Patents

Literature

63results about How to "Realize automatic refueling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

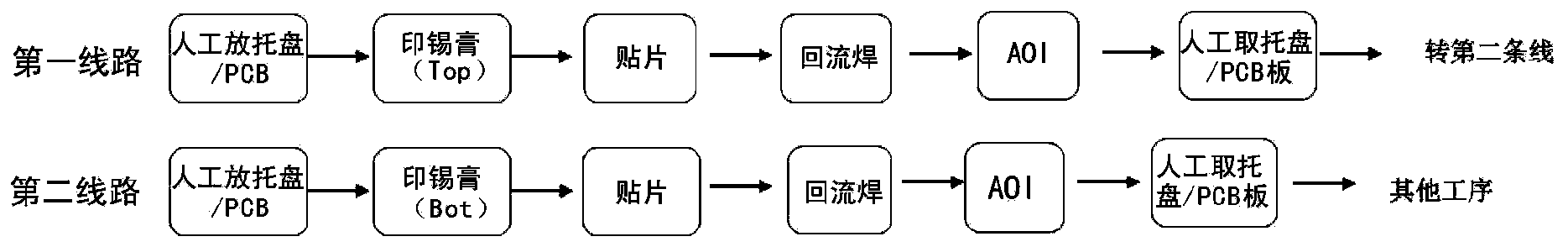

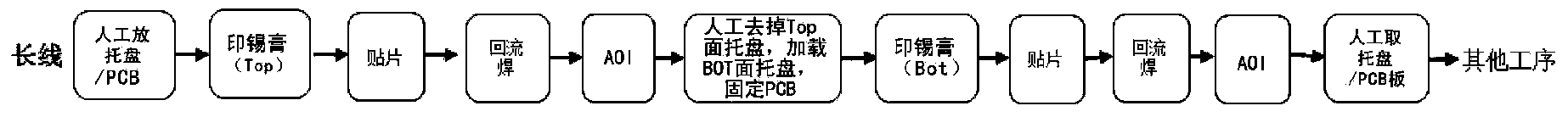

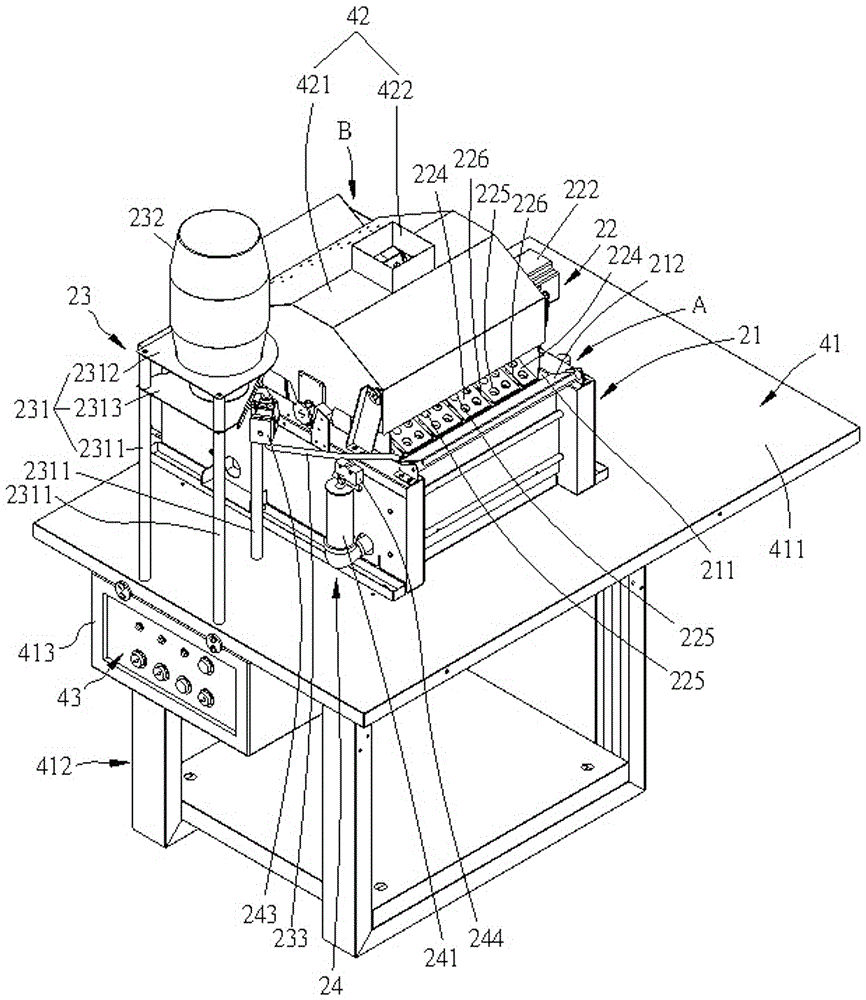

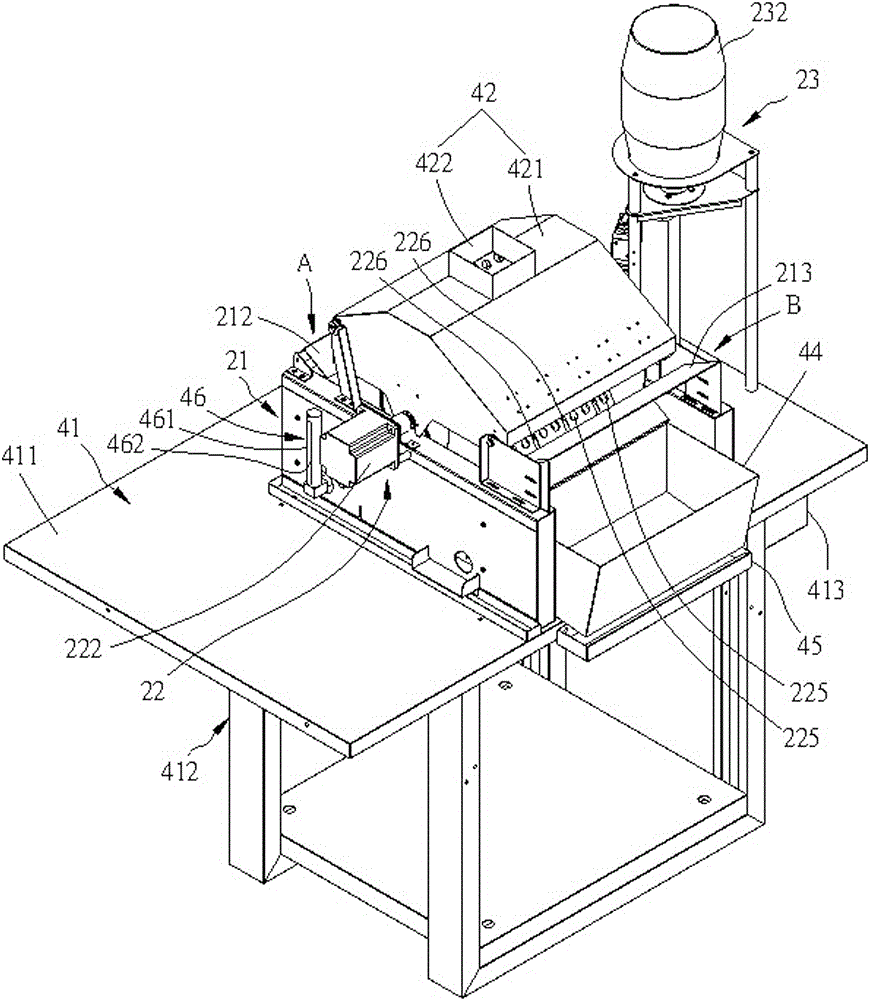

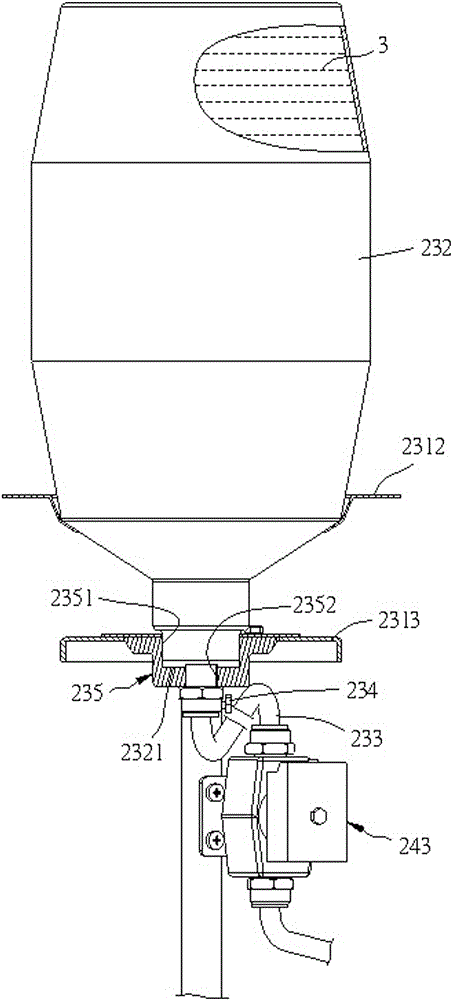

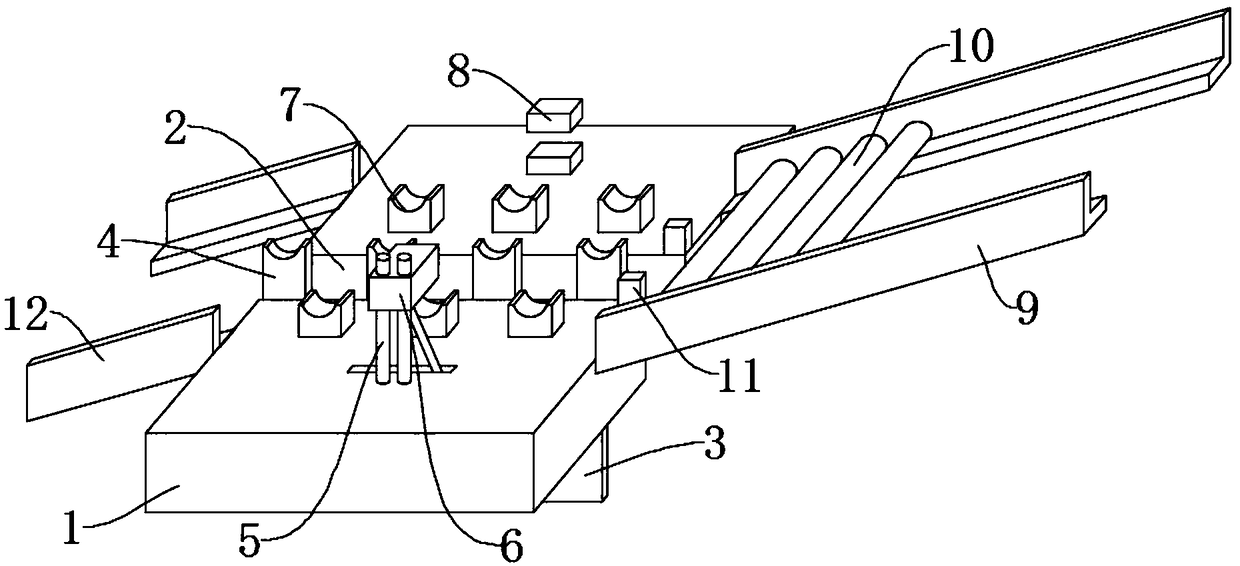

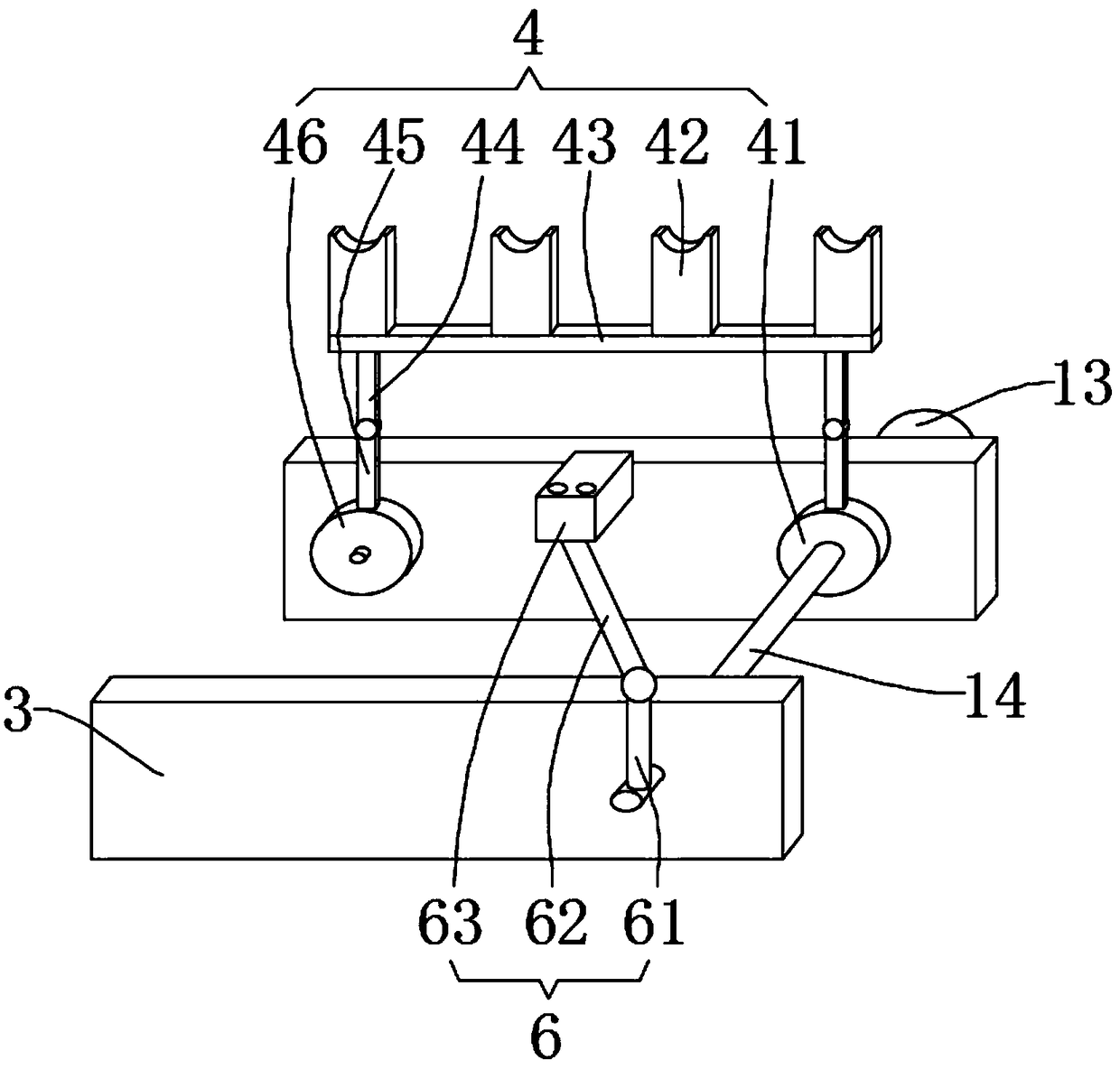

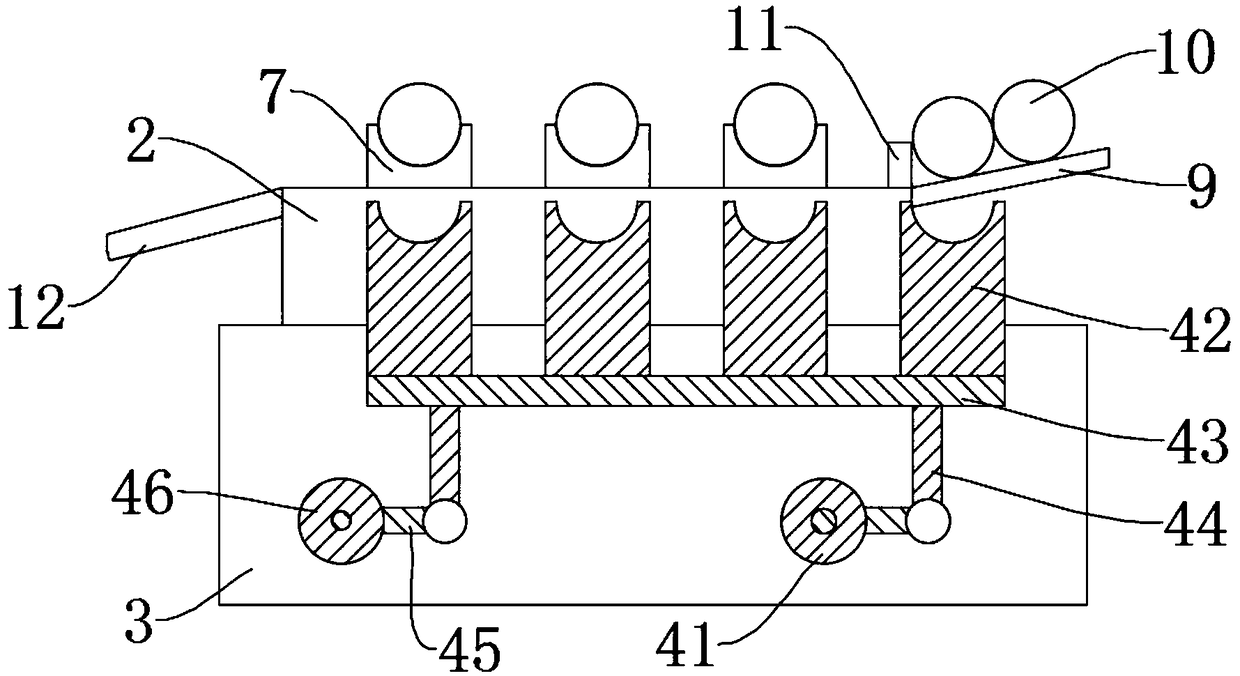

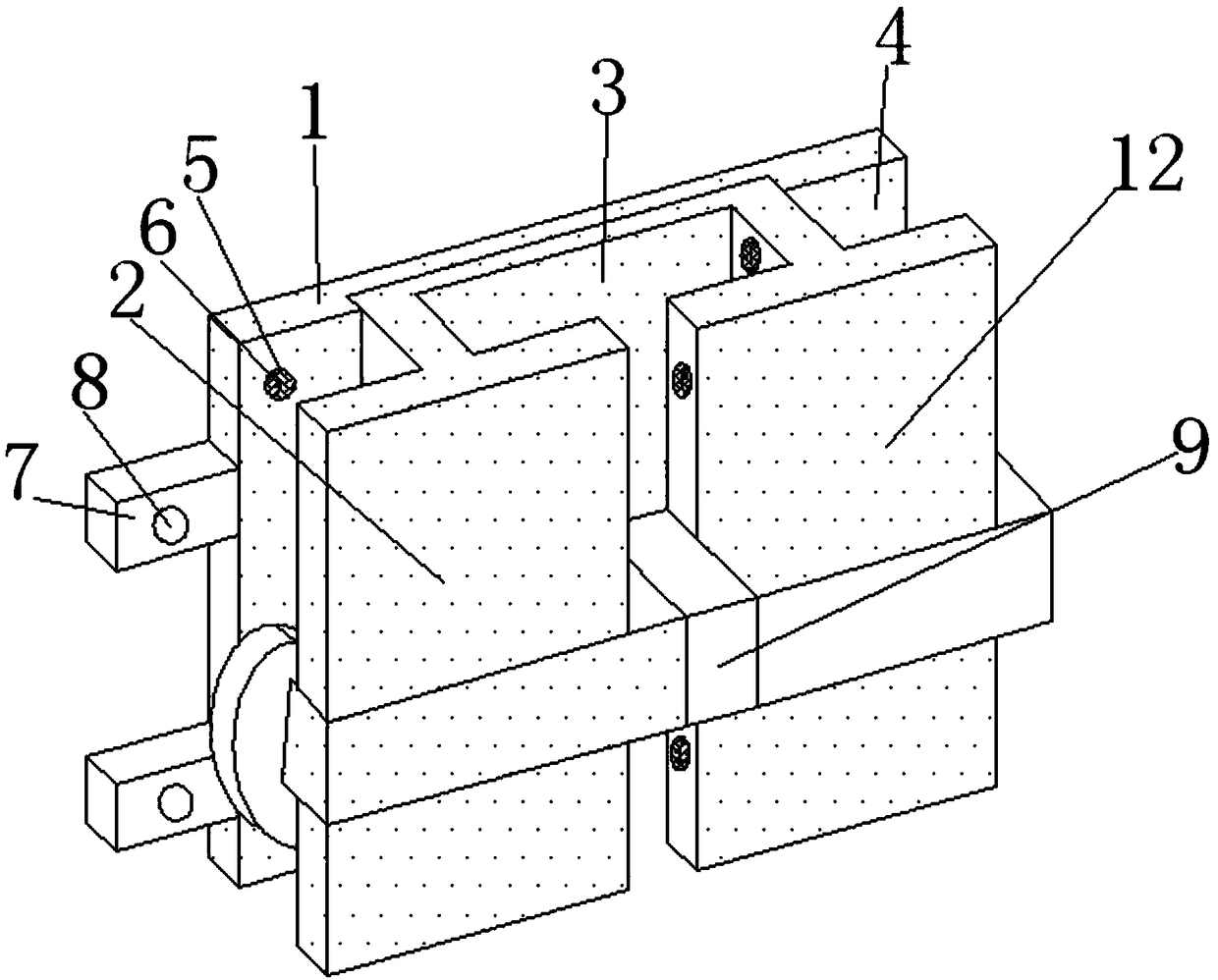

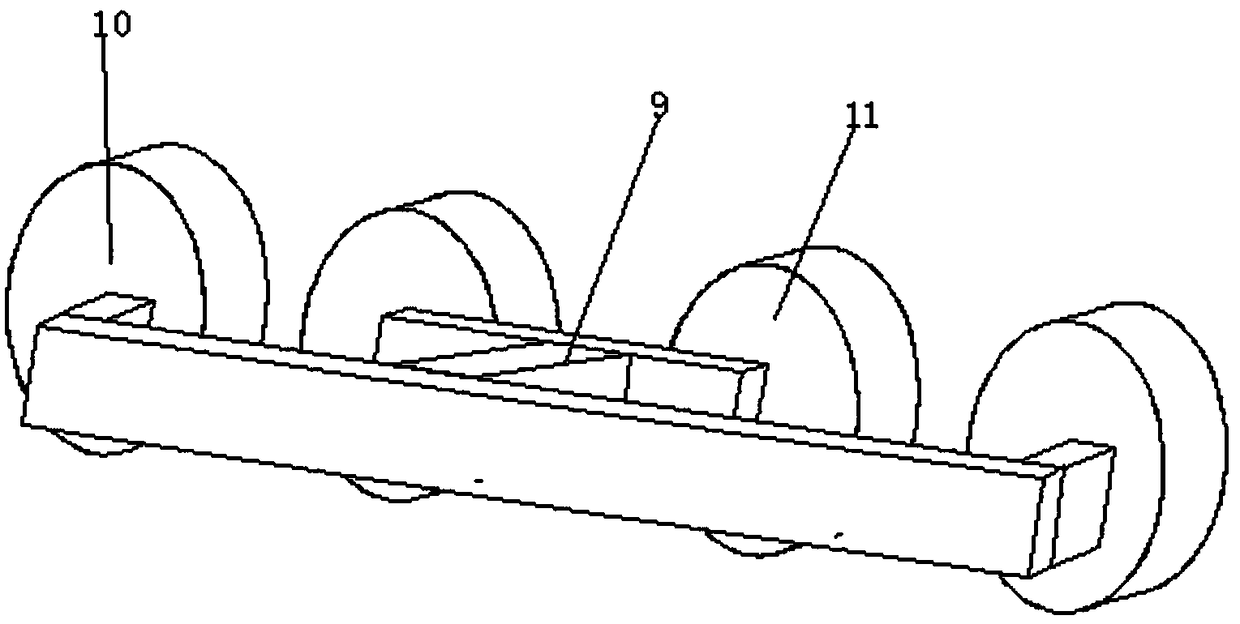

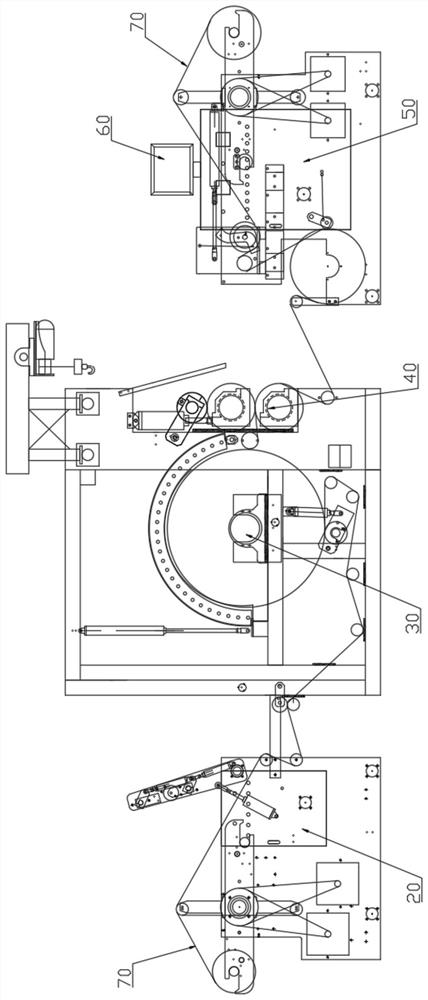

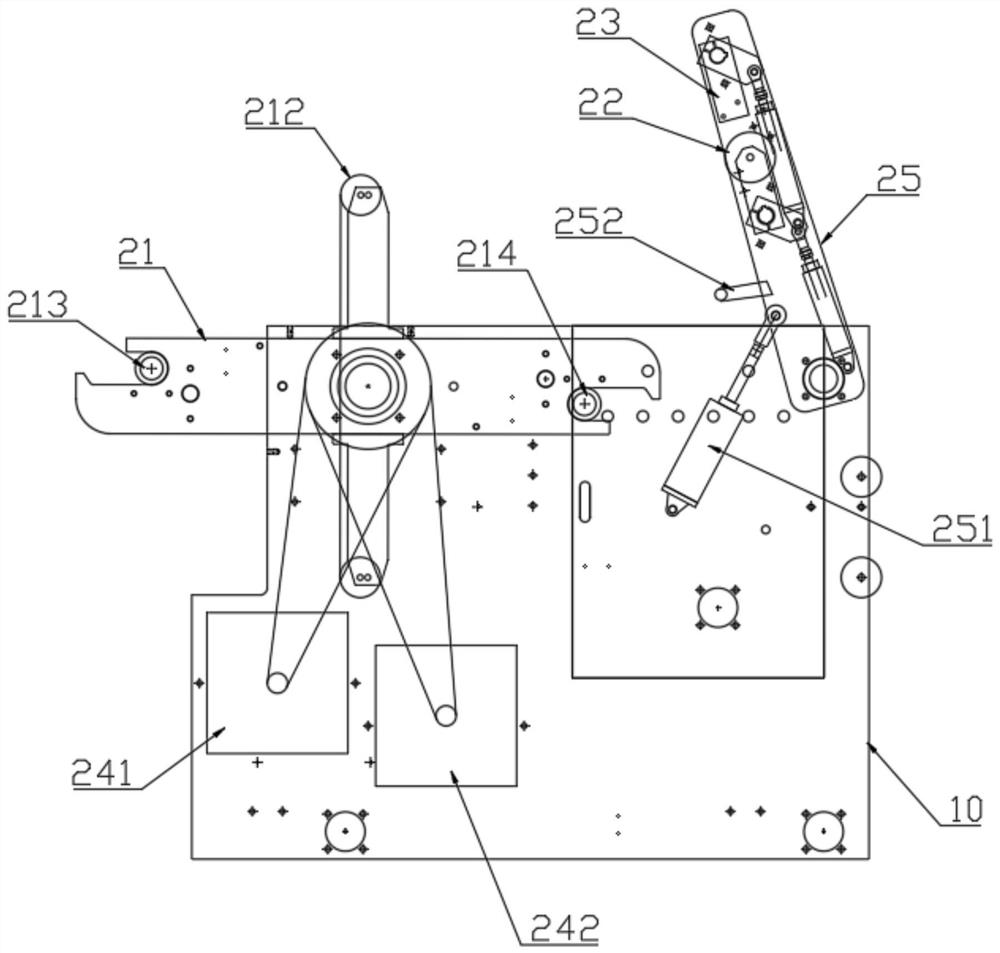

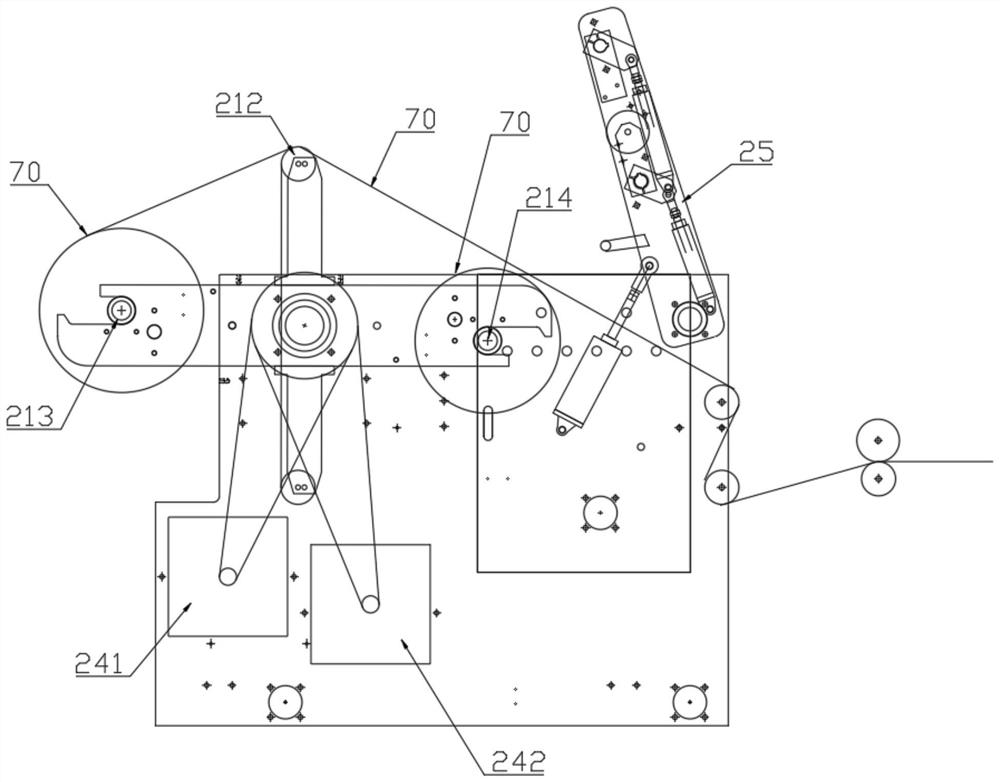

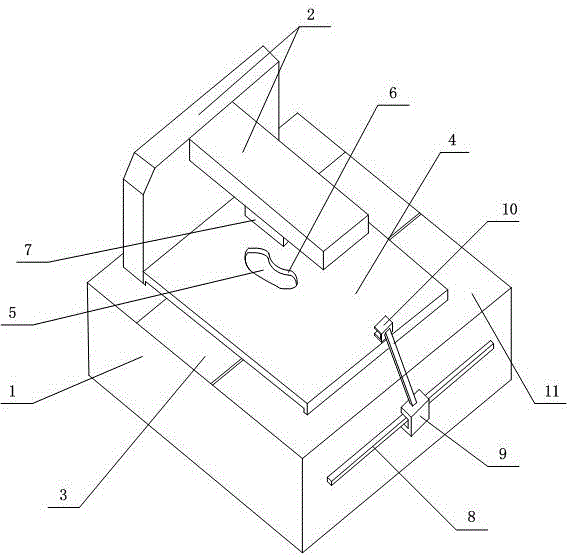

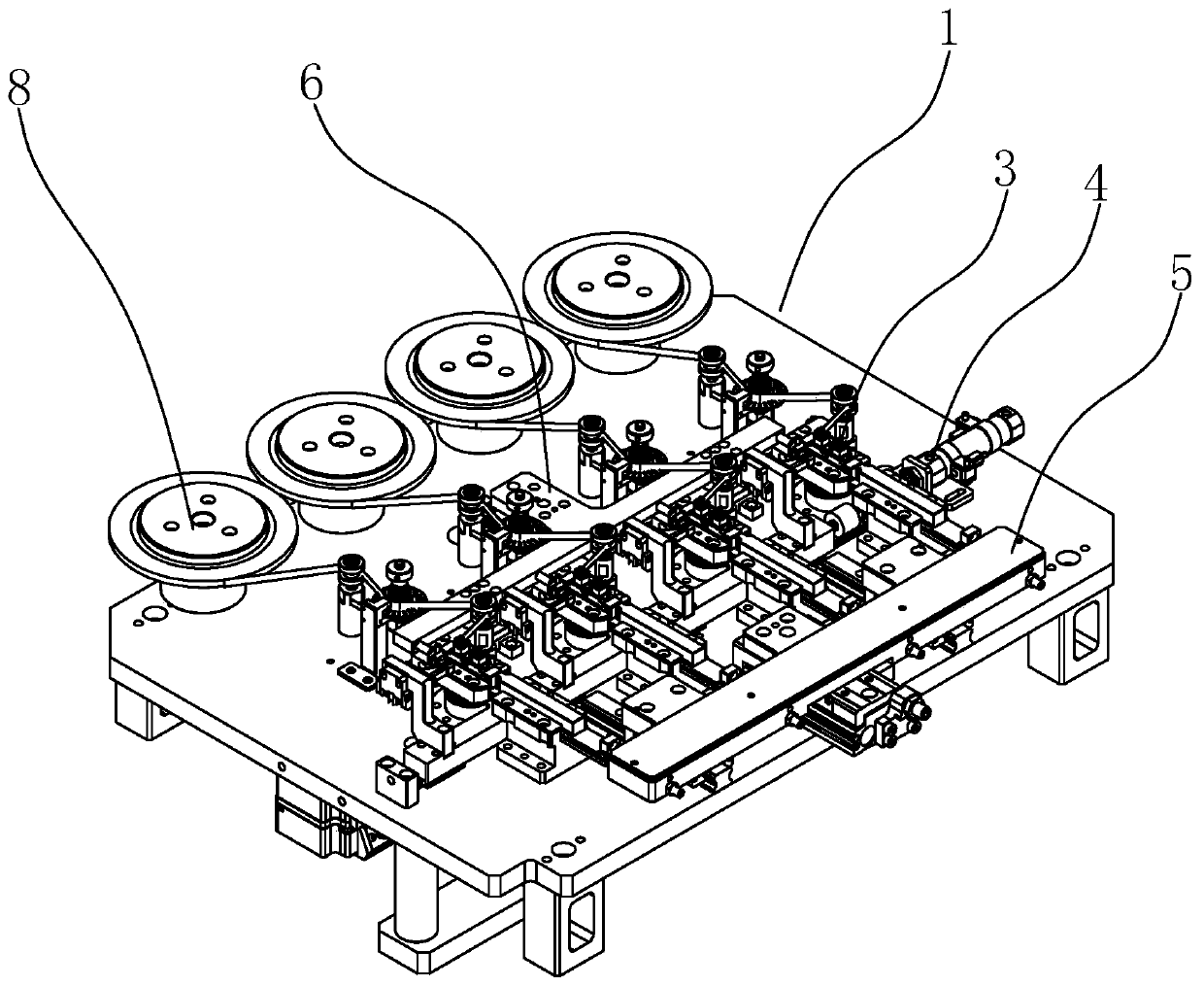

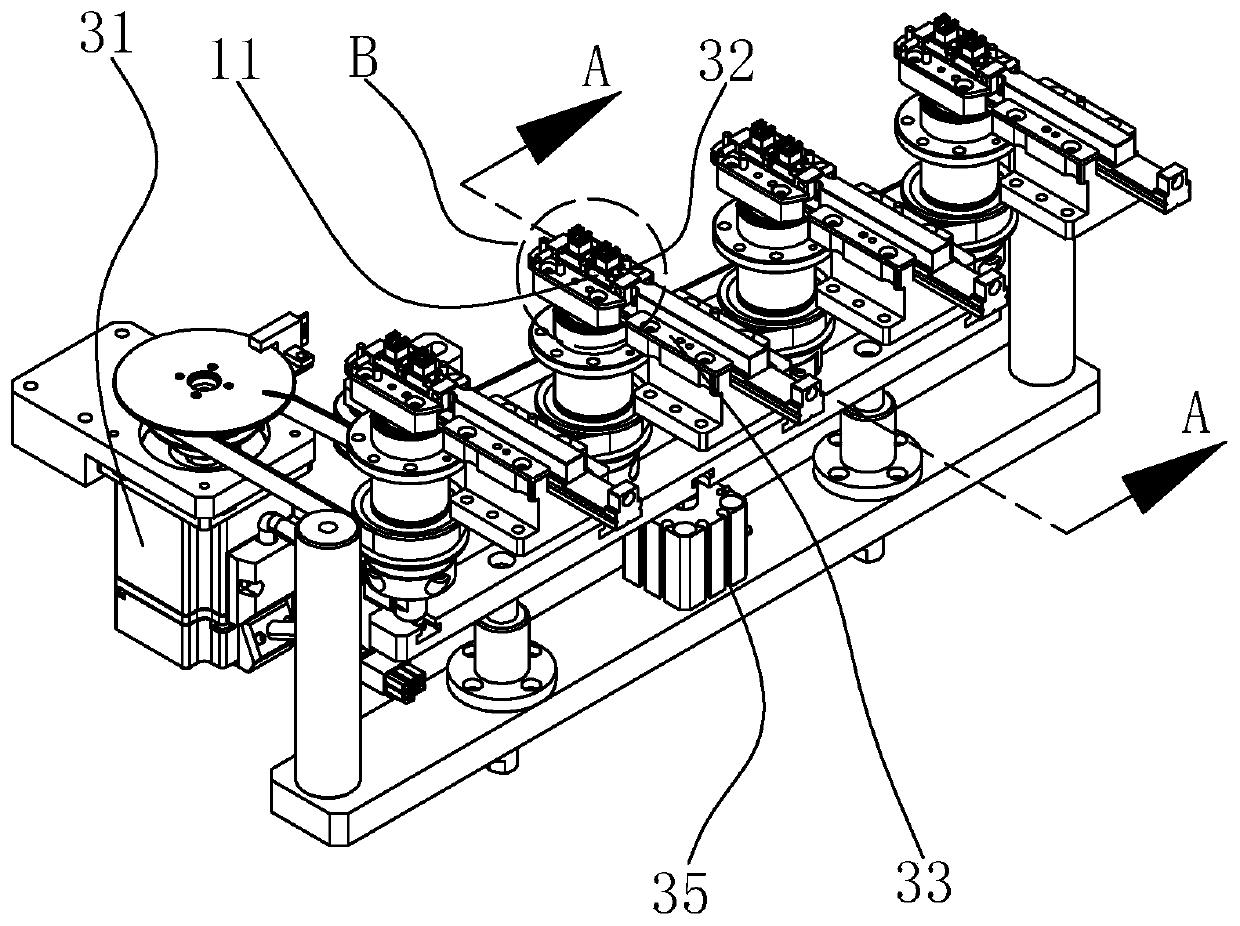

Automatic PCB detaching, overturning and pasting integrated machine

ActiveCN103763866AAchieve disassemblyImprove processing efficiencyPrinted circuit assemblingEngineeringMechanical engineering

The invention discloses an automatic PCB detaching, overturning and pasting integrated machine which comprises an equipment body, a machine hood arranged on the equipment body in a sleeved mode and a rack for supporting the equipment body. The equipment body comprises a conveying mechanism, a large gantry mechanism, small gantry mechanisms and automatic feeding and discharging mechanisms. At least two working stations are arranged on the large gantry mechanism and the small gantry mechanisms are arranged on one side of the large gantry mechanism in parallel. The small gantry mechanisms and the large gantry mechanism are matched for automatically detaching, overturning and pasting a PCB again. The automatic feeding and discharging mechanisms are arranged on one