Patents

Literature

71results about How to "Sustainable work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

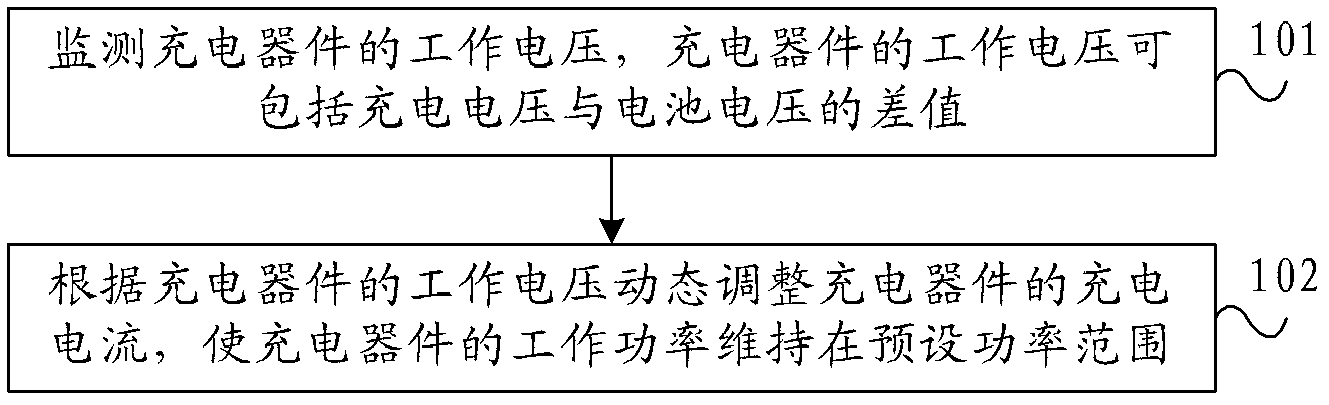

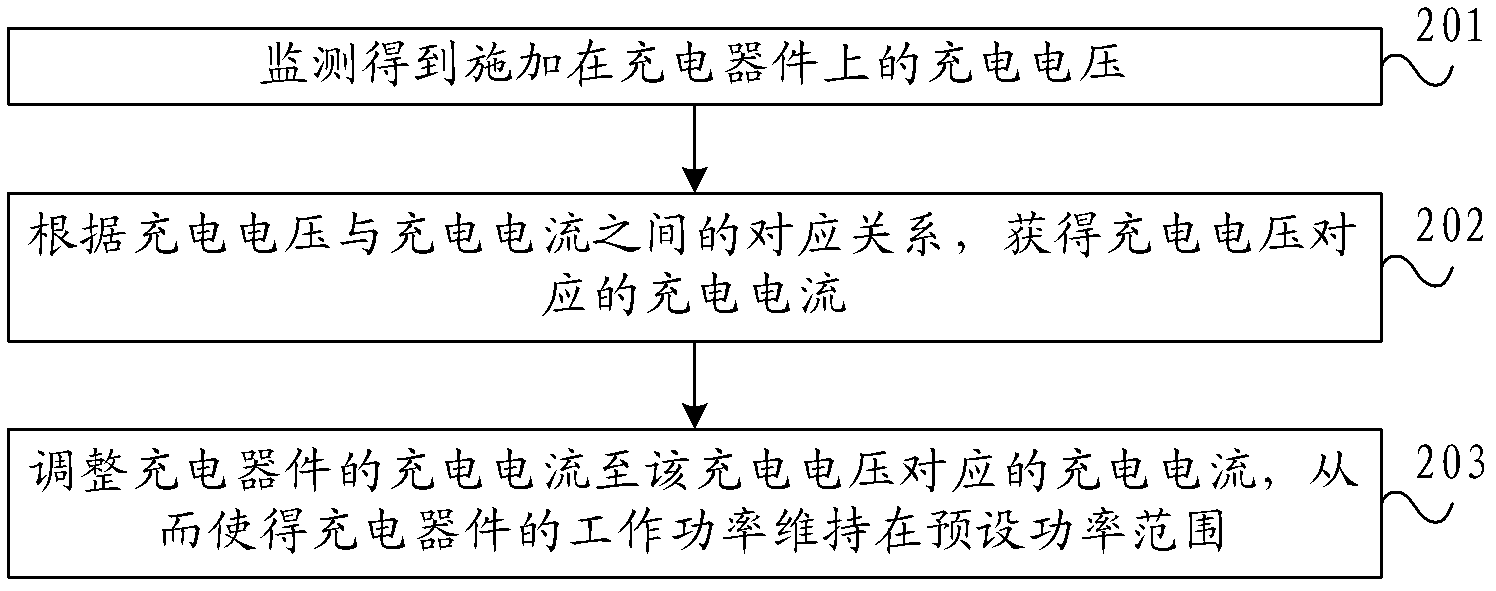

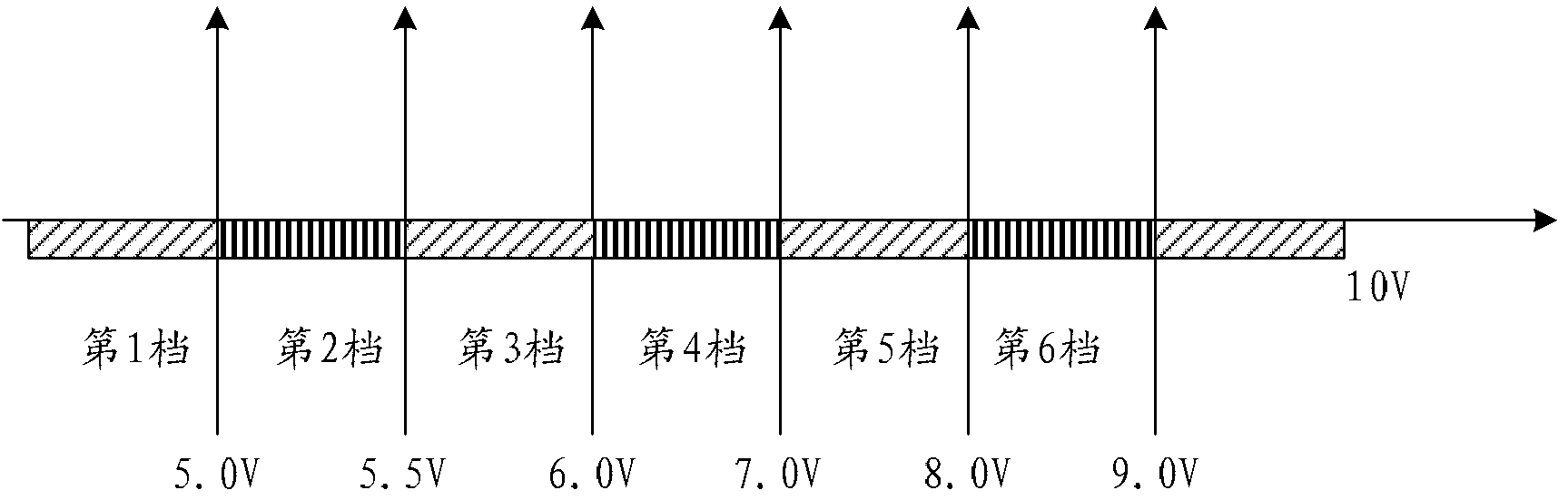

Battery charging control method and device and charging system and portable device.

InactiveCN102931693AAvoid damageSustainable workElectric powerBattery load switchingBattery chargeCharge current

The invention discloses a charging control method for adjusting a charging current of a charging device, including monitoring a working voltage of the charging device, wherein the working voltage includes a voltage difference between a charging voltage and a battery voltage; adjusting the charging current of the charging device dynamically according to the working voltage of the charging device to maintain a working power of the charging device within a predetermined power range.The charging control device comprises a voltage detection module and a current adjusting module. The charging system comprises a charging device and the charging control device.

