Medical injection water preparation system and control method thereof

A water for injection and preparation system technology, applied in separation methods, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as decreased operational stability, insufficient thermal efficiency of the first-effect evaporator, and inability to produce steam, etc., to achieve Stable operation, ideal water production efficiency, and the effect of overcoming insufficient thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations of the present invention are now described.

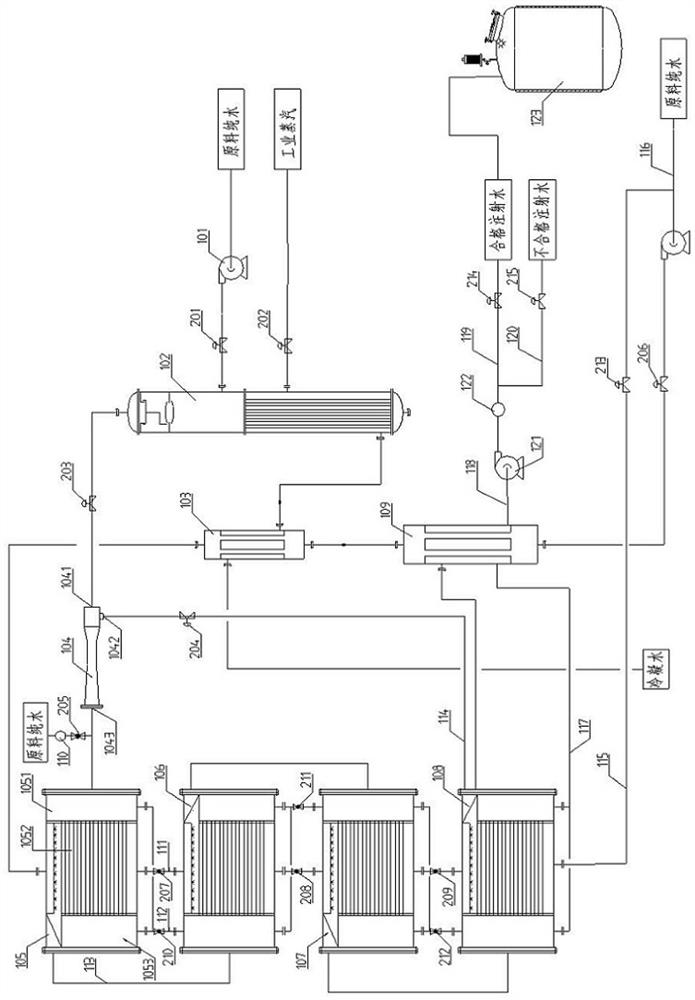

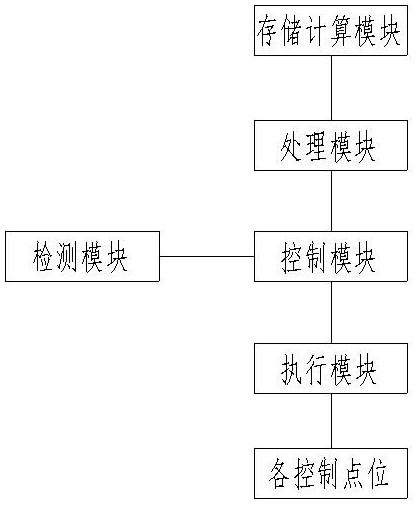

[0056] as attached figure 1 As shown, this embodiment discloses a medical injection water preparation system, including a preparation unit and a control unit. The preparation unit is used to prepare medical water for injection; the control unit is set in the preparation unit, and is used to control and adjust the preparation unit during the working process.

[0057] Wherein, the preparation unit includes a heat source module, a preparation module, and a storage module. The heat source module, the preparation module and the storage module are connected in sequence. The heat source module is used to provide a heat source for the preparation module. In this embodiment, the heat source module provides pure water vapor as a heat source for the preparation module. The preparation module ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com