side below the conveying mechanism in parallel and used for conveying cover plates or carriers to all the working stations. According to the automatic PCB detaching, overturning and pasting integrated machine, unloading of an old carrier and cover plates, overturning of the PCB and repeated pasting of the PCB and a new carrier are performed automatically and the machining efficiency of the PCB is improved. Meanwhile, labor force and labor cost are saved, cost is reduced and in addition, automatic feeding and discharging are achieved, especially materials can be automatically replaced in a non-stopping state.

Owner:SUZHOU INTELLIGENT AUTOMATION EQUIP CO LTD

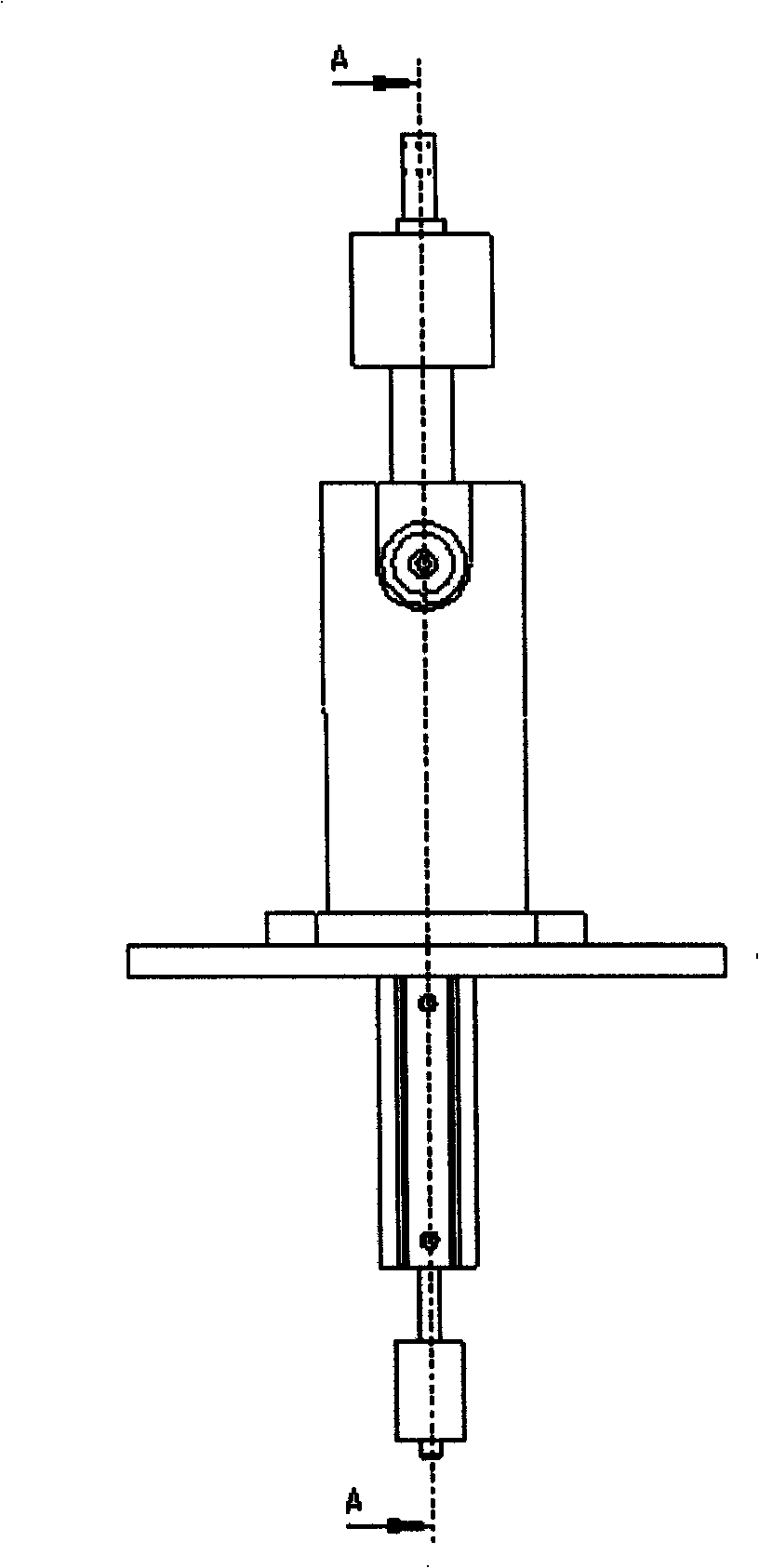

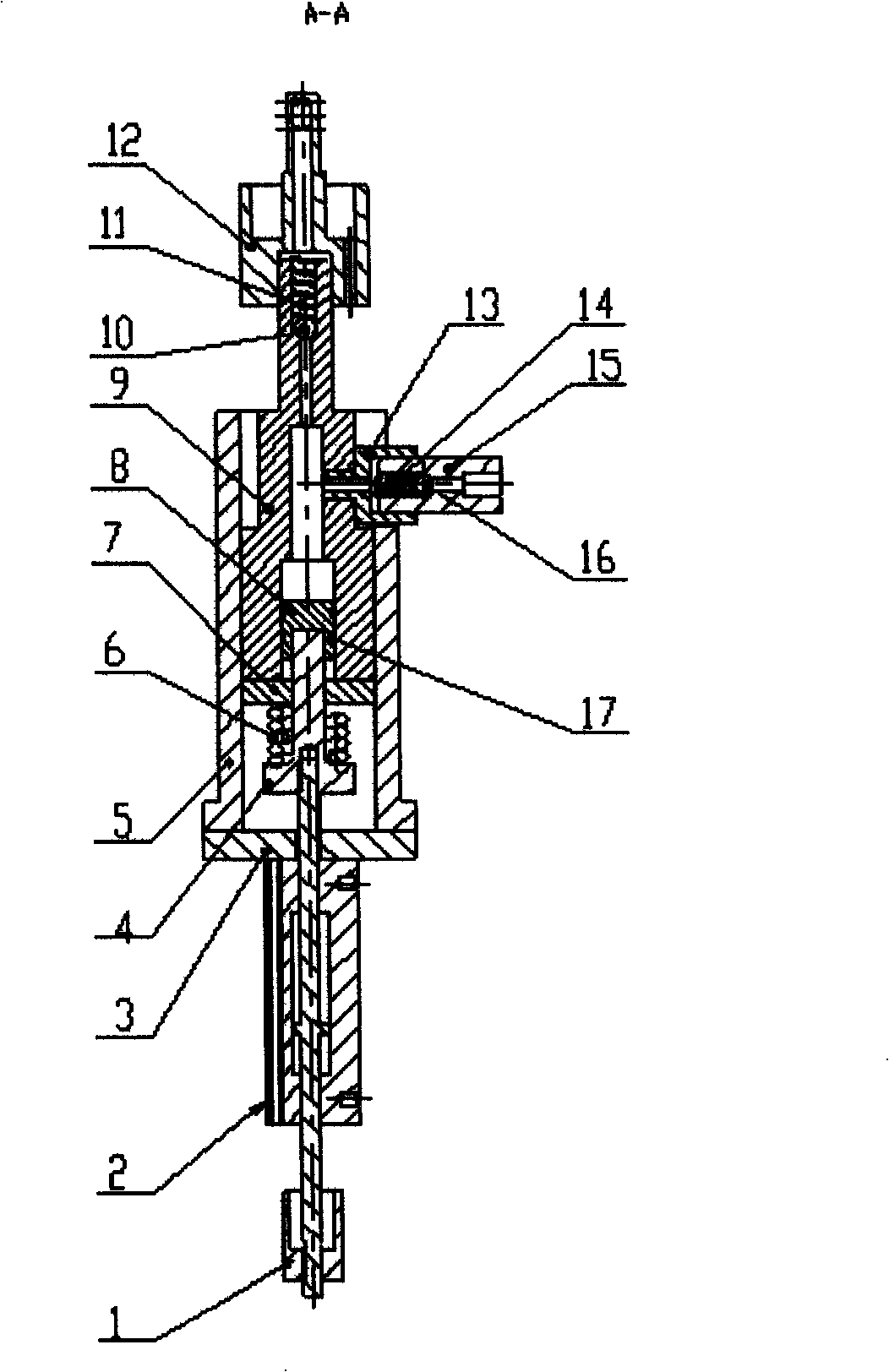

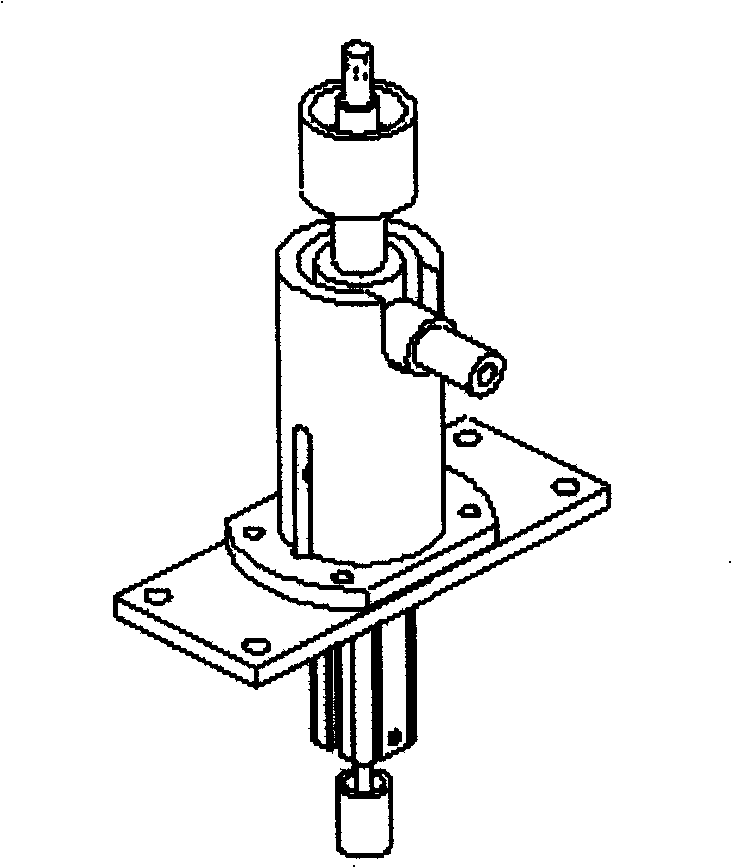

Automatic fuelling device

InactiveCN101266016ARefueling is suitable forRealize automatic refuelingLubricating pumpsMechanical componentsCheck valve

The invention relates to an automatically-oiling device, which comprises an oil pressure cylinder body, an oil pressure piston matched with the oil pressure cylinder body, and a piston rod connected with the oil pressure piston. The oil outlet of the oil pressure cylinder body is connected with an oil outlet spout, the oil inlet is connected with an inlet connector through an oil inlet check valve, and the outer end of the oil pressure piston is connected with a piston rod matched with a movement cylinder. The automatically-oiling device can realize self-oiling and control fuel charge. The automatically-oiling device has the advantages of reasonable, compact and reasonable structure, low cost, and convenient use. Furthermore, the automatically-oiling device is suitable for oiling various mechanical components.

