Novel mixing distributor for kiln

A distributor and kiln technology, which is applied in the field of lime kilns, can solve problems such as inability to realize efficient and rational production of lime kilns, uneven mixing of lime material components, and reduced service life of kilns, so as to improve utilization rate and fully calcine , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

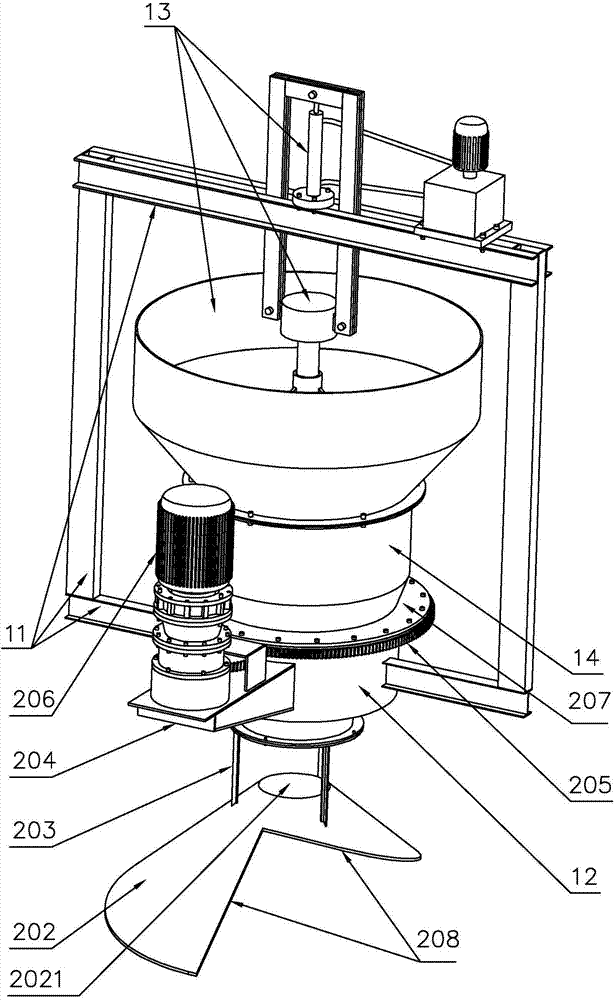

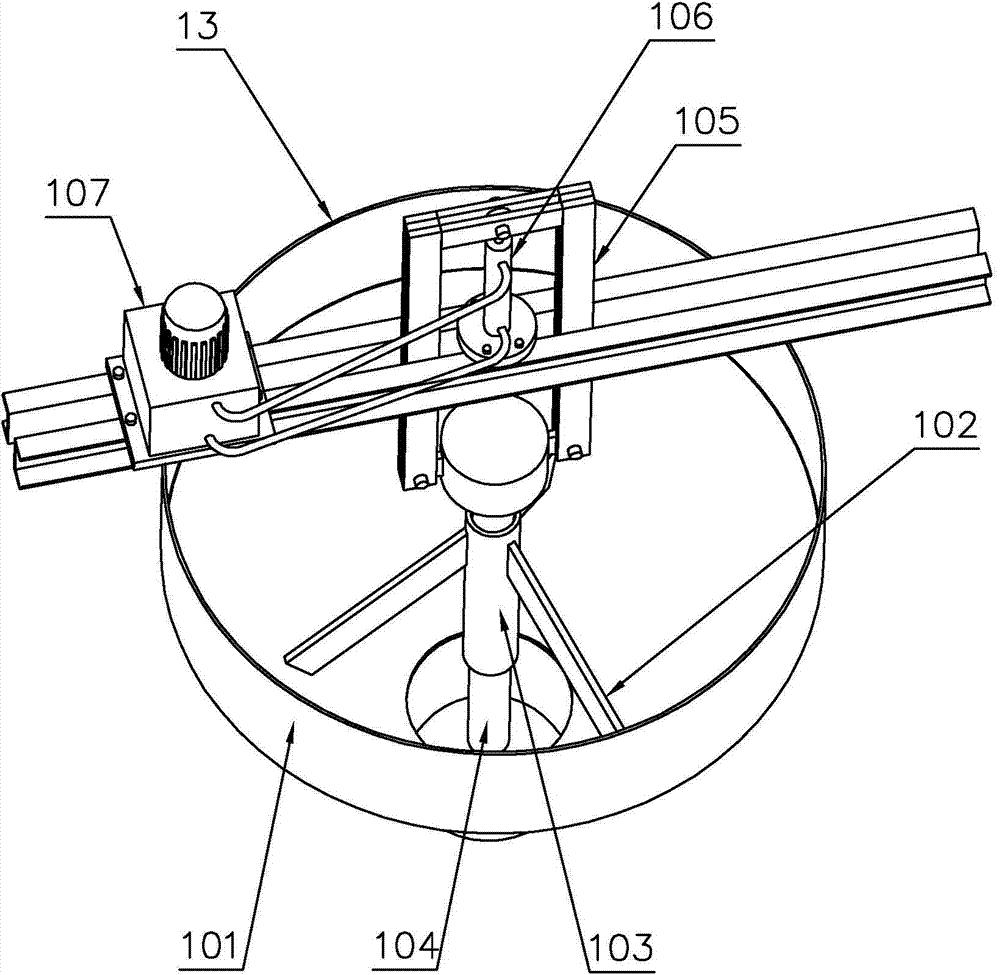

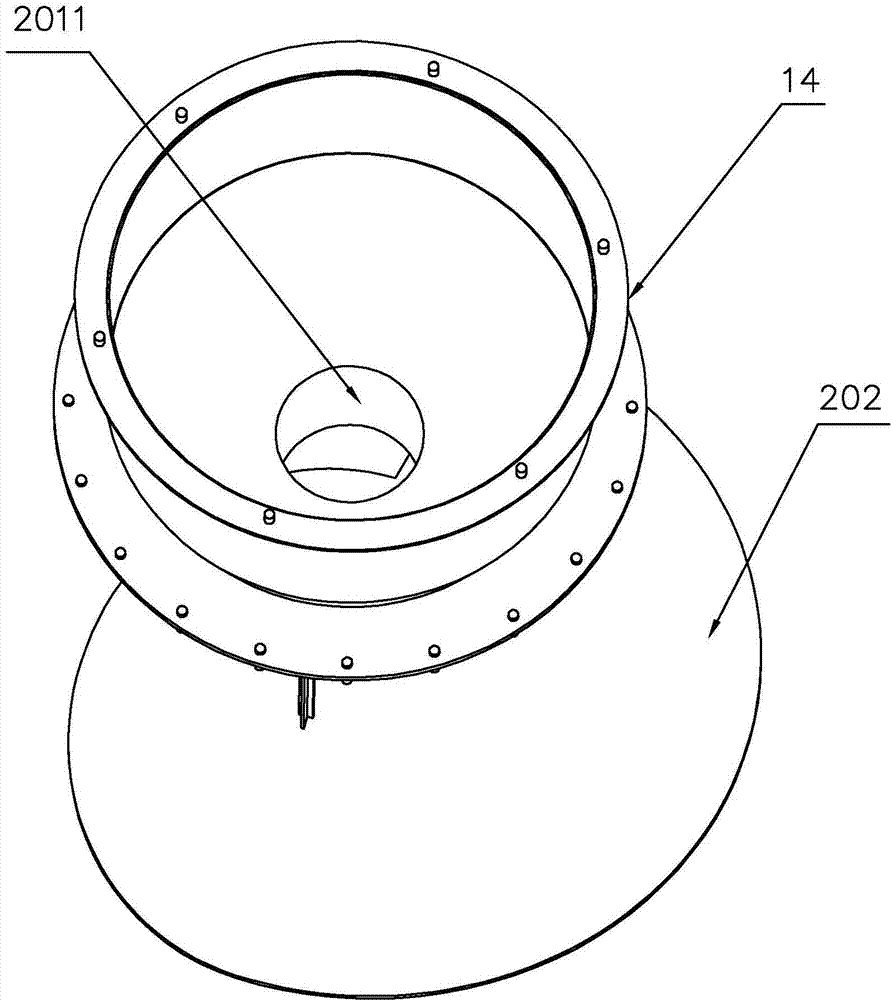

[0014] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-3 , to further specifically describe the technical solution of the present invention.

[0015] A new kiln mixing distributor, including a frame 11, a base 12, a material mixing mechanism 13, and a material distribution mechanism 14. The frame 11 is provided on both sides of the base 12, and a support is provided on one side of the base 12. Seat 204, a motor 206 is provided on the top of the support seat 204, a gear 205 is provided at the shaft end of the motor 206, and a slewing bearing is provided at the mouth of the base 12, and the slewing bearing is composed of a bearing outer ring and a bearing inner ring, and the bearing inner ring The base 12 is connected by screws, the outer ring of the bearing is provided with a gear 205, the gear 205 at the shaft end of the motor 206 meshes with the gear 205 of the outer ring of the bearing, the motor 206 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com