Owner:MEDIATEK SINGAPORE PTE LTD SINGAPORE

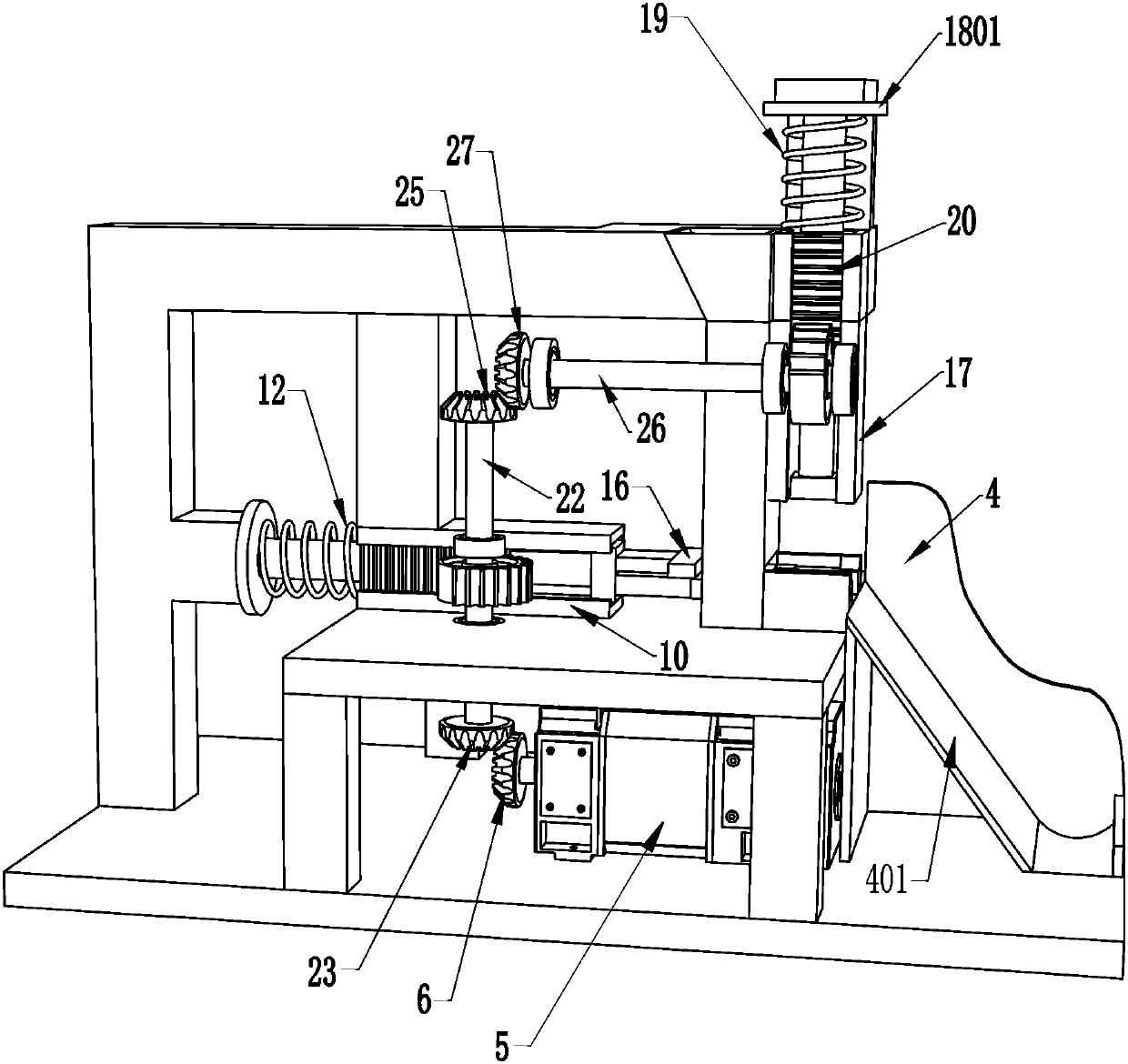

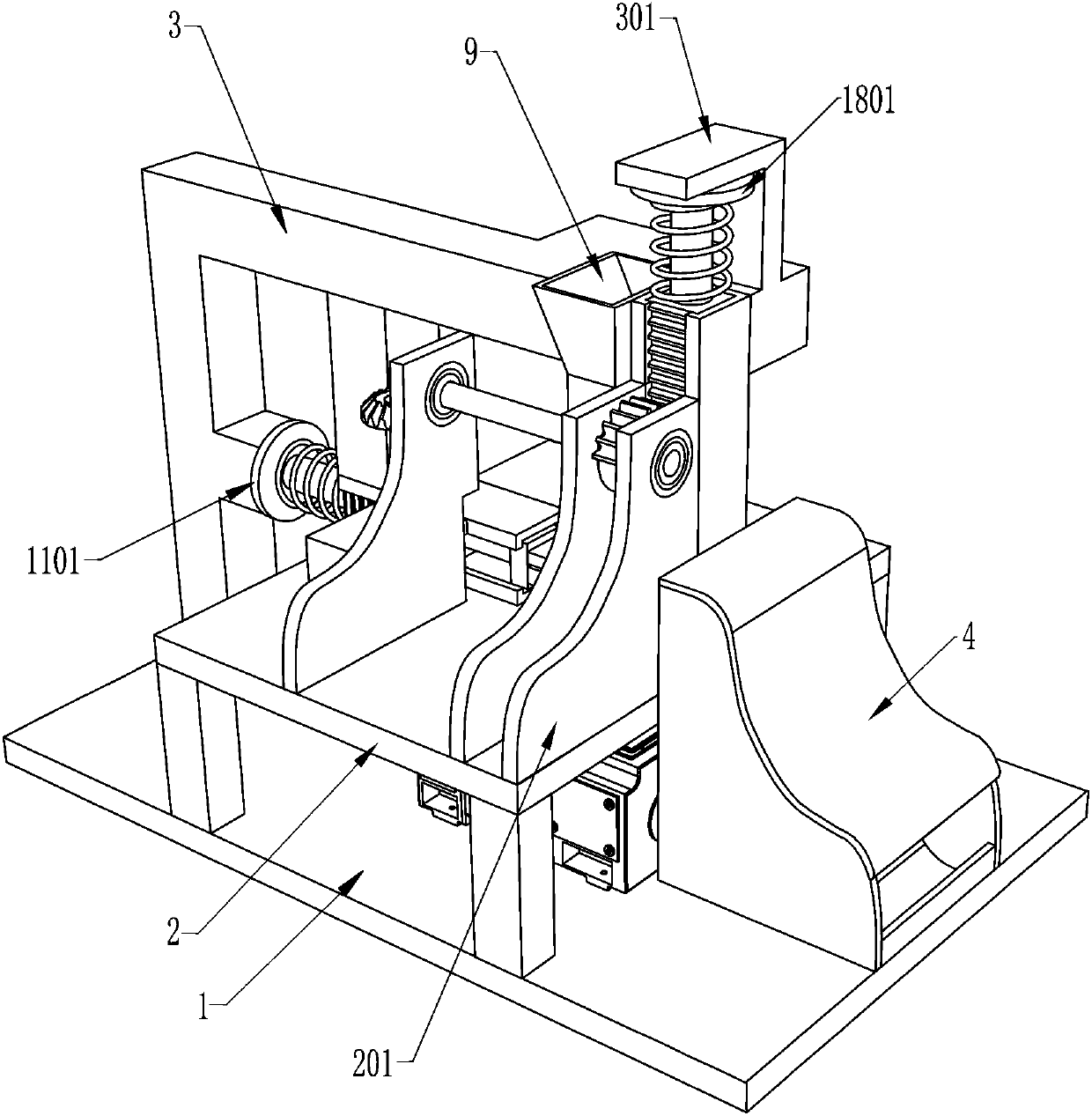

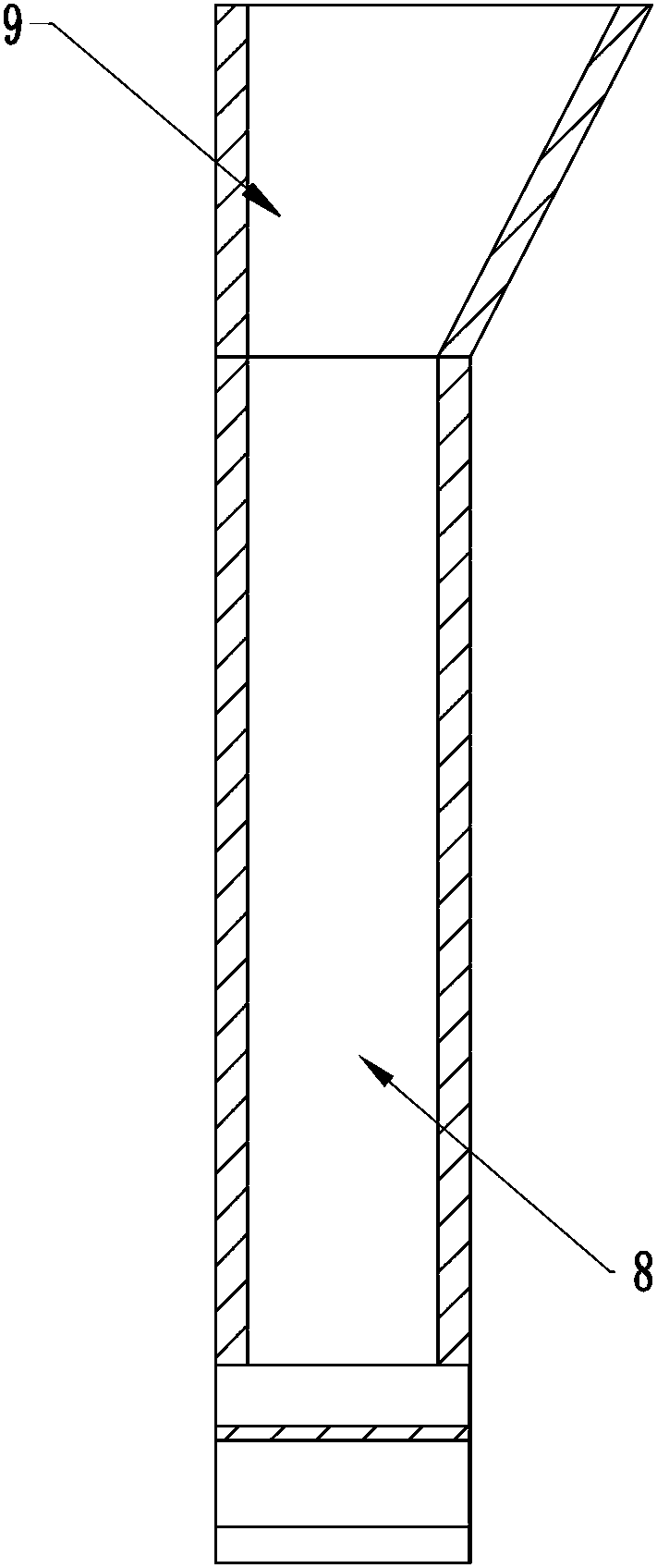

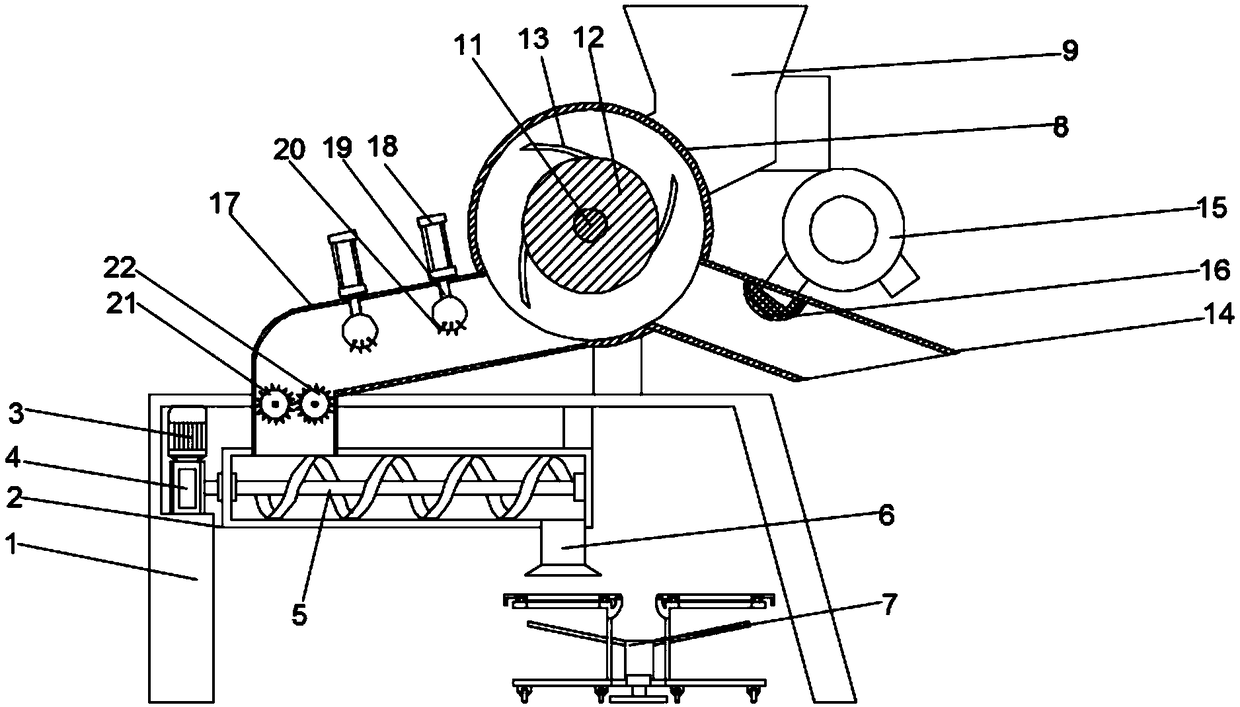

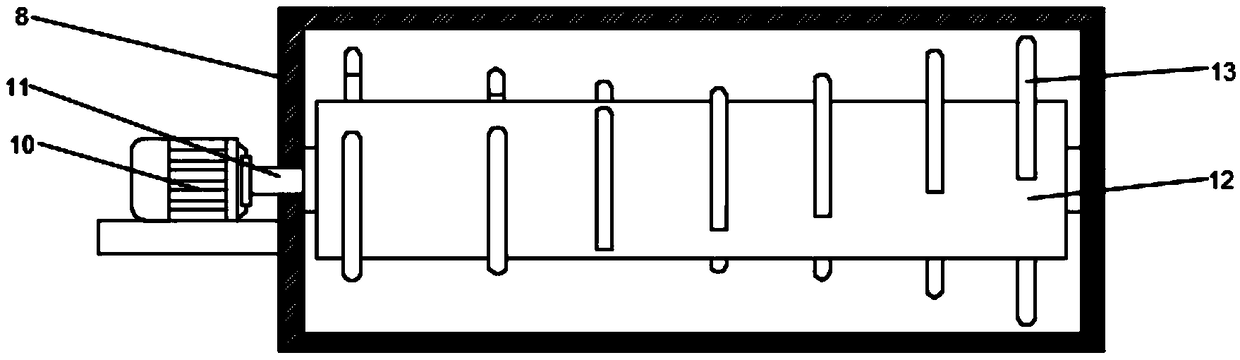

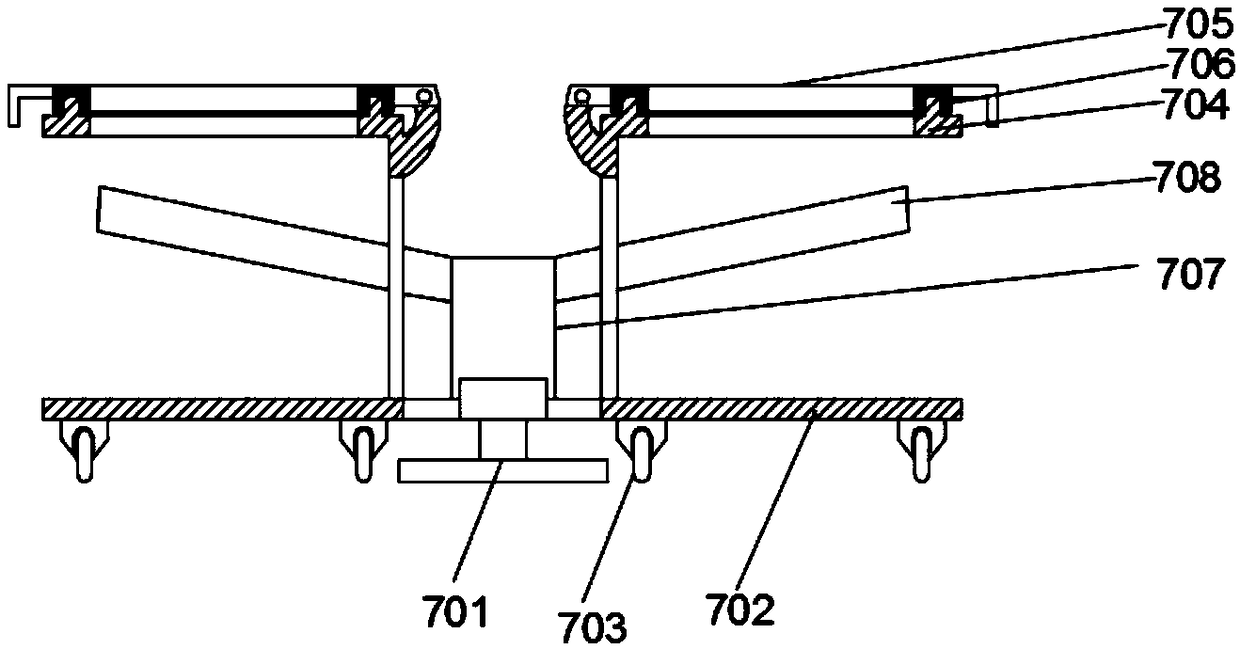

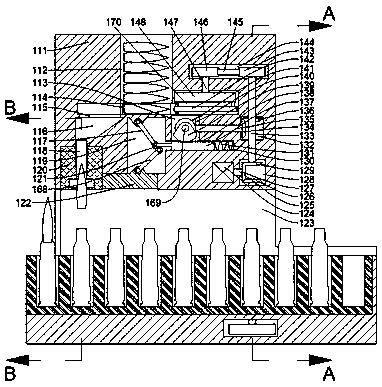

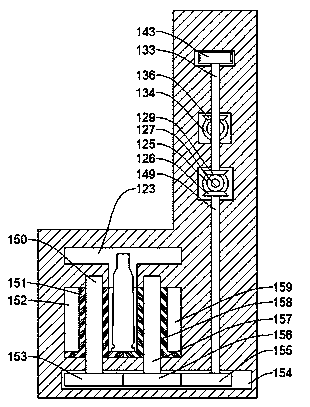

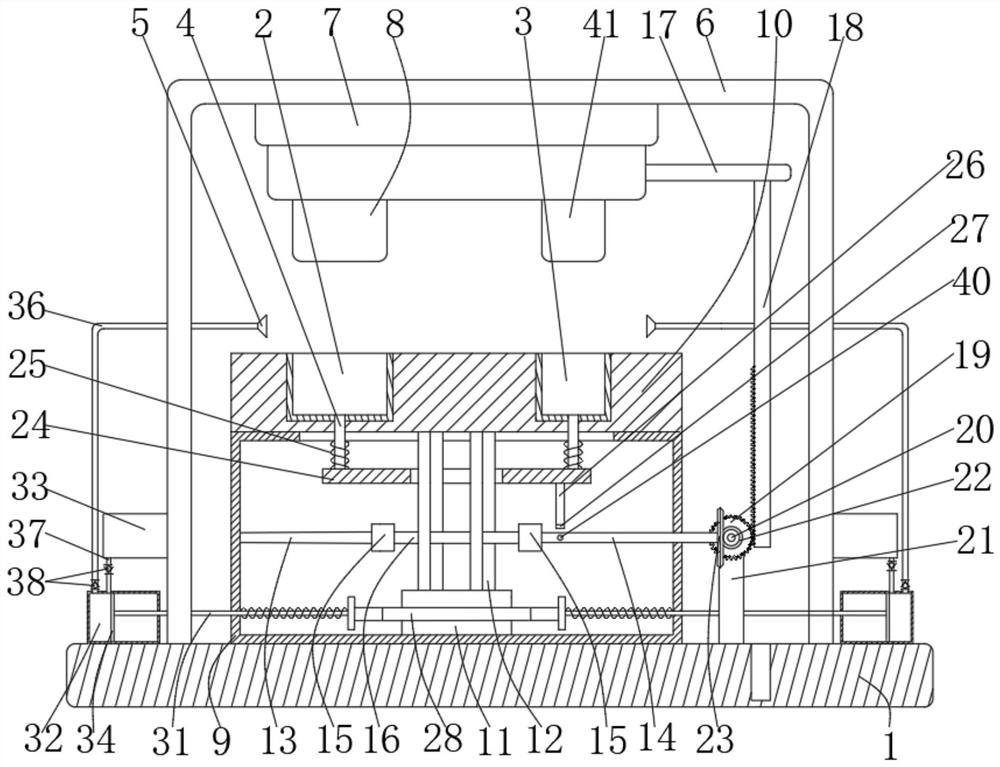

Self-discharging type stamping and forming all-in-one machine

InactiveCN111001720ARealize automatic feeding processSustainable workMetal-working feeding devicesPositioning devicesPunchingElectric machinery

The invention relates to a stamping and forming all-in-one machine, in particular to a self-discharging type stamping and forming all-in-one machine. The self-discharging type stamping and forming all-in-one machine can achieve automatic feeding, can continuously work, can save time, is easy and convenient to operate and can also avoid stamping accidents. The self-discharging type stamping and forming all-in-one machine comprises a chassis, a rack, an arc-shaped plate, a supporting column, an L-shaped block, a motor and the like. The rack, the supporting column and the motor are fixedly arranged on the chassis, the rack is located on the right side of the supporting column, and the motor is located below the rack. According to the invention, a stamped workpiece can be pushed out through apushing mechanism, and the other workpiece in a discharging frame can be pushed into a punching frame, so that people can take down the punched workpiece, the workpiece does not need to be placed manually, automatic feeding and continuous work can be achieved, a large amount of time is saved, operation is easy and convenient, and punching accidents can be avoided.

Owner:申继州

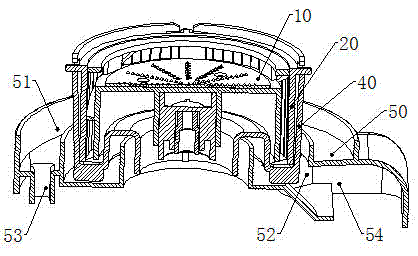

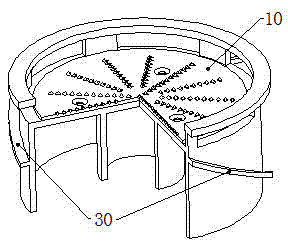

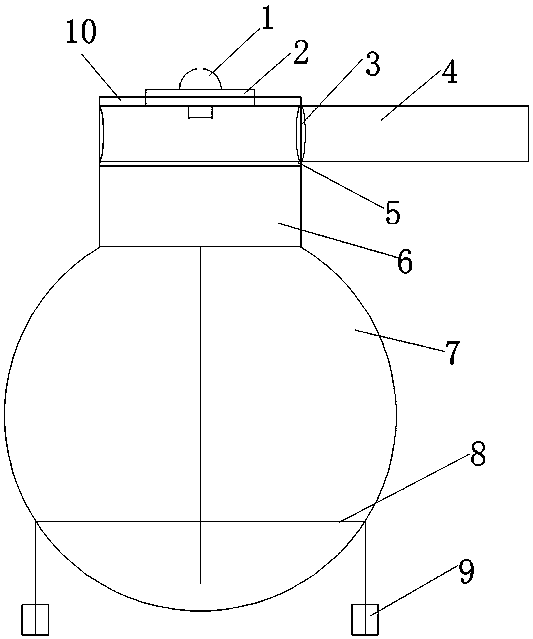

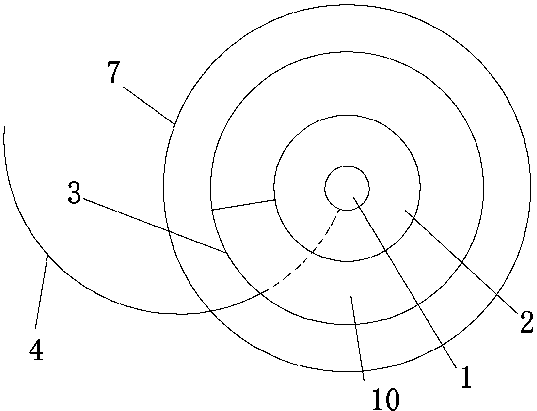

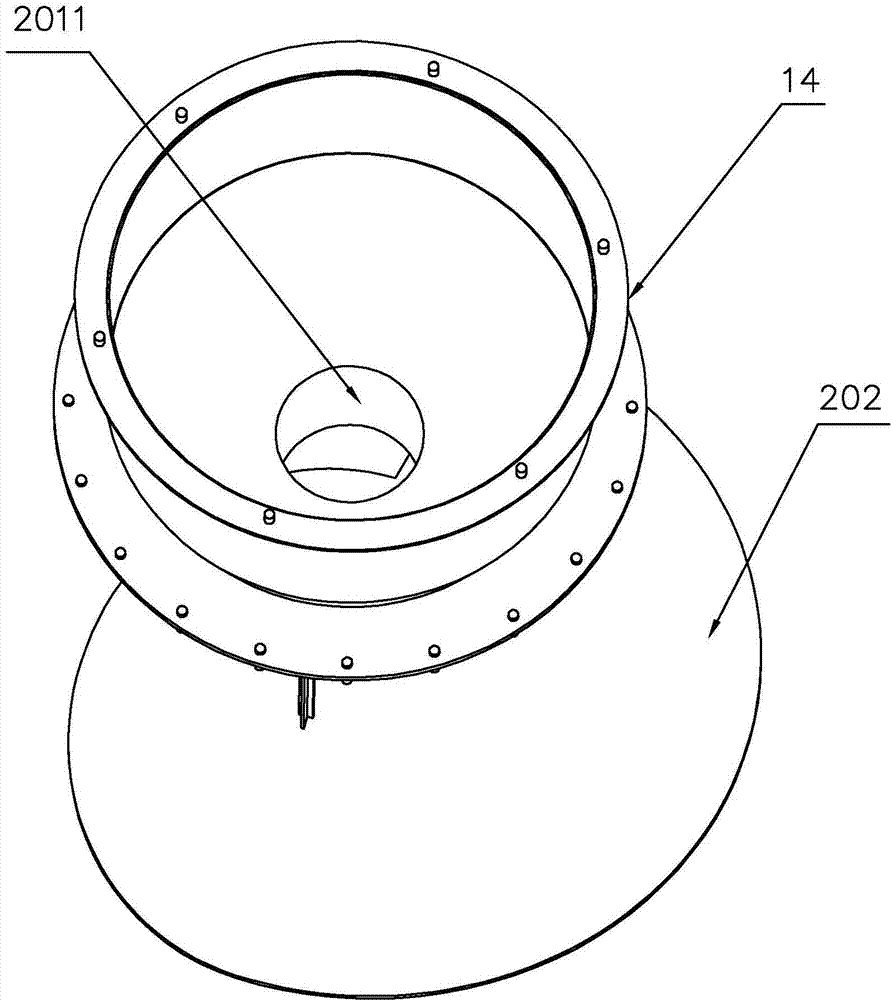

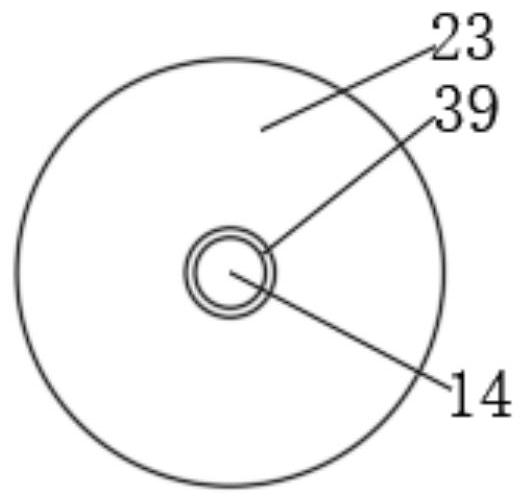

Juice extraction structure and juice extraction machine adopting same

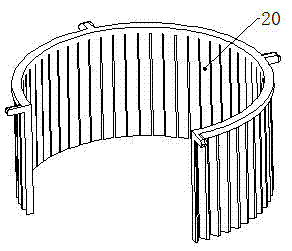

The invention relates to the technical field of domestic machinery for vegetable and fruit juice extraction processing, in particular to a juice extraction structure and a juice extraction machine adopting the juice extraction structure. The juice extraction structure comprises a cutter head frame and a dreg separating frame sheathed and arranged outside the cutter head frame. The juice extraction structure is characterized in that a dreg discharge structure realizing the relative movement with the dreg separation frame is arranged between the cutter head frame and the dreg separation frame, and the rotating speed difference between the dreg discharge structure and the dreg separation frame is 5 to 45rpm. The dreg discharge structure realizing the relative movement with the dreg separation frame is arranged between the cutter head frame and the dreg separation frame of the juice extraction structure, so the juice throwing and the continuous dreg discharge can be continuously realized in the work process of the juice extraction structure, the influence on the processing of the machine on the materials caused by the fruit dreg accumulation and storage is avoided, the fruit dreg cleaning after the machine halt is not needed, the vibration and the noise generated in the work process of the machine caused by the fruit dreg accumulation and storage distribution nonuniformity are also greatly reduced, the juice extraction structure can realize the continuous work, the processing efficiency and the juice yield are high, and in addition, the cleaning is simple and convenient. The juice extraction machine adopting the juice extraction structure has the advantages that the fruit dreg cleaning after the machine halt is not needed, the continuous work is realized, and the processing efficiency and the juice yield are high.

Owner:MIDEA GRP CO LTD

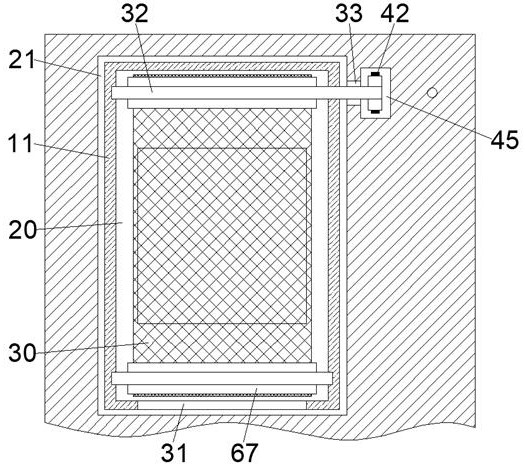

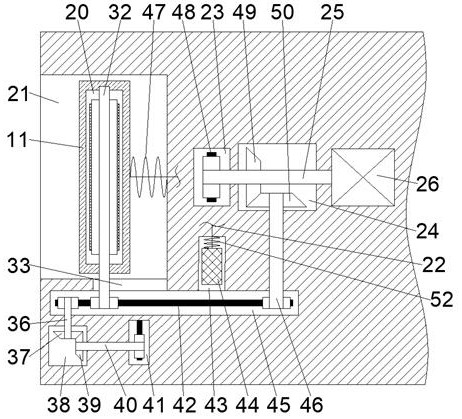

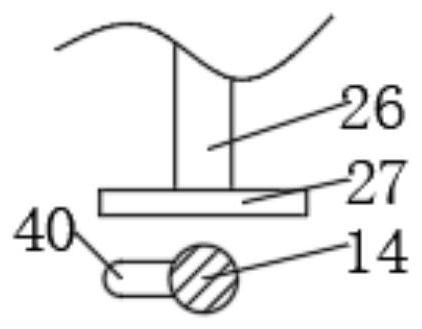

Tunnel geological advanced prediction radar antenna adaptive position-adjusting device

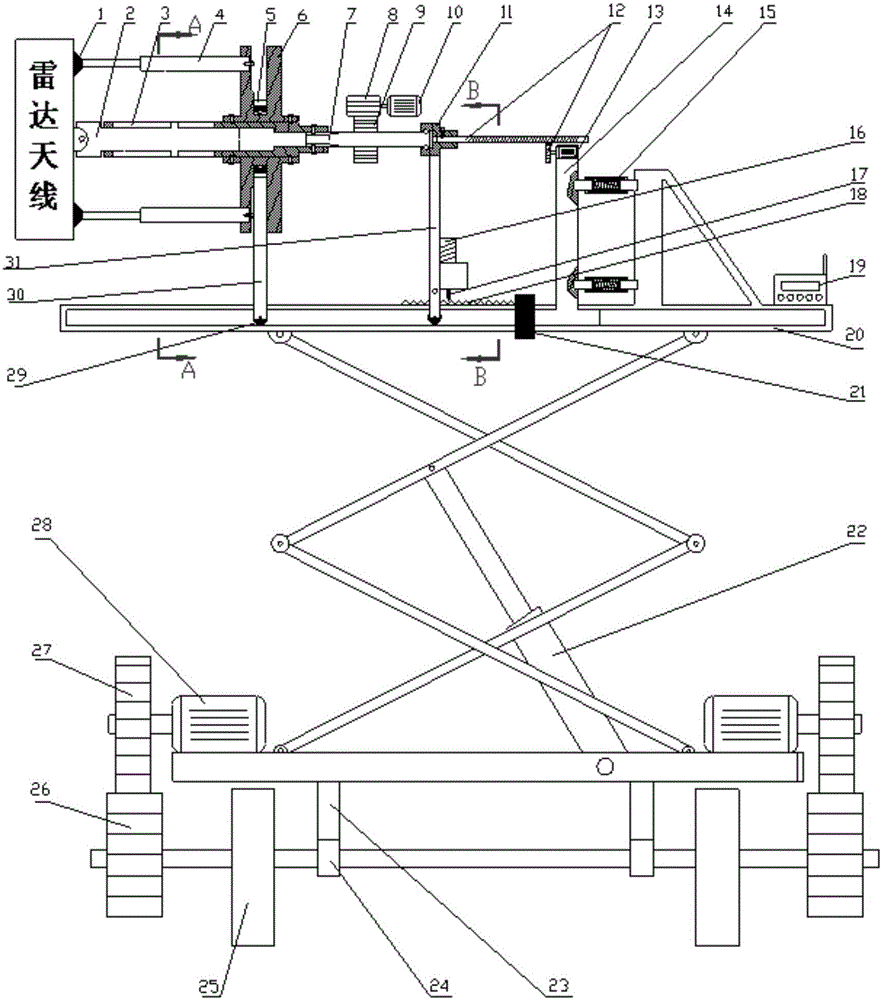

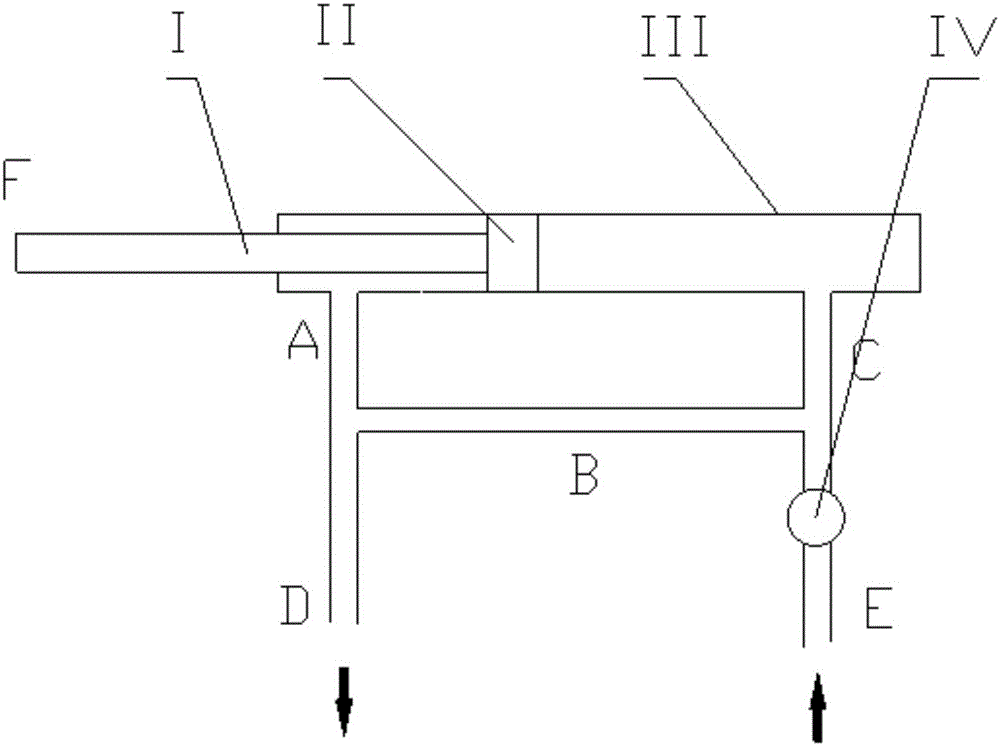

InactiveCN105098313ARegulating pressureIncrease contactAntenna supports/mountingsRadio wave reradiation/reflectionRadarEngineering

The invention discloses a tunnel geological advanced prediction radar antenna adaptive position-adjusting device comprising an adaptive part and a motion part. The adaptive part is mainly used to automatically control the pressure between a radar antenna and a working face. The motion part is composed of a walking device and an elevator, and is mainly used to control up-and-down and left-and-right motion of the adaptive part. By adopting the device, the pressure between a radar antenna and the working face of a tunnel can be automatically kept at a stable value, and the pressure value neither changes because of the bumpy working face of the tunnel nor changes as the distance between a measuring vehicle and the working face of the tunnel changes. The radar antenna can move freely on the working face in the horizontal and vertical directions, and the whole area of the working face can be measured.

