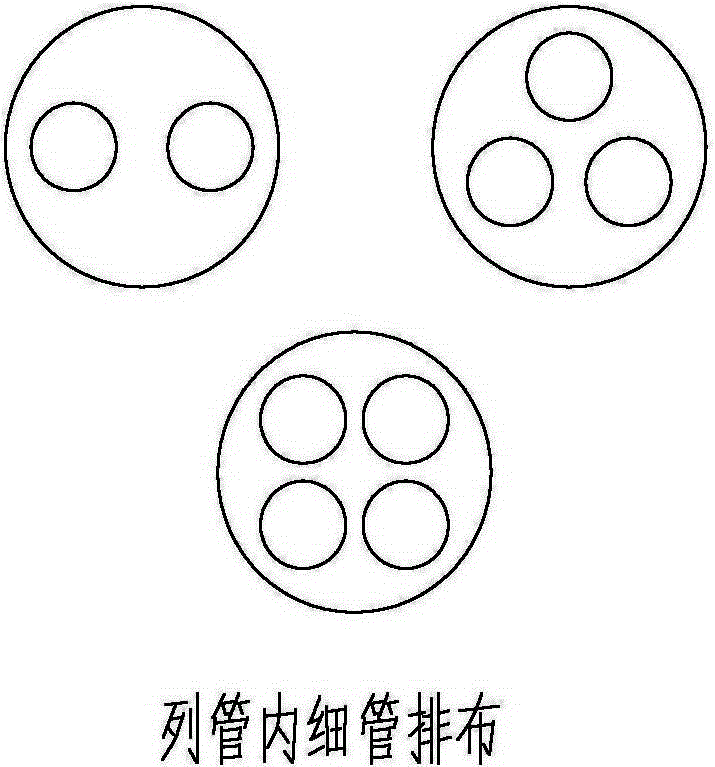

ActiveCN106595350AGood heat transfer coefficientStationary tubular conduit assembliesFlush cleaningEngineeringFluidized bed

The invention relates to a liquid-solid circulating fluidized bed heat exchanger. According to the liquid-solid circulating fluidized bed heat exchanger, the technical problems that in the traditional technology, a propylene epoxide device saponification waste liquid heat exchanger tube side is prone to scaling and the heat exchanging effect is decreased obviously after a long period of using are solved. The liquid-solid circulating fluidized bed heat exchanger comprises a lower tube case 1, a heat exchanger tube nest 2, an upper tube case 3, a liquid-solid separator 4, a downcomer 5, a solid particle trough 6, a liquid storage trough 7, a liquid circulating pump 8, a distributing case 9, a distributing disk 10 and a distributing plate 11. The distributing case 9 is connected with the heat exchanger tube nest 2 through thin tubes 12. The heat exchanger tube nest 2 is connected with the upper tube case 3. The upper tube case 3 is connected with the liquid-solid separator 4. Solid particles enter the solid particle trough 6 through the downcomer 5 and then go back to the lower tube case 1. Liquid enters the liquid storage trough 7 and is delivered into the lower tube case 1 through the liquid circulating pump 8. According to the technical scheme of the liquid-solid circulating fluidized bed heat exchanger, the technical problems are well solved, and the liquid-solid circulating fluidized bed heat exchanger can be used for operation cycle prolonging of the propylene epoxide device saponification waste liquid heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP +1

Jutecell and coffee carbon fiber knitted fabric and manufacturing method thereof

The invention relates to jutecell and coffee carbon fiber knitted fabric and a manufacturing method thereof. The manufacturing method comprises the steps that 35-45wt% of natural cotton fiber, 25-35wt% of jutecell fiber and 25-35wt% of coffee carbon fiber are woven to form blended yarns, and 94-96wt% of blended yarns and 4-6wt% of spandex are woven by a double-sided loom, and subjected to soaping, fixation, mellowing and drying to from the jutecell and coffee carbon fiber knitted fabric. Compared with the prior art, the jutecell and coffee carbon fiber knitted fabric is better in skin friendliness, air permeability, heat preservation property, heat transfer coefficient, quick in drying, excellent in peculiar smell eliminating function, good in warmth preservation property, elasticity, color and luster, antibacterial, mildewproof and hygroscopic, and can rise the temperature for heating within a short time.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Solar thermal receiver with concentric tube modules

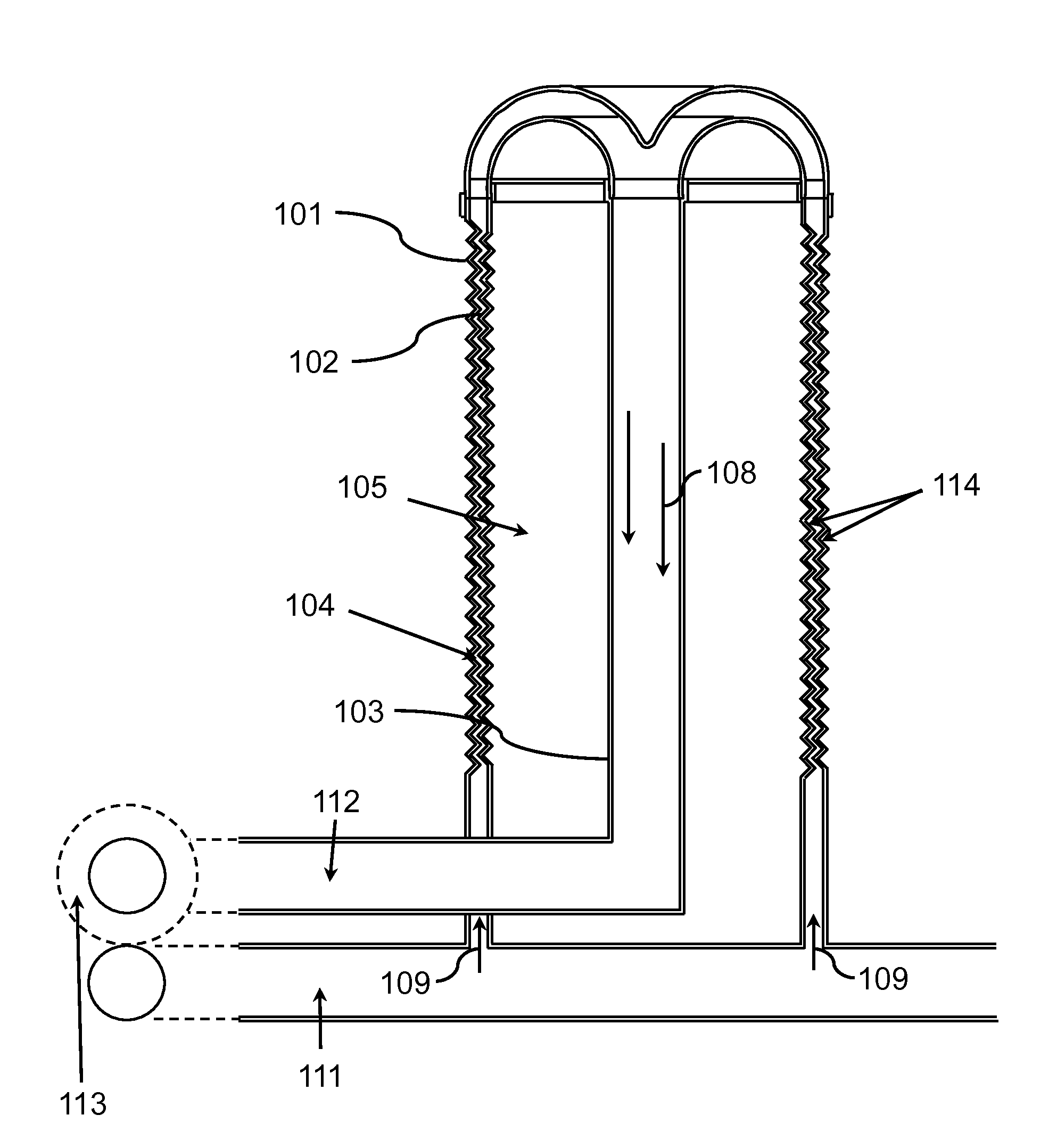

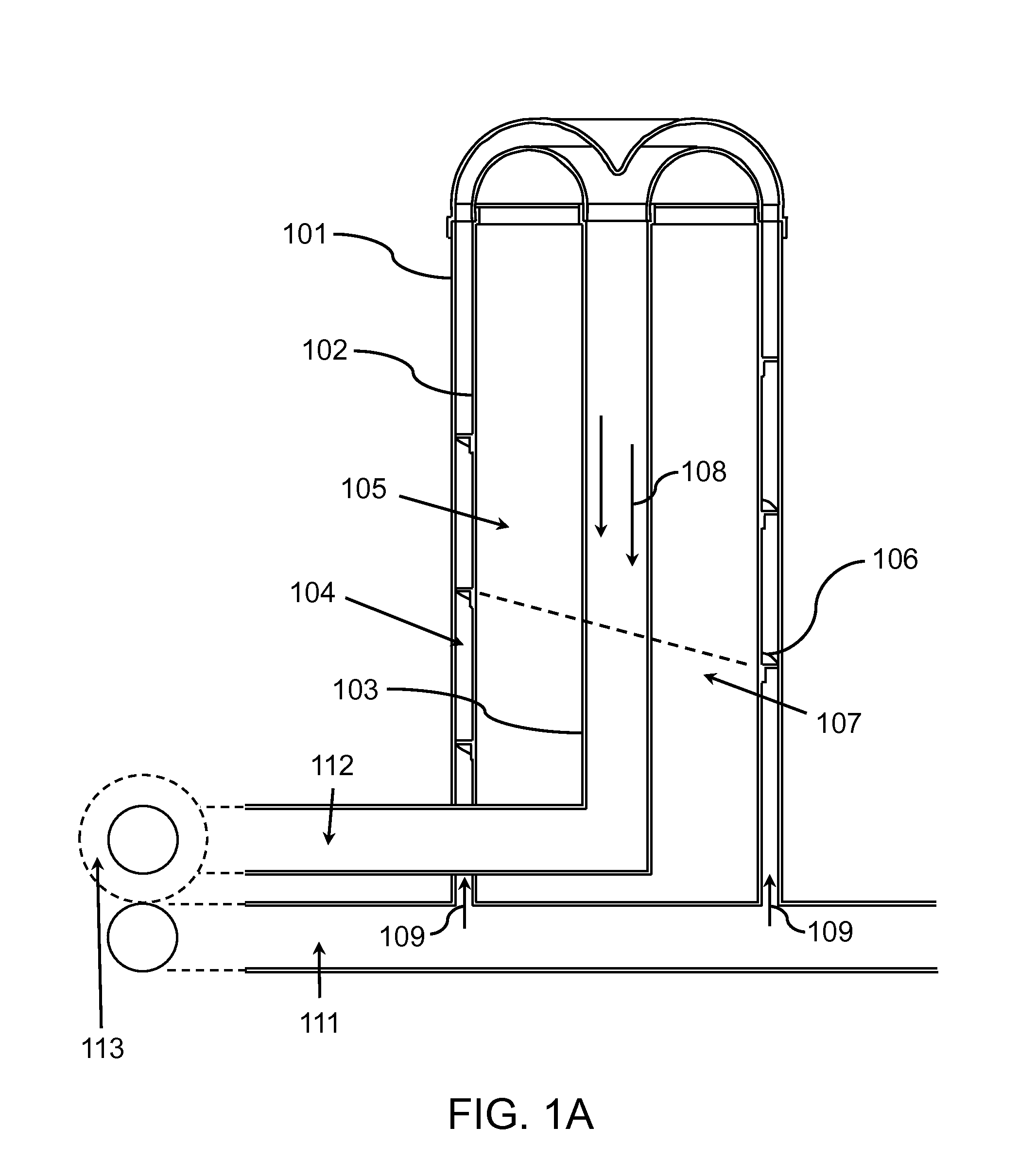

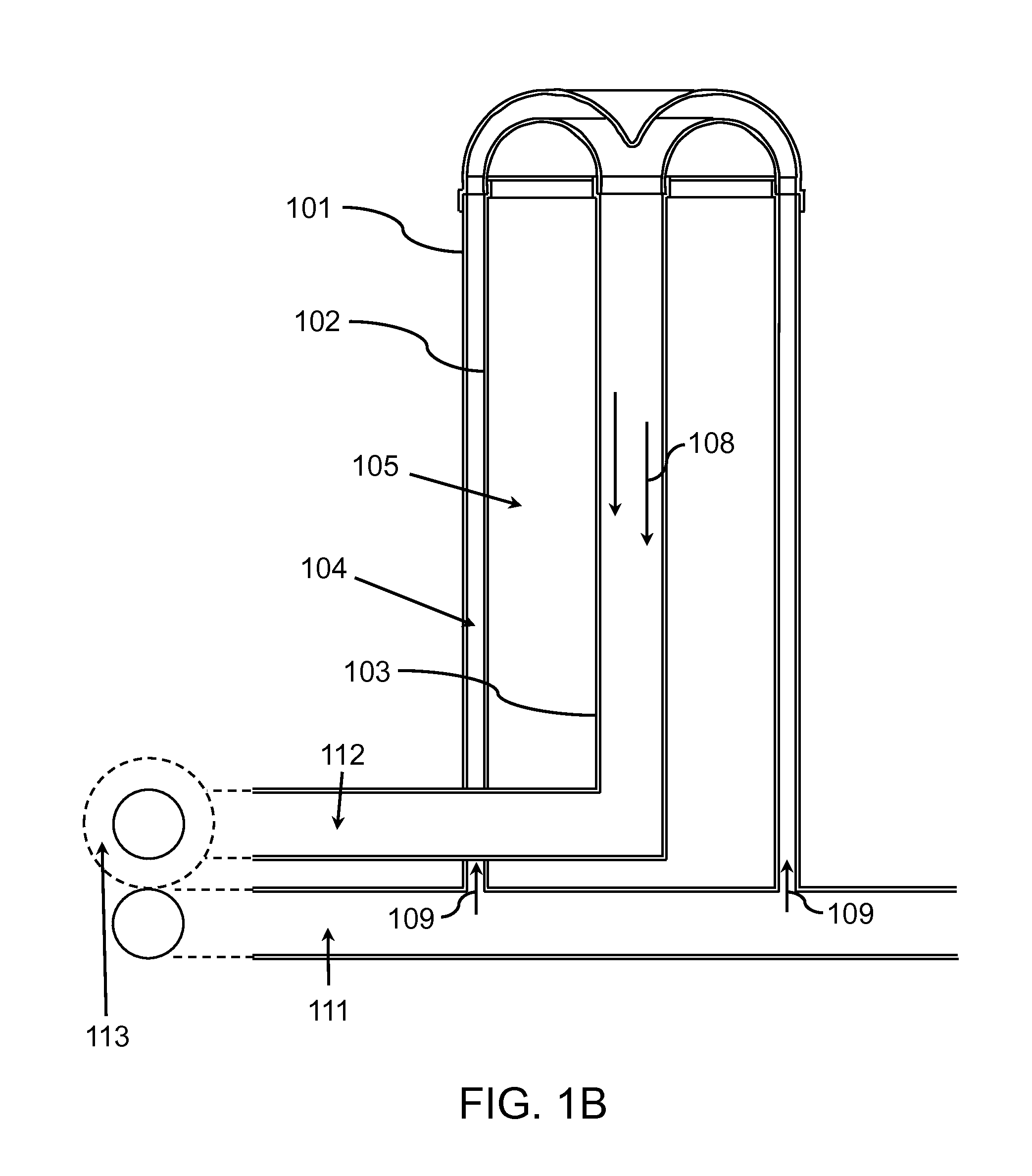

InactiveUS20130220310A1Adequate receiver characteristicGood heat transfer coefficientSolar heating energyHeat transfer optimizationThermal expansionEngineering

A solar thermal receiver with concentric tube modules is disclosed. The outer two tubes (101, 102) of each module form an annular gap (104) for the inlet flow (109) of a heat transfer fluid (HTF). A third inner tube (103) allows for the outlet flow (108) of the HTF. Each of the concentric tube modules is bottom-supported so as to allow for thermal expansion. Embodiments may include a structural element (750) to mitigate oscillation of the concentric tube modules and / or a top-mounted bell-shaped cap (534).

