Acrylic heat insulation coating with high reflectivity and preparation method of acrylic heat insulating coating

A high-reflectivity, acrylic technology, used in reflective/signal coatings, coatings, etc., can solve problems such as unsatisfactory cooling effect, elevated room temperature, poor thermal insulation performance of coatings, and achieve excellent covering ability and excellent reflection performance. , the effect of improving the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

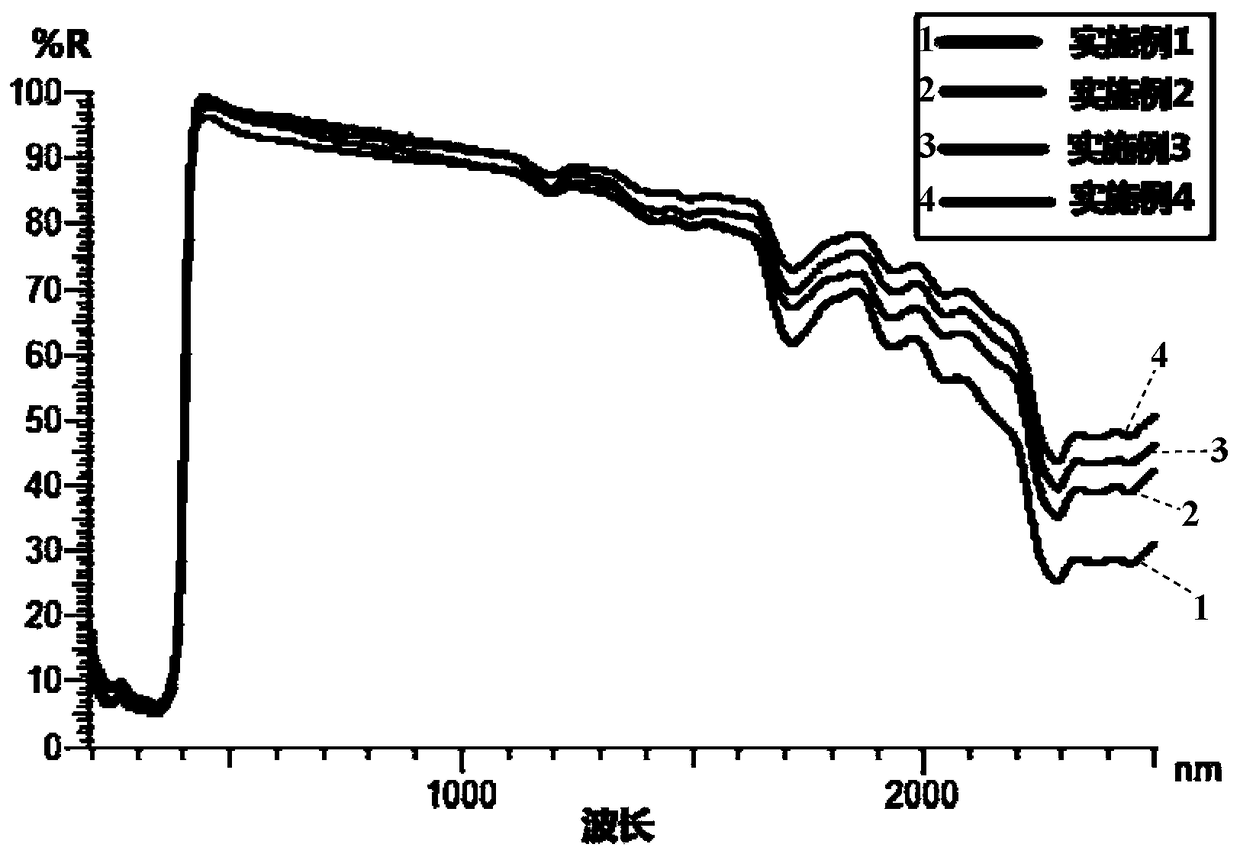

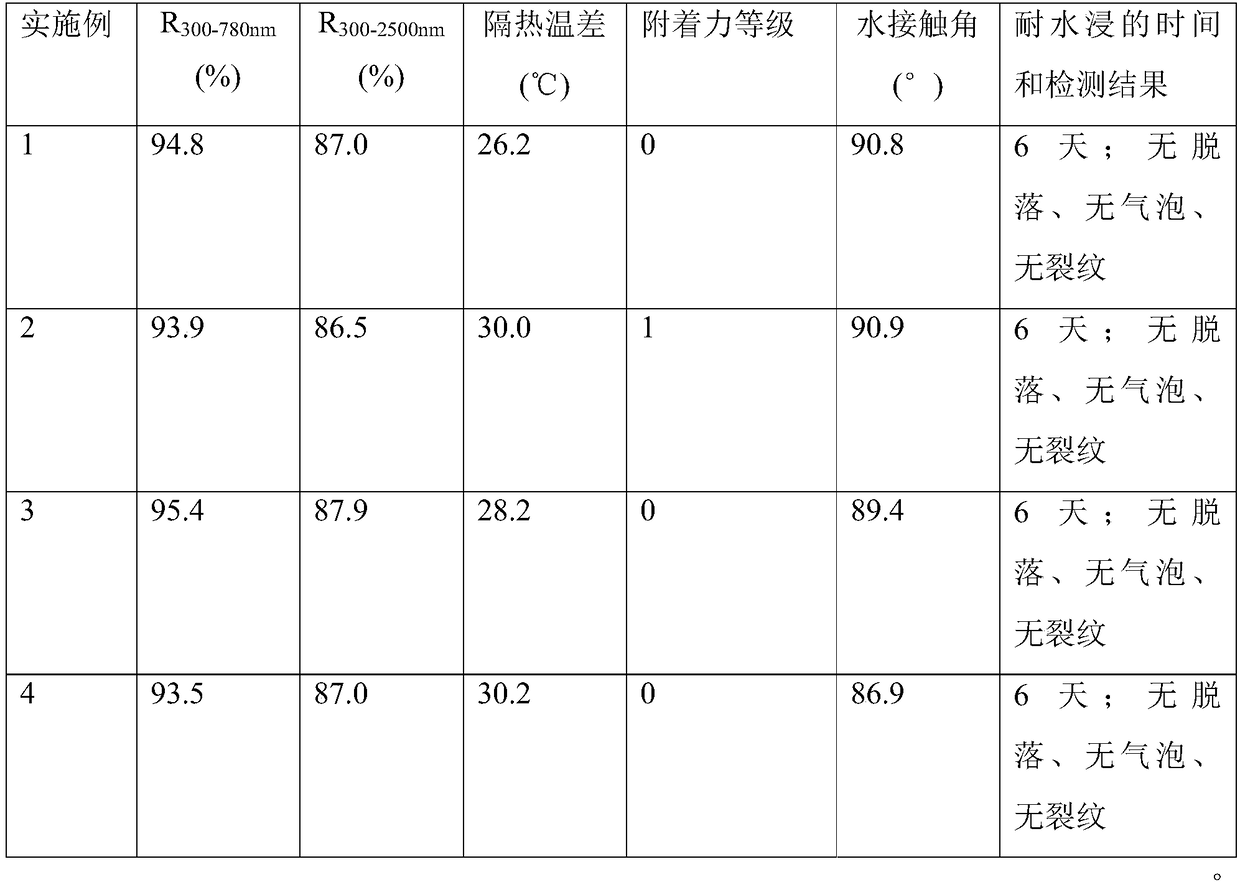

Examples

Embodiment 1

[0044] Proportion by mass percentage: Hydroxy acrylic resin (Taichang Resin Co., Ltd., 7119-X-50) is 44%, R-803 titanium dioxide (particle size range 200-900nm) is 26%, modified aluminum powder (surface coating Flake aluminum powder covered with titanium dioxide) is 9%, xylene is 8%, butyl acetate is 5%, high boiling point solvent DBE (divalent ester) is 1%, 245 leveling agent is 0.5%, BYK- 065 defoamer is 0.5%, 202P anti-sedimentation agent is 1wt%, and hollow glass microspheres (particle size range 10-30 μm, Shanghai Zhenxu Chemical Co., Ltd.) are 5%;

[0045] Preparation method: Add 6g of flake aluminum powder (particle size range 8-15μm) into 200ml of absolute ethanol for ultrasonic dispersion, and stir at 60°C for 30min, add 20ml of butyl titanate, continue to stir for 6h, and stand still to obtain white gray The precipitate was centrifugally filtered and dried at 100°C to obtain modified aluminum powder. Stir hydroxyacrylic resin, solvent, and various additives at a med...

Embodiment 2