Owner:CHANGAN UNIV

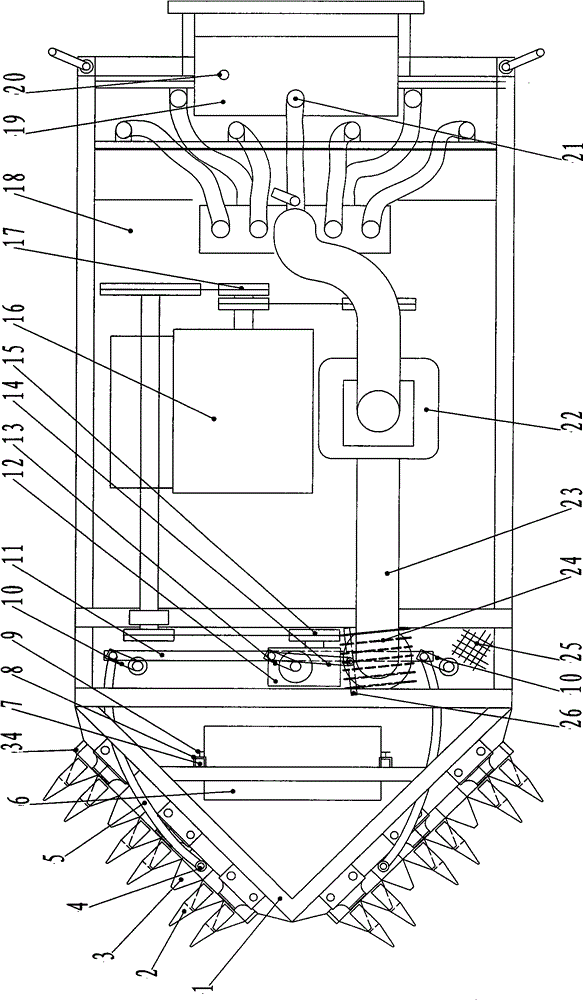

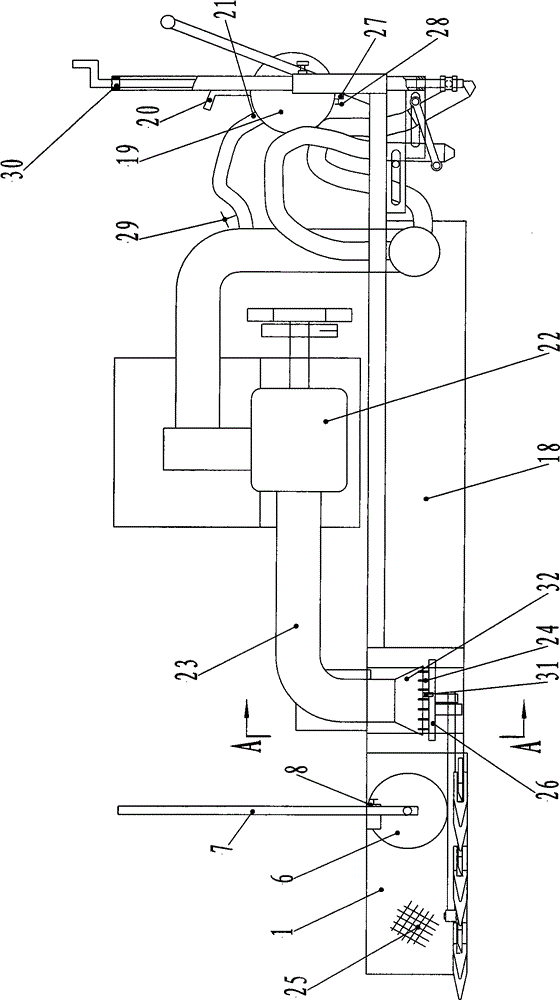

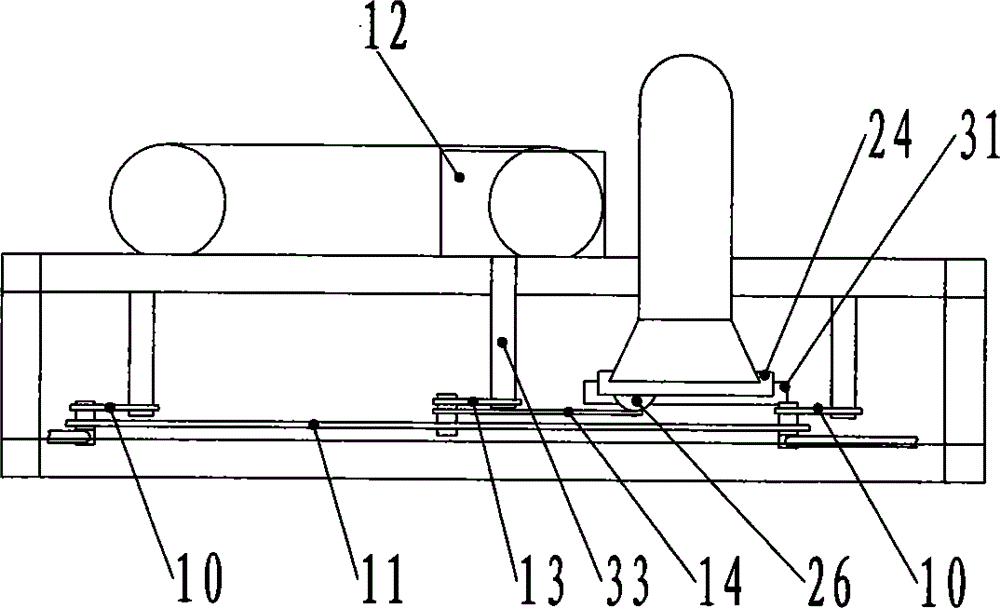

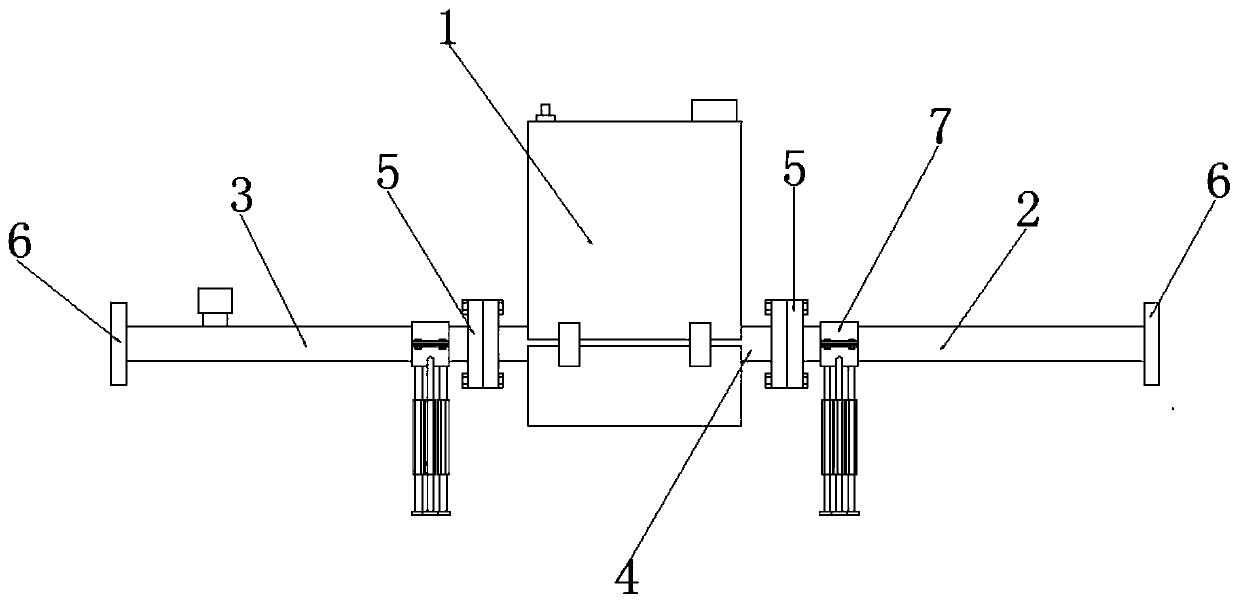

Cutting rod lotus root digging machine

InactiveCN104782313AImprove work efficiencySustainable workDigger harvestersAgricultural engineeringKnife blades

The invention discloses a cutting rod lotus root digging machine. The cutting rod lotus root digging machine comprises a buoyancy box, and an engine and a water pump are arranged on the buoyancy box. Symmetrical triangular cutting knife rests are arranged at the front end of the buoyancy box, a plurality of linkage blades are arranged on the two side edges of each cutting knife rest, protective teeth are arranged at the front ends of the blades, and the blades move to achieve cutting with the protective teeth. A driving device used for driving the blades to slide is arranged between the triangular cutting knife rests and the buoyancy box, a water inlet of the water pump is arranged beside the driving device, adjusting supporting float bowls are arranged at the middle positions of the cutting knife rests, and a balance water tank is arranged at the rear end of the buoyancy box. According to the lotus root digging machine, stems and leaves of lotus roots are removed first before the lotus roots are dug, removing the stems and leaves and digging the lotus roots can be conducted at the same time, the operating efficiency of harvesting the lotus roots is improved, the lotus roots of more than 200 kilograms can be dug per hour, the lotus roots of three mu can be harvested every day, and the cutting rod lotus root digging machine is suitable for ponds of different water depths.

Owner:刘万成

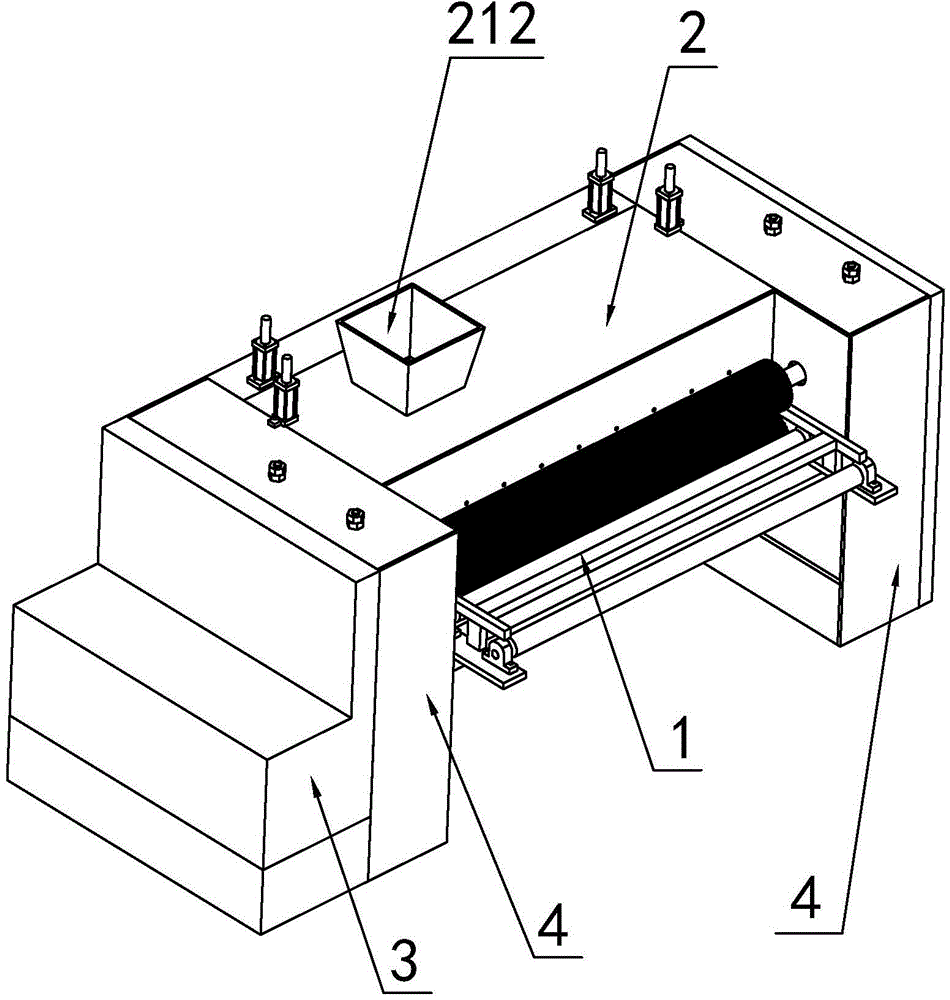

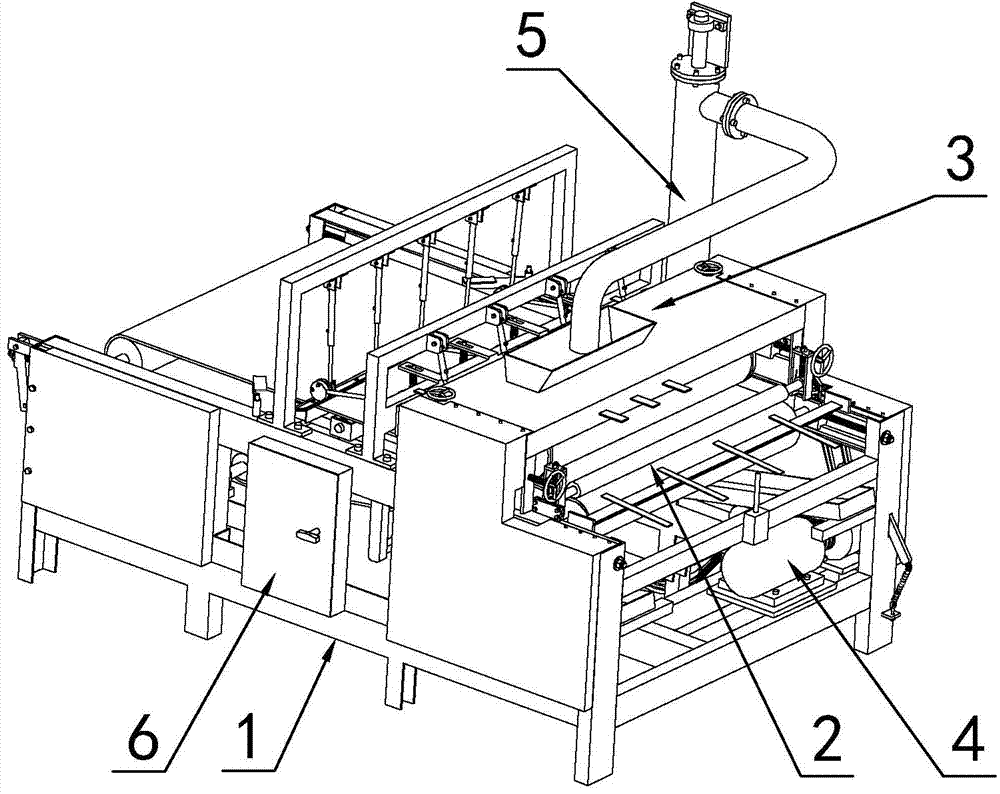

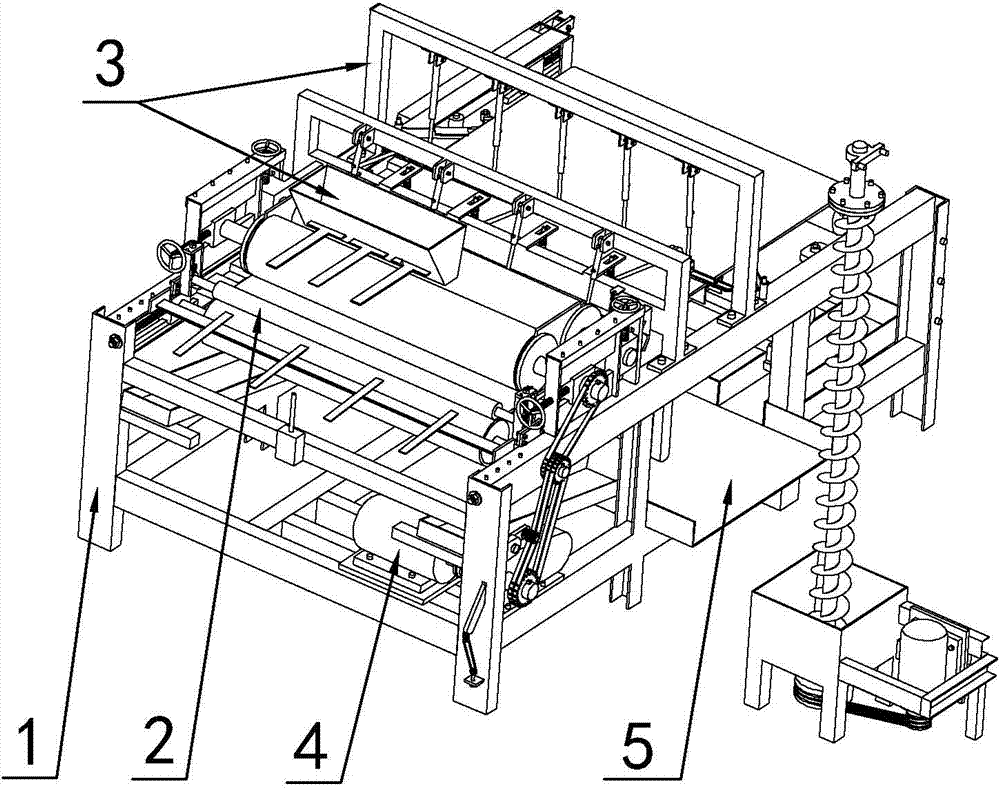

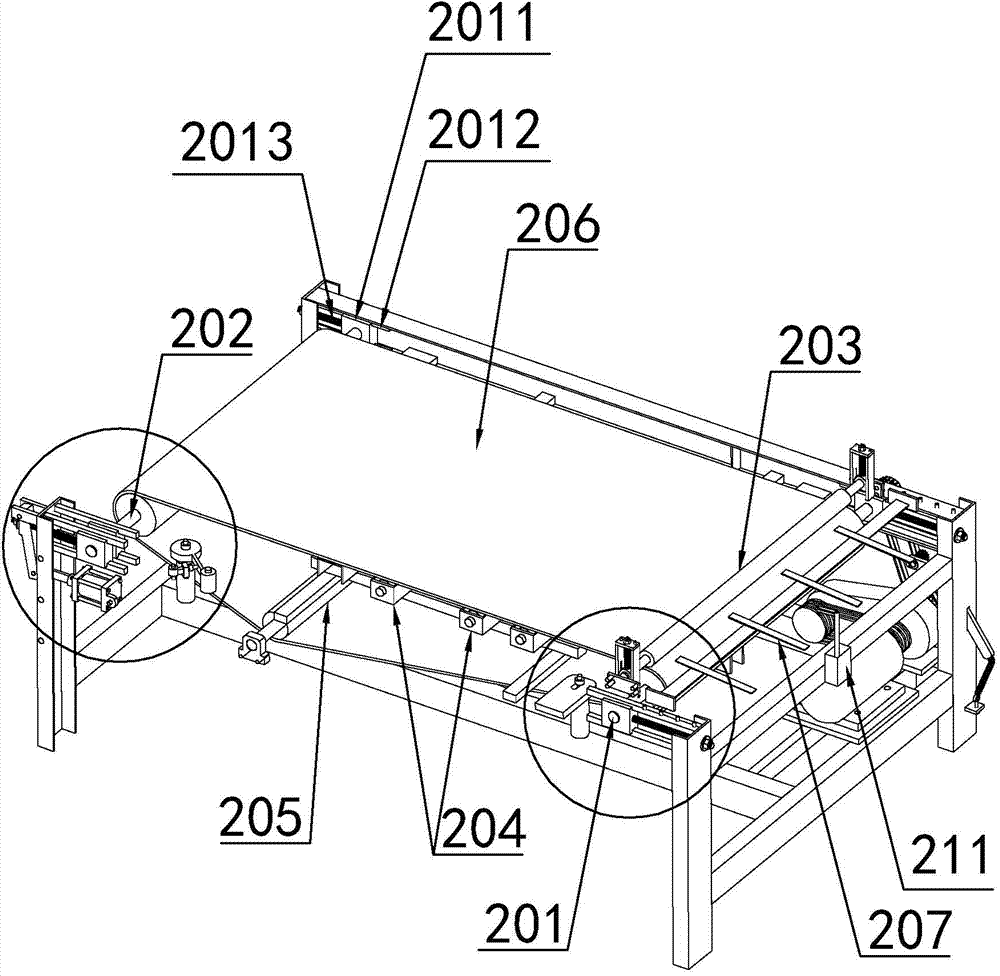

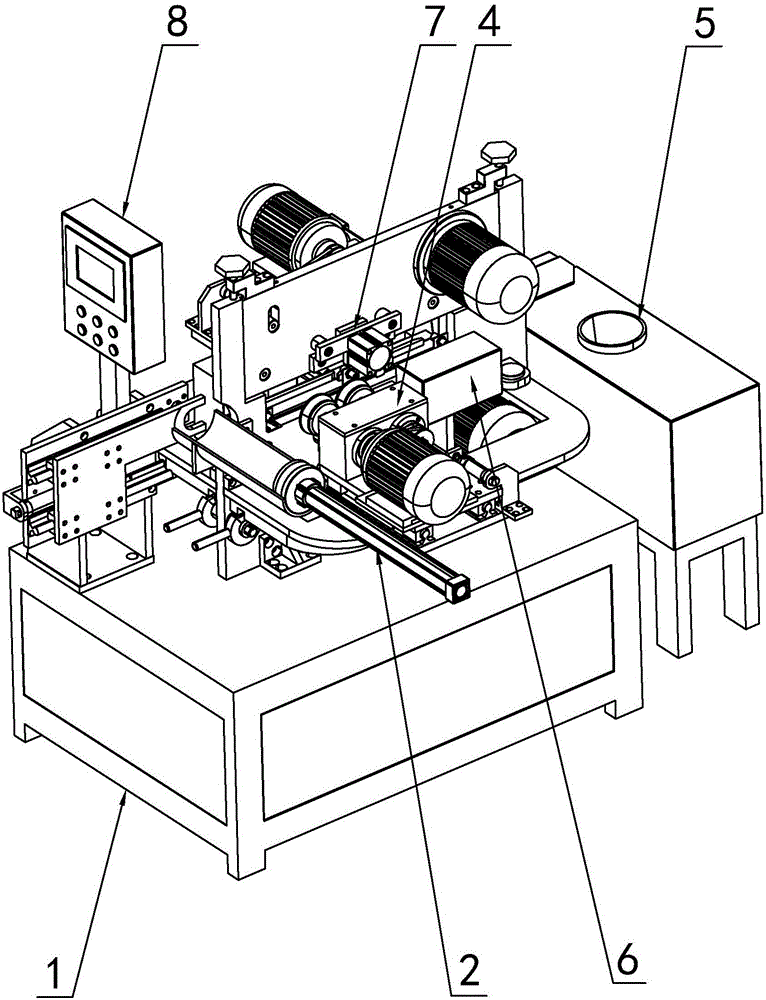

Novel and efficient four-side putty applying machine for plates

ActiveCN104858099AImprove efficiencyQuality improvementLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention discloses a novel and efficient four-side putty applying machine for plates. The novel and efficient four-side putty applying machine comprises a conveying mechanism, a coating and scrapping mechanism, a power mechanism and a rack, wherein the conveying mechanism comprises conveying rolls, supporting rolls and a protection framework; the coating and scrapping mechanism is arranged on one side of the conveying mechanism; the coating and scrapping mechanism comprises a plate feeding port, a putty tank, a putty applying roll, a stirring roll, tank inner scrapping blades and a plate discharging port; the putty tank mainly comprises putty baffles, a hopper and a collecting opening; an upper scrapping blade and a lower scrapping blade are arranged at the plate discharging port; a knife clip is arranged on one sides of the upper scrapping blade and the lower scrapping blade; an air cylinder is arranged at the top of the upper scrapping blade; the power mechanism comprises a motor, a speed reducer and a gear. The novel and efficient four-side putty applying machine for plates provided by the invention realizes the automatic plate putty applying, is time-saving, labor-saving, high in efficiency, good in quality, leak-free in putty and good in working environment of workers.

Owner:孟凡科

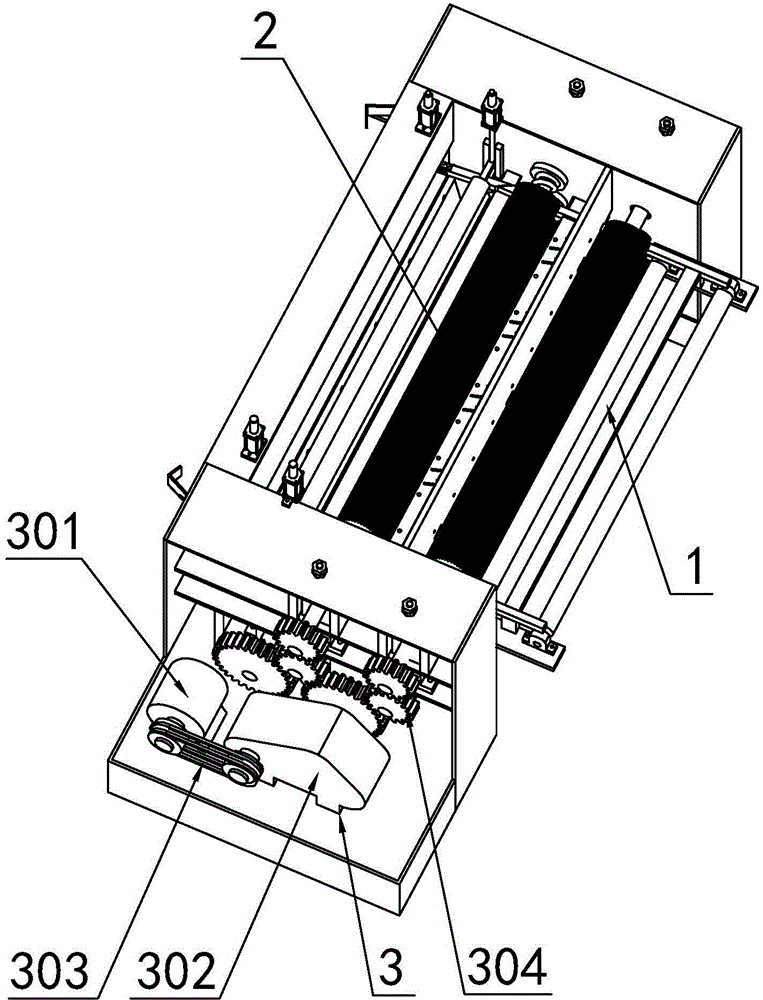

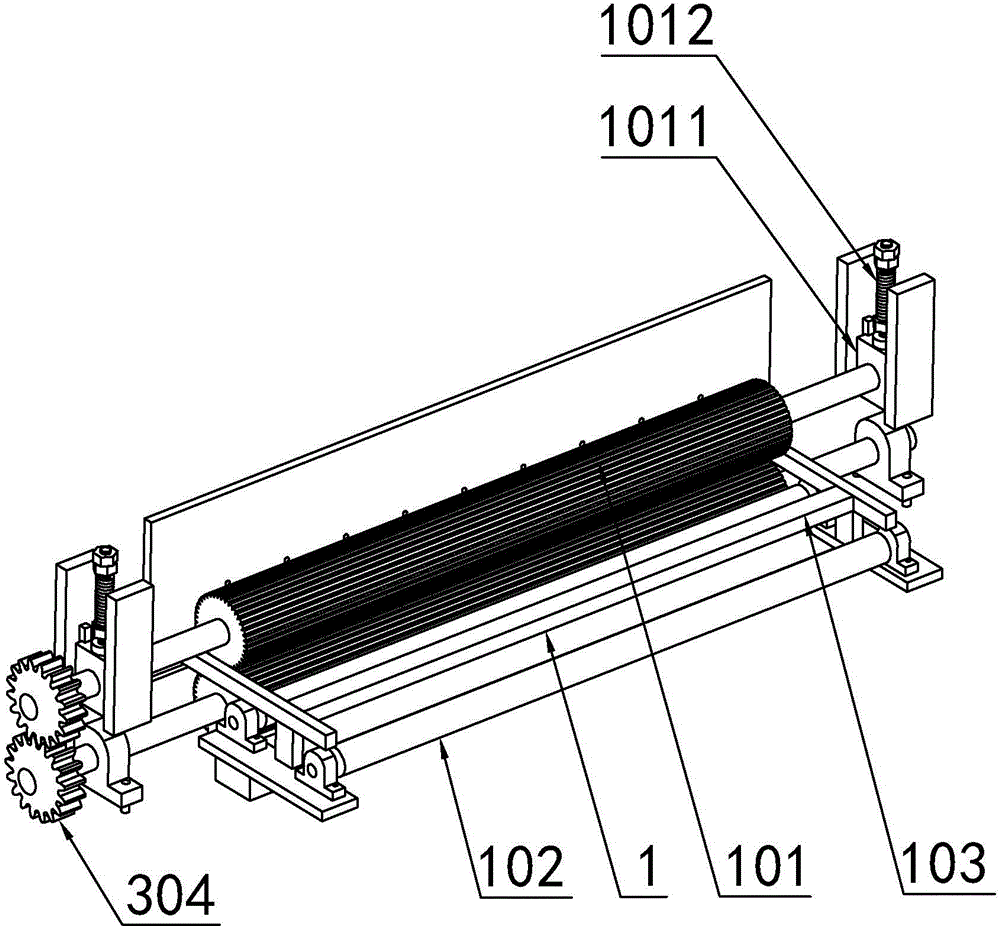

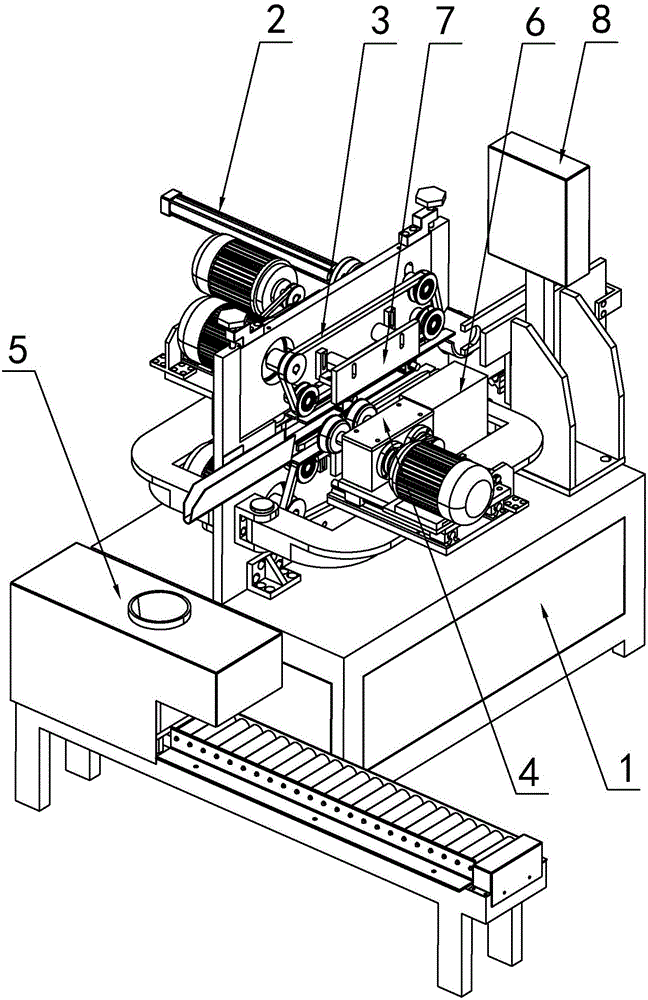

Novel efficient board single-side putty applying machine

ActiveCN104772256AImprove efficiencyQuality improvementLiquid surface applicatorsCoatingsSteel platesOn board

