Casting method based on novel oil pump body shell mould

An oil pump body and a new type of technology, applied in the field of hydraulic parts, can solve problems such as insufficient strength, difficult grinding of parting surface burrs, and broken sand cores, so as to reduce shrinkage and shrinkage, reduce processing costs, and ensure casting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] This embodiment is based on a casting method of a new type of oil pump casing, and the casting method includes the following steps:

[0032] (1) First, use metal to make the metal template required for the oil inlet pump body;

[0033] (2) Next, heat the metal template to 180-280°C, and then cover the molded sand hardened by heat on the metal template to solidify the molding sand;

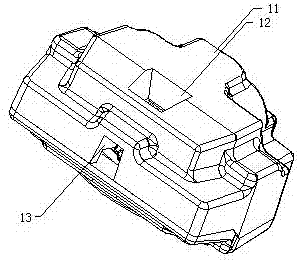

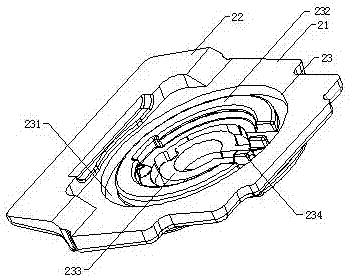

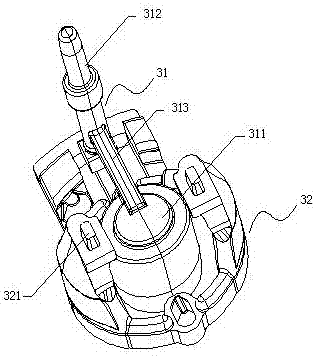

[0034] (3) Then, heat and solidify the molding sand to form a shell, such as figure 1 As can be seen from the schematic diagram shown, the shell shape is composed of an upper shell 1 and a lower shell 2. After the upper shell 1 and the lower shell 2 are molded together, the cavity of the oil pump body is formed. The upper shell 1 includes a shell body 11. There is an exhaust port 12 in the center of one side of the body body 11, and the cavity of the oil pump body is symmetrically distributed on both sides of the exhaust port. The notch 13 cooperates with the lower casing 2 to form a casti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com