Patents

Literature

93results about How to "Guaranteed surface flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

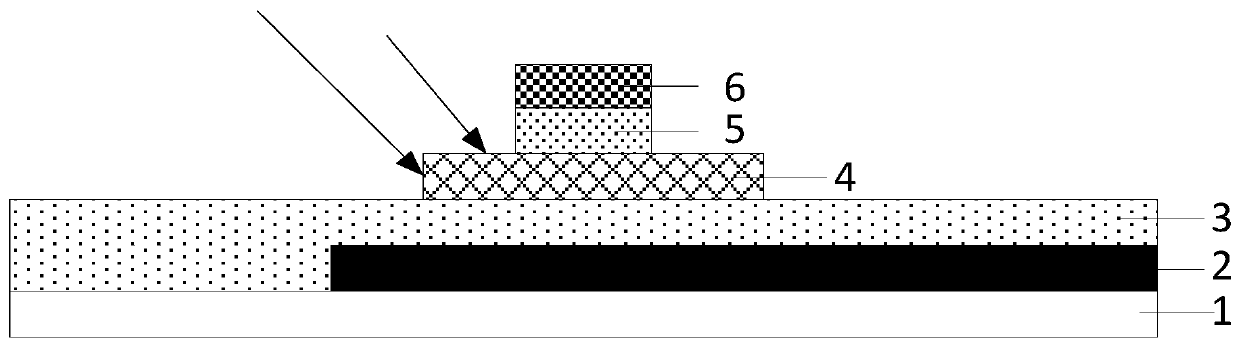

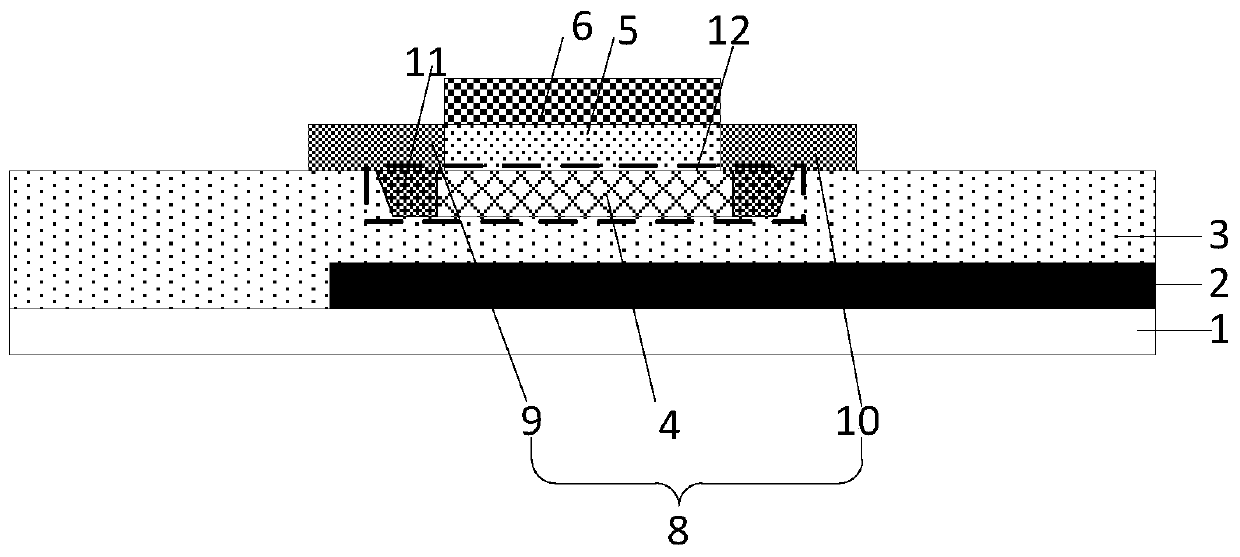

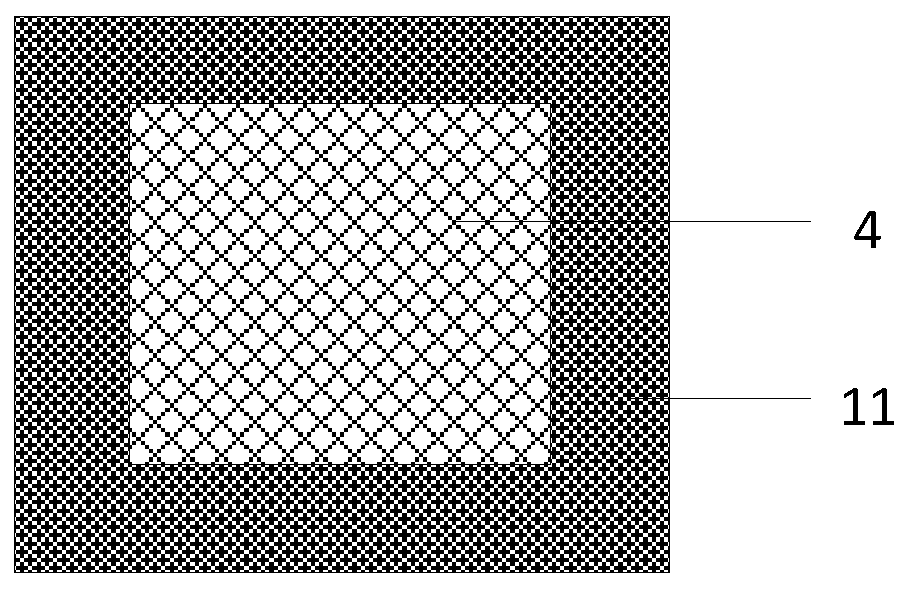

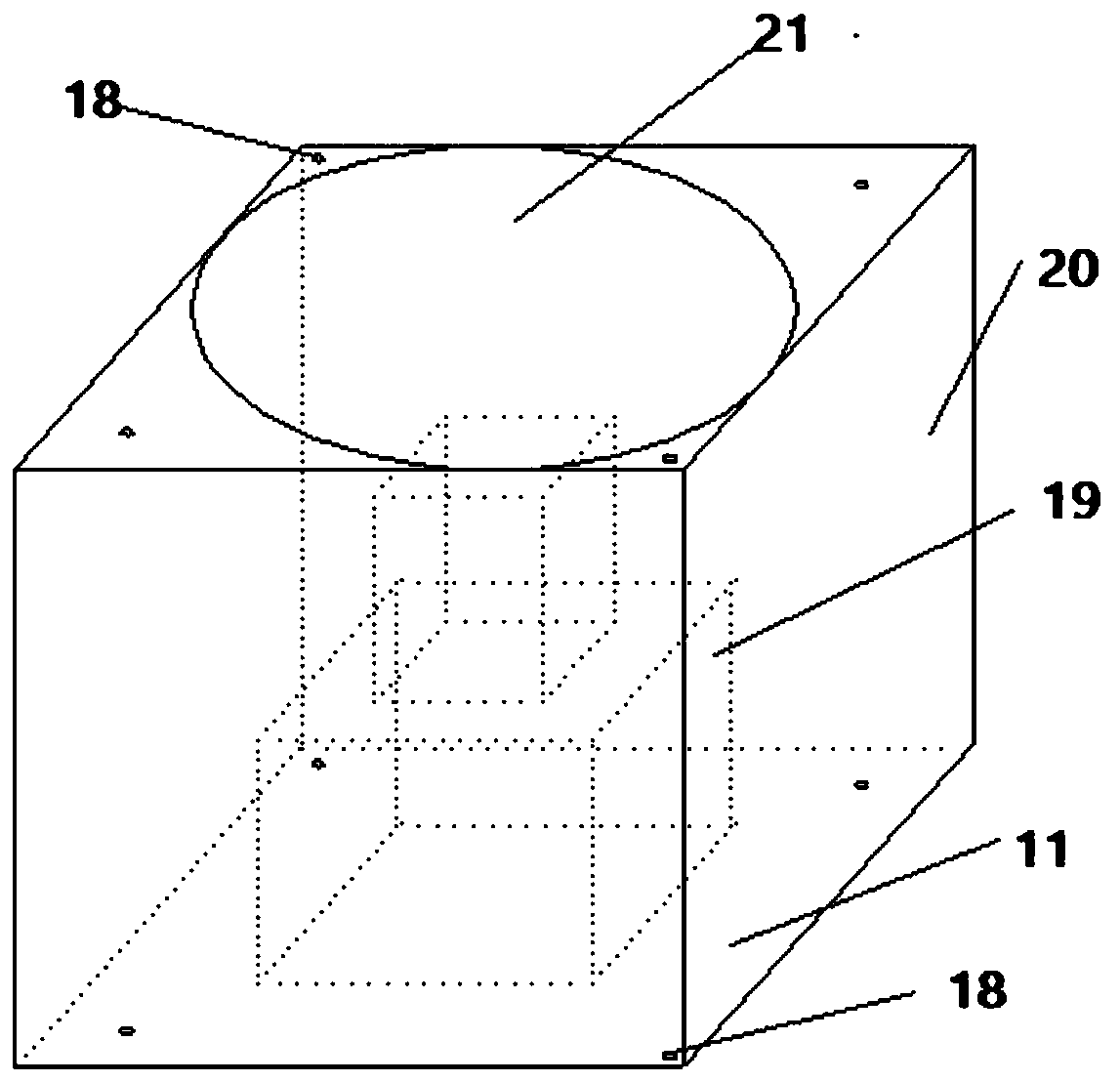

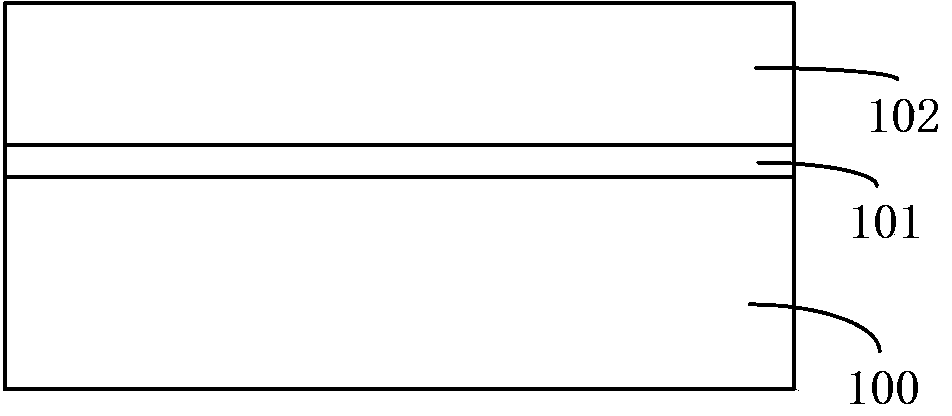

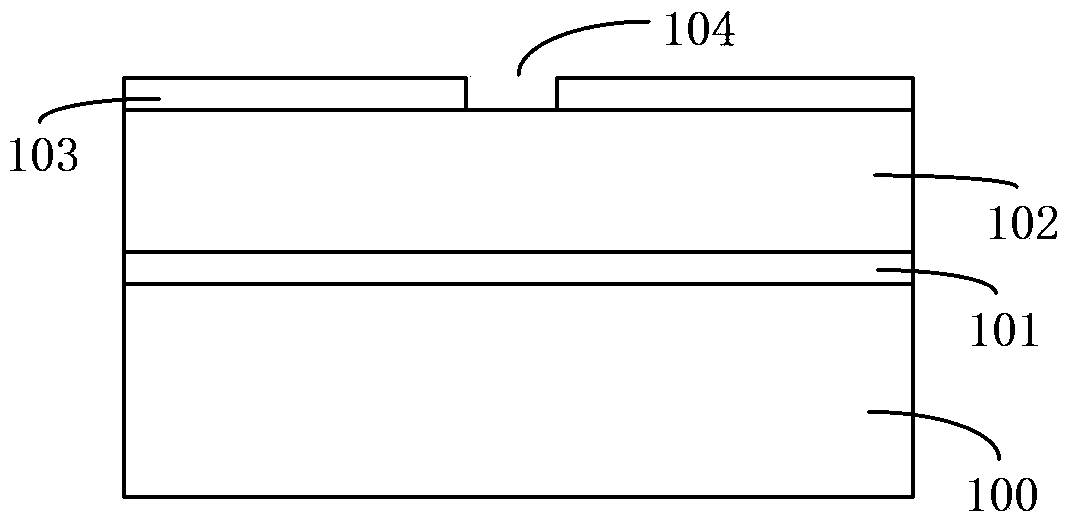

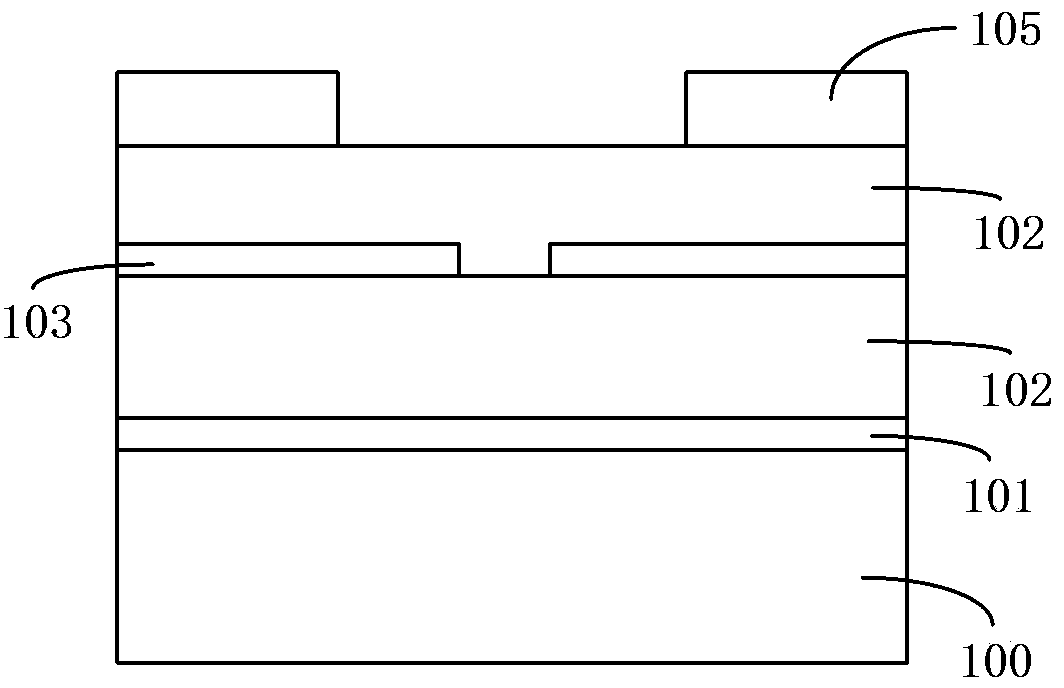

Array substrate, preparation method thereof and display panel

ActiveCN110911424AImprove job stabilityAvoid display unevennessTransistorSolid-state devicesPhysicsThin membrane

The invention discloses an array substrate, a preparation method thereof and a display panel, which are used for preventing a semiconductor region of an active layer of a thin film transistor from being illuminated, improving the working stability of the thin film transistor, avoiding uneven display pictures and improving the display effect. The array substrate comprises a substrate body, a shading layer located on the substrate body, a buffer layer located on the shading layer, an active layer located on the buffer layer and a shading part. The buffer layer is provided with a groove. The active layer includes a semiconductor region, and a first conductive region and a second conductive region connected to the semiconductor region. The semiconductor region and the shading part fill the groove. The orthographic projection of the shading part on the substrate is annular, the side surface of the semiconductor region is completely surrounded by the shading part, and the first conductor region and the second conductor region are located above the shading part and the semiconductor region. The orthographic projection of the shading layer on the substrate covers the orthographic projection of the semiconductor region on the substrate.

Owner:BOE TECH GRP CO LTD +1

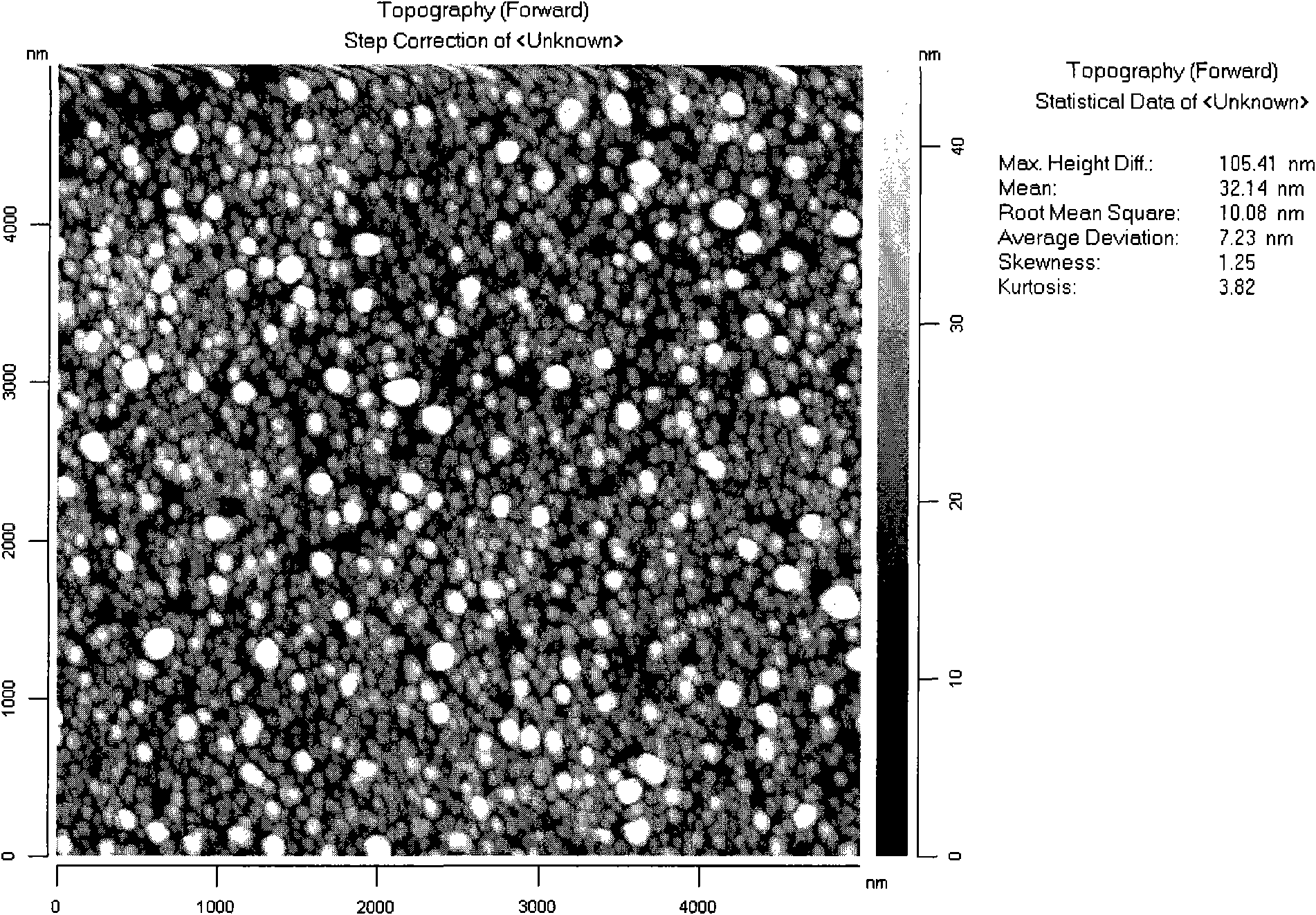

Method for preparing flexible polyester nickel-coating electrode

InactiveCN101892470AHigh mechanical strengthGood acid/alkali corrosion resistanceLiquid/solution decomposition chemical coatingPolyesterRms roughness

The invention belongs to the technical field of electric materials and devices, and relates to a method for preparing a flexible polyester nickel-coating electrode. The method particularly comprises the following steps of: performing surface silicification modification on a polyester substrate, and introducing silane coupler molecules, of which the tail ends contain active groups such as sulfhydryl groups, amino groups and acylamino groups on the premise of not damaging surface flatness; performing catalytic activation on the polyester substrate in mixed solution of silver nitrate and glucose so as to make a thin layer of silver catalyst coated on the polyester substrate undergoing silicification, wherein the silver catalyst layer and the substrate are connected by chemical bonds; and finally performing chemical nickel-plating in the presence of silver catalyst. The polyester nickel-coating electrode prepared by the method has the advantages of strong adhesion between the nickel coating layer and the substrate, stripping strength of more than 40N / cm, high smoothness, root-mean-square roughness(Rrms) of less than 15nm (the area is 5mu m*5mu m), high electric conductivity, and lower resistivity (5.3 mu omega.cm) compared with that of pure nickel. The flexible polyester nickel-coating electrode can be widely applied to solar batteries, membrane ion secondary batteries, flexible organic electric devices, and the like.