Owner:GREGORY CHRISTIAN THOMAS +1

Acrylic heat insulation coating with high reflectivity and preparation method of acrylic heat insulating coating

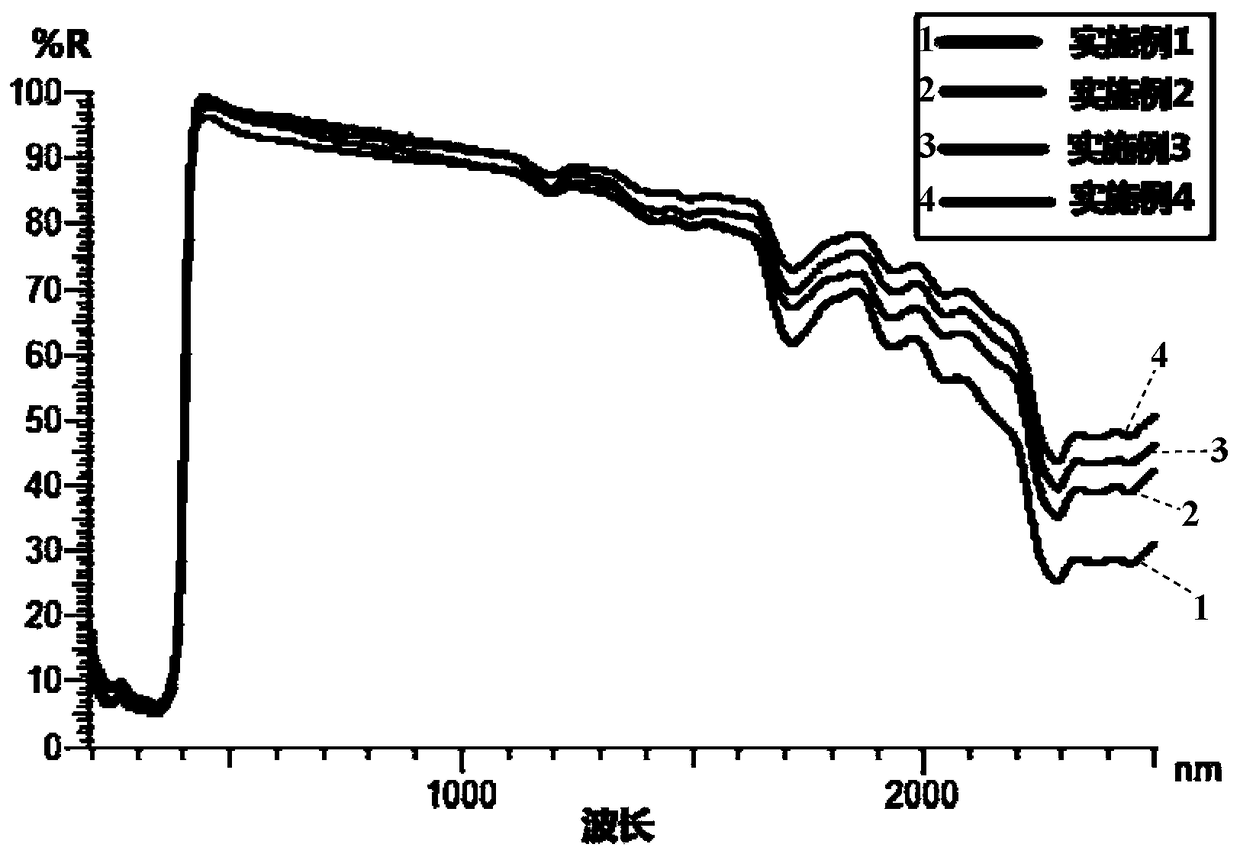

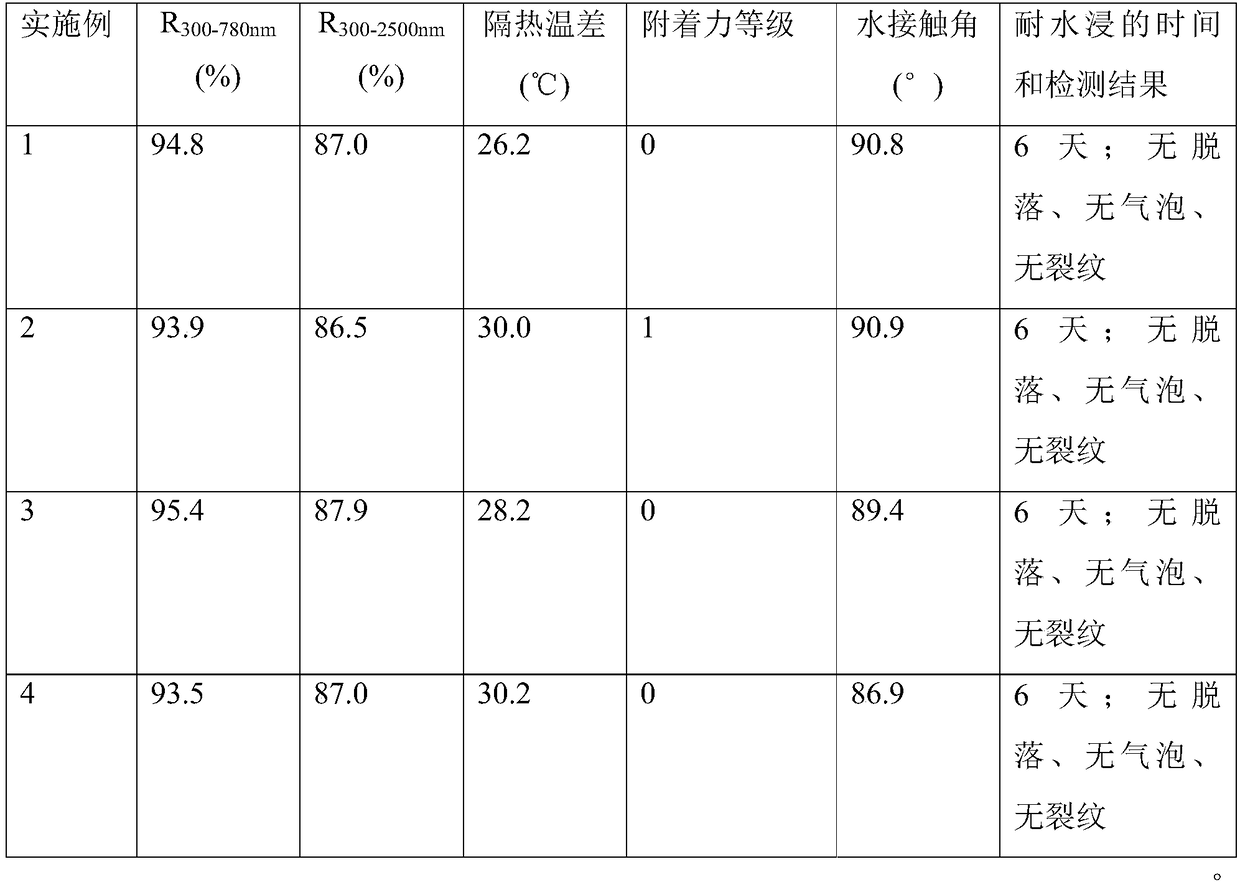

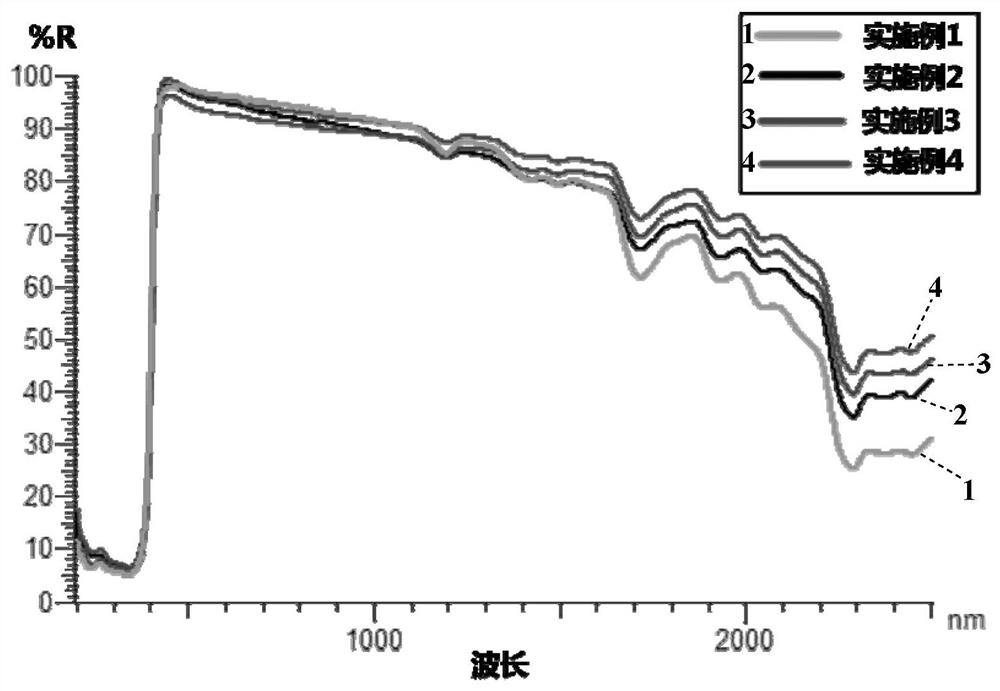

ActiveCN109233493AHigh dielectric constantStrong covering abilityReflecting/signal paintsHigh reflectivityLight wave

The invention relates to an acrylic heat insulation coating with high reflectivity and a preparation method of the acrylic heat insulating coating. The acrylic heat insulation coating with high reflectivity is prepared from 20wt%-55wt% of acrylic resin, 10wt%-33wt% of titanium dioxide, 6wt%-12wt% of modified aluminum powder, 3.2wt%-7.6wt% of heat insulation functional filler, 9wt%-17wt% of a mixedsolvent and the balance of aids, wherein the modified aluminum powder is flaky aluminum powder with the surface coated with titanium dioxide. Acrylic resin is used as a film forming substance, the high-reflectivity flaky aluminum powder with surface coated with titanium dioxide, titanium dioxide and the heat insulation functional filler with good heat insulation performance and very low heat transfer coefficient are added, so that the heat reflecting coating has the characteristic of integration of solar ray reflection, infrared light wave radiation and heat conduction barrier and has very good heat insulation and cooling effects.

