Patents

Literature

62results about How to "Fully calcined" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

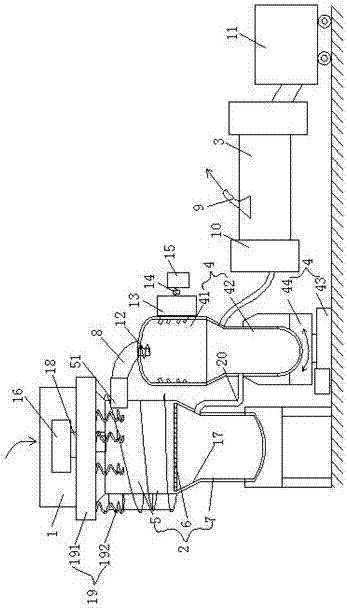

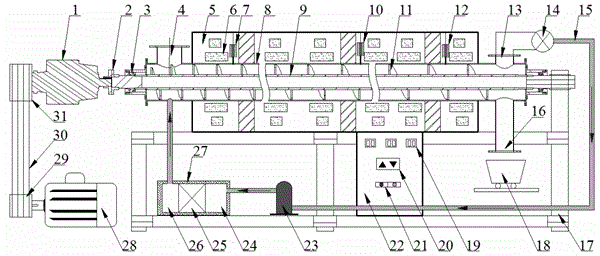

Fluidized calcination device and method for treating high-iron low-aluminum coal series kaolinite

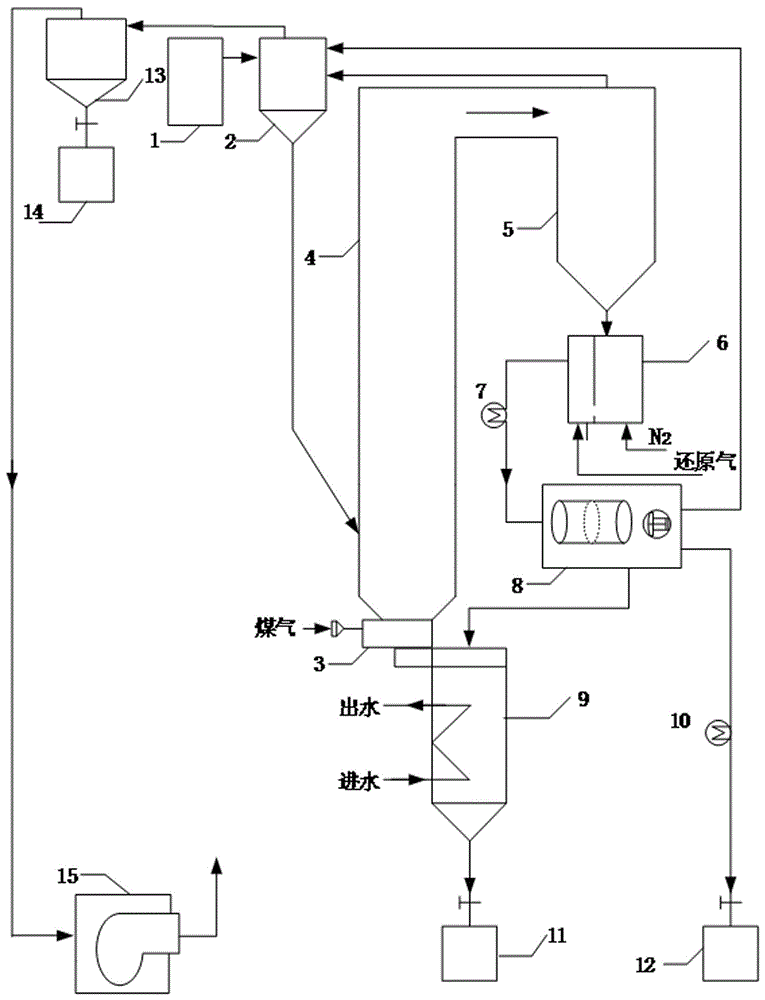

The invention relates to a fluidized calcination device and method for treating high-iron low-aluminum coal series kaolinite. The device comprises a feed bin, a gas burner, a suspended preheater, a suspended calcination unit, a cyclone separator, an iron removal reductor, an electric magnetic iron remover, a whiteness monitor, a material cooler and a Roots blower. The method comprises the following steps: putting the raw material high-iron low-aluminum coal series kaolinite in the feed bin, preheating the material subjected to primary separation in the suspended preheater, calcining in the suspended calcination unit, and carrying out reduction reaction in the iron removal reductor; and cooling to normal temperature, carrying out magnetic separation in the electric magnetic iron remover to remove magnetic iron minerals, inspecting by the whiteness monitor to obtain the acceptable product, and cooling to normal temperature. The device can efficiently treat high-iron coal series kaolinite, has the advantages of sufficient calcination process and high product whiteness, can effectively remove iron tramp minerals in the raw material, and can easily implement large-size industrial production.

Owner:NORTHEASTERN UNIV

Calcining method for preparing aluminum-electrolytic pre-baked carbon anode petroleum coke

The invention relates to a calcining method for preparing aluminum-electrolytic pre-baked carbon anode petroleum coke, which is characterized in that calcination temperature is controlled at 1300-1350 DEG C; the fluctuation range of temperature is not larger than 30 DEG C; discharging amount is controlled by the volatile matter content in the petroleum coke, and the volatile matter is controlled in 10-15%; the secondary ventilation quantity of a rotary kiln is 2000-2600 m3 / h, and the third ventilation quantity is 1600-2200m3 / h; and negative pressure is controlled in 20- 40Pa. the invention causes a calcining process to obtain system optimization, the coke performance after calcination is greatly improved, the oxidation resistance and the electrical conductivity after calcination are significantly increased, and the true density is more than 2.05g / cm3. The produced anode quality is more uniform and stable, the ratio of first-grade products is significantly increased, and the electrolytic carbon consumption is greatly reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

