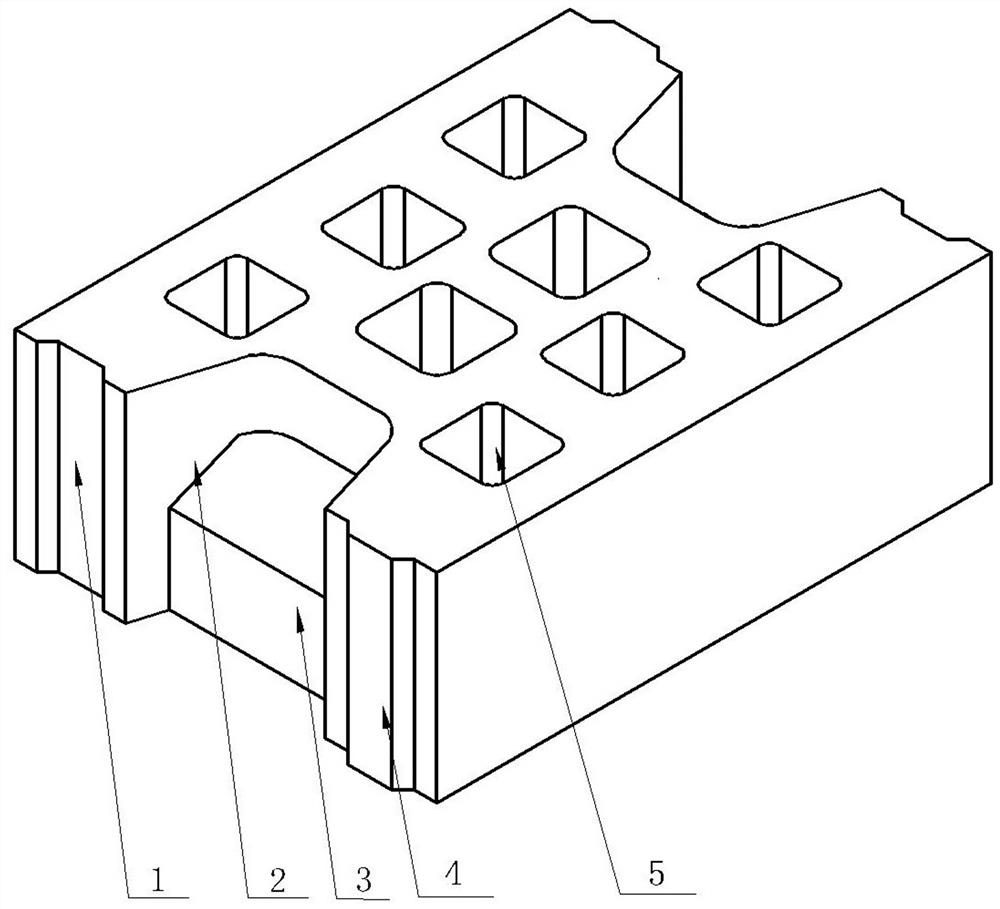

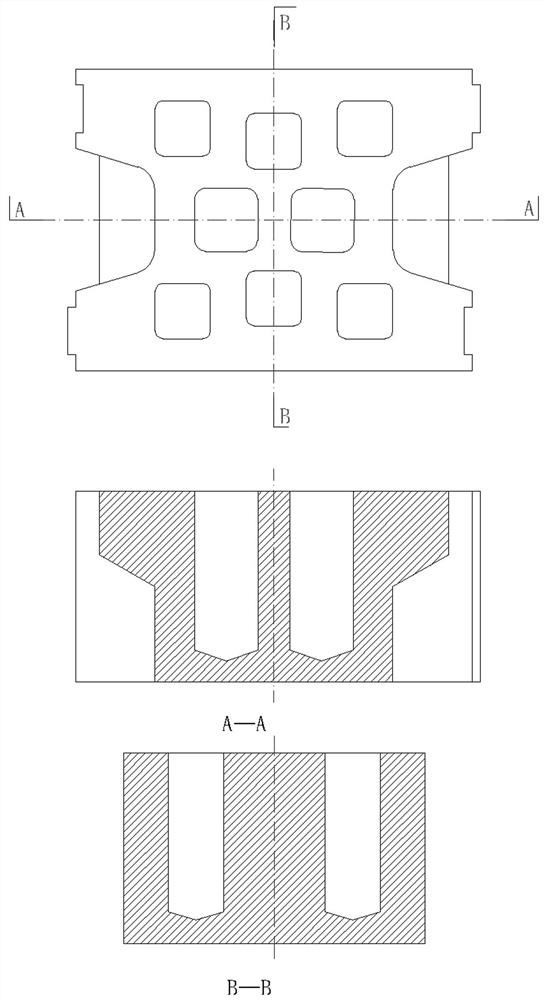

An energy-saving autoclaved fly ash hollow building wall material

A fly ash and autoclaving technology is applied in the field of building wall materials, which can solve the problems of large product size error, high production cost and high construction cost, and achieve the advantages of improved flexural strength, reduced weight, and improved thermal insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

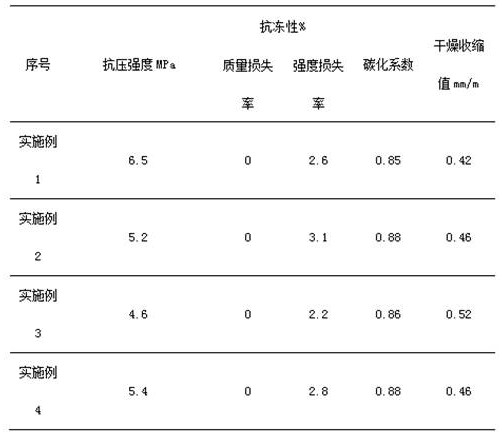

Embodiment 1

[0019] The energy-saving autoclaved fly ash hollow building wall material described in Example 1 has the following composition by weight of raw materials, which is prepared by steam curing process and combined with abrasive tools:

[0020] 55 parts of dry fly ash, 20 parts of carbide slag, 2 parts of gypsum, 25 parts of aggregate, 0.5 part of sodium metasilicate; the moisture content of molding is controlled at 6% according to the condition of the mixture.

[0021] The gypsum separation plant desulfurizes gypsum.

[0022] The aggregate is composed of furnace bottom slag and weathered quartzite in a weight ratio of 1:1, the particles of 1mm and below are not more than 20%, and the particles of 5mm-10mmm are not more than 15%.

Embodiment 2

[0024] The energy-saving autoclaved fly ash hollow building wall material has the following composition by weight of raw materials, which is prepared by steam curing process and combined with abrasive tools:

[0025] 60 parts of dry fly ash, 18 parts of carbide slag, 2 parts of gypsum, 22 parts of aggregate, 0.5 part of sodium metasilicate, and the moisture content of the molding is controlled at 7% according to the condition of the mixture. The porosity rate is 46%-50%.

[0026] The gypsum separation plant desulfurizes gypsum.

[0027] The aggregate is composed of furnace bottom slag and weathered quartzite in a weight ratio of 1:1, the particles of 1mm and below are not more than 20%, and the particles of 5mm-10mmm are not more than 15%.

Embodiment 3

[0029] The energy-saving autoclaved fly ash hollow building wall material has the following composition by weight of raw materials, which is prepared by steam curing process and combined with abrasive tools:

[0030] 60 parts of dry fly ash, 16 parts of carbide slag, 1 part of gypsum, 14 parts of aggregate, 1 part of sodium metasilicate, and the moisture content of molding is controlled at 8% according to the condition of the mixture. The porosity rate is 46%-50%.

[0031] The gypsum separation plant desulfurizes gypsum.

[0032] The aggregate is composed of furnace bottom slag and weathered quartzite in a weight ratio of 1:1, the particles of 1mm and below are not more than 20%, and the particles of 5mm-10mmm are not more than 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com