Owner:SHANGHAI UNIV

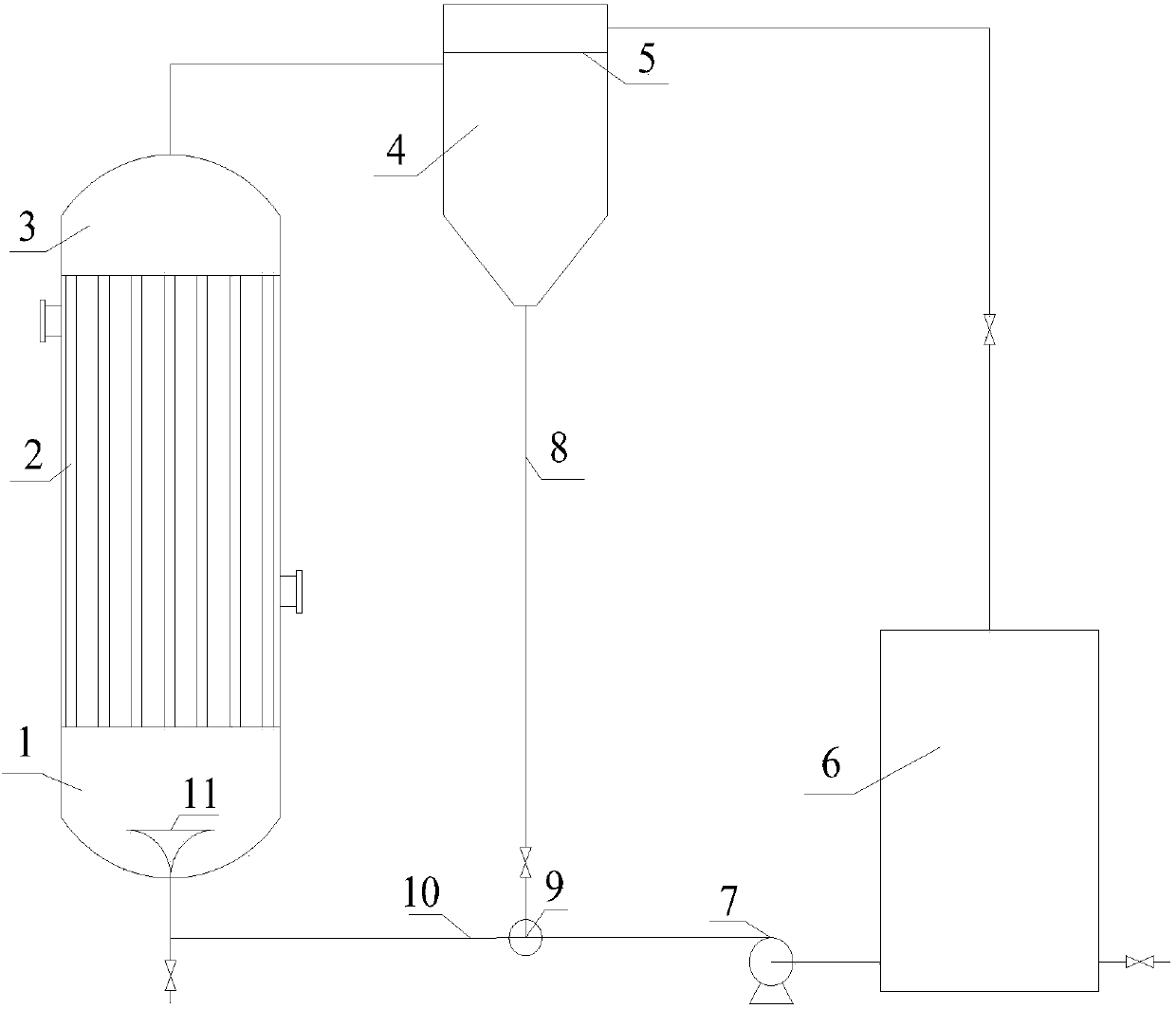

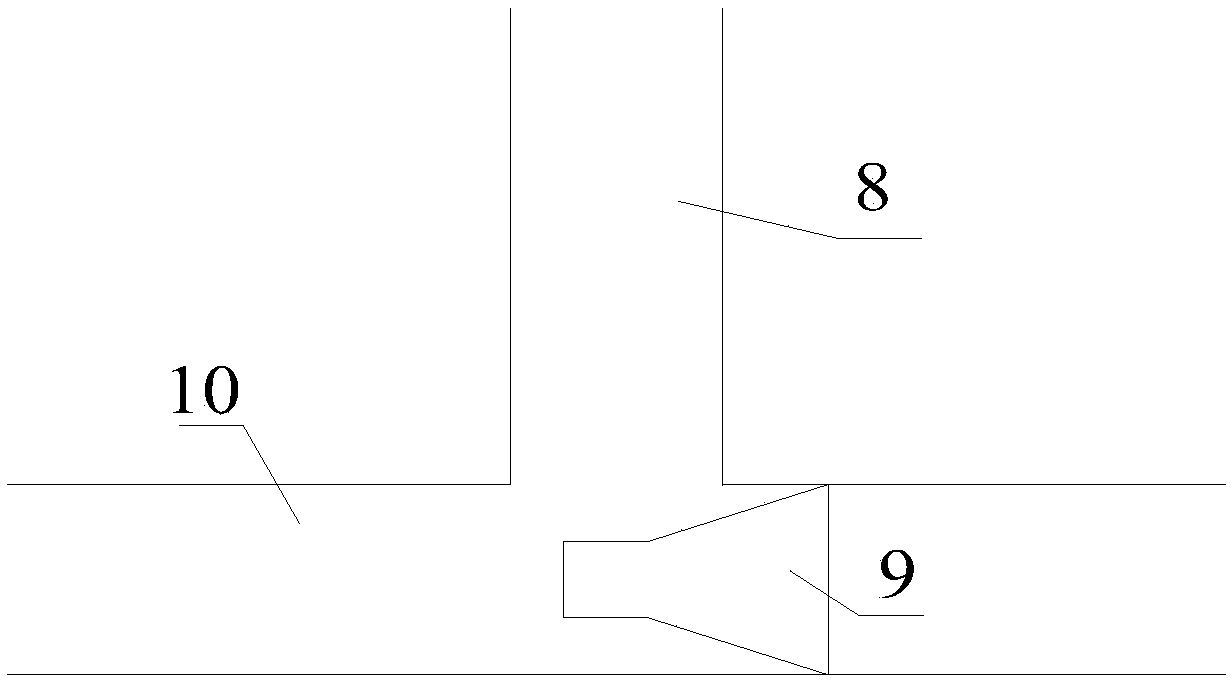

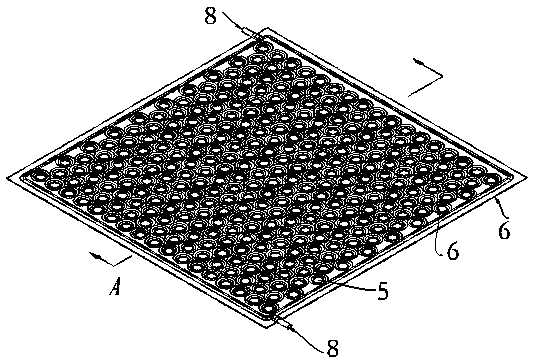

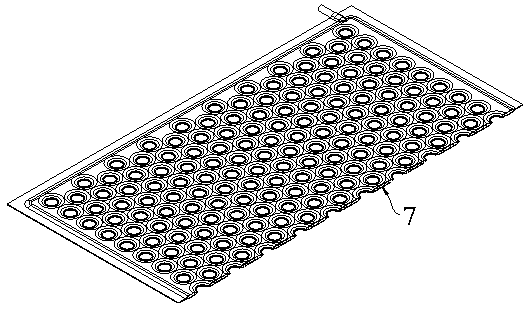

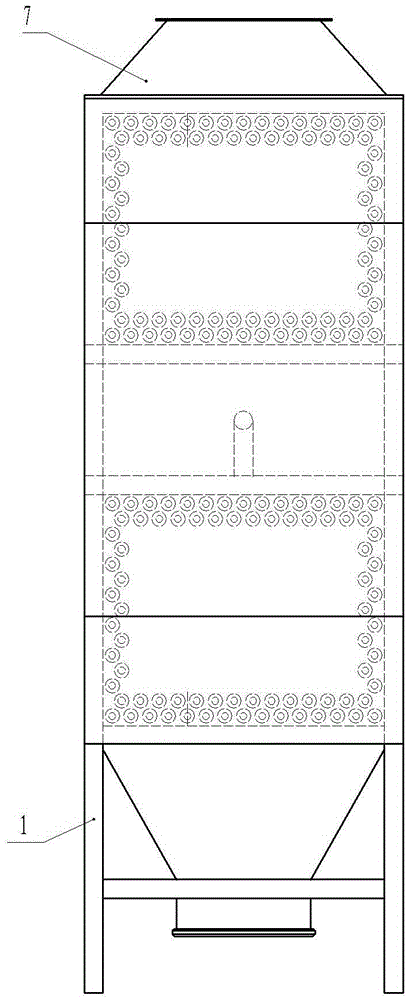

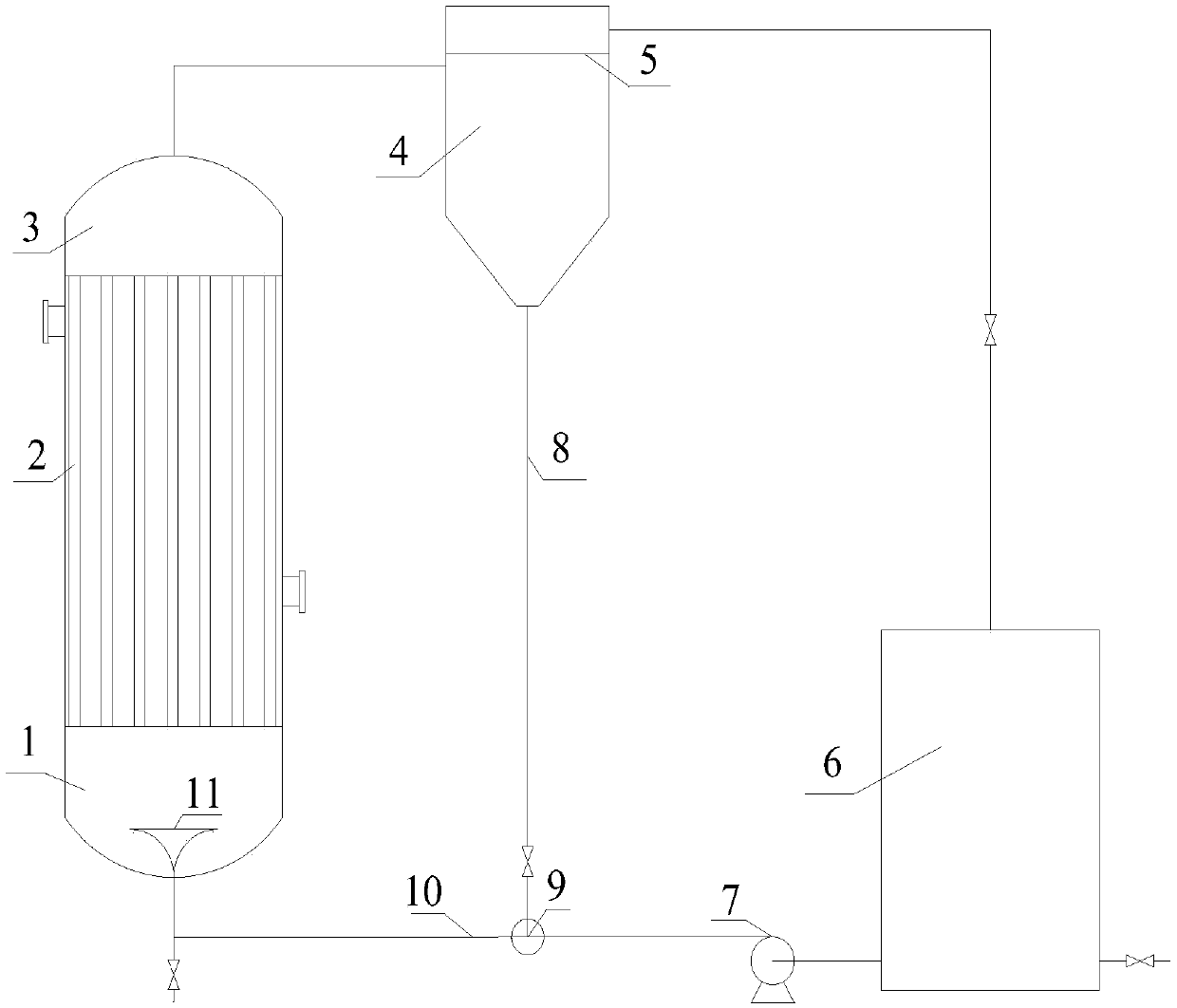

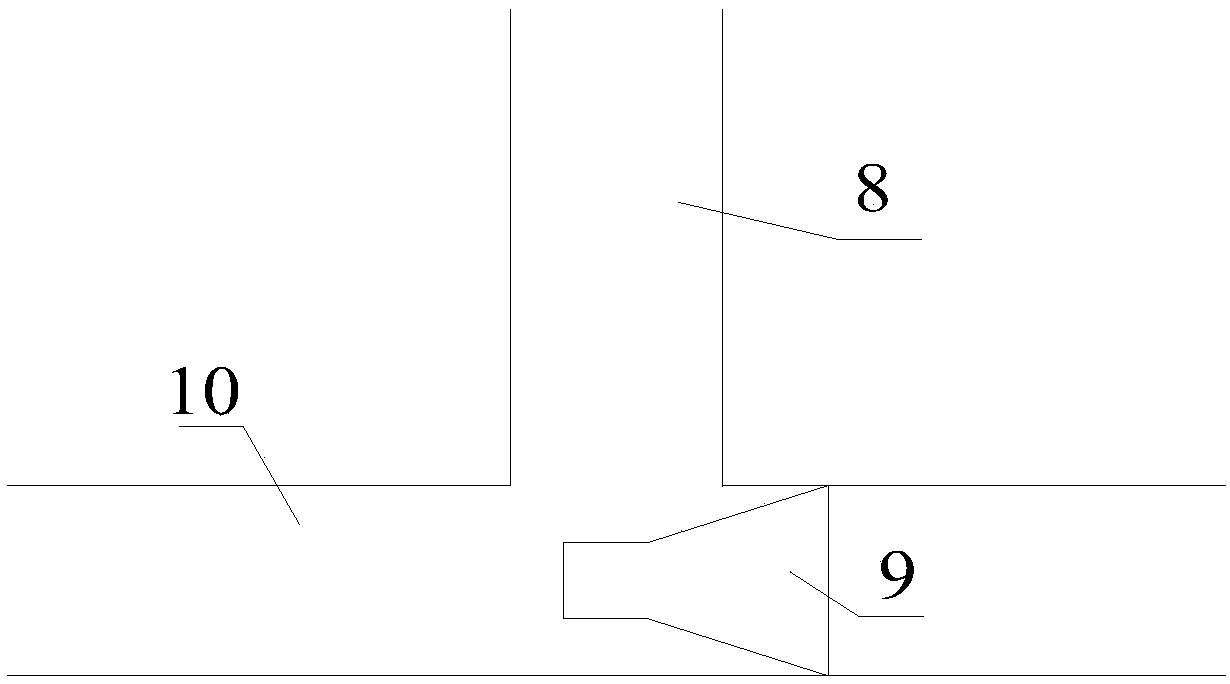

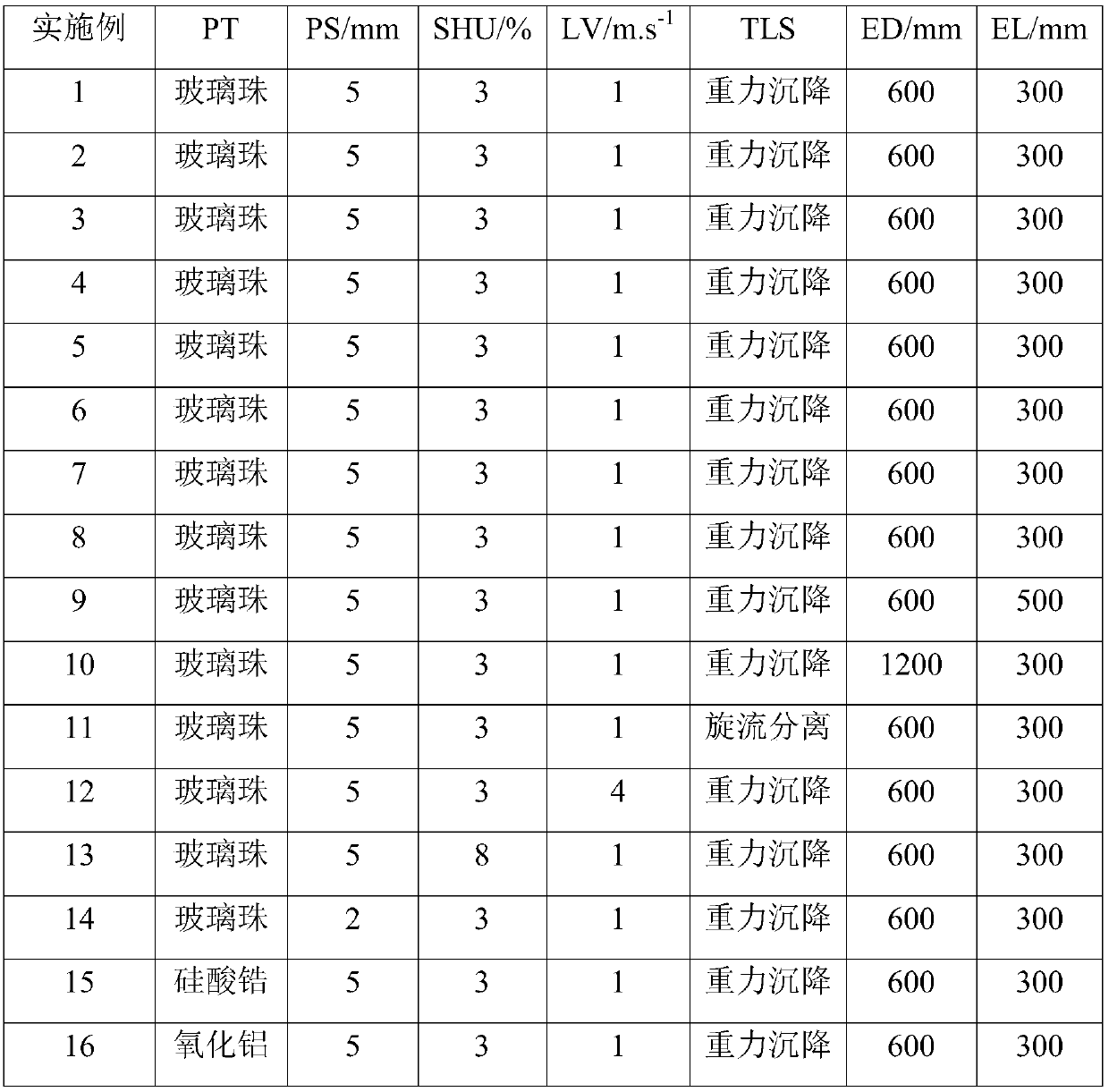

Self-cleaning fluidized bed heat exchanger

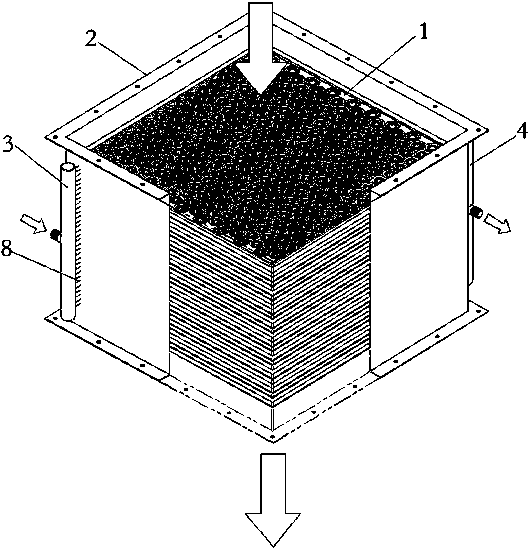

ActiveCN107764109AGood heat transfer coefficientThe heat transfer coefficient is still 97% of the original better technical effect is goodFlush cleaningFluidised bed heat exchangersPlate heat exchangerFluidized bed

The invention relates to a self-cleaning fluidized bed heat exchanger which is mainly used for solving the technical problems that in the prior art, the tube pass of a decarburization alkaline liquorcooler of an ammonia synthesizing device is prone to scaling, and the heat exchange effect is obviously decreased after long-period use. The self-cleaning fluidized bed heat exchanger comprises a lower tube box 1, a heat exchanger tube nest 2, an upper tube box 3, a liquid-solid separator 4, a particle filtering plate 5, a liquid storing tank 6, a liquid circulating pump 7, a downcomer 8, a spraynozzle 9, a horizontal pipe 10 and an expanding port 11, wherein the expanding port 11 is installed in the lower tube box 1, the upper tube box 3 is connected with the liquid-solid separator 4, solidparticles enter the spray nozzle 9 through the downcomer 8, and a liquid phase overflows from the upper portion of the particle filtering plate 5, enters the liquid storing tank 6 and circulates to the spray nozzle 9 through the liquid circulating pump 7. According to the technical scheme, the technical problems are well solved, and the self-cleaning fluidized bed heat exchanger can be used for prolonging the running cycle of the decarburization alkaline liquor cooler of the ammonia synthesizing device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Outer circulating fluidized bed heat exchanger

ActiveCN106595352AGood heat transfer coefficientThe heat transfer coefficient is still 95% of the original better technical effect is goodHeat exchanger casingsStationary tubular conduit assembliesMixed feedingPlate heat exchanger