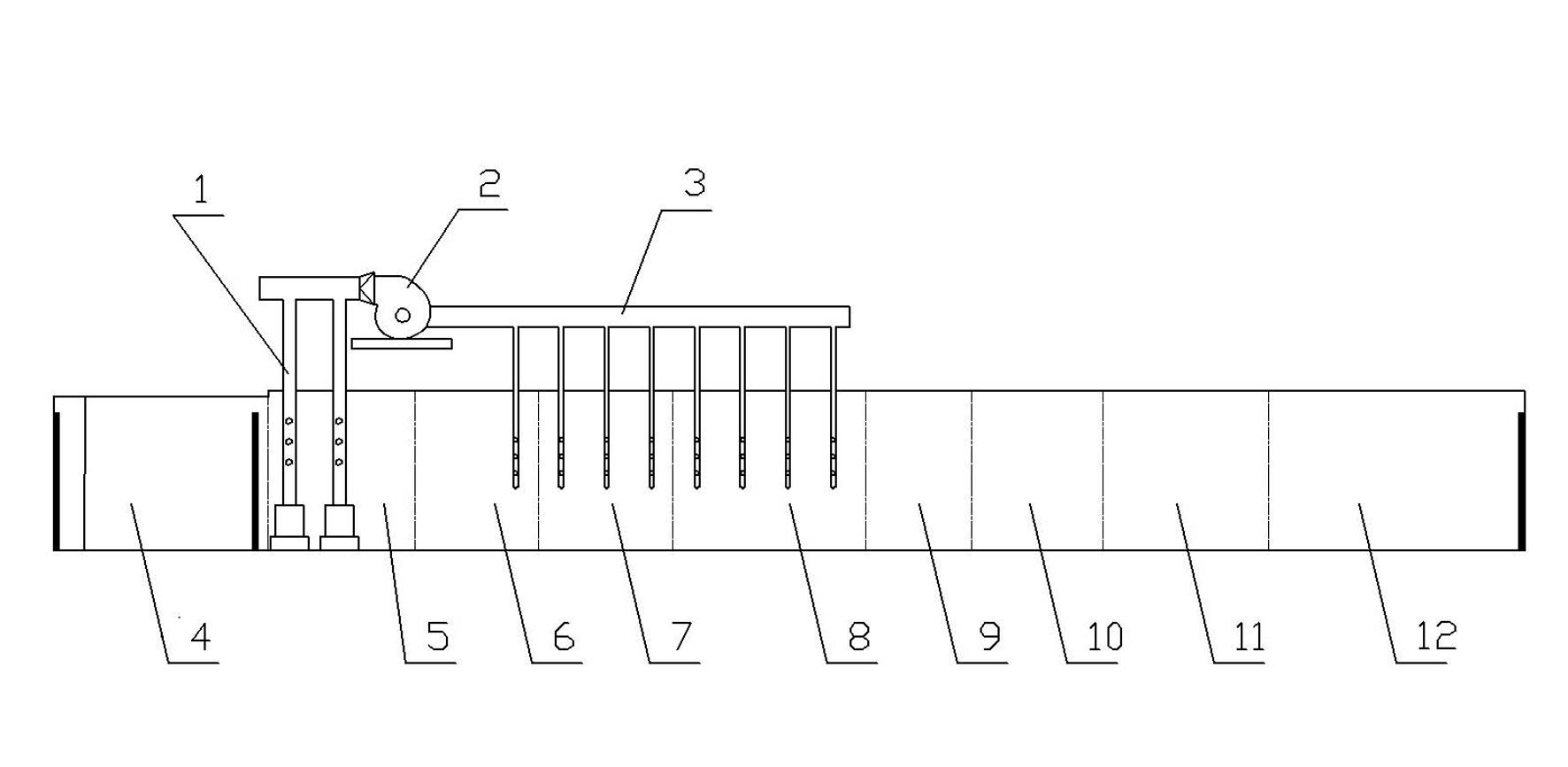

Method and device for sintering lime

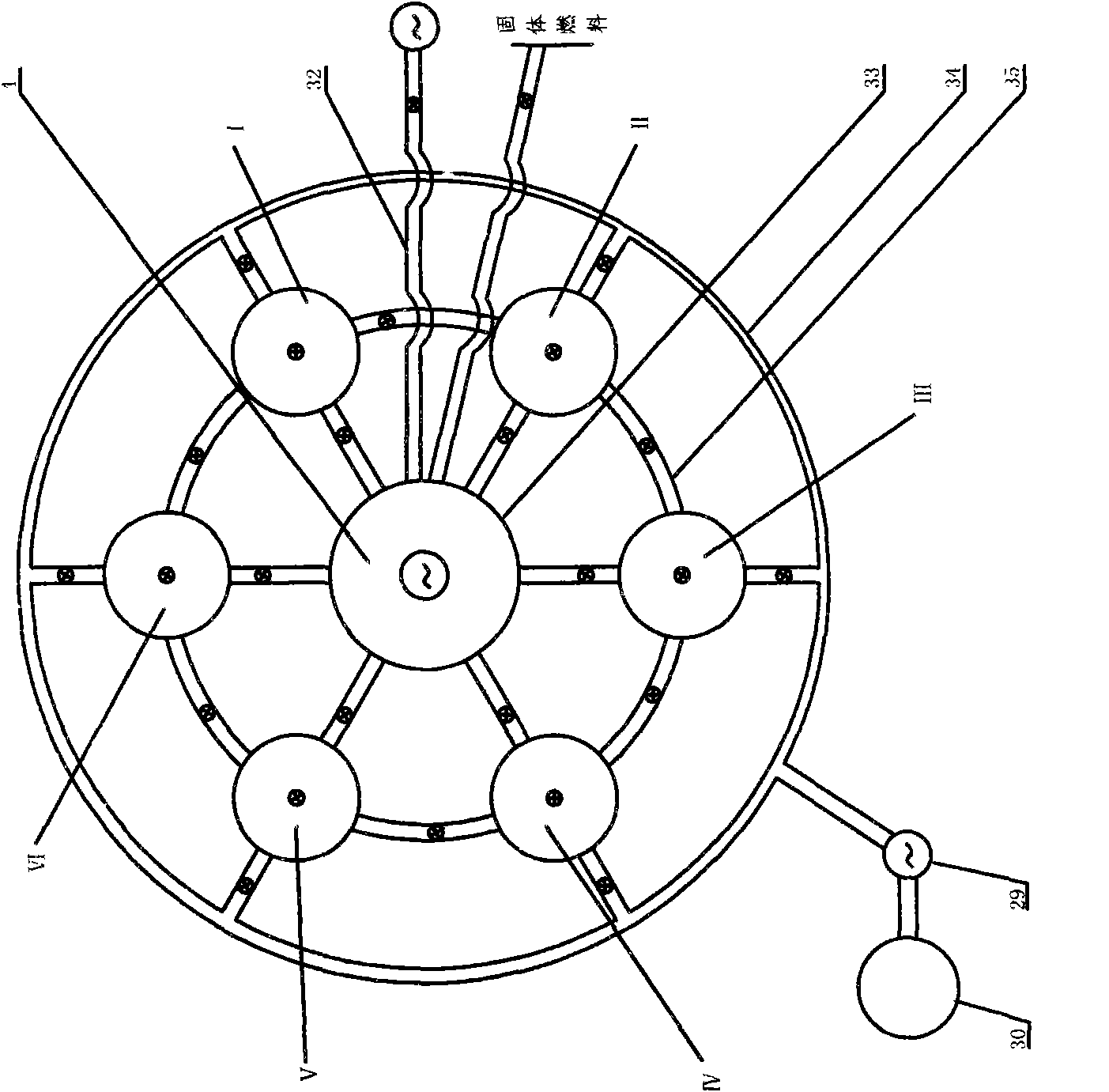

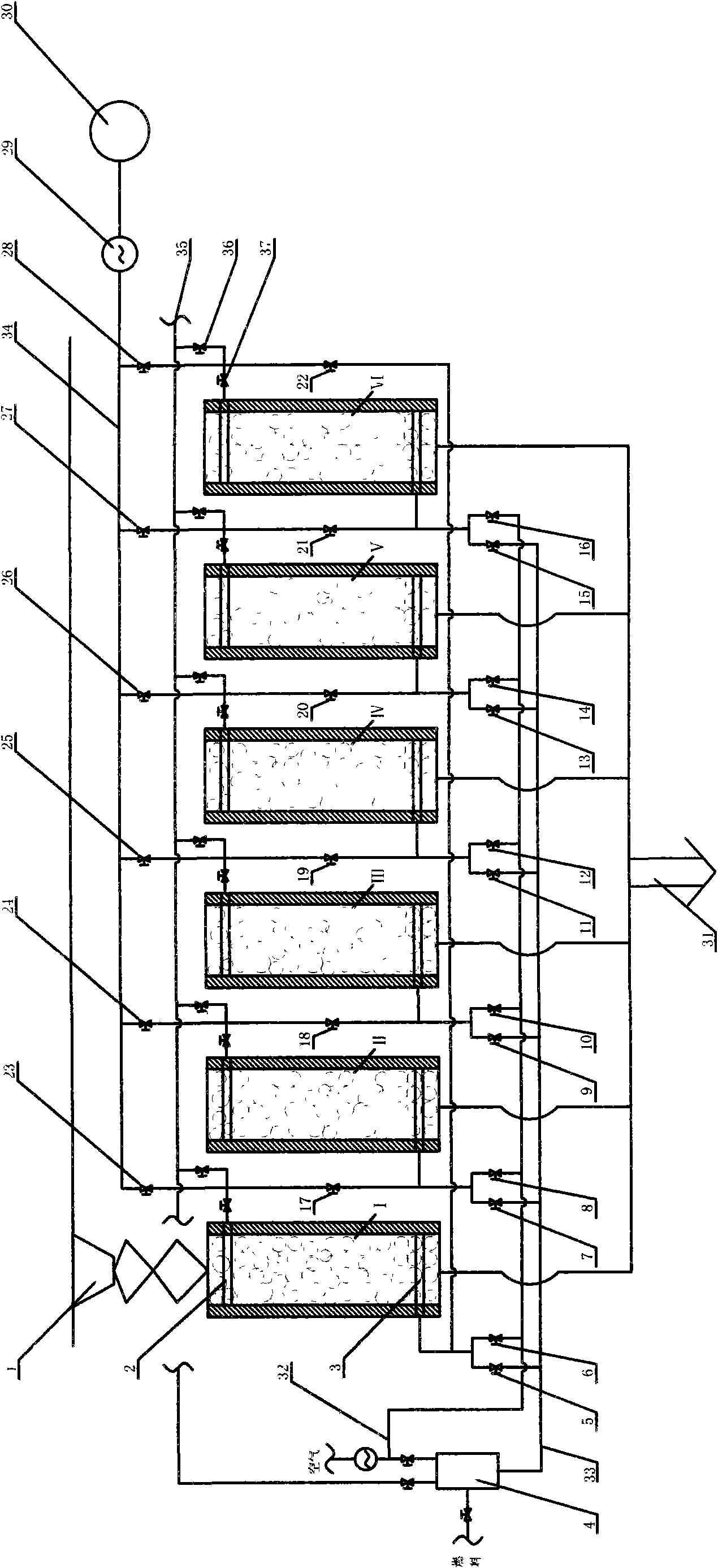

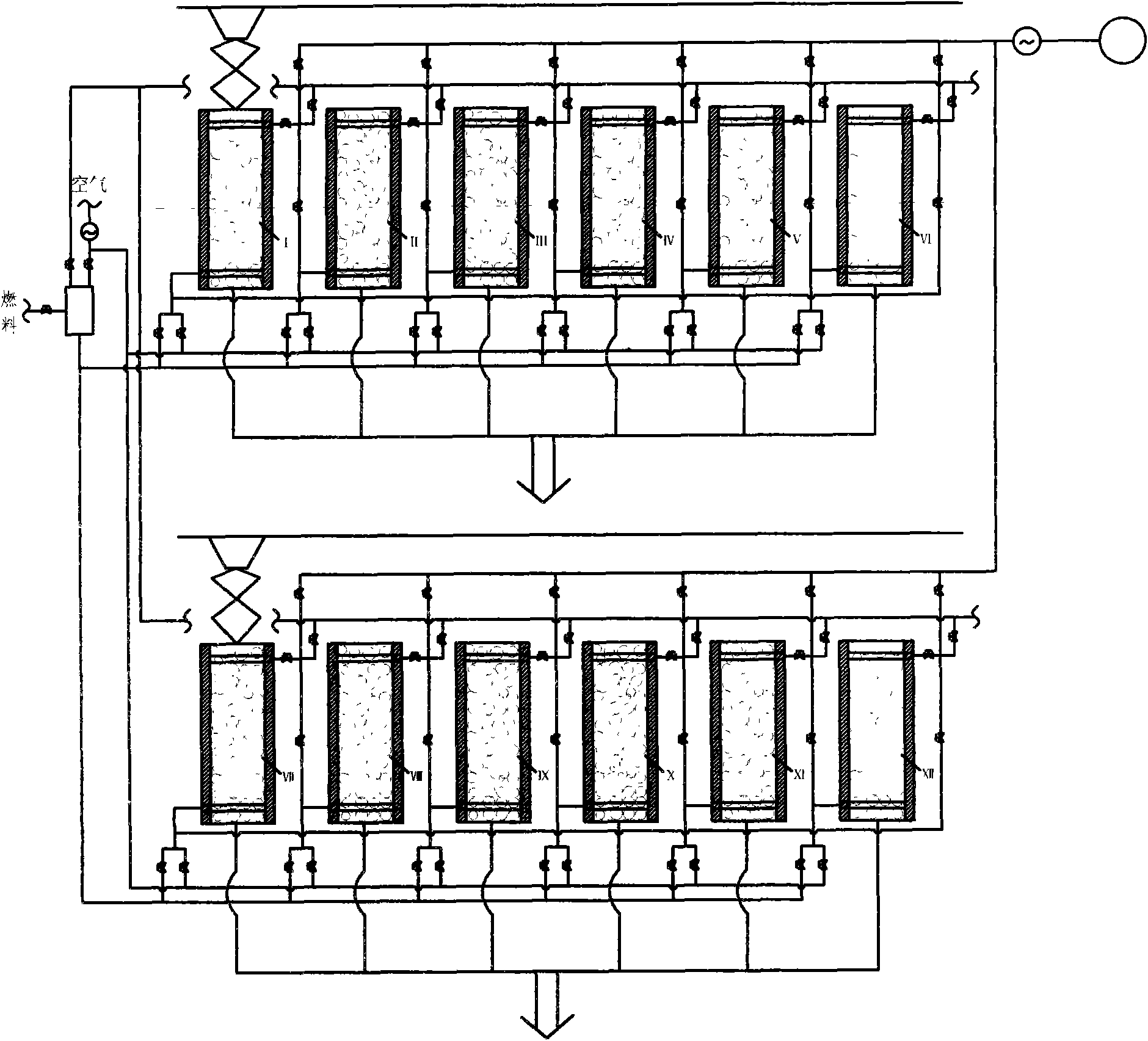

The invention relates to a method and a device for sintering lime. The device comprises a plurality of kilns which are distributed in a ring or matrix or other shapes. Solid fuel such as coal powder, and the like, or gas fuel or liquid fuel, or mixed fuels of solid, gas and liquid combusts in the kilns or a separately arranged combustion chamber, and generated high-temperature smoke sinters limestone in the kilns and preheats the limestone in other kilns. Each kiln is internally provided with an air inlet girder and an up-sucking girder. The top of each kiln is provided with a movable feeding device capable of feeding for each kiln in a system. The bottom of each kiln is provided with a movable discharging device connected with a discharging channel and gathering dust generated by each kiln. By using the method and the device for sintering lime, the limestone can be sintered more sufficiently and evenly and has good quality and high activity degree; and meanwhile, the invention can sufficiently utilize afterheat, save the energy source, improve the thermal efficiency of the system, lower the production cost and realize large-scale continuous production.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

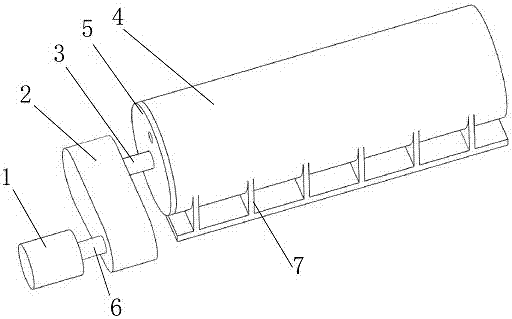

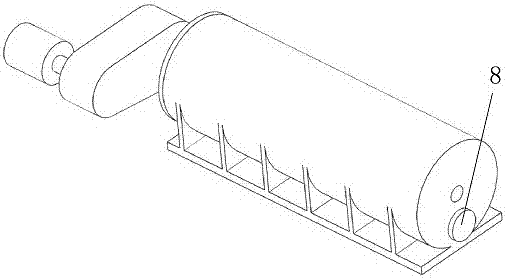

U-shaped internal-combustion rotating limekiln capable of recovering CO2

The invention belongs to the field of kiln, and provides a u-shaped internal-combustion rotating limekiln capable of recovering CO2. The limekiln is characterized in that the rotary kiln is horizontal, a u-shaped muffle heating furnace and a u-shaped calcining chamber are adjacently arranged inside the rotary kiln, blades are arranged on the inner wall of the muffle heating furnace and the inner wall of the calcining chamber, and a carbon dioxide collector is arranged through a limestone feeding inlet to communicate with the calcining chamber. Compared with present muffle rotary limekilns, the u-shaped internal-combustion rotating limekiln capable of recovering CO2 has significant advantages of reasonable structure, energy conservation, and emission reduction, and can recover and utilize materials and improve product quality.