Owner:SHANGHAI UNIV +1

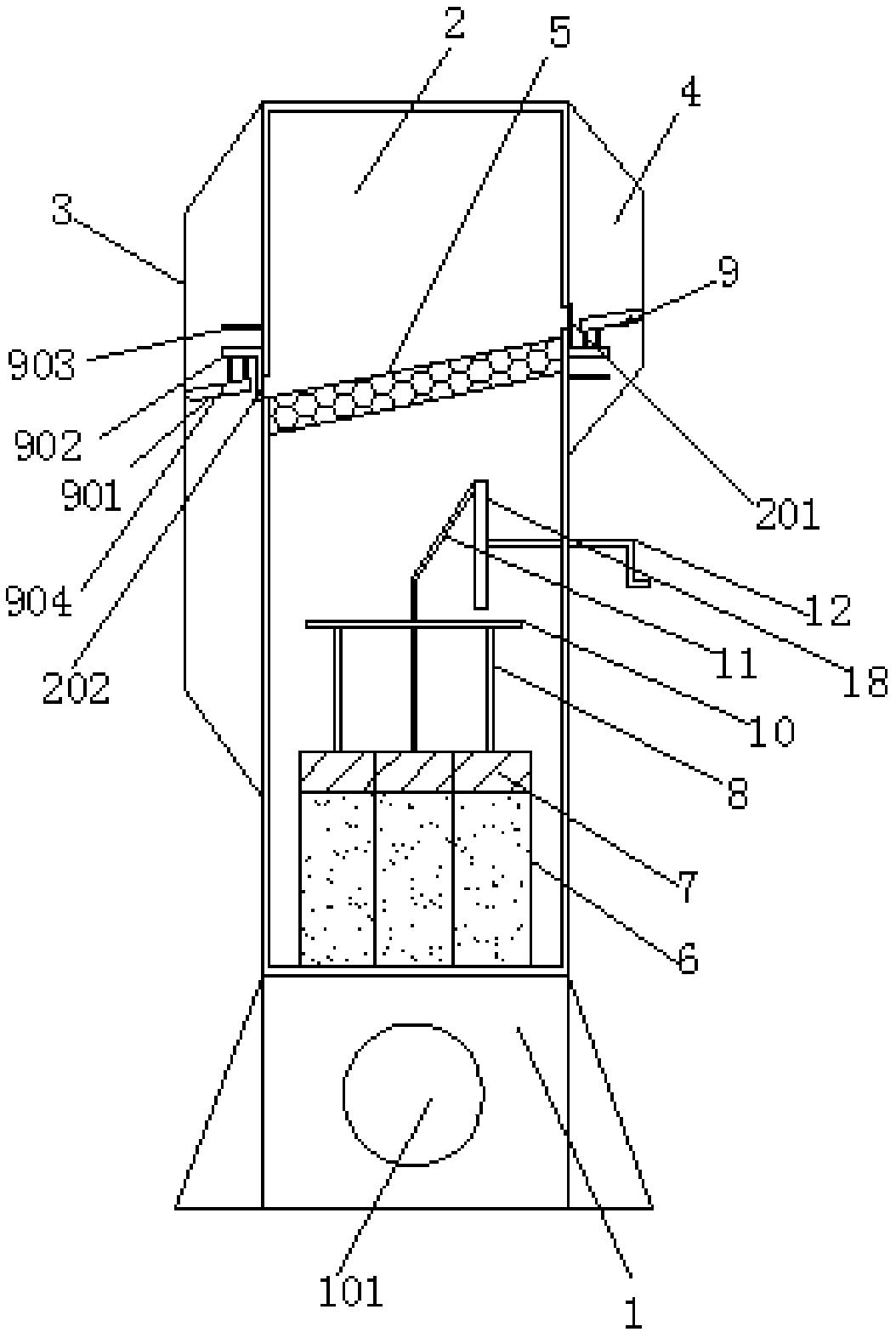

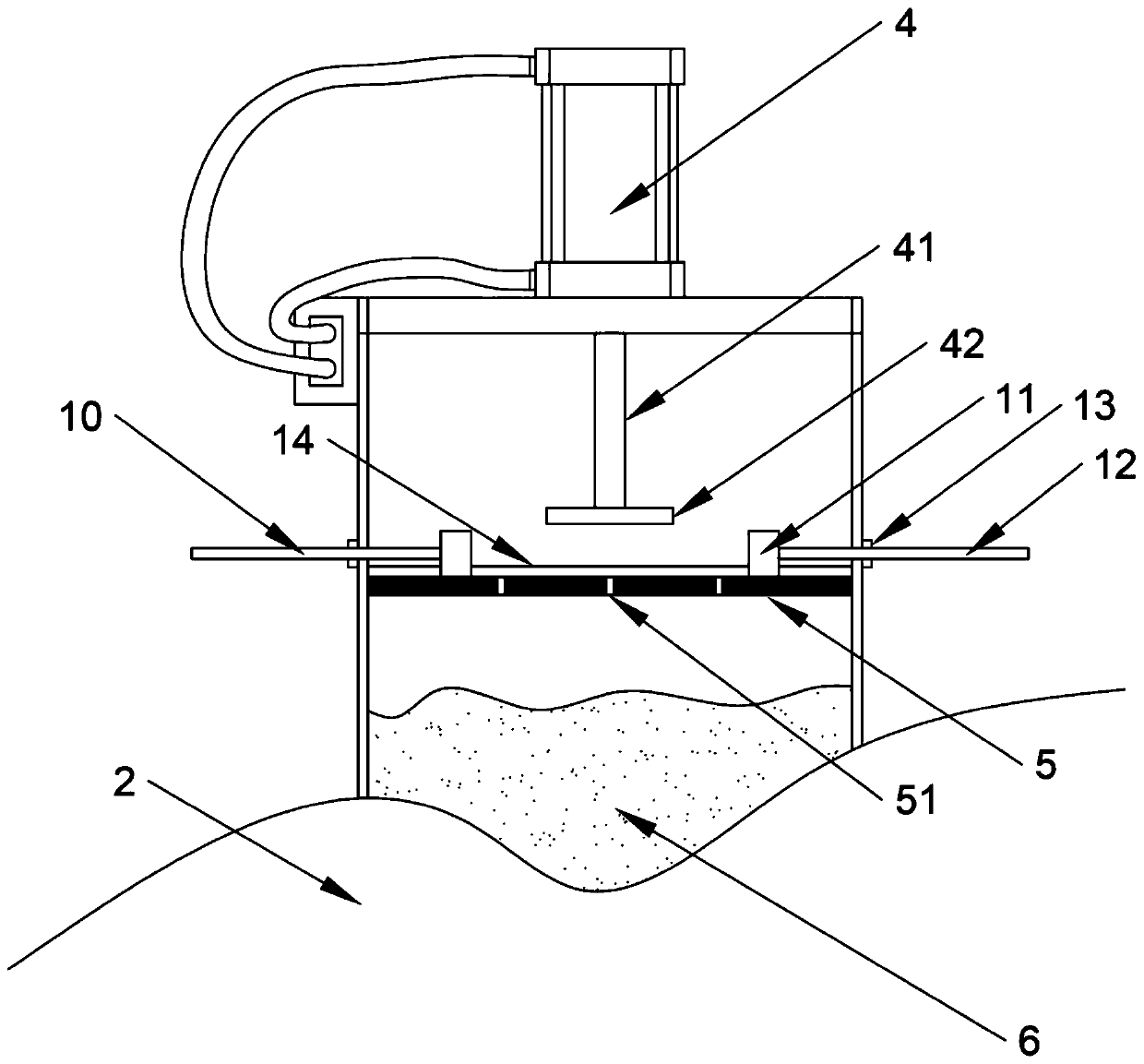

Oiling device of elasticizer

PendingCN109183215AQuality improvementImprove cleanlinessTextiles and paperYarnPetroleum engineering

The invention provides an oiling device of an elasticizer. The device includes an oil groove, an oil inlet roller assembly, an oiling device, an oil amount detecting device, a protofilament cylinder and a yarn guide device, wherein the oil groove is internally provided with the oil inlet roller assembly, the oil inlet roller assembly is provided with an oil inlet roller, a first tensioning shaft is disposed on the left side of the oil inlet roller, a second tensioning shaft is disposed on the right side of the oil inlet roller, the yarn guide device is disposed on the right side of the secondtensioning shaft, and the yarn on the protofilament cylinder penetrates through a first yarn conveying groove, the yarn guide groove and a second yarn conveying groove and is then guided out through the yarn guide device. The device is advantaged in that the yarn is directly wound at a lower side of the yarn guide groove of the oil inlet roller and is dipped in the oil groove, the yarn can be guaranteed to be uniformly wrapped by the oil, the excessive oil on the yarn can be scraped by an oil brush to the oil groove, the oil amount in the oil groove can be detected by the oil amount detectingdevice in real time, the oil amount detecting device is matched with the oiling device, automatic oiling is realized, and work efficiency and yarn oiling quality are improved.

Owner:浙江天祥新材料股份有限公司

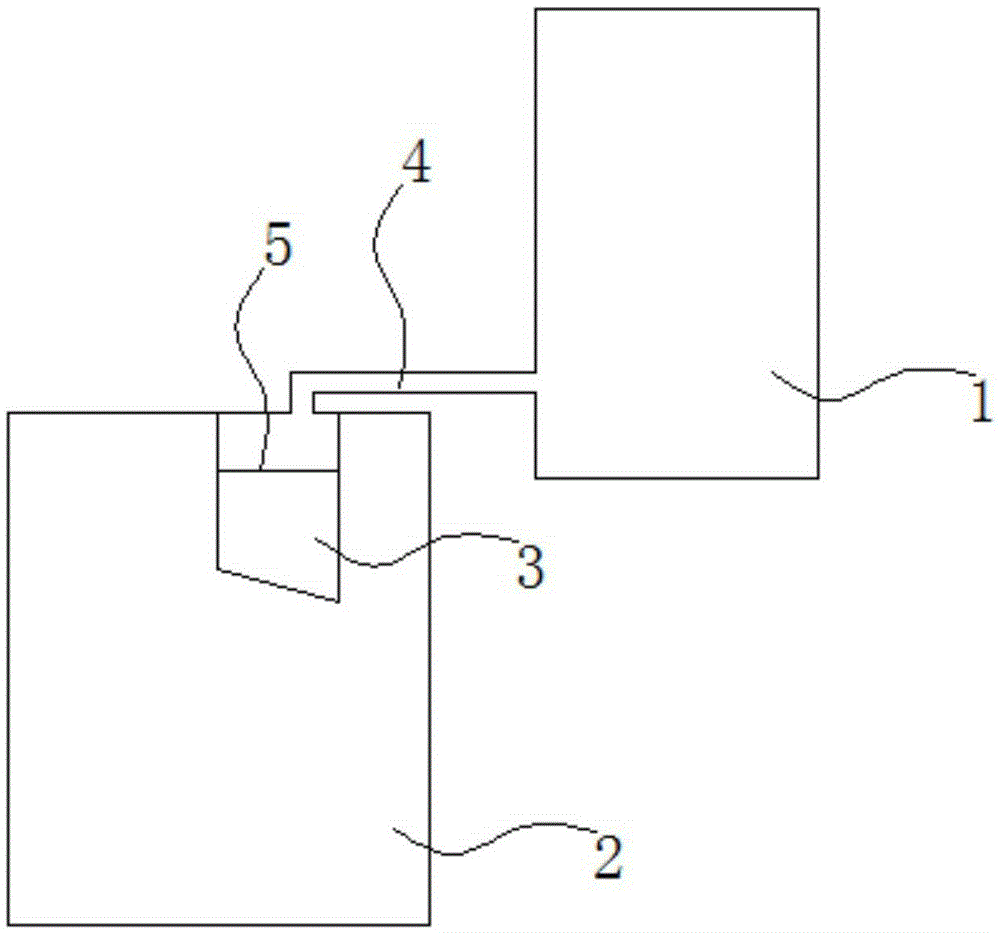

Board machining and feeding system

ActiveCN107915045ARealize automatic feedingIncrease productivityConveyorsDe-stacking articlesWood machiningWood plank

The invention discloses a board machining and feeding system, and belongs to the technical field of wood machining. The system comprises a material changing device, a material taking device and a material conveying device; the material changing device comprises a material changing conveying belt which is arranged in a front and back manner, multiple storage boxes with openings in the upper ends are placed on the upper end face of the material changing conveying belt, and are in cuboid shapes, the material taking device comprises multiple suction cups, , a suction cup rack, a connecting rod, afixed rack, multiple material taking photoelectric sensors and a material taking controller, the suction cups are arranged downwards, the suction cups are mounted on the suction cup rack, a vacuum pump is arranged on the suction cup rack, and the suction cups are connected with the vacuum pump through air pipes. The board machining and feeding system is used for solving the problem that during current board machining and feeding, the efficiency is low.

Owner:贵港沃斯顿科技有限公司

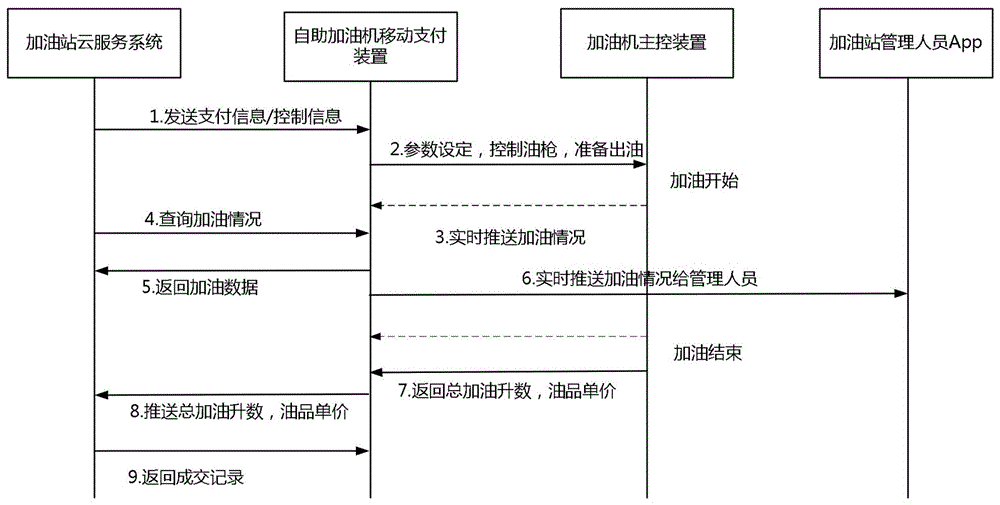

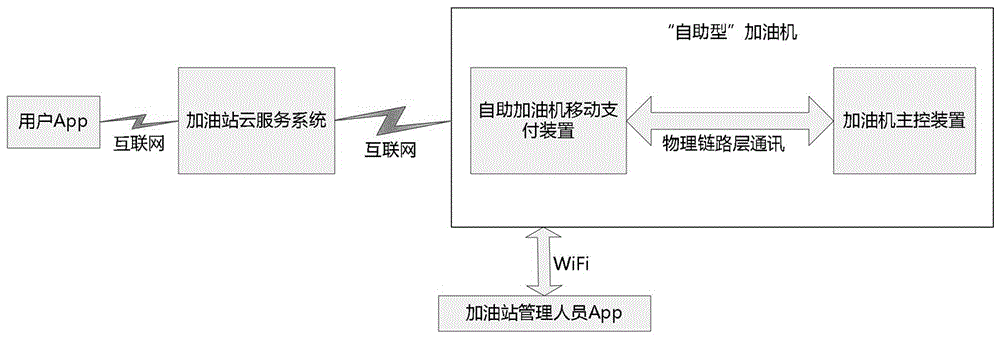

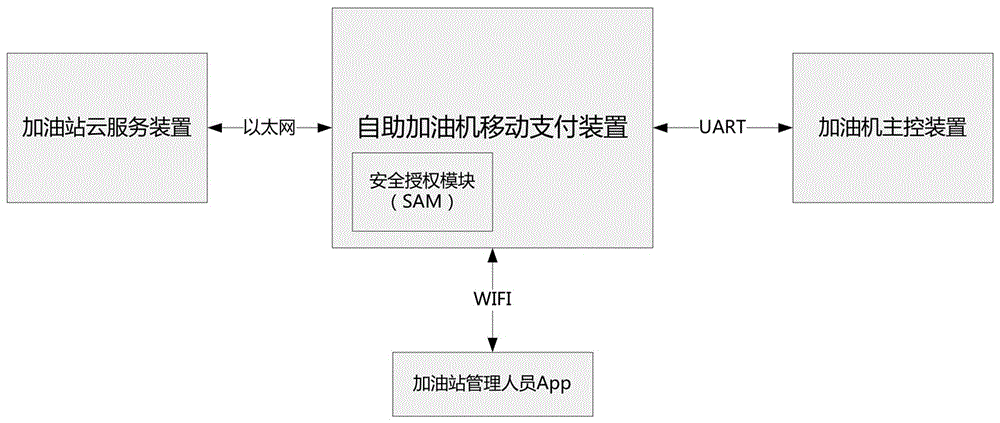

Self-service oiling machine mobile payment method and device supporting filling-up mode

InactiveCN105741427AThe effect of effective remote management of the refueling processRealize the effect of remote management of the refueling processPayment architectureApparatus for hiring articlesAuthorizationMobile payment

The invention aims at providing a self-service oiling machine mobile payment method and device supporting a filling-up mode.Oil engine remote monitoring and mobile payment functions are integrated, real-time oiling operation is completed through authorization information and oiling information provided by a filling station cloud service system, after oiling is completed, information of the total oiling amount and oil unit price is sent to the cloud service system in time, the cloud service system conducts settlement, the deal is closed, the cloud service system and an oiling machine master control device are integrated, and a self-service filling station is achieved.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

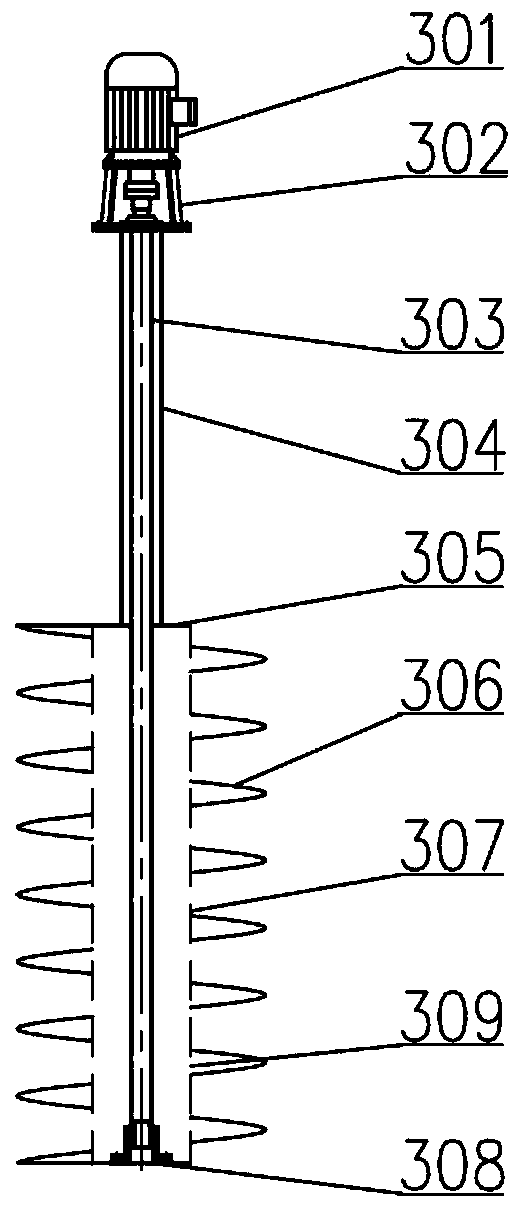

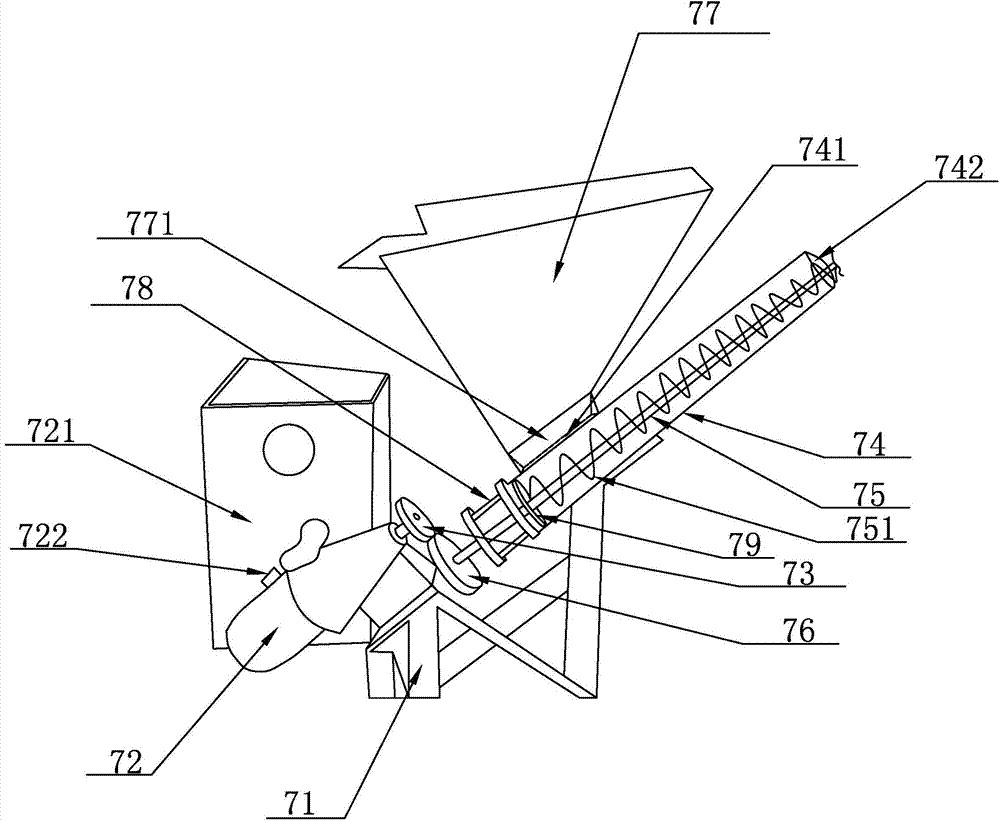

Novel activated carbon desulfurization and denitration device

ActiveCN109865414AAchieve purificationRealize storageDispersed particle separationActivated carbonPhysical chemistry

The invention relates to a novel activated carbon desulfurization and denitration device. The novel activated carbon desulfurization and denitration device comprises an activated carbon silo, an activated carbon adsorption box, a conical material discharging bin, a star-shaped material discharging valve, a spiral material discharging device and an ammonia spraying reaction chamber, wherein activated carbon can be contained in the activated carbon silo, the activated carbon silo, the activated carbon silo, the activated carbon adsorption box, the conical material discharging bin and the star-shaped material discharging valve are closely connected from top to bottom sequentially, and the spiral material discharging device is connected with the activated carbon silo and the activated carbon adsorption box; and the spiral material discharging device is automatically capable of material refueling and material discharging, and the ammonia spraying reaction chamber is closely disposed betweenthe activated carbon silo and the activated carbon adsorption box. Through the device, simultaneous desulfurization and denitrification can be achieved, the activated carbon has a large adsorption area, high adsorption efficiency and small system pressure drop, and the device is provided with an own material storage trough, so that automatic refueling and material discharging are achieved throughthe spiral material discharging device, and the automation level is high.

Owner:HEBEI AEROSPACE ENVIRONMENTAL ENG CO LTD

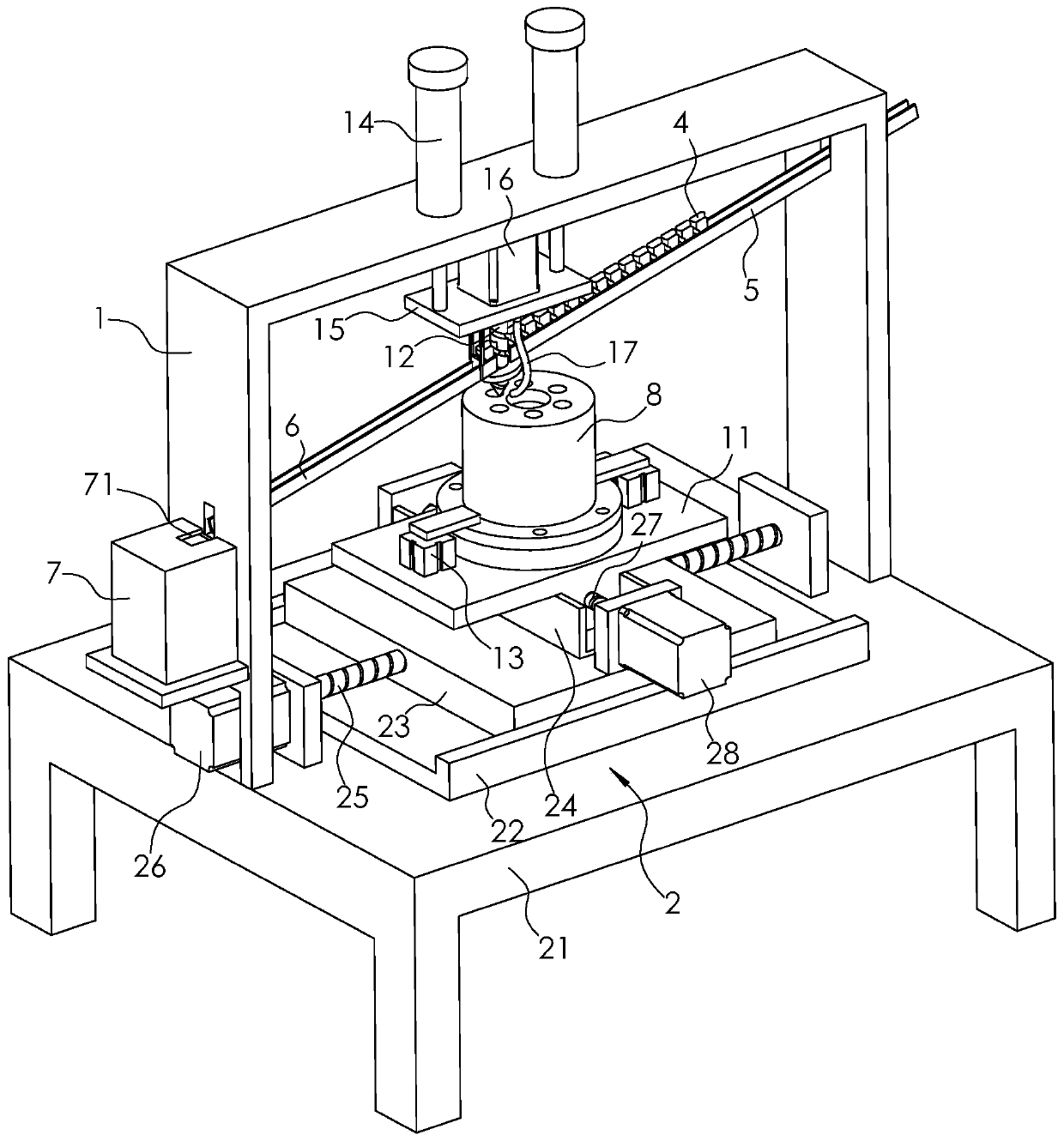

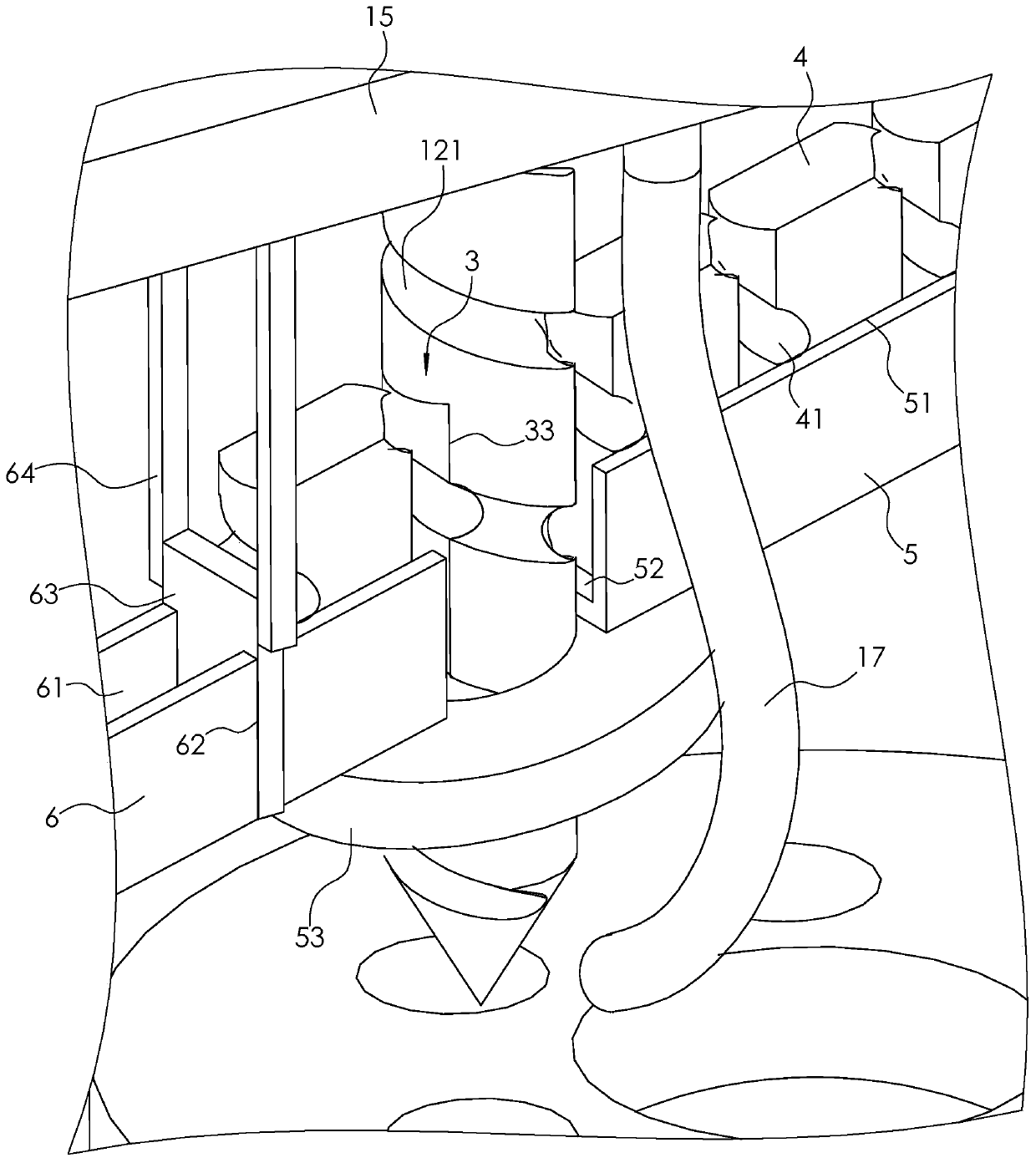

Planetary reducer shell machining process and drilling mechanism

ActiveCN110587235ARealize automatic refuelingGuaranteed cooling effectFeeding apparatusMaintainance and safety accessoriesHeat conductingCooling effect

The invention relates to the technical field of workpiece machining, especially relates to a planetary reducer shell machining process and a drilling mechanism. The process comprises a rack, the rackis provided with a working table, a driving component, a mounting plate, a drill bit, a driving part and a lifting part, the working table is provided with a clamp, the mounting plate is provided witha blowing device, the drill bit is provided with a through groove, the through groove comprises a groove body, a first notch and a second notch, the first notch is arranged at the first sliding rail,a plurality of heat conducting box and a driving piece, the first sliding rail is provided with a first sliding cavity and a limiting piece, the second groove is arranged at the mouth of the containing piece, the heat conducting boxes are filled with cooling mediums, the cooling mediums will rapidly cooling the drill bit, the driving piece and the containing piece realizes the heat conduction boxthe automatic material, and heat conduction box may be re-cooled so that the repeated utilization. The process ensures the cooling effect of the drill bit, saves resources, reduces the labor intensity of workers.