The invention discloses a novel efficient board single-side putty applying machine which comprises a rack, a transmission mechanism, a coating and scraping mechanism and a power mechanism. The rack comprises channel steel, angle steel, a steel plate and square steel, the transmission mechanism comprises a drive roller, a driven roller, a pressure roller, carrier rollers, a tensioning roller and a conveyer belt, the coating and scraping mechanism comprises a putty squeezing roller, a putty coating roller, a support, a double-edged knife and an oblique scraper, and the power mechanism comprises a motor, a speed reducer, an electric control cabinet and chain wheels; sliding bearing seats are arranged on the shaft ends of the drive roller and the driven roller, a screw is arranged on one side of the center of each bearing seat, a nut is arranged on the head of each screw, and the bearing seats are fixedly connected to the rack through the screws and the nuts; the double-edged knife, the putty coating roller and the conveyer belt form a triangle area together, and the rear side of the double-edged knife is provided with the oblique scraper. According to the novel efficient board single-side putty applying machine, automation of applying putty on boards is achieved, the time and the energy are saved, the efficiency is high, and the quality is high.

Owner:孟凡科

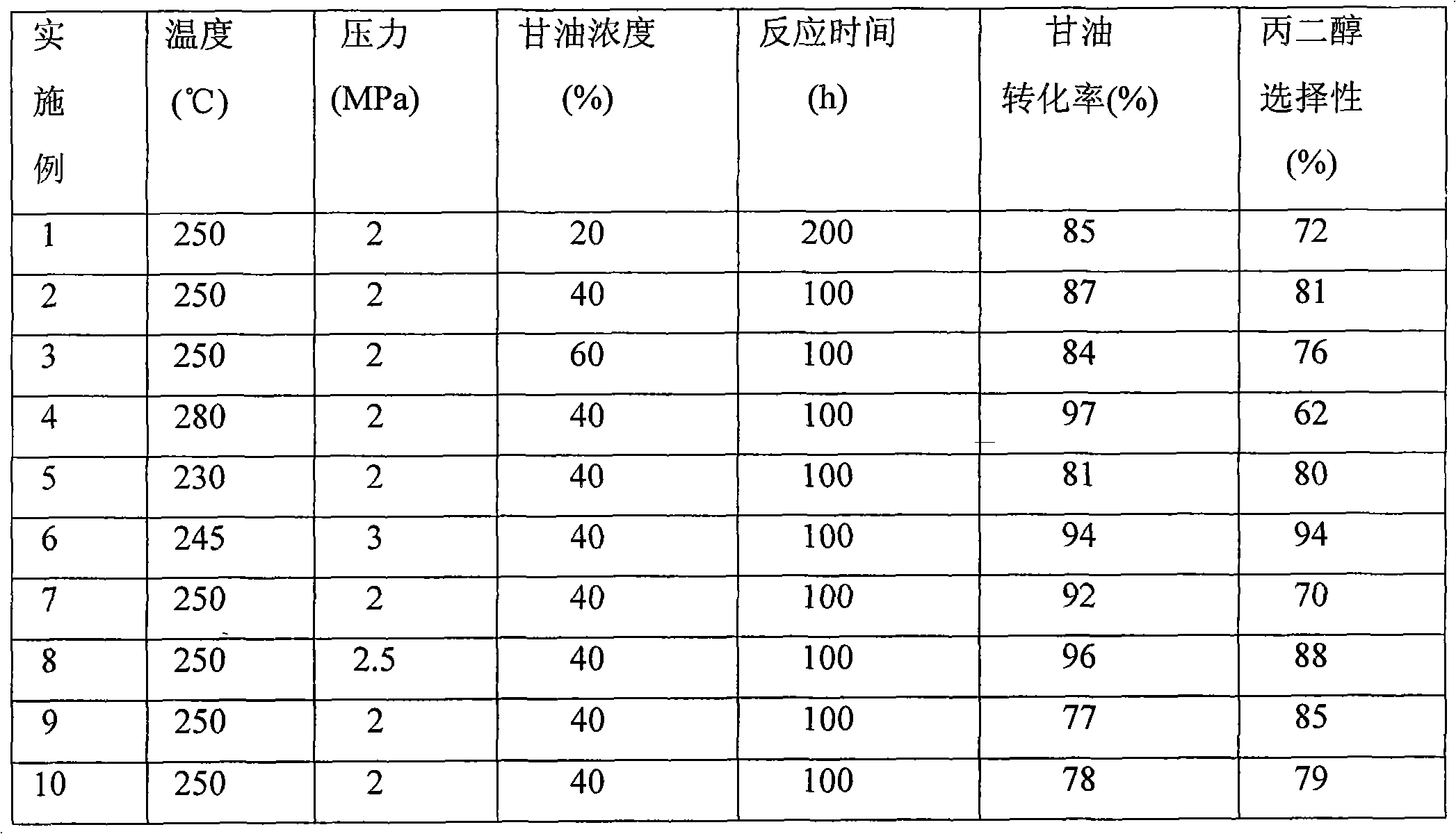

Method for preparing 1,2-propanediol through glycerol hydrogenation

InactiveCN102040477AExtended service lifeHigh activityPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsGlycerolReaction temperature

The invention provides a method for preparing 1,2-propanediol through glycerol hydrogenation. In the method, a copper-zinc-aluminum-carbon multiple-component composite catalyst is used; and the reaction temperature is 220-280 DEG C, the reaction pressure is 1.5-4Mpa; and the used catalyst contains the following non-oxygen elements by weight percent: 20-80% of Cu, 15-70% of Zn, 0.1-5% of Al and 1-6% of C. In the method provided by the invention, relatively lower reaction pressure is adopted, thus the investment cost and maintenance cost of the equipment can be reduced; and the catalyst has the advantages of long service life, high activity and excellent selectivity, and can work continuously and be suitable for industrialized sustainable production.

Owner:南京大学扬州化学化工研究院 +1

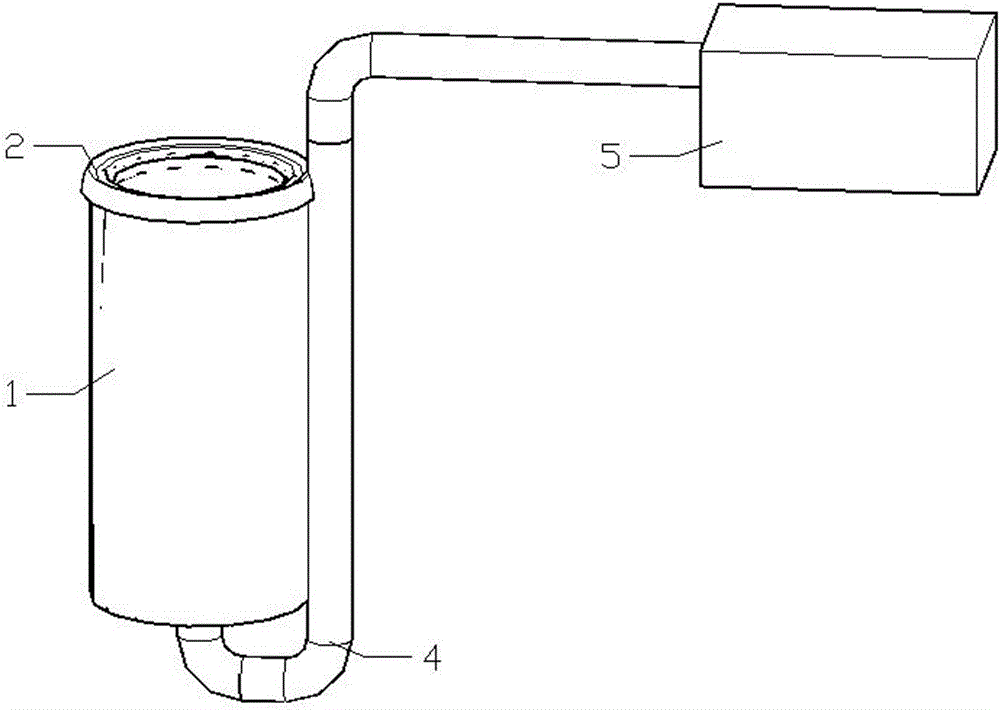

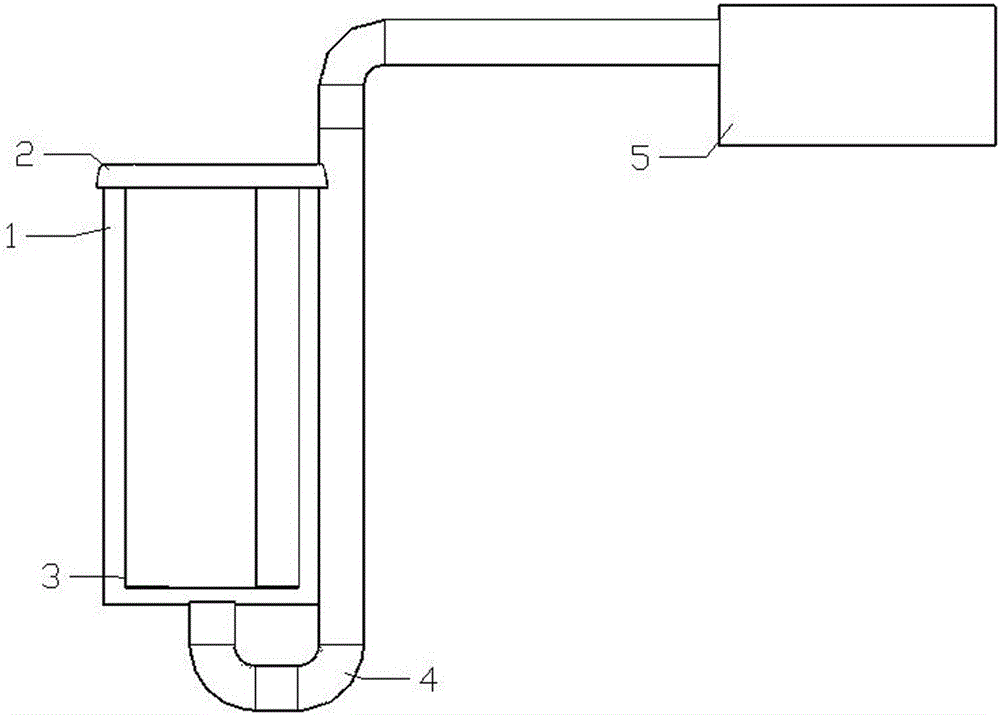

Water surface garbage collector

The invention discloses a water surface garbage collector which consists of a garbage collection barrel, a barrel sleeve, a filter screen, a water suction pipe and a water extraction pump, wherein the garbage collection barrel is fixed on the shoreside or the side of a ship; the barrel sleeve is mounted at the top end of the garbage collection barrel; the filter net is connected to the bottom end of the barrel sleeve; the barrel opening is lower than the water level; the water suction pipe is arranged at the bottommost end of the garbage collection barrel; and the water suction pipe is connected with the water extraction pump.

Owner:慕欣雨

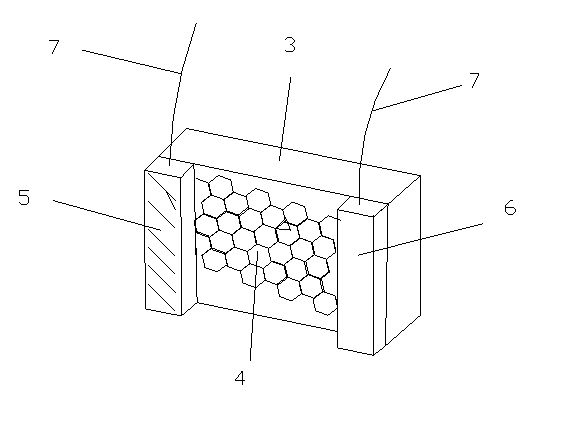

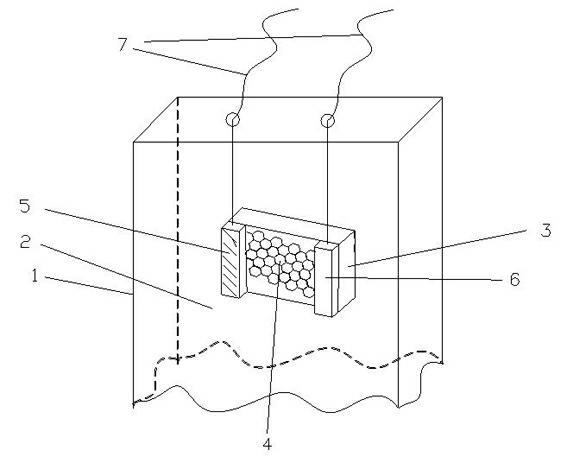

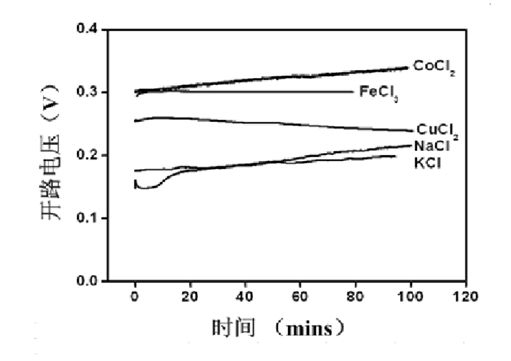

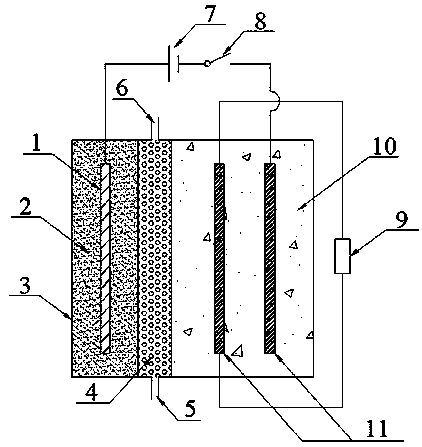

Power generation method adopting ionic thermal motion principle and graphene battery manufactured by power generation method

InactiveCN102496675AReduce security risksReduce performanceThermoelectric device detailsElectricityWork function

The invention discloses a power generating method adopting an ionic thermal motion principle. The power generating method comprises the following steps of: firstly, transferring graphene to a substrate and bonding a graphene film on the substrate; secondly, depositing a conducting material with a work function higher than that of the graphene at one end of the graphene film to obtain a first electrode and depositing a conducting material with a work function lower than that of the graphene at the other end of the graphene film to obtain a second electrode; thirdly, leading out the first electrode and the second electrode at two ends of the graphene film by using two metal wires; and fourthly, holding an ionic salt solution in a container casing, integrally immersing the substrate, the graphene film, the first electrode, the second electrode and the two metal wires in the ionic salt solution and leading the metal wires to the outside of the container casing. The invention also provides a graphene battery manufactured by using the power generating method. The power generating method adopting the ionic thermal motion principle and the graphene battery manufactured by the power generation method have the advantages of safety, reliability, no need of using power for charging, long service life of the graphene battery and no harm to a human body and environment.