Owner:赵光辉

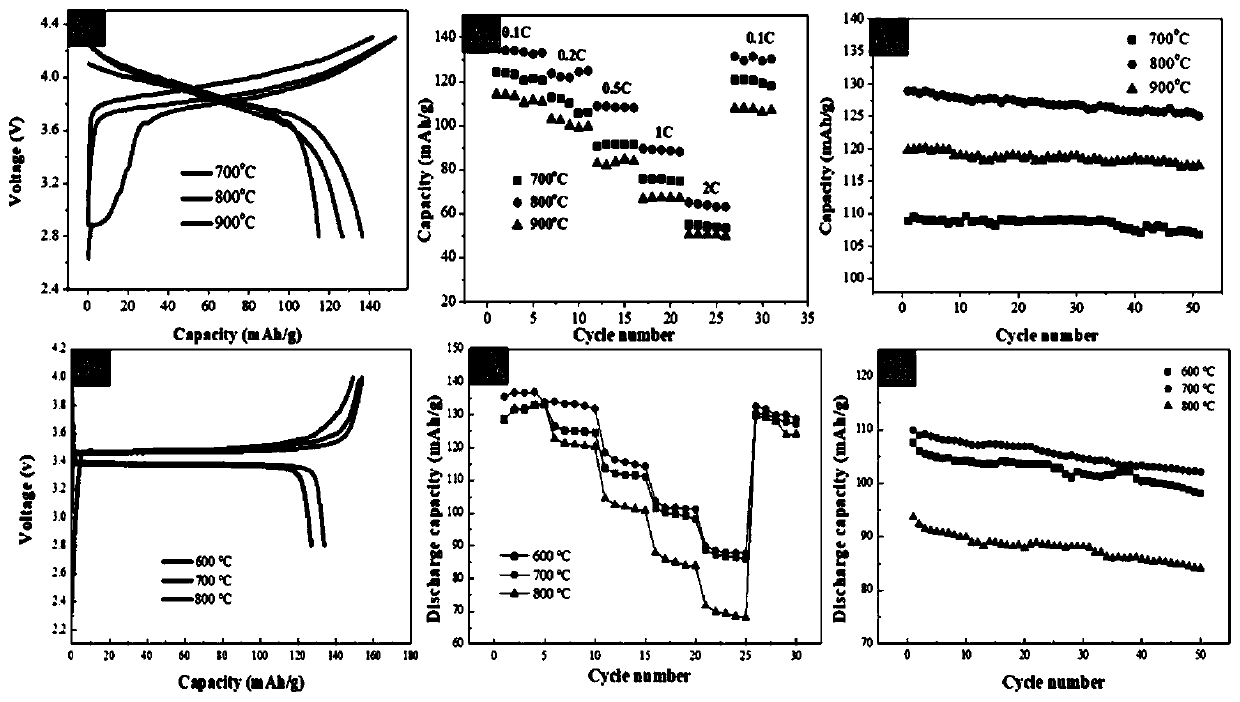

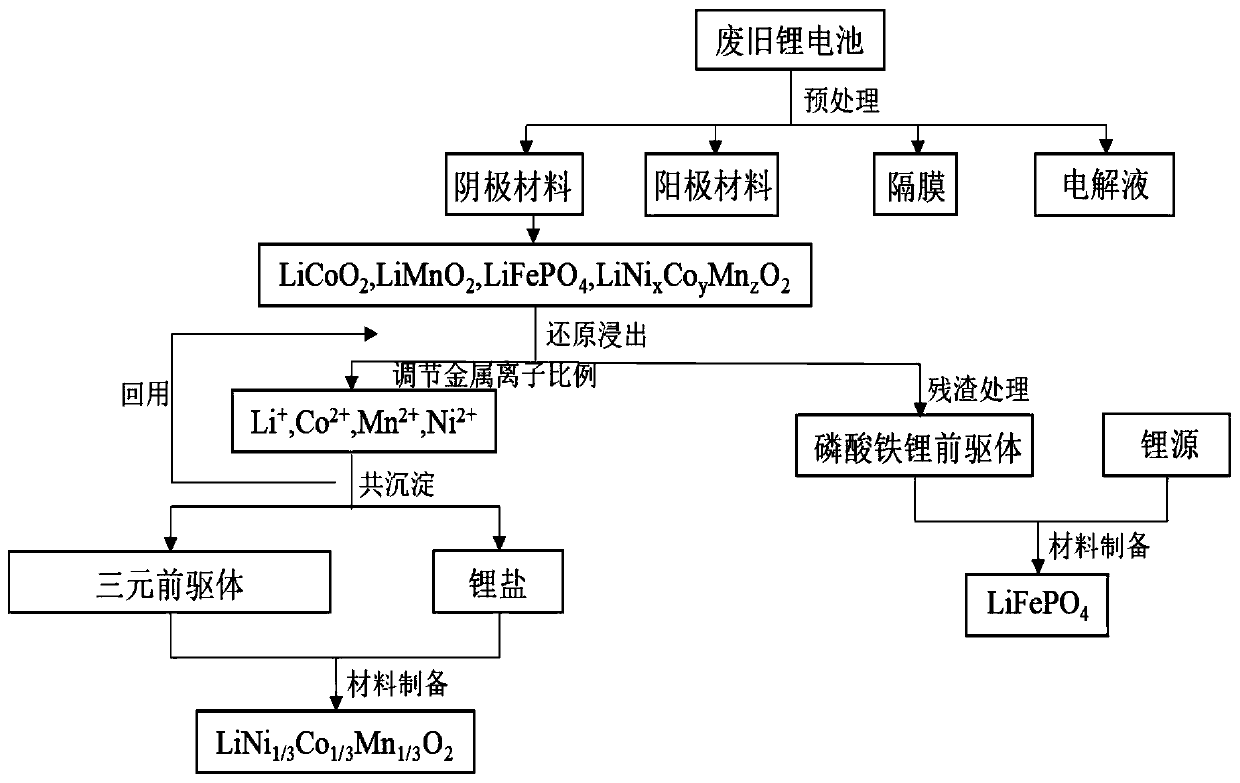

Novel process for simultaneously recovering valuable metals and iron from mixed waste lithium ion batteries

ActiveCN110592384AFully calcinedWell mixedWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionPre treatment

The invention discloses a novel process for simultaneously recovering valuable metals and iron from mixed waste lithium ion batteries. The novel process comprises the following step that S1, preprocessing is carried out, namely, the waste lithium batteries are subjected to pre-treatment procedures such as discharging, disassembling, stripping and the like; S2, leach is carried out, namely, the obtained waste lithium ion battery cathode materials are leached out after stripping to obtain a leaching solution containing Mn <2+>, Ni <2+>, Co <2+>, Li <+>, and the main metal in the leaching residueis iron; S3, the metal ion proportion in the leaching solution is adjusted, then the metal ions are subjected to precipitating, grinding and calcining to obtain LiNi1 / 3CO1 / 3Mn1 / 3O2 materials; and S4, after the FePO4 residue obtained in the step S2 is added to a lithium source to prepare LiFePO4 materials. The novel process has the advantages of high selectivity, wide application range and high recovery rate.