Owner:临安英明机械配件有限公司

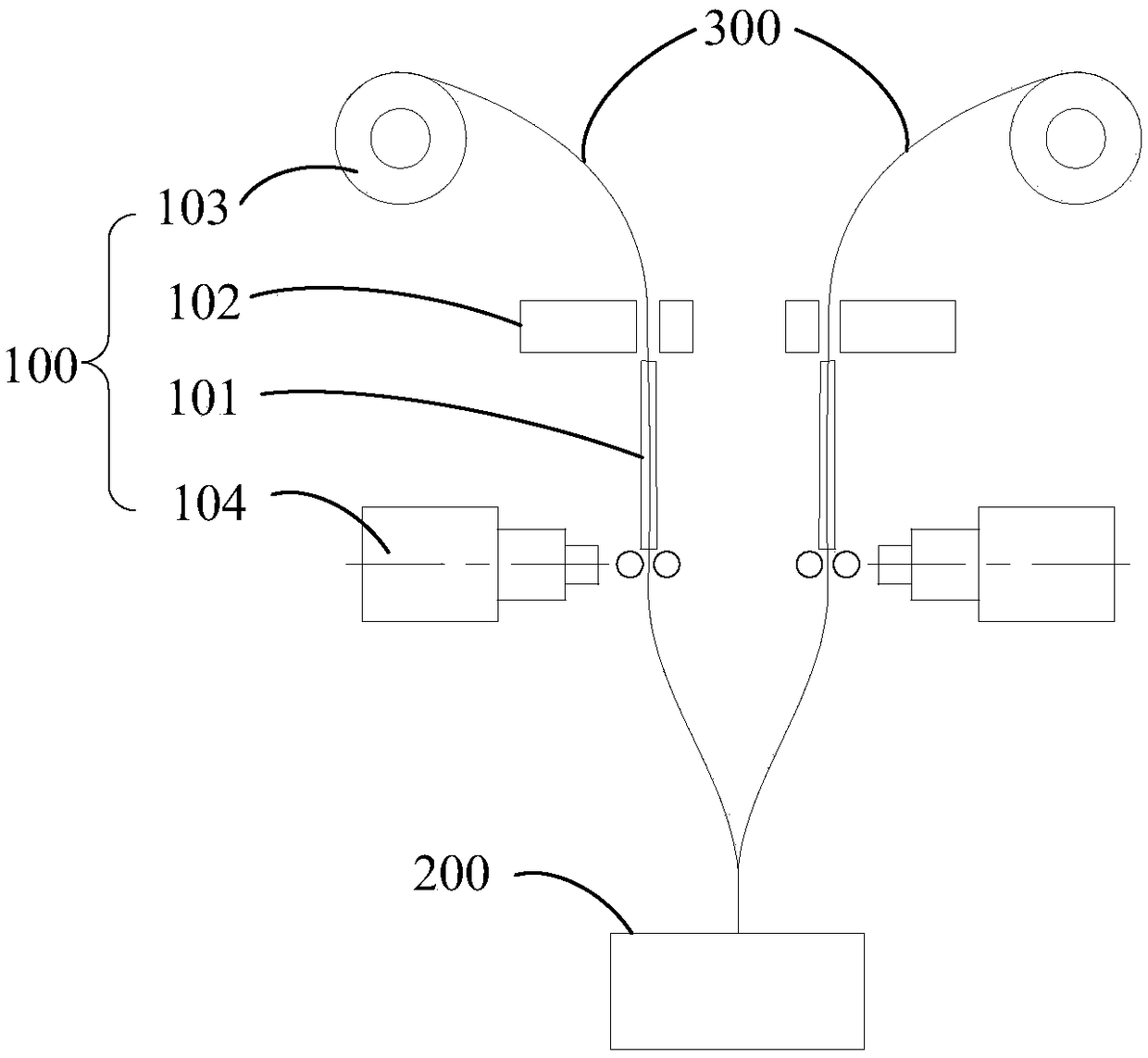

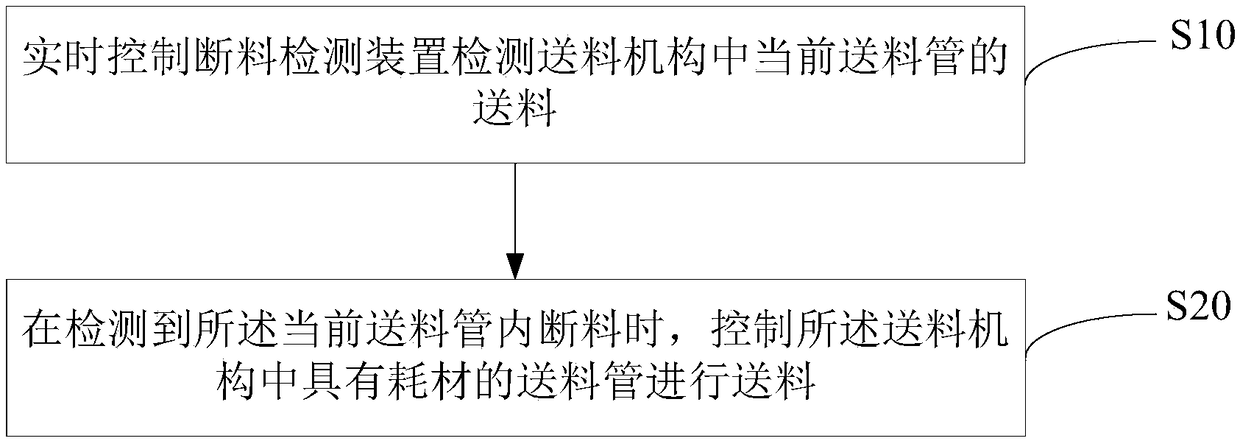

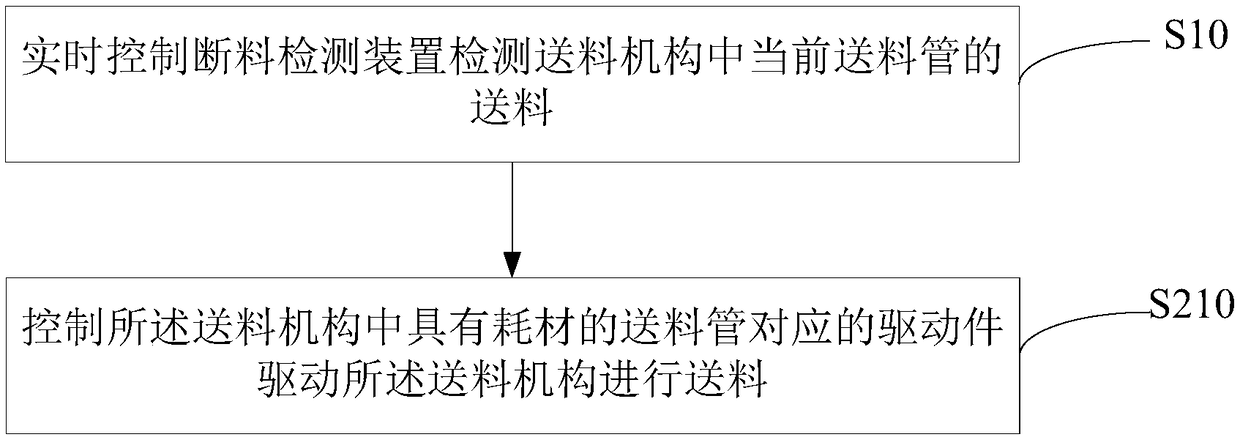

3D printer, control method of 3D printer and computer readable storage medium

InactiveCN108437445AAvoid wastingRealize automatic refuelingAdditive manufacturing apparatus3D object support structuresMaterial BreakEngineering

The invention discloses a 3D printer which comprises a control device, a feeding mechanism and a printing head assembly of the 3D printer. The feeding mechanism and the printing head assembly are connected with the control device, the feeding mechanism is connected with the printing head assembly of the 3D printer and comprises at least two sets of feeding pipes, each set of feeding pipe is provided with a material breaking detecting device, and the control device controls the feeding pipes, provided with consumable items, in the feeding mechanism to conduct feeding when the material breakingdetecting devices detect material breaking of the feeding pipes. The invention further discloses a control method of the 3D printer and a computer readable storage medium. The 3D printer is provided with the at least two sets of feeding pipes and material breaking detecting devices, when the material breaking detecting devices detect material breaking of the inner end of one feeding pipe, the other feeding pipes provided with the consumable items are switched for feeding, the aims that in the 3D printer printing process, human interference is not needed, and automatic switching of materials iscarried out are achieved, and printing failures and consumable item waste are avoided.

Owner:SHENZHEN SOONGON TECH

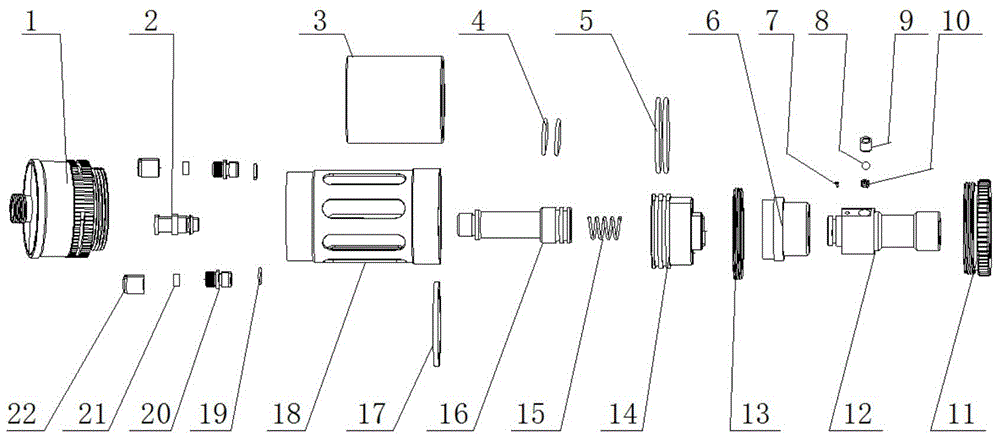

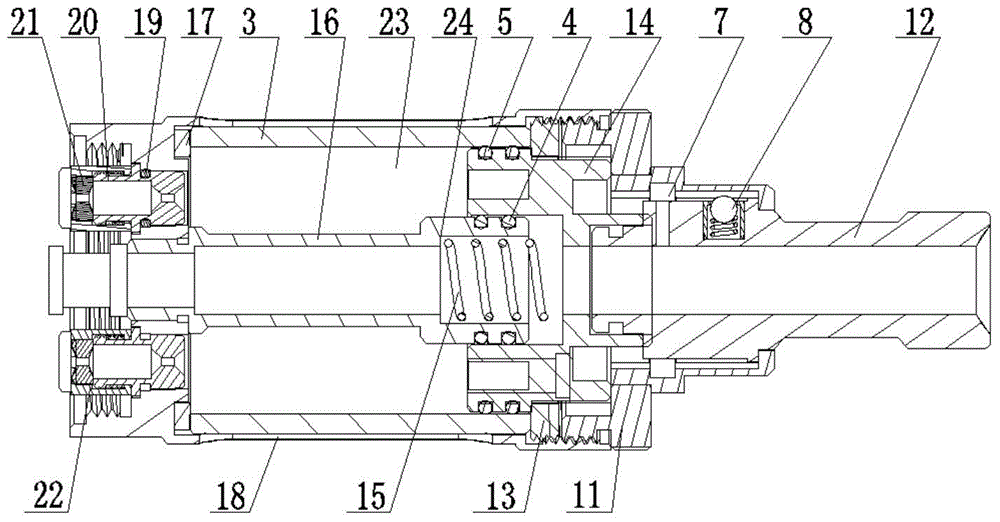

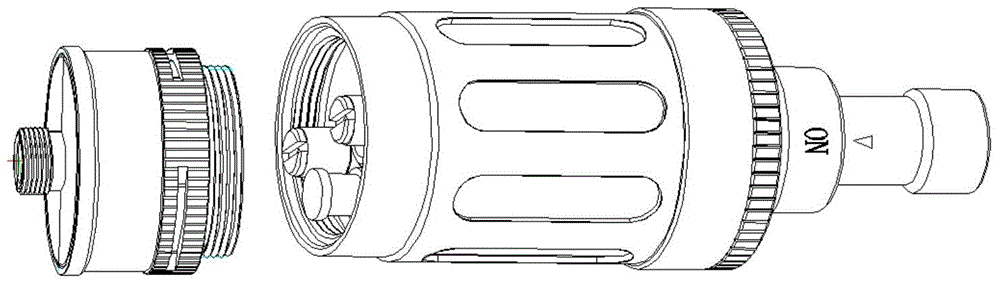

Automatic oil injection device of electronic cigarette and mechanical dripping device capable of controlling dripping amount

ActiveCN105982358ARealize automatic refuelingRealize functionTobacco devicesEngineeringElectronic cigarette

The invention discloses an automatic oil injection device of an electronic cigarette. The automatic oil injection device comprises a drip tip assembly, a cartridge assembly and an atomizer assembly. The drip tip assembly, the cartridge assembly and the atomizer assembly and sequentially assembled. The cartridge assembly comprises a main body housing, a transparent inner barrel, a smoke duct, an elastic sliding sealing device, an oil dripping device and an oil injection device. The transparent inner barrel is arranged in the main body housing and the transparent inner barrel is a barrel body with left end sealed; and the smoke duct is arranged in the center of the transparent inner barrel. Both the oil dripping device and the oil injection device are arranged at the left end of the transparent inner barrel and are located on the outer side of a nozzle of the smoke duct. The elastic sliding sealing device is arranged at the right end of the transparent inner barrel and is arranged in the axial direction of the right end of the transparent inner barrel in a sliding mode. The drip tip assembly comprises a drip tip main body, an adjusting base and an adjusting mechanism; the adjusting base sleeves the periphery of the drip tip main body and is fixedly connected to the cartridge main body housing. The adjusting mechanism is arranged between the drip tip main body and the adjusting base; and the drip tip main body is capable of sliding and rotating in the adjusting base in an axial direction by virtue of the adjusting mechanism. The left end of the drip tip main body is fixedly connected to the elastic sliding sealing device.

Owner:INNOKIN TECH

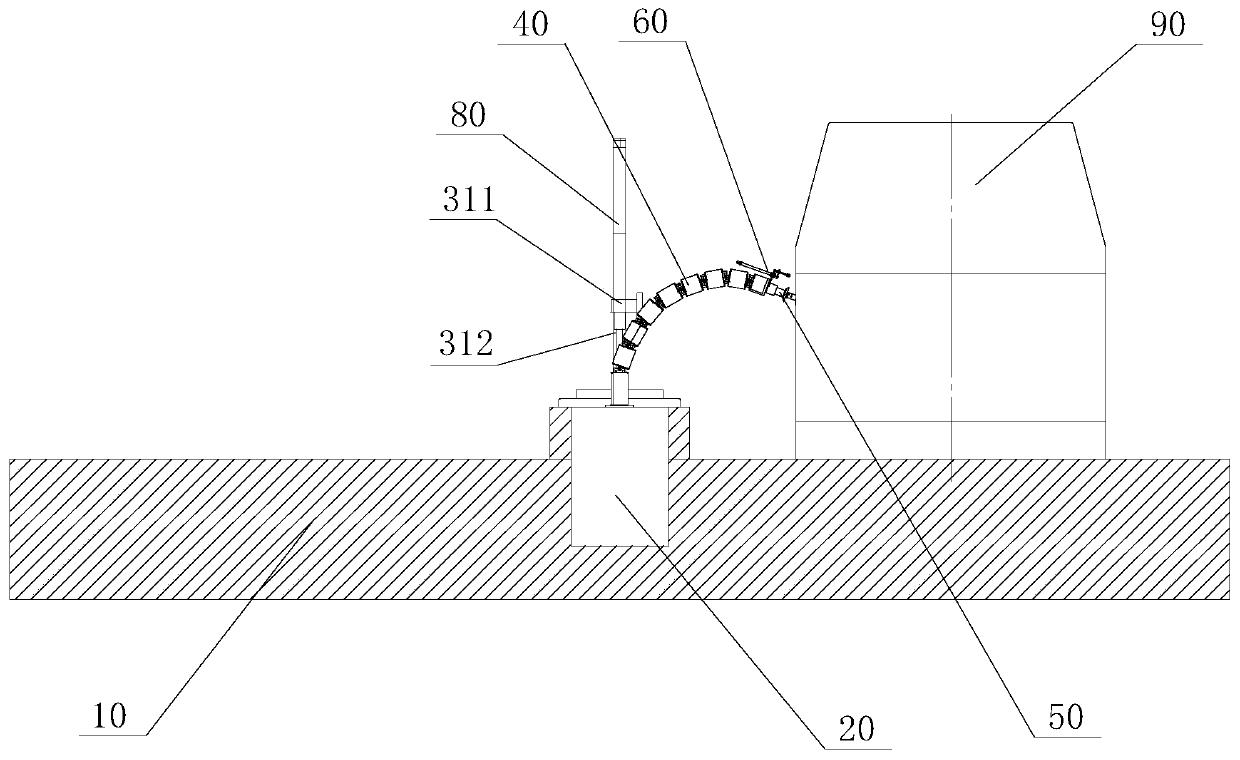

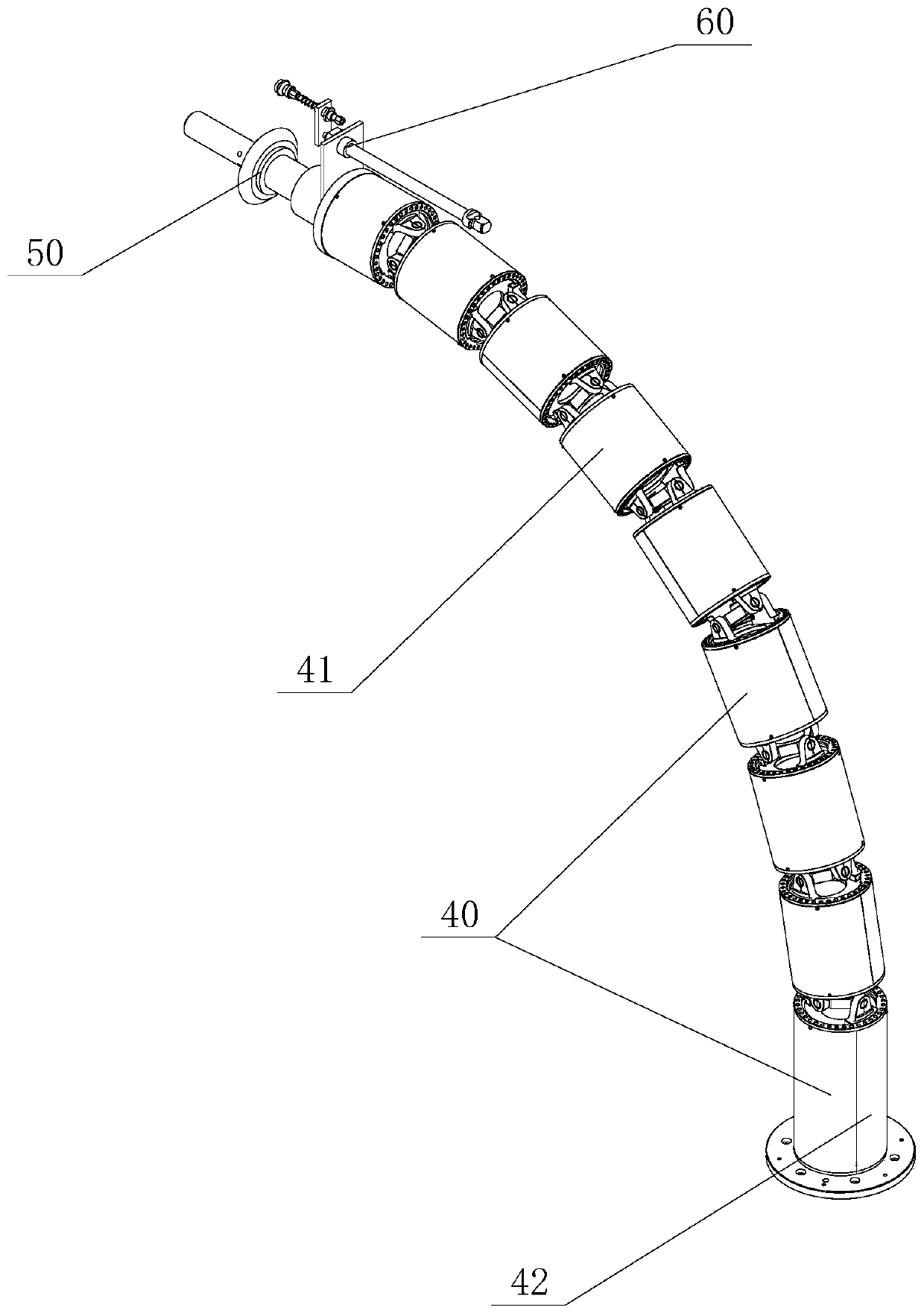

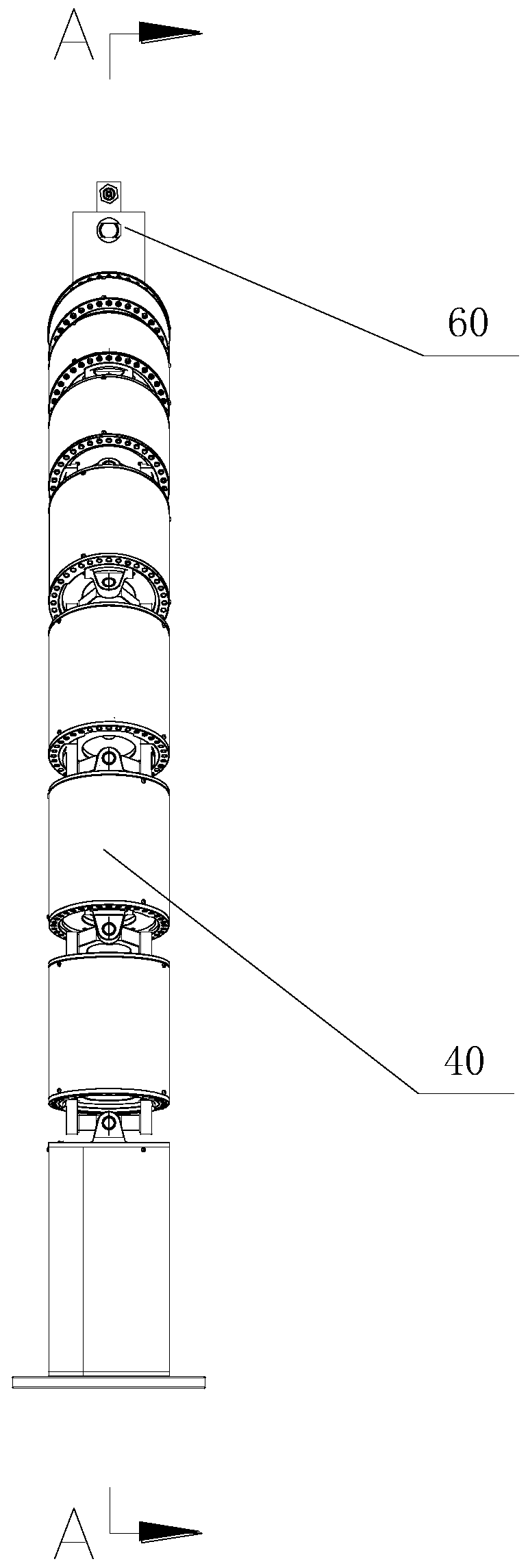

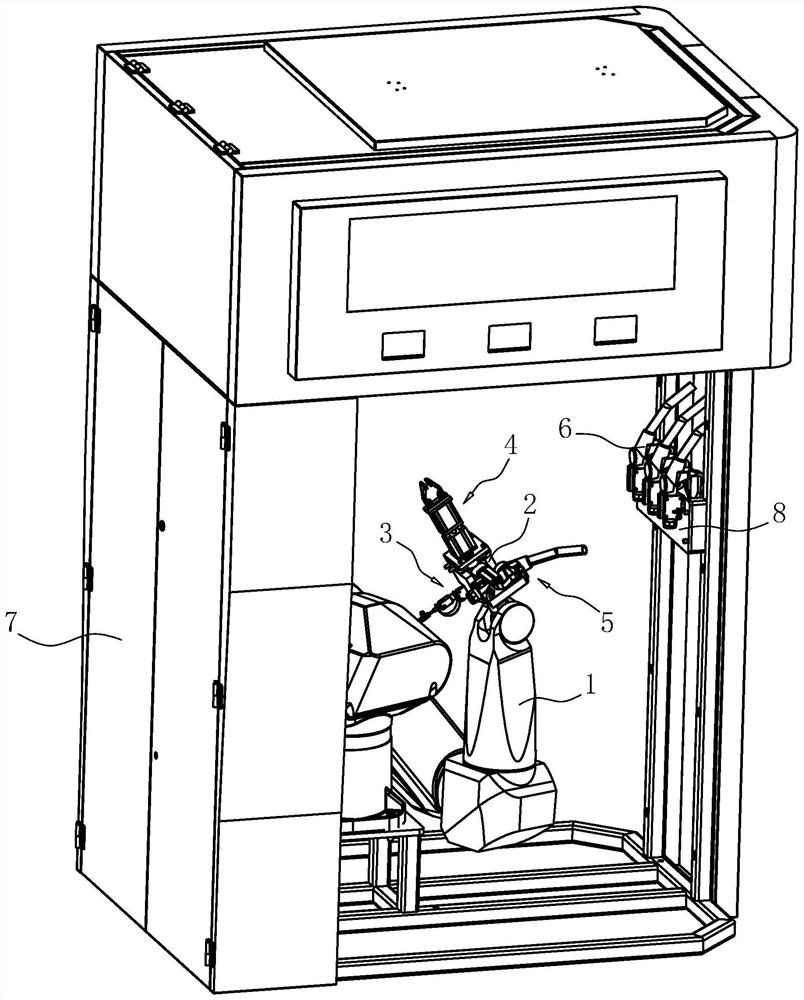

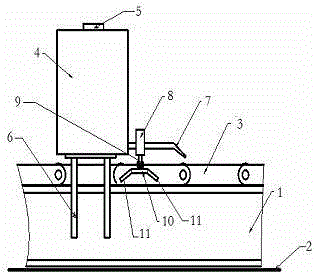

Snake arm refueling robot device and system

PendingCN110329979ASolve explosion-proofSolve the protection problemLiquid transferring devicesSimulationRobot

The invention discloses a snake arm refueling robot device and system. The snake arm refueling robot device includes a refueling island, a control driver, a refueling vision device, a snake robot arm,an integrated oil gun and a refueling cover opening and closing device, wherein the refueling island comprises a first embedded cavity; the control driver is installed in the first embedded cavity; the refueling vision device and the snake robot arm are separately arranged at the upper portion of the refueling island; the integrated oil gun and the refueling cover opening and closing device are separately installed at the tail end of the snake robot arm; and the refueling vision device, the snake robot arm, the integrated oil gun and the refueling cover opening and closing device are separately electrically connected with the control driver. The device can achieve automatic refueling and improve the refueling speed, and can meet the requirements of explosion-proof and IP protection level,so that the customer experience is improved well.