Owner:SHENZHEN NATAN TECH

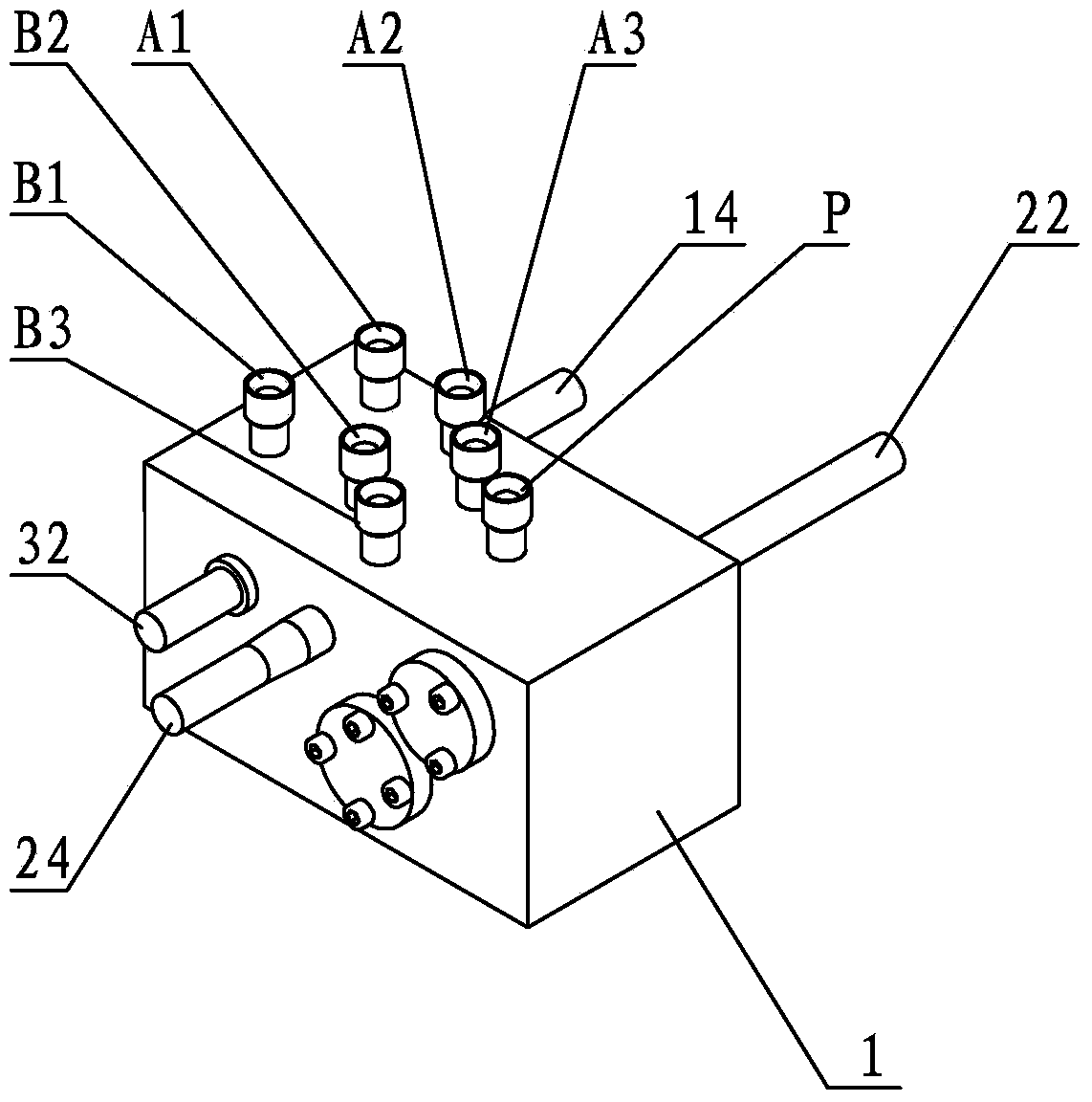

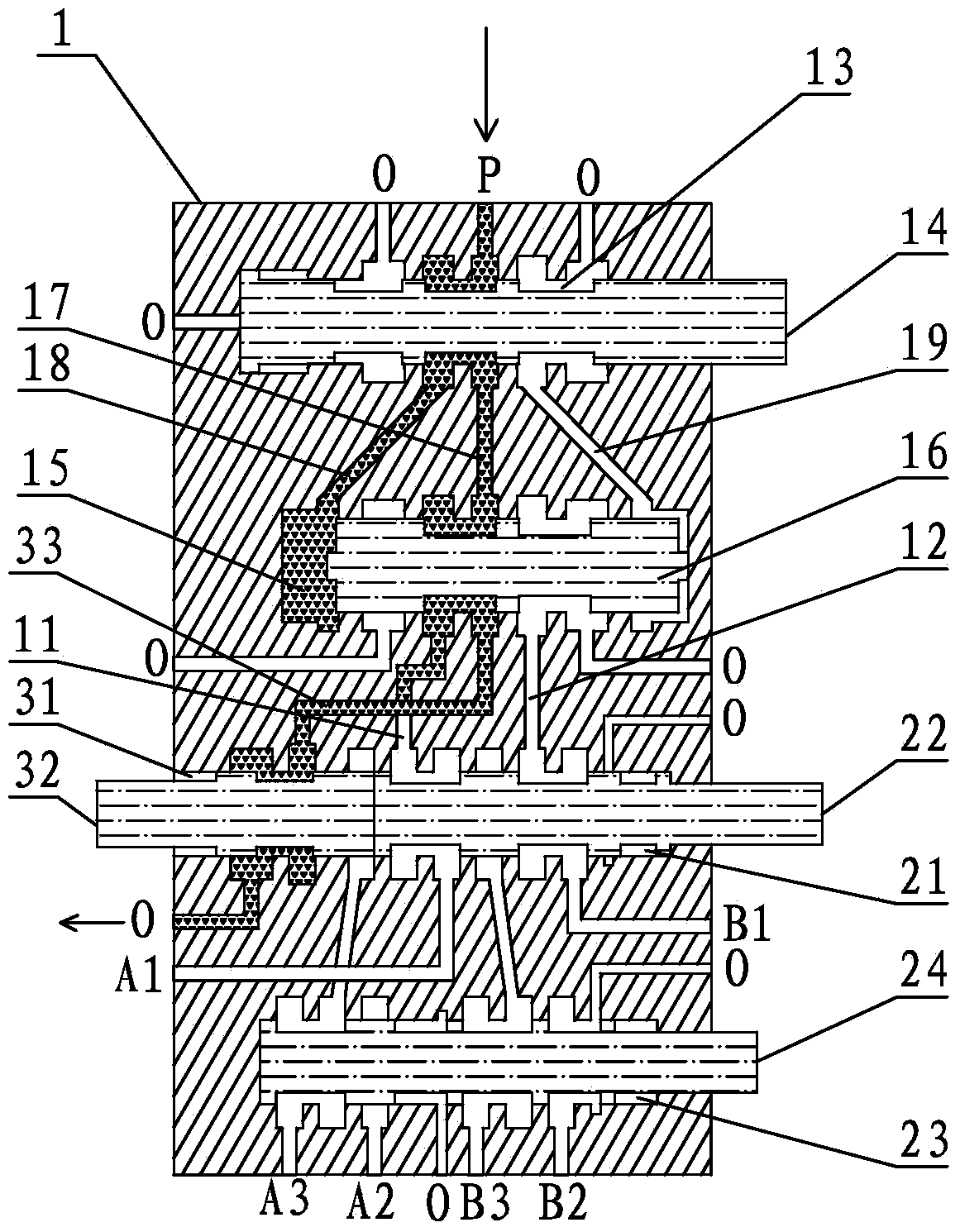

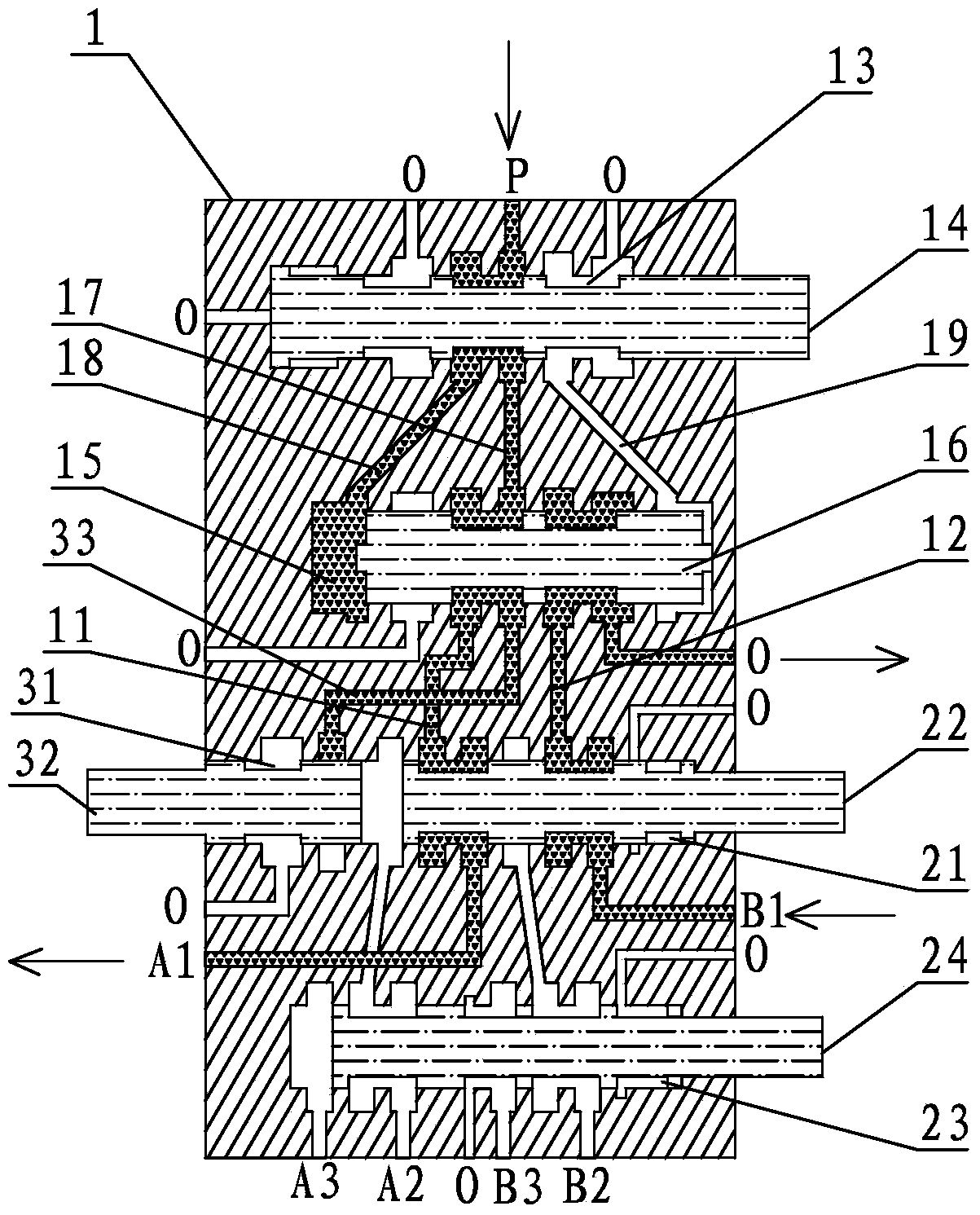

Multi-channel hydraulic control valve

ActiveCN103452937AImprove performanceEasy to controlServomotor componentsSteering controlMechanical valve

The invention discloses a multi-channel hydraulic control valve which comprises a valve body, wherein a reversing valve group and a change-over valve group are arranged in the valve body; the reversing valve group is connected with the change-over valve group through a first connecting oil passage and a second connecting oil passage; a reversing valve core in the reversing valve group acts to enable the first connecting oil passage and the second connecting oil passage to be in switching connection between an oil inlet and respective oil unloading openings respectively; a plurality of groups of oil cylinder connecting openings are formed in the change-over valve group, and change-over valve cores used for switching the oil cylinder connecting openings which are communicated with the first connecting oil passage and the second connecting oil passage are arranged on the change-over valve group. The multi-channel hydraulic control valve disclosed by the invention completely adopts a mechanical mechanism to realize the control to hydraulic oil channels, has the advantages of simple structure, low cost, stability in performance of mechanical valves and convenience for maintenance, is used for steering control of oil cylinder pistons and switching control of oil cylinders in a multi-channel hydraulic power system, facilitates the realization of automation control, and has a wide application prospect.

Owner:冯广建

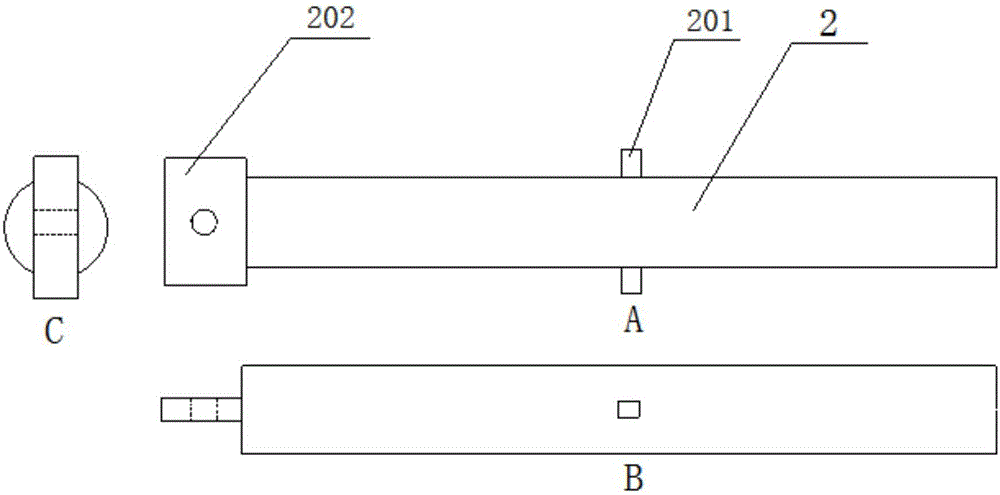

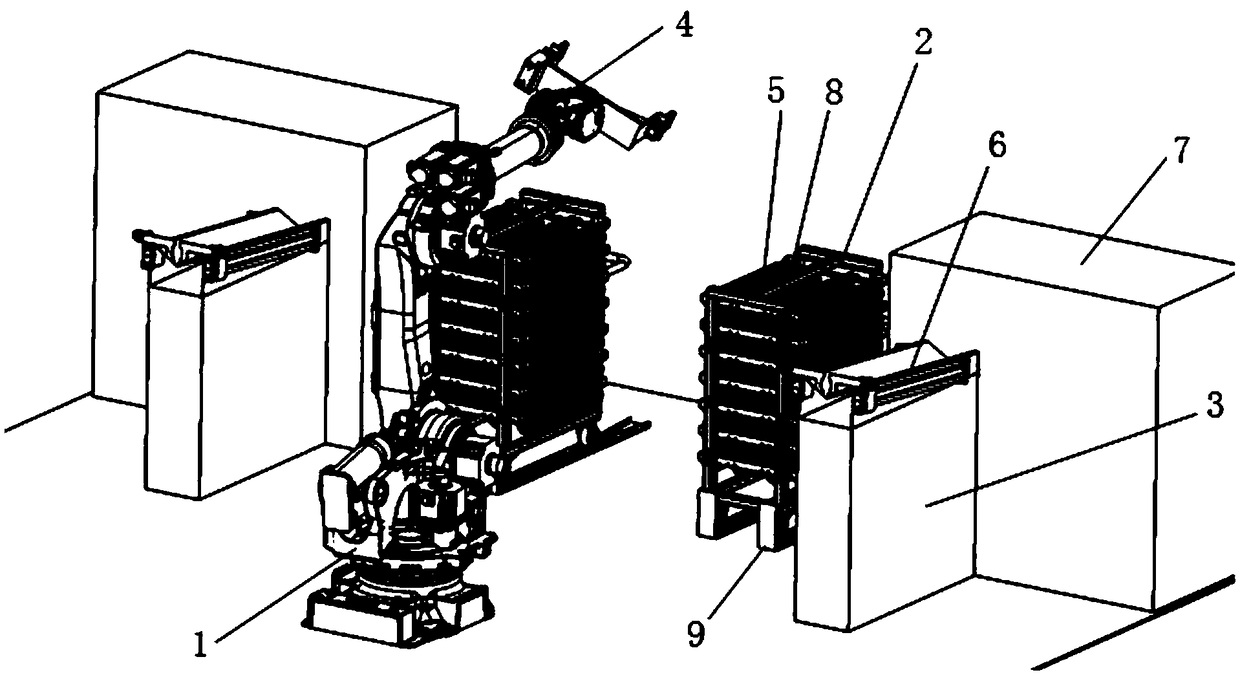

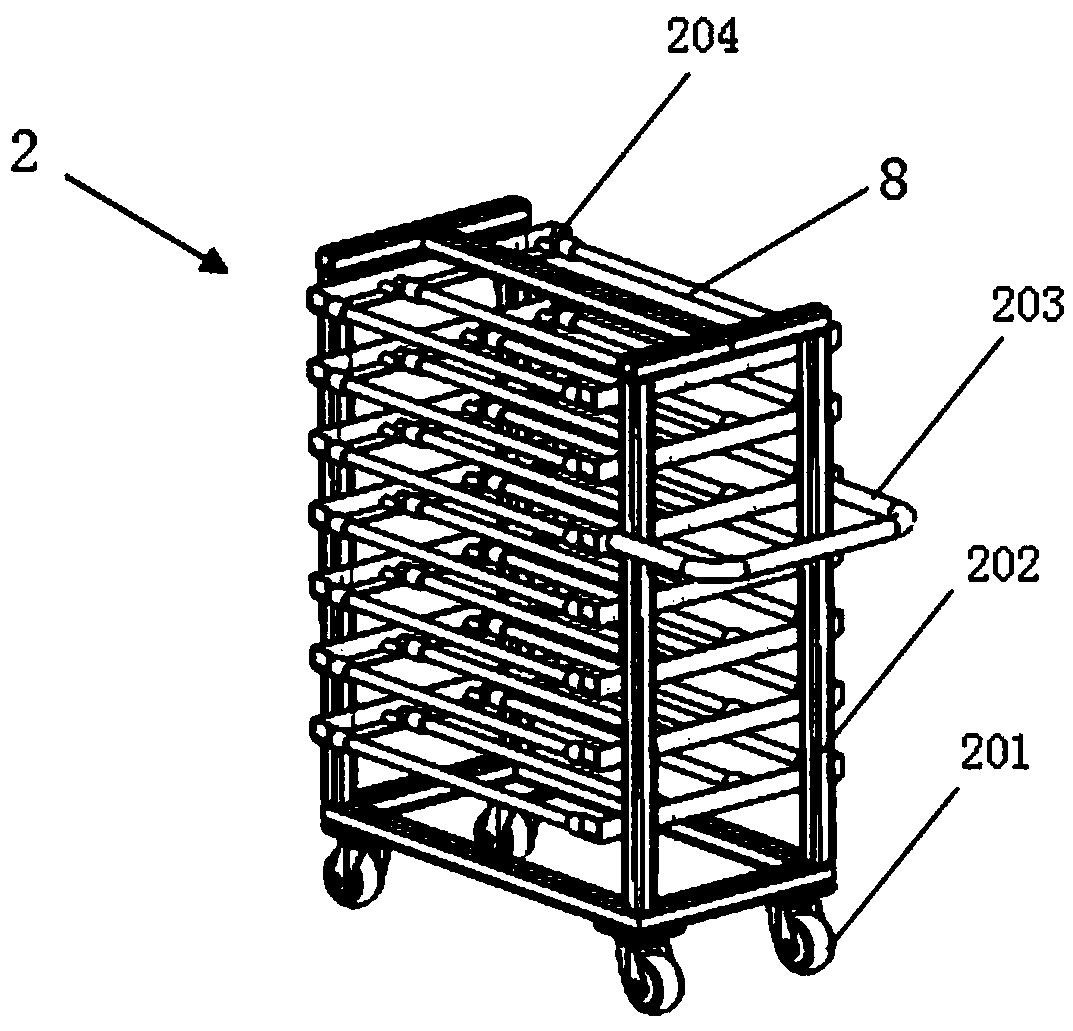

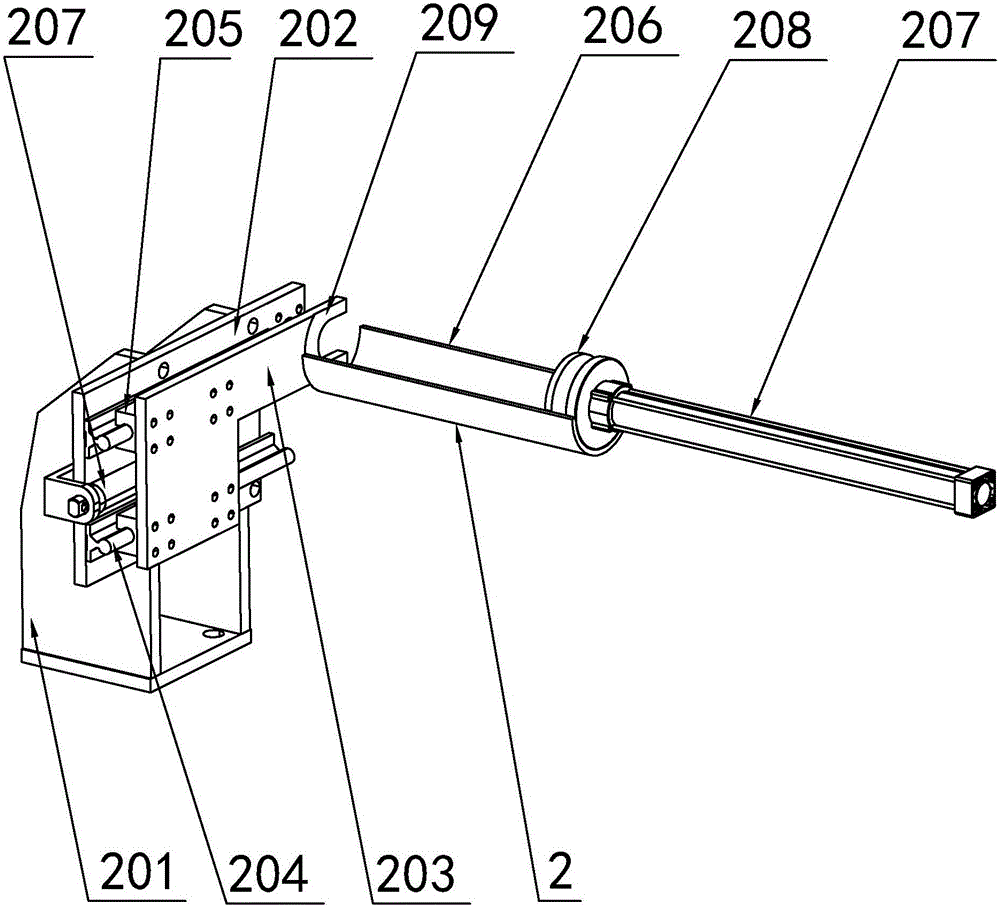

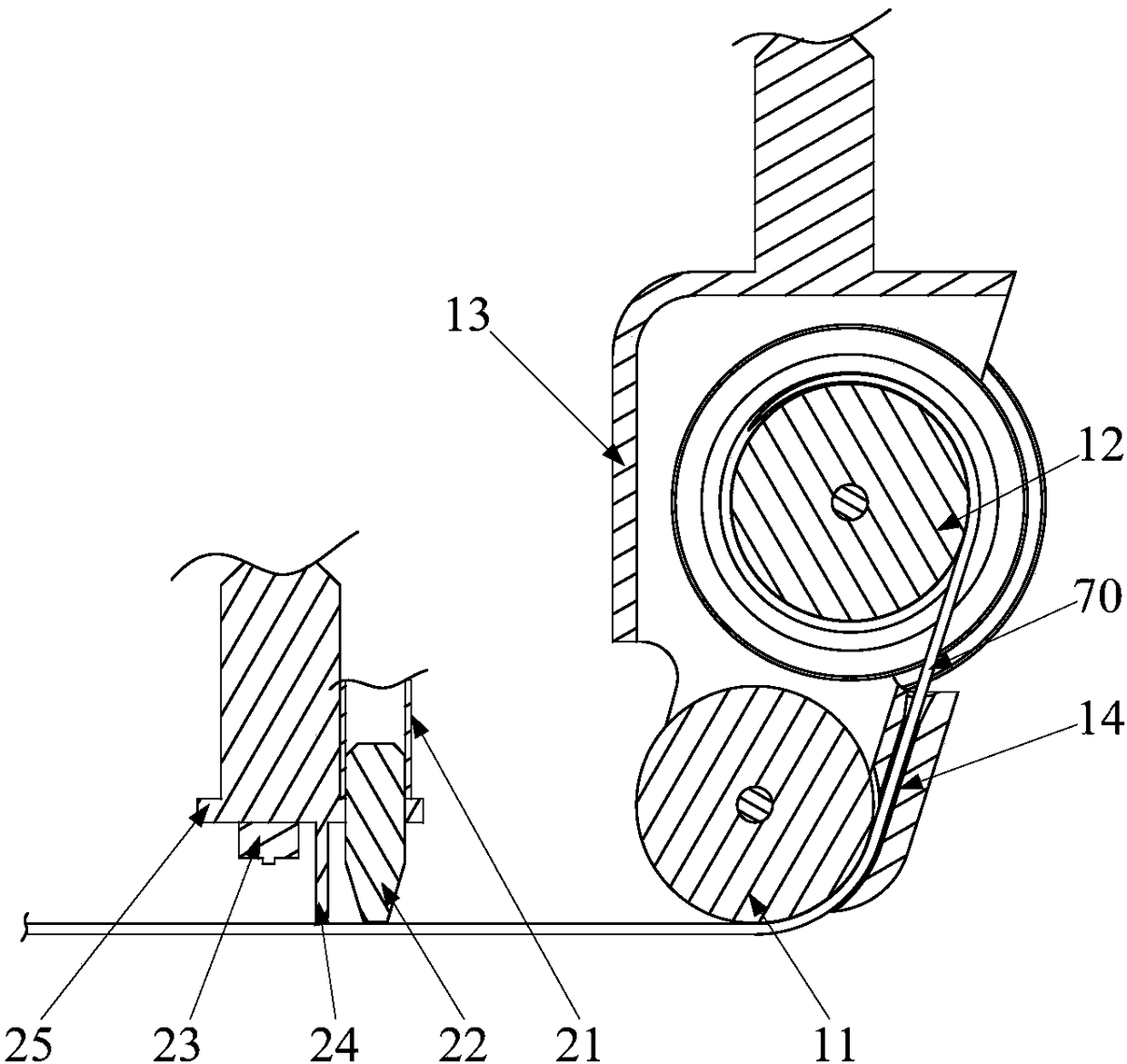

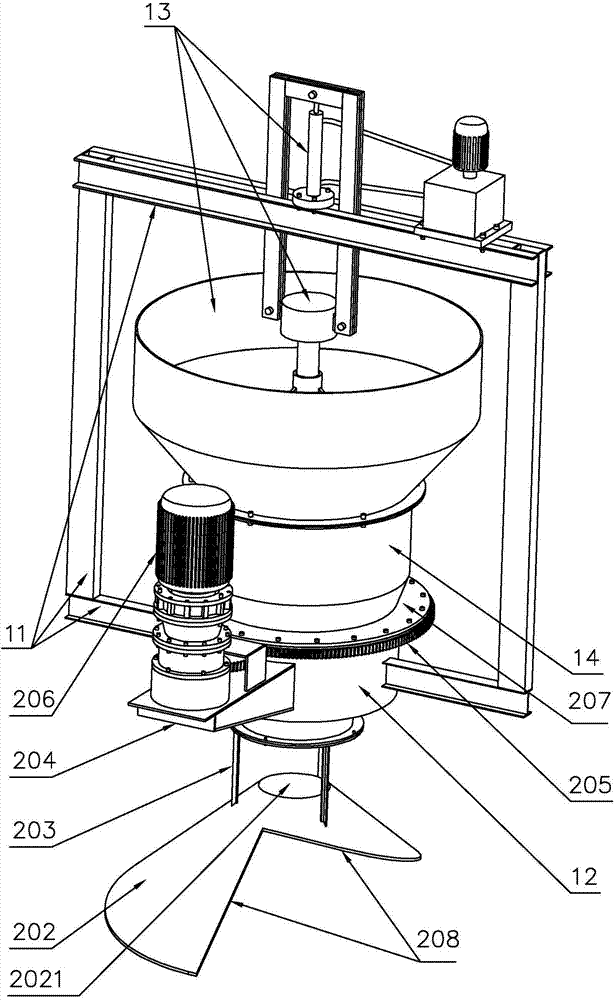

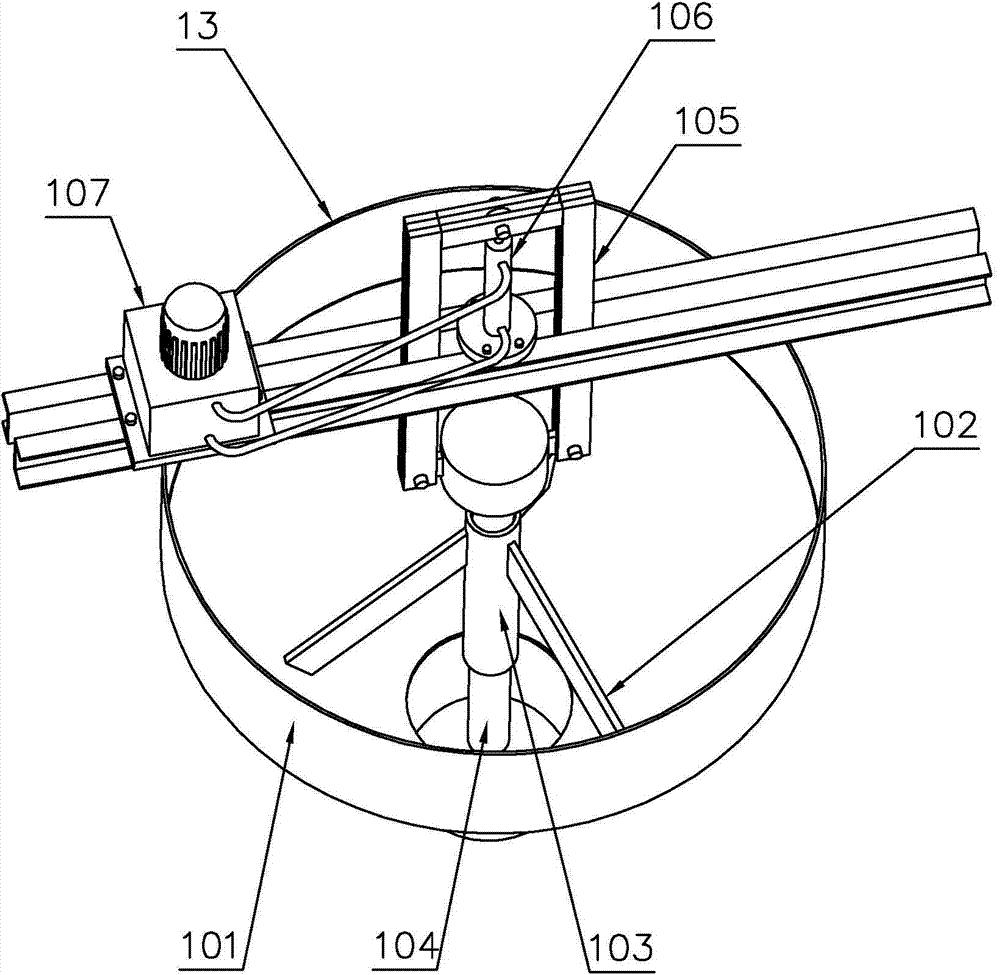

Automatic feeding device for piston rings

PendingCN109290945AImprove shipping efficiencyRealize large-scale automatic feedingGrinding feedersPiston ringEngineering

The invention discloses an automatic feeding device for piston rings. The automatic feeding device comprises a material conveying robot and feeding units arranged beside the material conveying robot.Each feeding unit comprises a feeding table matched with the material conveying robot and a hand push material trolley. A material grabbing mechanism is arranged at the end portion of an arm of the material conveying robot. Multiple rows of loading rods which can be taken and placed at will and are used for being sleeved with the piston rings are arranged on the hand push material trolleys. A material pressing mechanism is arranged on each feeding table. A positioning device used for positioning each hand push material trolley is arranged on the ground. The material conveying robot takes the loading rods sleeved with the piston rings out from the hand push material trolleys through the material grabbing mechanism and places the loading rods on the feeding tables, the loading rods are extracted out, then the material pressing mechanisms are used for sending the piston rings into feeding ports of grinding machines. The automatic feeding device has the beneficial effects that the efficiency is high, and parts are not damaged.