Owner:FUDAN UNIV

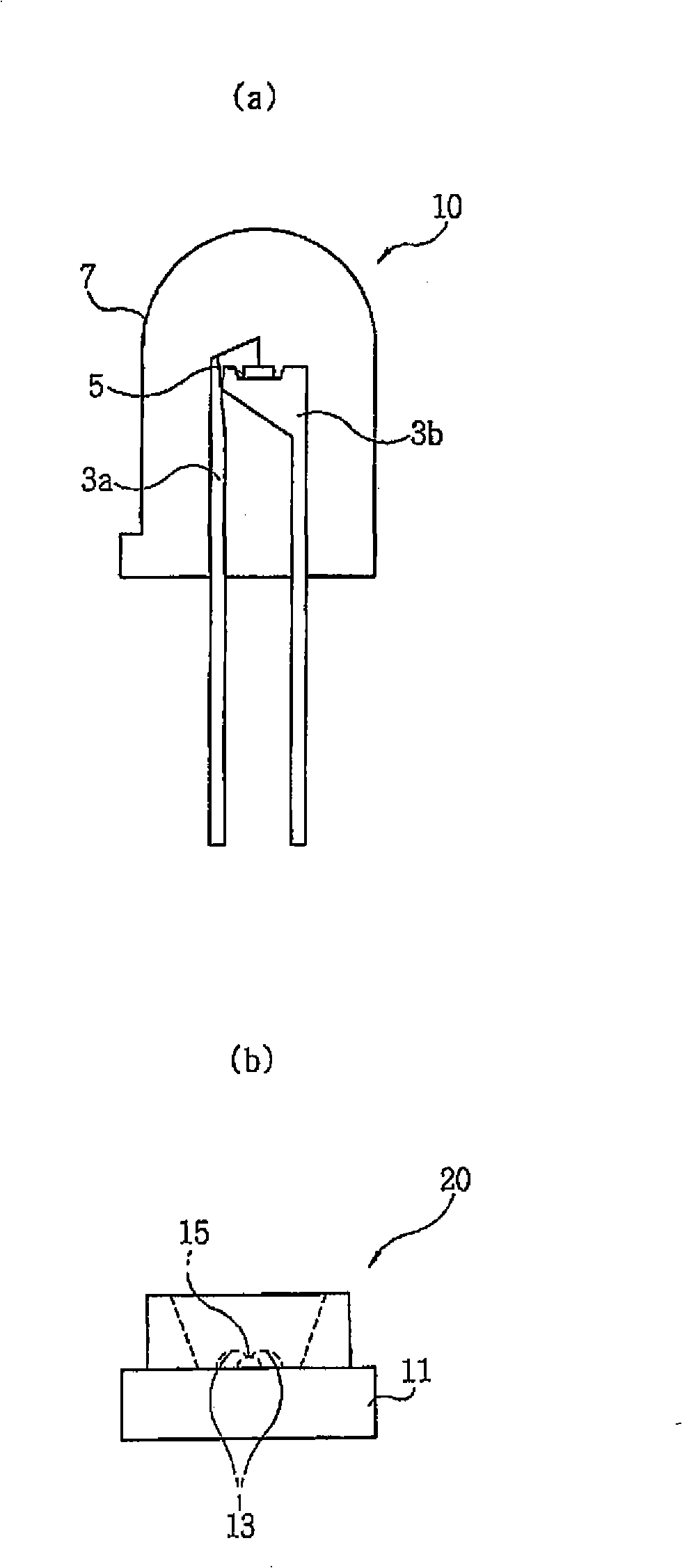

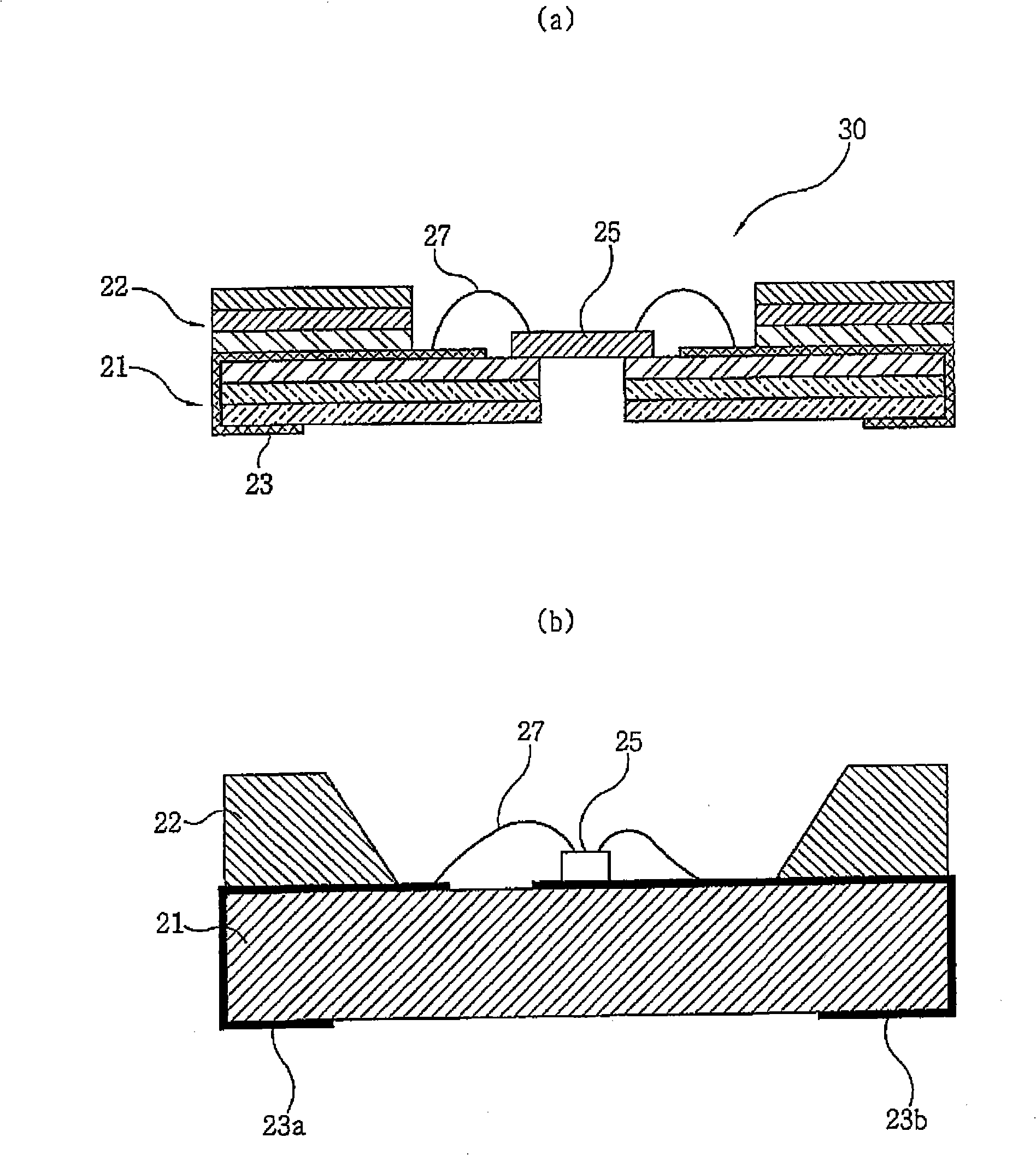

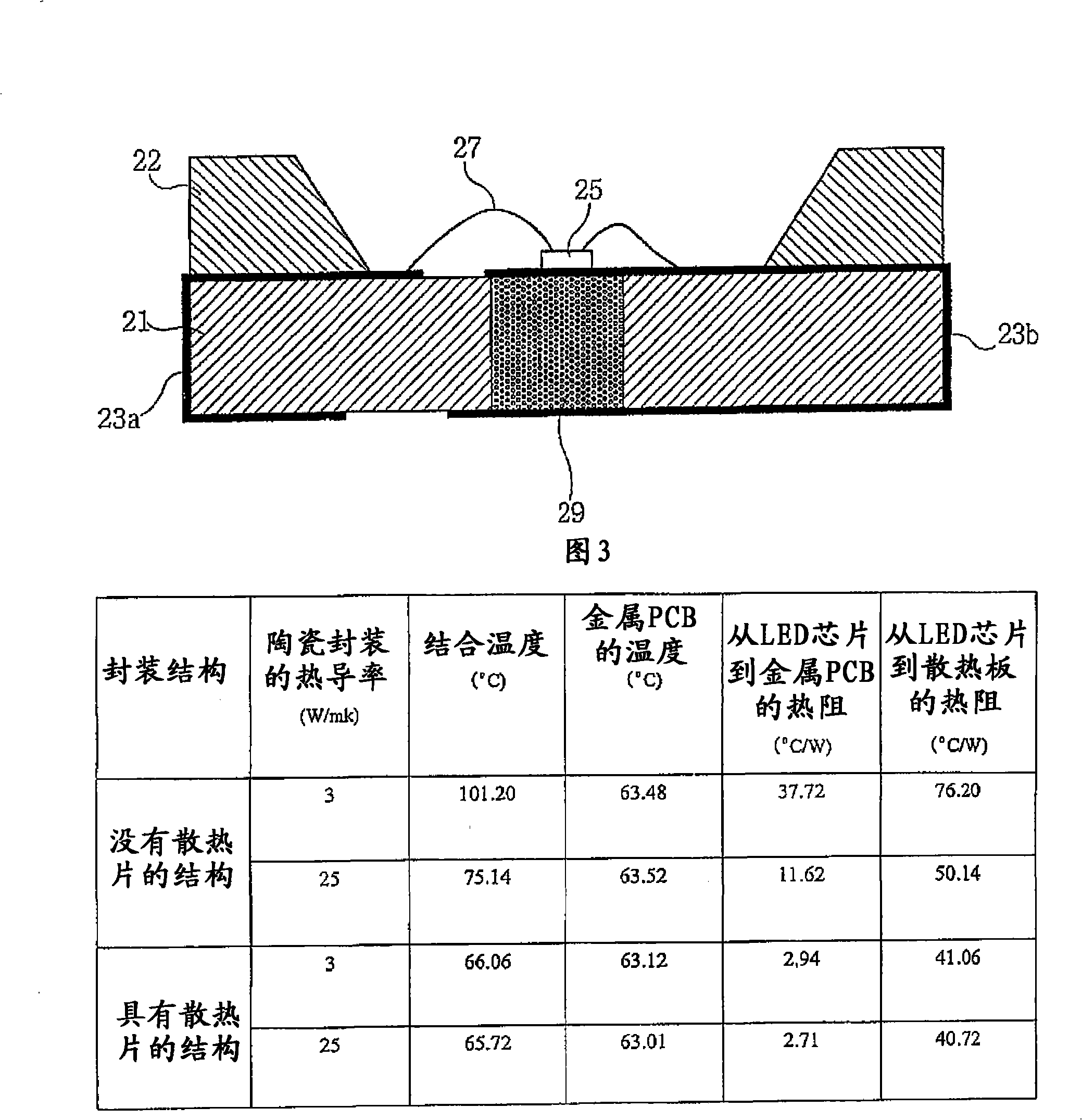

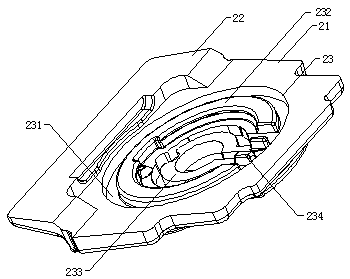

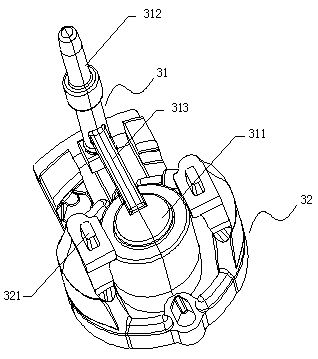

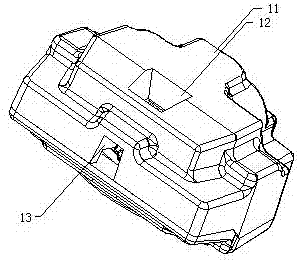

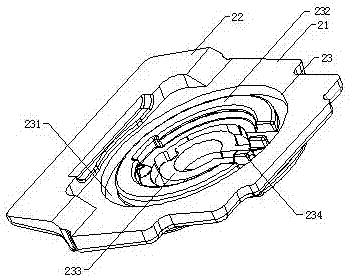

Electronic parts packages

InactiveCN101317277AEasy to operateEffective distributionSolid-state devicesSemiconductor devicesLight emitting deviceLight-emitting diode

The present invention relates to an electronic part package capable of effectively radiating heat. A heat radiating member is buried below the mounting region of the light emitting device of the substrate so as to be separated from the mounting region of the light emitting device in a vertical direction, and is exposed to the lower surface of the substrate. A heat transfer member, which has thermal conductivity higher than that of the substrate, is formed between the mounting region of the light emitting device and the heat radiating member. Accordingly, since the substrate includes an effective heat radiating structure, it is possible to quickly radiate heat generated form the light emitting device.

Owner:阿莫先思电子电器有限公司

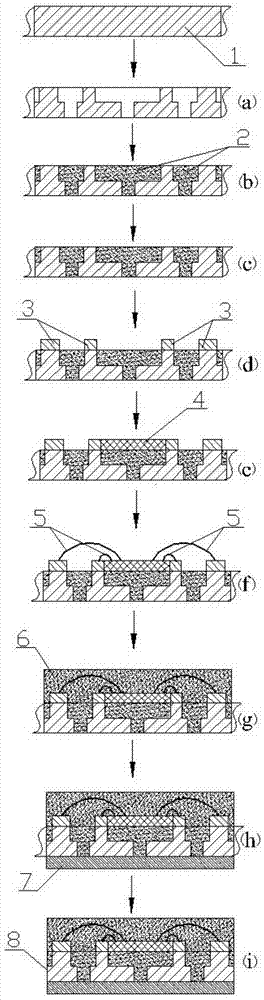

Manufacturing method of pre-packaged lead frame

InactiveCN103500713AReduce manufacturing costGuaranteed surface flatnessSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyElectrolysis

The invention provides a manufacturing method of a pre-packaged lead frame. The manufacturing method of the pre-packaged lead frame comprises the following steps of etching; pre-packaging an etching area of a base material by utilizing an epoxy resin material; removing the epoxy resin remained on the surface of the base material through electrolysis or mechanical polishing; electroplating an electroplating area of the front surface of the base material. According to the manufacturing method of the pre-packaged lead frame, which is provided by the invention, the manufacturing cost of the lead frame is low; when a lead frame manufactured by the method provided by the invention is used for manufacturing integrated circuit assemblies, the obtained integrated circuit assemblies have smooth surfaces, and the integral performance is ensured.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Manufacturing method of glazed brick and product thereof

The invention relates to a manufacturing method of a glazed brick and a product thereof. The method includes: A) a step of blending raw materials, performing ball milling, performing spray granulation, pressing to form a green brick, drying the green brick and spraying a base glaze on the green brick; B) a step of printing patterns on the green brick after the A) step, and spraying a transparent glaze; C) a step of printing patterns on the green brick after the B) step, drying, spraying a transparent glaze again and drying; D) a step of spraying a transparent glaze on the green brick after the C) step and drying; and E) a step of kilning the green brick in the D) step, polishing with an inelastic module, packaging and putting the brick into storage. When the product is exposed to light, the ray of light is subjected to two times of transmission and refraction, so that the patterns are strong in stereoscopic effects, add radiance and beauty to each other, are natural and grand, and can achieve decorative effects similar to that of natural stone.