Owner:广州市双枪智能科技有限公司

Oil gun grabbing device

PendingCN108190825AImprove securityFunctionalLiquid transferring devicesMechanical engineeringEngineering

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH +1

Automatic oiling system controlled based on internet

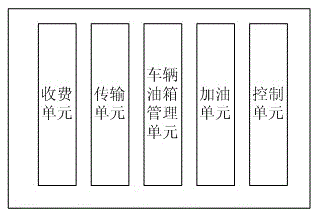

InactiveCN105608799ARealize automatic refuelingImprove efficiencyPayment architectureApparatus for hiring articlesManagement unitThe Internet

The invention discloses an automatic oiling system controlled based on the internet. The automatic oiling system comprises a charging unit, a delivering unit, a vehicle oil tank management unit, an oiling unit and a control unit. The charging unit is used for automatically generating charging information based on the oiling amount input by a user and charging corresponding fees from a client terminal. The delivering unit is used for delivering a vehicle to be oiled to a preset position. The vehicle oil tank management unit is used for opening or closing an oil tank cover of the vehicle based on control information. The oiling unit is used for automatically adding oil in the corresponding amount input by the user into an oil tank after the vehicle oil tank management unit sends a signal indicating that the oil tank cover is successfully opened and transmitting oiling finishing information to the control unit after oiling is completed. The control unit controls the whole process. The automatic oiling system has the advantages that automatic oiling is achieved, time and labor are saved, and efficiency is high.

Owner:SICHUAN XUNJI TECH CO LTD

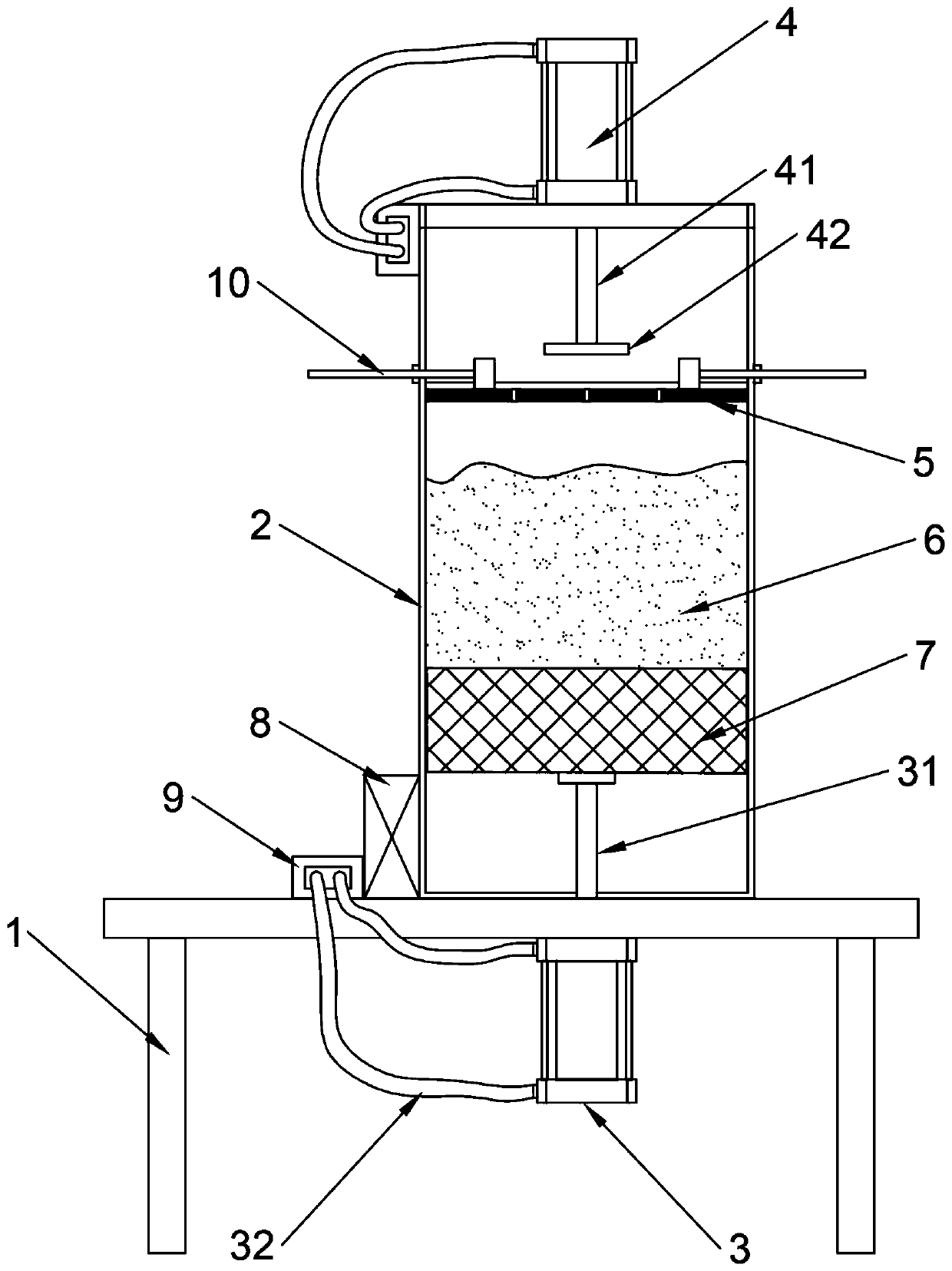

Automatic frying machine

ActiveCN105961470ARealize automatic refuelingConsume with confidenceOil/fat bakingDeep fat fryersPetroleum engineering

The invention relates to an automatic frying machine. The automatic frying machine comprises a frying tank, a pushing unit, an oil supply unit and an automatic oil adding unit; the frying tank can enable multiple to-be-fried materials to be fried into multiple cooked fried materials; the pushing unit is used for pushing the to-be-fried materials in the frying tank and can enable the cooked fried materials to be transferred out of the frying tank; the oil supply unit is arranged outside the frying tank and can supply needed oil materials; the automatic oil adding unit is arranged outside the frying tank. Particularly, the automatic oil adding unit comprises an oil level detection assembly connected to the frying tank and a control valve connected with the oil supply unit, the liquid level of the oil materials in the frying tank is sensed through the oil level detection assembly, the control valve controls the oil supply unit to be started and stopped according to the liquid level, then the effect of adding oil into the frying tank timely is achieved, and therefore not only can the oil be automatically added, but also a consumer can clearly know the oil material source.

Owner:潍坊国宝自动化智能新技术有限公司

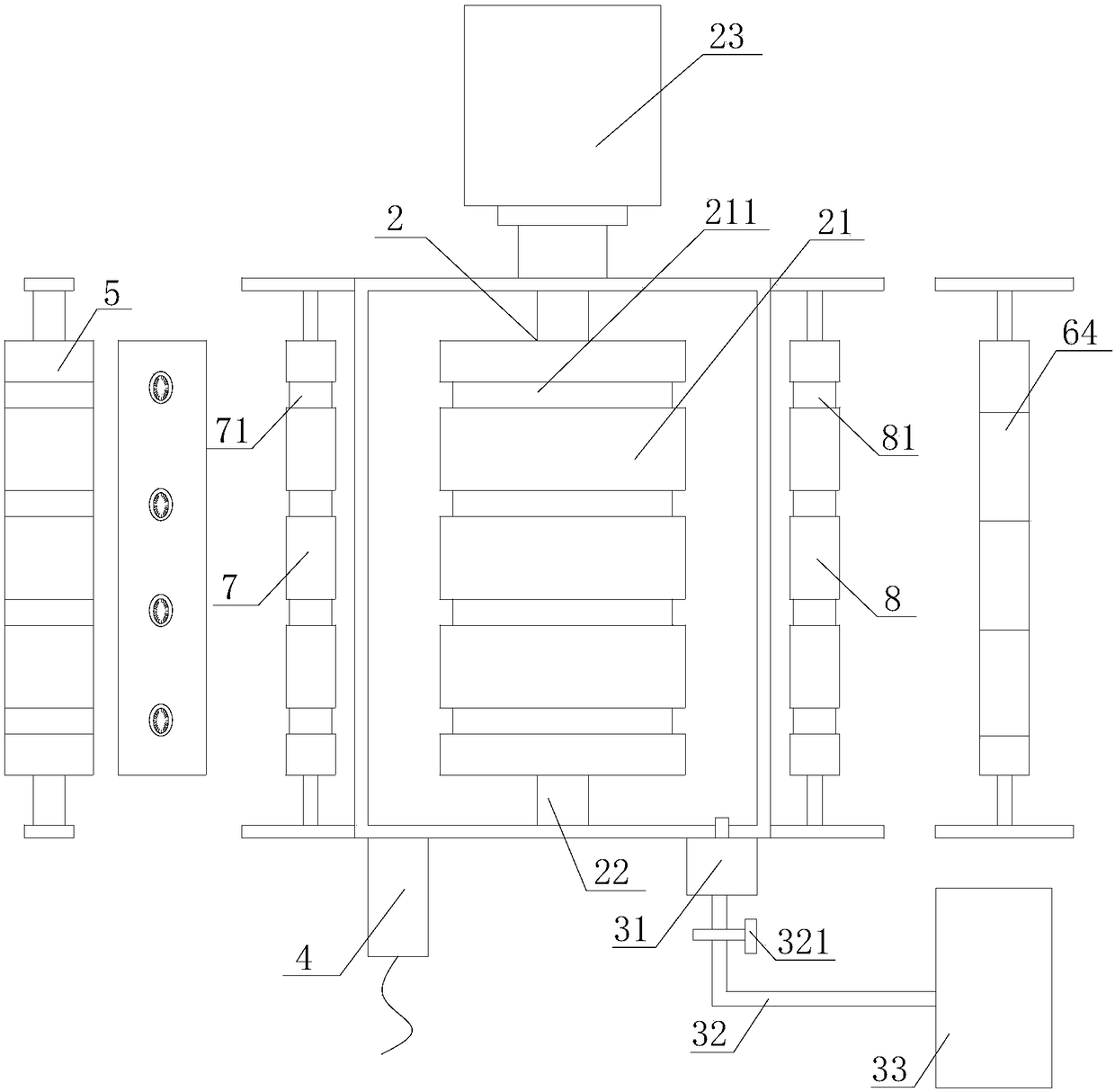

High-performance continuous forging and pressing device for alloy steel rods

ActiveCN109261883AEasy to forgeEasy to transport awayEngine componentsHandling devicesMotor driveMaterials science

The invention discloses a high-performance continuous forging and pressing device for alloy steel rods. The device includes a worktable, a sliding groove is formed in the worktable, a feeding groove is connected with one end of the sliding groove and contains the steel rods, the other end of the sliding groove is connected with a discharge groove, and a bearing platform is installed on the top ofthe sliding groove; fixing plates are installed on both sides of the bottom of the sliding groove, and a rotating shaft is rotatably sleeved with the fixing plates; a motor is installed on the fixingplate on one side of the sliding groove, an output shaft of the motor is connected with the rotating shaft, one end of the rotating shaft is provided with a conveying mechanism, the conveying mechanism is clamped into the sliding groove, a guide rail is installed on one side of the worktable, a clamping mechanism is installed between the guide rail and the other end of the rotating shaft, and a forging and pressing mechanism is installed on the other side of the worktable. The steel rods slide down along the feeding groove, the motor drives the rotating shaft to rotate, the conveying mechanismlifts the steel rods onto the bearing platform one by one, the rotating shaft drives the clamping mechanism to move at the same time, the clamping mechanism presses the steel rods on the bearing platform, and the forging and pressing mechanism conducts forging and pressing on the end face of each steel rod; after forging and pressing are finished, the clamping mechanism loosens the steel rods, and the conveying mechanism lifts the steel rods to the discharge groove.

Owner:安徽震祥精工科技有限公司

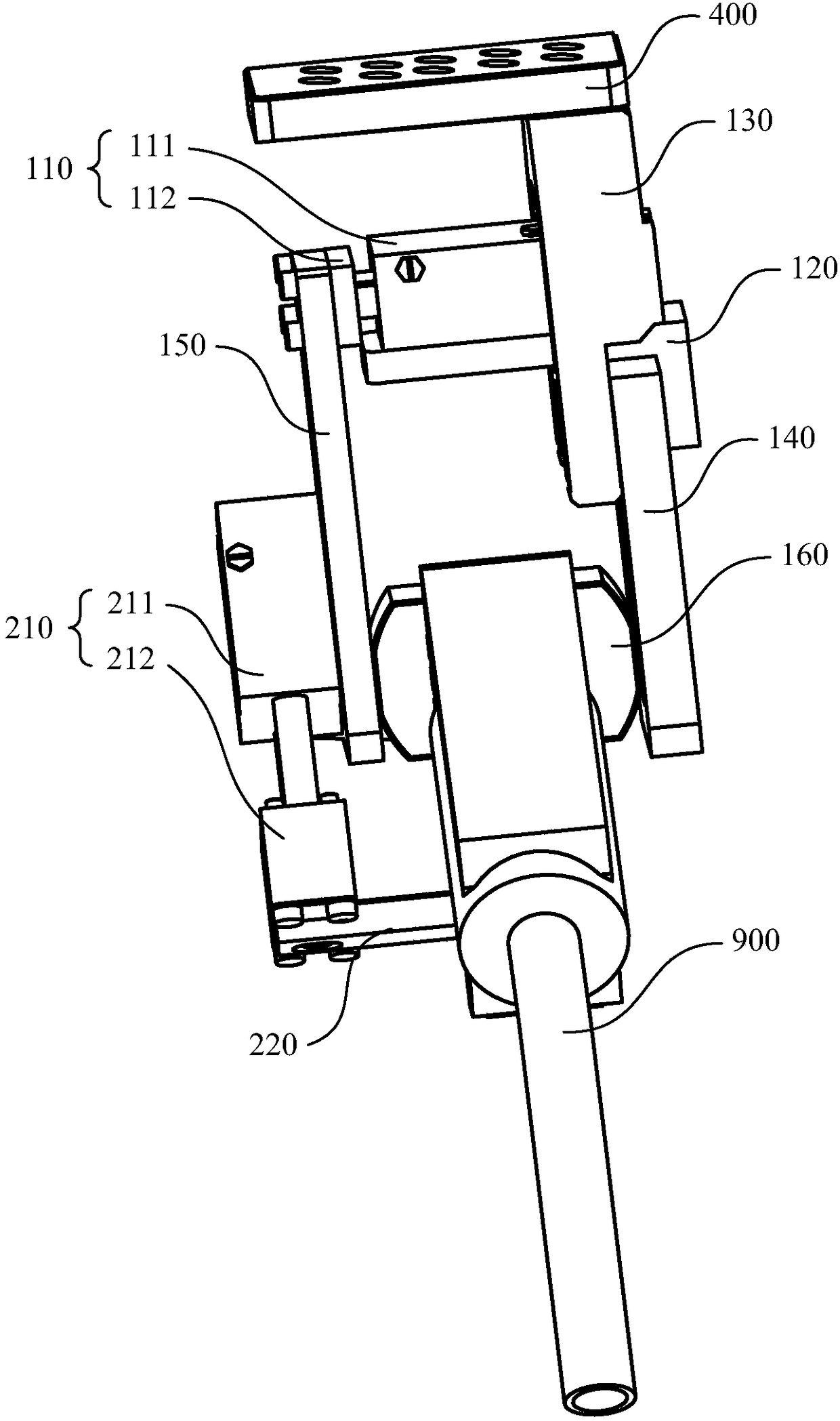

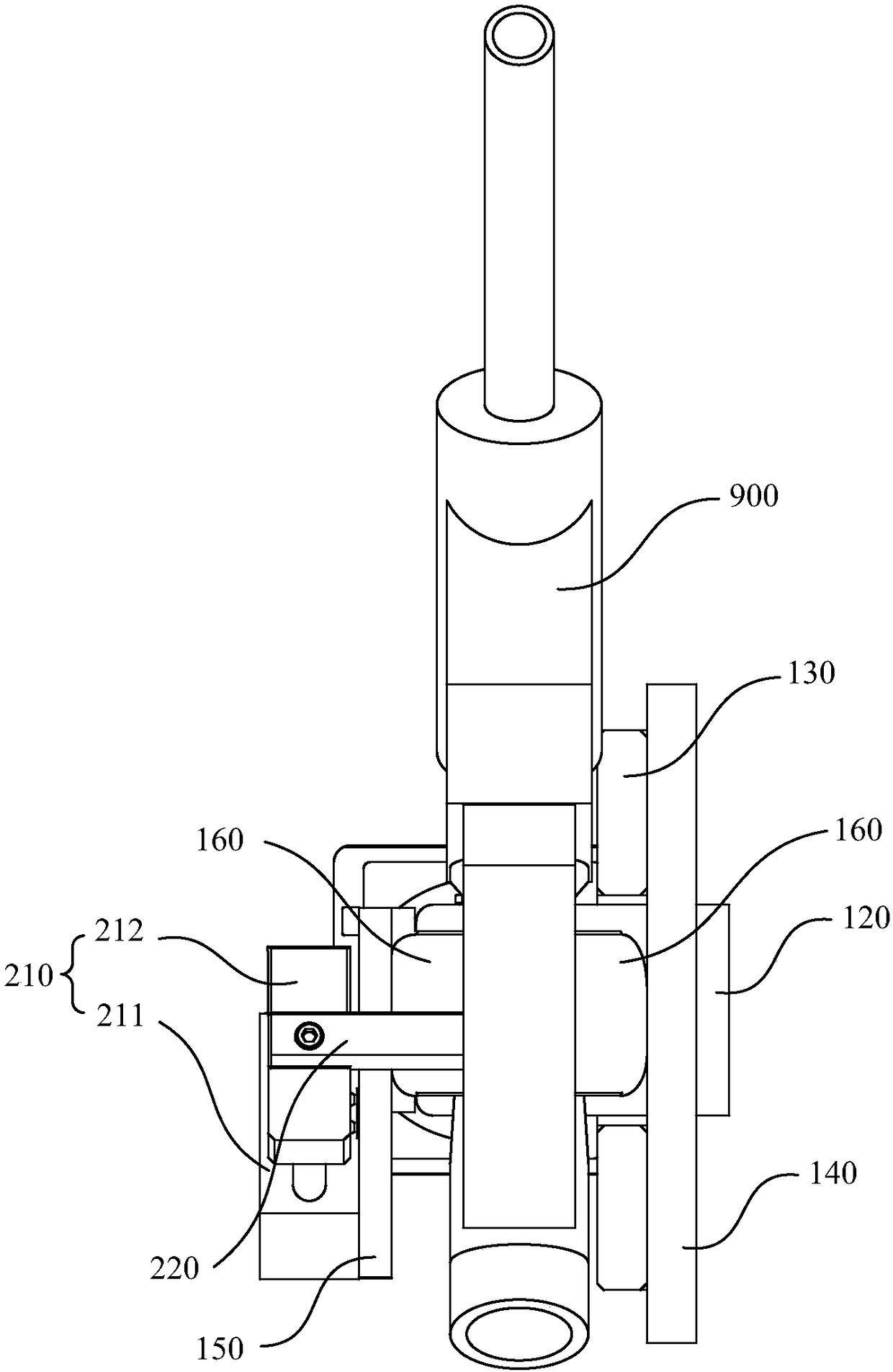

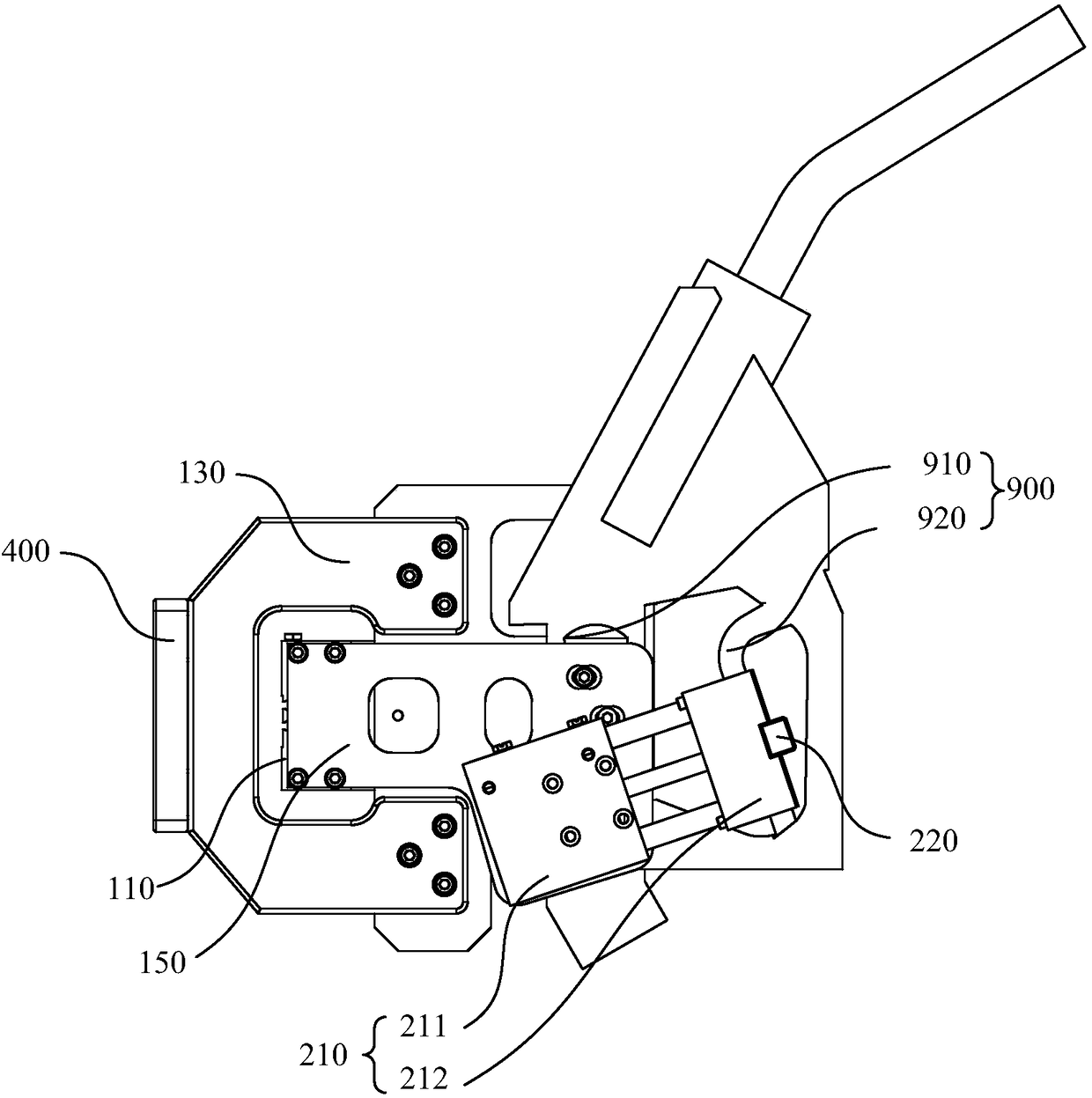

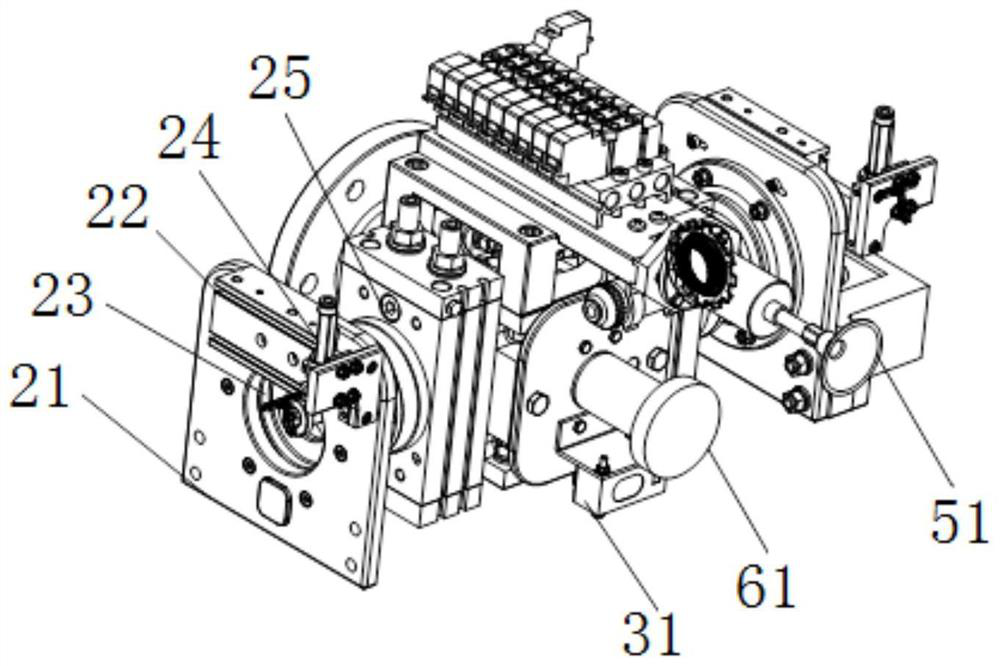

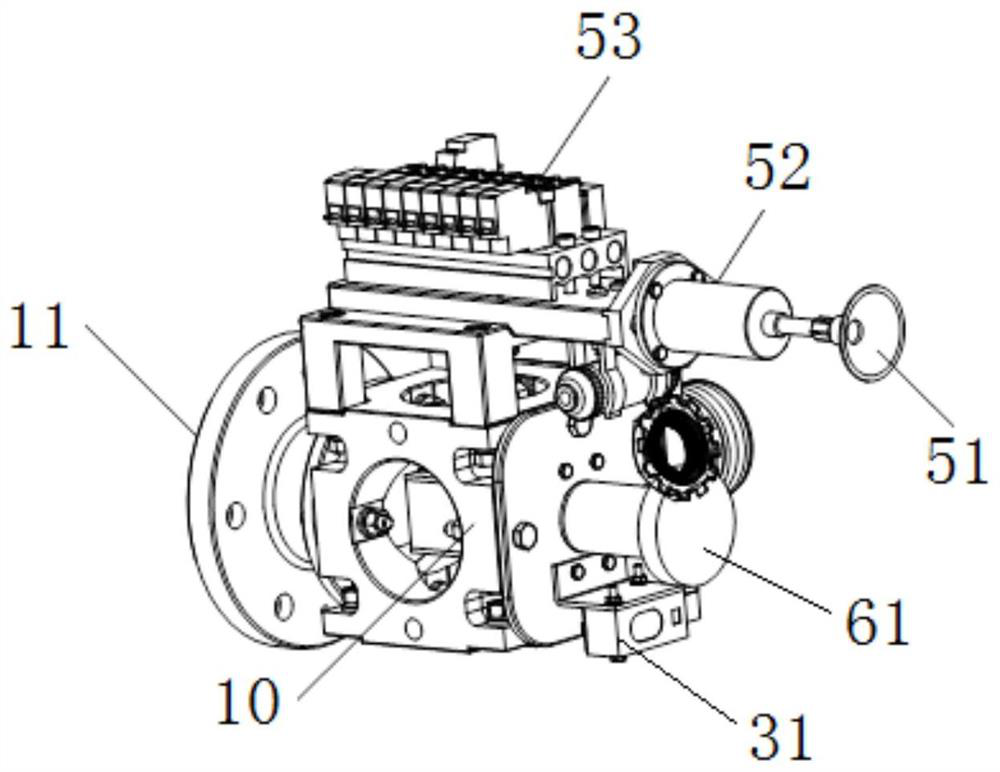

Refueling robot tail end assembly and refueling robot

PendingCN113582122AReduce investmentRealize automatic refuelingLiquid transferring devicesEngineeringPetrol station

The invention relates to refueling equipment, and particularly relates to a refueling robot tail end assembly and a refueling robot. According to the technical scheme, the refueling robot tail end assembly is characterized by comprising a rack block, wherein the rack block is provided with an outer cover opening and closing mechanism used for opening or buckling an outer cover of an oil tank, an inner cover screwing mechanism used for screwing an inner cover of the oil tank, and an oil gun grabbing mechanism used for grabbing an oil gun. No special worker needs to participate in the whole refueling process and operation after refueling is finished, and the worker input of a gas station is reduced.

