Battery pole piece manufacturing production line and pole piece manufacturing process thereof

A battery pole piece and production line technology, which is applied to battery electrodes, manufacturing tools, and other manufacturing equipment/tools, etc., can solve the problems of stopping the whole line, failing to supply materials normally, affecting the cutting accuracy of tabs and pole pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

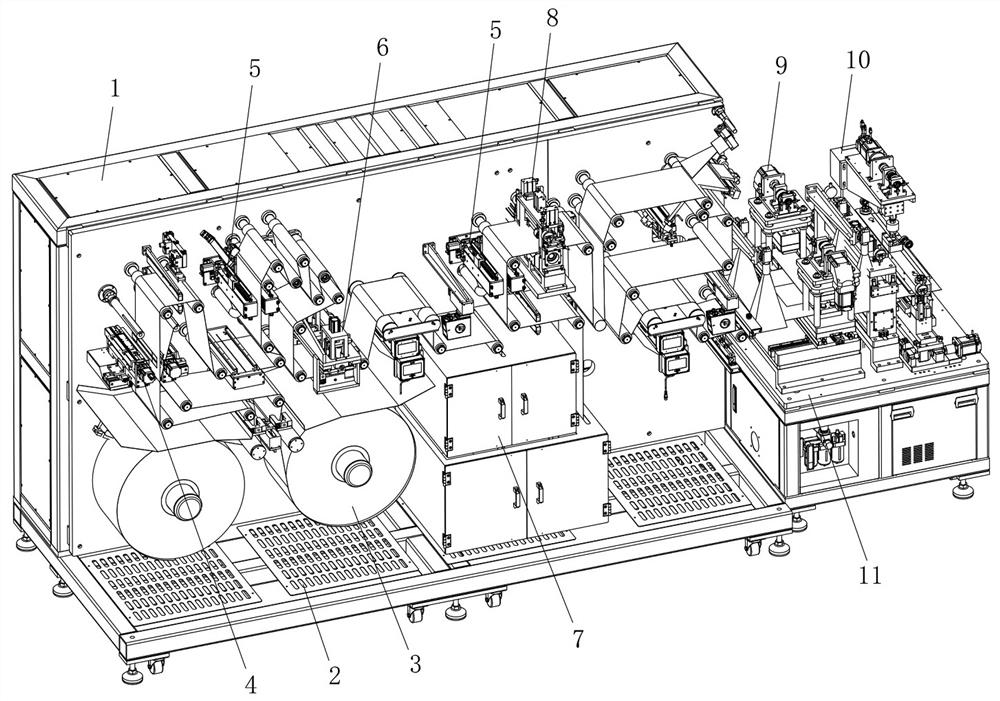

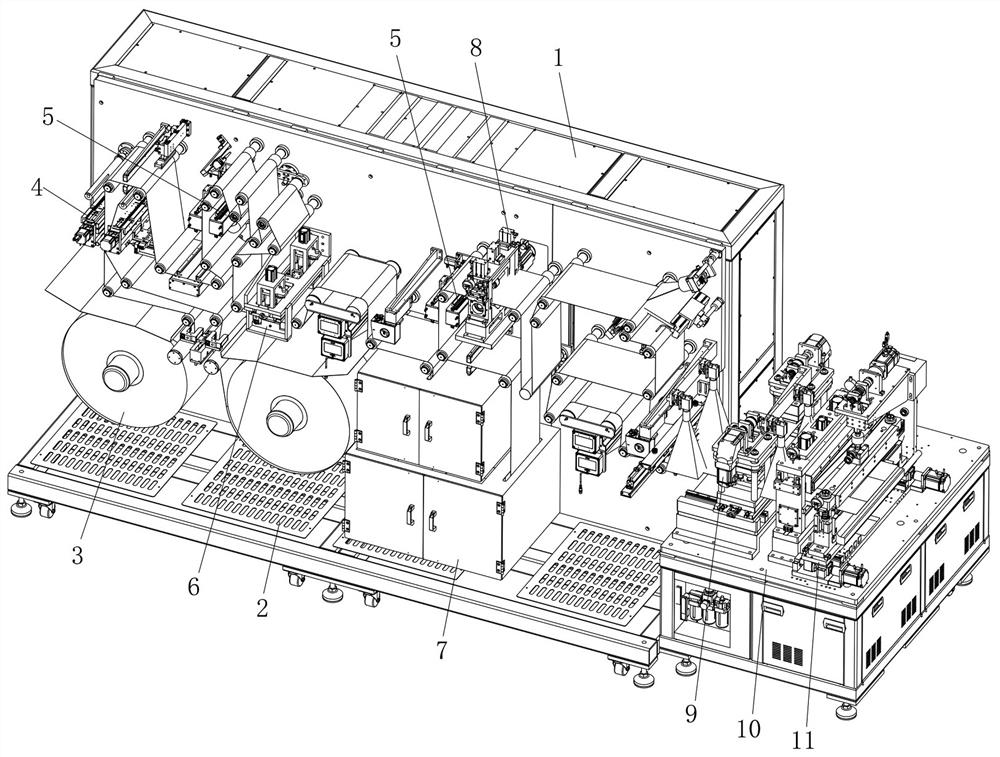

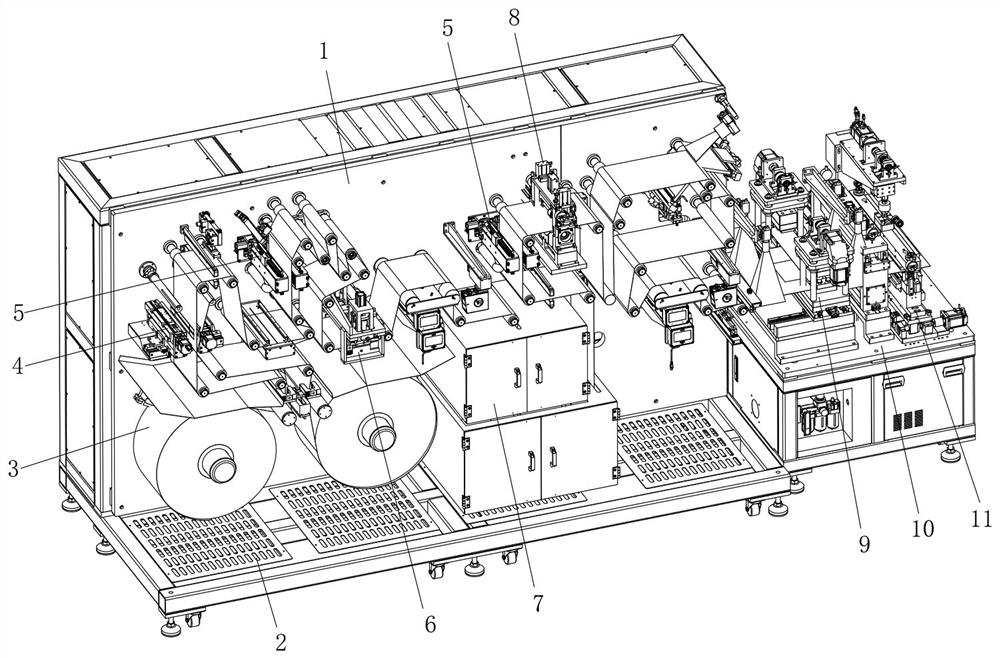

[0108] The present invention will be further described below in conjunction with accompanying drawing:

[0109] Such as Figure 1 to Figure 41 As shown, the technical solution adopted by the present invention is as follows: a production line for making battery pole pieces, which includes a machine platform arranged horizontally and a frame vertically arranged on one side of the machine platform, and also includes feeding materials arranged at intervals along the linear direction. Mechanism, driving mechanism, lug cutting mechanism, traction mechanism and pole piece cutting mechanism, wherein,

[0110] The above-mentioned feeding mechanism is arranged on the side wall of the frame, and the feeding mechanism includes at least two material rolls, on which the pole piece belt is wound, and the lead-out direction of the pole piece belt is provided with a refueling assembly, which connects the refueling assembly Connect and cut off the pole strips exported from different rolls;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com