Owner:SHAANXI UNIV OF SCI & TECH

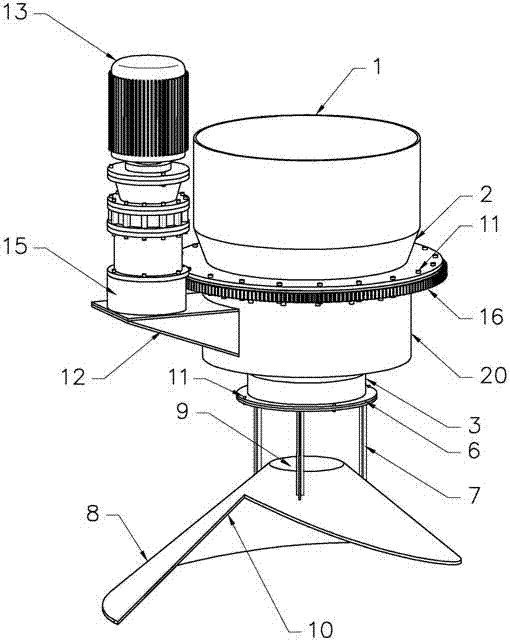

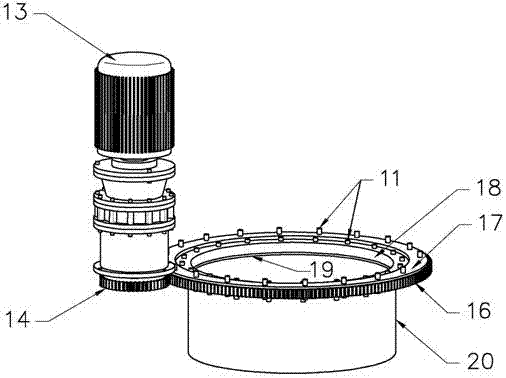

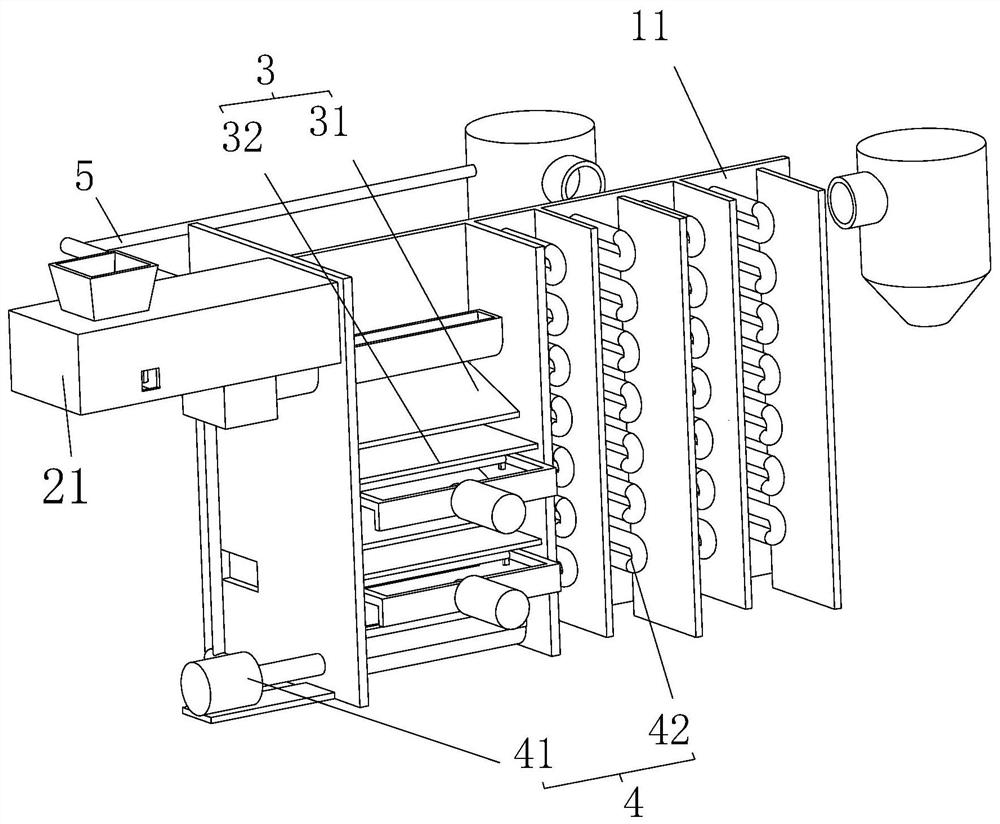

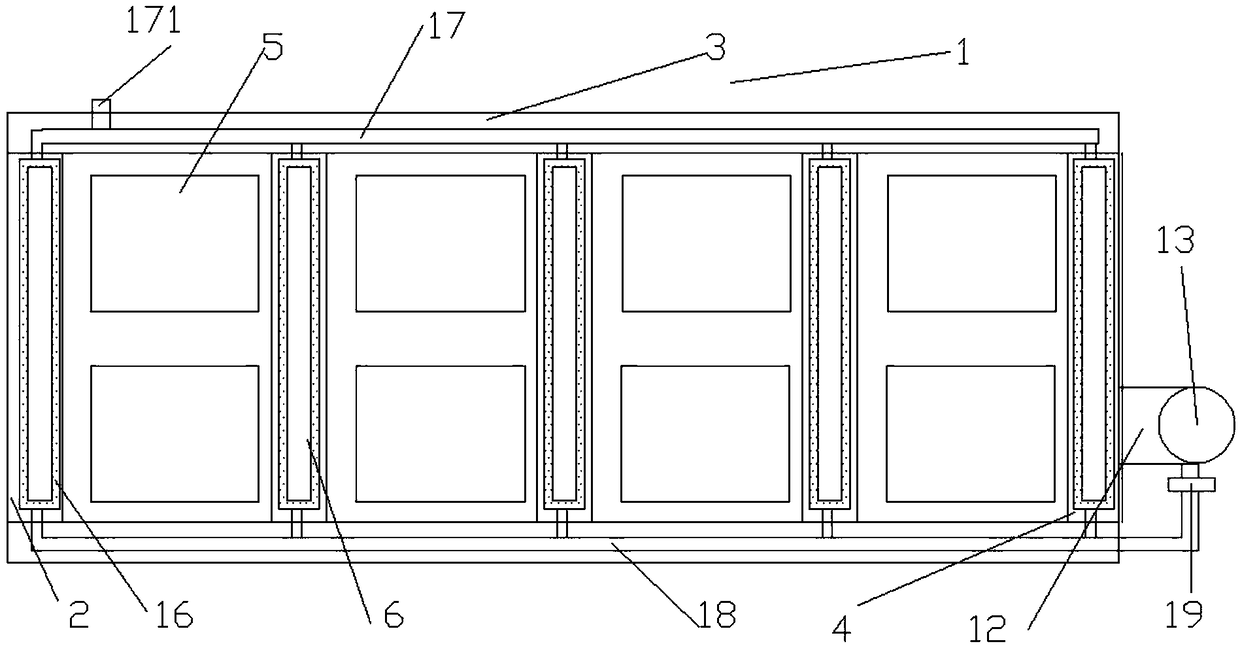

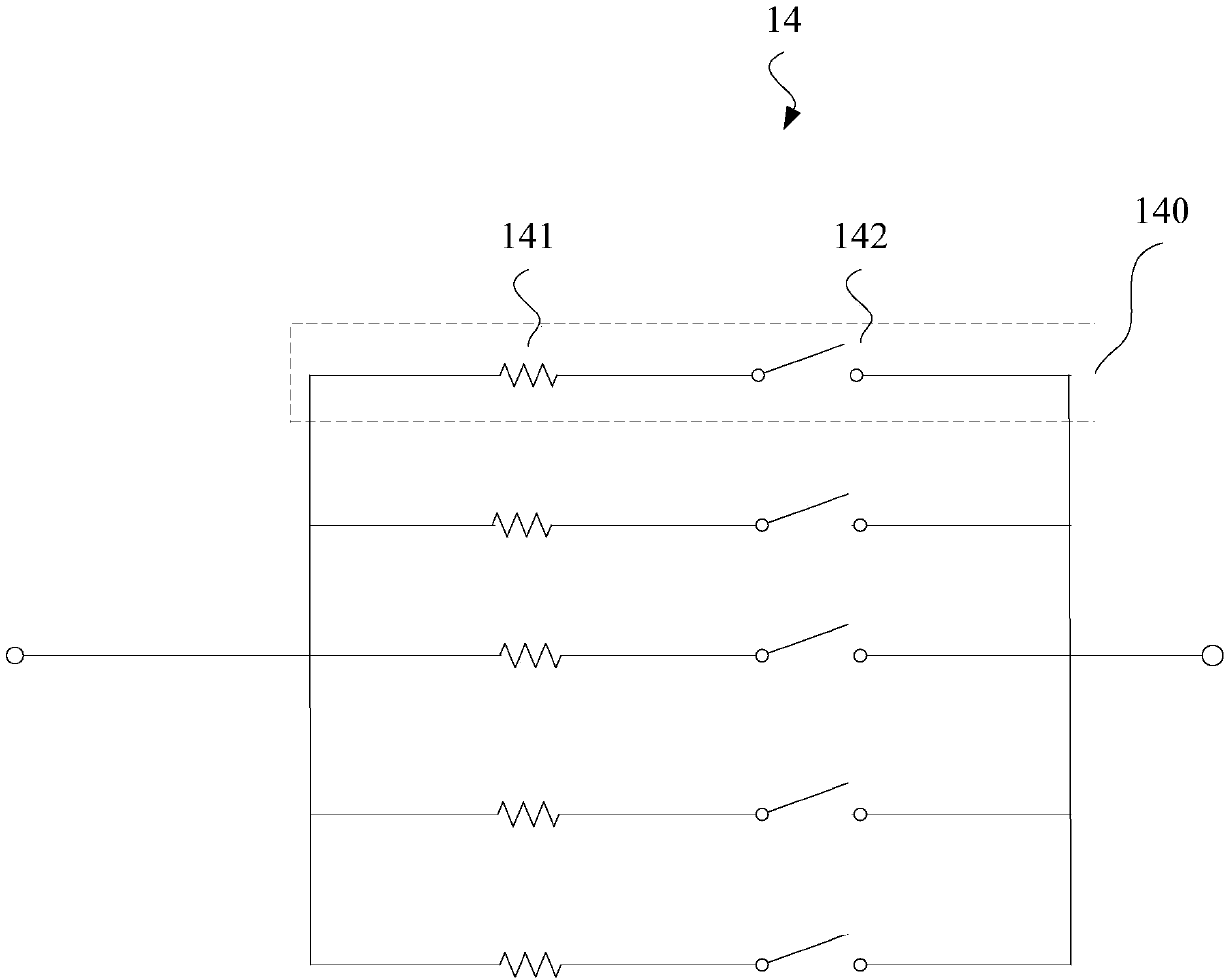

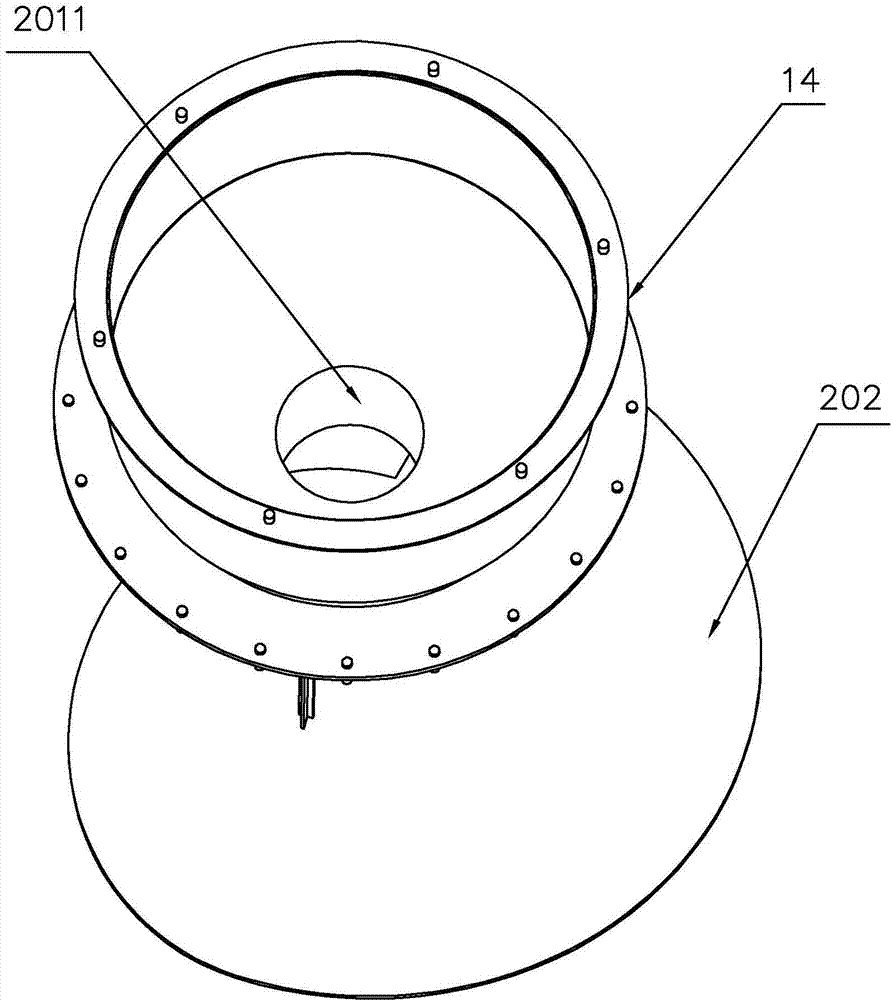

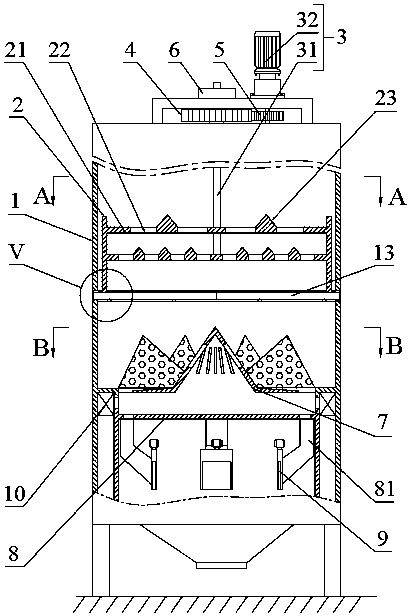

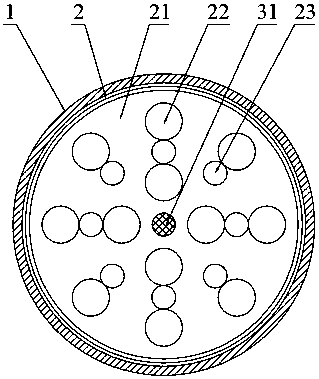

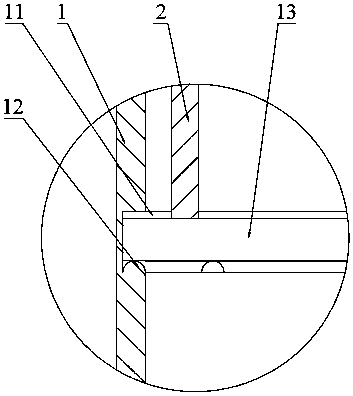

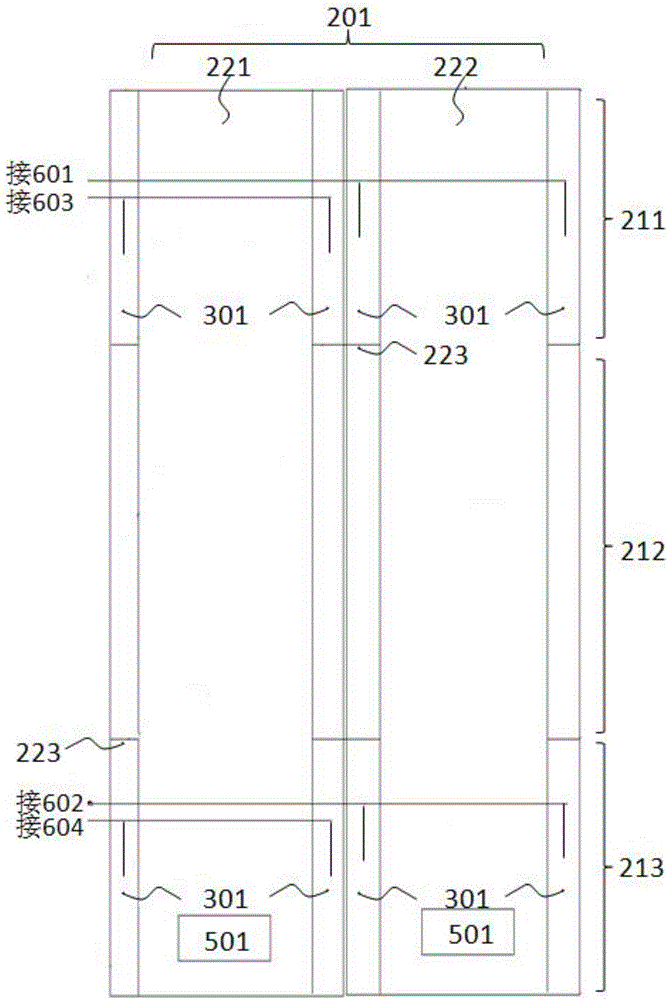

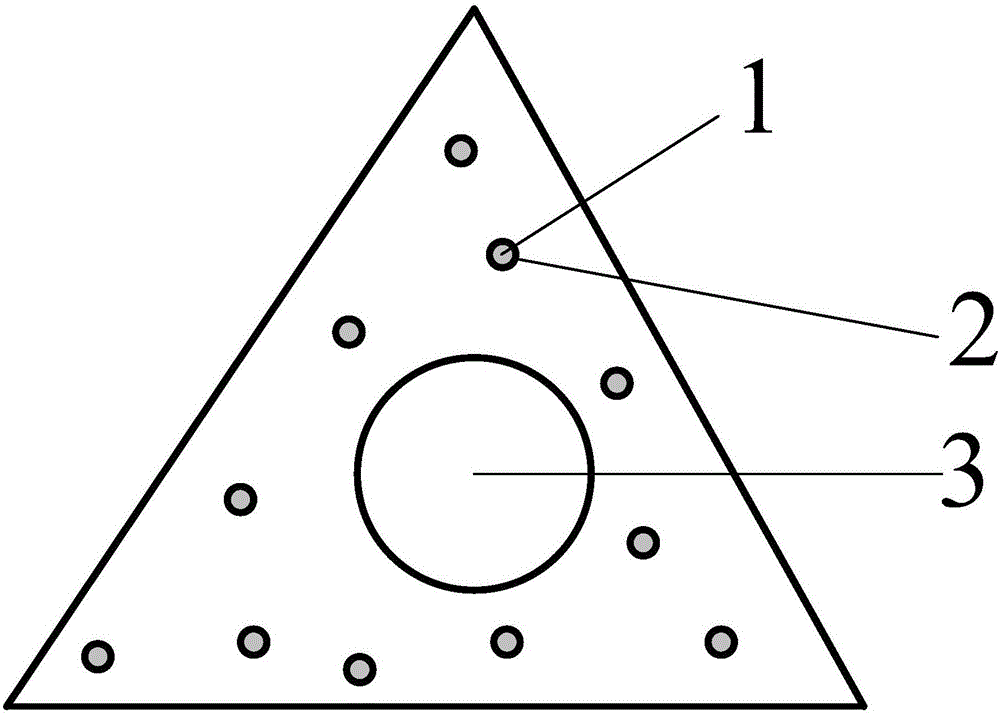

Uniform distribution device for lime kiln

ActiveCN104230188AEfficient and rationalized productionEvenly distributedLime productionLime kilnSurface structure

The invention relates to a uniform distribution device for a lime kiln. The uniform distribution device mainly comprises a feeding device, a transmission device and a discharge device, wherein the feeding device mainly comprises a feeding hopper, a taper hopper I and a discharge opening I; the discharge device mainly comprises three connecting frames, a distributing hopper and a flange; the flange at the opening of the discharge device is connected with a flange at the bottom of the discharge opening I of the feeding device through a bolt; the three connecting frames are arranged at the lower part of the flange; one ends of connecting frames are welded to the flanges and are distributed in a triangular way; the other ends of the connecting frames are connected with the distributing hopper; the distributing hopper adopts a taper surface structure; a circular platform is arranged at the upper part of the distributing hopper; the transmission device mainly comprises a bearing platform, a motor, a gear I, a gear II, a disc I, a bearing, a disc II and a base. The uniform distribution device realizes uniform distribution of the lime kiln, enables material to directly and uniformly drop onto the lime kiln plane, reduces the labor intensity of workers, is simple in overall operation and flexible to rotate, and has high efficiency and practicability.