Owner:FOSHAN DONGPENG CERAMIC +2

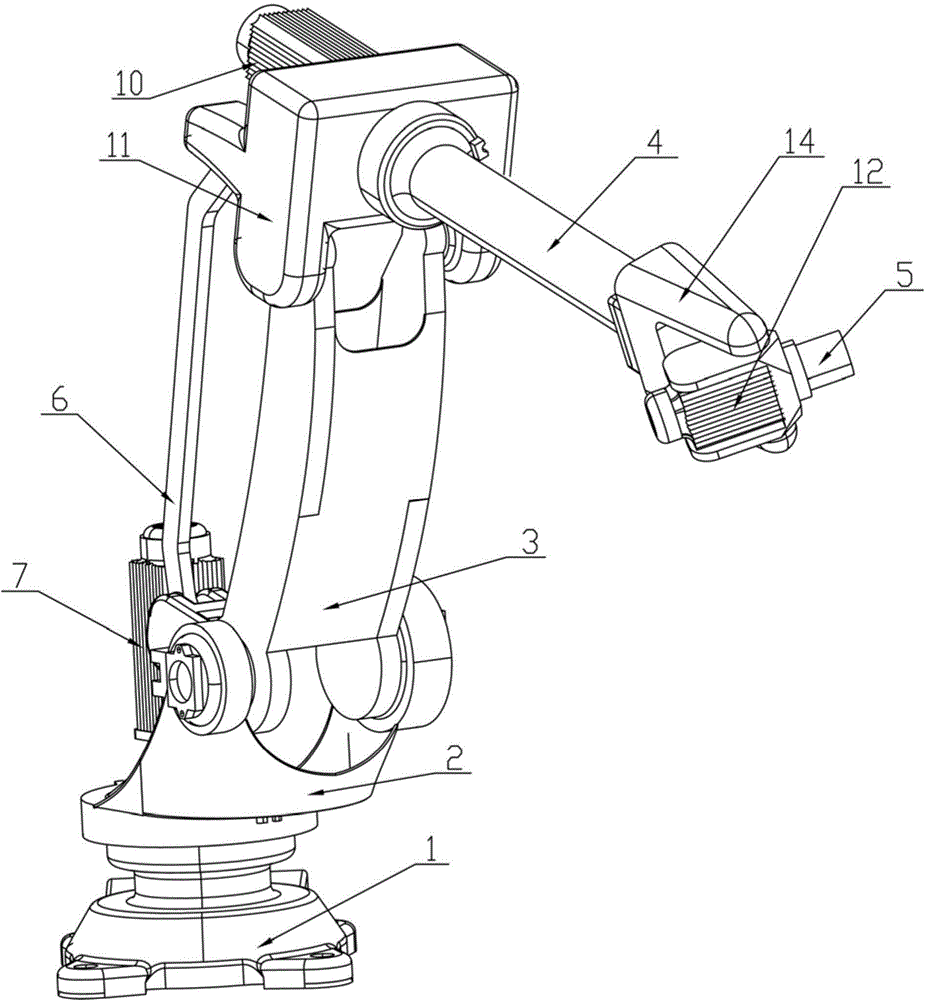

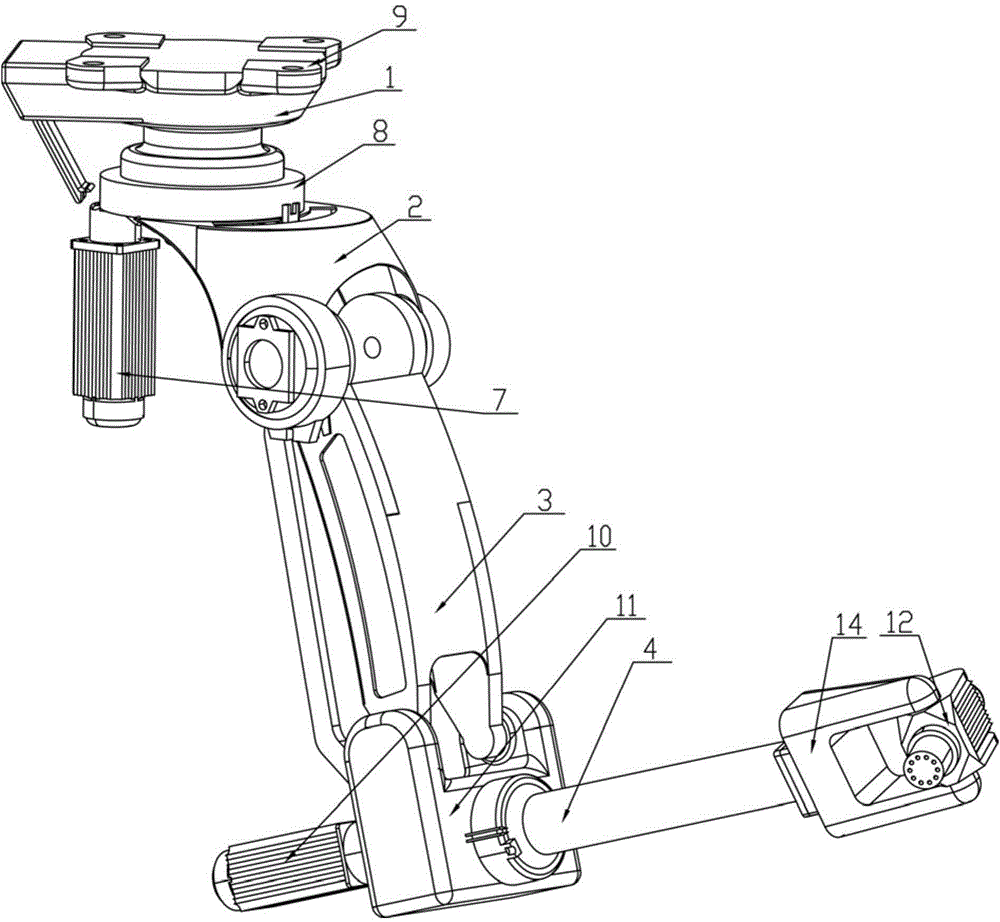

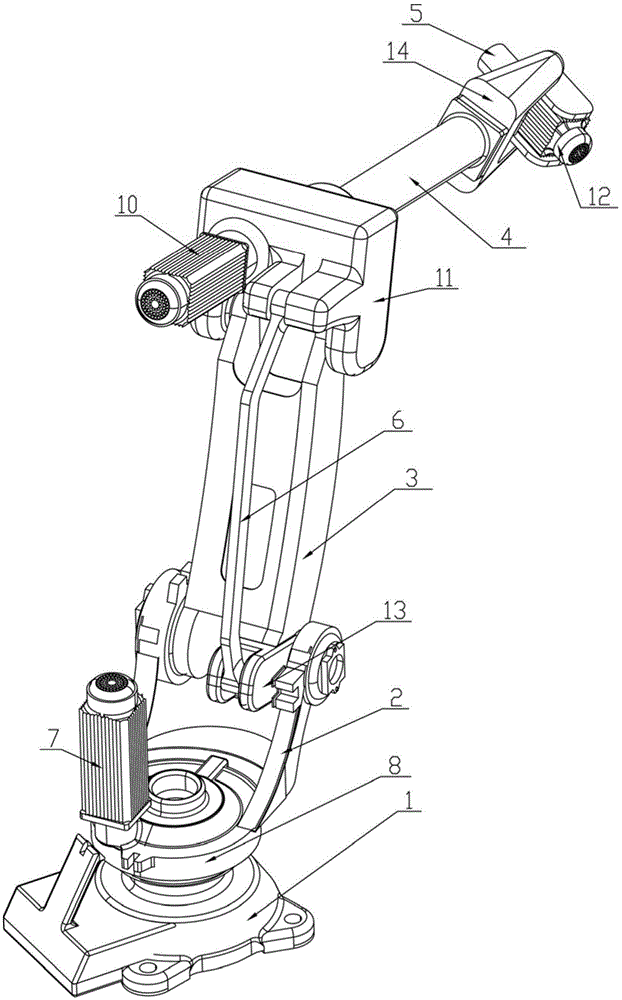

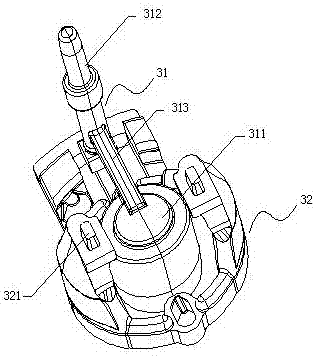

Six-axis manipulator

InactiveCN104669247AImprove work efficiencyGuaranteed surface flatnessProgramme-controlled manipulatorManipulatorEngineering

The invention discloses a six-axis manipulator comprising a base, a turntable movably mounted on the base, a lower arm hinged to the turnplate, an upper arm hinged to the lower arm and an operating part hinged to the upper arm. A connecting bar is disposed between the lower arm and the upper arm. One end of the connecting bar is hinged to the lower arm, and the other end thereof is hinged to the upper arm. The six-axis manipulator has the advantages that manual work is replaced, work efficiency is improved, surface smoothness of a product is guaranteed, surface quality of the product is improved, influence on the body of a worker is avoided and the six-axis manipulator features simple structure and wide operating range.

Owner:WENZHOU POLYTECHNIC

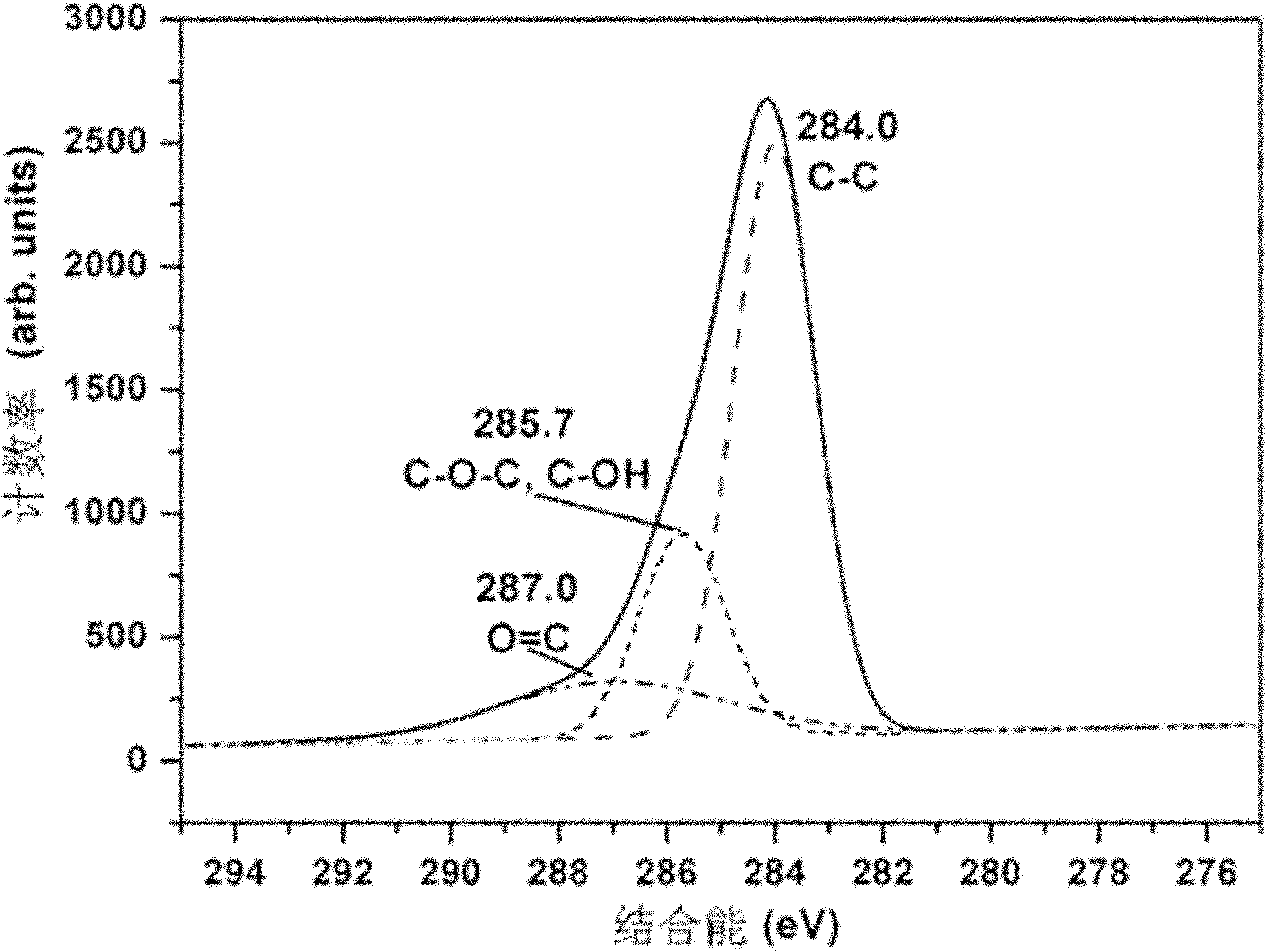

Method for preparing graphite oxide/macromolecular water-based cold rolling lubricating additive

InactiveCN102041139AStrong combinationImprove wear reduction performanceAdditivesDimethyl formamideEmulsion

The invention discloses a method for preparing a graphite oxide / macromolecular water-based cold rolling lubricating additive, and relates to a method for preparing a graphite oxide-based lubricating additive. The method solves the problems that the conventional cold rolling liquid has short service life, is easy to settle and break emulsion and has poor lubricating performance, poor anti-rust level, high viscosity and high residual carbon quantity and residual iron quantity. The method comprises the following steps of: adding graphite oxide into mixed solution of thionyl chloride and methylbenzene, performing reflux reaction to obtain graphite acetyl chloride, then adding the graphite acetyl chloride and water-soluble macromolecules into N,N-dimethyl formamide to react, drying the reaction system, dispersing the dried product into water, then adding ethanol to obtain sediment, and drying the sediment. The molecular structure of the water-based cold rolling lubricating additive has flexible polymer molecular chains, so the anti-friction performance of the lubricating additive is improved; the lubricating additive forms stable solution in water, and the solution has low viscosity, is not easy to settle and has long service life; and the lubricating additive has good anti-rust level and low residual carbon quantity and residual iron quantity. Through the water-based cold rolling lubricating additive, the friction spot diameter of the base liquid is reduced by 26.2 percent.

Owner:HARBIN INST OF TECH

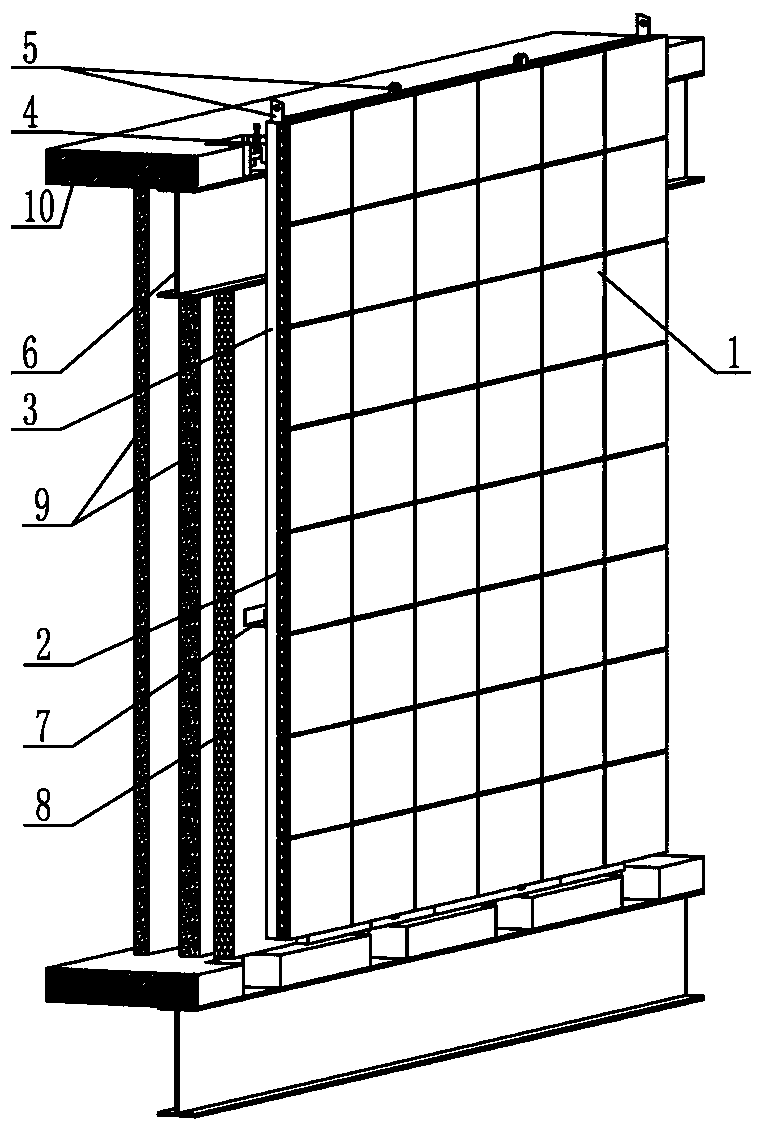

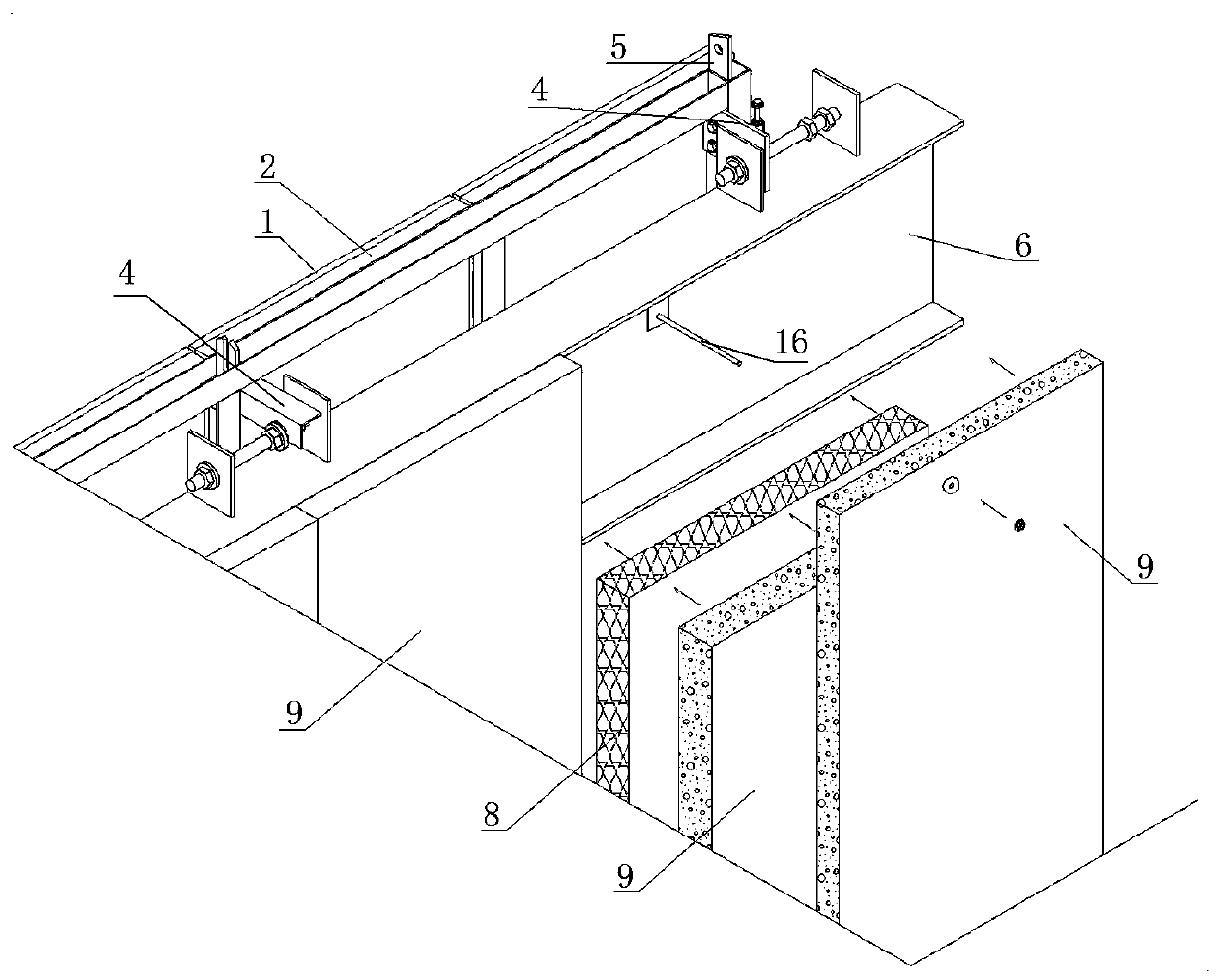

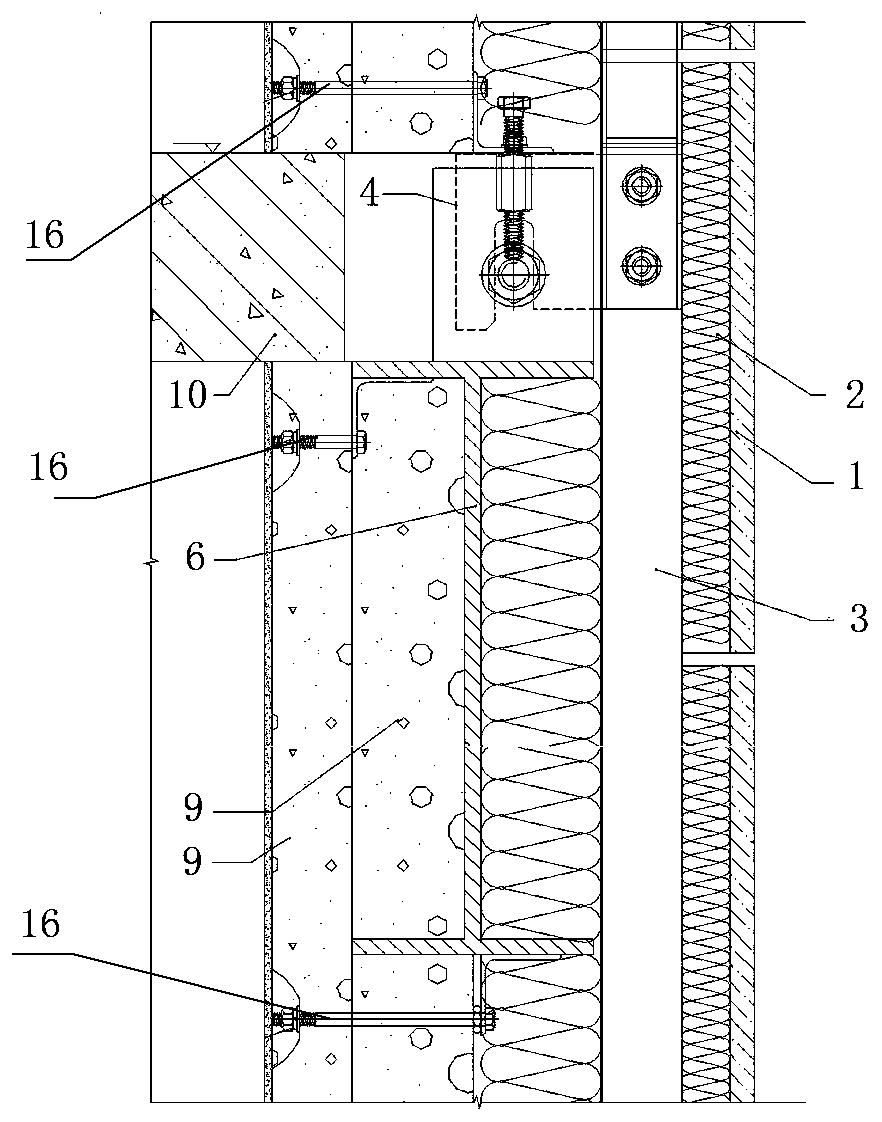

Steel-structured prefabricated building unit composite wall and assembly method thereof

PendingCN107859204ACompact structureCompact structure and assemblyWallsClimate change adaptationEngineeringBuilding unit

The invention relates to a steel-structured prefabricated building unit composite wall, involving floor plates and steel beams and comprising an insulation decorating unitary plate and a main unitarywall both arranged between two adjacent floor plates; the insulation decorating unitary plate is connected with the steel beams through a cladding positioning device; a connection beam that is horizontal is arranged between the steel beams, and the main unitary wall and the insulation decorating unitary plate are connected to form an integrated unitary composite wall through the connection beam and the steel beams. The unitary composite wall is of prefabricated combination connected structure, and the decoration effect of an exterior wall is achieved; by using the main unitary wall, wall integral strength and insulating property are guaranteed, and mounting quality and mounting efficiency are also improved.