Owner:BEIJING SANKI GASOLINEEUM TECH

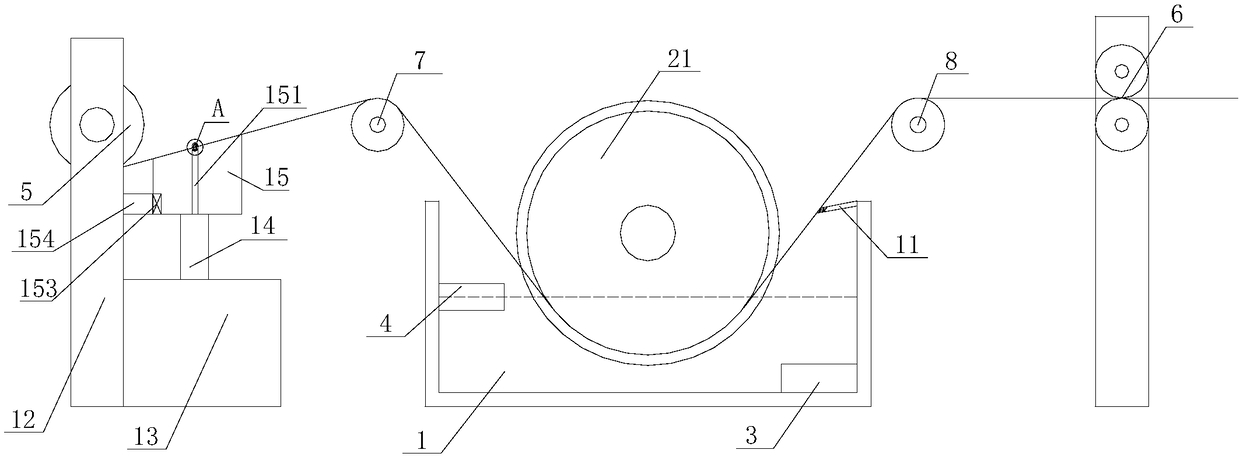

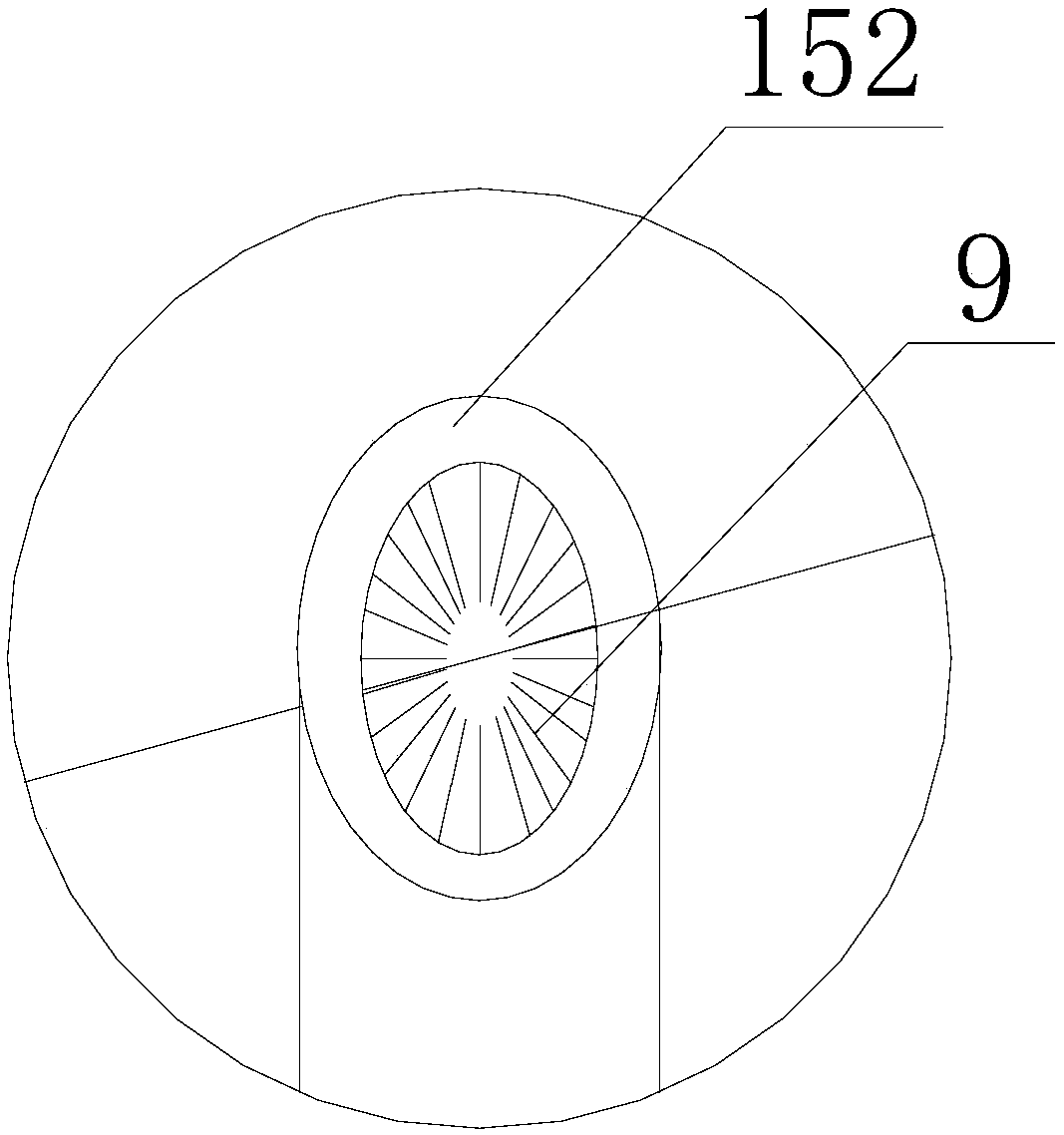

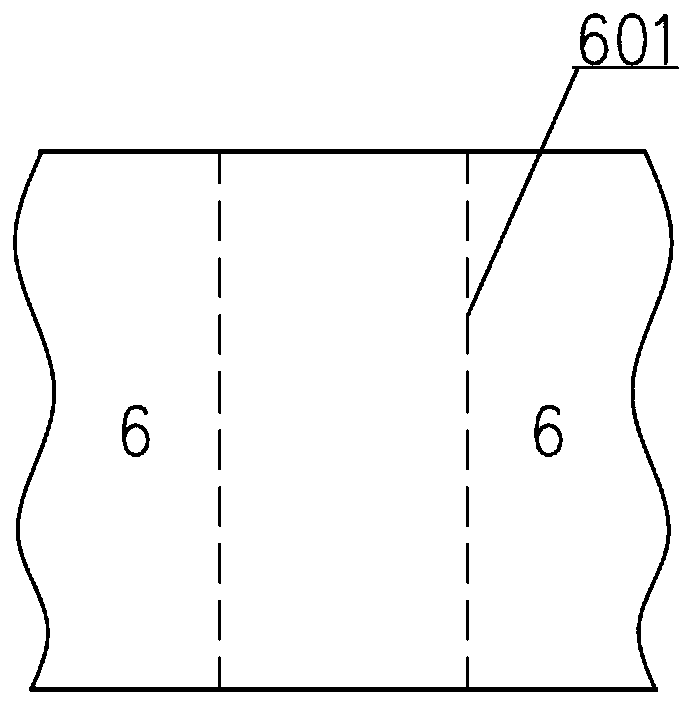

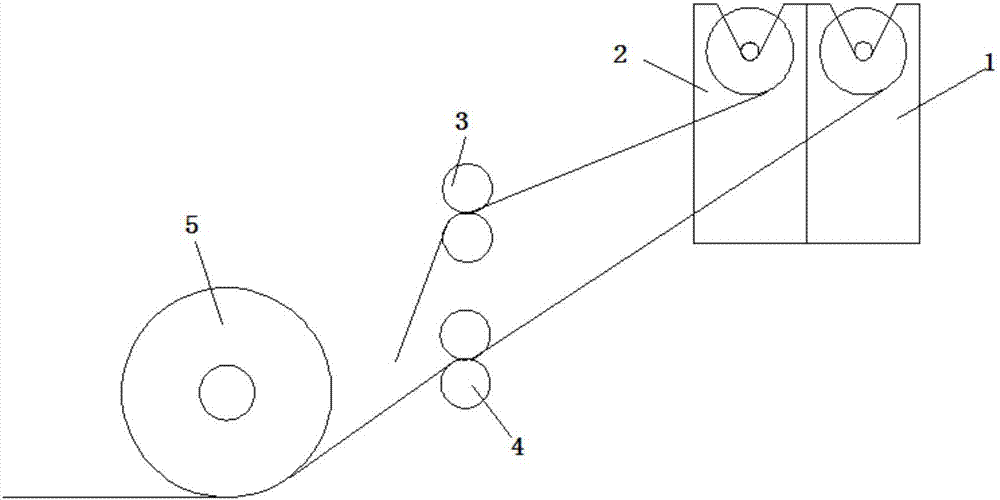

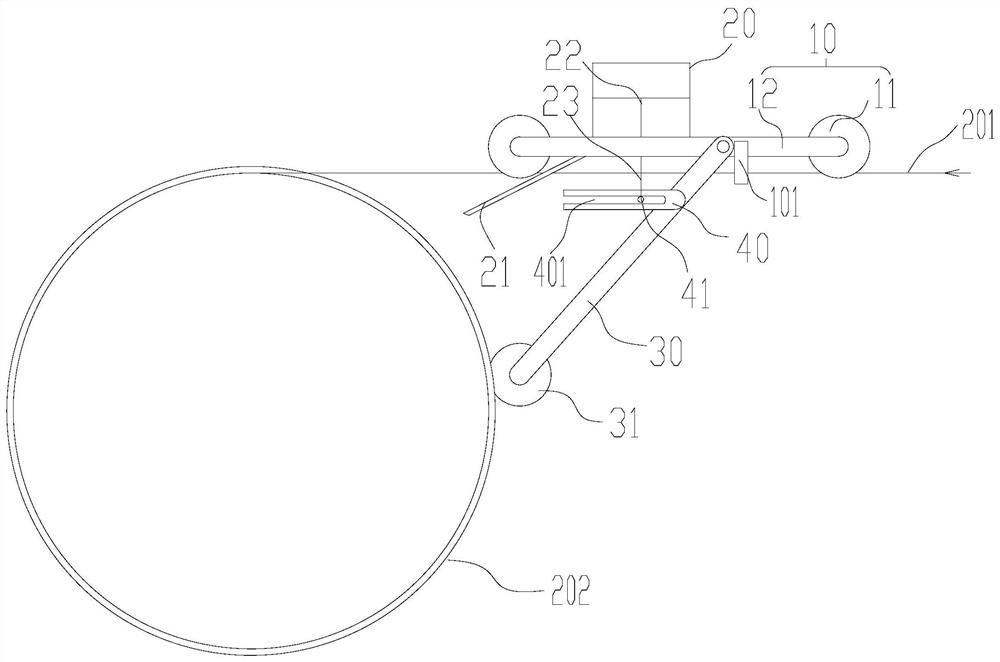

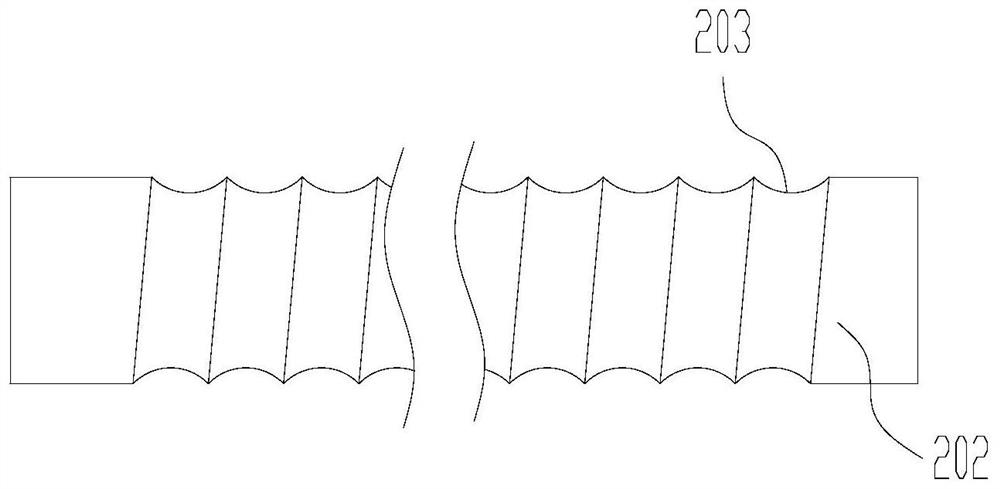

Coiled material automatic-changing system and waterproof coiled material hot-melting and laying locomotive

PendingCN107355051ARealize automatic refuelingImprove construction efficiencyRoof toolsMechanical engineeringAutomotive engineering

The invention provides a coiled material automatic-changing system and a waterproof coiled material hot-melting and laying locomotive. The coiled material automatic-changing system comprises a first coiled material support, a second coiled material support, a first guide device, a second guide device and a changing-starting device, wherein the first coiled material support and the second coiled material support are used for being loaded with coiled materials; the first guide device is used for guiding the waterproof coiled material released from the first coiled material support to the position under a laying roller in a tensioning mode; the second guide device is used for guiding the waterproof coiled material released from the second coiled material support to the position under the laying roller; and the changing-starting device is electrically connected with the first guide device or the second guide device and used for starting the first guide device or the second guide device to convey the end portion of the corresponding waterproof coiled material to the position under the laying roller. According to the coiled material automatic-changing system and the waterproof coiled material hot-melting and laying locomotive, by arranging the two coiled material supports, automatic changing between the two coiled materials can be achieved, locomotive halt is not needed, and the construction efficiency is enhanced greatly.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF ENG

Noiseless corrosion-resistant elevator guide rail

The invention discloses a noiseless corrosion-resistant elevator guide rail. The noiseless corrosion-resistant elevator guide rail comprises a base and a guide rail body; the guide rail body is fixedly connected to one side of the base; the joint of the base and the guide rail body is fixedly provided with a No.1 rail slot; the two sides of the No.1 rail slot are each fixedly provided with a No.2rail slot; No.1 guide wheels are movably arranged inside the No.1 rail slot; the No.1 guide wheels are two groups of No.1 guide wheels which are the same in model number; and each No.2 rail slot is internally movably provided with No.2 guide wheels. According to the noiseless corrosion-resistant elevator guide rail disclosed by the invention, by combination of the No.1 guide wheels and the No.2 guide wheels, a fixing frame can freely move up and down between the No.1 rail slot and the No.2 rail slots; meanwhile, the guide wheels make contact with the rail slots, so the friction between the fixing frame and the guide rail body is effectively reduced, and thus generation of noises is reduced; the base and the surface of the guide rail body are each fixedly provided with a corrosion-resistantlayer which is prepared from a cobalt-based alloy material, and the corrosion resistance of the base and the guide rail body can be effectively improved by virtue of the corrosion-resistant layers, so the noiseless corrosion-resistant elevator guide rail is suitable for being widely popularized and applied.

Owner:浙江西豪电梯成套设备制造有限公司

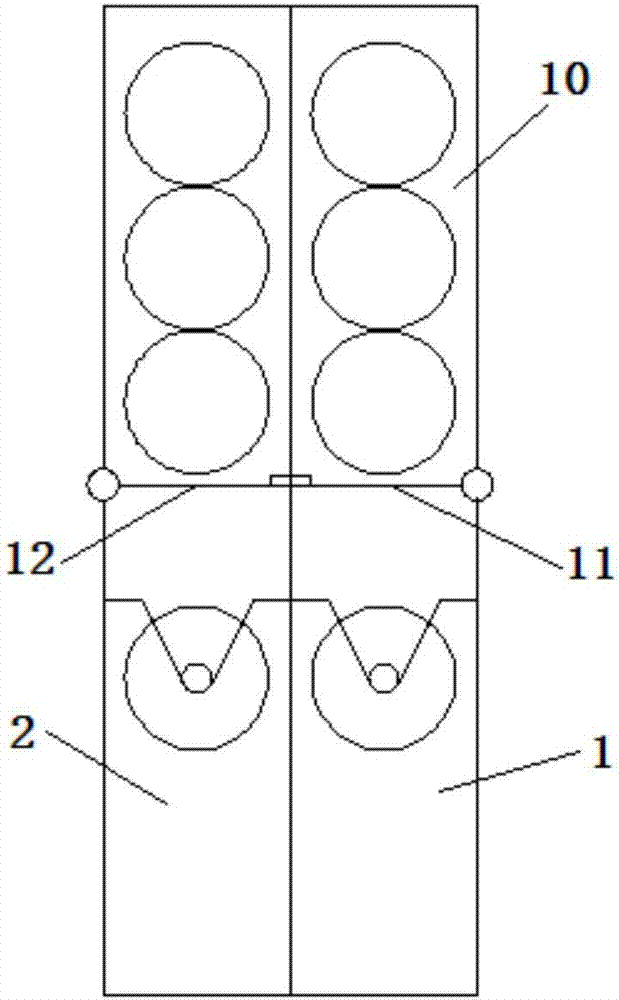

Embossing machine

InactiveCN113119527AAchieve embossingRealize intelligent operationBag making operationsFinal product manufactureAssembly disassemblyEngineering

The invention relates to an embossing machine. The embossing machine comprises a support, a double-station roller feeding mechanism, a heating device, an embossing device and a double-station roller receiving mechanism. By arranging a feeding bearing frame and a receiving bearing frame, double-station work of the feeding mechanism and the receiving mechanism can be achieved, switching of coiled materials can be achieved without stopping the machine for feeding or receiving, the working efficiency of the machine is greatly improved, the structure is ingenious, intelligent operation of switching of the coiled materials is achieved, and manpower and material resources are saved; and the double-station roller feeding mechanism, the heating device, the embossing device and the double-station roller receiving mechanism can be independently installed and arranged, assembly, disassembly or maintenance and replacement are convenient, and transportation is convenient.

Owner:中山市中伟机械设备有限公司

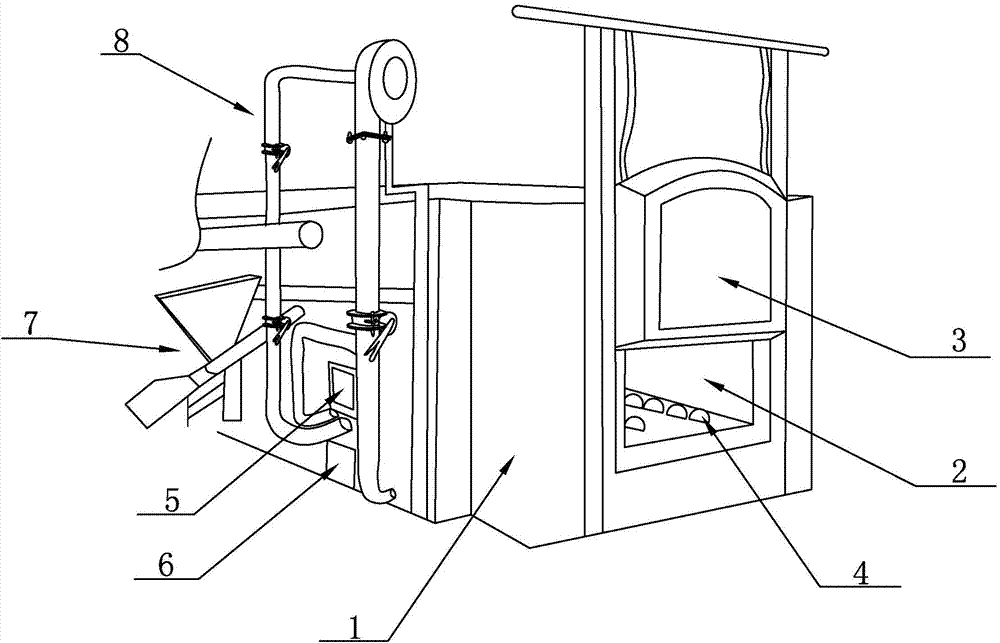

Novel calcining kiln

InactiveCN104713356AFirmly connectedEasy to assemble and disassembleFurnace typesWaste heat treatmentSlagKiln

The invention discloses a novel calcining kiln, which comprises a kiln body, wherein a sintered product tunnel is formed in one end of the kiln body; a gate is arranged at the entrance of the sintered product tunnel; at least one row of rollers are fixedly mounted at the bottom of the sintered product tunnel; the rollers are uniformly arranged from outside to inside; a fuel inlet is formed in one side of the kiln body; a fuel slag collection cavity is formed in the kiln body below the fuel inlet; an automatic fuel feeding device is arranged at the fuel inlet; and a smoke discharge device is fixedly arranged on the kiln body at the upper end of the fuel inlet. By adopting the above technical scheme, automatic fuel feeding can be realized, the smoke discharge effect is good, the degree of automation is high, the structure is simple, the working efficiency is high and the manufacturing cost is low.

Owner:FUJIAN ZHONGMAO PRECISION CASTING

Automated shoe mold cutting machine

The invention discloses an automated shoe mold cutting machine. The automated shoe mold cutting machine comprises a rack, a working platform, a pressing mold mechanism arranged on one side of the working platform, a shoe mold plate arranged on the working platform and a horizontal guide rail arranged on the side of the rack; a shoe mold hole is formed in the shoe mold plate, and a cutter die of which the shape is the same as that of the shoe mold hole is arranged on the side wall of the shoe mold hole; the pressing mold mechanism is provided with a pressing block located over the shoe mold hole; a conveyor belt is arranged between the working platform and the shoe mold plate; the guide rail is provided with a sliding block used for moving on the guide rail back and forth; a sliding rod is connected to the sliding block, and a chuck is arranged on the sliding rod and located on the side of the shoe mold plate; the pressing mold mechanism, the conveyor belt, the sliding block and the chuck are all connected with a transmission control device. According to the automated shoe mold cutting machine, automatic material replacing in the cutting process and automatic molded shoe material taking are achieved, manual material taking and replacing are omitted, the working efficiency is improved, and meanwhile damage of a cutter die in existing equipment to a discharging plate in the cutting process is avoided.

Owner:成都卡美奇鞋业有限公司

Dedusting and desulfurizing device

The invention discloses a dedusting and desulfurizing device which comprises a chimney and a dust collection box, wherein the chimney and the dust collection box are connected sequentially from top tobottom, an opening is formed in the upper part of the chimney, a plurality of filtering screen barrels are fixed at the bottom of the chimney, the lower parts of the filtering screen barrels are connected with the dust collection box, sliding pistons are further arranged in the filtering screen barrels in a sliding manner and connected with a transmission mechanism by fulcrum bars, a desulfurizing plate which is located above the filtering screen barrels and arranged in an inclined manner is further fixed in the chimney, a discharge pipe and a feed pipe are further fixed on the two opposite sides in the chimney respectively, a discharge port which is located above the desulfurizing plate is formed in the surface, in contact with the chimney, in the discharge pipe, a feed part which is located above the desulfurizing plate is formed in the surface, in contact with the chimney, in the feed pipe, and electromagnetic door mechanisms are arranged at the discharge port and the feed port; the problem that the smoke exhausted from a village domestic chimney cannot be effectively filtered so as to reduce the contents of the particles and sulfur dioxide in the smoke is solved.