Owner:刘建轻

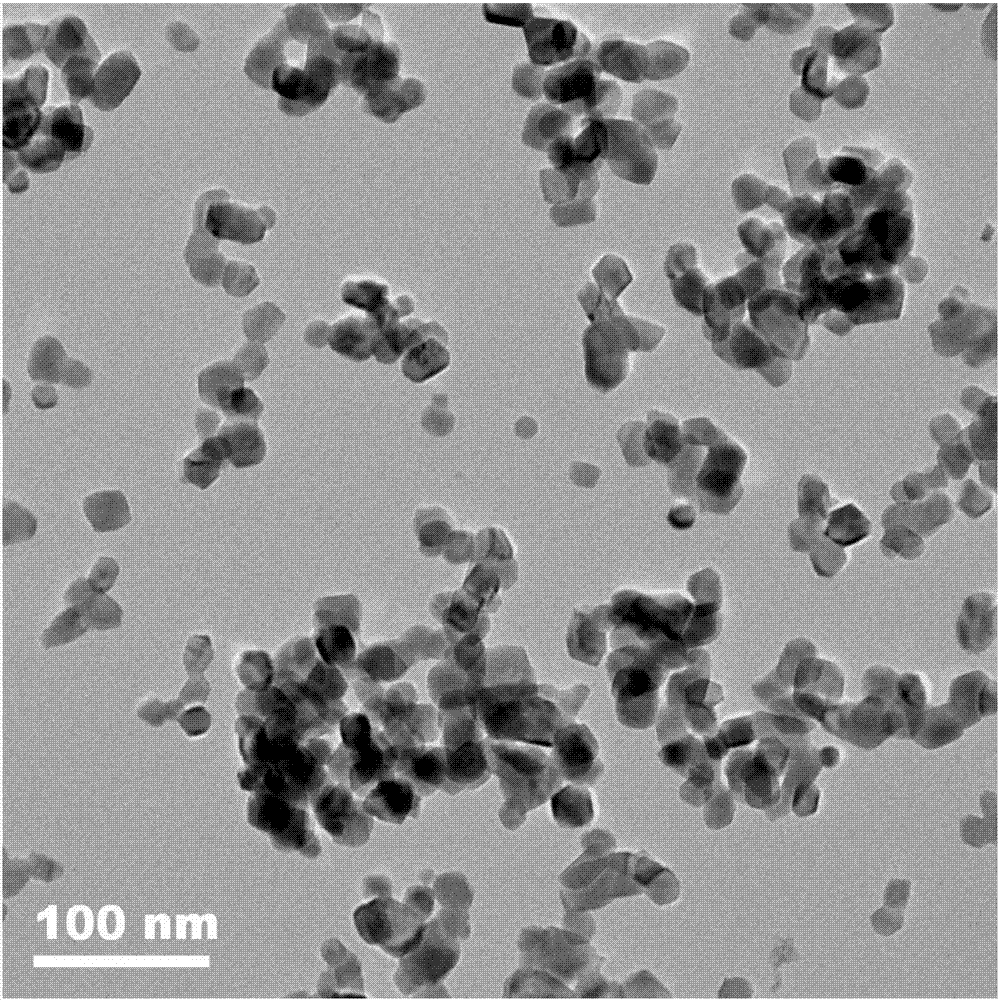

Preparation method for ultra-pure 3Y yttria-stabilized zirconia

The invention discloses a preparation method for ultra-pure 3Y yttria-stabilized zirconia. The method comprises the following steps: (1) dissolving zirconium oxychloride and ultra-pure water at a ratio, thereby acquiring a zirconium oxychloride filtrate; (2) dissolving yttrium nitrate and ultra-pure water at a ratio and filtering, thereby acquiring a yttrium nitrate filtrate; (3) preparing ultra-pure ammonium hydroxide; (4) performing rotational flow reaction on the zirconium oxychloride filtrate, the yttrium nitrate filtrate and a dispersing agent; (5) dropwise adding the ultra-pure ammonium hydroxide into a reaction solution acquired in the step (4), and performing rotational flow reaction, thereby acquiring emulsion; (6) filtering the emulsion with a ceramic membrane, performing electroosmosis, filtering and washing with a nanofiltration membrane, removing chlorinate and removing impurities; (7) performing space circular drying on the filtered emulsion, thereby acquiring powder; (8) freely falling and calcining the powder; and (9) crushing the calcined powder with air flow, thereby acquiring the end product of powder. The reaction condition according to the invention is under normal pressure and low temperature; the method is simple and is easily controlled; the purity of the end product is high and can reach up to 99.999%; the particle is stable; and the particle size is uniform and is about 20nm.

