Novel efficient environment-friendly polishing machine of cutting sheet

A technology of cutting discs and polishing machines, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding racks, etc., can solve problems such as high labor intensity, uneven polishing, large dust, etc., and achieve stable operation Reliable, simple and convenient operation, and the effect of preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-9 , to further specifically describe the technical solution of the present invention.

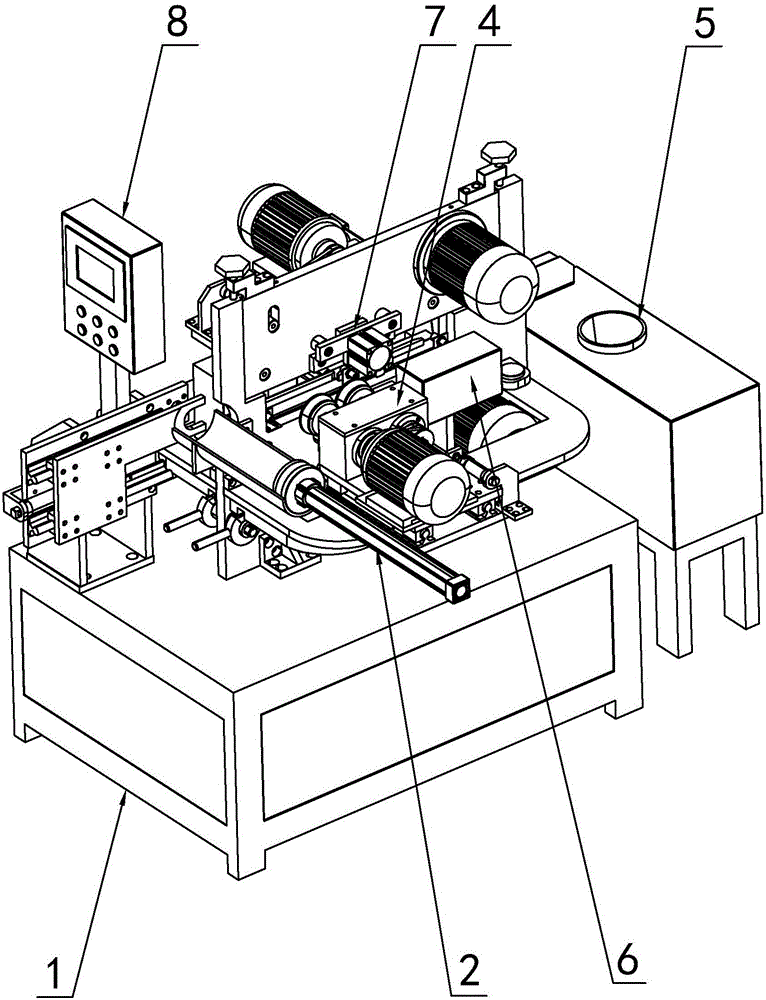

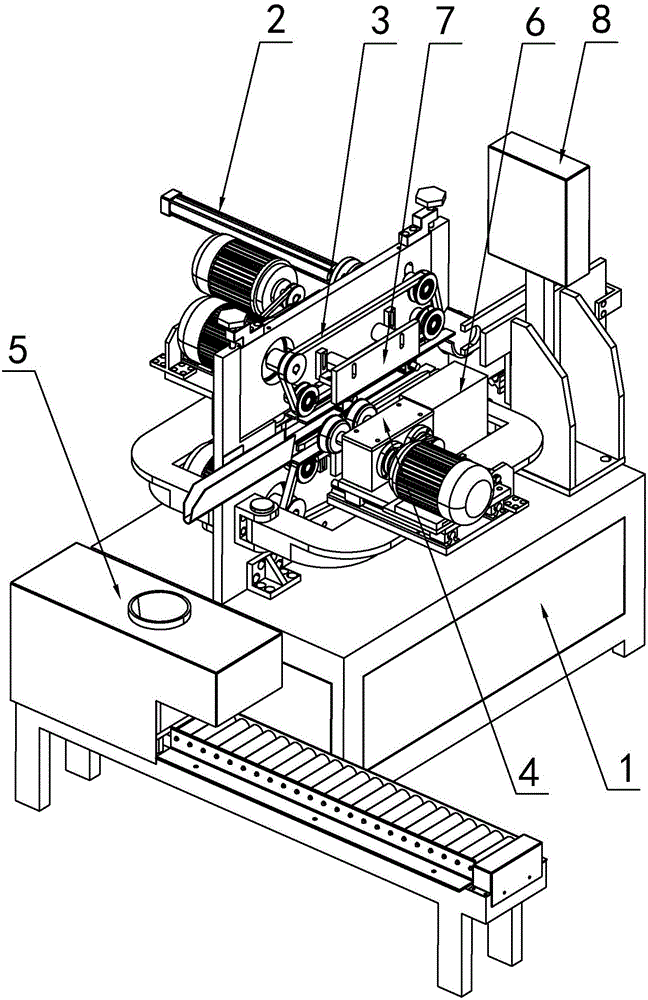

[0031] A new high-efficiency and environmentally friendly cutting disc polishing machine, including a frame 1, a feeding mechanism 2, a