Owner:YUHUAN CNC MACHINE TOOL

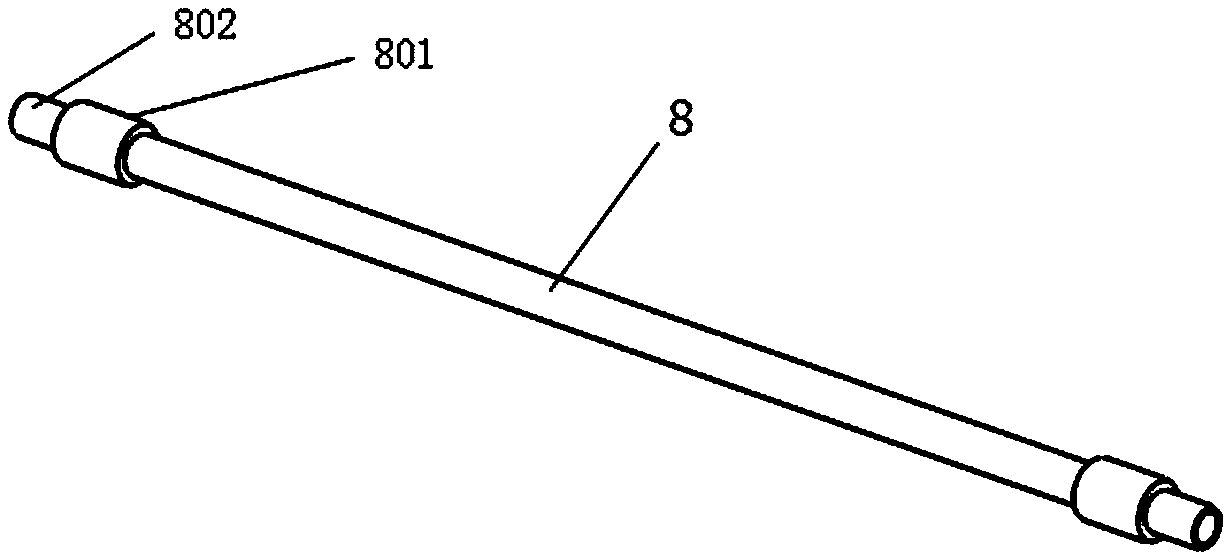

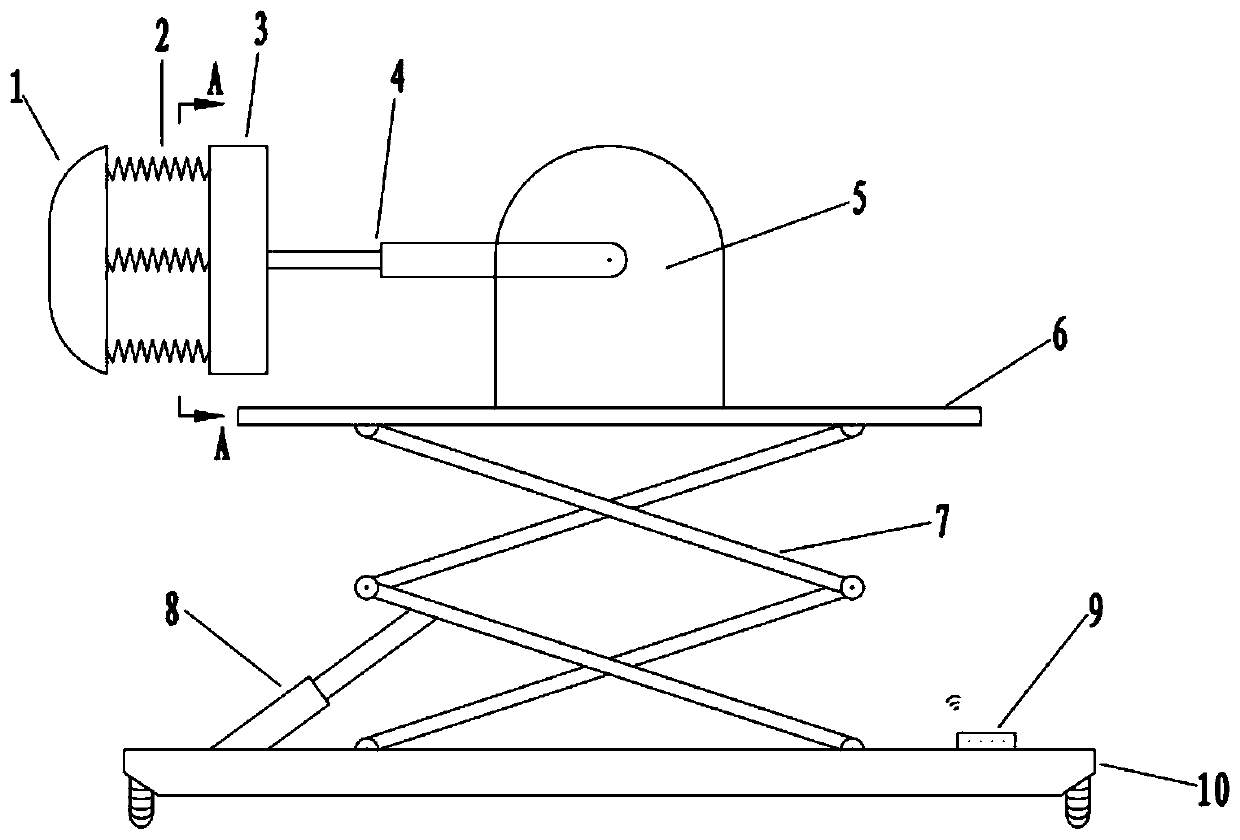

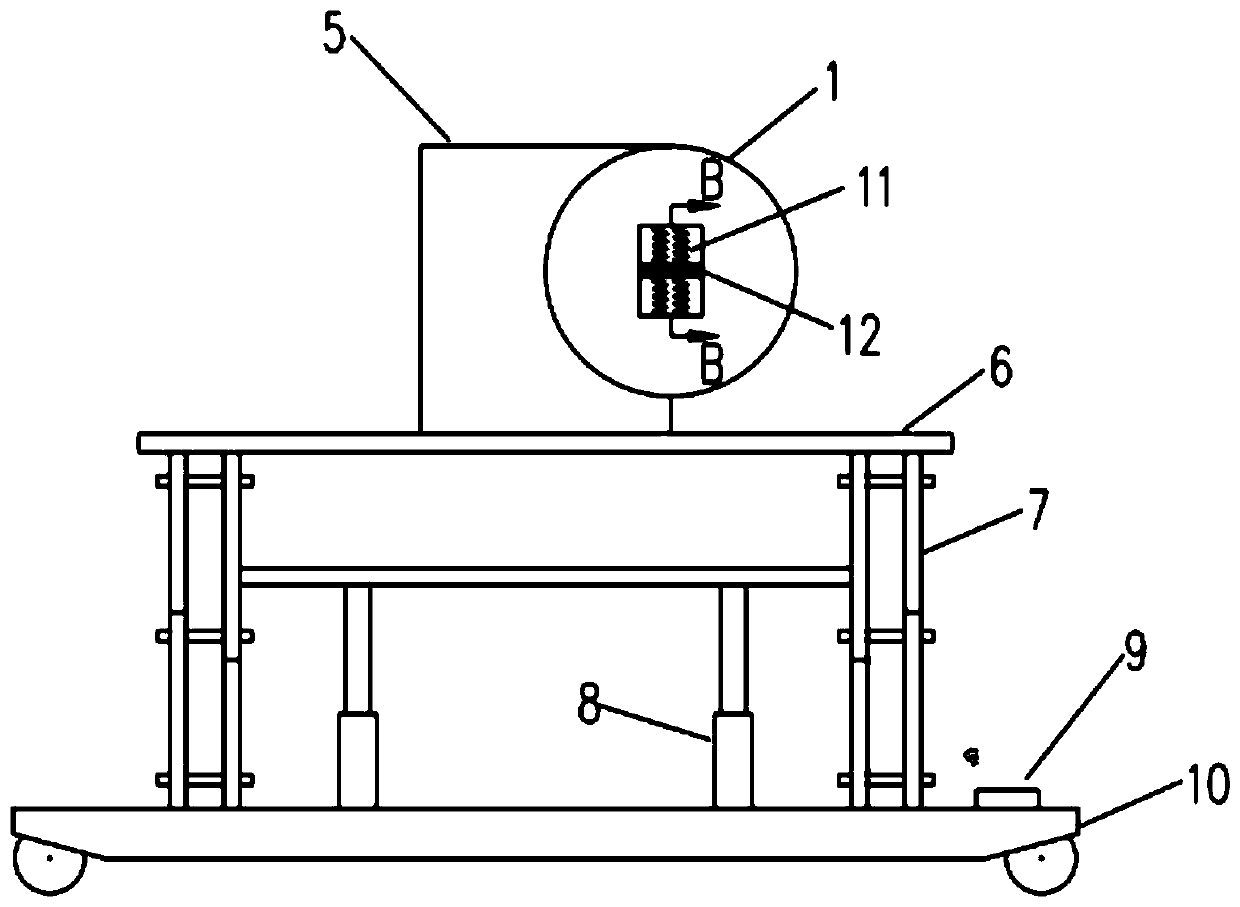

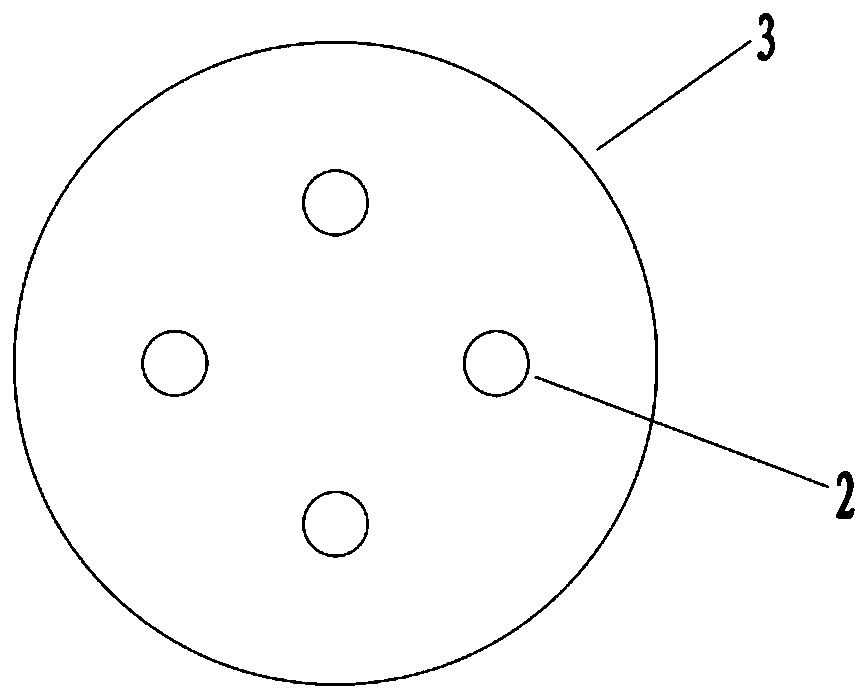

Highway tunnel geological detection system with self-adaptive fitting device and method

InactiveCN110534869AEnsure safetySolve the real problemAntenna supports/mountingsSeparate antenna unit combinationsSocial benefitsRadar

The invention discloses a highway tunnel geological detection system with a self-adaptive fitting device and method. Through cooperation of a lifting trolley and a rotating motor, a radar antenna in an antenna clamping box can stably move forwards along the uneven tunnel surface, and through the telescopic characteristic of a first spring in the antenna clamping box, the radar antenna does not change along with the uneven tunnel surface or the change of the distance between the advancing trolley and the tunnel surface. Thus, the problem that the tunnel surface height measured by manpower is too large and touch is difficult is solved; continuous work can be achieved, and the cruising ability is high; workers do not need to work high above the ground, and safety of the workers is guaranteed.The scheme is reasonable, the structure is simple, used equipment is conventional, and good economic benefits and social benefits are achieved.

Owner:CHANGAN UNIV

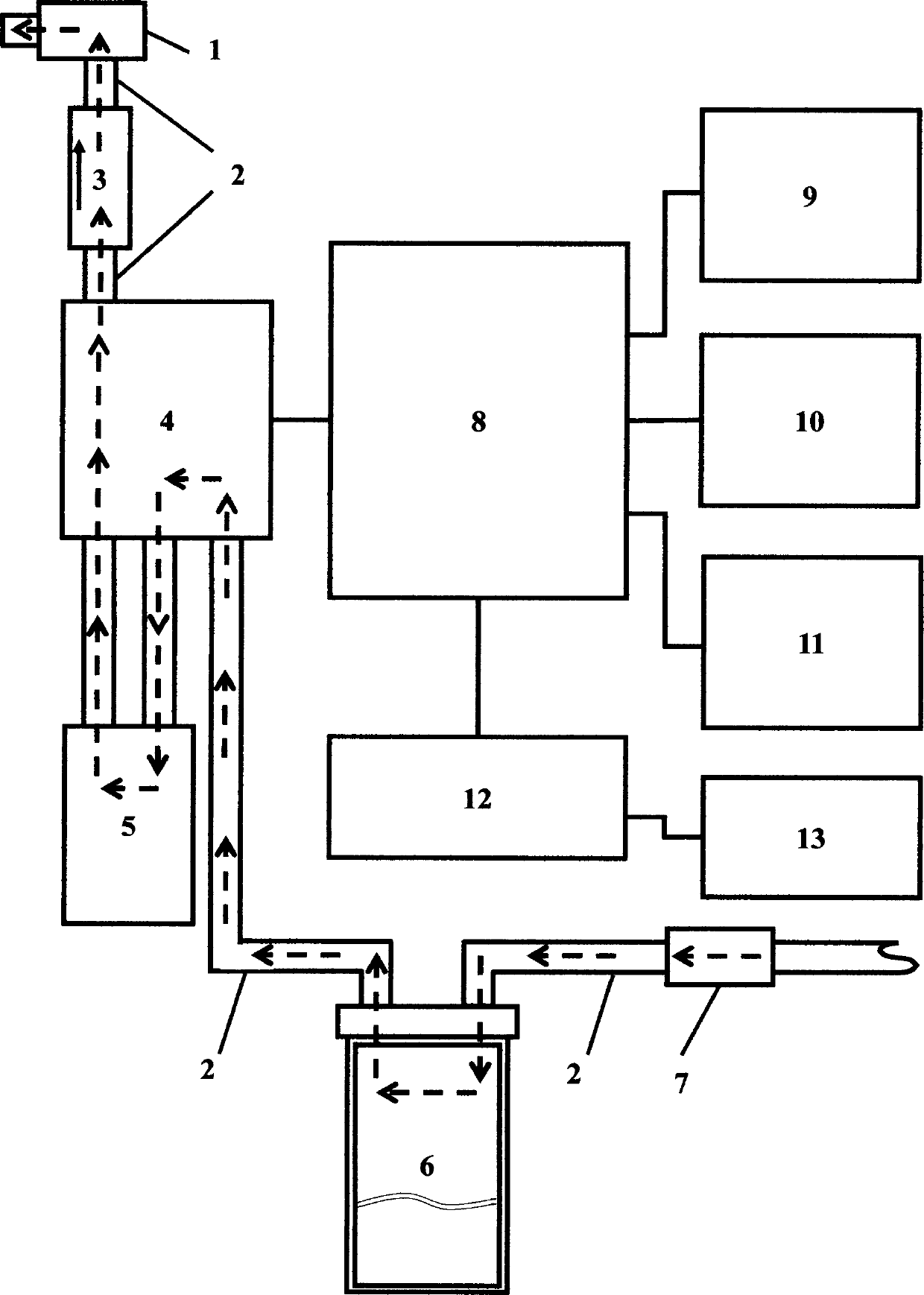

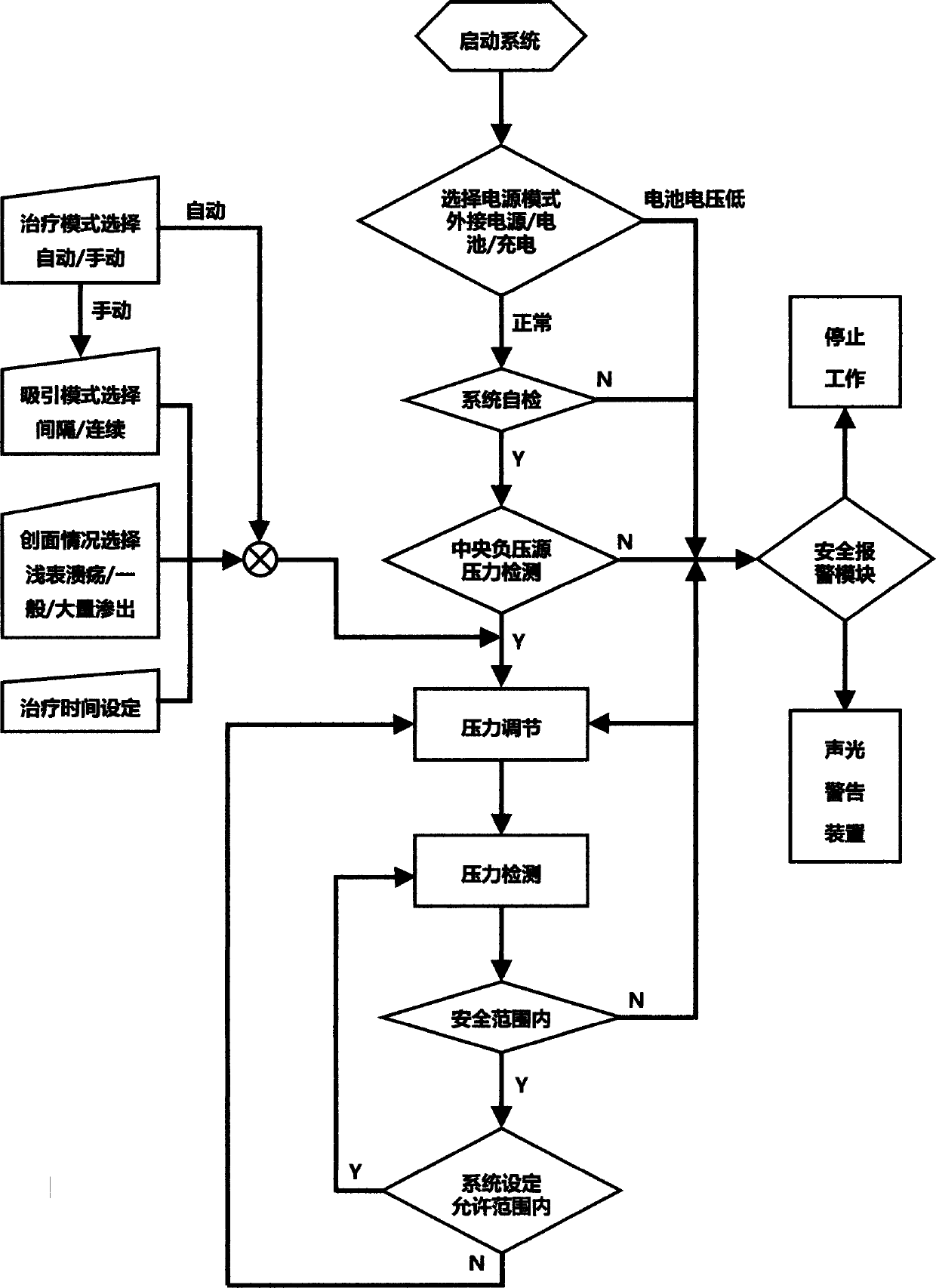

Central negative pressure based healing-assisted treatment system

The invention discloses a central negative pressure based healing-assisted treatment system. The healing-assisted treatment system is based on the hospital central negative pressure source to adjust pressure according to the specific situation of a patient's wound, provide an intermittent drainage manner and a continuous negative pressure drainage manner, which are most beneficial to accelerating wound healing, wherein the intermittent drainage manner is to absorb the liquid for 5 minutes and stop for 2 minutes. The system is good in treatment effect, controllable in pressure, high in safety, free of noise, high in stability, long in service life, and extremely low in system price and use cost, can effectively protect the central negative pressure system from being polluted, reduces the secondary infection possibility of the patient's wound, and overcomes the defects of the existing electric suction apparatus, the manually operated suction apparatus and the pure central negative pressure system in negative pressure wound healing-assisted treatment.

