Battery cell circulating supply outer plate lamination production line and production process thereof

A plate lamination and production line technology, which is applied in the field of cell cycle supply outer plate lamination production line and its production process, can solve the problems of wrinkling on the surface of the diaphragm, difficulty in effectively ensuring the position accuracy of the lamination, and low lamination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

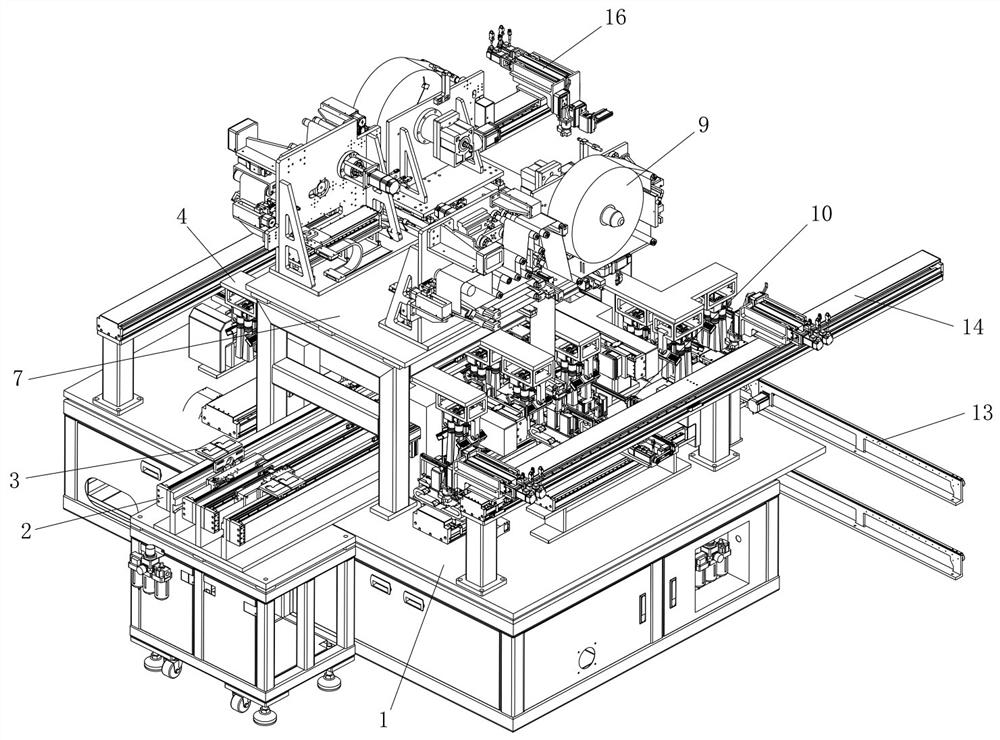

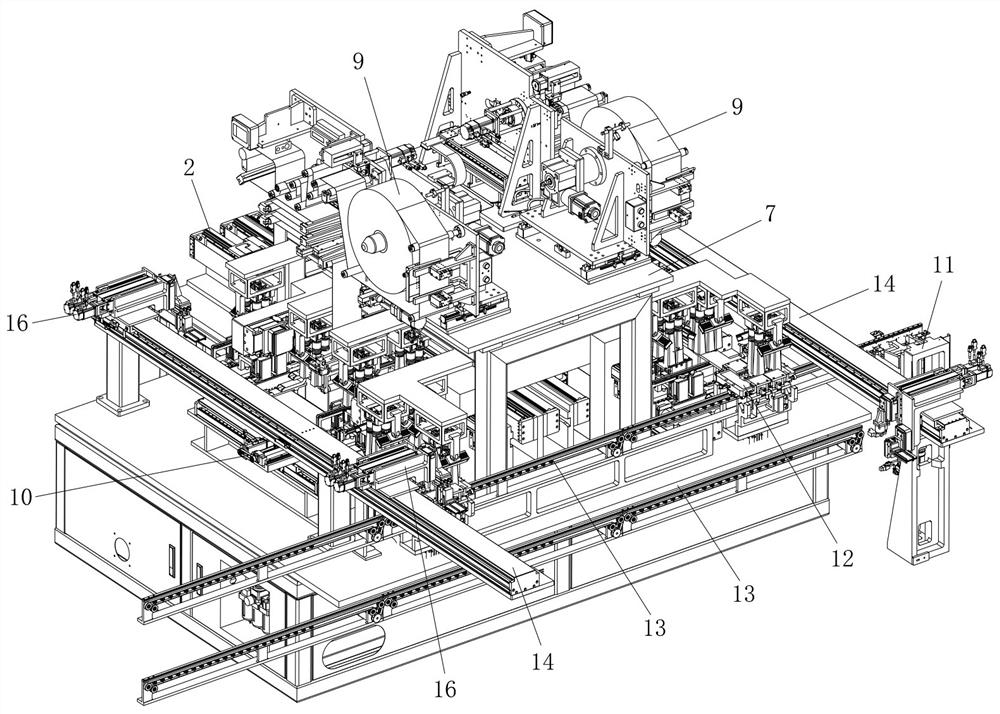

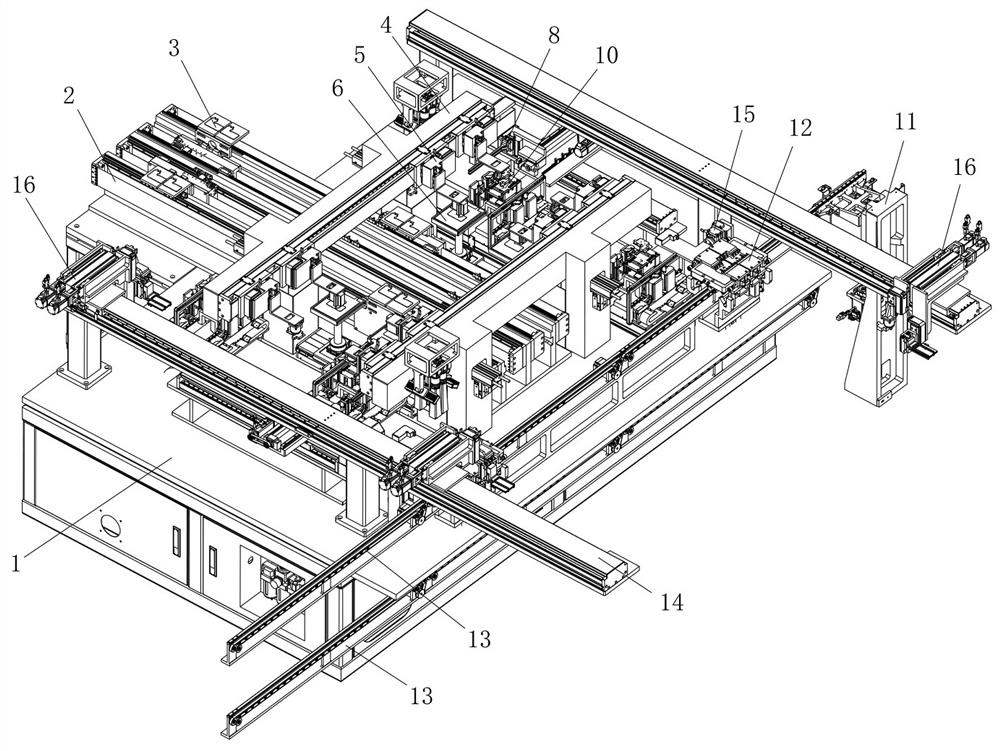

[0066] The present invention will be further described below in conjunction with accompanying drawing:

[0067] Such as Figure 1 to Figure 25 As shown, the technical solution adopted by the present invention is as follows: a production line for battery cell circulation for outer plate lamination, including a horizontally arranged machine 1, and also includes a pole piece supply mechanism 2, a film supply mechanism 9, an outer plate supply mechanism, a stacking Sheet mechanism and blanking mechanism 16, wherein,

[0068] The above-mentioned pole piece supply mechanism is arranged horizontally on the machine platform and extends outward perpendicular to one side of the machine platform for automatic transmission of pole pieces;

[0069] The above-mentioned outer plate supply mechanism is set on the other side of the machine, and the outer plate supply mechanism circulates the outer plate along the closed-loop rectangular transportation path;

[0070] The above-mentioned stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com