Owner:SHENYANG SANXIN IND

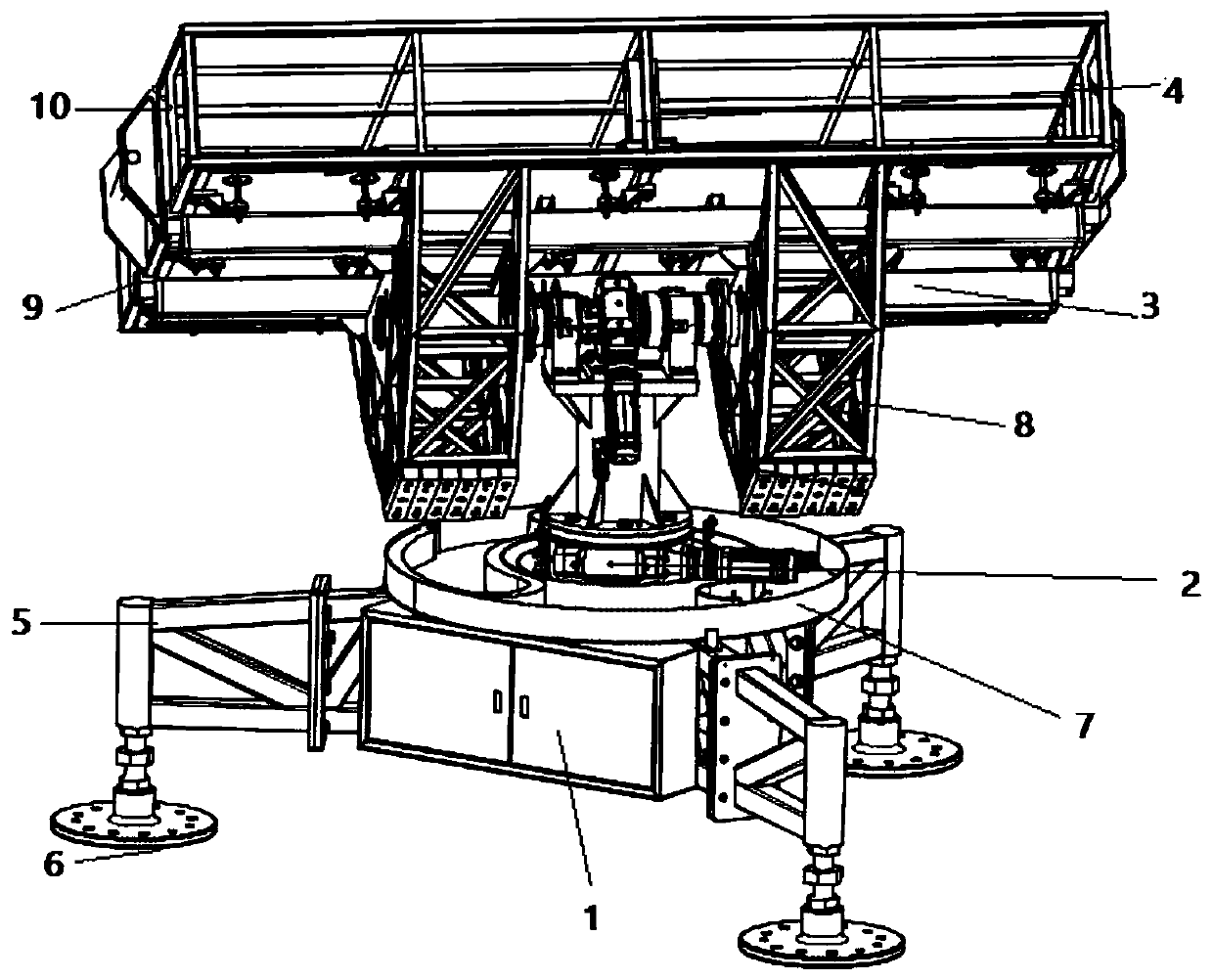

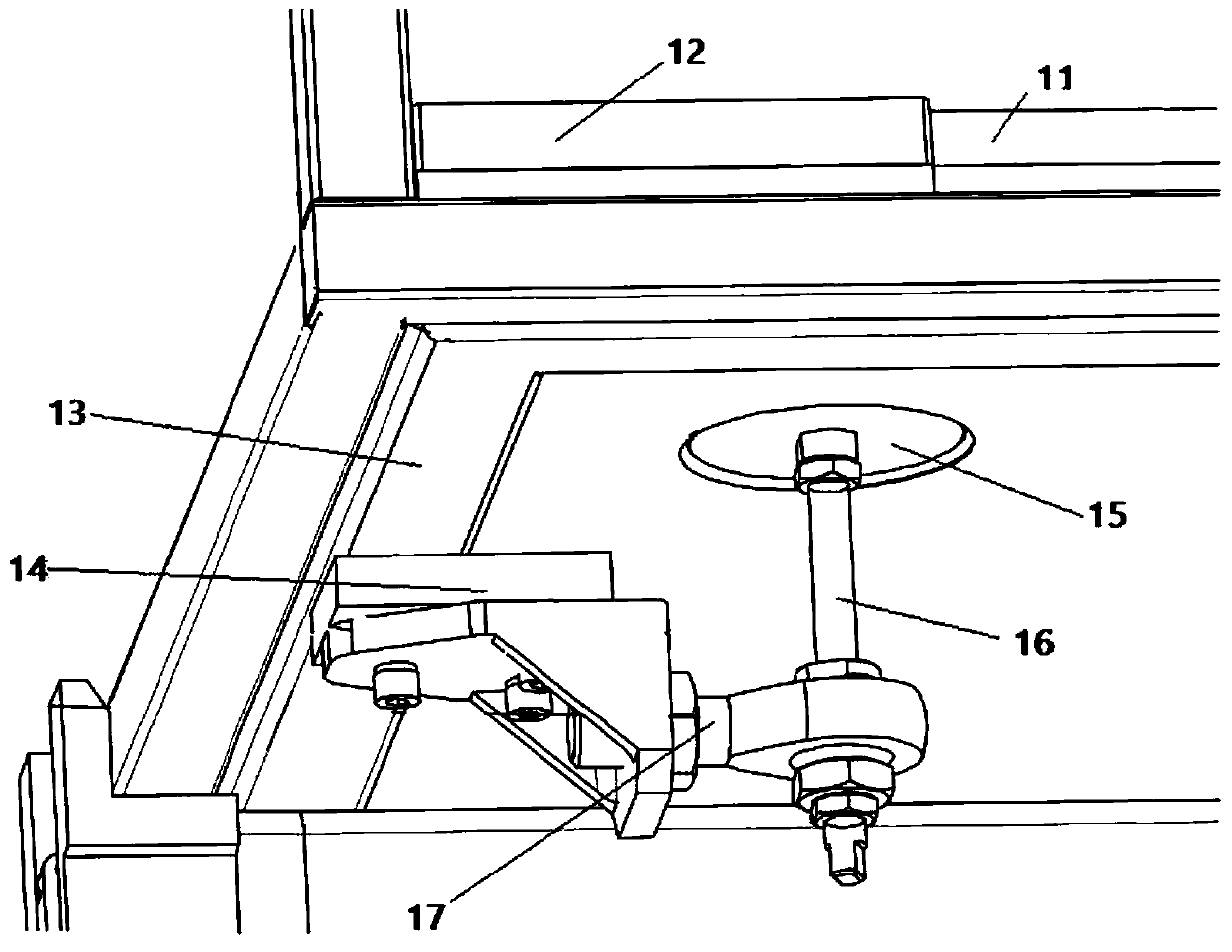

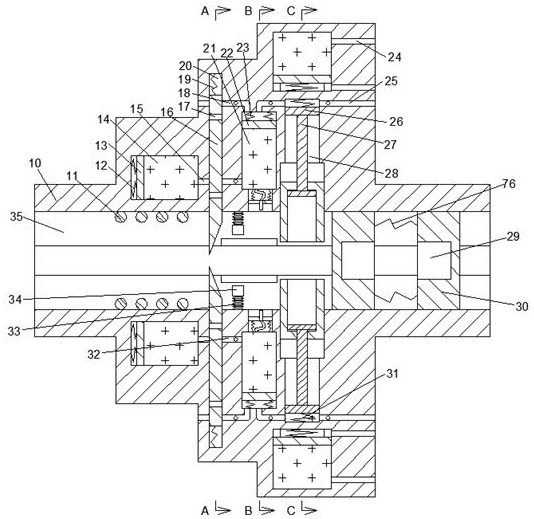

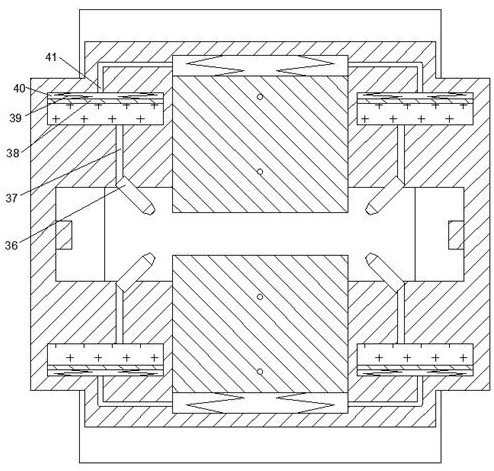

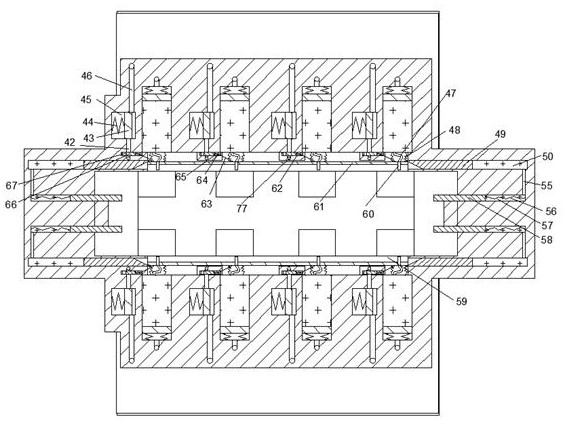

Novel automatic full-spectrum radiometric calibration reference target device

ActiveCN110243393AGuaranteed surface flatnessGuaranteed Surface AccuracyRadiation pyrometrySpectrum investigationMiddle infraredImaging quality

The invention discloses a novel automatic full-spectrum radiometric calibration reference target device, and relates to the technical field of the aerial remote sensing. The device comprises a reflector module, a sun sensor module, an attitude regulation and control module and an electric control system; the attitude regulation and control module is connected with the reflector module and used for driving the reflector module to rotate; the sun sensor module is arranged on the reflector module, and an optical axis of the sun sensor module is parallel to a reflector normal of the reflector module; and the sun sensor module and the attitude regulation and control module are connected with electric control system. The device disclosed by the invention is suitable for the full-spectrum radiometric calibration of high-orbit and low-orbit optical remote sensing satellites, thereby realizing the absolute radiometric calibration and image quality assessment of satellite loads at different orbits at the sun reflection waveband, the middle infrared waveband and the hot infrared waveband (0.35 micron to 12.5 micron).

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

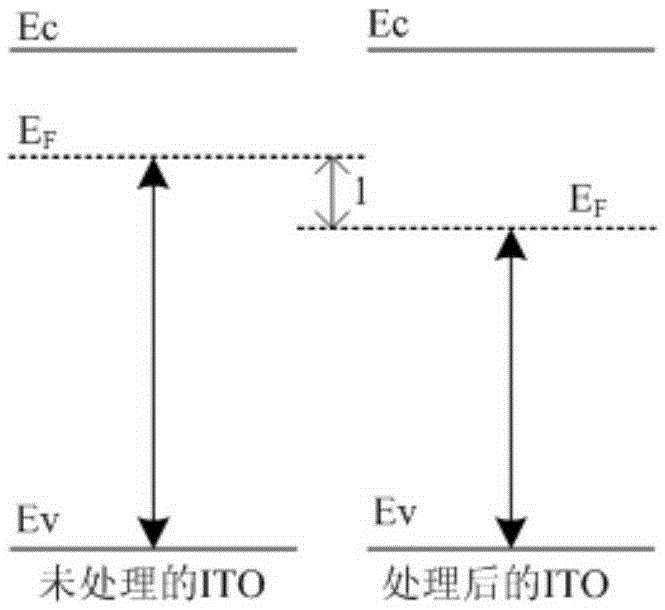

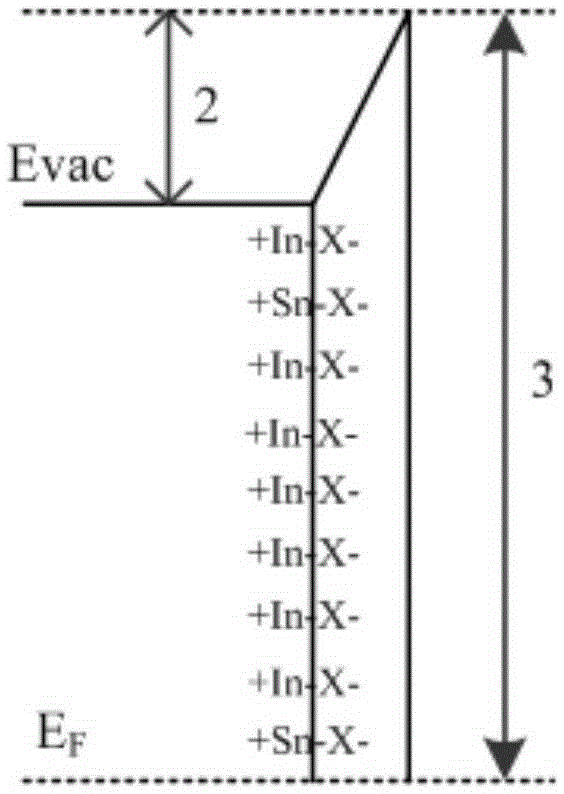

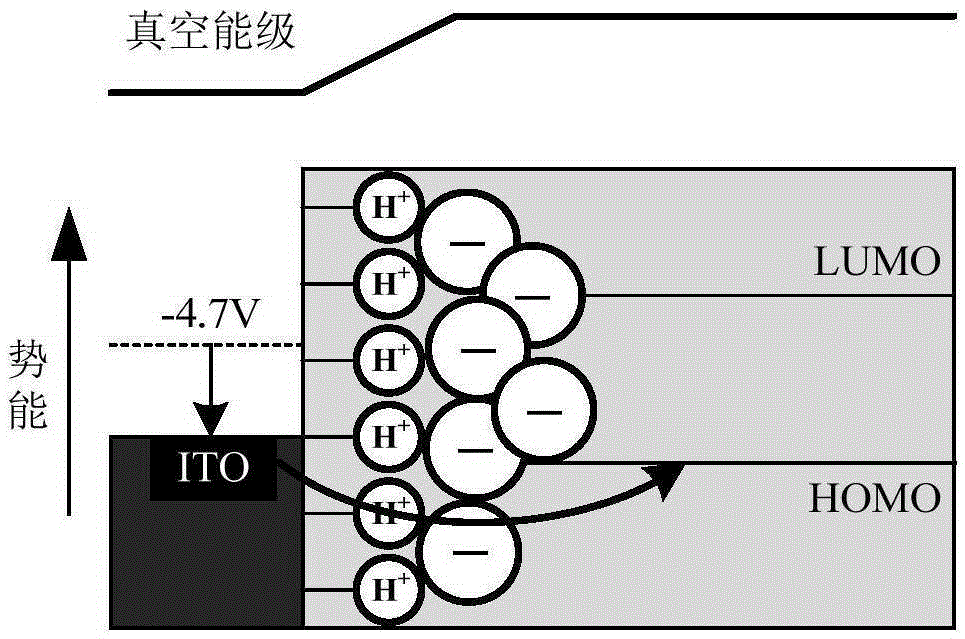

Modified ITO anode and preparation method and application thereof

ActiveCN105355803AEasy to operateEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentFlat panel display

The invention is suitable for the flat panel display technology field, and provides a modified ITO anode and a preparation method and applications thereof. The preparation method comprises the following steps: providing an ITO substrate, the ITO substrate comprising a substrate and an ITO film formed on the substrate through deposition, and cleaning and drying the ITO substrate in sequence; taking an HF solution or an HC1 solution as an electrolyte, the ITO substrate as an electrolytic bath anode and a molybdenum electrode as an electrolytic bath cathode, and then placing the ITO substrate and the molybdenum electrode side by side in a reaction container, conducting constant voltage electrochemical processing on the ITO film, and obtaining a surface-modified ITO electrode; and cleaning and drying the surface-modified ITO electrode.

