Optical fiber installation device and vehicle lamp assembly system

A technology for installing equipment and optical fibers, which is applied in the fields of optical fiber installation equipment and car light assembly systems, can solve problems such as difficulties in installing and fixing optical fibers, and achieve the effects of good appearance consistency, high intelligence, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

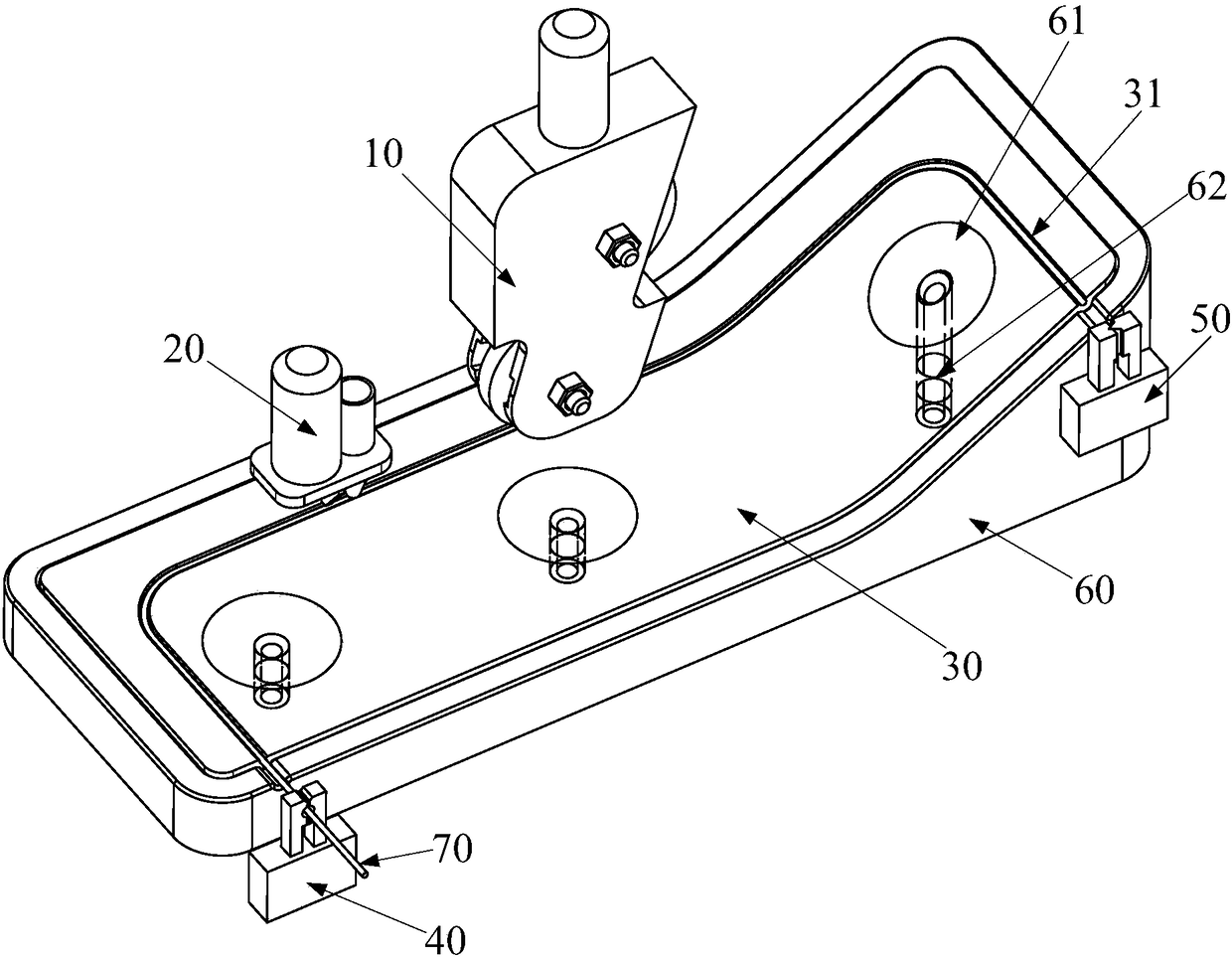

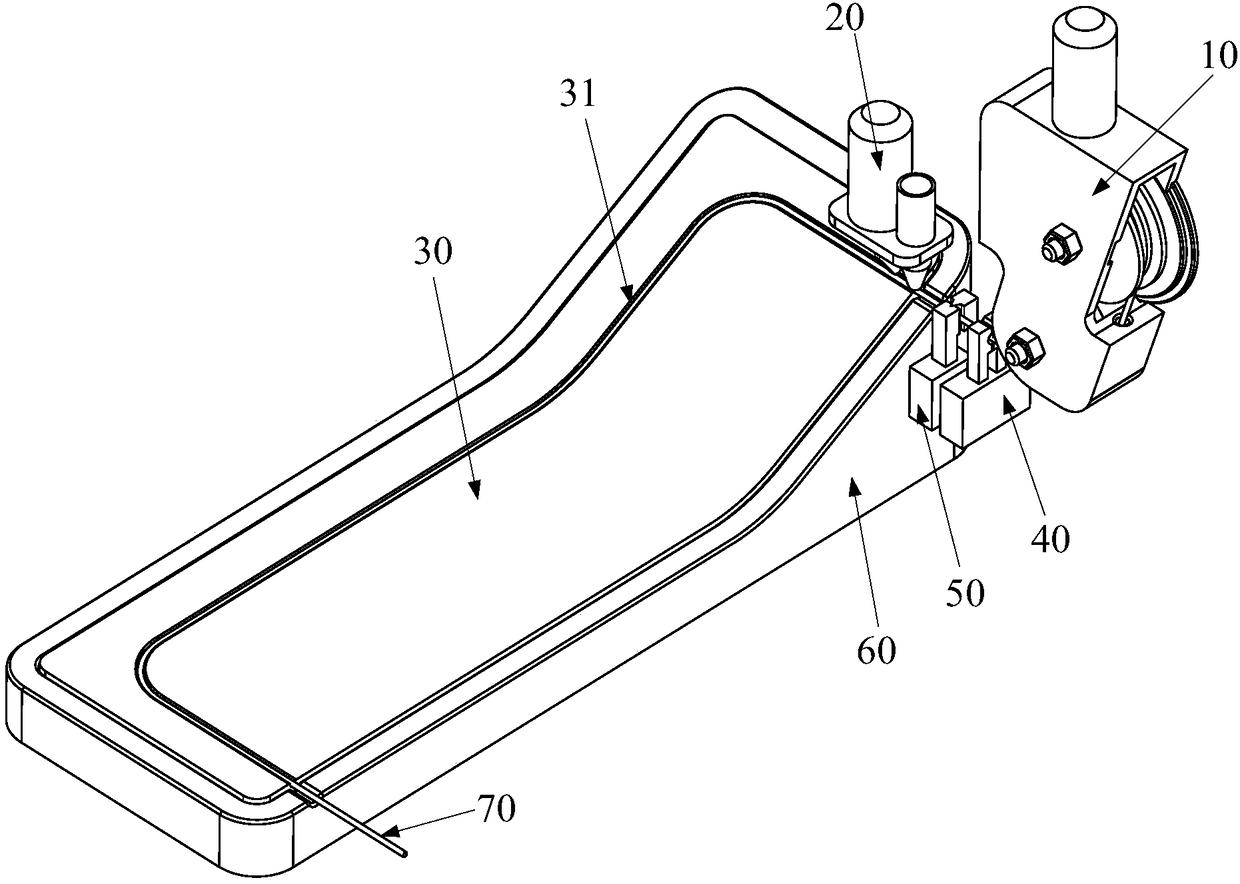

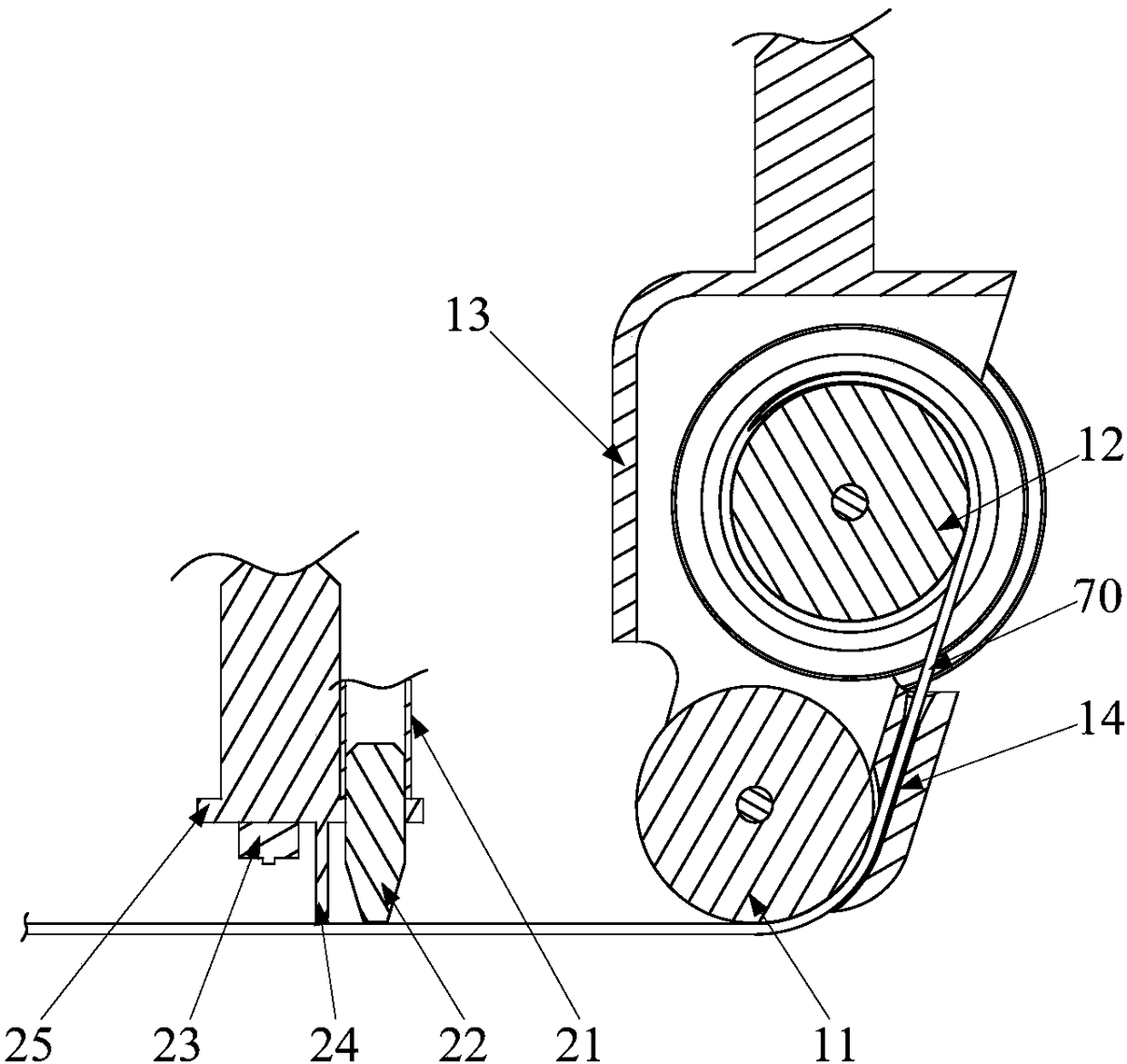

[0036] Such as Figure 1-Figure 4 As shown, the optical fiber 70 installation equipment provided by the embodiment of the present invention includes: a laying mechanism 10, a glue application mechanism 20, and a driving mechanism. The mechanism is respectively connected with the laying mechanism 10 and the gluing mechanism 20 to drive the laying mechanism 10 and the gluing mechanism 20 to move along the optical fiber placement groove 31. The laying mechanism 10 is used to place the optical fiber 70 in the optical fiber placement groove 31, and the gluing mechanism 20 It is used to apply glue to the optical fiber 70 located in the optical fiber arranging groove 31 so that the optical fiber 70 is fixed in the optical fiber arranging groove 31 .

[0037] The optical fiber 70 installation device of the embodiment of the present invention is used to install the optical fiber 70 on the optical fiber fixing carrier 30, and the optical fiber fixing carrier 30 is the internal fittings,...

Embodiment 2

[0061] Embodiment 2 of the present invention provides a vehicle lamp assembly system, including the optical fiber installation device provided in Embodiment 1 above. The optical fiber installation equipment is used to install the optical fiber to the optical fiber fixed carrier. In addition, the car light assembly system can also include light source installation equipment, reflector installation equipment, overall assembly equipment, etc.

[0062] The vehicle lamp assembly system has the same advantages as the optical fiber installation device provided in the first embodiment above compared with the prior art, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com