Dustproof heat dissipation power distribution cabinet device suitable for construction site

A dust-proof, power distribution cabinet technology, applied in substation/distribution device housing, substation/switchgear cooling/ventilation, substation/switch layout details, etc. Reduce the heat dissipation effect of the power distribution cabinet and other problems to ensure the effect of normal heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

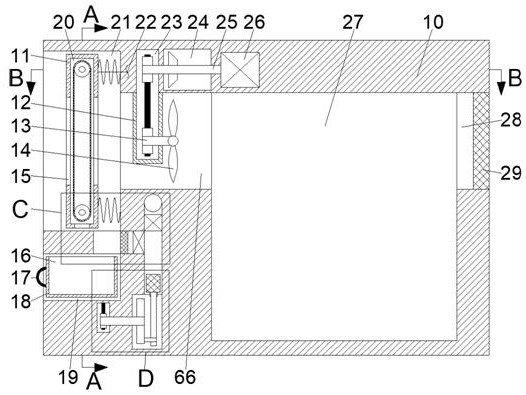

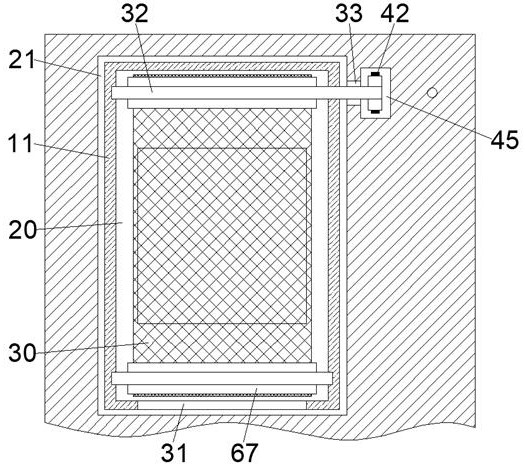

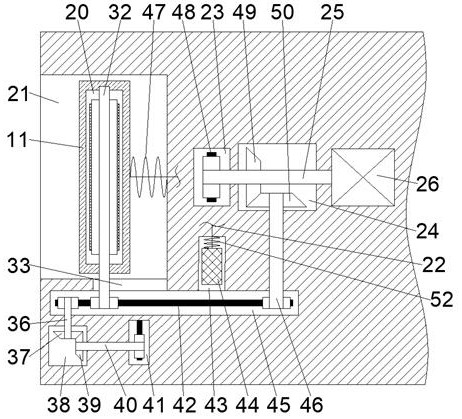

[0017] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0018] A dust-proof heat-dissipating power distribution cabinet device suitable for construction sites, described in conjunction with accompanying drawings 1-5, includes a main body box 10, and a power distribution cavity 27 is arranged inside the main body box 10, and the left end of the power distribution cavity 27 is connected to A fan cavity 66 is provided, and the left end wall of the fan cavity 66 is connected with a dust filter cavity 21 opening to the left. Roller chamber 33, the front wall of the roller chamber 33 is connected with a clutch pulley chamber 45, the dust filter chamber 21 is slidingly connected with a filter box 11, and the filter box 11 is provided with a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com