A powdery coke analyzing device and analyzing method thereof

An analysis device and powder technology, which are applied in separation methods, chemical instruments and methods, filter regeneration, etc., can solve the problems of hazard analysis effect and operation safety, high thermal analysis reaction temperature, and high reaction activity of powder coke. Ensure long-term stable operation, high heat exchange area, simple and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

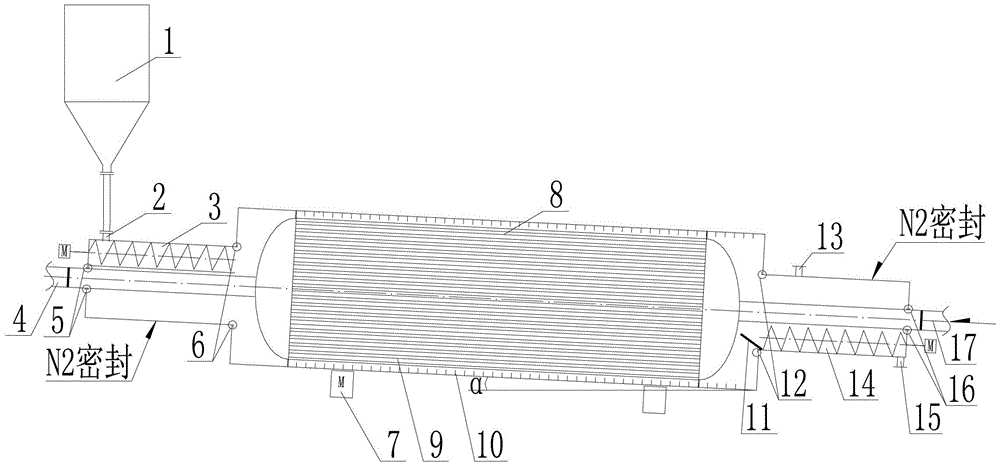

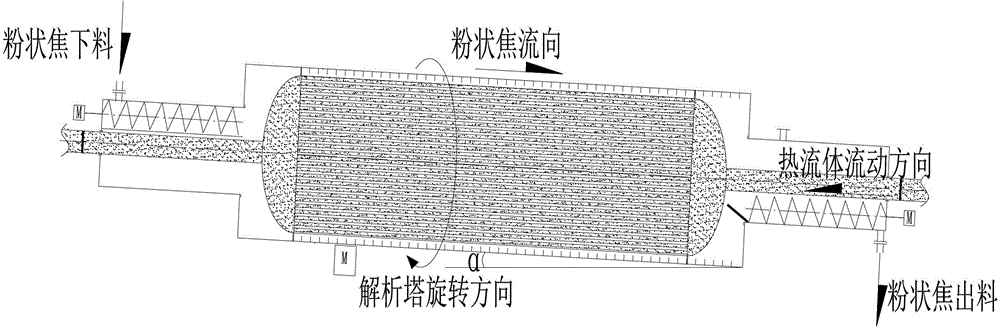

[0031] Such as figure 1 As shown, in order to monitor and maintain a certain material level with a material level meter (not shown in the figure) for the feeding of the lower hopper 1 during analysis, to prevent gas leakage in the tower, the lower hopper 1 itself includes a feed pipe, Or between the lower hopper and the feeding screw feeder, a powdered coke feeding pipe for connection is separately provided. The feeding pipe should have a certain length or height so that the lower hopper 1 and the feeding screw feeder The feeding port 2 of 3 is at a certain height. At the same time, a certain level of material needs to be maintained in the lower hopper to seal the gas in the analysis device and prevent the gas in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com