Owner:杭州九朋新材料有限责任公司

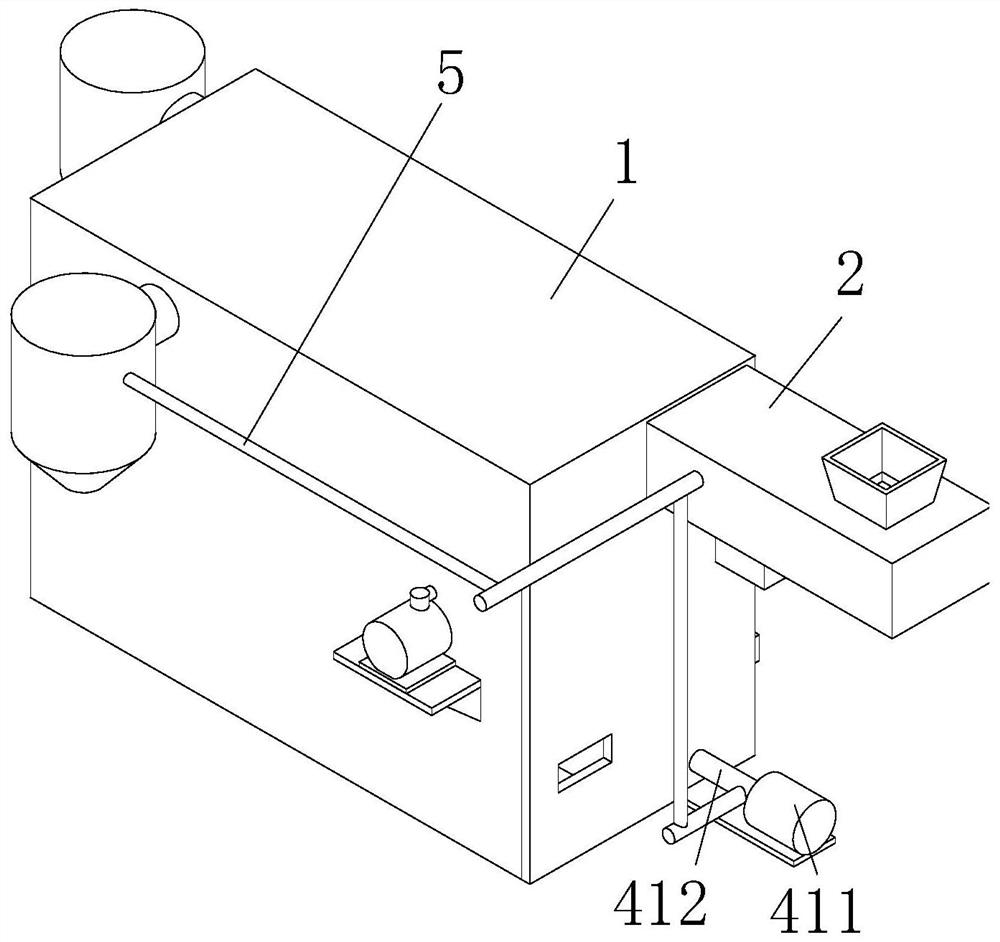

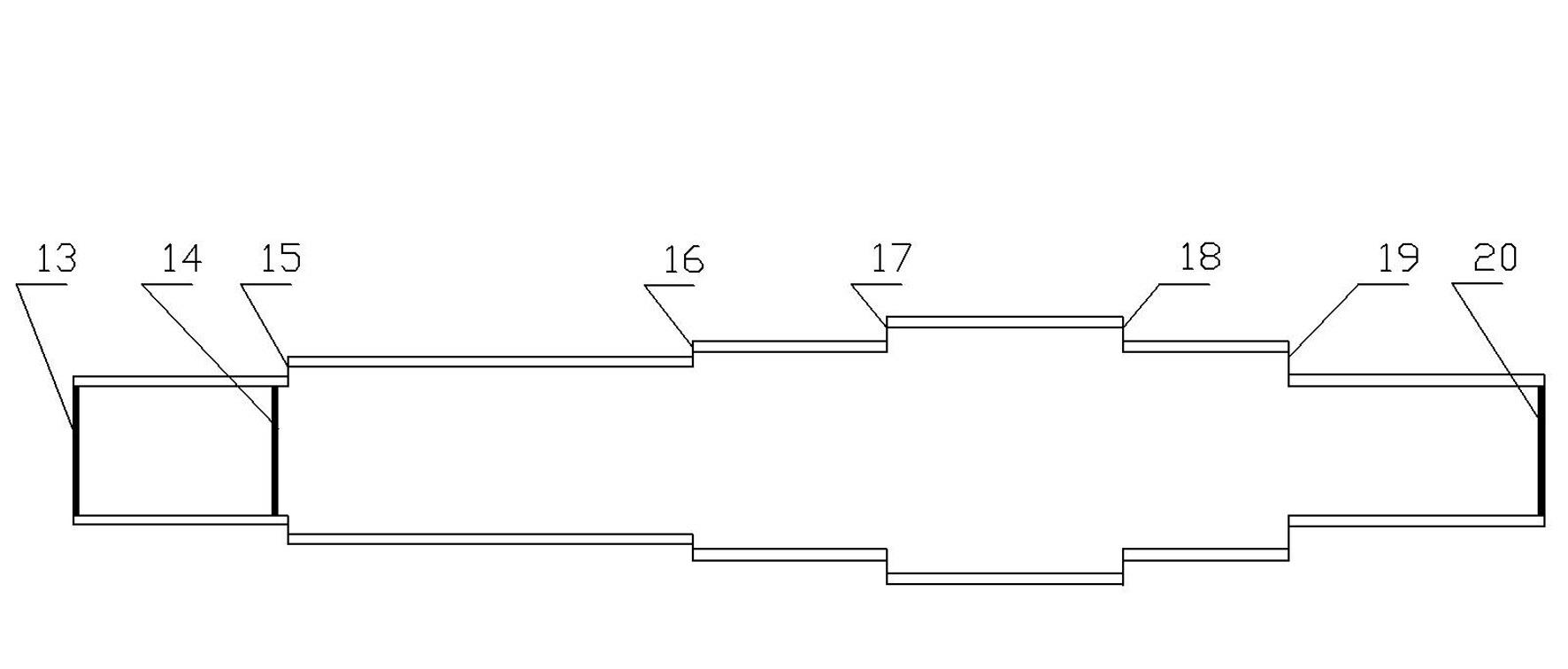

Calcining equipment for gypsum powder

The invention discloses calcining equipment for a gypsum powder. The equipment comprises a calcining box, a pre-drying feeding device is arranged at the top of one side of the calcining box, and the interior of the calcining box is divided into a heating cavity and a calcining cavity through a heat conduction partition plate; a hot baking calcining device is arranged in the calcining cavity, the hot baking calcining device comprises a plurality of heat dissipation plates, and an adjusting part is arranged at the bottom of each heat dissipation plate; and a wind power calcination device is arranged at the bottom of the hot baking calcination device and comprises a wind power transmission component and a heating power component, the heating power component is arranged on one side of the heat conduction partition plate, the wind power transmission component is arranged at the bottom of the hot baking calcination device, the side wall of the heating cavity is provided with a transmission pipe, and the transmission pipeline is used for conveying hot air exhausted by the heating cavity into the pre-drying feeding device and the wind power transmission component. According to the calcining equipment, exhaust heat can be recycled, raw materials and clinker are convenient to separate, pollution of gypsum powder is avoided, and the processing quality is high.