Owner:TCL CORPORATION

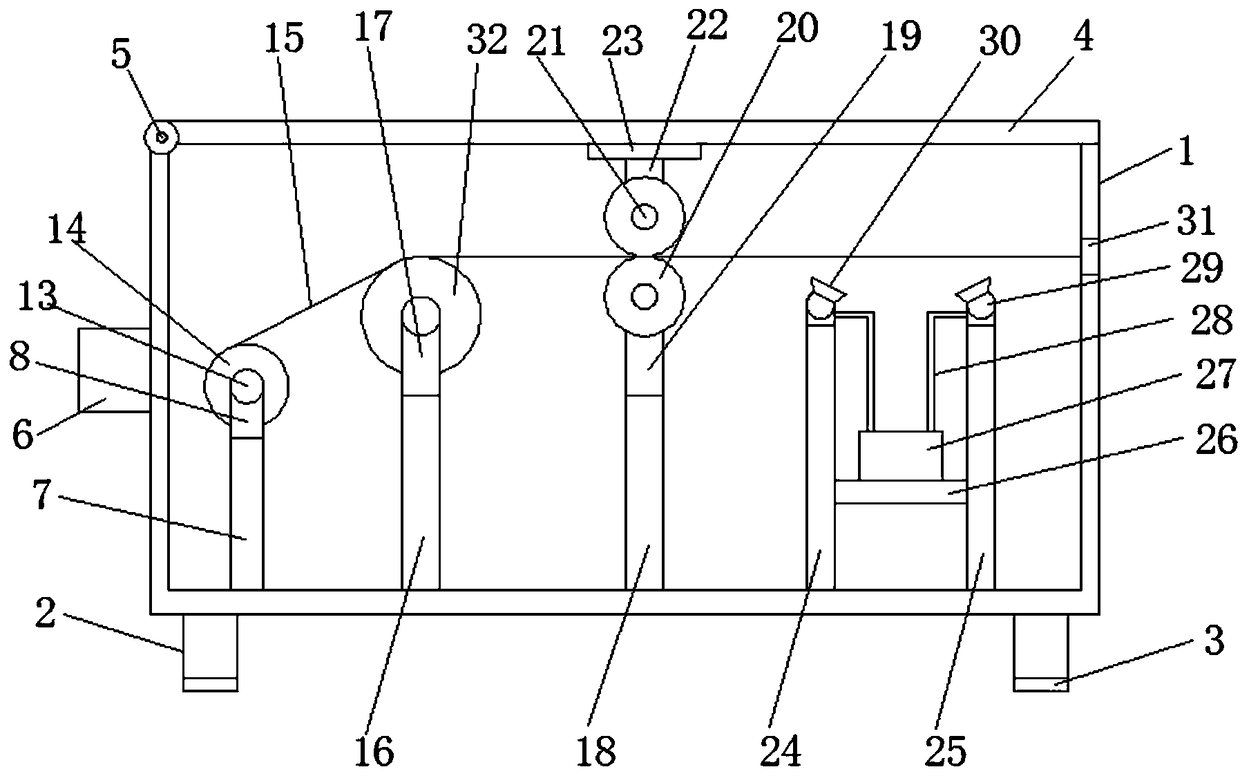

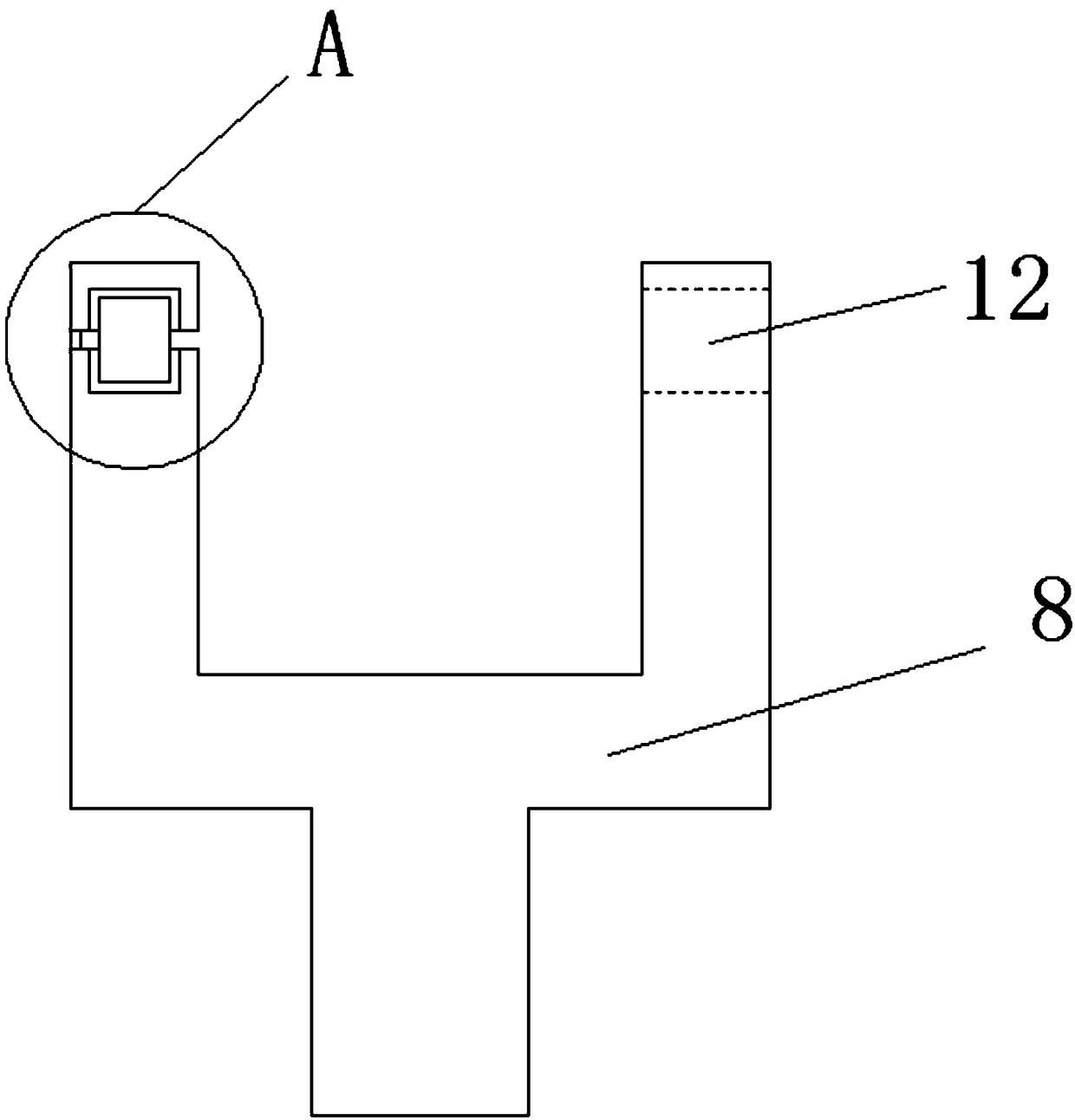

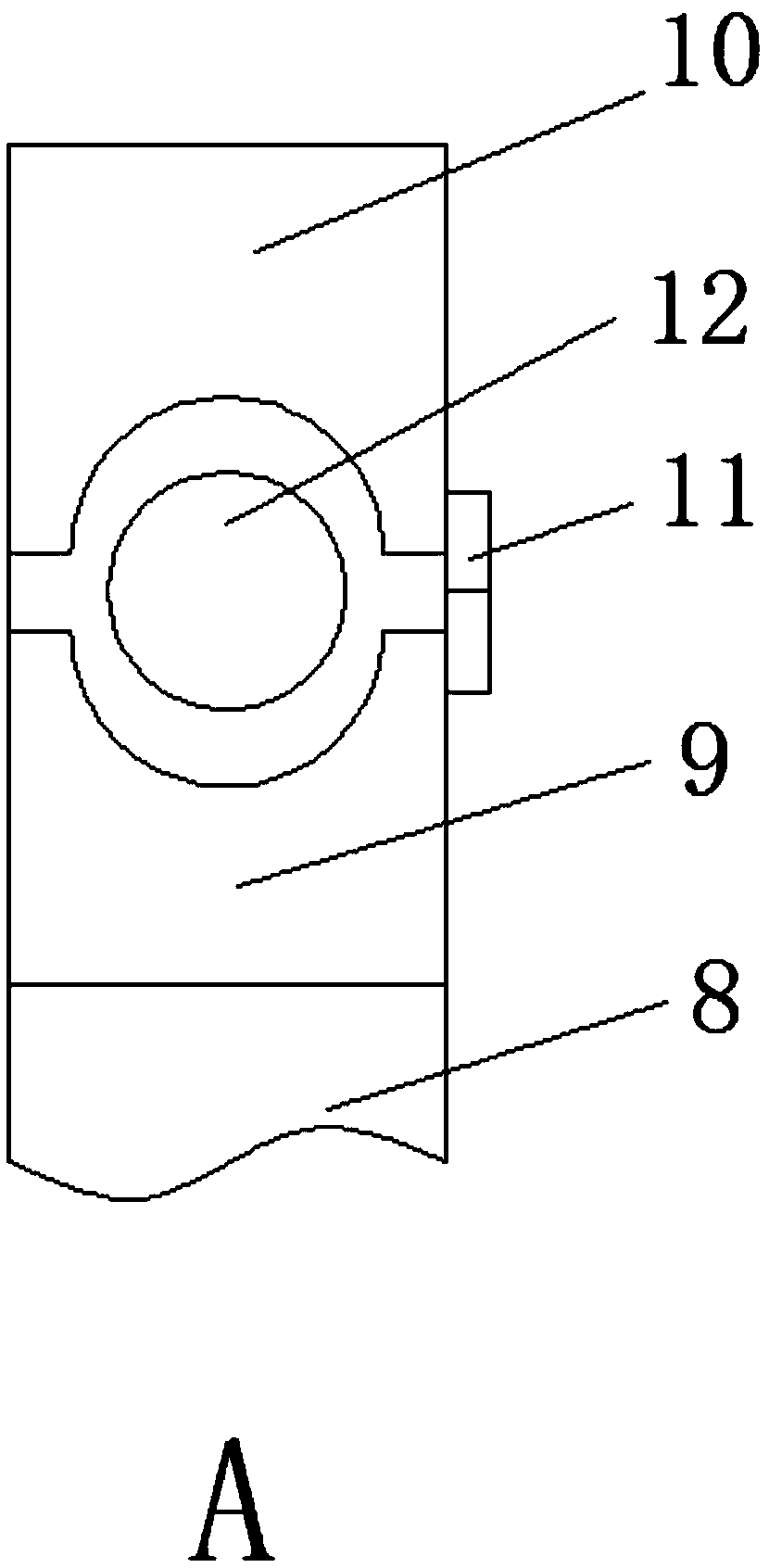

Textile yarn guiding device with humidifying device

InactiveCN108950847AAvoid pollutionGuaranteed surface flatnessWeft knittingWarp knittingTextile yarnElectric machinery

The invention discloses a textile yarn guiding device with a humidifying device. The textile yarn guiding device comprises a shell. Multiple supporting foot pads are arranged at the bottom of the shell, a top cover is arranged on the top of the shell, a drive motor is arranged on one side of the shell, a guide-out opening is formed in the other side of the shell, a first supporting rod is arrangedon one side of the inner bottom of the shell, a first supporting frame is arranged on the top of the first supporting rod, a first bearing block is arranged on one side of the top of the first supporting frame, a second bearing block matched with the first bearing block is arranged on the top of the first bearing block, one side of the first bearing block and one side of the second bearing blockare fixedly connected, and the other side of the first bearing block and the other side of the second bearing block are connected through a buckle. The device has the advantages that the device is reasonable in design and convenient to use, the surface smoothness of textile yarn is effectively guaranteed, the possibility that the textile yarn is contaminated is effectively avoided, and in addition, potential safety hazards caused by static are effectively eliminated.

Owner:芜湖瀚德信息科技有限公司

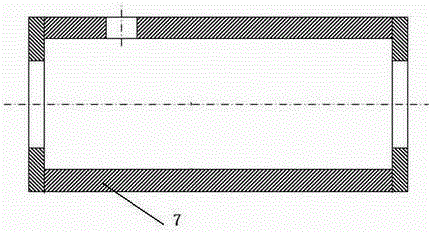

Rigid layer of fixed abrasive polishing roll for Roll-to-Roll chemical-mechanical polishing machine and preparation method of rigid layer

InactiveCN105150120AGuaranteed surface flatnessGuaranteed removal rateAbrasion apparatusGrinding devicesSocial benefitsPolishing

The invention discloses a rigid layer of a fixed abrasive polishing roll for a Roll-to-Roll chemical-mechanical polishing machine and a preparation method of the rigid layer. The rigid layer comprises components in percentage by weight as follow: 0.5%-10% of the abrasive, 5%-45% of light-cured resin, 5%-41% of a reactive diluent, 4%-7% of a photoinitiator, 0.05%-5% of an accelerant, 0.05%-3% of a surface performance regulator, 0.05%-5% of an adjuvant, 1%-4% of filler and 0.02% of pigments. The rigid layer of the fixed abrasive polishing roll for the Roll-to-Roll chemical-mechanical polishing machine and the preparation method of the rigid layer have the advantages of simple operation process, low cost, broad market prospect and remarkable economic and social benefits, and facilitates industrialization, popularization and application.

Owner:HENAN INST OF SCI & TECH

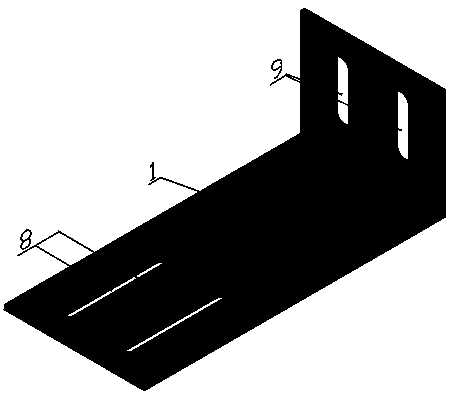

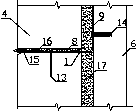

Frame infill wall using stress self-releasing connecting device and manufacturing method

InactiveCN108951940ANot adversely affectNo stress concentrationWallsProtective buildings/sheltersEngineeringStructural engineering

The invention relates to a frame infill wall using a stress self-releasing connecting device and a manufacturing method. The frame infill wall using the stress self-releasing connecting device and themanufacturing method are used for earthquake proof of an infill wall frame structure. The frame infill wall comprises an infill wall (5), wherein the infill wall (5) is laid by autoclaved aerated concrete blocks (4), masonry mortar (15) and by arranging basalt fiber grids (16) in a horizontal mortar joint of block masonry in a through length mode. The infill wall (5) is connected with a frame column (6) by an L-shaped stress self-releasing connecting piece (1) and a plate connecting piece (2), and the L-shaped stress self-releasing connecting piece (1) and the plate connecting piece (2) are arranged in an alternate combination mode of "one L-shaped stress self-releasing connecting piece (1) one plate connecting piece (2)". The infill wall (5) is connected with a frame beam (7) by an L-shaped stress self-releasing connecting piece (3). The frame infill wall using the stress self-releasing connecting device and the manufacturing method aim to solve the problems of brittleness and poor integrality of an infill wall of a conventional infill wall frame structure and complicated interaction between the infill wall and a frame of the conventional infill wall frame structure.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

Method for manufacturing semiconductor device

ActiveCN103681462AGuaranteed surface flatnessAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingPlasma etchingSemiconductor

The invention provides a method for manufacturing a semiconductor device. The method comprises the following steps: providing a semiconductor substrate; sequentially forming an etching stopping layer and an interlayer dielectric layer on the semiconductor substrate; forming a groove and a through hole for filling interconnected metal; removing the etching stopping layer below the through holes by using a plasma etching process, wherein the removing process comprises the following steps: firstly, performing post-etching treatment process so as to remove residual etching substances and impurities formed in the groove and the through hole, and secondly performing plasma etching by using an etching gas based on CF4, CO2 and CO. According to the method, when the etching stopping layer below the through hole is etched, the damage to the interlayer dielectric layer is small, and moreover substances which are hard to be removed after the etching are not formed at the bottom of the through hole, so that the surface flatness of the side wall and the bottom of the through hole is ensured.

Owner:SEMICON MFG INT (SHANGHAI) CORP

High precision brass strip processing technology

InactiveCN108048675AGuaranteed surface flatnessImprove toughnessProfile control deviceNon-ferrous metalRaw material

The invention relates to a non-ferrous metal processing technology, in particular to a high precision brass strip processing technology. The high precision brass strip processing technology provides the following technical scheme that the high precision brass strip processing technology comprises the following the steps that a, raw materials are selected; b, the raw materials in the step a are molten and stirred; c, casting and heating are conducted; d, repeated rolling, cooling and double-sided milling are conducted; e, primary rolling is conducted; f, annealing and cooling are conducted; g,secondary rolling is conducted; h, blank materials subjected to secondary rolling in the step g is subjected to secondary annealing; i, the blank materials subjected to secondary annealing in the steph is subjected to primary pickling; j, the blank materials subjected to primary pickling in the step i is subjected to tertiary rolling, annealing and pickling; k, the blank materials subjected to pickling in the step j is subjected to quartus rolling, and a strip-shaped finished product is formed; and l, the trip-shaped finished product in the step k is subjected to degreasing pickling, surfacepassivating and drying. By adopting the technical scheme, a brass strip processed through the high precision brass strip processing technology is smooth in surface, high in quality and low in cost.

Owner:瑞安市五星铜业股份有限公司

Stacking system for metal plate machining

InactiveCN112407969AImprove practicalityImprove versatilityStacking articlesSupporting framesEngineeringStructural engineering

The invention discloses a stacking system for metal plate machining, and belongs to the technical field of metal plate machining. The system comprises a body, wherein the body comprises a feeding mechanism, a material moving mechanism and a material receiving mechanism. The feeding mechanism comprises a supporting frame body, wherein the top surface of the supporting frame body is fixedly connected with a mounting base, the top surface of the mounting base is fixedly connected with a lower conveying assembly, the top surface of the lower conveying assembly is fixedly connected with a set of pressing push rods distributed in a rectangular array mode, and the top ends of the set of pressing push rods are fixedly connected with a pressing flattening assembly matched with the lower conveying assembly; the material moving mechanism comprises a connecting frame body. By designing the feeding mechanism, the material moving mechanism and the material receiving mechanism, the device can complete stacking operation of the metal plates in batches in an automatic mode, a fixed specification type structure of traditional stacking arrangement is changed into an adjustable structure, and by adjusting specification, the device can adapt to stacking operation of the plates of multiple specifications.