Owner:CENT SOUTH UNIV

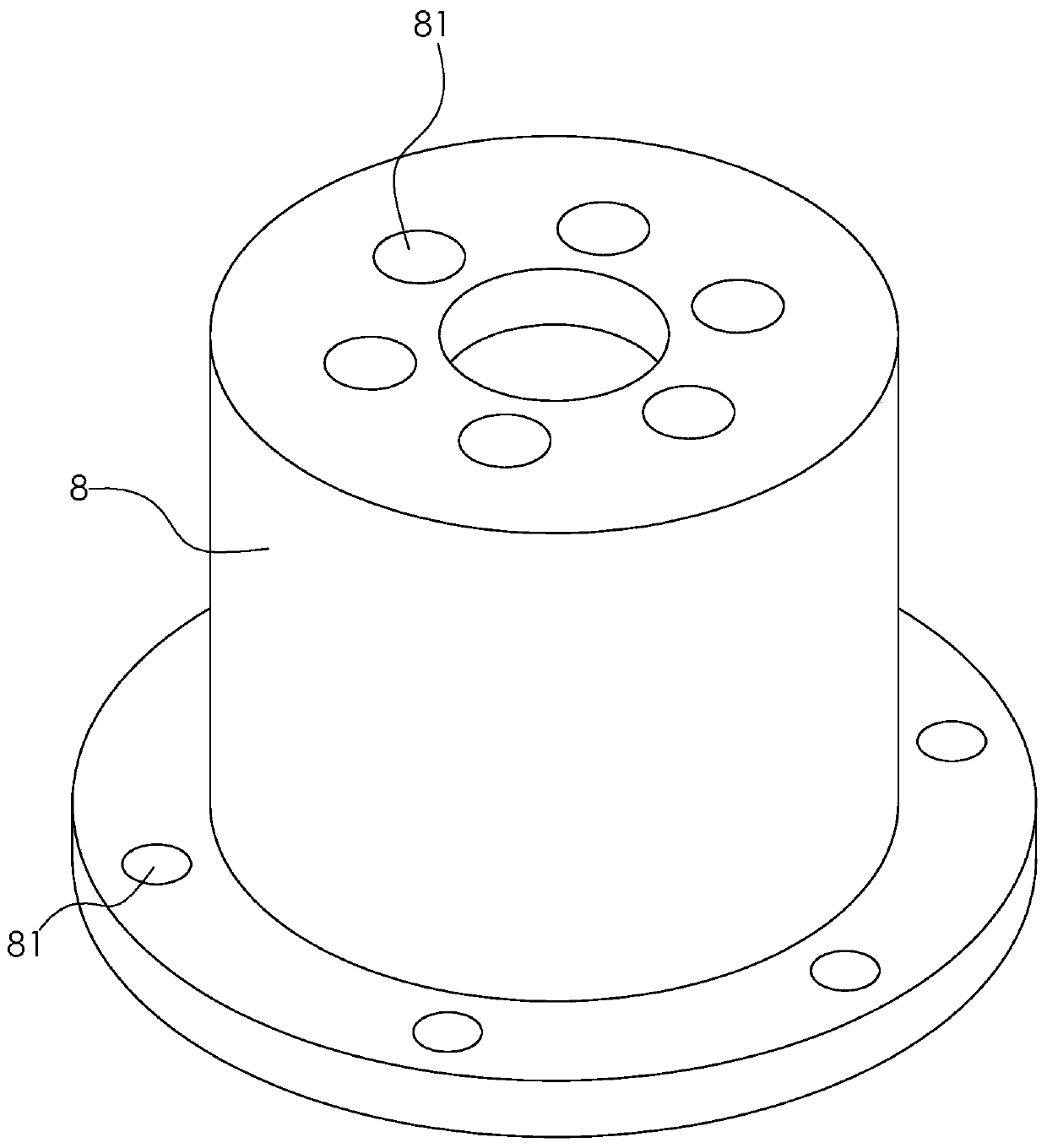

Trailer bearing grease filling machine

InactiveCN109827057AEnsure safetyEnsure reliabilityEngine lubricationEngineeringMechanical engineering

The invention provides a trailer bearing grease filling machine. The trailer bearing grease filling machine comprises a base, a grease storage tank, a lower cylinder and an upper cylinder. The greasestorage tank is arranged on the base. The lower cylinder is fixedly arranged on the bottom surface of the base and controls a piston in the grease storage tank to slide up and down along the inner side of a tank body through a connecting rod. A working cover plate is fixedly arranged on the tank body of the grease storage tank, multiple grease outlet holes are formed in the working cover plate, and a limiting mechanism is arranged on the upper surface of the working cover plate. The lower cylinder is arranged on a frame located on the top of the grease storage tank and connected with a force application plate through a push rod, and the force application plate and the working cover plate are parallel. The limiting mechanism comprises multiple limiting sliding blocks. Each limiting slidingblock is arranged in a limiting track which is located on the working cover plate, each limiting sliding block is connected with an adjusting rod, and the adjusting rods stretches out of the grease storage tank, and are fixed and limited by fixing nuts. The trailer bearing grease filling machine is reasonable in design and simple in structure, the grease filling speed is high, filling is uniform,and dead-angle-free grease filling of a bearing is basically achieved. The bearing can be rapidly lubricated, and the grease consumption is effectively reduced.

Owner:江苏卡满行物联科技有限公司

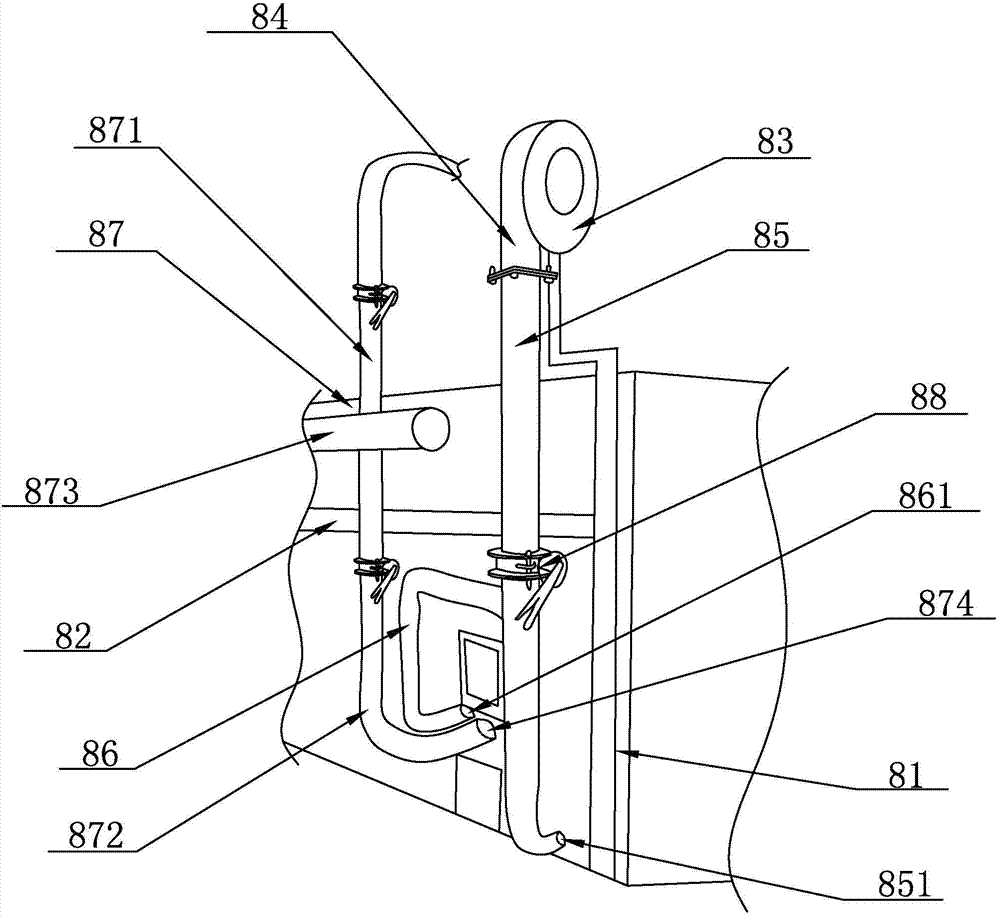

Diesel generator set with automatic oiling function

InactiveCN105351125ASustainable workAvoid damageExhaust apparatusSilencing apparatusSolenoid valveFuel tank

The invention provides a diesel generator set with the automatic oiling function. The diesel generator set comprises a diesel generator, an oil storage barrel and a control device. The diesel generator comprises an oil tank. The oil tank is connected with the oil storage barrel through an oil delivery pipe. The oil delivery pipe is provided with a solenoid valve. The oil tank is provided with an oil level sensor. The control device automatically adjusts the opening degree of the solenoid valve according to a signal of the oil level sensor. According to the diesel generator set, the diesel generator can be oiled according to the actual requirements, the diesel generator set can work continuously, and damage to the diesel generator due to insufficient oil is avoided.

Owner:江苏瑞昌哥尔德发电设备股份有限公司

Elevator cable guide vehicle oil adding device

InactiveCN104864253ARealize automatic refuelingCome on in timeEngine lubricationFuel tankCoking plant

The invention relates to an elevator cable guide vehicle oil adding device, in particular to an elevator cable guide vehicle automatic oil adding device in a dry-method coke quenching device of a coking plant. The elevator cable guide vehicle oil adding device comprises a movable trolley. The movable trolley is arranged on a rail. Chains are arranged on the two sides of the movable trolley respectively. An oil tank is arranged on the movable trolley. Oil pipes with openings above the chains are arranged on the side wall of the bottom of the oil tank and provided with valves. Vertically-downward valve rods are arranged on the valves. Impacting iron is arranged on the chains and arranged below the valve rods of the valves. The elevator cable guide vehicle oil adding device has the advantages that the valves are controlled by the impacting iron to be opened and closed, oil is added to the chains only when the movable trolley reciprocates and not added when the movable trolley stops, automatic oil adding is achieved accordingly, oil adding is timely and even, and oil is saved.

Owner:SHANDONG IRON & STEEL CO LTD

A High-frequency Transformer Automatic Gluing Mechanism

ActiveCN108010697BRealize automatic refuelingReduce labor intensityEncapsulation/impregnationMetal working apparatusTransformerEngineering

Owner:珠海市欧科锐智能装备有限公司

Hoist drum refueling device

ActiveCN113415748BRealize automatic refuelingExtended service lifeWinding mechanismsConduits/junctionsWinchLubrication

Owner:HEBEI HUAFENG ENERGY TECH DEV CO LTD

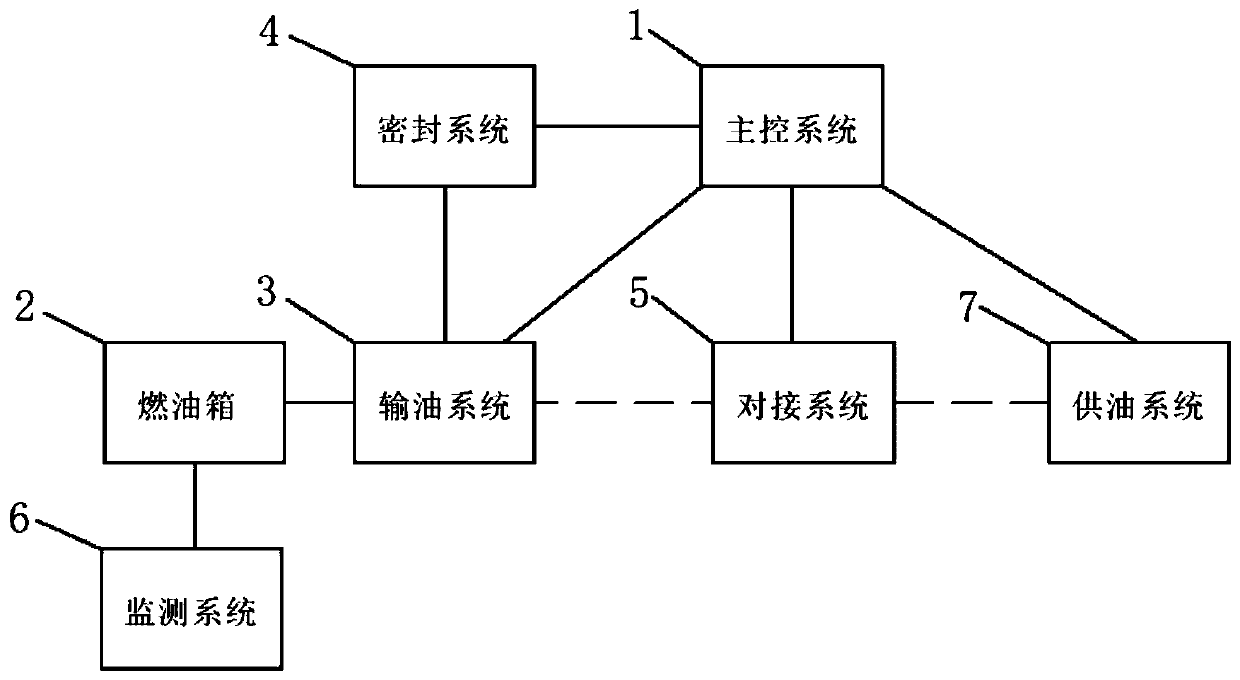

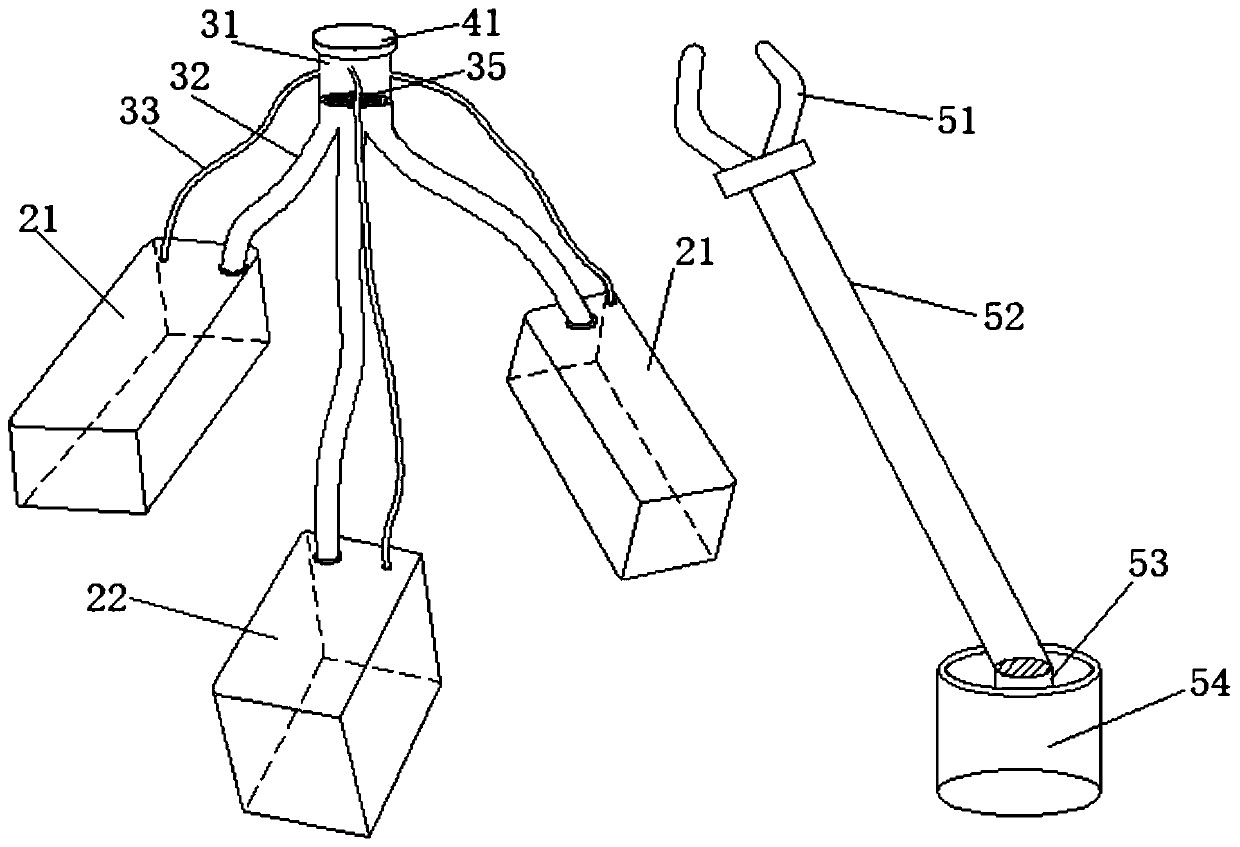

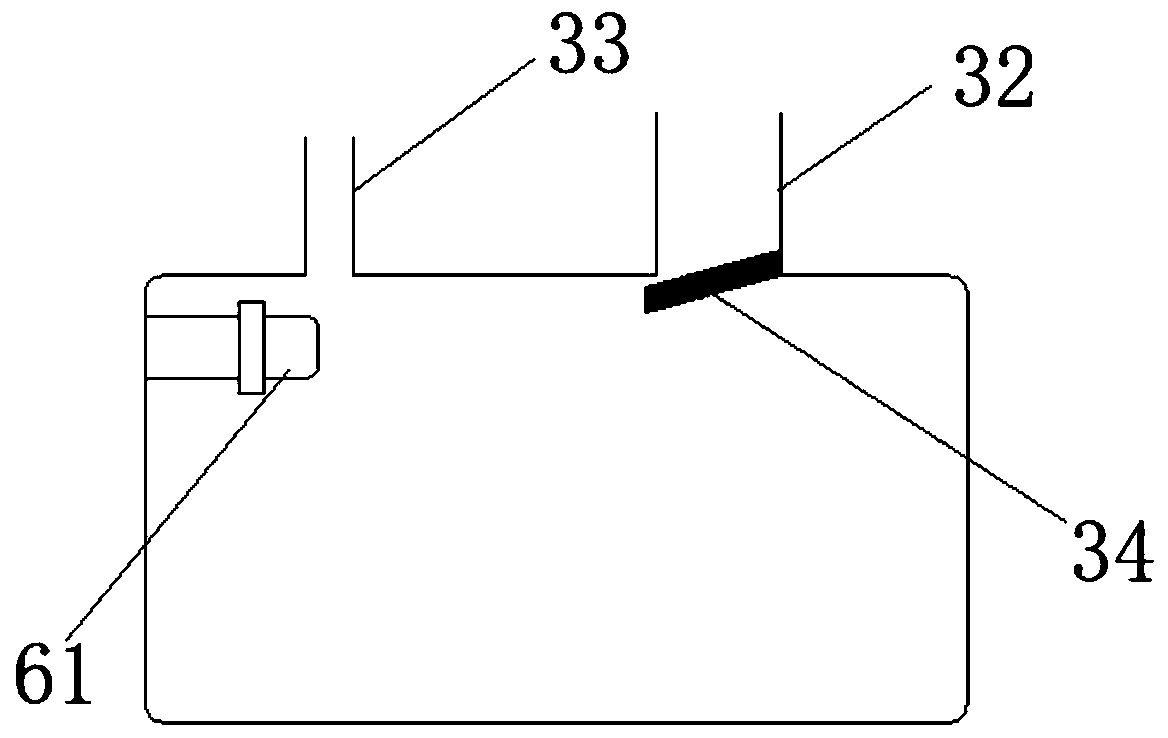

An amphibious unmanned ship refueling system and refueling method with adjustable fuel delivery rate

ActiveCN108408678BHigh degree of automationLow costLiquid transferring devicesControl systemButt joint

The invention relates to the technical field of unmanned ships, and provides an amphibious unmanned ship oiling system with an adjustable oil conveying rate and an oiling method. The oiling system comprises a master control system, fuel oil boxes, an oil conveying system, a sealing system, a butt-joint system, a monitoring system and an oil supply system, wherein a main oiling hole is sealed by asealing cover of the sealing system; the master control system is used for controlling opening and closing of the sealing cover; the master control system is used for controlling the butt-joint systemfor inserting an oiling gun into the main oiling hole; the monitoring system is used for monitoring oil amount of the fuel oil box in real time and feeding back the oil amount to the master control system; and the oil supply system is set with different oil conveying rates. The oiling system provided by the invention can realize automatic oiling, so that automatic degree of an amphibious unmannedship is increased, and worker cost is reduced; and meanwhile, oiling holes of multiple fuel oil boxes are integrated as one main oiling hole, and the oil conveying rate is controlled and regulated according to an oiling state, so that the oil supply system is in a full-load working state all the time, oil conveying efficiency is improved, and fuel oil is prevented from overflowing.

Owner:青岛无疆技术有限公司

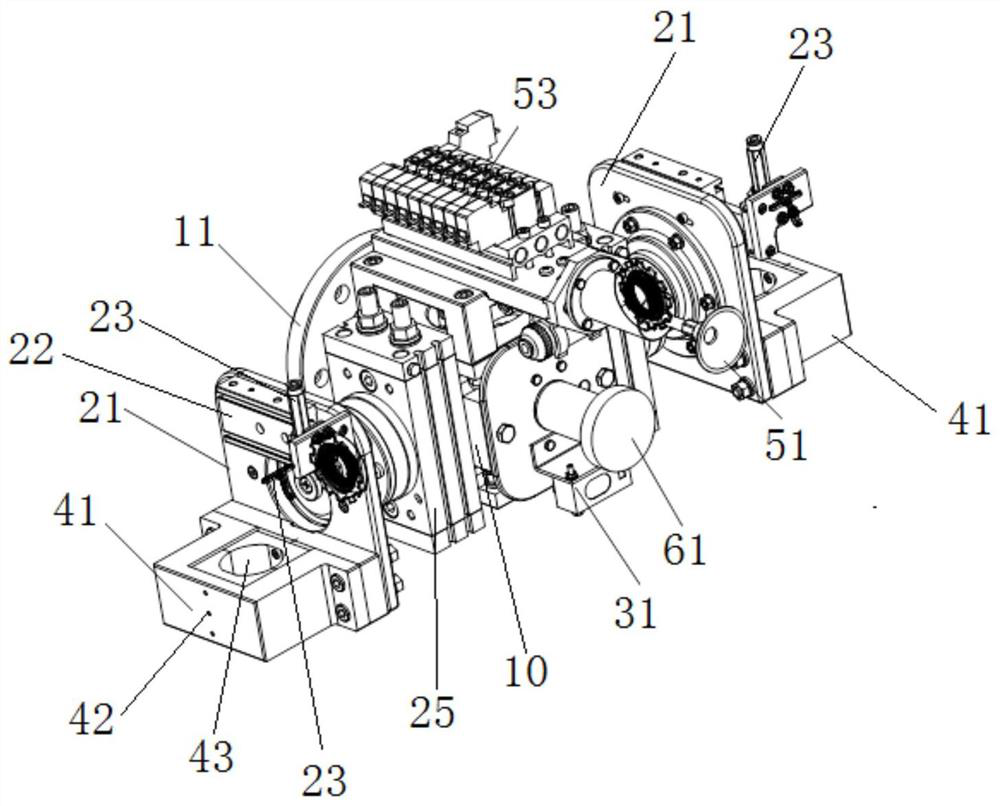

Refueling aids and refueling systems

ActiveCN112777554BRealize automatic refuelingSave human effortLiquid transferring devicesFuel tankElectrical and Electronics engineering

The invention relates to the technical field of refueling equipment, and discloses a refueling auxiliary device and a refueling system. The auxiliary refueling device of the present application includes a base body (10), a sensing part, a mounting part and an operating part, and the base body is used to be arranged on an external moving device so that the auxiliary refueling device can follow the movement of the external moving device; The position sensing part is installed on the base body, and the position sensing part is used to sense the position of the oil filling port of the fuel tank and is used to feed back the position signal of the oil filling port to the external moving device; the installation part is used to install the oil filling gun (20): The operation part is installed on the base body, the installation part is installed on the operation part, and the operation part is configured to be able to operate a refueling switch of the refueling gun installed on the installation part. The refueling auxiliary device provided by the present application can realize automatic refueling, and does not need to manually take and hold the refueling gun for refueling, so as to save manpower and reduce costs.