Owner:江西中科高博科技服务有限公司

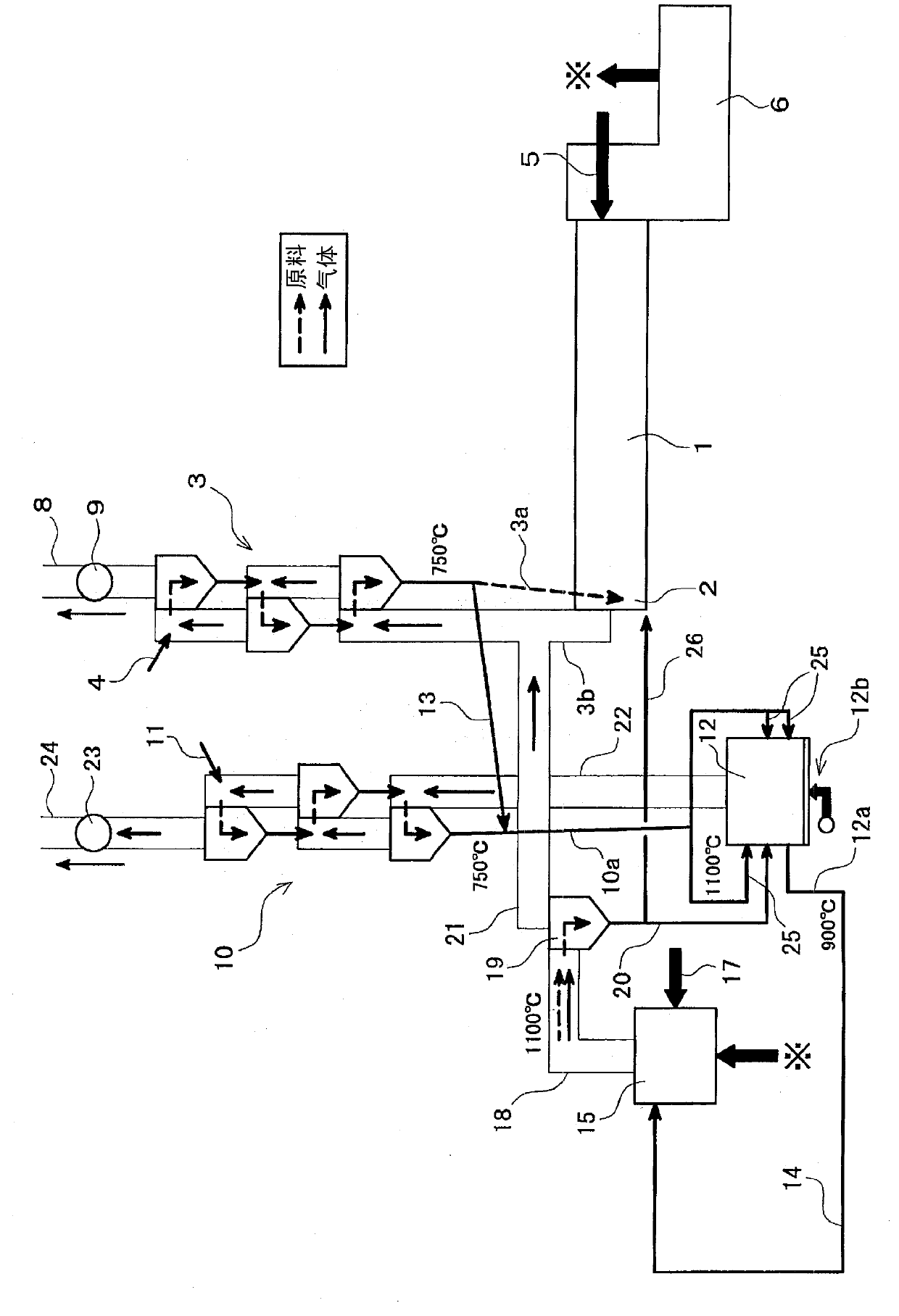

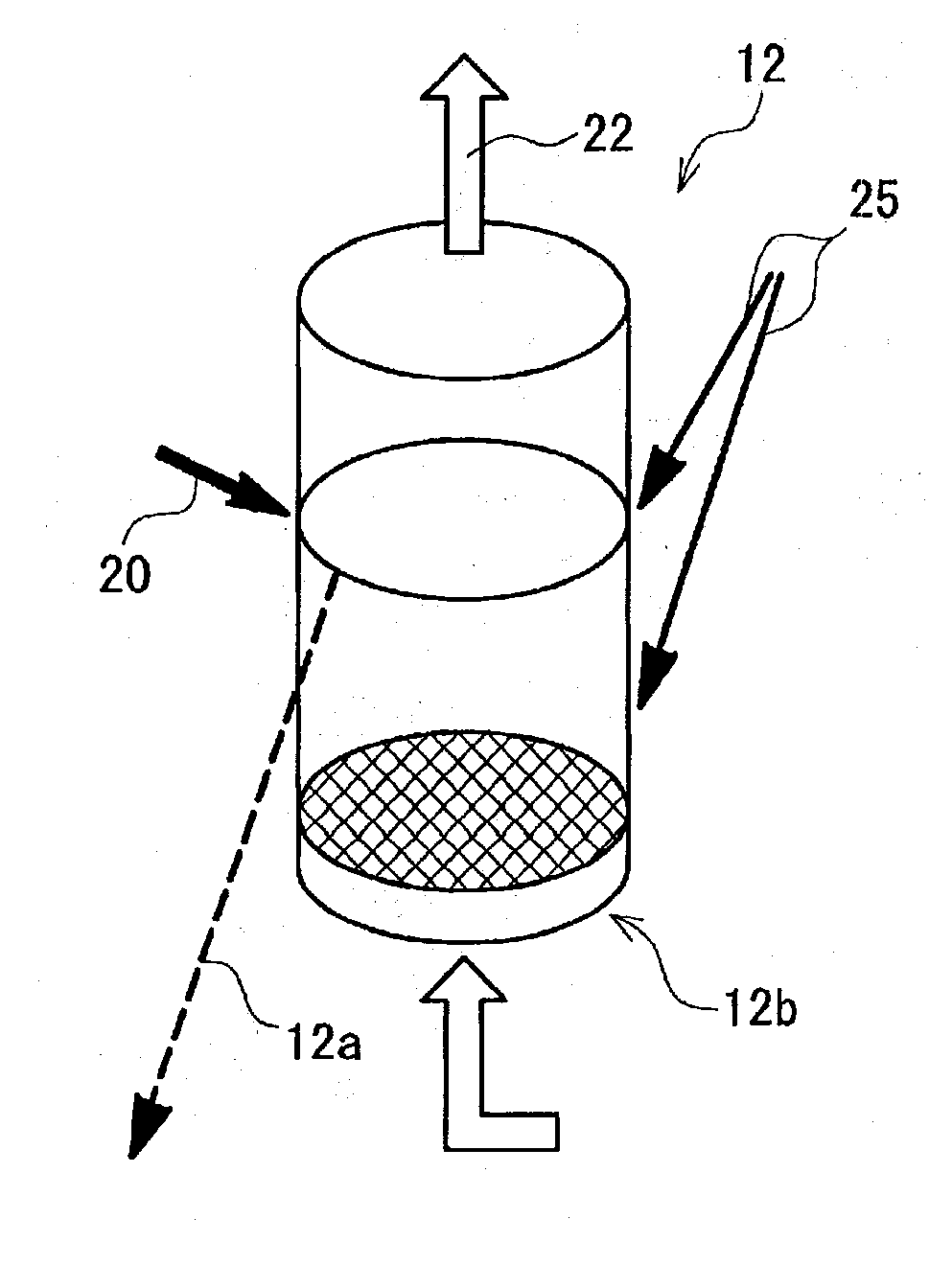

Mixing/calcining Furnace

InactiveCN102597677AInhibition processing capacityEasy to separateRotary drum furnacesFluidised-bed furnacesHigh concentrationCement manufacturing

Owner:MITSUBISHI MATERIALS CORP

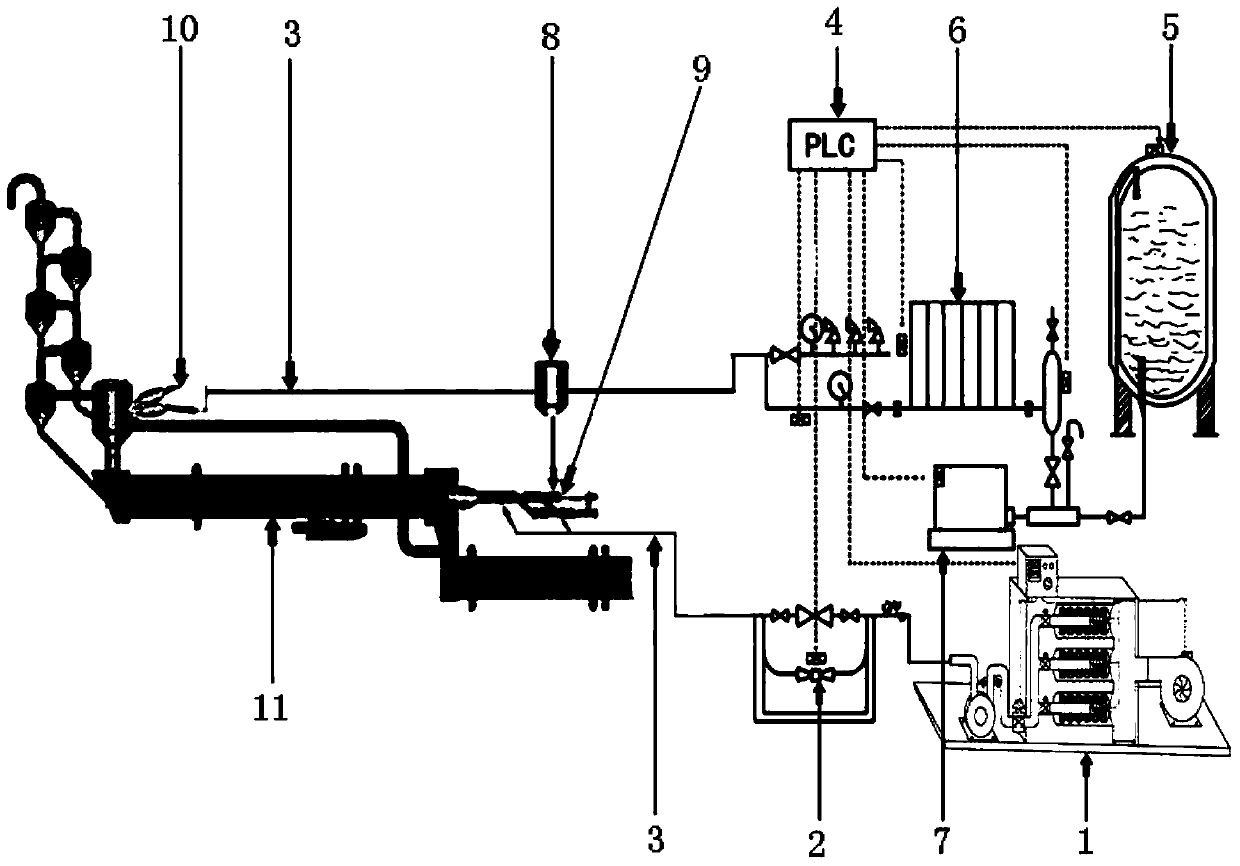

Oxygen-enriched combustion-supporting and pulverized coal pure-oxygen compensation energy conservation system of rotary kiln

InactiveCN104197696AFully calcinedImprove efficiencyRotary drum furnacesIndirect carbon-dioxide mitigationDecompositionCalcination

The invention relates to an oxygen-enriched combustion-supporting and pulverized coal pure-oxygen compensation energy conservation system of a rotary kiln. The system comprises a dry-process rotary kiln combustion system, a PLC (programmable logic controller) smart system, a magnetic energy oxygenerator and a liquid oxygen storage tank, the output end of the magnetic energy oxygenerator is connected with a pressure regulating system, the pressure regulating system is connected with a kiln head coal-injection duct terminal of the dry-process rotary kiln combustion system through an oxygen supply pipe, the output end of the liquid oxygen storage tank is connected with the input end of a gasifier, the output end of the gasifier is connected with the input end of a booster pump, the output end of the booster pump is connected with a pure oxygen heater, the pure oxygen heater is connected with the kiln head coal-injection duct terminal and a decomposition kiln coal-injection duct terminal through oxygen supply pipes, and the magnetic energy oxygenerator, the pressure regulating system, the liquid oxygen storage tank, the gasifier and the booster pump are all connected with the PLC smart system. The system is used on a cement dry-process rotary kiln to guarantee sufficient calcinations, benefit is increased, emission is reduced, energy is saved, and one of oxygen-enriched combustion methods of the dry-process rotary kiln is advanced and satisfactory.

Owner:YANTAI JIUZHOU ENVIRONMENTAL PROTECTION & ENERGY SAVING TECH

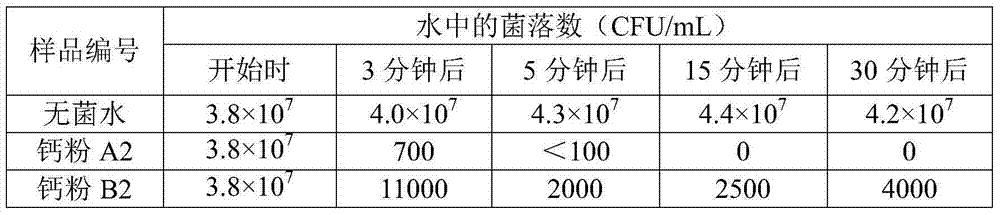

Preparation process of pure natural superfine calcium powder

The invention provides a process for preparing pure natural ultrafine calcium powder. The process comprises the following steps: selecting materials, cleaning, crushing, calcining, grinding, hydrolyzing and performing superfine grinding. According to the invention, calcining under inert gases is not needed, the combustion is sufficient, and the heating time is greatly shortened and is only several hours. Therefore, the production efficiency is improved, the labor time is reduced, the product cost is reduced, and the increasingly extending requirement of the market can be met. The calcined products are hydrolyzed, so that lots of heat energy is released, the instability in the transport and storage process is reduced, and thus the product has high safety. Moreover, the substances such as calcium hydroxide belong to slight soluble strong base substances in water, so the product has long-acting good bacteriostatic action. Meanwhile, the hydrolyzed product is ground again, so that the grinding time is shortened, the abrasive particles can be ground into a narrower range, the acting superficial area is enlarged, the effect is improved, and the cost is reduced.

Owner:QINGDAO SHIAN BIOLOGICAL ENG

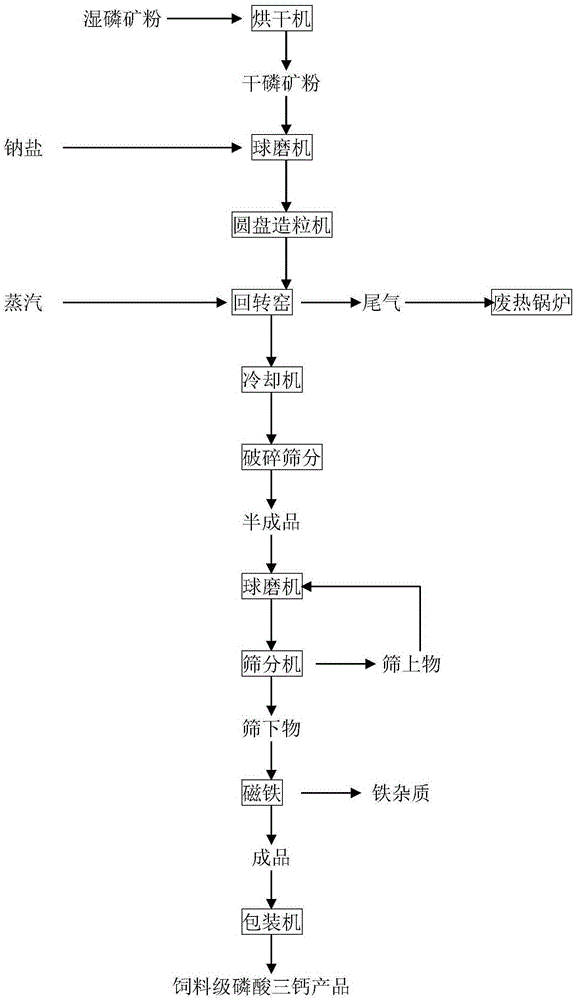

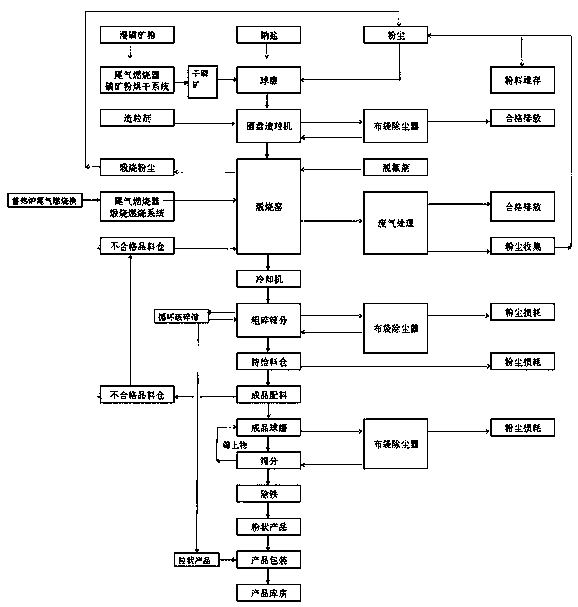

Production method of feed-grade tricalcium phosphate

InactiveCN106698377AFacilitate the decomposition and defluorinationDecomposition defluorination promotionEnergy inputPhosphorus compoundsDecompositionPhosphate product