The invention relates to an outer circulating fluidized bed heat exchanger. The outer circulating fluidized bed heat exchanger is mainly used for solving the technical problem that the tube pass of a reformed hydrogenation unit reaction effluent / mixed feeding heat exchanger is easy to scale in the prior art, and thus the heat exchange effect can be lowered obviously after long-period use. The outer circulating fluidized bed heat exchanger comprises a lower tube box 1, heat exchanger tube nests 2, an upper tube box 3, a solid-liquid separator 4, a down pipe 5, a solid particle groove 6, a liquid storage tank 7, a liquid circulating pump 8, lower edge sleeves 9, a distribution plate 10, a baffle 11 and a horn pipe. The heat exchanger tube nests 2 are connected with the upper tube box 3, and the upper tube box 3 is connected with the solid-liquid separator 4. Solid particles enter the solid particle groove 6 through the down pipe 5 and then return to the lower tube box 1. Liquid enters the liquid storage tank 7 and then is pumped to the lower tube box 1 through the liquid circulating pump 8. By the adoption of the technical scheme, the technical problem is well solved, and the outer circulating fluidized bed heat exchanger can be used for prolonging the operation cycle of the reformed hydrogenation unit reaction effluent / mixed feeding heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP +1

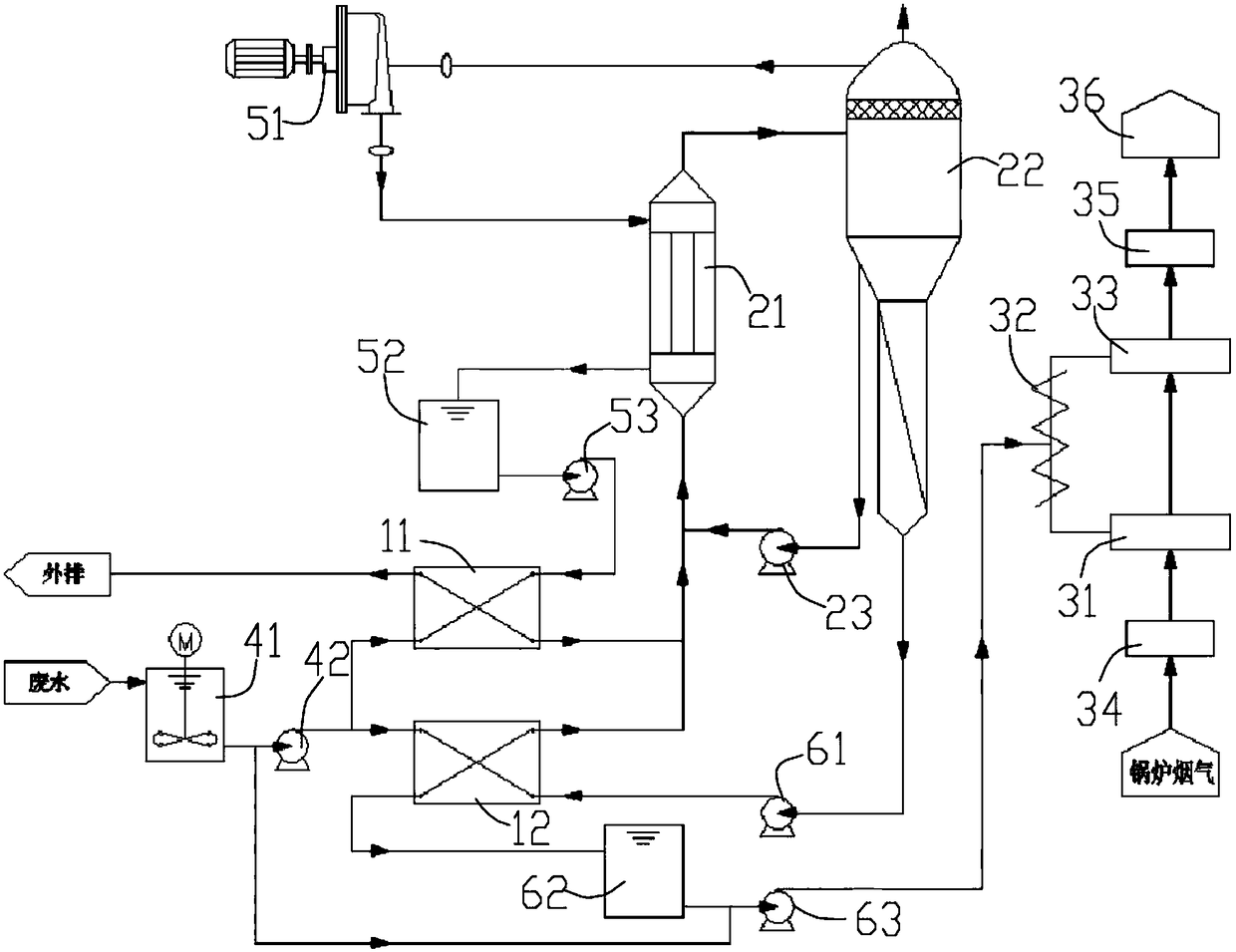

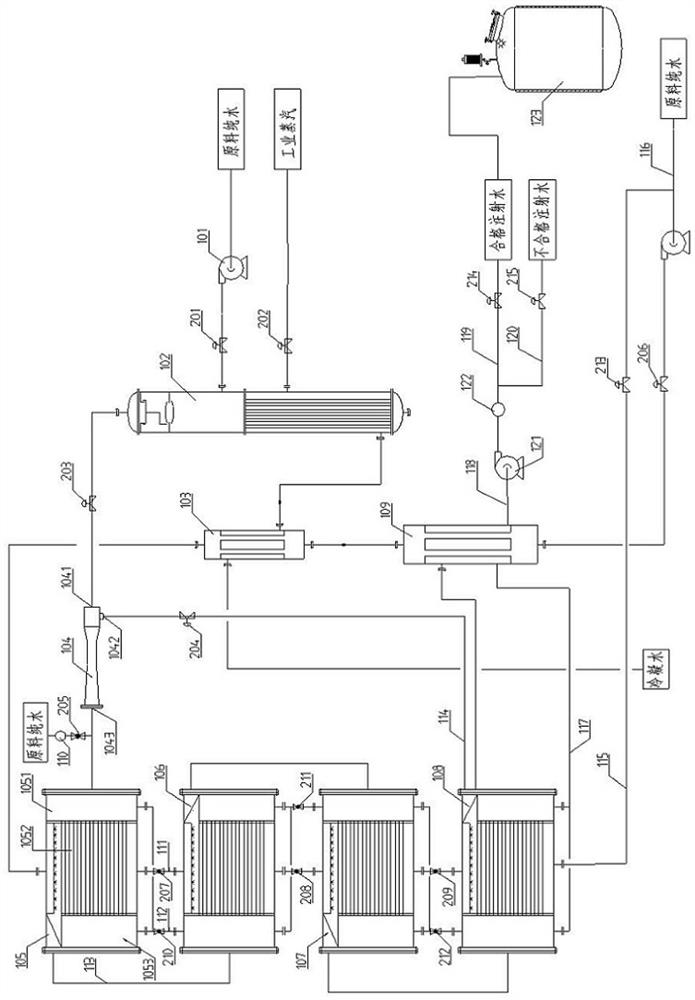

MVR concentration and swirling-flow atomization cooperated processing process and system

PendingCN108383313AReduce doseNo processing issuesMultistage water/sewage treatmentWater/sewage treatment by heatingAir preheaterFlue gas

The invention discloses an MVR concentration and swirling-flow atomization cooperated processing process and system. The process combines the MVR evaporation technology and a bypass flue swirling-flowatomization evaporation drying method to treat desulfurization waste water, the desulfurization waste water is subjected to preprocessing and heat exchanging and is concentrated in an MVR evaporationsystem, the concentrated desulfurization waste water is atomized by the swirling-flow atomization method and then enters a boiler bypass flue at the rear of an air preheater, boiler hot flue gas is used to evaporate and dry the wastewater, salt in the dried wastewater forms a powdered product, and the dried product enters an electrostatic precipitator along with the flue gas and is processed therein. The MVR concentration and swirling-flow atomization cooperated processing process and system can effectively lower energy consumption and can solve the salt treatment problem in desulfurization waste water zero emission.