Owner:宁波曼汶智能装备有限公司

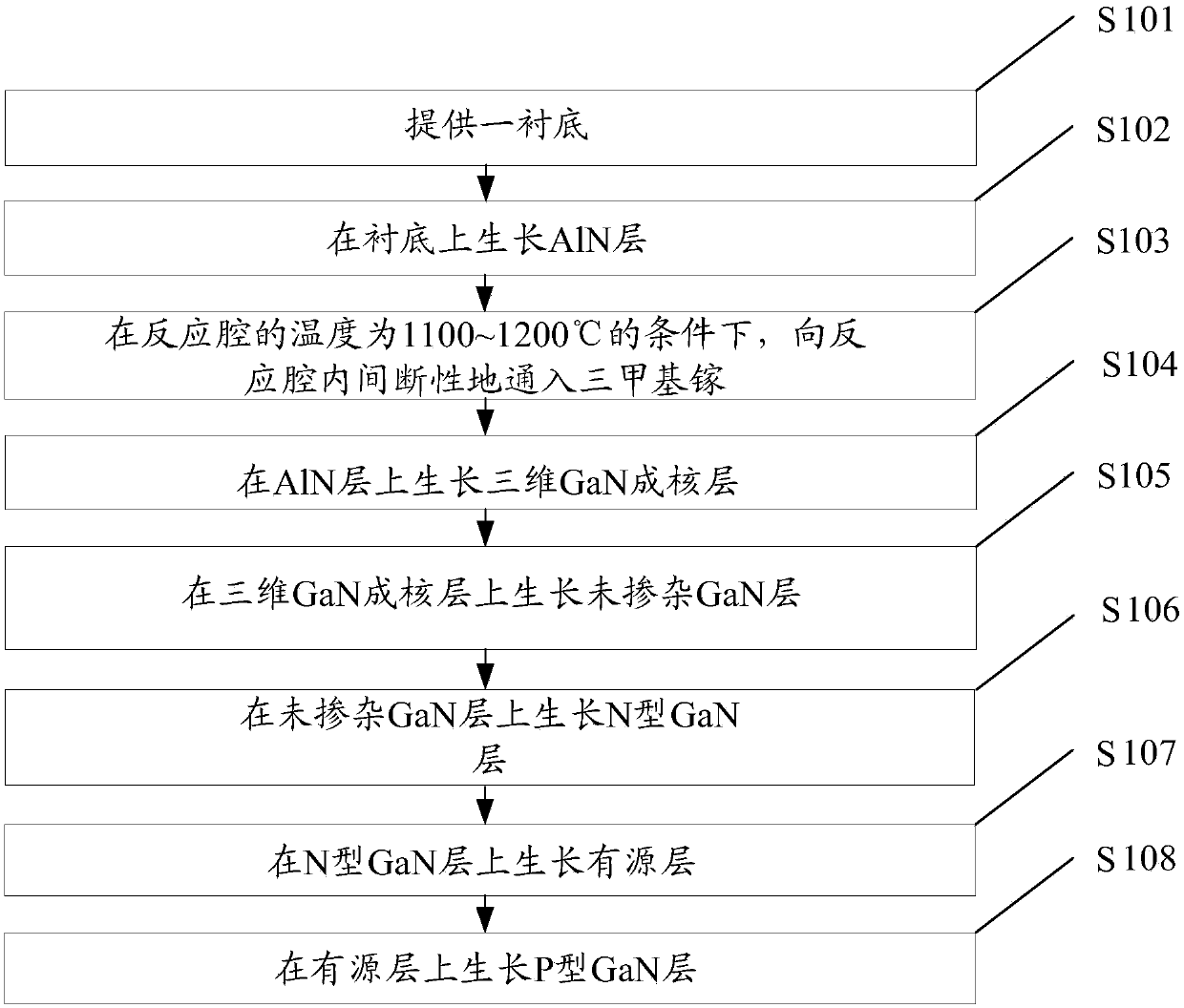

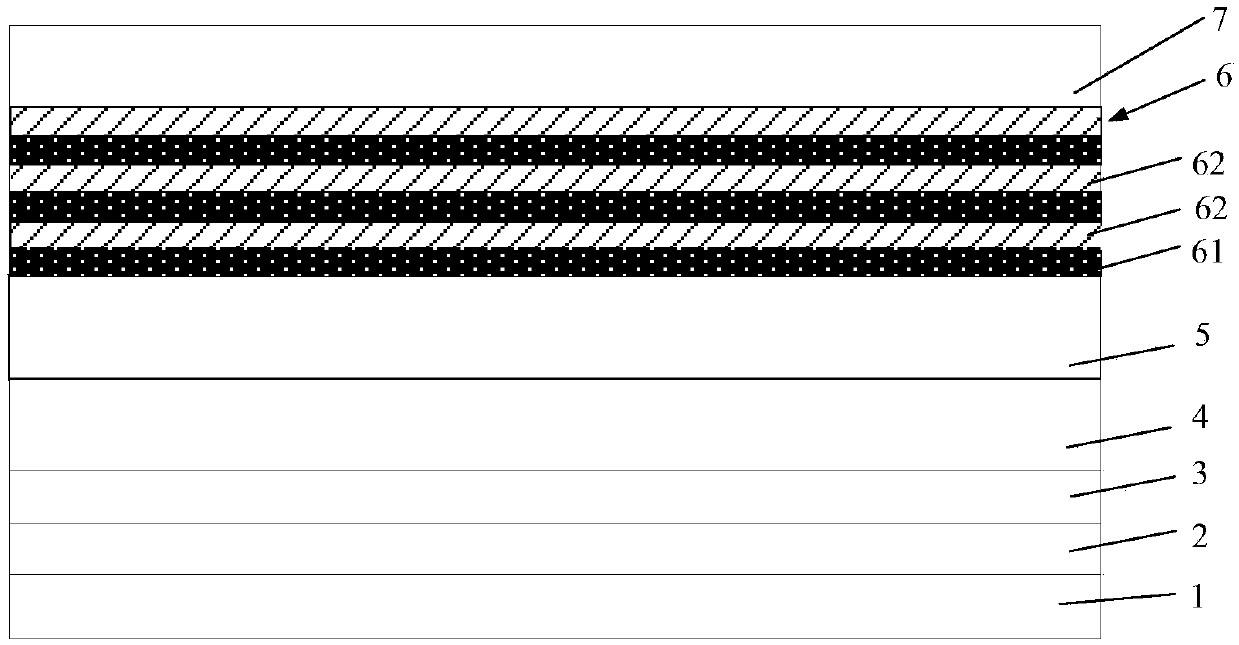

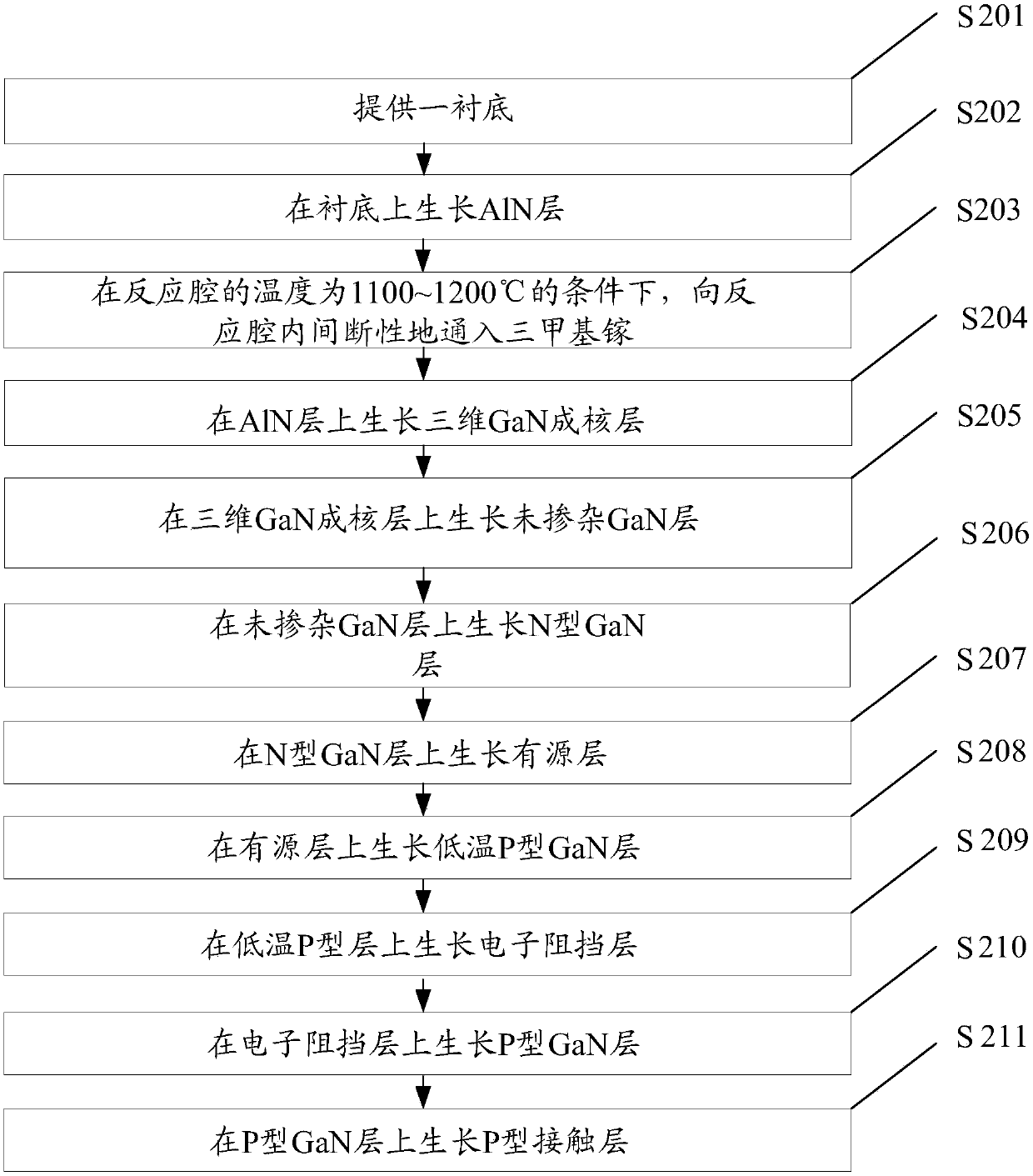

Preparation method of epitaxial wafer of light-emitting diode

The invention discloses a preparation method of an epitaxial wafer of a light-emitting diode, and belongs to the field of light-emitting diode manufacturing. The preparation method comprises the following steps: trimethyl gallium is introduced into a reaction cavity, wherein the trimethyl gallium acts on an AlN layer, gallium atoms in the trimethyl gallium are attracted by micro-pits with lower potential energy on the surface of the AlN layer far away from the substrate, and the gallium atoms are filled into the micro-pits on the AlN layer, so that the surface of the AlN layer is relatively flat; the trimethyl gallium is intermittently introduced, so that the protrusion at the micro-pits due to excessive gallium atom filling can be avoided, the roughness of the surface of the AlN layer faraway from the substrate is reduced, the surface flatness of a three-dimensional GaN nucleation layer grown on the AlN layer is ensured, and the surface flatness of the whole epitaxial wafer is further ensured, which is beneficial to improving the light-emitting uniformity of the light-emitting diode. The gallium atoms fill the micro-pits on the AlN layer, so that the defect of the AlN layer at the micro-pits can be prevented from being transferred to the three-dimensional GaN nucleation layer, the quality of the three-dimensional GaN nucleation layer is improved, the crystal quality of the epitaxial wafer is ensured, and the luminous efficiency of the light-emitting diode is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

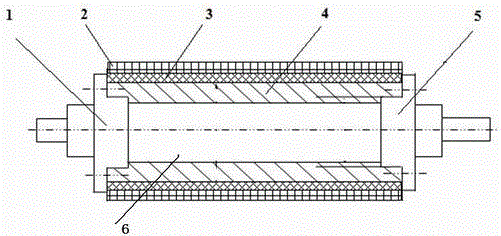

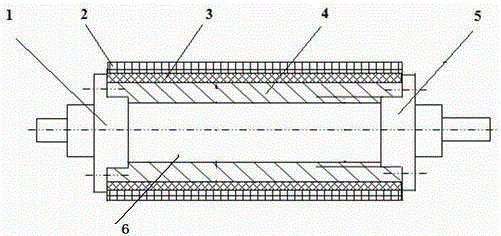

Fixed abrasive polishing roll for Roll-to-Roll chemical mechanical polisher and preparation method for fixed abrasive polishing roll

InactiveCN105215865AGuaranteed surface flatnessGuaranteed surface qualityAbrasion apparatusGrinding devicesMaterial removalPolishing

The invention discloses a fixed abrasive polishing roll for a Roll-to-Roll chemical mechanical polisher and a preparation method for the fixed abrasive polishing roll. According to the technical scheme, a polishing roll left-end supporting mechanism and a polishing roll right-end supporting mechanism are arranged on the two sides of the fixed abrasive polishing roll respectively; the fixed abrasive polishing roll is provided with a fixed abrasive polishing roll base body layer; an elastic layer is arranged in the exterior of the fixed abrasive polishing roll base body layer; a rigid layer is arranged in the exterior of the elastic layer. The surface of the fixed abrasive polishing roll is not liable to be deformed plastically; pore spaces in the surface of the fixed abrasive polishing roll are not liable to be blocked; the capacities for containing a polishing solution and removing scraps of the fixed abrasive polishing roll are not decreased with time; the material removal rate is even and uniform. In addition, a polishing pad does not need to be repaired and maintained, so that the polishing efficiency is improved.

Owner:HENAN INST OF SCI & TECH

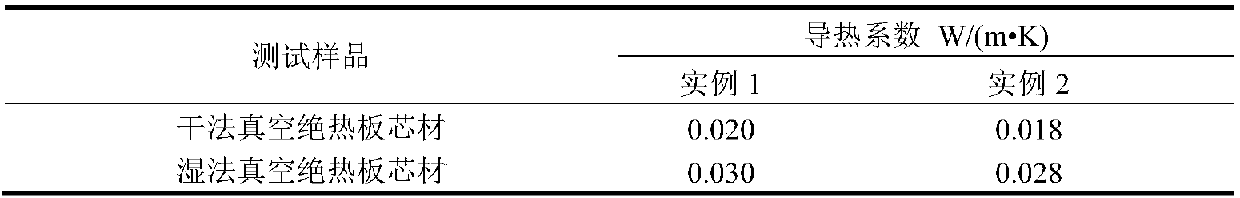

A kind of high-strength and low thermal conductivity superfine glass fiber cotton dry-process hot-pressed core material and its preparation method

ActiveCN107558289BHigh porosityLower fiber forming temperatureGlass making apparatusSynthetic cellulose/non-cellulose material pulp/paperGlass fiberHigh intensity

The invention relates to a high-strength low-heat conductivity coefficient ultra-fine glass fibre cotton dry hot-pressed core material and a preparation method thereof, and belongs to the technical field of glass fibres. The ultra-fine glass fibre cotton dry hot-pressed core material is prepared from the following components in percentage by weight: 62.5 to 65.5 percent of SiO2, 8.5 to 12.5 percent of R2O, 5.5 to 8.5 percent of B2O3, 4 to 7.5 percent of CaO, 2.8 to 5.2 percent of Al2O3, 1.8 to 4.2 percent of MgO and less than 0.38 percent of Fe2O3+ZnO+BaO, wherein the R in R2O is Na or K; thecore material has the advantages of low heat conductivity coefficient, and high tensile and bending strength. The preparation method of the high-strength low-heat conductivity coefficient ultra-fine glass fibre cotton dry hot-pressed core material specifically comprises six processes of forming fibres, collecting cotton, rolling, paving the cotton, performing hot-pressing and cutting; continuous dynamic hot pressing is adopted in a core material production process; the preparation method has the advantages of high production efficiency, high yield, low production cost and the like.

Owner:宣汉正原微玻纤有限公司

Hydrophobic maintenance seal coat material for roads and preparation method of seal coat material

ActiveCN110003670AImprove hydrophobicityGood water sealing effectBuilding insulationsFilling materialsDiluent

The invention discloses a hydrophobic maintenance seal coat material for roads and a preparation method of the seal coat material. The hydrophobic maintenance seal coat material for the roads is prepared from the following components in parts by weight: 100 parts of cementing materials, 12-20 parts of a hydrophobic additive, 5-12 parts of a nano modified stain resistant agent, 2-6 parts of a surface modifier, 1-3 parts of an activator, 2-4 parts of a wetting agent, 16-24 parts of light hydrophobic aggregate, 6-10 parts of filling materials, 4-8 parts of a diluent, 2-6 parts of a leveling agent, 7-11 parts of silica gel powder, 1-2 parts of a defoaming agent and 2-5 parts of a stabilizer. The material has good hydrophobicity and water seal performance, can isolate external water outside therange of the road surface by excellent hydrophobicity, inhibits external water from penetrating into the interior of the road surface layer, effectively solves the problem of water damage to the roads, improves durability of the roads, and has good effect of improving performance of the road surface.

Owner:GUANGDONG UNIV OF TECH

Straightening method of tempered steel plate

InactiveCN103008401AEliminate side wave defectsGuaranteed surface flatnessSheet steelThermal treatment

The invention provides a straightening method of a tempered steel plate, and the method is characterized in that after a steel plate which is thermally treated is tempered, the steel plate is cooled to 140DEG C to 160DEG C on a thermal treatment cold bed, then the steel plate is conveyed by a roller bed to the front of a cold straightening machine, and the steel plate is enabled to enter the cold straightening machine to be straightened at the temperature of 80 to 100 DEG C; a small roll gap is set in the primary two passes, so that the steel plate is bent; and a large roll gap is set in a third pass, so that the steel plate is flattened. Due to the adoption of the method, the edge wave defects of the steel plate can be eliminated, the surface smoothness of the steel plate can be guaranteed, and the qualification rate of the steel plate shape can be improved by more than 30 percent.

