Heat exchanger with net type lung-shaped heat exchange plates

A technology of heat exchangers and heat exchange plates, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of reducing the flow rate outside the plate and low heat exchange efficiency, so as to reduce flow resistance and improve The effect of heat transfer coefficient and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

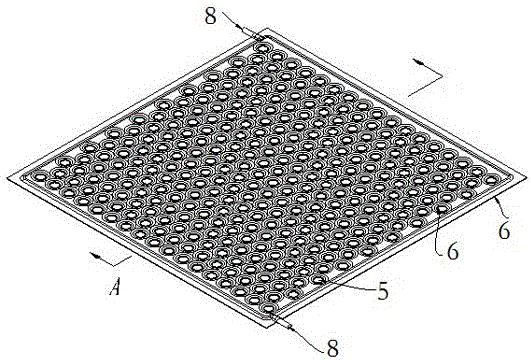

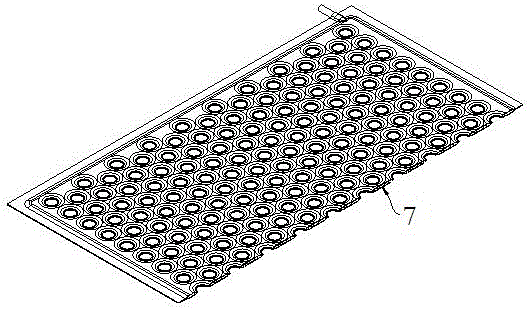

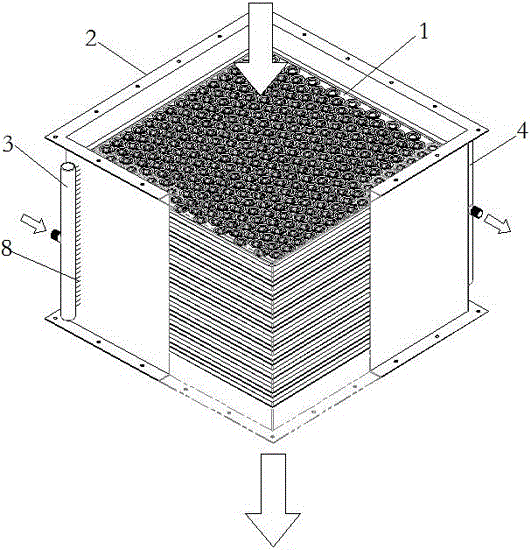

[0015] The present invention is a heat exchanger with a net type lung-shaped heat exchange plate, such as figure 1 , figure 2 Combine image 3 As shown, it includes the mesh heat exchanger plate 1, the heat exchanger shell 2, the liquid inlet pipe 3 and the liquid outlet pipe 4. The mesh heat exchanger plates 1 are arranged at equal intervals from top to bottom. A lung-shaped hollow structure is formed in the heat exchanger shell 2, the liquid inlet pipe 3 and the liquid outlet pipe 4 are respectively arranged longitudinally on the heat exchanger shell 2, and the mesh heat exchanger plate 1 consists of two The plates with through holes 5 are superimposed on top and bottom and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com