conveying mechanism 3, and a polishing mechanism 4. The frame 1 includes channel steel, angle steel, steel plate, and square steel. The frame 1 is welded and bolted. The way of connection is fixed connection, and the frame 1 is used to carry and fixedly connect the feeding mechanism 2, the conveying mechanism 3, and the polishing mechanism 4; the side of the frame 1 is provided with a control cabinet 8.

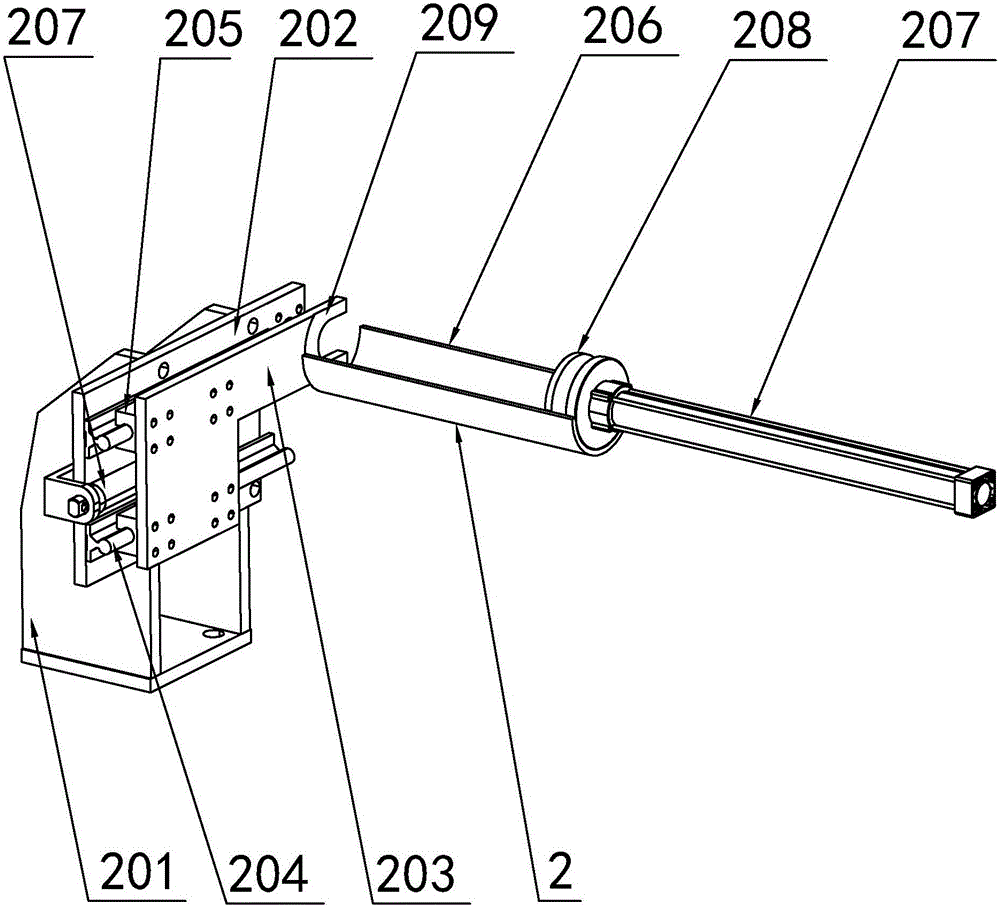

[0032]The feeding mechanism 2 comprises a support 201, a fixed seat 202, a push plate 203, a trough 206, a cylinder 207, a push block 208, and a slot 209. The support 201 is provided with a fixed seat 202, and the fixed seat 202 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com