Automatic feeding device for piston rings

An automatic feeding, piston ring technology, applied in the direction of grinding feed movement, grinding machine parts, metal processing equipment, etc. , to achieve the effect of improving transportation efficiency, ensuring uninterrupted and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

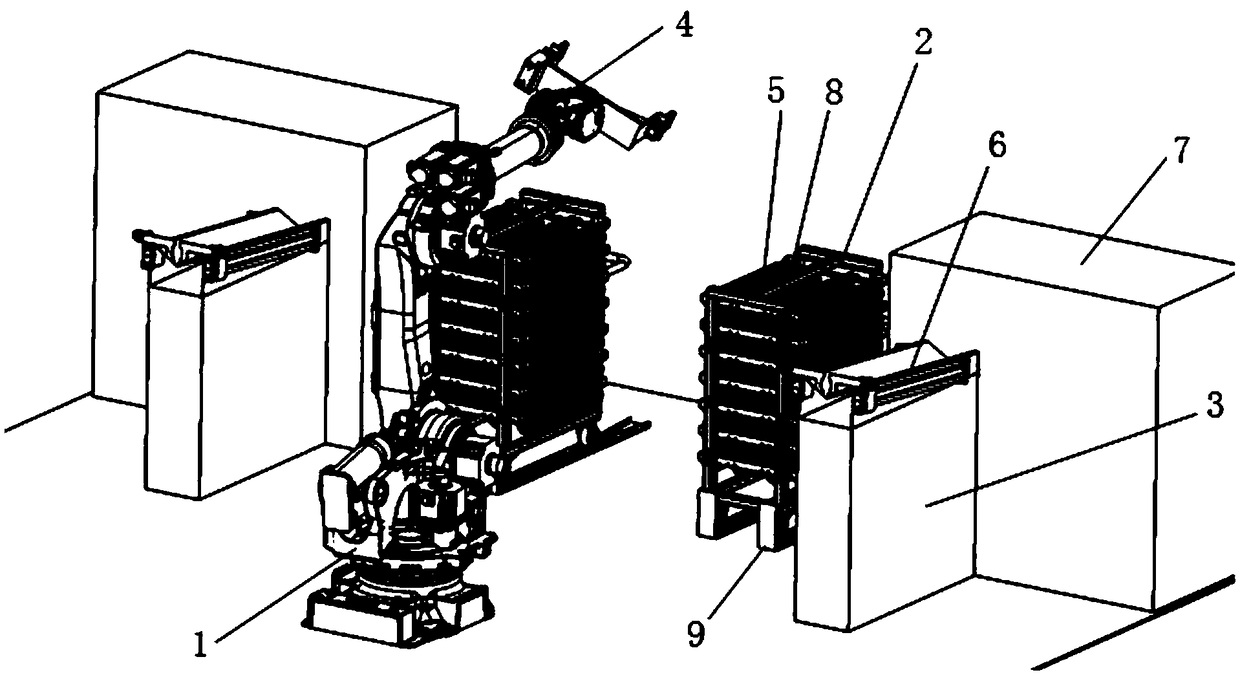

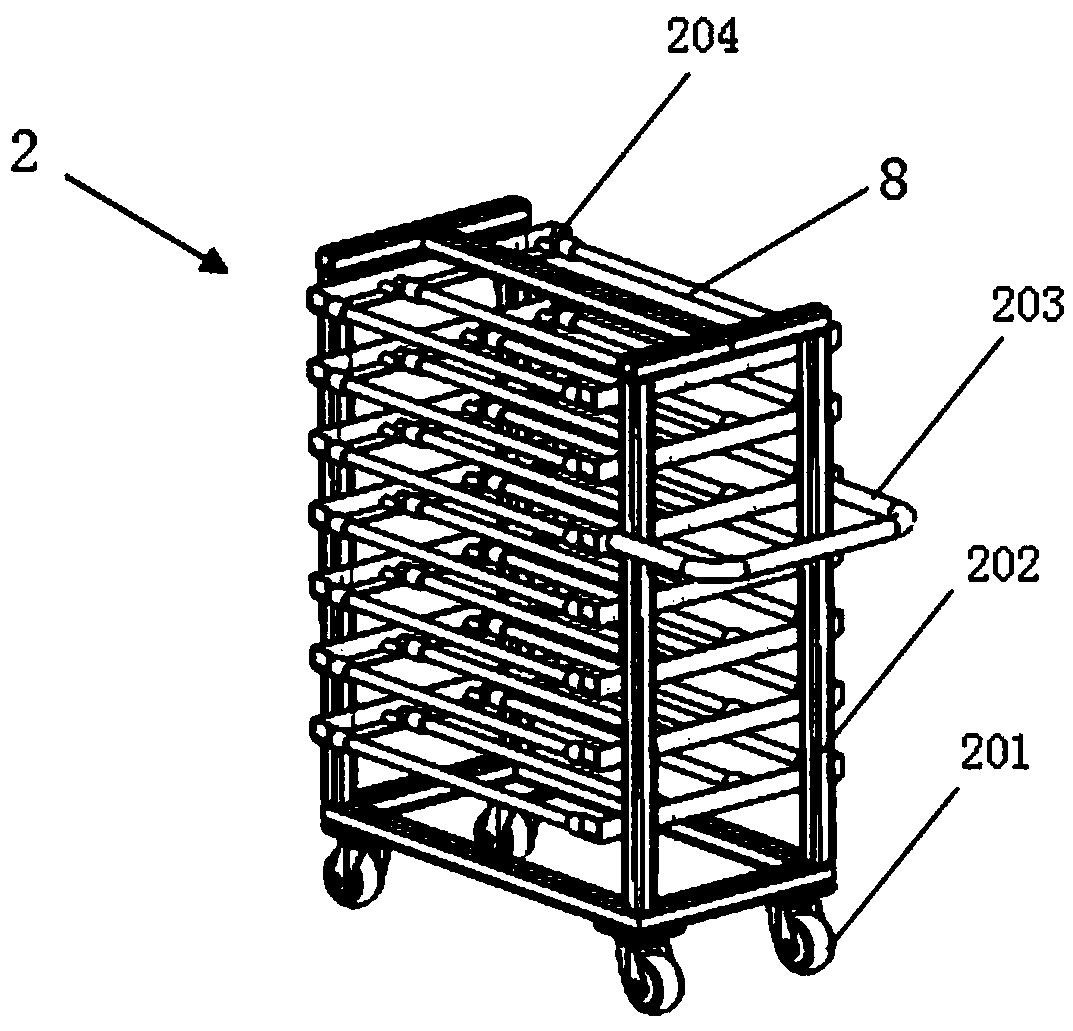

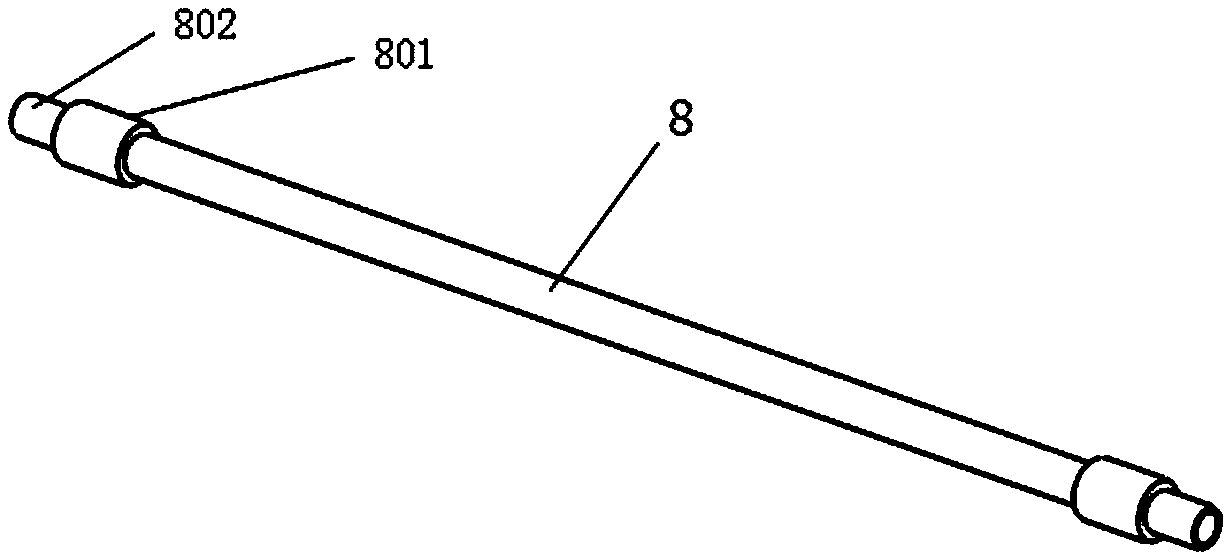

[0026] See figure 1 , the piston ring automatic feeding device provided by the present invention comprises a feeding robot 1, and 2 feeding units symmetrically arranged on the side of the feeding robot 1 form 2 feeding stations, and each feeding unit includes a A feeding platform 3 and a trolley 2 are matched with the transport robot 1; the end of the mechanical arm of the transport robot 1 is provided with a grasping mechanism 4, and the trolley 2 is provided with multiple rows for free pick-and-place. On the loading rod 8 of the sleeve piston ring 5, the feeding platform 3 is provided with a pressing mechanism 6, and each loading platform 3 is connected with the feeding port of a grinding machine 7; 2 Positioning device 9 for positioning; the material transport robot 1 takes out the charging rod 8 of the piston ring 5 from the trolley 2 through the grasping mechanism 4, and places it on the loading table 3, and pulls out the charging rod 8 , and then the piston ring 5 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com