Owner:CHINA PETROLEUM & CHEM CORP +1

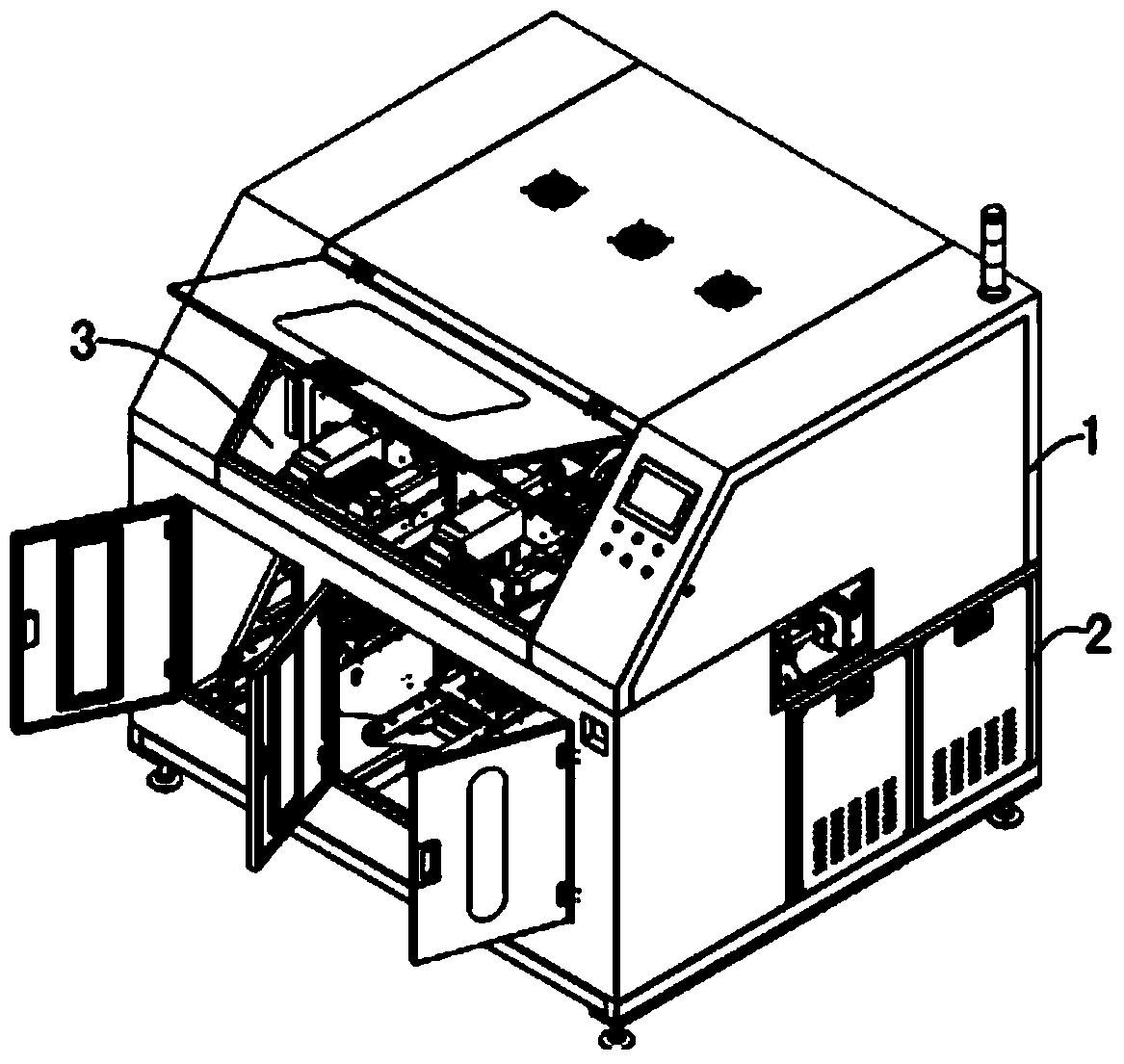

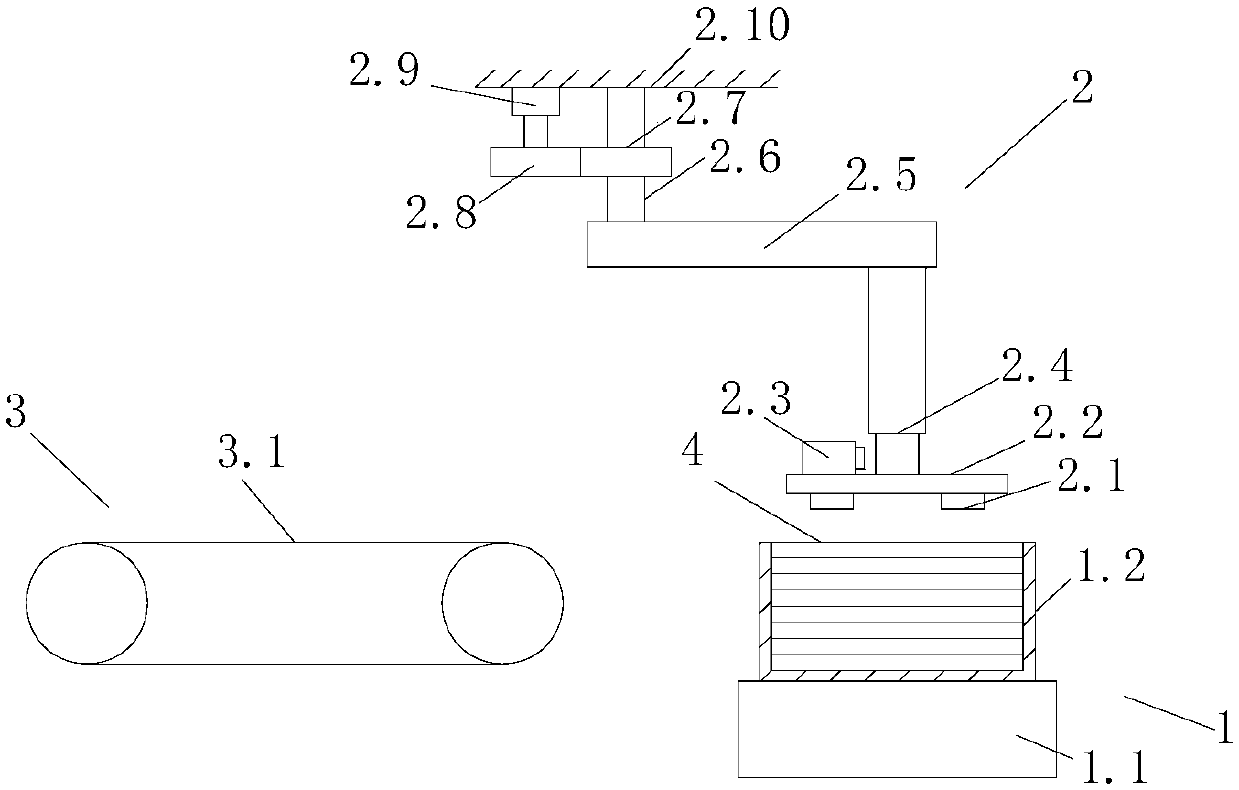

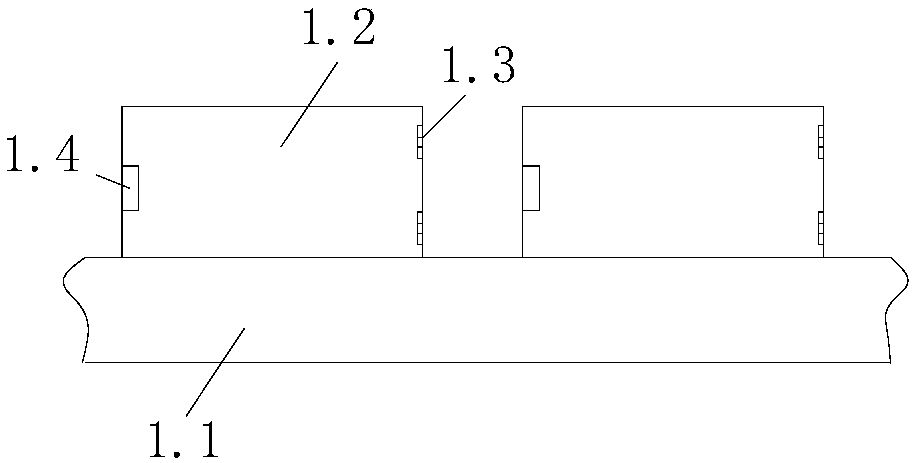

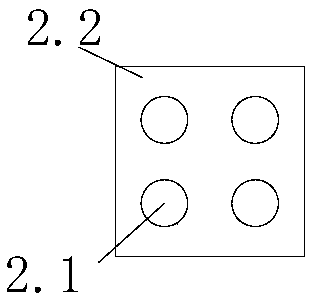

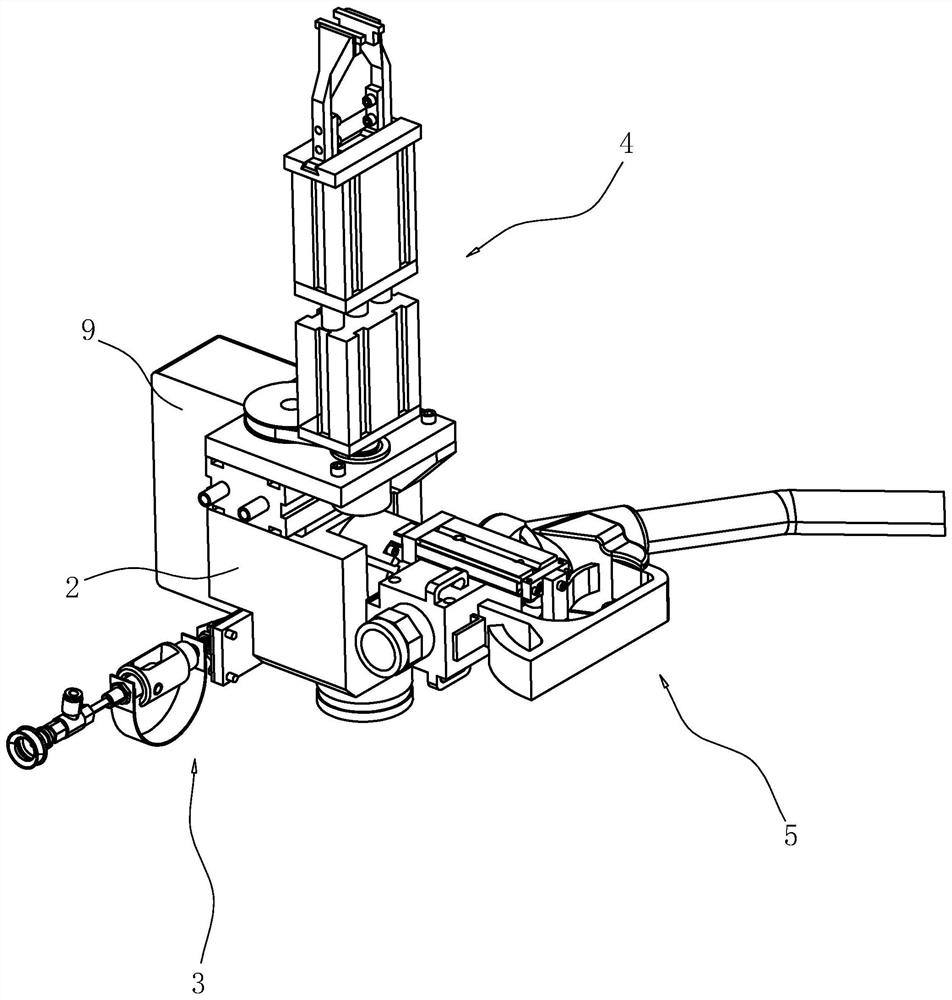

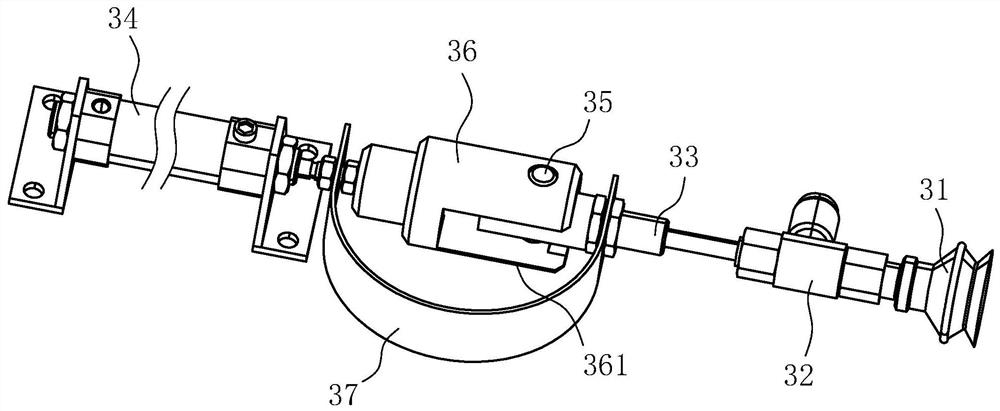

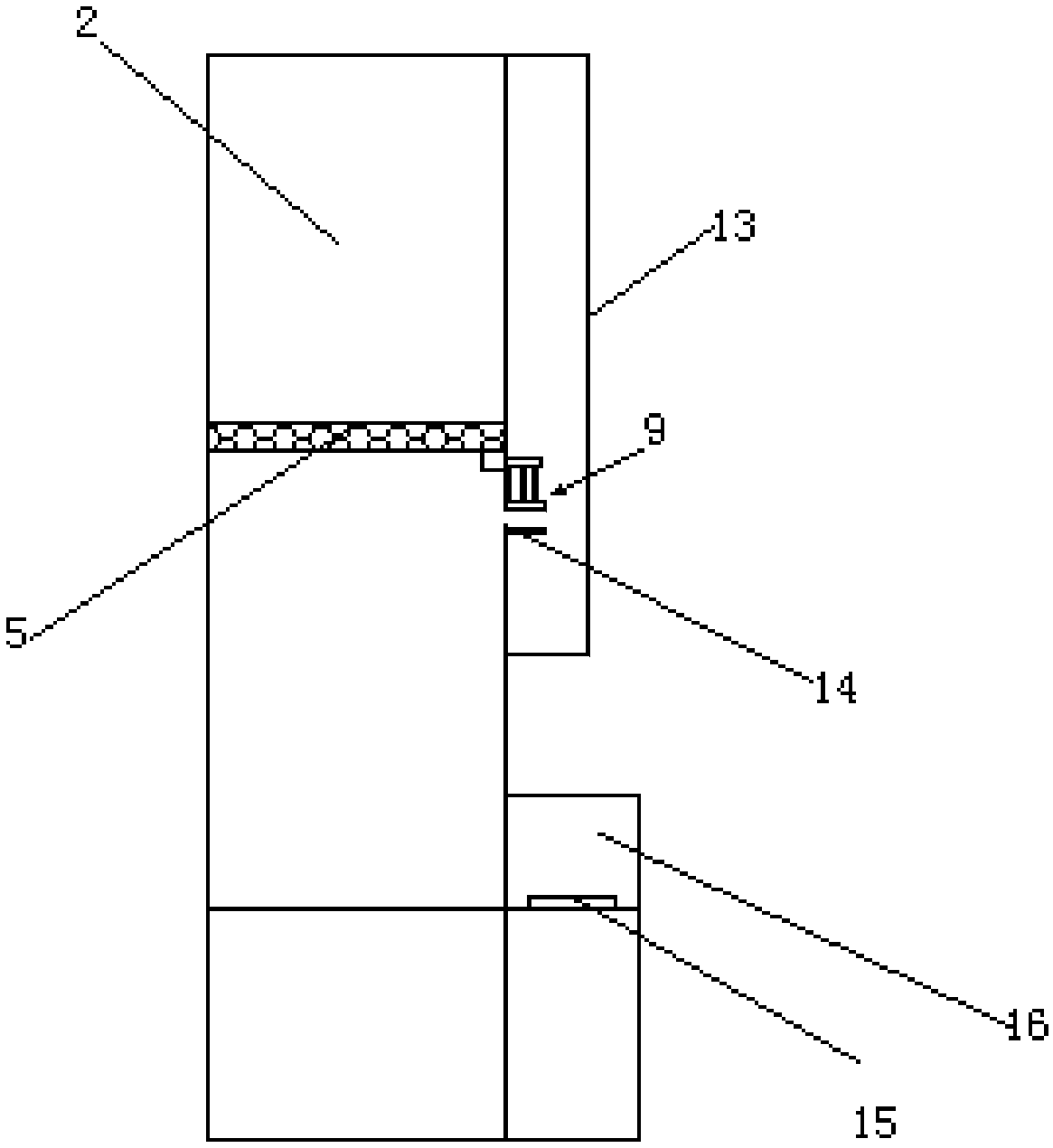

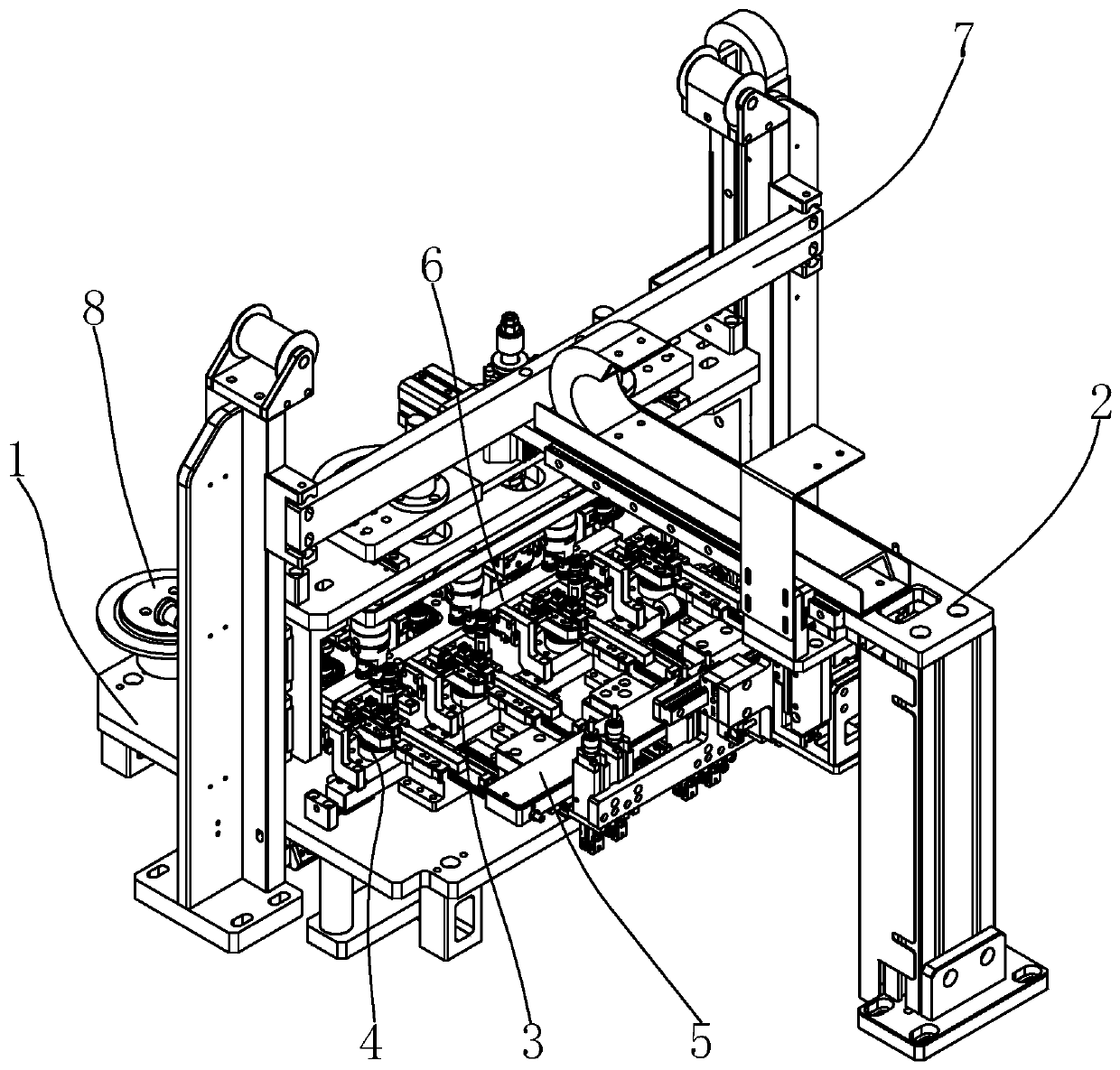

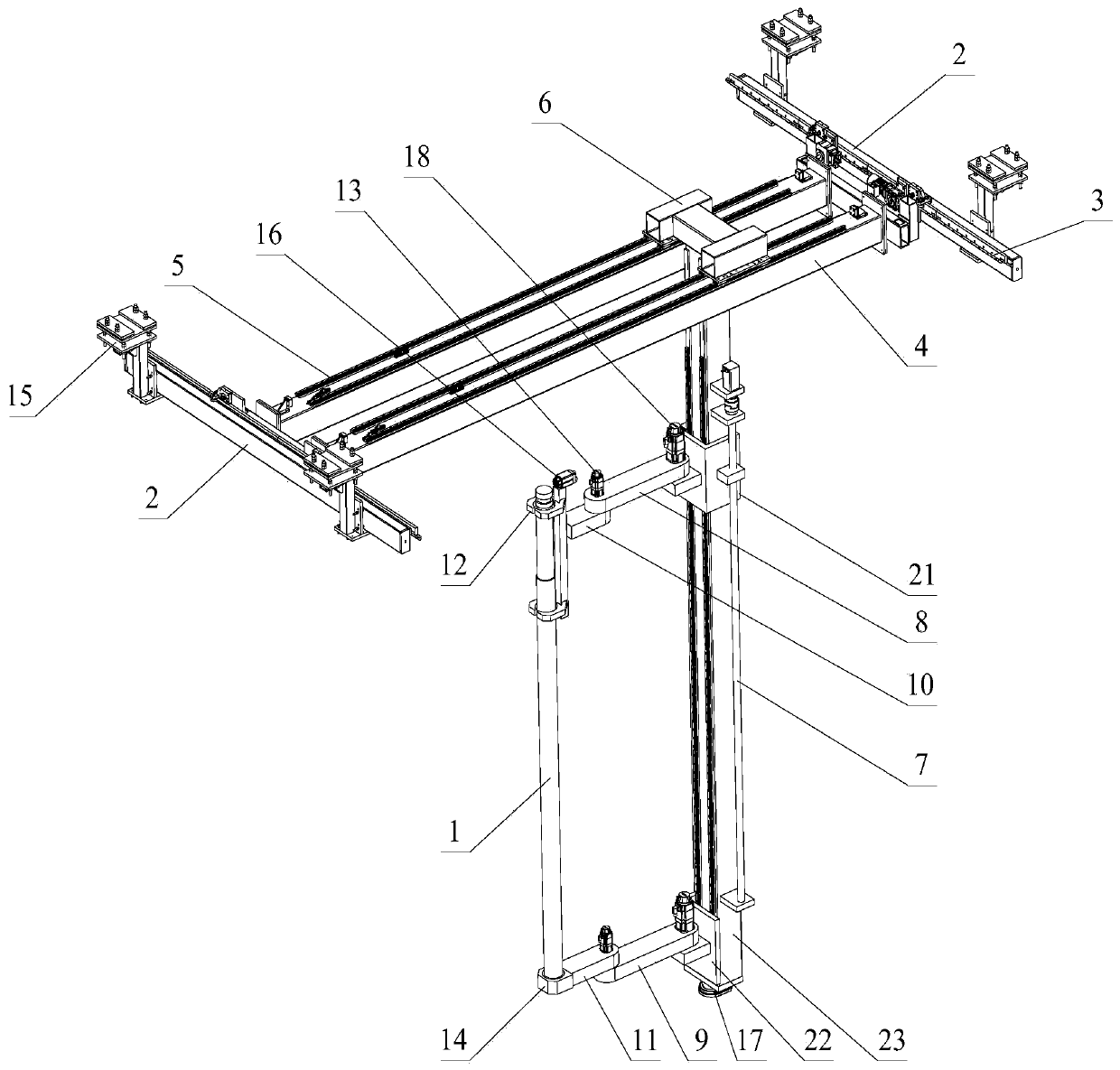

An automatic refueling device for optical fiber preform

ActiveCN108395094BRealize automatic refuelingEasy to useGlass making apparatusEngineeringMechanical engineering

The invention relates to an automatic material changing device for an optical fiber prefabricated rod. The automatic material changing device is characterized in that the automatic material changing device comprises a moving substrate, wherein the moving substrate is installed on a movement cross beam; the movement cross beam is connected with a fixed longitudinal beam through a longitudinal driving mechanism; a vertical rack is connected with the moving substrate and is respectively provided with an upper movement seat and a lower movement seat which are arranged at intervals; the upper movement seat and the lower movement seat are respectively provided with an upper mechanical arm and a lower mechanical arm; the front end of the upper mechanical arm and the front end of the lower mechanical arm are respectively correspondingly provided with an upper clamping jaw and a lower clamping jaw. The automatic material changing device has the following beneficial effects: 1: the processes ofautomatically fetching materials, operating and discharging can be finished, the use is convenient; 2: the automatic material changing device can be accurately connected with a material fetching pointand a discharging point so as to safely and reliably realize the automatic material changing of the prefabricated rod, work efficiency is improved, and accident hidden dangers are reduced; 3: a laseranticollision system can be provided with different safe distances and working time in each above stage so as to avoid a situation that the normal work of the system is affected duo to misjudgment, and therefore, system operation reliability is further improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

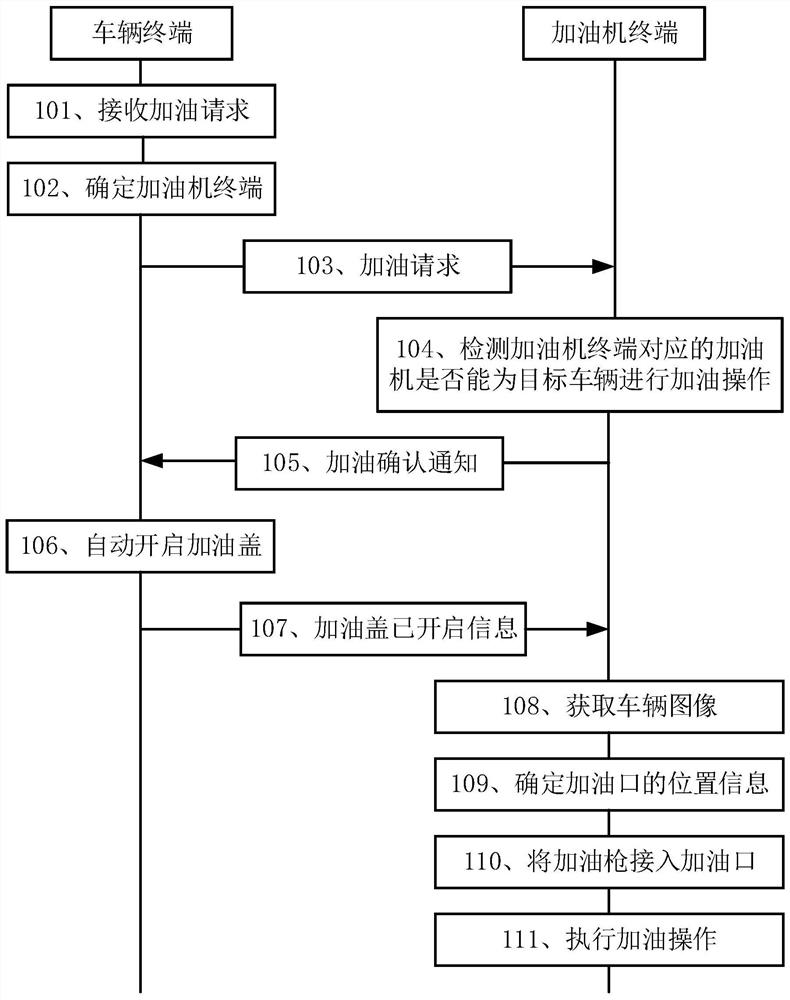

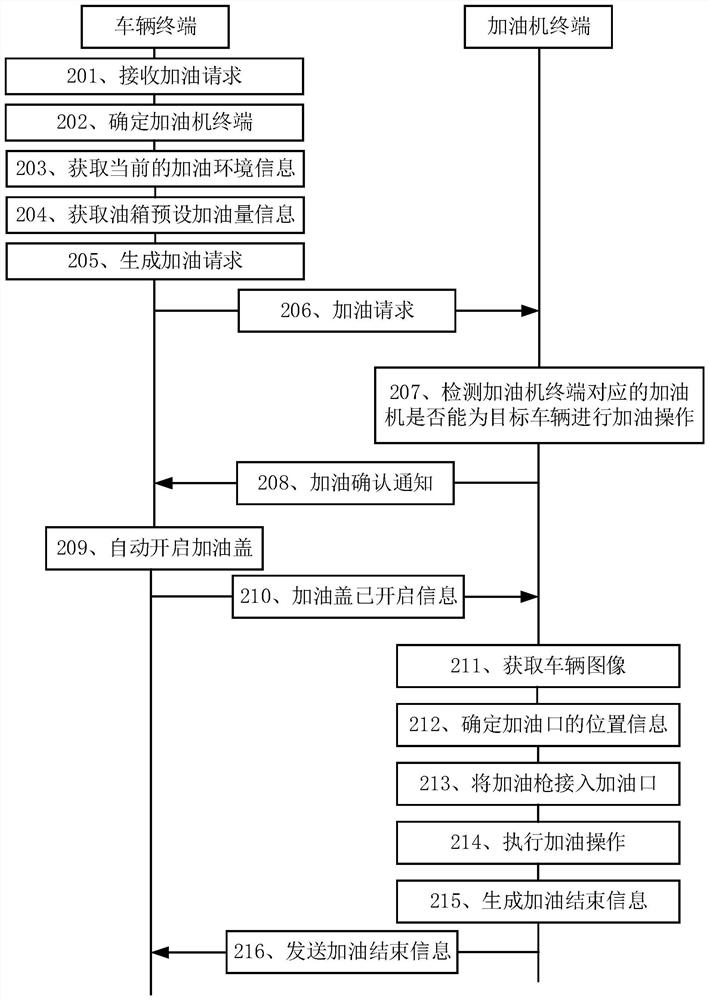

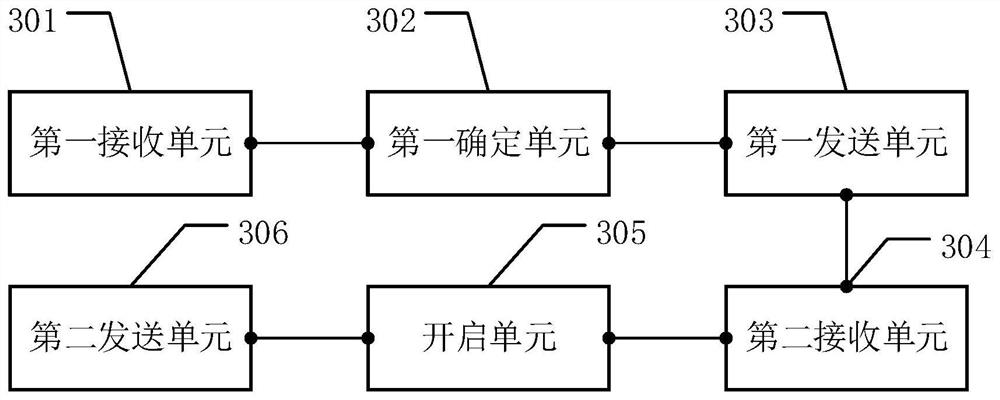

Vehicle refueling method and system

InactiveCN113816327ARealize automatic refuelingImprove experienceLiquid transferring devicesReliability engineeringReal-time computing

The embodiment of the invention discloses a vehicle refueling method and system. The method and system are used for automatically opening a refueling cover when a vehicle is refueled, so that the user experience is improved. The method comprises the steps that a vehicle terminal receives a refueling request; the vehicle terminal determines a refueling machine terminal according to the refueling request; the vehicle terminal sends the refueling request to the refueling machine terminal, wherein the refueling request is used for determining whether the refueling machine terminal can perform refueling operation or not; the vehicle terminal receives a refueling confirmation notification sent by the refueling machine terminal, wherein the refueling confirmation notification indicates that the refueling machine terminal can perform refueling operation; the vehicle terminal automatically opens the refueling cover according to the refueling confirmation notification; and the vehicle terminal generates and sends information that the refueling cover is opened to the refueling machine terminal.

Owner:深圳市修远文化创意有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com