Continuous crystallization process for monopotassium phosphate

A crystallization technology of potassium dihydrogen phosphate, which is applied in the field of continuous crystallization process of potassium dihydrogen phosphate, which can solve the problems of easy leakage and splashing of materials, large equipment footprint, and product quality differences, so as to reduce the secondary nucleation phenomenon , low labor intensity, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

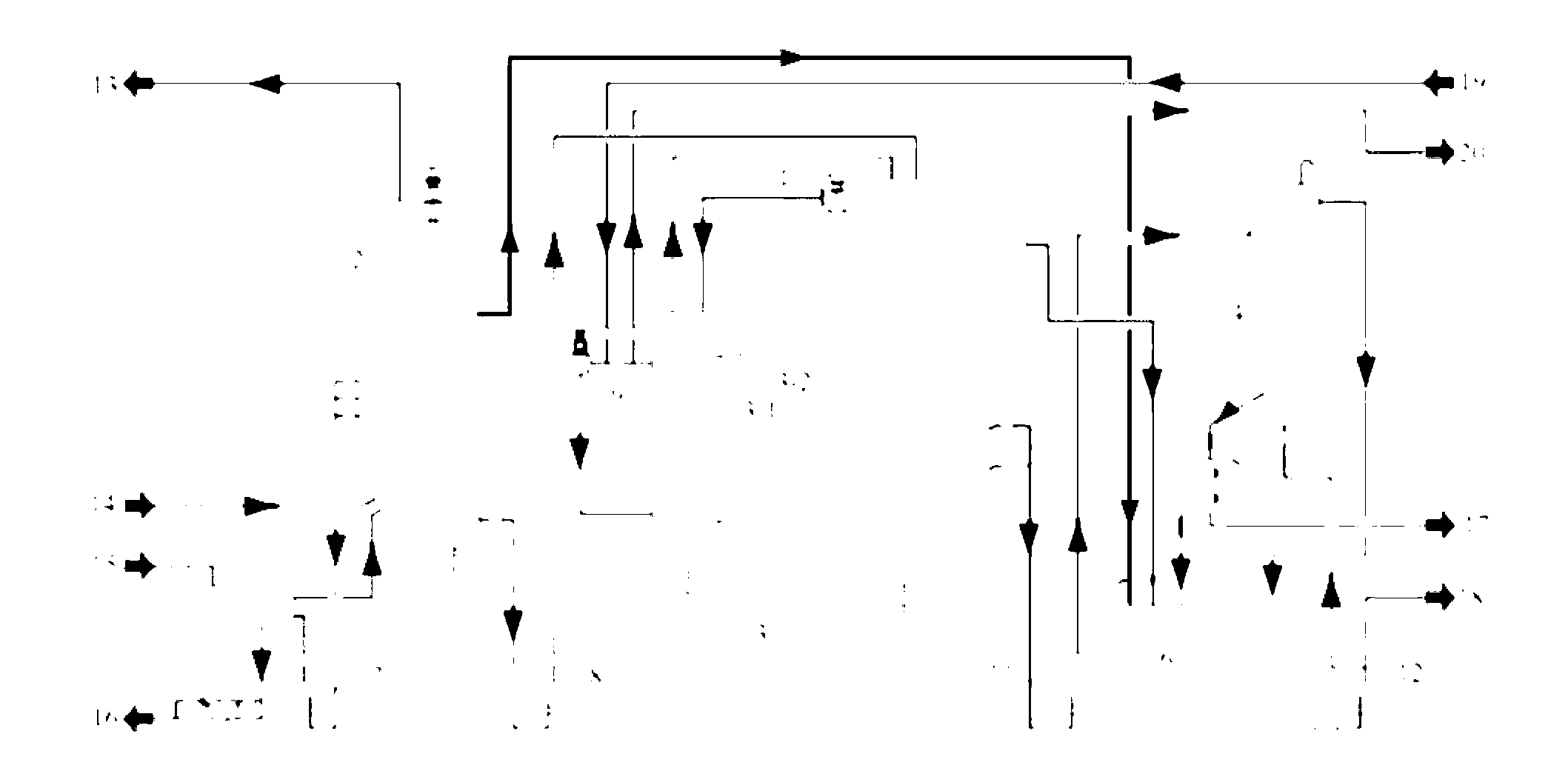

Image

Examples

Embodiment 1

[0026] The feed liquid to be crystallized is potassium dihydrogen phosphate solution produced by the neutralization method, and the material state of the feed liquid to be crystallized is: the temperature is 95° C., and the concentration is 44.2%.

[0027] The equipment used in the present invention mainly includes a primary continuous flash crystallizer 2, a secondary continuous cooling crystallizer 3, a thickener 4 and a centrifuge 5. The first-stage continuous flash crystallizer 2 is a DTB vacuum crystallizer, and the feed port at the bottom is connected with the inlet 14 of the feed liquid to be crystallized, and the feed liquid to be crystallized enters the DTB vacuum crystallizer with a feed rate of 22500kg / h. It enters the bottom of the guide tube in the center of the inner center of the DTB vacuum crystallizer, and then starts to rise from the bottom of the guide tube along the guide tube under the push of the propeller, and rises to the liquid level in the DTB vacuum c...

Embodiment 2

[0039] The difference between this embodiment and Example 1 is that the feed liquid to be crystallized is a potassium dihydrogen phosphate solution produced by ion exchange, and the material state of the feed liquid to be crystallized is: the temperature is 96° C., and the concentration is 44.1%.

[0040] The feed port of the first-stage continuous flash crystallizer 2 is connected with the dynamic filter, and the feed port of the dynamic filter is connected with the feed liquid inlet 14 to be crystallized.

[0041] The feed liquid to be crystallized enters the dynamic filter at a feed rate of 6430kg / h, and the feed liquid to be crystallized from the dynamic filter enters the DTB vacuum crystallizer. The flow velocity of the secondary clear liquid in the tube side of the external cooler 3-1 is 1.65m / s.

[0042] The primary magma discharged from the discharge port of the first-stage continuous flash crystallizer 2, the secondary magma discharged from the discharge port of the s...

Embodiment 3

[0048] The difference between this embodiment and Example 1 is that the feed liquid to be crystallized is a potassium dihydrogen phosphate solution produced by ion exchange, and the material state of the feed liquid to be crystallized is: the temperature is 93° C., and the concentration is 39.6%.

[0049] The feed liquid to be crystallized enters the DTB vacuum crystallizer at a feed rate of 12380kg / h. The flow velocity of the secondary clear liquid in the tube side of the external cooler 3-1 is 1.8m / s.

[0050] The primary magma discharged from the discharge port of the first-stage continuous flash crystallizer 2, the secondary magma discharged from the discharge port of the secondary continuous cooling crystallizer 3, and the three times discharged from the discharge port of the thickener 4 The state of the crystal slurry is shown in Table 3 below.

[0051] table 3

[0052]

Primary slurry

Secondary crystal slurry

Tertiary crystal slurry

temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com