Online continuous hot-pressed dry vacuum insulation panel core preparation method and product

A vacuum insulation panel and dry process technology, applied in heat exchange equipment, mechanical equipment, textiles and papermaking, etc., can solve problems such as low production efficiency, low thermal conductivity, and inability to match the speed of glass fiber wool, and improve production. Efficiency, reduced thermal conductivity, improved thickness uniformity and overall mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

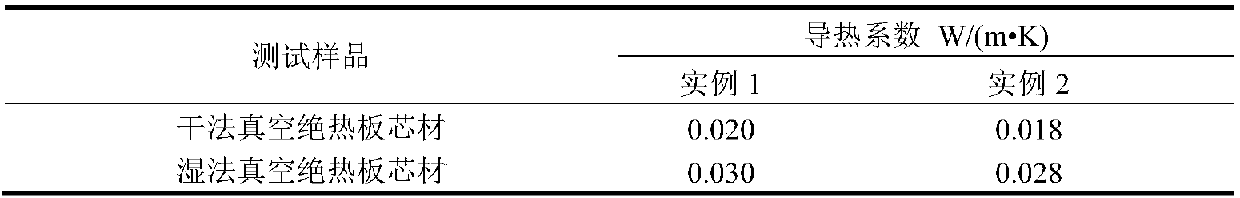

Embodiment 1

[0024] Preparation of an on-line continuous hot-pressing dry-process vacuum insulation panel core material

[0025] (1) Fiber formation: Weigh 67 parts of quartz sand, 7.5 parts of soda ash, 4 parts of potassium feldspar, 1.5 parts of albite, 6 parts of calcite, 5.5 parts of borax, and 8.5 parts of dolomite according to the mass ratio, and put them into the kiln after uniform mixing Calcined in a furnace, and smelted into a glass liquid with uniform composition, no impurities and transparent glass, the temperature of the obtained glass liquid is 1040°C; the glass liquid flows into the high-speed rotating centrifugal disc with a temperature of 980°C through the leakage plate at a flow rate of 200kg / h The superfine glass fiber is thrown out, and the obtained superfine glass fiber is composed of the following components in terms of mass percentage: SiO 2 : 67wt%, R 2 O: 12.5wt%, R is Na or K, B 2 o 3 : 6wt%, CaO: 5.5wt%, Al 2 o 3 : 5wt%, MgO: 3wt%, Fe 2 o 3 : 1wt%, 94% of ...

Embodiment 2

[0033] Preparation of an on-line continuous hot-pressing dry process vacuum insulation panel core material

[0034](1) Fiber formation: Weigh 68 parts of quartz sand, 6.5 parts of soda ash, 5 parts of potassium feldspar, 2.5 parts of albite, 5 parts of calcite, 4.5 parts of borax, and 8.5 parts of dolomite according to the mass ratio, and put them into the kiln after uniform mixing Calcined in a furnace, and smelted into a glass liquid with uniform composition, no impurities and transparent glass, the temperature of the obtained glass liquid is 1040°C; the glass liquid flows into the high-speed rotating centrifugal disc with a temperature of 990°C through the leakage plate at a flow rate of 300kg / h The superfine glass fiber is thrown out, and the obtained superfine glass fiber is composed of the following components in terms of mass percentage: SiO 2 : 68.5wt%, R 2 O: 9wt%, R is Na or K, B 2 o 3 : 6.5wt%, CaO: 5.5wt%, Al 2 o 3 : 5.5wt%, MgO: 3.5wt%, Fe 2 o 3 : 1.5wt%, 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com