[0047] Proportion according to mass percentage: hydroxyacrylic resin (Taichang Resin Co., Ltd., 7119-X-50) is 46%, titanium dioxide titanium dioxide (particle size range 200 ~ 900nm, Yunnan Xinli, R-803) is 23%, Hollow glass microspheres (particle size range 10-30 μm, Shanghai Zhenxu Chemical Co., Ltd.) 5%, modified aluminum powder (flaky aluminum powder coated with titanium dioxide on the surface) 9%, xylene 7.5%, acetic acid Butyl ester is 4.5%, high boiling point solvent DBE is 0.9%, BYK-161 dispersant is 2%, 245 leveling agent is 0.44%, BYK-065 defoamer is 0.66%, 202P anti-settling agent is 1%;

[0048] Preparation method: Add 6g of flake aluminum powder (particle size range 8-15μm) into 200ml of absolute ethanol for ultrasonic dispersion, and stir at 60°C for 30min, add 20ml of butyl titanate, continue to stir for 6h, and stand still to obtain white gray The precipitate was centrifugally filtered and dried at 100°C to obtain modified aluminum powder; the hydroxyacrylic ac...

Embodiment 3

[0050] Proportion by mass percentage: Hydroxy acrylic resin (Taichang Resin Co., Ltd., 7119-X-50) is 46%, titanium dioxide (particle size range 200-900nm, Yunnan Xinli, R-803) is 23%, modified Aluminum powder (flake aluminum powder coated with titanium dioxide on the surface) is 9%, xylene is 7.7%, hollow glass microspheres (particle size range 10-30 μm, Shanghai Zhenxu Chemical Co., Ltd.) is 4%, butyl acetate 5% for high boiling point solvent DBE, 2.3% for BYK-161 dispersant, 0.5% for 245 leveling agent, 0.5% for BYK-065 defoamer, 1% for 202P anti-settling agent;

[0051] Preparation method: Add 6g of flake aluminum powder (particle size range 8-15μm) into 200ml of absolute ethanol for ultrasonic dispersion, and stir at 60°C for 30min, add 20ml of butyl titanate, continue to stir for 6h, and stand still to obtain white gray The precipitate was centrifugally filtered and dried at 100°C to obtain modified aluminum powder; the hydroxyacrylic acid emulsion, solvent, and various a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com