Owner:GUANGDONG DEGA POWER ENVIRONMENTAL PROTECTION TECH CO LTD

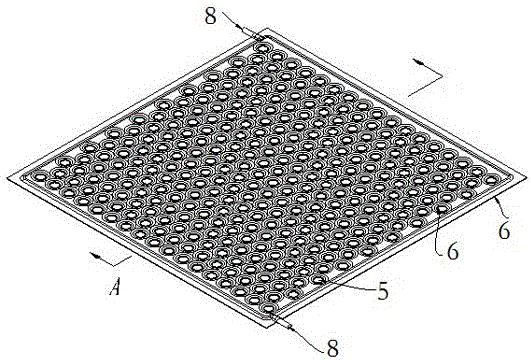

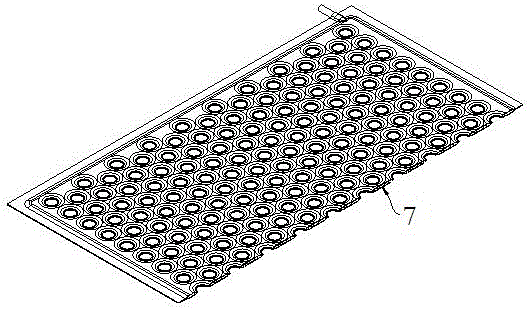

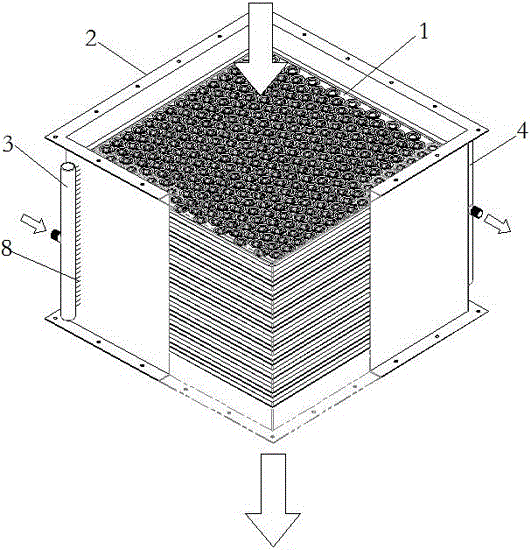

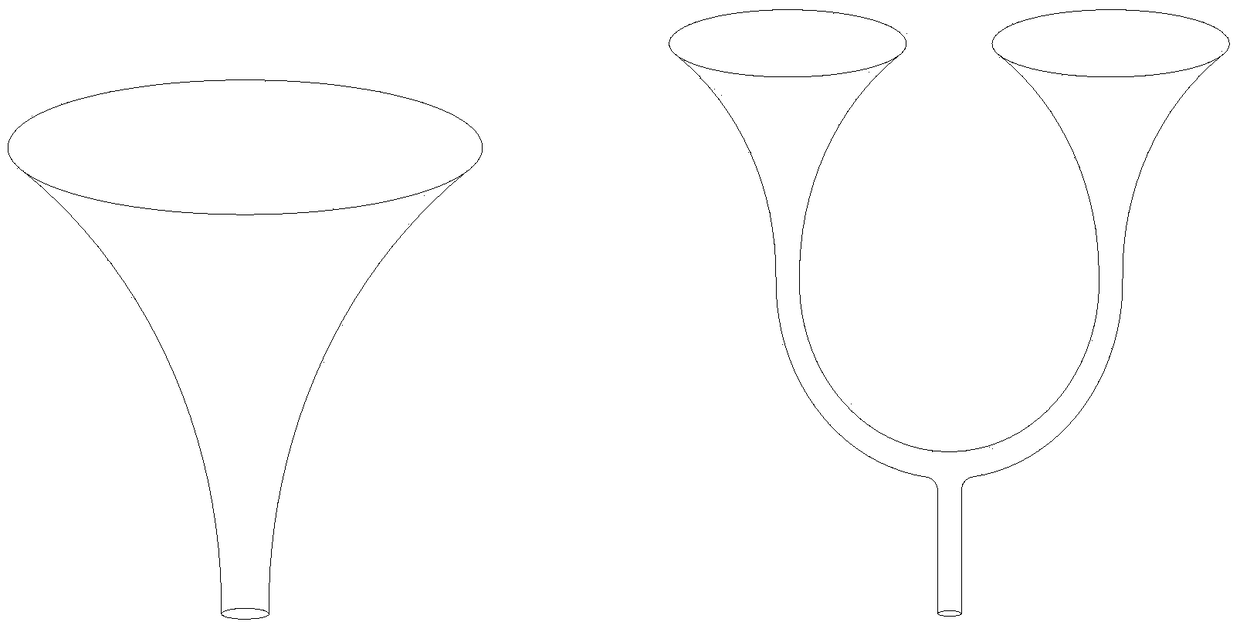

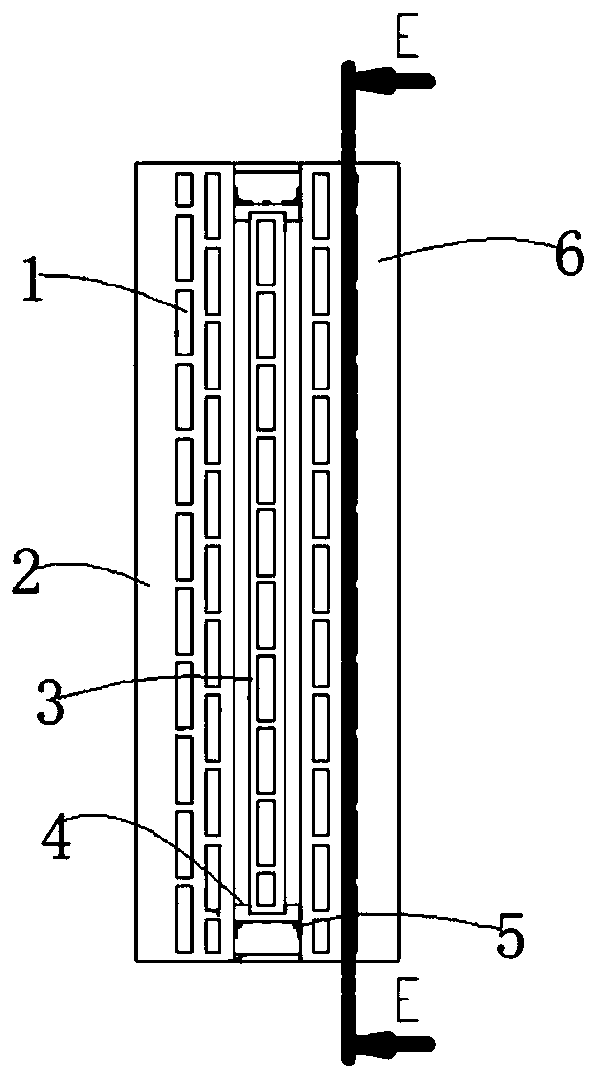

Heat exchanger with net type lung-shaped heat exchange plates

ActiveCN106152838ACompact structureLow flow resistanceLaminated elementsStationary plate conduit assembliesEngineeringExchange coefficient

The invention discloses a heat exchanger with net type lung-shaped heat exchange plates. The heat exchanger with the net type lung-shaped heat exchange plates comprises net type heat exchanger plates, a heat exchanger shell, a liquid inlet tube and a liquid outlet tube, wherein the net type heat exchanger plates are distributed in the heat exchanger shell from top to bottom at equal intervals to form a lung-shaped hollow structure; the liquid inlet tube and the liquid outlet tube are respectively arranged on the heat exchanger shell in the longitudinal direction; and according to each net type heat exchanger plate, two plate bodies with through holes are superposed vertically, the peripheries of the plate bodies and side seams of the through holes are welded together in an argon arc welding or laser welding mode, and a fluid channel in each plate is formed. By the heat exchanger with the net type lung-shaped heat exchange plates, fluid flowing resistance of the outside of each plate is reduced, meanwhile, large Reynolds number can be obtained at low speed, turbulent flow is formed, heat exchange coefficient is increased effectively, therefore, the heat exchanger is simple, efficient and energy-saving, and is compact in structure, occupied space and initial investment are saved, the resistance of the product is lower than that of a traditional plate type heat exchanger, and the heat exchange coefficient can be high.

Owner:SEHENSTAR ENERGY TECH SUZHOU

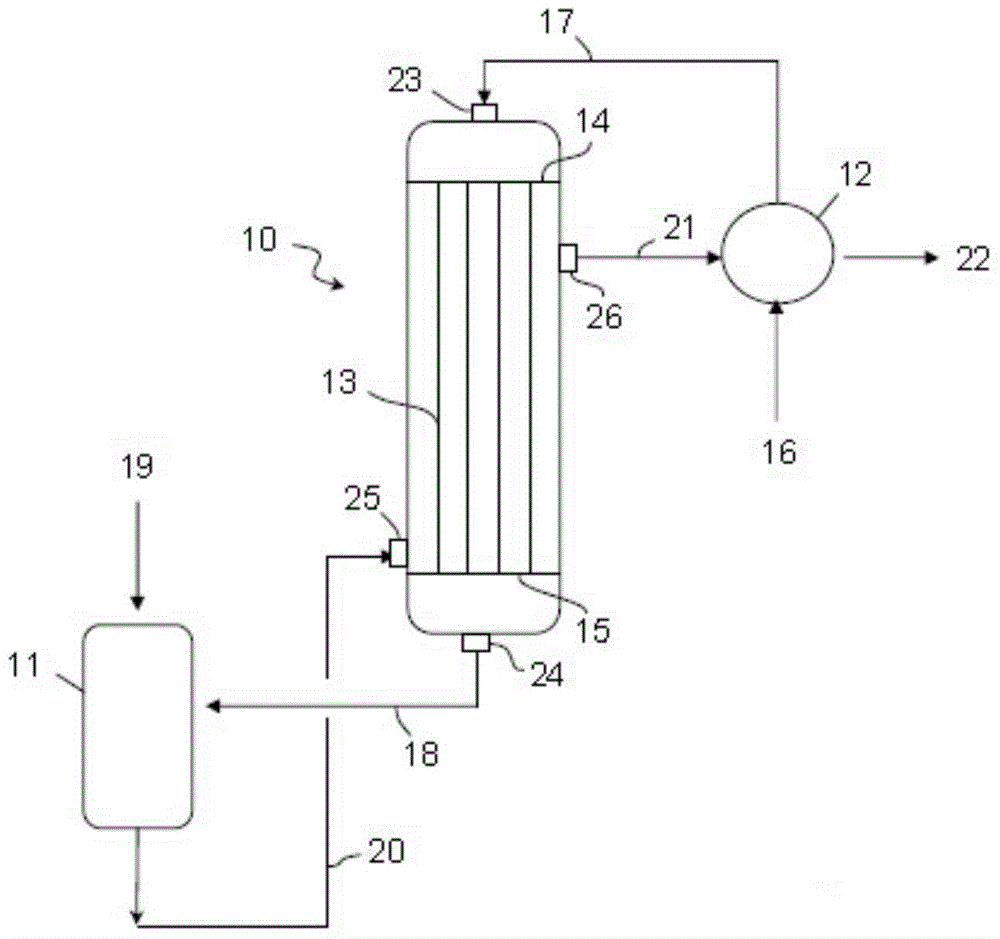

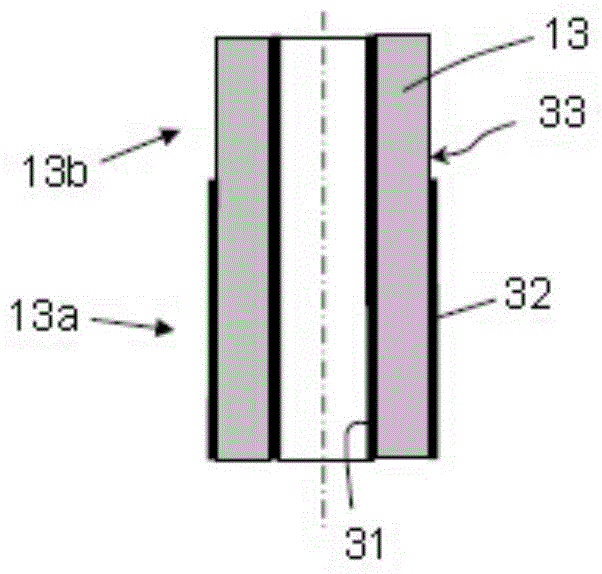

A process for gas-heated reforming of a hydrocarbon source and related equipment

InactiveCN104350007AReduce pressure dropGood heat transfer coefficientHydrogenHydrogen/synthetic gas productionSteam reformingProcess engineering

A process and equipment for steam reforming of a hydrocarbon source gas, where the hydrocarbon source gas and a steam flow are partially reformed while passing in a bundle of tubes (13) of a reformer (10), with a catalytically active inner surface; a partially reformed product gas (18) leaving said tubes is mixed with an oxidation agent (19) and subject to a combustion process; a combusted partially reformed gas (20) is introduced in the shell side of said reformer and further reformed by contact with the outer surface of said tubes (13), said outer surface of the tubes being also catalytically active.

Owner:CASALE SA

A kind of aluminum silicon draining agent and preparation method thereof

ActiveCN104493150BImprove performanceNo pollution in the processMelt-holding vesselsSteelmakingEnvironmental resistance

The invention provides an aluminum-silicon drainage agent and a preparation method thereof, belonging to the field of unshaped surface refractory materials used in the steelmaking industry. The technical solution of the present invention is: an aluminum-silicon drainage agent, which is composed of ceramic bead sand with a particle size of 0.5-1.2 mm, desert quartz sand with a particle size of 0.3-0.9 mm, phosphorus flake graphite with a particle size of ≤75 μm, and an adhesive It is made by first drying ceramic bead sand and desert quartz sand, then adding phosphorus flake graphite and binder, and stirring in a cylinder mixer to make it. The aluminum-silicon drainage agent of the present invention can effectively increase the casting rate of the product, so that the casting rate of the product can reach more than 98%, and at the same time greatly reduce the cost of the product, effectively reduce the emission of waste gas and dust, clean and environmentally friendly, and adapt to the current steel industry's requirements for product quality, Price and purity requirements of molten steel.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Medical injection water preparation system and control method thereof

ActiveCN113753994AGuaranteed uptimeOvercoming the problem of insufficient thermal efficiencyWater/sewage treatment by heatingMultiple-effect evaporationWater useWater production

The invention provides a medical injection water preparation system and a control method thereof. The medical injection water preparation system comprises a preparation unit and a control unit, wherein the preparation unit is used for preparing medical injection water; the control unit is arranged in the preparation unit and used for controlling and adjusting the preparation unit in the working process, so that in the medical injection water preparation system, the pressure of a steam generator is kept at 0.4-0.8 MPa, and the liquid level is kept at 5-35 cm; steam ejected from a steam outlet of a steam ejector is maintained to be saturated steam with a temperature of 112-125 DEG C; the temperature drop between two adjacent falling film evaporators is kept at 3-5 DEG C; and the water production ratio of qualified product water of the medical injection water preparation system is not less than 8. The system has the beneficial effects that the overheating phenomenon existing after pure water steam and supplementary steam are mixed is overcome, and the problem that the heat efficiency of the first-effect evaporator is insufficient due to elimination of the steam superheat degree is solved; and possible pipe emptying, pipe submerging and other bad working conditions in the system are eliminated, and high operation stability and ideal water production efficiency of the injection water preparation system are guaranteed.