Owner:ANGANG STEEL CO LTD

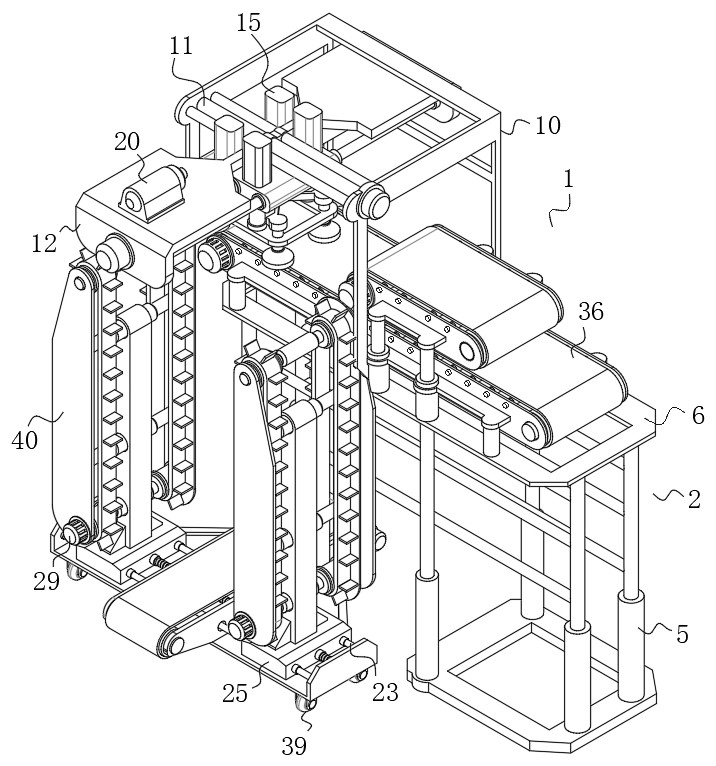

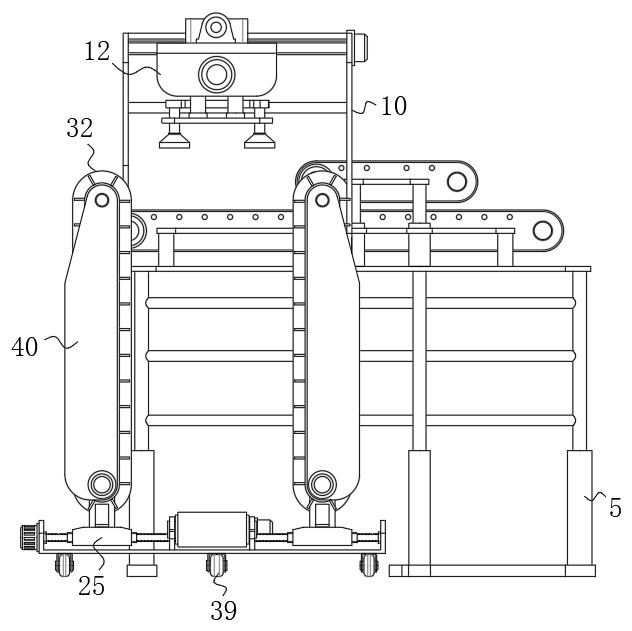

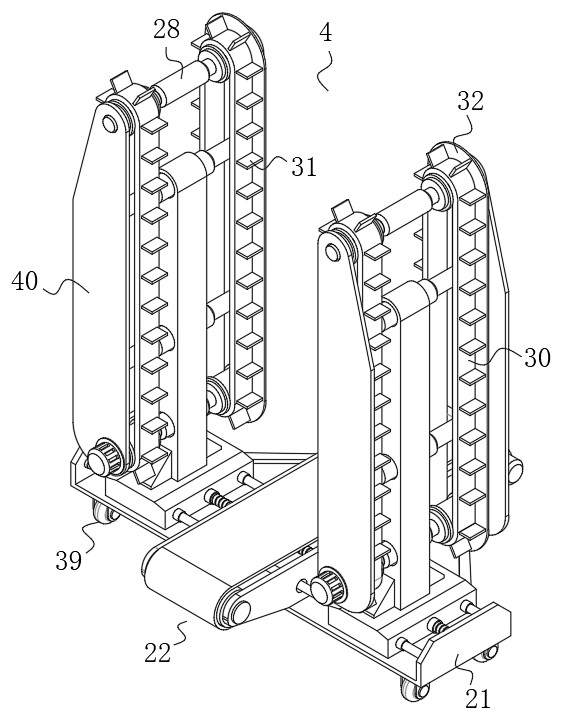

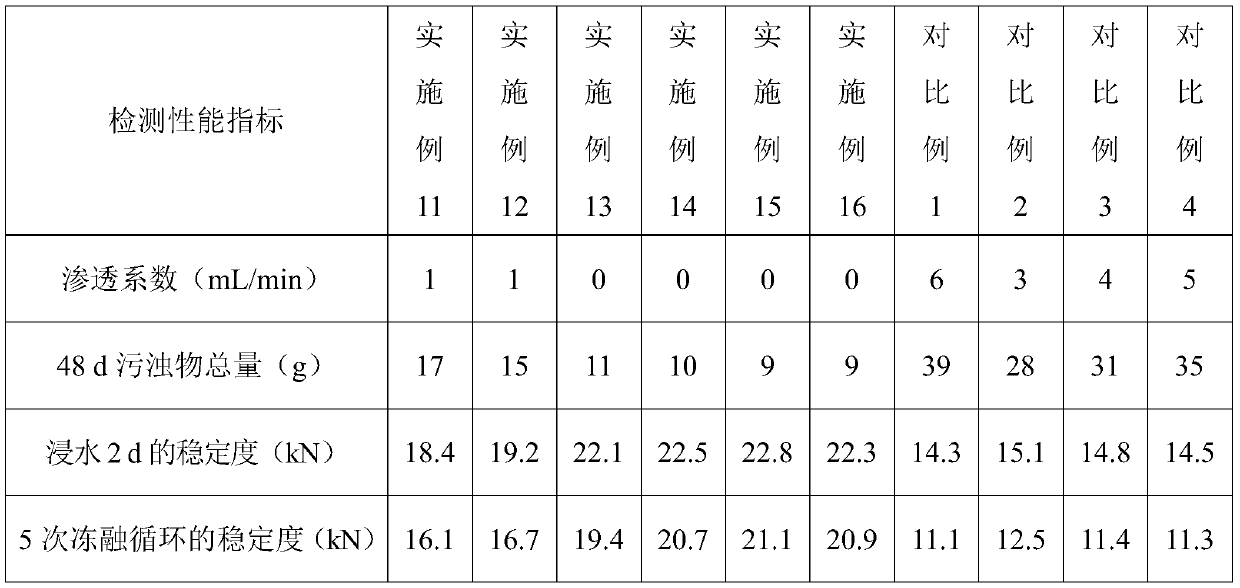

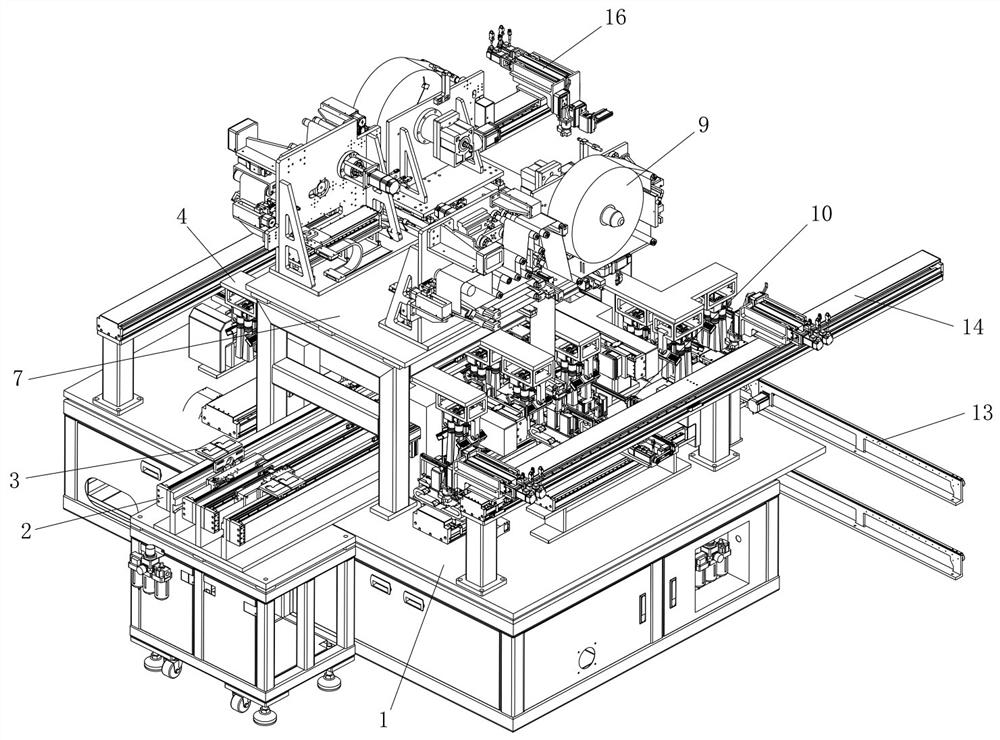

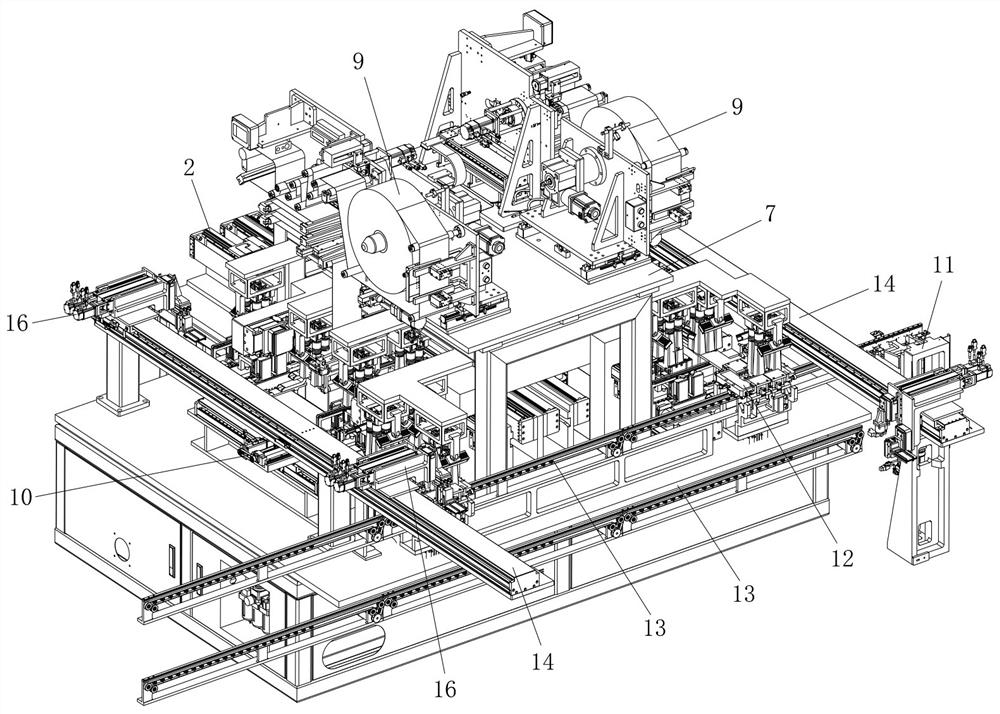

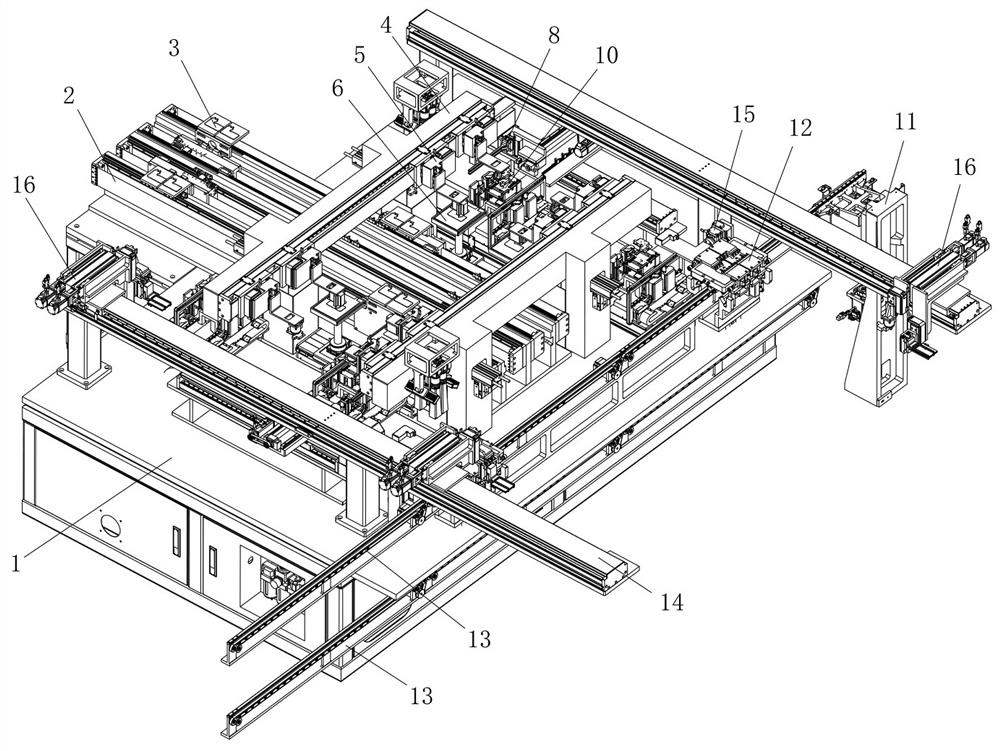

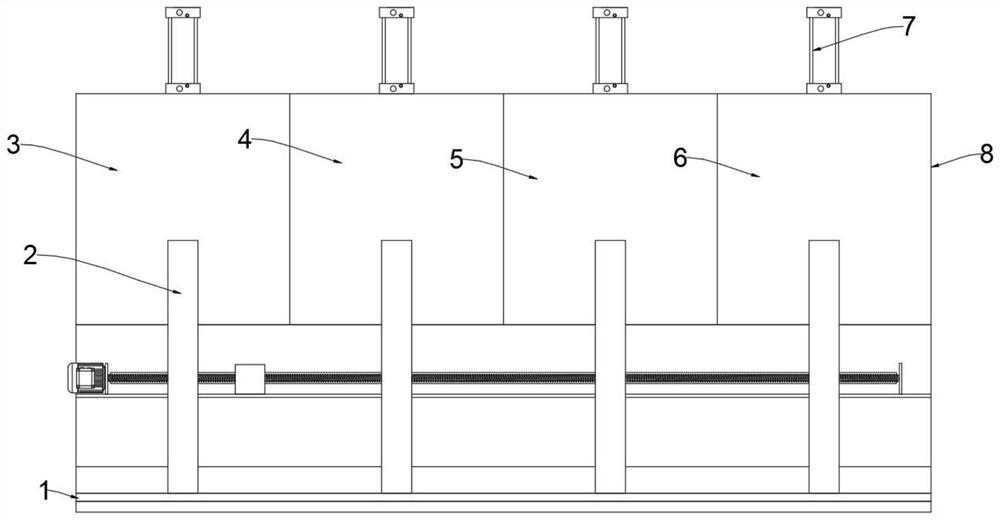

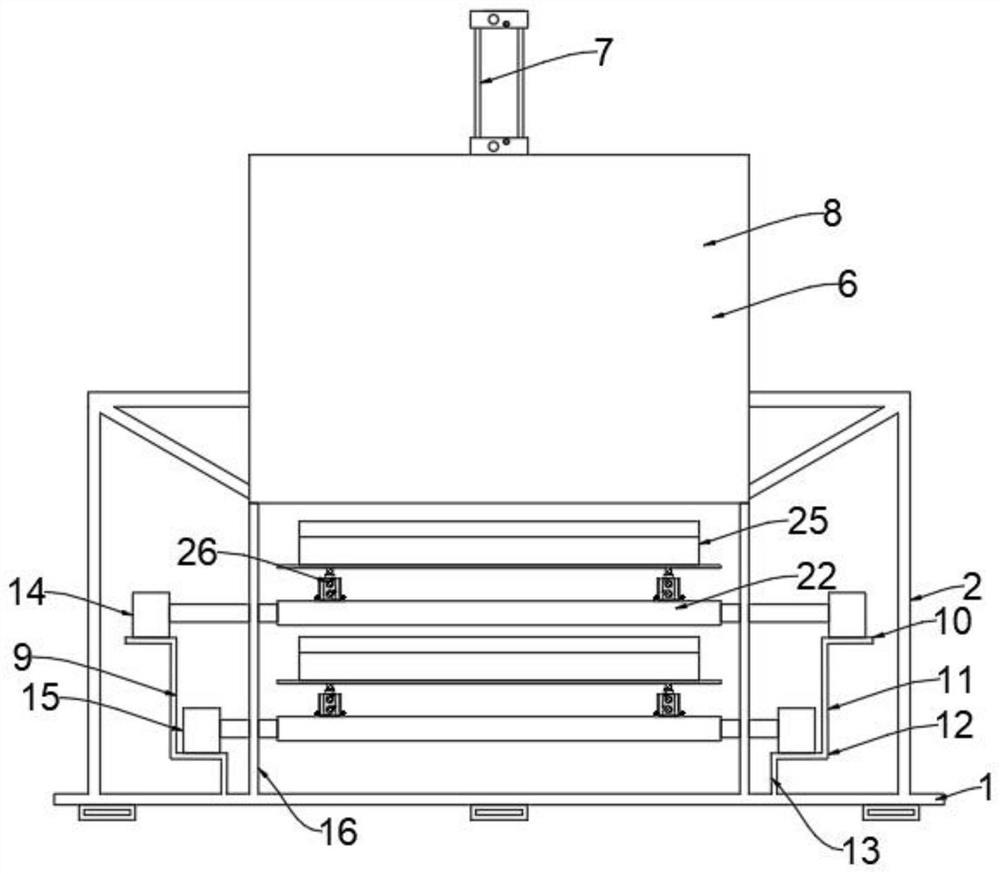

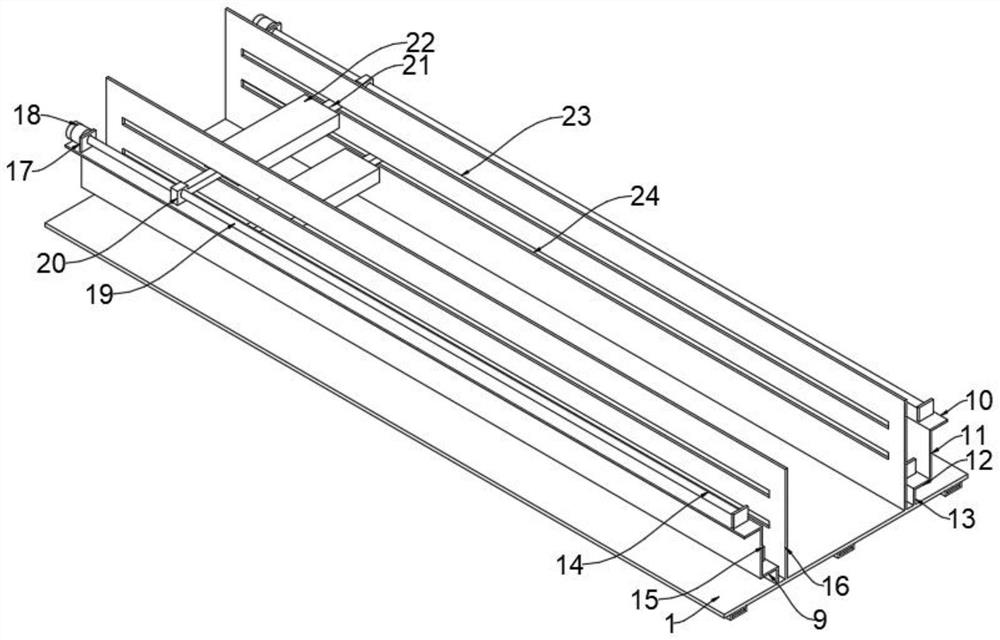

Battery cell circulating supply outer plate lamination production line and production process thereof

ActiveCN114122527AImplement automatic exportEnsure loading stabilityFinal product manufactureElectrolyte accumulators manufactureProduction lineEngineering

The invention discloses a battery cell circulation supply outer plate lamination production line and a production process thereof, the battery cell circulation supply outer plate lamination production line comprises a pole piece supply mechanism, a film supply mechanism, an outer plate supply mechanism, a lamination mechanism and a blanking mechanism, the pole piece supply mechanism is horizontally arranged on a machine table, and is perpendicular to one side edge of the machine table to extend outwards; the outer plate supply mechanism is arranged on the other side of the machine table; the lamination mechanism is arranged at the side part of the pole piece supply mechanism; the film supply mechanism is erected above the lamination mechanism; and the discharging mechanism is arranged at the side part of the lamination mechanism and is used for carrying and discharging the battery cells formed after lamination. Closed-loop circulation supply of the outer plates is achieved, the outer plates are automatically clamped and fixed and loosened through single power, the carrying stability of the outer plates is effectively guaranteed, meanwhile, alternate film drawing, pressing and covering and automatic cutting-off of the laminated diaphragms are achieved, the surface flatness of the diaphragms during lamination is effectively guaranteed, and the lamination efficiency is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Mechanical and electrical product surface repairing device for accurately repairing concave parts and protrusions

InactiveCN111633378AGuaranteed surface flatnessImprove repair efficiencySpray boothsStructural engineeringElectric power

The invention discloses a mechanical and electrical product surface repairing device for accurately repairing concave parts and protrusions. A box is included and internally provided with an electricsliding rail groove which is in left-right communication, wherein the front end wall and the rear end wall of the electric sliding rail groove are symmetrically provided with electric guide rails. Theinterior of the electric sliding rail groove is electrically connected with left-right-symmetry electric sliding blocks. The electric sliding blocks are connected through first springs. The oppositeend faces of the left and right electric sliding blocks are provided with clamping grooves with openings towards the first springs. Drying pipes are fixedly arranged in the electric sliding rail groove in an upper-lower symmetry manner. Inclined block grooves provided with openings towards the electric sliding rail groove and located on the right sides of the drying pipes are symmetrically arranged on the upper end wall and the lower end wall of the electric sliding rail groove. The inclined block grooves are internally connected with first inclined blocks. The inclined block grooves are internally connected with the first inclined blocks. The top faces of the first inclined blocks and the inclined block grooves are connected through second springs. Paint repairing mechanisms are symmetrically arranged on the front sides and the rear sides of the inclined block grooves. Double-face concave parts and protrusions of a mechanical and electrical product can be treated at the same time, andafter filling liquid filling and protrusion abrasion, paint spraying can be conducted on the surface of the mechanical and electrical product in time.