Owner:TIANJIN YIOUSI TECH CO LTD

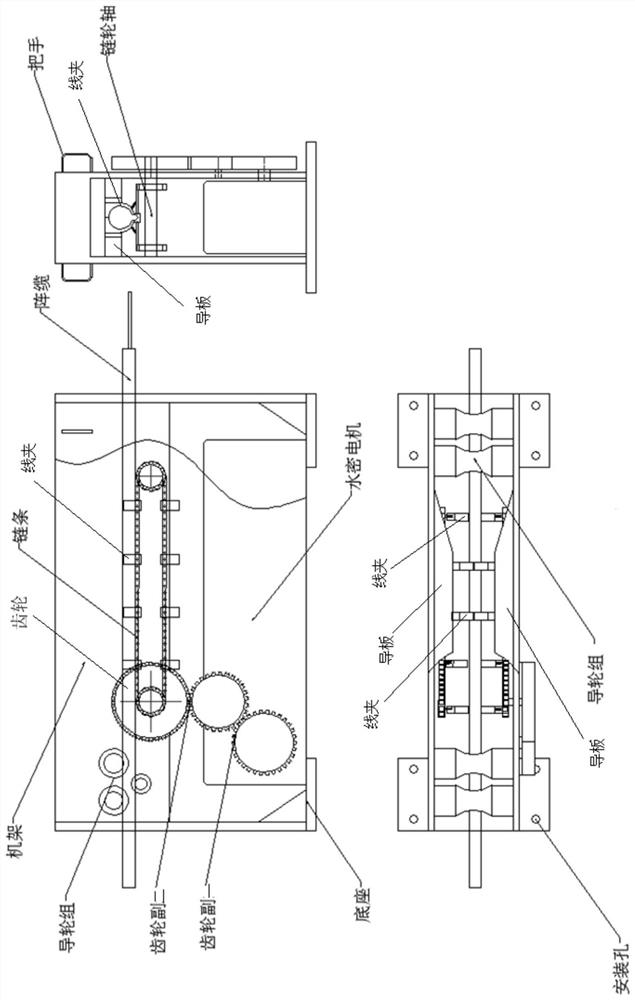

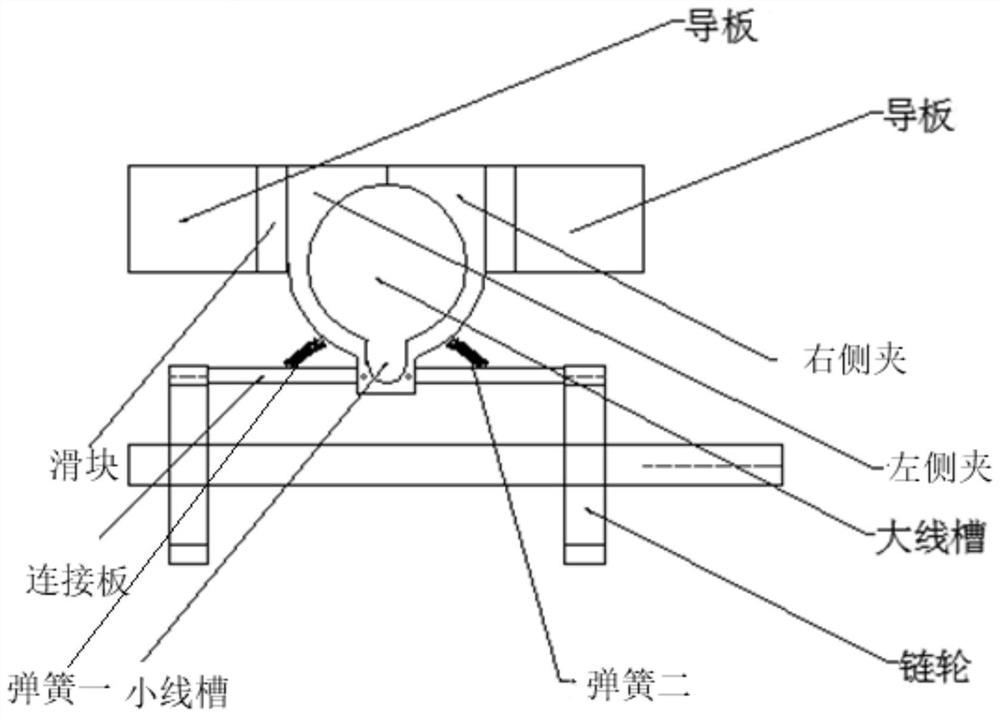

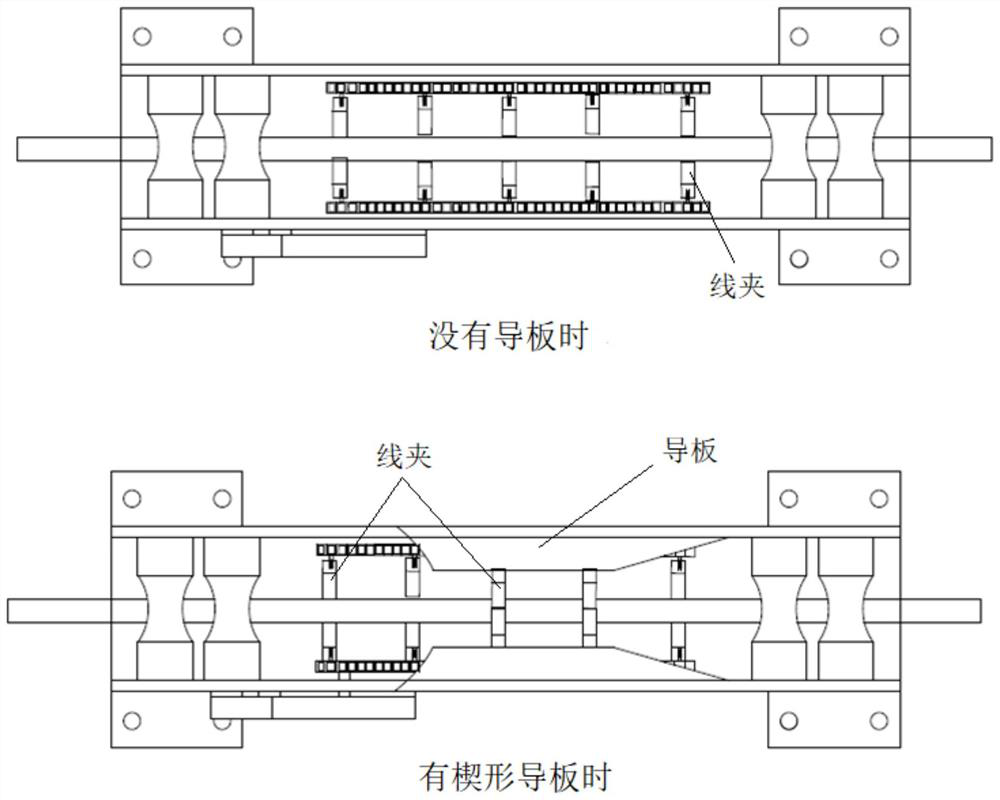

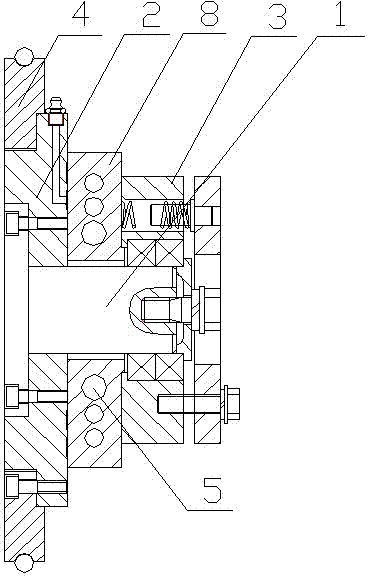

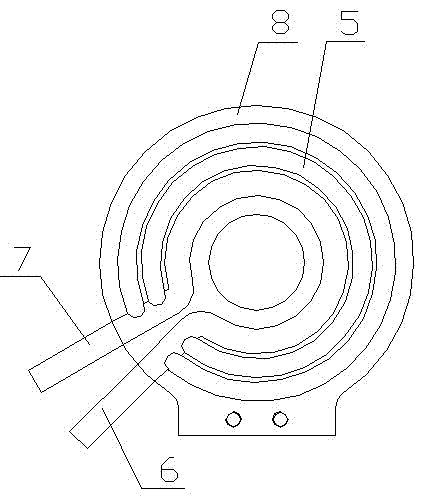

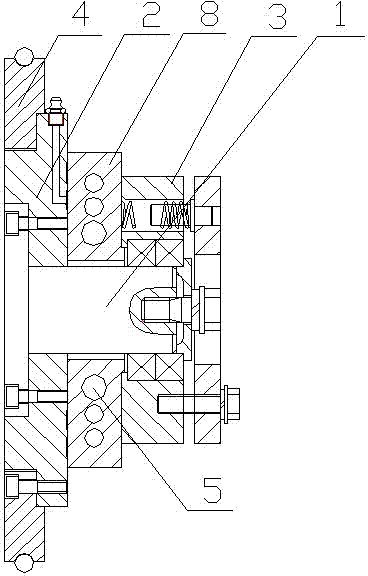

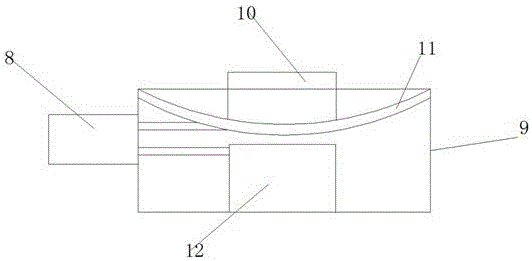

Traction device for multi-wire-diameter array cables

PendingCN111960181AImprove traction work efficiencyHigh degree of automationFilament handlingSprocketElectrical and Electronics engineering

The invention discloses a traction device for multi-wire-diameter array cables. The traction device for the multi-wire-diameter array cables comprises a transmission device, a wire clamp and guide plates, wherein the transmission device comprises a chain wheel and a chain, a connection plate vertical to the transmission direction of the chain is arranged on the chain, and the wire clamp is arranged at the middle of the connection plate; the wire clamp comprises a left-side clamp, a right-side clamp, a spring I and a spring II; the left-side clamp and the right-side clamp are installed at the middle of the connection plate in a rotatable and bottom-bonded manner, the upper parts of the back parts of the left-side clamp and the right-side clamp are bonded with the side surfaces of the two guide plates which are located at the two sides of the wire clamp, and the distance of the middle sections of the two guide plates is the width of the wire clamp after being closed; the inner side of each of the left-side clamp and the right-side clamp comprises n arc shapes with diameters which are sequentially reduced from top to bottom, n is not less than 2, and in the closed state, n wire grooves with diameters which are sequentially reduced from top to bottom are formed. According to the traction device for the multi-wire-diameter array cables, through a plurality of the separate wire clamps and through formation for a plurality of the wire grooves in the wire clamps, traction for the array cables with many dimensions is realized.

Owner:中科长城海洋信息系统有限公司

Wheel-type electrode for welding machine

InactiveCN102513682AReduce temperature riseReduce the temperatureElectrode featuresWelding with roller electrodesEngineeringCooling channel

The invention discloses a wheel-type electrode for a welding machine, relating to the technical field of manufacturing of welding machines, in particular to an improved wheel-type electrode of the welding machine. The wheel-type electrode comprises a wheel shaft, a wheel body and a welded plate, wherein the wheel body and the welded plate are sleeved on the wheel shaft respectively; the wheel body is fixed on the front part of the wheel shaft; the welded plate is connected to the back part of the wheel shaft through a bearing; welding wheels are matched with and fixedly connected to the periphery of the wheel body; a cooling plate is arranged between the wheel body and the welded plate and is sleeved on the wheel shaft; the end faces of the wheel body, the cooling plate and the welded plate are in contact with one another; at least three cooling passages which are coaxially arranged are arranged in the cooling plate; a radial entering passage and a discharging passage are formed in the cooling plate; and the two ends of each cooling passage are communicated with the entering passage and the discharging passage respectively. According to the arrangement, the welding machine can continuously work without intermittent outage, and the welding efficiency is increased; besides, the temperature rise of the welding wheels is reduced, so that sputtering during welding can be reduced, meanwhile the service life of the welding machine is prolonged.

Owner:江苏华光双顺机械制造有限公司

Device and method for controlling chloride ion permeation of reinforced concrete

ActiveCN111041496AFree from corrosionControl penetrationArtificial islandsUnderwater structuresReinforced concreteChloride

The invention discloses a device and method for controlling chloride ion permeation of reinforced concrete. The device comprises a concrete protection layer and a cathode protection loop, and furthercomprises a monitoring circuit and a porous absorption layer arranged between the concrete protection layer and a protected concrete main body, wherein a liquid inlet is formed in the lower part of the porous absorption layer, and a liquid outlet is formed in the upper part of the porous absorption layer; the monitoring circuit comprises a monitoring power supply; and the two ends of the monitoring power supply are respectively connected with the two ends of another reinforcing steel bar except the protected reinforcing steel bar in the protected concrete main body. The device can directionally move and remove harmful chloride ions in the reinforced concrete and the protection device at the same time, so that the purposes of recovering the function of the reinforced concrete structure andprolonging the service life of the reinforced concrete structure and the service life of an anode of the protection device are achieved. The device is low in energy consumption and simple and convenient to mount; the protection current does not need to be continuously started, so that over-protection of the reinforced concrete structure can be effectively avoided; and the damage to the anode in the using process is reduced, and regular replacement is not needed.

Owner:HOHAI UNIV

Novel efficient environment-friendly polishing machine of cutting sheet

ActiveCN105058176AEasy to operateAdaptableGrinding carriagesGrinding drivesSteel platesDiamond cutting

The invention discloses a novel efficient environment-friendly polishing machine of a cutting sheet. The novel efficient environment-friendly polishing machine comprises a rack, a feeding mechanism, a conveying mechanism and a polishing mechanism. The rack comprises channel steel, angle steel, a steel plate and square steel, and a control electric cabinet is arranged on one side of the rack. The feeding mechanism comprises a support, a fixed seat, a push plate, a trough, an air cylinder, a push block and a clamping groove. The conveying mechanism comprises an upper conveying set and a lower conveying set. The upper conveying set comprises an adjusting plate, a belt, a motor, carrier rollers and backup plates. The lower conveying set comprises a supporting plate, a belt, a motor, carrier rollers and backup plates. The polishing mechanism comprises a front polishing set and a back polishing set, and the front polishing set and the back polishing set are each provided with a roll brush, a U-type support and the corresponding motor. The diamond cutting sheet is high in polishing efficiency and good in polishing effect, time and labor are saved, no dust pollution is generated in the polishing process, and environment is protected.

Owner:南通通力油泵有限公司

Discarded fungus package disposal device for edible fungus production

ActiveCN109229676AEasy to collectSmall footprintPlastic recyclingGrain treatmentsEngineeringPollution

The invention discloses a discarded fungus package disposal device for edible fungus production, which comprises: a bracket; a feeding shell fixed on the top of the inner wall of the bracket; a feeding motor, which is fixed on the top of the inner wall of the bracket; a decelerator, which is connected on the bottom of the feeding motor by an output shaft; a screw feeding shaft, which is connectedby the output shaft on one side of the decelerator; and one end of the screw feeding shaft away from the decelerator runs through the feeding shell and extends to the inside of the feeding shell. Thediscarded fungus package disposal device relates to the technical field of the fungus package disposal techniques. According to the discarded fungus package disposal device for edible fungus production, the goal of stripping the discarded fungus package, collecting the discarded fungus package conveniently, and preventing the clogging of the discarded fungus package feed can be achieved, the spaceoccupied by the discarded fungus package is saved, the transportation of the discarded fungus material and the next processing to the discarded fungus material are convenient, thereby working continuously, not leaking the materials, avoiding the pollution to the environment, being convenient for the people to concentrate the processing to the plastics, preventing the fungus package to clog, making the feed material more unobstructed, and enhancing the work efficiency.

Owner:JIANGSU YUGUAN MODERN AGRI S AND T CO LTD

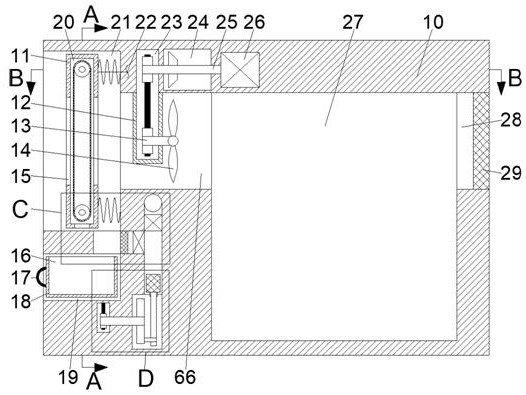

Dustproof heat dissipation power distribution cabinet device suitable for construction site

InactiveCN112563917ARealize automatic cleaningPlay a role in clearing the collectionSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlControl theory

The invention relates to the related field of power distribution cabinets, and discloses a dustproof heat dissipation power distribution cabinet device suitable for a construction site, which comprises a main body box, a power distribution cavity is arranged in the main body box, and the left end of the power distribution cavity is communicated with a fan cavity; the left end wall of the fan cavity is communicated with a dust filter cavity with an opening to the left, a filter box is matched with a monitoring spring to monitor the blockage condition of a dust filter screen in real time, so that when the dust is blocked to a certain degree, a friction roller is triggered to rotate to drive the dust filter screen to transmit downwards, and the position of the filter part of the dust filter screen is exchanged; therefore, the dust filter screen on one side is blocked to transmit downwards, and the filter screen on the unblocked part continues to work, so that normal heat dissipation in the power distribution cabinet body is ensured, dust transmitted downwards along with the dust filter screen can be removed and collected through the dust removal piston, automatic cleaning of the dustfilter screen is realized, and the dust filter screen can continuously work.

Owner:南京青之白数码科技发展有限公司

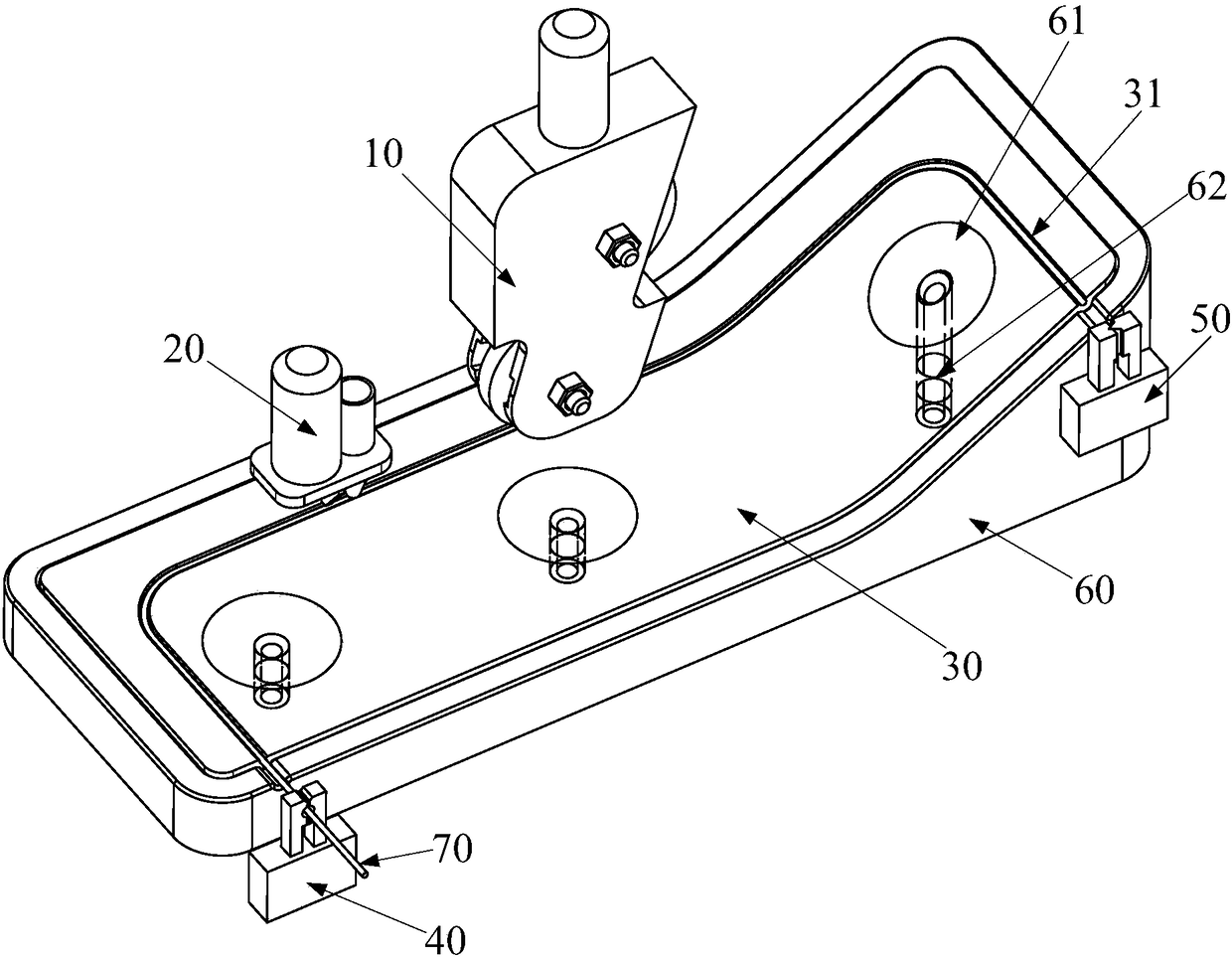

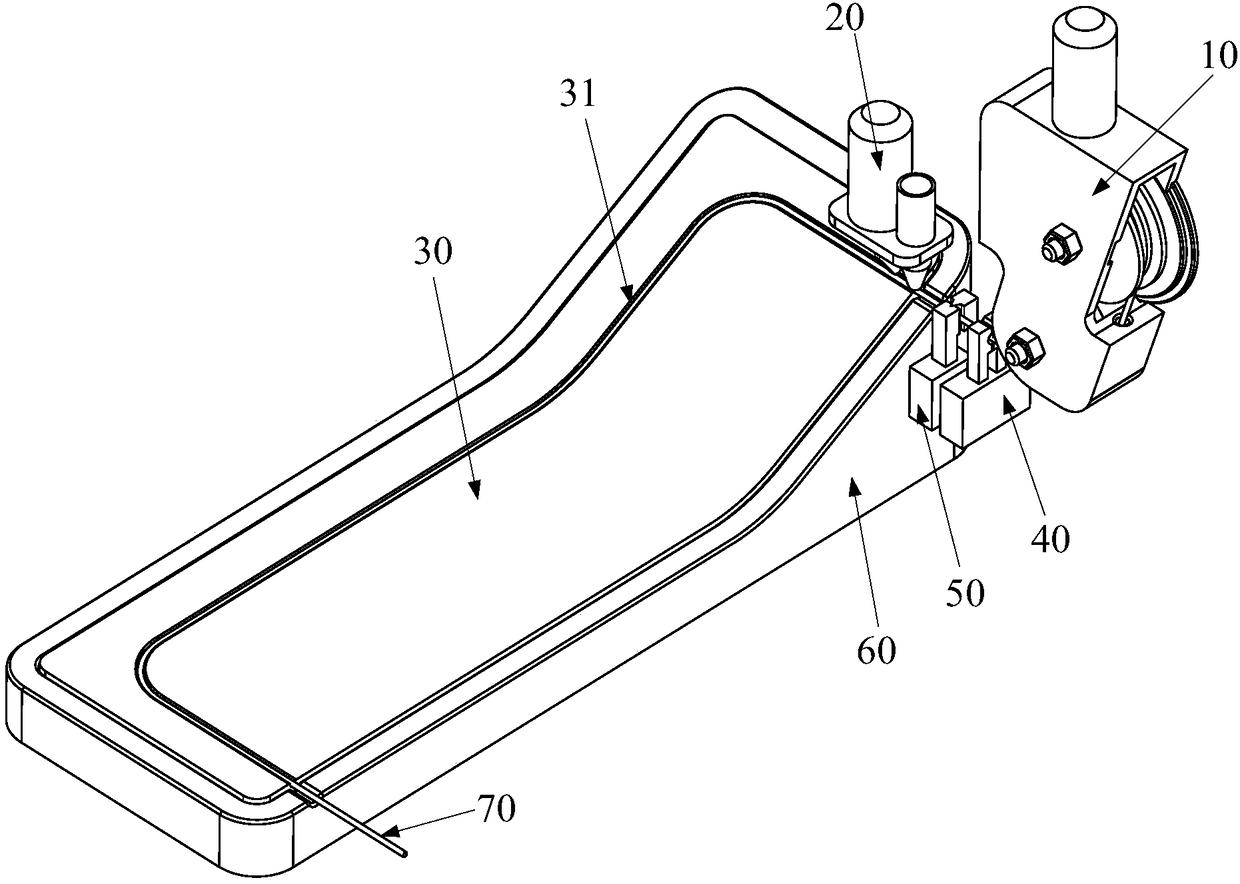

Optical fiber installation device and vehicle lamp assembly system

PendingCN108508560ATension is easy to controlAvoid breakingOptical fibre/cable installationFiberEngineering

The invention provides an optical fiber installation device and a vehicle lamp assembly system, relates to the technical field of vehicle lamp assembly systems and aims to solve the problem of difficult mounting and fixing of optical fibers. The optical fiber installation device comprises a laying mechanism, a gluing mechanism and a driving mechanism, wherein the optical fiber is arranged in the laying mechanism, an optical fiber placing groove is arranged on the optical fiber fixing carrier, the driving mechanism is respectively connected with the laying mechanism and the gluing mechanism todrive the laying mechanism and the gluing mechanism to move along the optical fiber placing groove, and the laying mechanism is used for placing the optical fiber in the optical fiber placing groove.The optical fiber installation device is used for installing the optical fiber into the optical fiber fixing carrier, and fixing the optical fiber in the optical fiber fixing carrier through the glueliquid. The device has the advantages of high efficiency, small manual labor amount, high yield, high reliability and good appearance consistency, and the fiber track can be space three-dimensional.

Owner:HASCO VISION TECHNOLOGY CO LTD

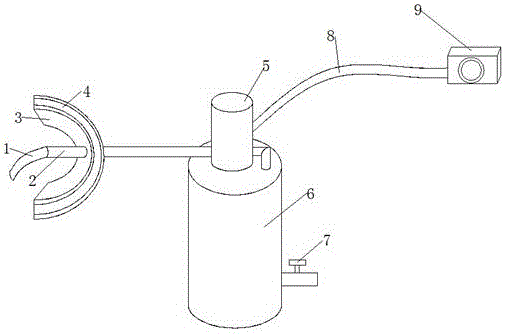

Self-help oral saliva suction and separation device

The invention discloses a self-help oral saliva suction and separation device which comprises a rubber hose. The rubber hose is connected with a catheter, a tooth support which is circular-arc-shaped is connected on the outer wall of the catheter in a sleeved manner, a groove is formed in each of the top and the bottom of the tooth support, one end, away from the rubber hose, of the catheter is connected with a water pump, a storage tank is arranged below the water pump, the water pump is connected with the storage tank through an air guide tube, a water outgoing valve is arranged on the outer wall of the bottom of the storage tank, the water pump is connected with a lead, a switch is arranged on one side of the lead, a button is arranged on the switch and extends to the inner side of the switch, and an elastic metal piece is arranged below the button. Compared with conventional self-help saliva suction devices, the self-help oral saliva suction and separation device is higher in comfort, simple and convenient to operate, energy resource saving, capable of working continuously and large in saliva suction space, workload of doctors and nurses can be reduced, convenience is brought to oral operation, and success rate of the operation is increased to certain extent.