Owner:山东沃德净水科技有限公司

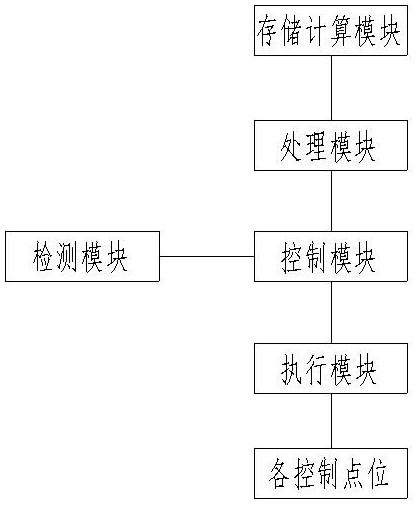

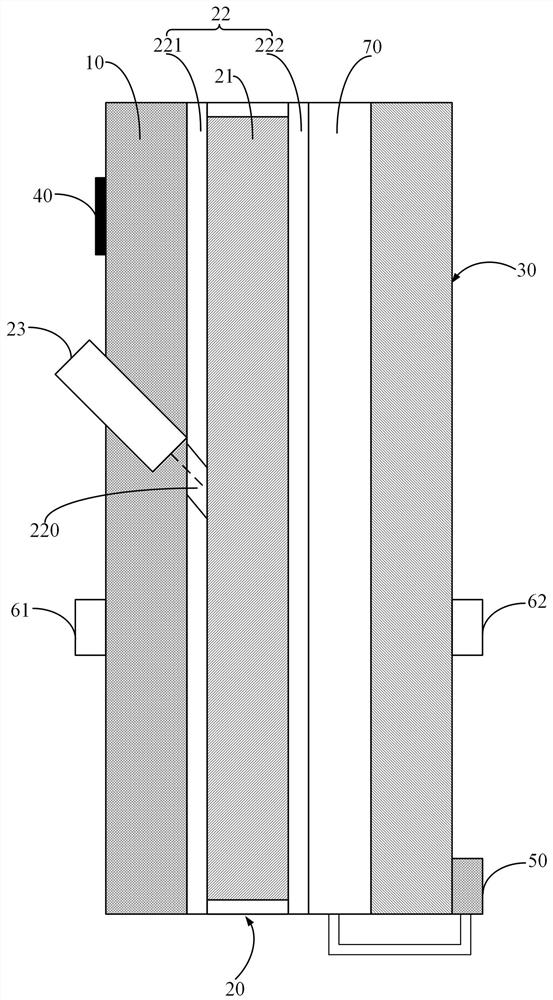

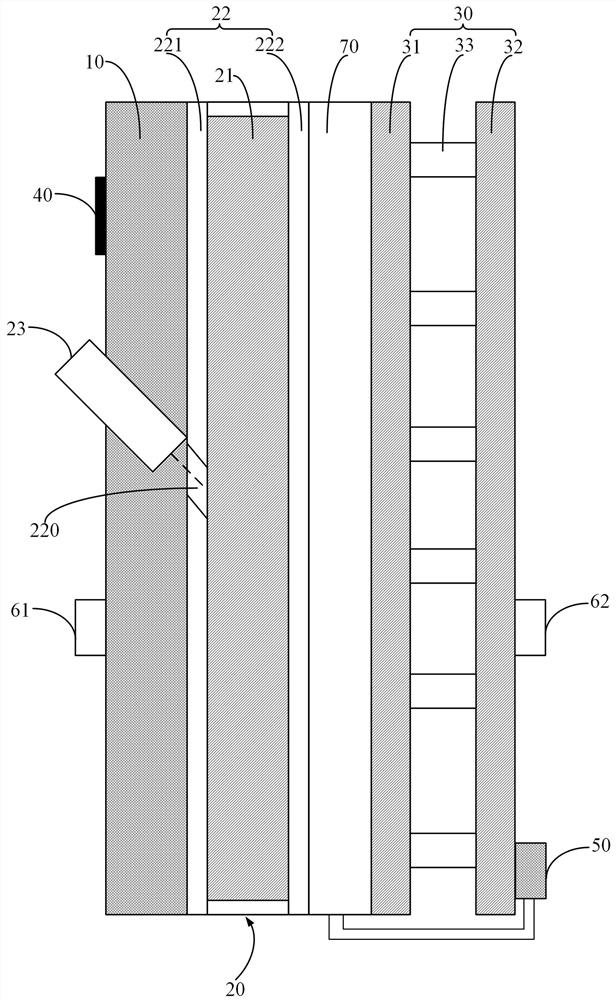

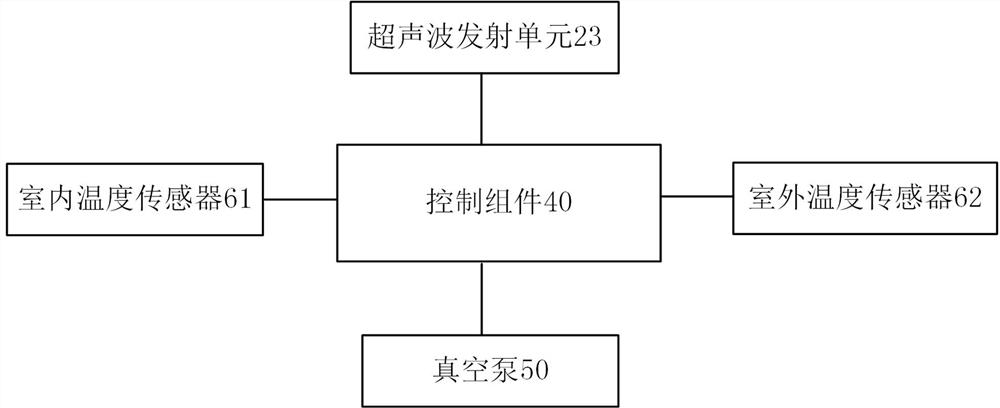

Heat exchange regulation and control system and heat exchange regulation and control method

InactiveCN112303773AGood heat transfer coefficientImprove insulation effectMechanical apparatusSpace heating and ventilation safety systemsControl systemEngineering

The invention is suitable for the technical field of building construction, and provides a heat exchange regulation and control system and a heat exchange regulation and control method. The heat exchange regulation and control system comprises a wall body, a heat exchange regulation and control assembly, a heat exchanger, a control assembly, a vacuum pump and a temperature sensing assembly. The heat exchange regulation and control assembly comprises a heat preservation layer, an ultrasonic reflecting layer and an ultrasonic transmitting unit, the outer surface of the heat preservation layer iswrapped by the ultrasonic reflecting layer, an ultrasonic inlet is formed in the ultrasonic reflecting layer, and ultrasonic waves generated by the ultrasonic transmitting unit enter the heat preservation layer through the ultrasonic inlet. A closed space is formed between the ultrasonic reflecting layer and the heat exchanger, and the vacuum pump communicates with the closed space and is electrically connected with the control assembly. The temperature sensing assembly comprises an indoor temperature sensor and an outdoor temperature sensor which are electrically connected with the control assembly. The heat exchange regulation and control system can meet different requirements of different regions and different seasons for the building wall heat exchange performance, and energy consumption can be effectively reduced.

Owner:北京天通慧智科技有限公司 +1

Anti-scaling fluidized bed heat exchanger

ActiveCN106595351BGood heat transfer coefficientCorrosion preventionStationary tubular conduit assembliesFluidized bedLiquid storage tank

The invention relates to an anti-scaling and de-scaling heat exchanger for a fluidized bed. The anti-scaling and de-scaling heat exchanger is aimed at solving the technical problem in the prior art. Therefore, tube passes of a decarburized lye cooler of a synthetic ammonia device are not easily scaled. After long-term use, the heat exchange effect is still good. The anti-scaling and de-scaling heat exchanger is composed of a lower tube box 1, a heat exchanger tube array 2, an upper tube box 3, a liquid-solid separator 4, a descending tube 5, a solid particle groove 6, a liquid storage tank 7, a liquid circulating pump 8, a distribution box 9, a spherical plug 10, a baffle plate 11, a distribution disc 12, a distribution plate 13, slim tubes 14 and a lower-edge sleeve tube 15. An outlet of the distribution box 9 is connected with the slim tubes 14. The heat exchanger tube array 2 is connected with the upper tube box 3 connected with the liquid-solid separator 4. Solid phase enters the solid particle groove 6 through the descending tube 5. Liquid phase enters the liquid storage tank 7. The solid phase and liquid phase circulate to return the lower tube box 1. The anti-scaling and de-scaling heat exchanger for the fluidized bed has following beneficial effects: by adoption of the technical scheme, the above technical problem is solved; and the anti-scaling and de-scaling heat exchanger can be used for prolonging running cycle of the decarburized lye cooler of the synthetic ammonia device.

Owner:CHINA PETROLEUM & CHEM CORP +1

External circulating fluidized bed heat exchanger

ActiveCN106595352BGood heat transfer coefficientHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerMixed feeding

The invention relates to an outer circulating fluidized bed heat exchanger. The outer circulating fluidized bed heat exchanger is mainly used for solving the technical problem that the tube pass of a reformed hydrogenation unit reaction effluent / mixed feeding heat exchanger is easy to scale in the prior art, and thus the heat exchange effect can be lowered obviously after long-period use. The outer circulating fluidized bed heat exchanger comprises a lower tube box 1, heat exchanger tube nests 2, an upper tube box 3, a solid-liquid separator 4, a down pipe 5, a solid particle groove 6, a liquid storage tank 7, a liquid circulating pump 8, lower edge sleeves 9, a distribution plate 10, a baffle 11 and a horn pipe. The heat exchanger tube nests 2 are connected with the upper tube box 3, and the upper tube box 3 is connected with the solid-liquid separator 4. Solid particles enter the solid particle groove 6 through the down pipe 5 and then return to the lower tube box 1. Liquid enters the liquid storage tank 7 and then is pumped to the lower tube box 1 through the liquid circulating pump 8. By the adoption of the technical scheme, the technical problem is well solved, and the outer circulating fluidized bed heat exchanger can be used for prolonging the operation cycle of the reformed hydrogenation unit reaction effluent / mixed feeding heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP +1

A heat exchanger of a mesh-type lung-shaped heat exchange plate

ActiveCN106152838BCompact structureLow flow resistanceLaminated elementsStationary plate conduit assembliesEngineeringExchange coefficient

The invention discloses a heat exchanger with net type lung-shaped heat exchange plates. The heat exchanger with the net type lung-shaped heat exchange plates comprises net type heat exchanger plates, a heat exchanger shell, a liquid inlet tube and a liquid outlet tube, wherein the net type heat exchanger plates are distributed in the heat exchanger shell from top to bottom at equal intervals to form a lung-shaped hollow structure; the liquid inlet tube and the liquid outlet tube are respectively arranged on the heat exchanger shell in the longitudinal direction; and according to each net type heat exchanger plate, two plate bodies with through holes are superposed vertically, the peripheries of the plate bodies and side seams of the through holes are welded together in an argon arc welding or laser welding mode, and a fluid channel in each plate is formed. By the heat exchanger with the net type lung-shaped heat exchange plates, fluid flowing resistance of the outside of each plate is reduced, meanwhile, large Reynolds number can be obtained at low speed, turbulent flow is formed, heat exchange coefficient is increased effectively, therefore, the heat exchanger is simple, efficient and energy-saving, and is compact in structure, occupied space and initial investment are saved, the resistance of the product is lower than that of a traditional plate type heat exchanger, and the heat exchange coefficient can be high.

Owner:SEHENSTAR ENERGY TECH SUZHOU

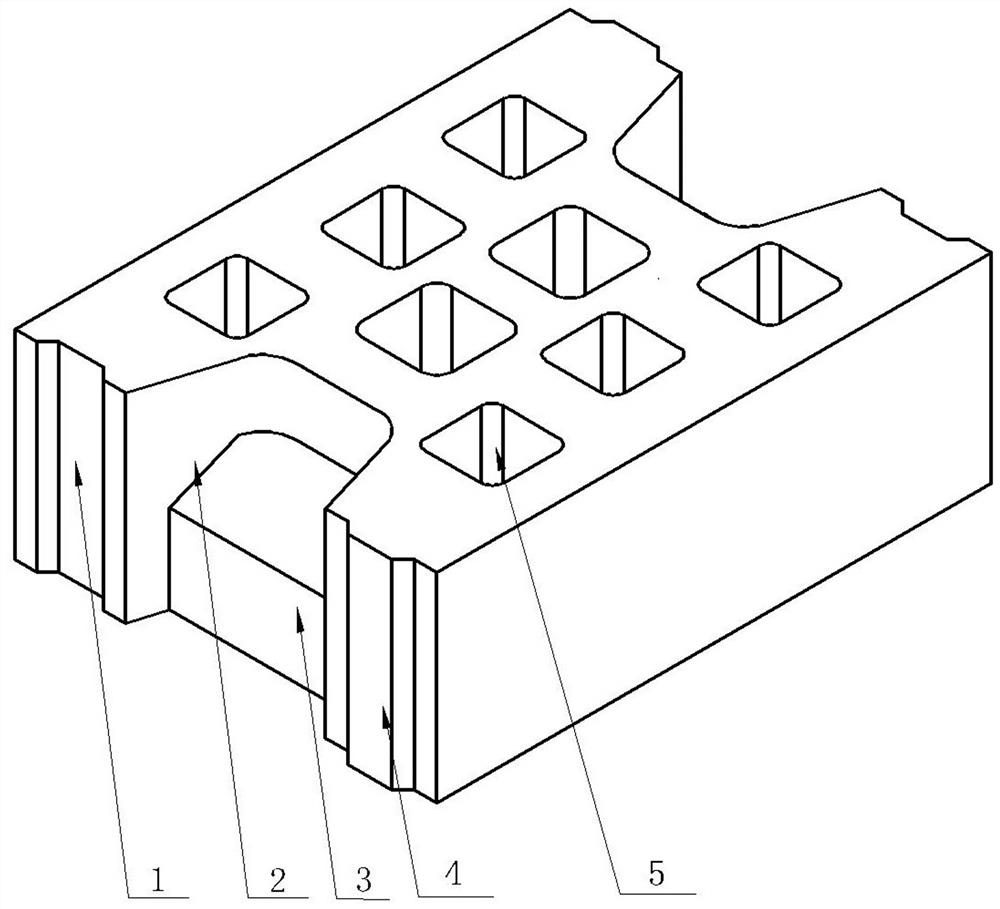

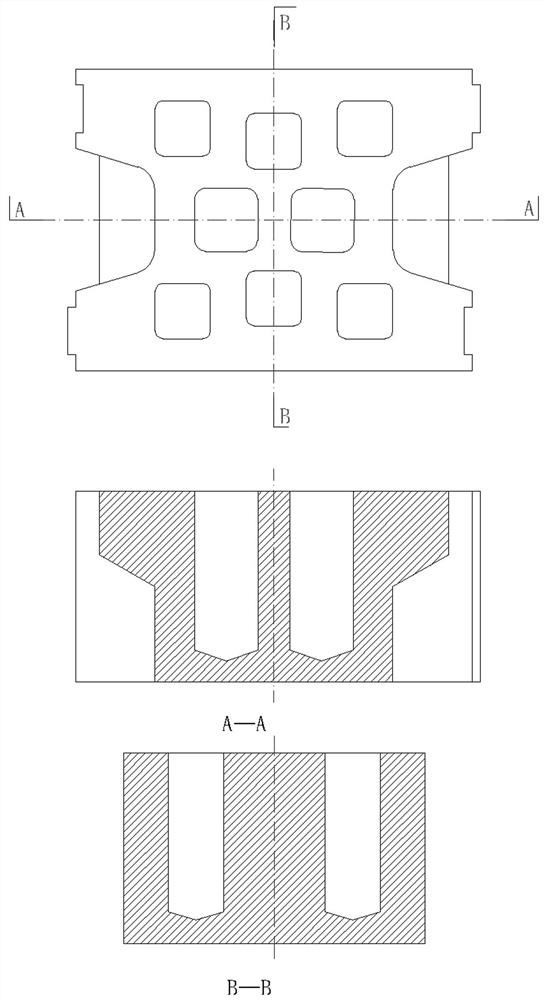

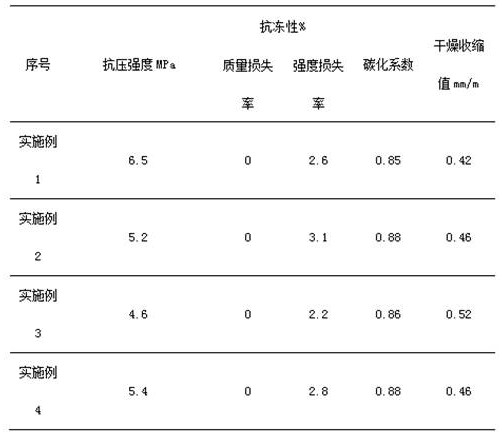

An energy-saving autoclaved fly ash hollow building wall material

ActiveCN109678552BGuarantee the fullness requirements of the slurryGuaranteed surface flatnessCeramicwareSodium metasilicateThermal insulation

