A process for gas-heated reforming of a hydrocarbon source and related equipment

A gas and hydrocarbon source technology, applied in chemical instruments and methods, hydrogen/synthesis gas production, inorganic chemistry, etc., can solve problems such as low efficiency, catalyst low efficiency, process optimization constraints, etc., to achieve high equipment efficiency, reduce pressure drop, effective heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

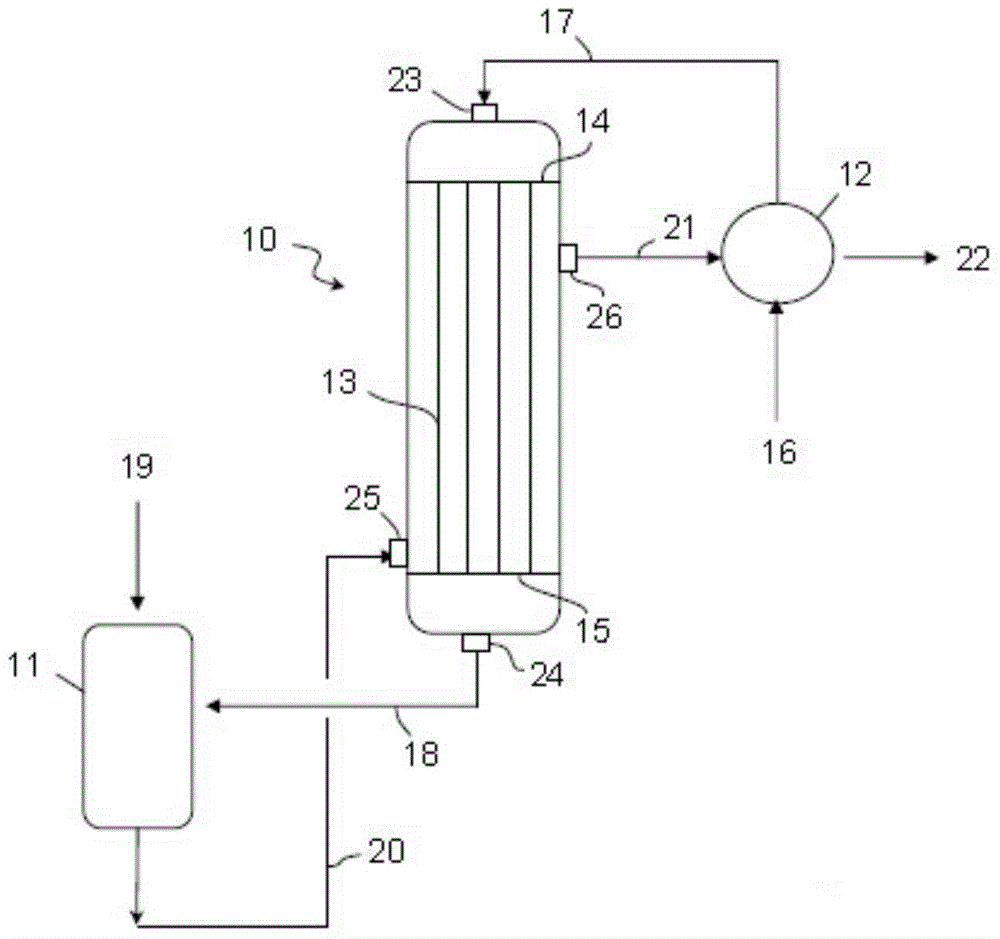

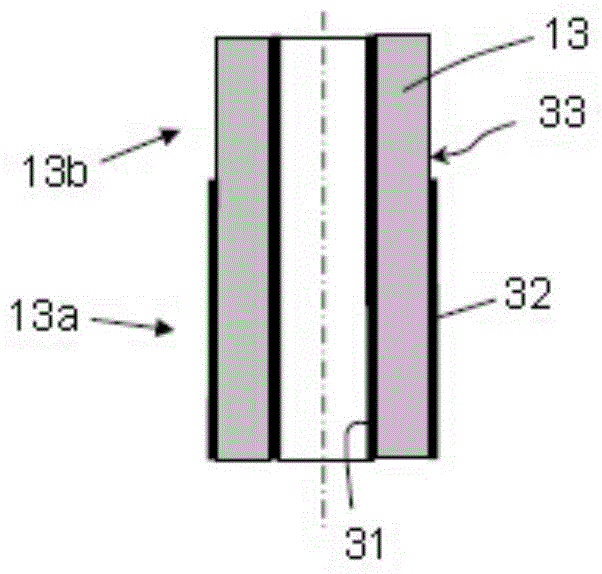

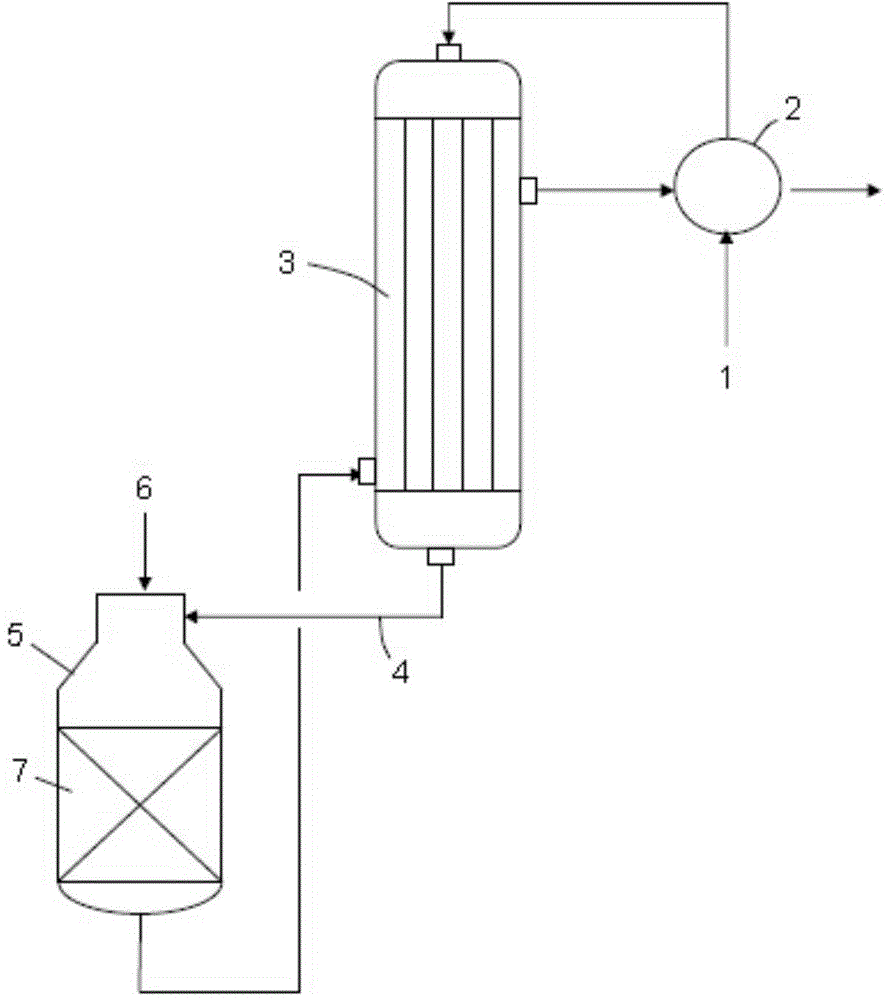

[0036] refer to figure 1 , the equipment for steam reforming includes a reforming furnace 10 , a combustion furnace 11 and a preheater 12 . The reformer 10 comprises a bundle of tubes 13, preferably made of ceramic material. The tubes 13 are preferably straight tubes supported by two opposing tube sheets 14,15.

[0037] The reformer 10 has the following main connections: an air inlet 23 and an air outlet 24 for communicating with the tube side (ie, the inside of the tube 13 ); an air inlet 25 and an air outlet 26 for communicating with the shell side. Preferably, as shown in the figure, the tube side inlet 23 is at the top of the reformer and the tube side gas outlet 24 is at the bottom; the shell side inlet 25 is at the lower part of the shell side and the shell side outlet 26 is at the upper part of the shell side. However, different settings are also possible.

[0038] A gas source 16 comprising a hydrocarbon source and steam is heated in a preheater 12 and enters the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com