Owner:潘秀岳

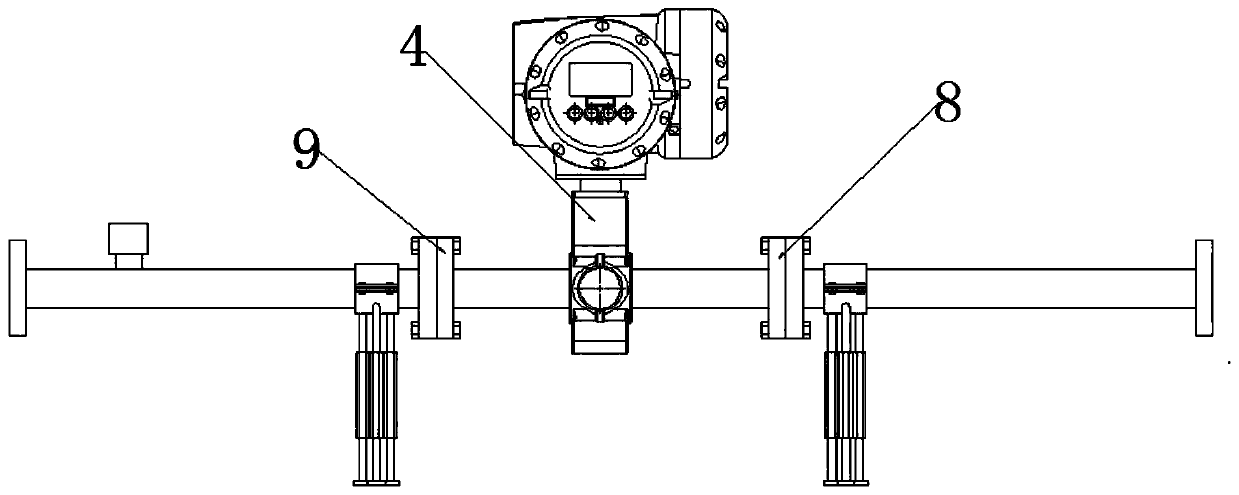

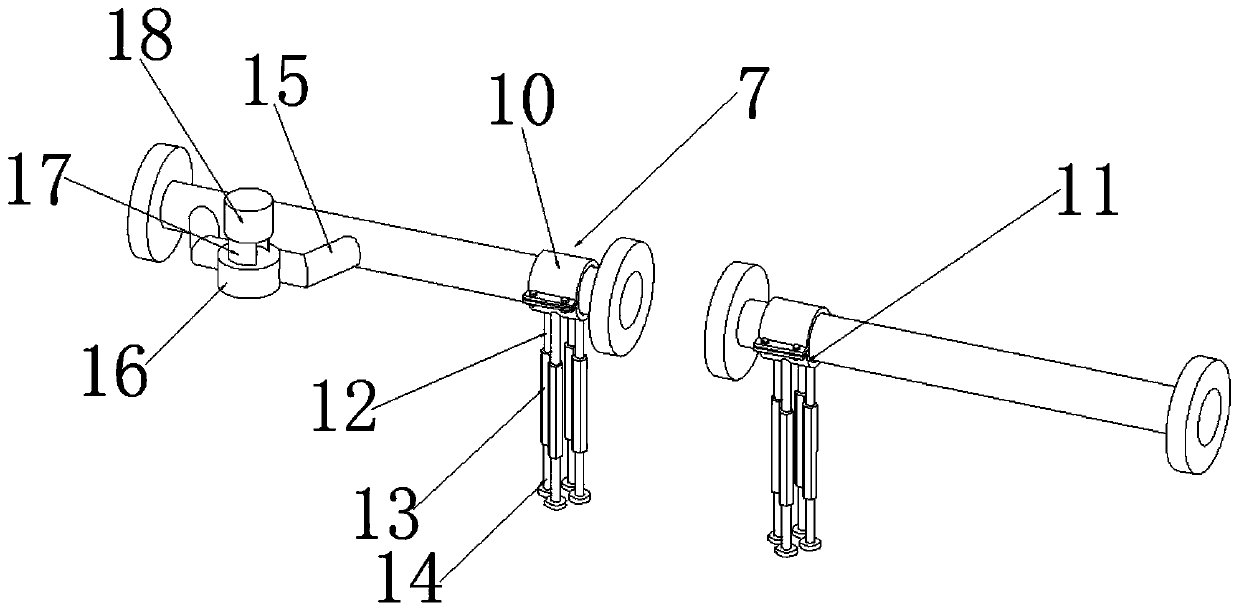

Industrial flow instrument for industrial production, and use method thereof

ActiveCN110749358ASustainable workAvoid battery drain situationsMachines/enginesVolume meteringElectromagnetic interferenceProcess engineering

The invention discloses an industrial flow instrument for industrial production. The industrial flow instrument comprises a shielding box, a first buffer tube, a second buffer tube, a flowmeter and afixing mechanism, wherein the first buffer tube is installed at one end of the flowmeter, the second buffer tube is installed at the other end of the flowmeter, and the shielding box is installed outside the flowmeter. The normal use of the flowmeter near a motor, a transmitter or other power supplies capable of easily causing electromagnetic interference can be guaranteed through the shielding box; a cooling mechanism can maintain the normal temperature in the shielding box; the first buffer tube and the second buffer tube cannot drive the flowmeter to produce vibration in the normal work theservice life of the flowmeter is prolonged, the measurement precision is improved; a generator is operated to generate electricity, the generated electricity is transmitted to an electric connector through a lead, and is supplied to an instrument for use after the voltage is regulated by the voltage regulator, the condition of electricity exhaustion during operation is avoided, and the industrialflowmeter can continuously operate.

Owner:JIANGSU MICRO WAVE ELECTRONICS TECH

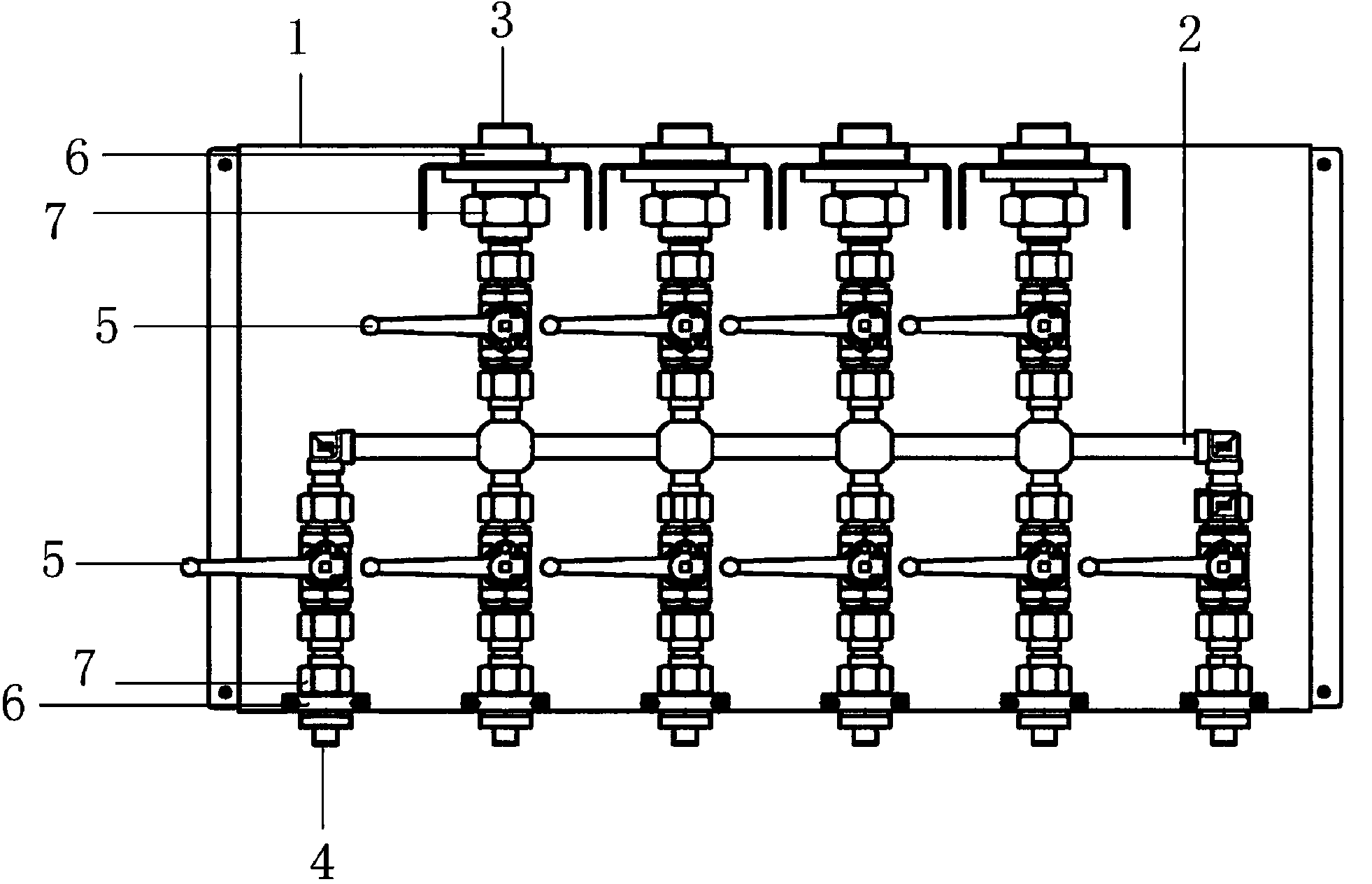

Efficient SF6 gas processing tool

ActiveCN104295886AImprove work efficiencyImprove inflation efficiencyContainer discharging methodsContainer filling under pressureVacuum pumpingProduct gas

The invention discloses an efficient SF6 gas processing tool. The efficient SF6 gas processing tool comprises a platy fixed base, a public connecting pipe installed on the fixed base and at least four joints used for connecting SF6 equipment air chambers and vacuumizers, wherein the two ends of the public connecting pipe are closed, at least four connectors are arranged on a pipe body of the public connecting pipe, and the joints are correspondingly connected to the connectors. With the adoption of the efficient SF6 gas processing tool, as a plurality of vacuumizers are connected with the efficient SF6 gas processing tool, air recycling and vacuum pumping are simultaneously carried out on a plurality of air chambers, and working efficiency is greatly improved; in addition, the plurality of air chambers can be inflated by virtue of a plurality of bottles of SF6 or N2 gas, and thus inflation efficiency is improved; structure is simple, manufacturing cost is low, time for processing SF6 during SF6 equipment overhaul and repairing work can be greatly shortened, manpower and material source consumption is saved, and power failure time of equipment is shortened.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU

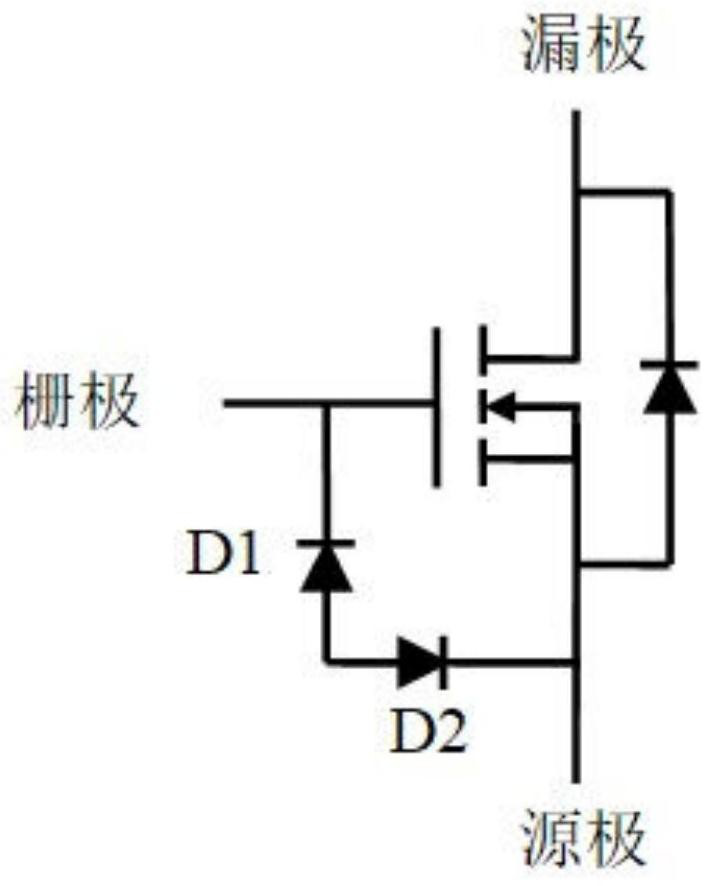

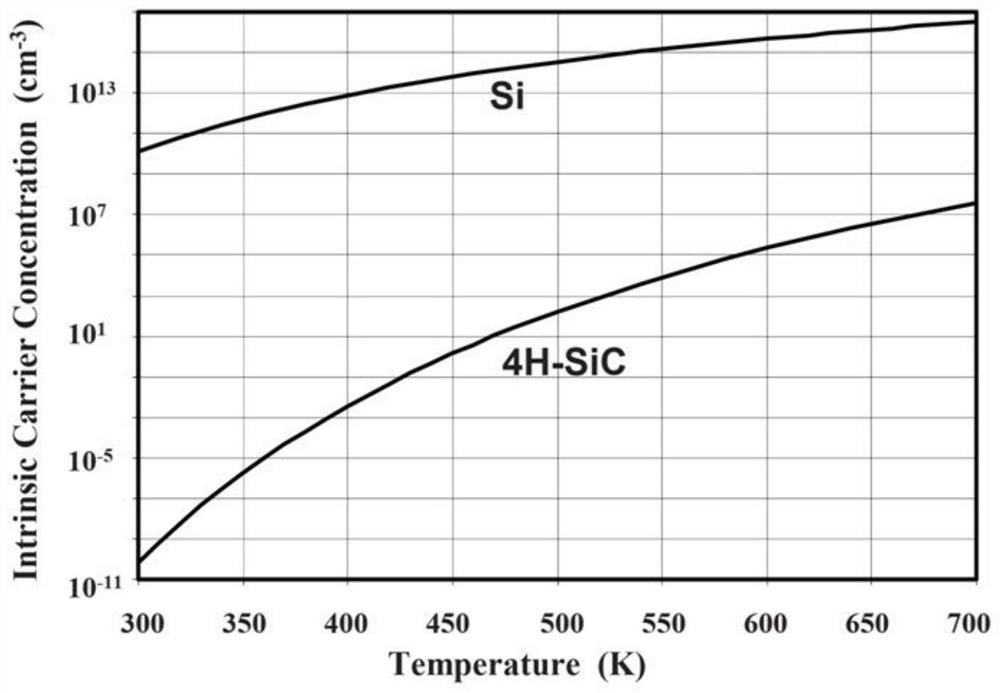

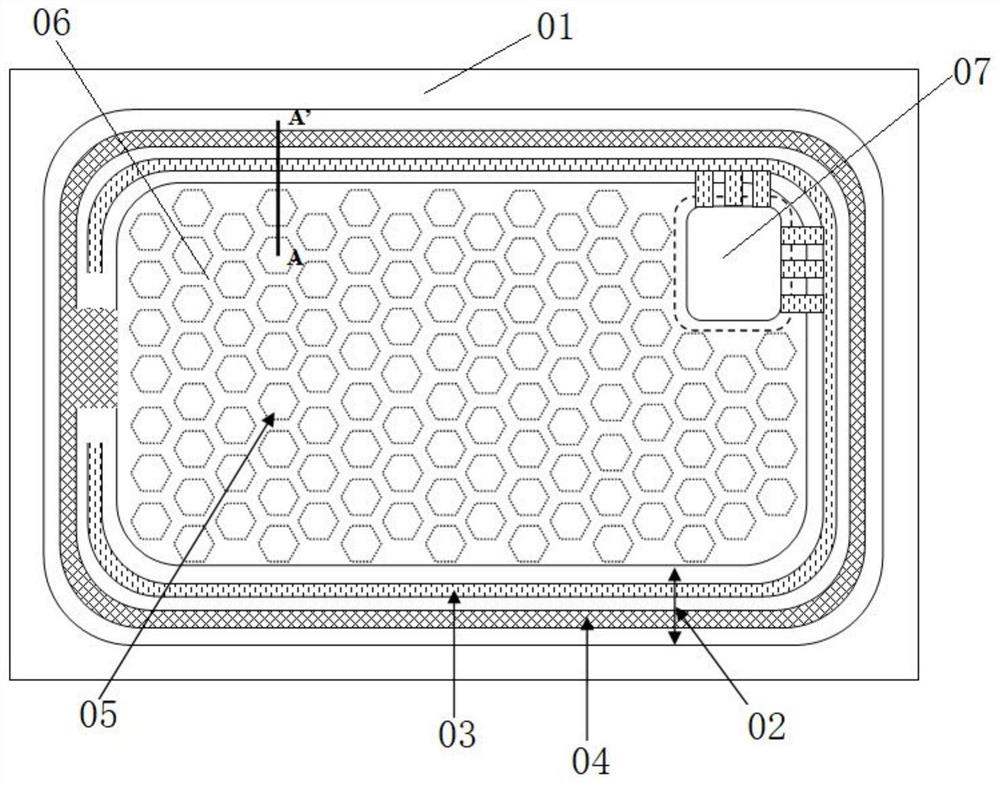

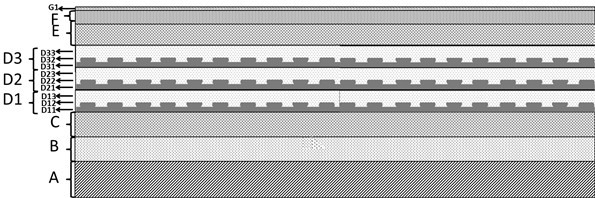

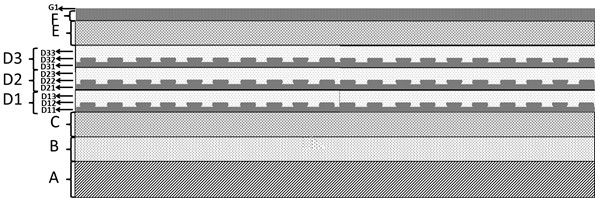

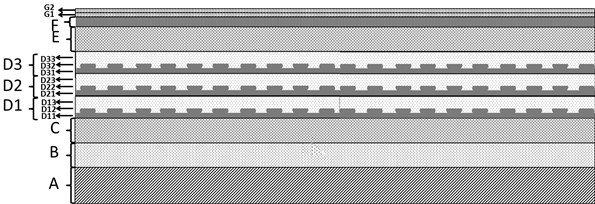

SiC MOSFET (Metal Oxide Semiconductor Field Effect Transistor) device of integrated gate protection structure

The invention relates to the technical field of semiconductors and particularly relates to a SiC MOSFET device with an integrated gate protection structure. The device sequentially comprises a scribing groove region, a terminal region, a p + main ring, a gate runway and a source runway on the p + main ring, an active region formed by connecting a plurality of primitive cell structures in parallel,and pressing block metal of a source and a gate on the active region from the edge to the center, the device is characterized in that two or more polycrystalline silicon pn diode structures which arereversely connected in series are integrated between the gate runway and the source runway to serve as a gate protection structure of the device. According to the device, the gate protection device is integrated on the chip, when the gate voltage of the device exceeds the maximum allowable voltage, the gate protection device is broken down, so the gate source voltage is clamped at the maximum allowable voltage, and the MOS gate medium is protected from bearing high voltage.

Owner:安徽芯塔电子科技有限公司

Large-caliber ammunition press-up device

InactiveCN109297371AImprove shooting training timeReduce the burden onAmmunitionEngineeringMechanical design

The invention discloses a large-caliber ammunition press-up device. The large-caliber ammunition press-up device comprises a press-up device, an elastic pressing cavity is formed in the elastic pressing device, the elastic pressing cavity is arranged in the elastic pressing cavity, and further comprises a press-up part arranged in the end wall of the top of the press-up cavity, a fixing componentarranged in the end wall at the bottom of the elastic pressing cavity, a transmission device is arranged between the bullet pressing part and the fixing part, the mechanical design of the equipment isreasonable and ingenious, the equipment is quite convenient to install, maintain and overhaul, meanwhile, the equipment can greatly improve the bullet pressing efficiency, lighten the burden of soldiers and improve the shooting training time of soldiers, the consistency of the press-in depth of the bullet is ensured at the same time, the probability of firing of the ammunition can be ensured after the two-time or multiple-time bullet pressing is guaranteed, the equipment can be guaranteed to work continuously, the size of the equipment is greatly reduced, the portability of the equipment is further improved, the device has high automation degree in the using process, and the device has relatively high use and popularization values.

Owner:兰溪德比电子科技有限公司

River channel cleaning device

The invention discloses a river channel cleaning device. The bottom of a hollow floating seat is connected to a net bag, and the top is pivotally connected to a ring frame. Driven by the motor on the top of the ring frame, the power source is the solar panel on the top of the ring frame. A river channel cleaning device of the present invention uses the rotating arc-shaped arm to draw the impurities in the channel into the net bag; the solar panel continuously supplies power to the motor to maintain a continuous working state; the floating seat makes the cleaning device suspended on the water surface and follows the water flow Float to clean up impurities at any point on the water surface of the river. The utility model has the advantages of simple structure, high efficiency of cleaning impurities on the water surface of the river, sustainable work, green energy, saving a lot of manpower and material resources, and has strong practicability and wide applicability.

Owner:黄福芝

Novel mixing distributor for kiln

The invention discloses a novel mixing distributor for a kiln. The mixing distributor comprises a frame, a base, a mixing mechanism and a distributing mechanism, wherein the frame is arranged on two sides of the base; a support seat is arranged on one side of the base; a motor is arranged above the support seat; the distributing mechanism comprises a distributing hopper, a distributing device and connecting rods; the mixing mechanism is arranged above the distributing mechanism and comprises a mixing hopper and stirring blades; a shaft sleeve is arranged in the center of the mixing hopper; the stirring blades are arranged on the side wall of the shaft sleeve; a discharge opening is formed in the center of the bottom of the mixing hopper; a lifting shaft is arranged in the center of the shaft sleeve; a bracket is arranged on two sides of the lifting shaft; an oil cylinder is arranged in the center of the bracket; the bottom of the oil cylinder is arranged on the frame; a hydraulic tank is arranged on one side of the oil cylinder; and a bottom cover is arranged at the bottom of the lifting shaft. Through the novel mixing distributor for the kiln, materials are mixed uniformly, distributed consistently and calcined fully in the lime kiln, and the efficient and reasonable production of the lime kiln is realized.

Owner:刘建轻

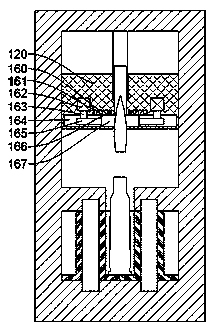

Middle seal punching die structure

PendingCN112935067AAchieve intermittent effectSustainable workShaping toolsPunchingStructural engineering

The invention discloses a middle seal punching die structure. The middle seal punching die structure comprises a bottom plate and a punching part, and a switching part is linked with the upward moving process of the punching part through a linkage part I. The middle seal punching die structure further comprises four ejector rods used for ejecting workpieces in two lower concave dies I and two lower concave dies II, and the four ejector rods are in transmission connection with the switching part through a linkage part II. The middle seal punching die structure further comprises a spraying mechanism capable of spraying towards the direction of the workpieces through a spray head when the switching part is switched. According to the middle seal punching die structure, through vertical movement of a punching machine, the two groups of concave dies I and lower concave dies II can be switched back and forth, the concave dies can be staggered from the position under the punching machine after being deflected every time the workpieces are taken out, so that the safety of a user is guaranteed when the workpieces are replaced, and the situation that the working efficiency is reduced due to repeated shutdown is avoided.

Owner:上海探见智能家居有限公司

Preparation method of refrigeration-free anti-reflection InP-based quantum dot/quantum well coupled EML epitaxial wafer

PendingCN114188823AStable jobGood effectLaser detailsLaser optical resonator constructionDistributed feedback laserOptical isolator

According to the preparation method of the refrigeration-free anti-reflection InP-based quantum dot / quantum well coupling EML epitaxial wafer, a quantum well electric absorption modulation region which is covered by an ohmic contact layer and is horizontally coupled with a quantum dot stacking region is additionally arranged in the quantum dot stacking region in a quantum dot laser based on an InP substrate. The electro-absorption modulated laser is prepared through molecular beam epitaxy or metal organic chemical vapor deposition and is formed by integrally growing a quantum dot distributed feedback laser and a quantum well electro-absorption modulator in a butt-joint growth mode; the electro-absorption modulated laser combines the characteristics of excellent reflection resistance and high temperature stability of a quantum dot laser and the characteristic of high modulation rate of a quantum well electro-absorption modulator, and realizes stable work at 5-75 DEG C under the conditions of no optical isolator and no refrigeration. The preparation method is clear and simple in steps and easy to operate, and the prepared electro-absorption modulated laser is good in effect, stable in performance, capable of working continuously, high in practicability and wide in applicability.

Owner:JIANGSU HUAXING LASER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com