Owner:HENAN BUILDING MATERIALS RES & DESIGN LNSTITUTE CO LTD

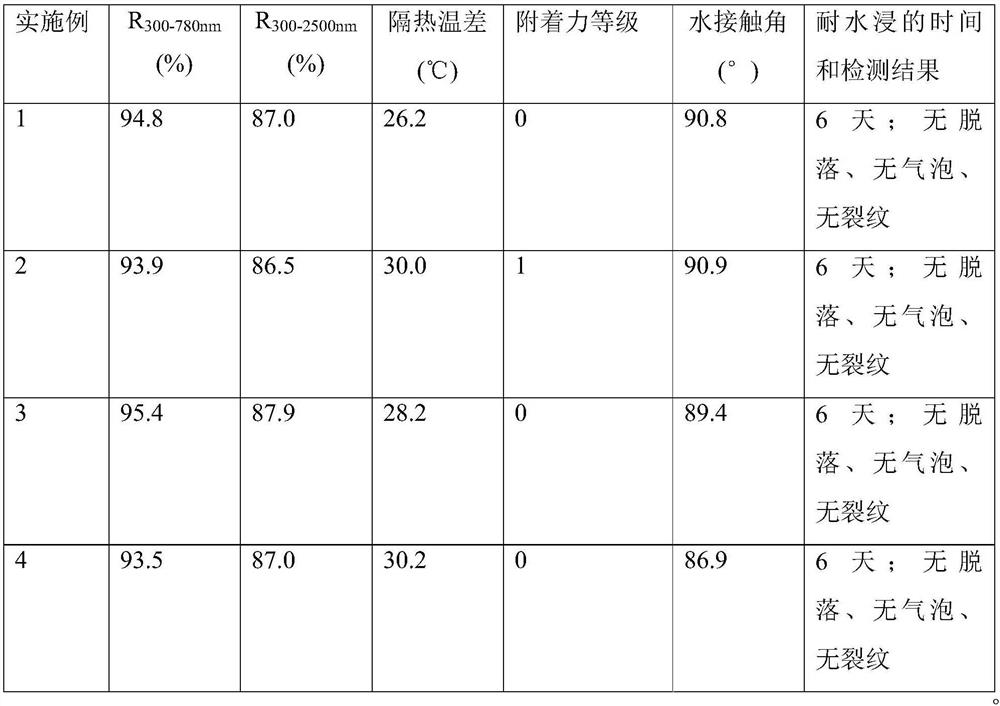

A kind of high-reflectivity acrylic heat-shielding paint and preparation method thereof

ActiveCN109233493BGood insulation function packingGood heat transfer coefficientReflecting/signal paintsAcrylic resinPhysical chemistry

The invention relates to an acrylic heat insulation coating with high reflectivity and a preparation method of the acrylic heat insulating coating. The acrylic heat insulation coating with high reflectivity is prepared from 20wt%-55wt% of acrylic resin, 10wt%-33wt% of titanium dioxide, 6wt%-12wt% of modified aluminum powder, 3.2wt%-7.6wt% of heat insulation functional filler, 9wt%-17wt% of a mixedsolvent and the balance of aids, wherein the modified aluminum powder is flaky aluminum powder with the surface coated with titanium dioxide. Acrylic resin is used as a film forming substance, the high-reflectivity flaky aluminum powder with surface coated with titanium dioxide, titanium dioxide and the heat insulation functional filler with good heat insulation performance and very low heat transfer coefficient are added, so that the heat reflecting coating has the characteristic of integration of solar ray reflection, infrared light wave radiation and heat conduction barrier and has very good heat insulation and cooling effects.

Owner:SHANGHAI UNIV

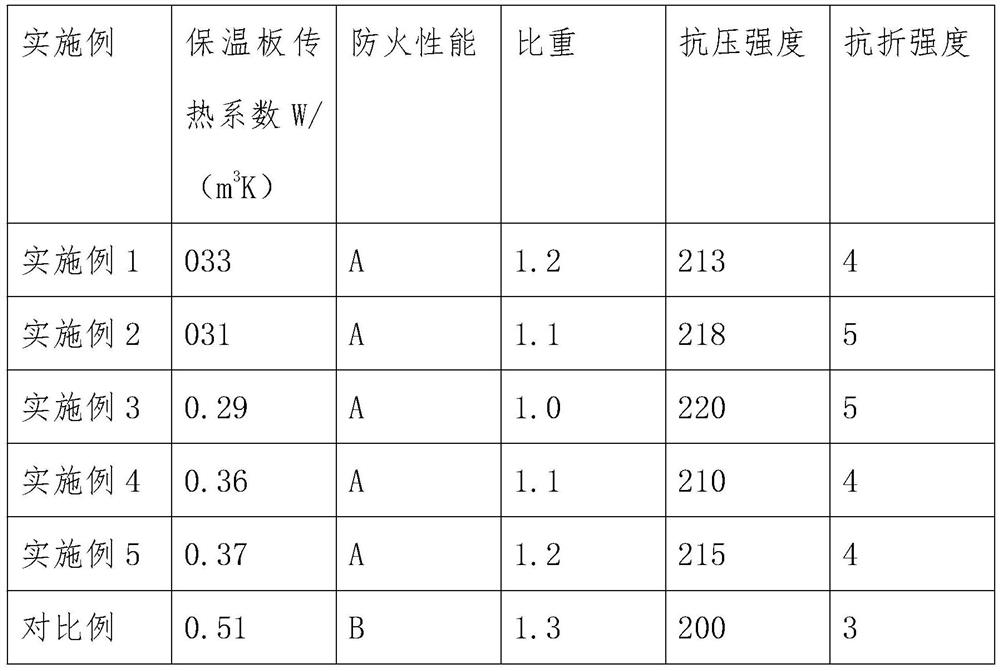

Insulation board and manufacturing method thereof

The invention discloses an insulation board which is prepared from the following raw materials in parts by weight: 25 to 33 parts of slag powder, 20 to 28 parts of sawdust, 18 to 26 parts of straw fiber, 10 to 18 parts of adhesive, 15 to 23 parts of polystyrene resin, 22 to 30 parts of foaming agent, 8 to 16 parts of antioxidant, 5 to 13 parts of stabilizer, 1 to 5 parts of fire retardant and 5 to 13 parts of catalyst. Further, the insulation board comprises the following raw materials in parts by weight: 25 parts of slag powder, 20 parts of sawdust, 18 parts of straw fibers, 10 parts of an adhesive, 15 parts of polystyrene resin, 22 parts of a foaming agent, 8 parts of an antioxidant, 5 parts of a stabilizer, 1 part of a fireproof agent and 5 parts of a catalyst. The prepared heat insulation board is good in heat transfer coefficient, fireproof performance, specific gravity, compressive strength and breaking strength and has low heat conductivity so that better heat insulation performance is guaranteed, and the insulation board has excellent toughness and rigidity.

Owner:上海望实建筑工程有限公司

Boiler Air Preheater

ActiveCN103267302BNot easy to corrodeReduce dust accumulationCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention discloses an air preheater for a boiler, relating to the technical field of manufacturing of a heat exchanger. The air preheater for the boiler comprises a heat exchanger casing which is provided with a smoke inlet and a smoke outlet; a heater exchange pipe box is arranged in the heat exchanger casing and provided with an upper heat exchange pipe box with an air outlet, and a lower heat exchange pipe box with an air outlet, and an air channel is connected between the upper heat exchange pipe box and the lower heat exchange pipe box; each of the upper heat exchange pipe box and the lower heat exchange pipe box is provided with a plurality of heat exchange pipes which are inserted between two mounting plates, the outer surface of each heat exchange pipe is provided with fins, and a turbulator component is inserted in each heat exchange pipe; and an acoustic wave soot blower is arranged between the upper heat exchange pipe box and the lower heat exchange pipe box. Compared with the prior art, the air preheater has the advantages that the total heat exchange coefficient of the air prehater is improved by 2-4 times.

Owner:GUANGXI ZHIYUAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

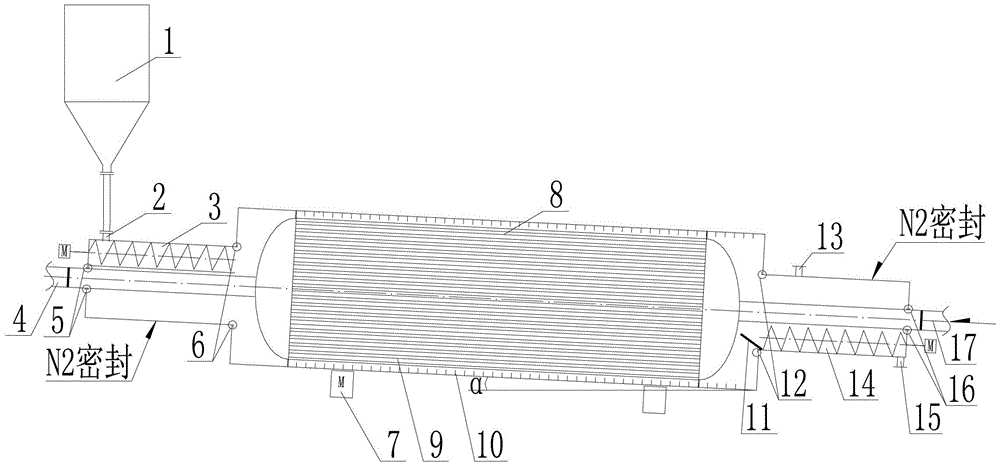

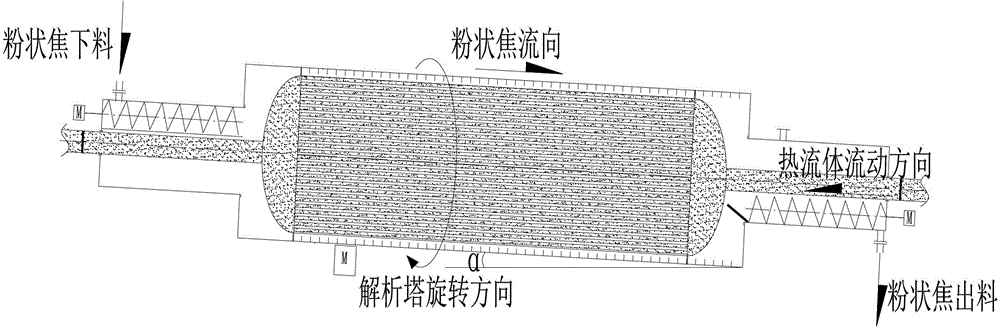

A powdery coke analyzing device and analyzing method thereof

ActiveCN103071474BPrevent leakageSimple structureDispersed particle separationCombustible gas purificationDesorptionNitrogen

The invention provides a powdery coke desorption device. The powdery coke desorption device comprises an unloading cabin (1), an inlet material screw feeder (3), a rotary desorption tower (9), a rotary motor (7), and an outlet material screw unloading machine (14). The unloading cabin (1) is connected to a material inlet (2) of the inlet material screw feeder (3) by a feeding pipe. The rotary desorption tower (9) comprises a heat exchange tube (8) combined with the tower body. The inlet material screw feeder (3) installed on an upper part of the rotary desorption tower (9), the outlet material screw unloading machine (14) installed on a lower part of the rotary desorption tower (9), and the rotary desorption tower (9) are arranged in a housing filled with nitrogen. Joints of the rotary desorption tower (9), and the inlet material screw feeder (3) and the outlet material screw unloading machine (14) are sealed by high temperature-resistant seal rings (6, 12). The rotary motor (7) is connected to the exterior of the tower body of the rotary desorption tower (9).