Owner:义乌市故宏机械科技有限公司

A casting method based on a new type of oil pump shell mold

ActiveCN107321919BEasy to polishGuarantee casting qualityFoundry mouldsFoundry coresChromiteMolding sand

The invention relates to a casting method based on a novel oil pump body shell mould. The casting method comprises the following steps that (1) heating and solidifying are conducted on molding sand to form the shell mould, the shell mould consists of an upper shell body and a lower shell body, and after mould clamping is conducted on the upper shell body and the lower shell body, an oil pump body mould cavity is formed; (2) a set of sand cores of an oil pump body is formed through chromite sand, the sand cores are correspondingly an inner sand core and an outer sand core, the sand cores are combined to form a sand core main body, and the sand core main body is horizontally arranged in the lower shell body; (3) a sand box is manufactured through sand, the upper shell body and the lower shell body are embedded in the sand box, a sand layer covers a cavity between the outer surfaces of the upper shell body and the lower shell body and the inner side of the sand box , and the sand layer is internally provided with a gating and risering system which communicates with the shell mould; and (4) casting is conducted on the interior of the mould cavity through the gating and risering system, and the oil pump body is formed. The casting method has the advantages that through the casting method, burrs of parting mould surfaces of the oil pump body are easy to polish, and sand core fracture in the casting process is not easily caused.

Owner:江苏力源金河铸造有限公司

Casting method based on novel oil pump body shell mould

ActiveCN107321919AFast exhaustReduce porosity and shrinkageFoundry mouldsFoundry coresChromiteMolding sand

The invention relates to a casting method based on a novel oil pump body shell mould. The casting method comprises the following steps that (1) heating and solidifying are conducted on molding sand to form the shell mould, the shell mould consists of an upper shell body and a lower shell body, and after mould clamping is conducted on the upper shell body and the lower shell body, an oil pump body mould cavity is formed; (2) a set of sand cores of an oil pump body is formed through chromite sand, the sand cores are correspondingly an inner sand core and an outer sand core, the sand cores are combined to form a sand core main body, and the sand core main body is horizontally arranged in the lower shell body; (3) a sand box is manufactured through sand, the upper shell body and the lower shell body are embedded in the sand box, a sand layer covers a cavity between the outer surfaces of the upper shell body and the lower shell body and the inner side of the sand box , and the sand layer is internally provided with a gating and risering system which communicates with the shell mould; and (4) casting is conducted on the interior of the mould cavity through the gating and risering system, and the oil pump body is formed. The casting method has the advantages that through the casting method, burrs of parting mould surfaces of the oil pump body are easy to polish, and sand core fracture in the casting process is not easily caused.

Owner:江苏力源金河铸造有限公司

A kind of manufacturing method of glazed tile and its product

The invention relates to a manufacturing method of a glazed brick and a product thereof. The method includes: A) a step of blending raw materials, performing ball milling, performing spray granulation, pressing to form a green brick, drying the green brick and spraying a base glaze on the green brick; B) a step of printing patterns on the green brick after the A) step, and spraying a transparent glaze; C) a step of printing patterns on the green brick after the B) step, drying, spraying a transparent glaze again and drying; D) a step of spraying a transparent glaze on the green brick after the C) step and drying; and E) a step of kilning the green brick in the D) step, polishing with an inelastic module, packaging and putting the brick into storage. When the product is exposed to light, the ray of light is subjected to two times of transmission and refraction, so that the patterns are strong in stereoscopic effects, add radiance and beauty to each other, are natural and grand, and can achieve decorative effects similar to that of natural stone.

Owner:FOSHAN DONGPENG CERAMIC +2

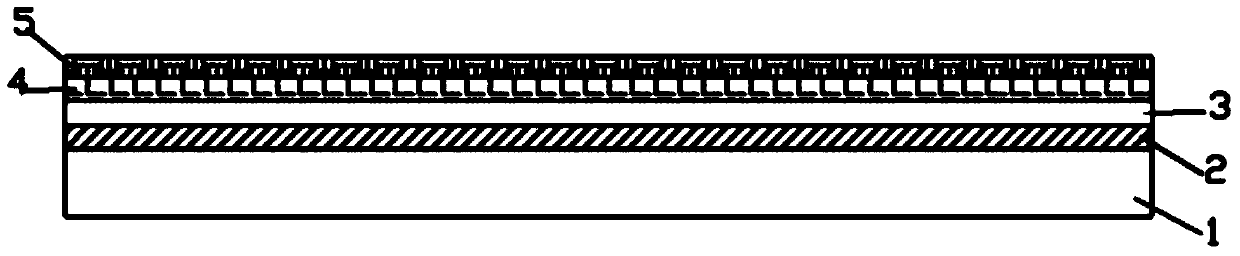

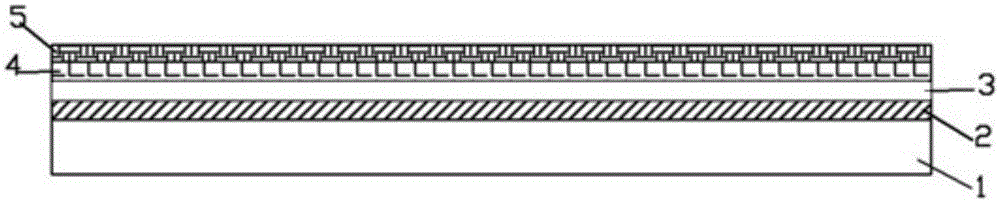

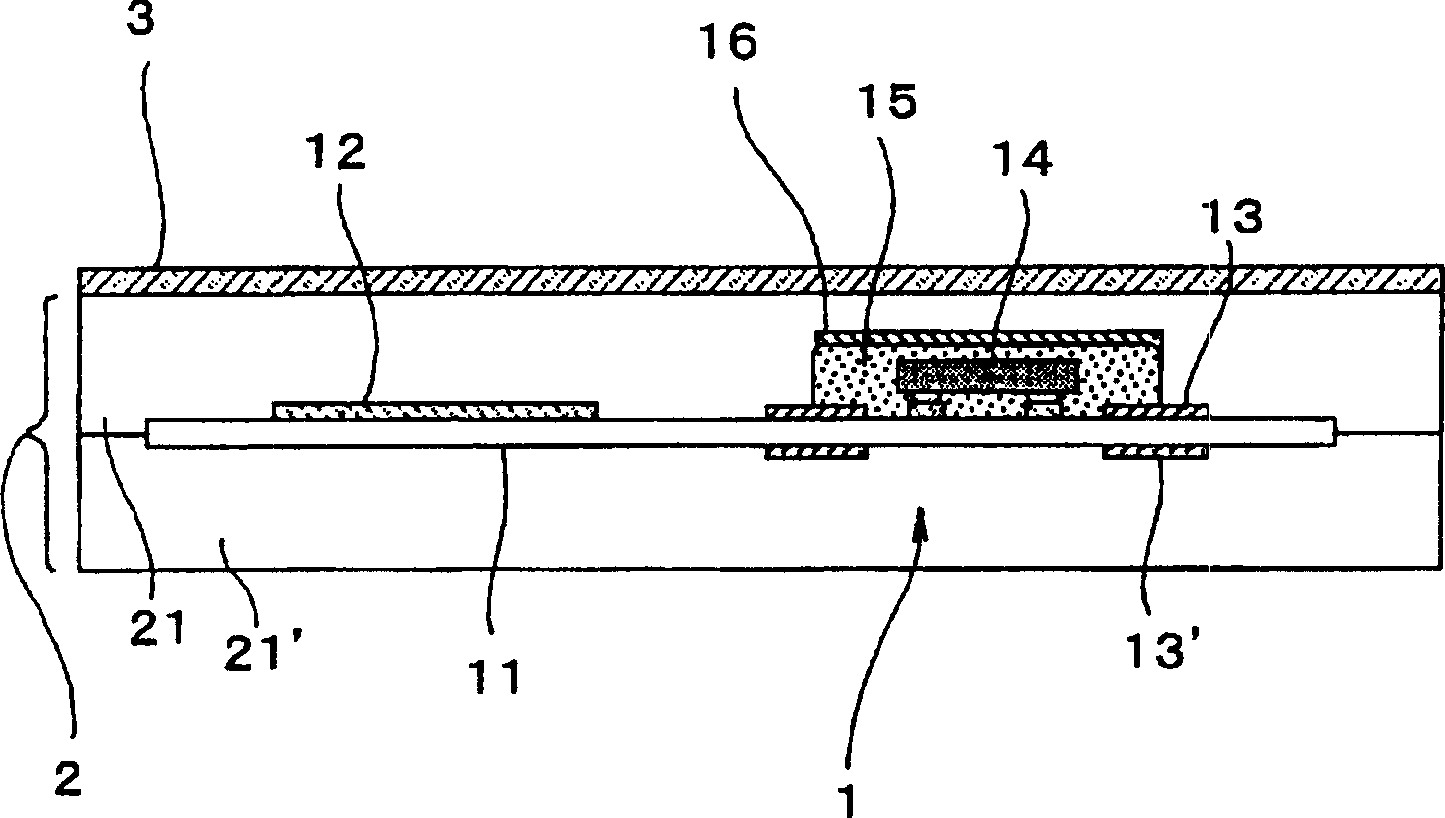

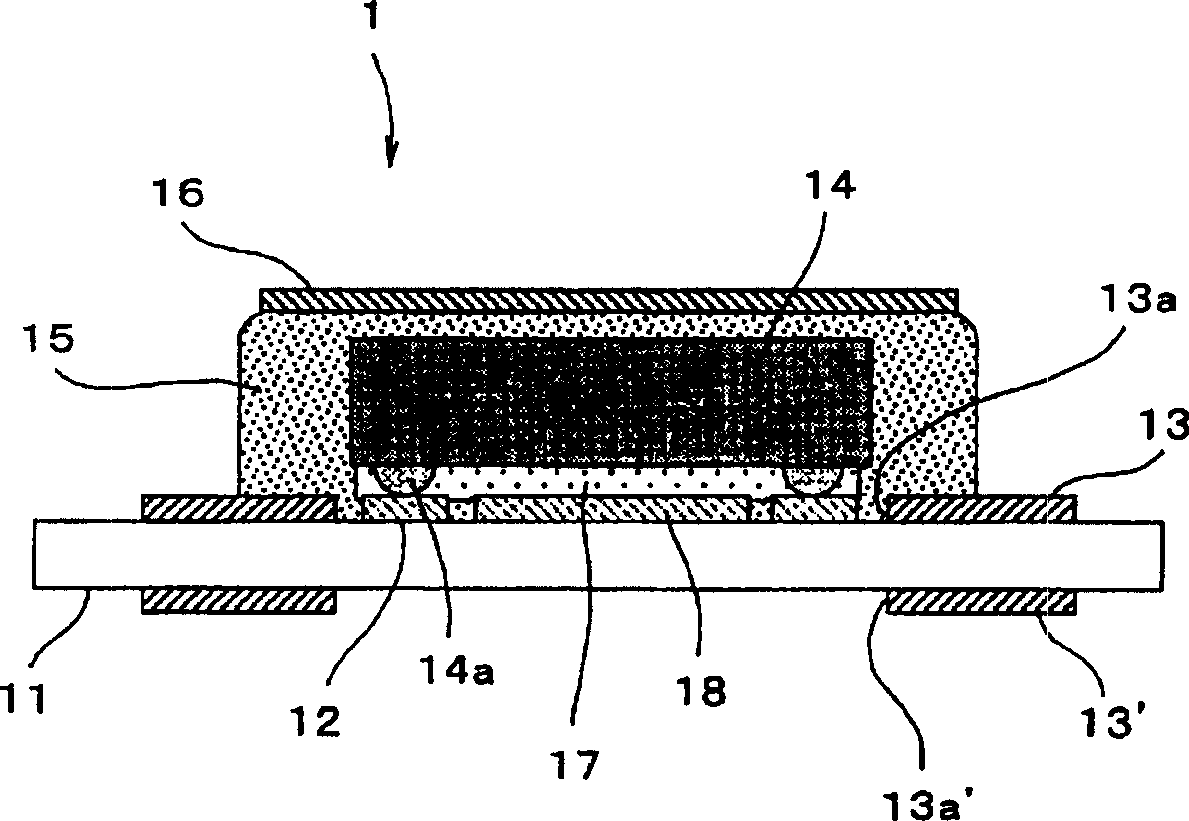

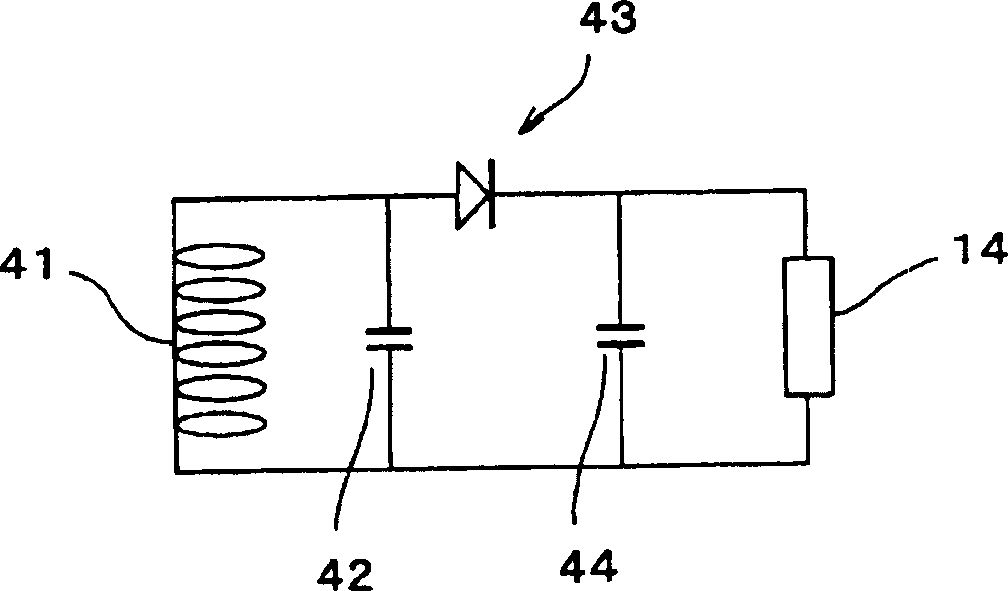

IC card

InactiveCN1529872AGuaranteed surface flatnessWill not deformOther printing matterSemiconductor/solid-state device detailsRecording layerElectrical and Electronics engineering

An IC card having high reliability, which is not only in that printing can be surely conducted with respect to the reversible display layer provided on the surface of the card substrate, but also in that the IC chip is surely protected by the reinforcing sheet. An IC card which has: an IC module (1) including an IC chip (14) mounted on an insulating substrate (11), and a reinforcing sheet (16) provided over the IC chip (14) through a sealing resin (15) for sealing the IC chip (14); a card substrate (2) comprised of a resin for sealing the IC module (1); and a reversible recording layer (3) provided on at least one surface of the card substrate (2), wherein reinforcing film patterns (13), (13') having openings (13a), (13a') which expose the IC chip (14) mounted portion are provided on at least one of the IC chip (14) mounted surface and the non-mounted surface of the insulating substrate (11).

Owner:SONY CORP

Rapid overhauling method for water conveyance canal without water supply shutdown

ActiveCN109811725AGuaranteed surface flatnessImprove construction efficiencyArtificial water canalsFoundation engineeringSocial benefitsEngineering

The invention discloses a rapid overhauling method for a water conveyance canal without water supply shutdown, and solves the technical problems that surface evenness after underwater charging of existing mold bag concrete cannot meet the requirement, construction cost is high and construction efficiency is low. The rapid overhauling method comprises following steps: original structure dismounting, regional division, manufacturing of a mold bag skeleton, mounting of a mold bag, manufacturing of a lifting frame, lifting launching, charging of concrete and dismounting operation. The rapid overhauling method for the water conveyance canal without water supply shutdown not only can guarantee the surface evenness after underwater charging of the mold bag concrete, but also is high in construction efficiency and low in cost, has quite high ecological benefit and social benefit and has quite good popularization and application prospects.

Owner:中国南水北调集团中线有限公司河南分公司 +1

Hot bending forming device for vehicle-mounted glass processing and processing method thereof

ActiveCN114436513AReduced risk of burstingGuaranteed surface flatnessGlass reforming apparatusGlass productionIn vehicleEngineering

The invention discloses a hot bending forming device for vehicle-mounted glass processing and a processing method thereof, relates to the related field of glass processing, and aims to solve the problems that an existing small hot bending forming device is small in occupied area but difficult to continuously carry out processing production work, and a large continuous hot bending furnace generally aims at processing production of a large number of products and transversely occupies the plant area, so that the production efficiency is low. And the occupied space is huge. Side supporting frames are fixedly welded to the front end and the rear end of the upper end of the supporting bottom plate, side fixing vertical plates are fixedly welded to the upper end of the supporting bottom plate along the inner sides of the side supporting frames, and a preheating mechanism, a heating mechanism, a first cooling mechanism and a second cooling mechanism are fixedly welded to the upper ends of the two side fixing vertical plates. The preheating mechanism, the heating mechanism, the first cooling mechanism and the second cooling mechanism are sequentially arranged from left to right, and the side supporting frame comprises a first mounting transverse plate, a first connecting vertical plate, a second mounting transverse plate and a second connecting vertical plate.

Owner:广东睿华光电科技有限公司

Online continuous hot-pressed dry vacuum insulation panel core preparation method and product

ActiveCN107630293ALow thermal conductivityGuaranteed thermal conductivityThermal insulationPipe protection by thermal insulationGlass fiberProduction line

The invention relates to an online continuous hot-pressed dry vacuum insulation panel core preparation method and a product, and belongs to the technical field of glass fibers. The preparation methodincludes a cotton spreading process and a hot-pressing process, can also include a fiber forming process, a cotton collecting process and a rolling process before the cotton spreading process and canfurther include a slitting process after the hot-pressing process. A superfine glass fiber production process and a hot-pressing process in the prior art are separated and can be independently performed, the speed matching problem of hot-pressing and superfine glass fiber production lines in the prior art is solved, the production process of superfine glass fibers with different performances can be matched with the hot-pressing process, glass fiber dry rolled cotton can directly serve as a raw material for preparing a vacuum insulation panel core, and the vacuum insulation panel core is more flexibly prepared. Besides, the hot-pressing mode in the method is continuous hot-pressing, stay holding time is omitted, continuous production is realized, production efficiency is effectively improved, and production cost is reduced.

Owner:宣汉正原微玻纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com