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

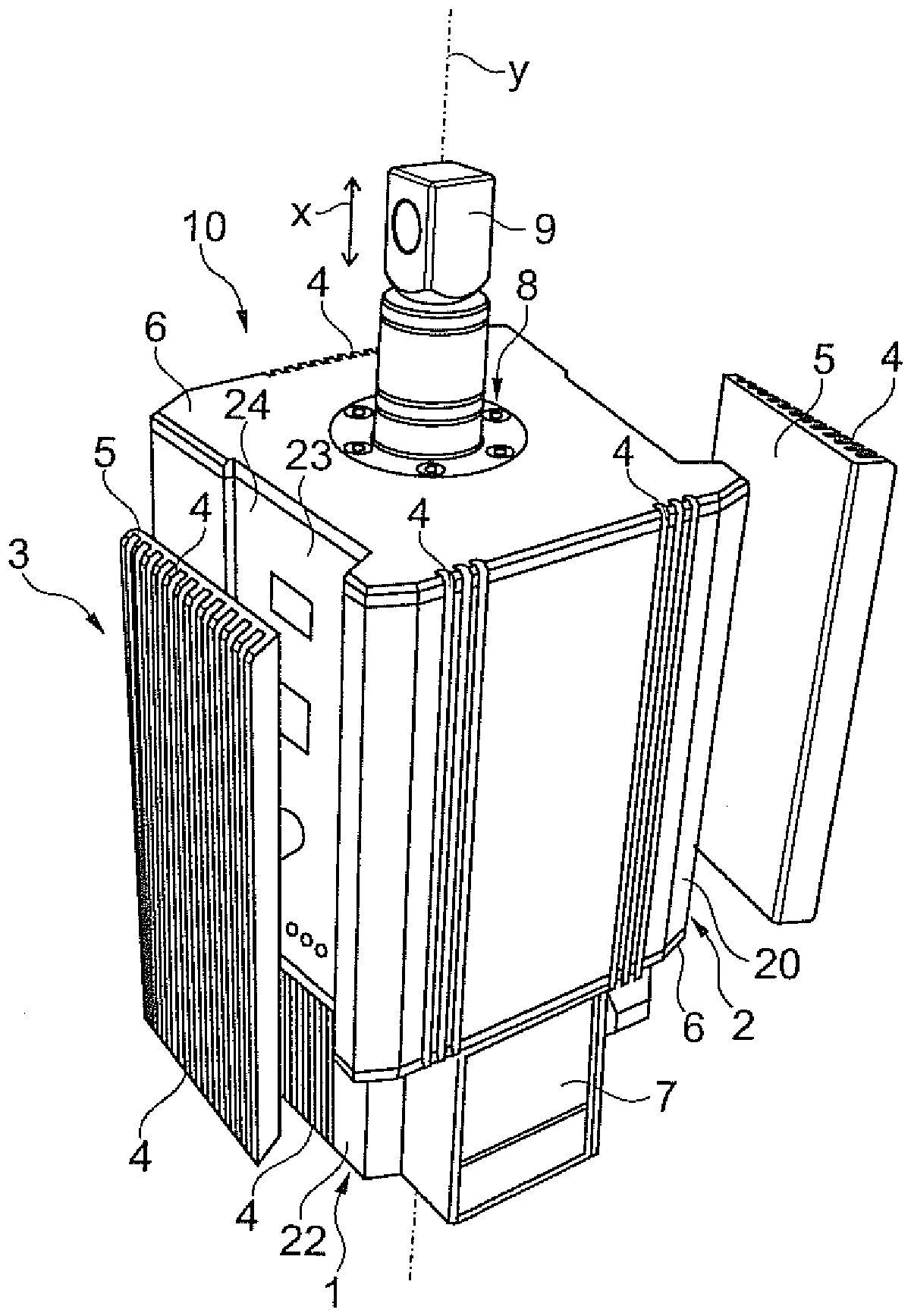

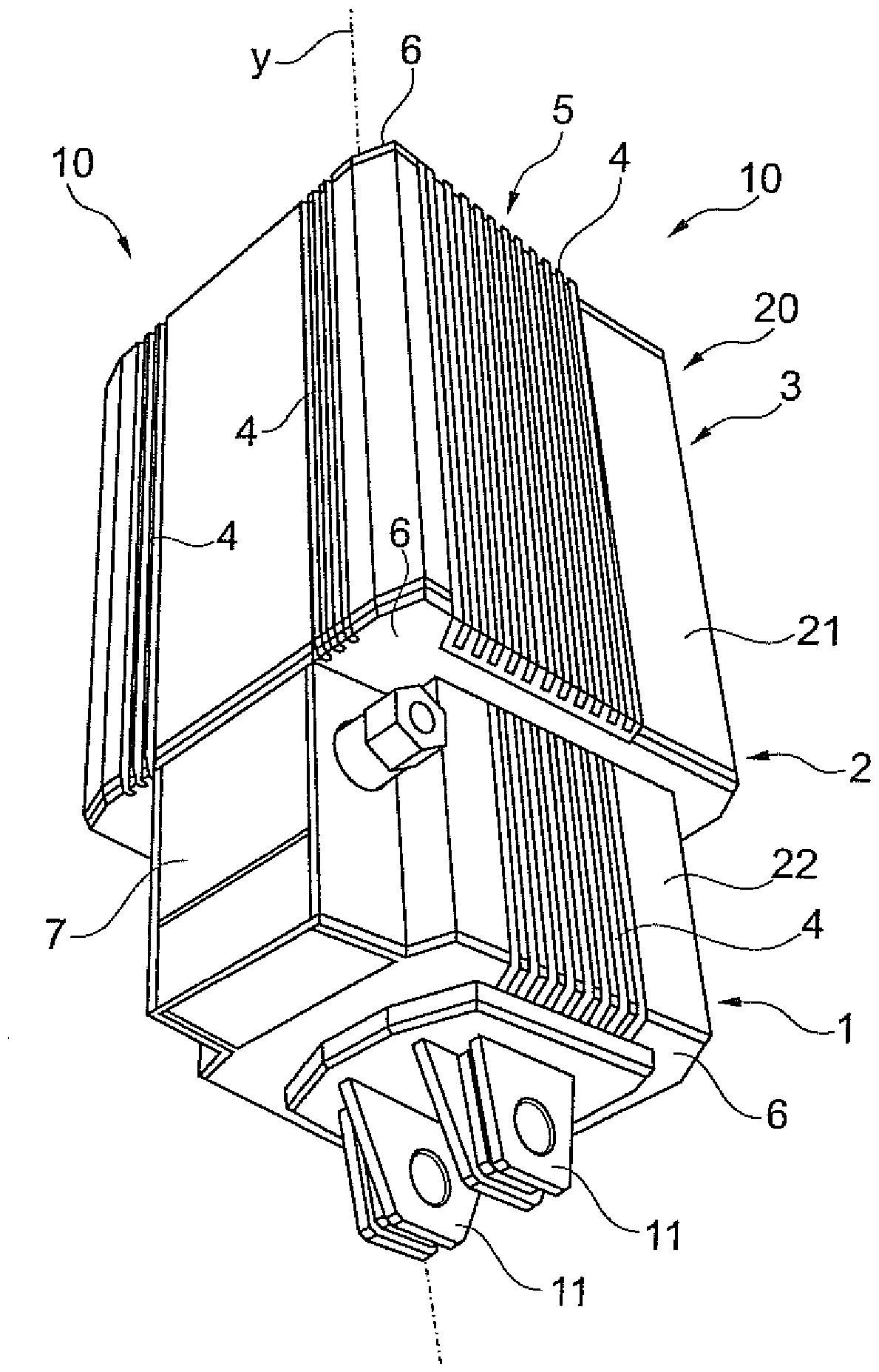

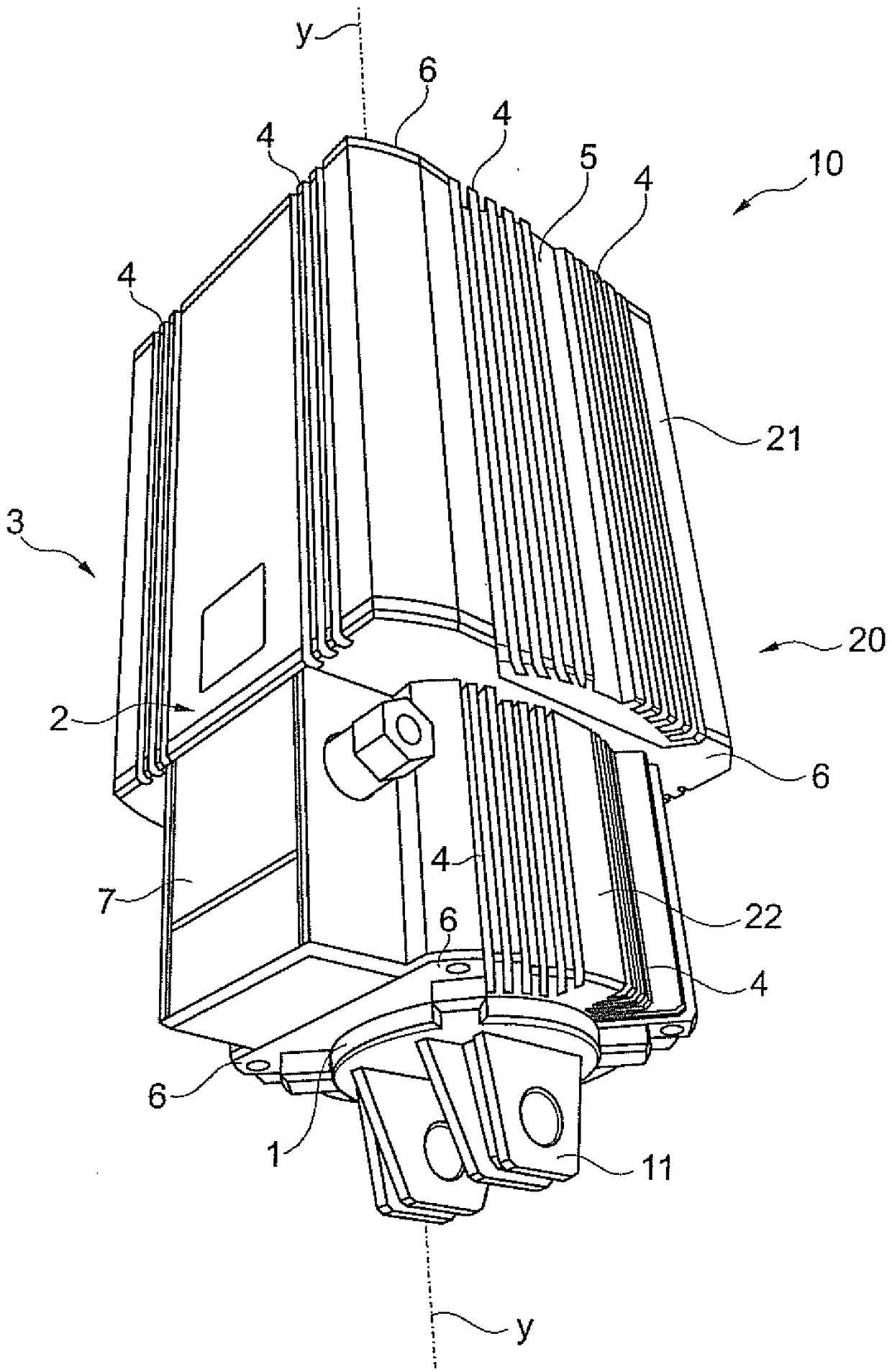

Electrohydraulic actuating device with cooling modules

InactiveCN109476284AEasy to manufactureGood removal effectVehicle sub-unit featuresBrake coolingElectro hydraulicEngineering

An electrohydraulic actuating device (10), having an electric motor (1) and having a pump (2) driven by said electric motor, for the operation of a hydraulic control cylinder (8) of a hydraulic unit (3), wherein the motor (1) and the hydraulic unit (3) are each accommodated in a housing part (21, 22) of a housing (20), and wherein the housing (20) is equipped, at least in sections, with outwardlypointing cooling fins (4), wherein the housing (20) has a cuboidal or rectangular cross-sectional shape with substantially straight wall sections (23) situated at least on two opposite sides, which wall sections are formed with planar depressions or cutouts (24) which are continuous in the longitudinal direction, and the cooling fins (4) are provided at least partially in the form of removable plate-like cooling modules (5) which, for the insertion and installation thereof, are adapted in terms of shape and depth to the depressions or cutouts (24) of the housing (20).

Owner:EMG AUTOMATION

Non-fouling fluidized bed heat exchanger

ActiveCN106595348BGood heat transfer coefficientCorrosion preventionStationary tubular conduit assembliesFluidized bedEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous crystallization process for monopotassium phosphate

InactiveCN103159194BReduce manufacturing costEasy to operatePhosphorus compoundsMatingSmall footprint

The invention discloses a continuous crystallization process for monopotassium phosphate. The continuous crystallization process comprises the following specific steps of: introducing a feed liquid to be crystallized into a first-stage continuous flash crystallizer so as to be separated into a primary clear liquid, primary crystal mush and secondary steam; discharging the primary crystal mush from the first-stage continuous flash crystallizer and feeding the primary crystal mush into a second-stage continuous cooling crystallizer, wherein the second-stage continuous cooling crystallizer is composed of an Oslo crystallizer and an external cooler; separating the primary crystal mush into secondary crystal mush and a secondary clear liquid in the Oslo crystallizer; discharging the secondary crystal mush from the Oslo crystallizer, feeding the secondary crystal mush into a thickener and separating the secondary crystal mush into triple clear liquid and triple crystal mush; discharging the triple crystal mush from the thickener, feeding the triple crystal mush into a centrifugal machine, and separating the triple crystal mush into solid monopotassium phosphate and a centrifugal liquid; and discharging the solid monopotassium phosphate from the centrifugal machine. The continuous crystallization process is stable in operation, low in energy consumption and low in labor intensity; and by using the continuous crystallization process, the operation stability and the product quality are greatly improved, the on-site operation environment is improved, and the production cost of the monopotassium phosphate is reduced. A mating device for the process is small in floor area and high in capacity.

Owner:HEBEI NUODA CHEM EQUIP

Self-cleaning fluidized bed heat exchanger

ActiveCN107764109BGood heat transfer coefficientFlush cleaningFluidised bed heat exchangersSolid particleEngineering

The invention relates to a self-cleaning fluidized bed heat exchanger which is mainly used for solving the technical problems that in the prior art, the tube pass of a decarburization alkaline liquorcooler of an ammonia synthesizing device is prone to scaling, and the heat exchange effect is obviously decreased after long-period use. The self-cleaning fluidized bed heat exchanger comprises a lower tube box 1, a heat exchanger tube nest 2, an upper tube box 3, a liquid-solid separator 4, a particle filtering plate 5, a liquid storing tank 6, a liquid circulating pump 7, a downcomer 8, a spraynozzle 9, a horizontal pipe 10 and an expanding port 11, wherein the expanding port 11 is installed in the lower tube box 1, the upper tube box 3 is connected with the liquid-solid separator 4, solidparticles enter the spray nozzle 9 through the downcomer 8, and a liquid phase overflows from the upper portion of the particle filtering plate 5, enters the liquid storing tank 6 and circulates to the spray nozzle 9 through the liquid circulating pump 7. According to the technical scheme, the technical problems are well solved, and the self-cleaning fluidized bed heat exchanger can be used for prolonging the running cycle of the decarburization alkaline liquor cooler of the ammonia synthesizing device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Concrete bundle superimposed thermal insulation material and preparation method thereof

ActiveCN111302720ALow thermal conductivityIncrease the lengthHeat conservationMechanical engineering

The invention discloses a concrete bundle superimposed thermal insulation material, which comprises the following raw materials in parts by weight: 20-40% of slag, 20-40% of fly ash, 20-40% of biomassash, 12-19% of saw dust, 3-13% of old clothes fibers, 13-40% of cement, 5-15% of lightweight aggregate and 0.2-0.5% of an additive, and is composed of an inner wall plate, an outer wall plate, a thermal insulation partition plate, an air beam, a trough plate, an installation corner, a bundle end plug and concrete, wherein the surface of the air bundle is a rough surface, and the thermal insulation partition plate is installed between the inner wall plate and the outer wall plate. According to the invention, air beams are arranged in a multilayer staggered manner, so that the thermal bridge length is increased and the thermal resistance is increased so as to increase the thermal resistance of the thermal insulation building material and reduce the heat transfer coefficient of the thermal insulation building material; and the produced thermal insulation building material is high in strength through a special formula, the A-grade fireproof smokeless non-toxic effect is achieved through inorganic materials, and the environmentally-friendly building material is manufactured through industrial solid waste, old clothes fibers and other resources and is economical and environmentally friendly.

Owner:黄通

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com