The invention discloses a production method of feed-grade tricalcium phosphate. The method comprises the following steps: 1, drying of phosphorus rock powder; 2, mixing and ball milling; 3, disc granulation; 4, calcination defluorination; 5, cooling, crushing and sieving; 6, ball-milling of a semi-finished product; 7, screening deironing; and 8, product packaging. The method has the following advantages: 1, the raw material component and the granularity range of the phosphorus rock powder are prescribed; 2, addition of a sodium salt to raw materials facilitates decomposition defluorination of phosphorus rocks; 3, addition of phosphoric acid to the raw materials improves the content of phosphorus in the above product and facilitates granulation and calcination defluorination; 4, addition of steam in the calcining process promotes decomposition defluorination of the phosphorus rocks; 5, the product goes through the area of an electromagnet or a permanent electromagnet to remove iron fillings and other metal impurities, so operation control is simple, and the impurity removal efficiency is high; and 6, calcination tail gas is fully used to produce saturated steam and superheated steam, so energy is saved, and the energy consumption and the production cost are reduced. The method is suitable for producing the feed-grade tricalcium phosphate product.

Owner:WENGFU (GRP) CO LTD

Calcinion method for calcining coal gangue to produce cement additive

InactiveCN102173607ALow costA large amount of cement is addedCement productionCoal waterFree cooling

The invention relates to a calcinion method for calcining coal gangue to produce a cement additive. The method comprises the following steps of: selecting a convenient-to-transport flat area in a place with stacked coal gangue; laying a ventilation pipe, a combustion layer and a coal layer with the thickness of 9 to 11 cm in sequence; igniting the combustion layer and stacking coal gangue; and continuously blowing air through the pipe to support the combustion of coal gangue for 6 to 7 days, and naturally cooling to obtain a sintered material which can be used as a cement additive. The invention has the benefits that: the coal gangue is fully utilized and 1.9 tons of cement additive is produced per 2 tons of coal gangue; the addition amount of the cement additive is 3 to 4 times that of the basalt, so that the cement cost is greatly reduced; the cement grade of the additive is about 250#, the addition amount in cement is increased and reaches 25% for ordinary cement and 30% to 40% for pozzolanic cement; owing to the natural cooling process, the sintered material is fragile and easy to mill; and the blower has a high blowing capacity, the coal gangue has a large combustion value, and the coal gangue on the surface of the coal gangue stack combusts completely.

Owner:CHIBI CITY MOYU CEMENT

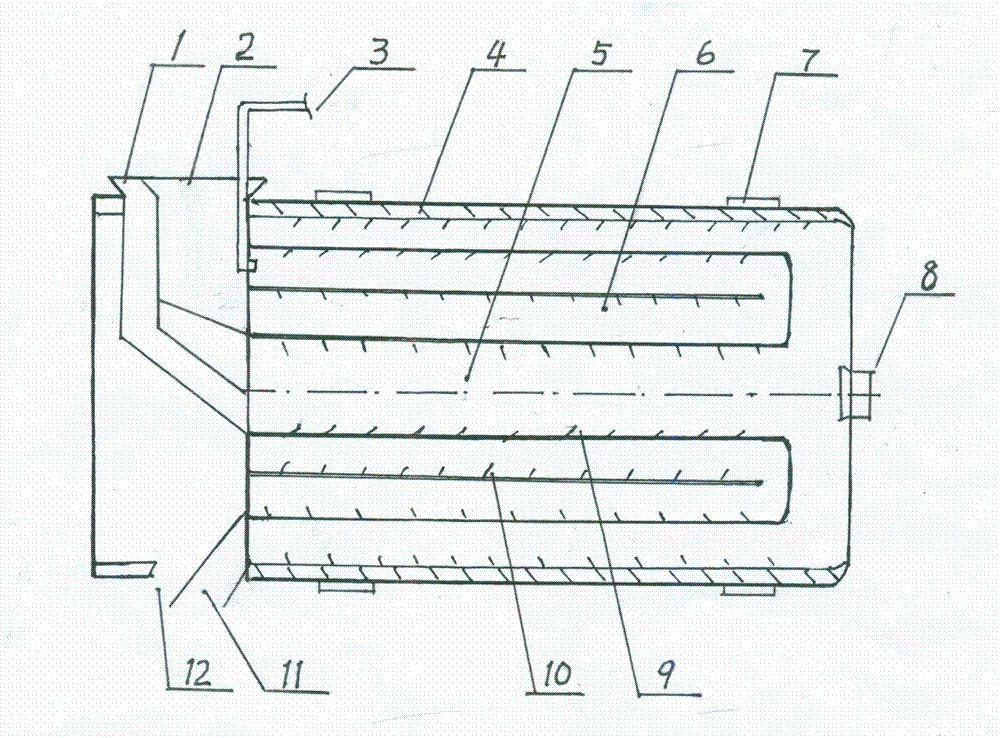

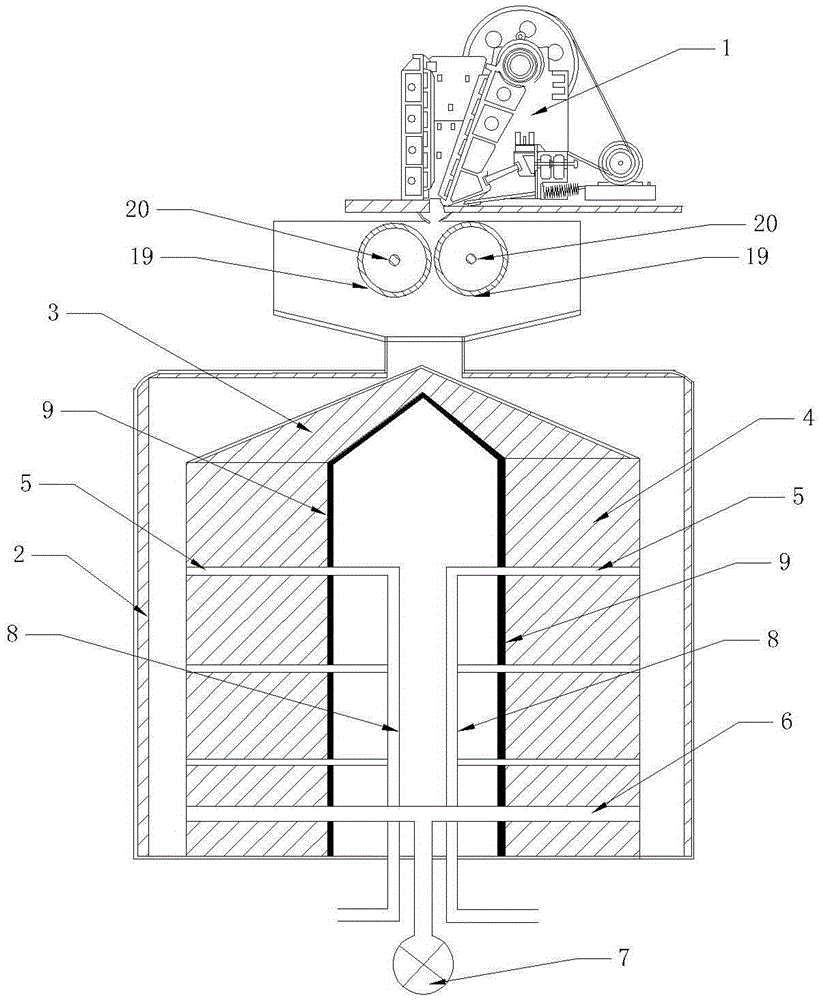

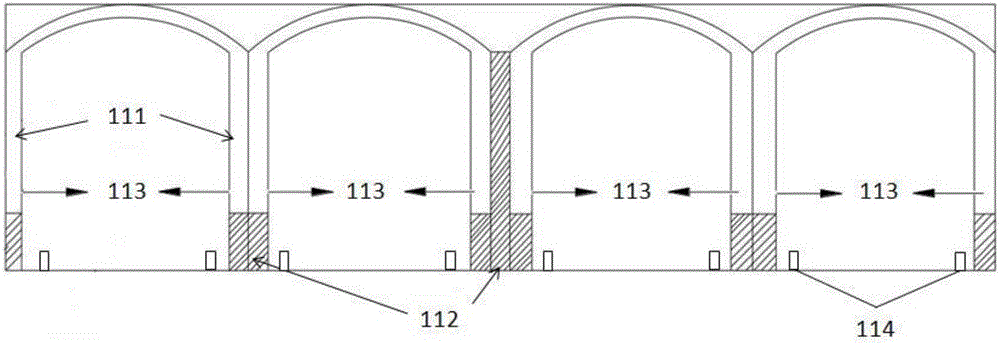

Needle-shaped calcined petroleum coke production technology and calcining furnace for technology

The invention provides a needle-shaped calcined petroleum coke production technology and a calcining furnace for the technology and in particular relates to the technical field of petroleum coke production. The calcining furnace is a pot type calcining furnace and comprises a furnace body and a flue; a plurality of groups of pot bodies which are distributed in parallel are arranged in the furnacebody along the length direction; each group of the pot body is composed of two pot bodies which are distributed along the width direction of the furnace body; the furnace body is internally provided with a plurality of heating walls; the adjacent two groups of the pot bodies are separated through the heating walls; one heating wall is arranged in each of a front wall and a rear wall; each heatingwall is internally and sequentially provided with a volatilization layer composed of a fire channel, a calcining layer and a cooling layer, which are communicated with one another; each volatilizationlayer is communicated with a natural gas pipeline; the flue comprises a plurality of flue gas secondary channels and a flue gas general channel; and each cooling layer is communicated with the flue gas general channel through the flue gas secondary channels. According to the calcining furnace, natural gas is introduced into the pot type calcining furnace and is mixed with volatile components in needle-shaped calcined petroleum coke to be combusted, so that the temperature of the calcining layer reaches 1400 DEG C and the true density of a finished product reaches 2.15.

Owner:镇江东亚碳素焦化有限公司

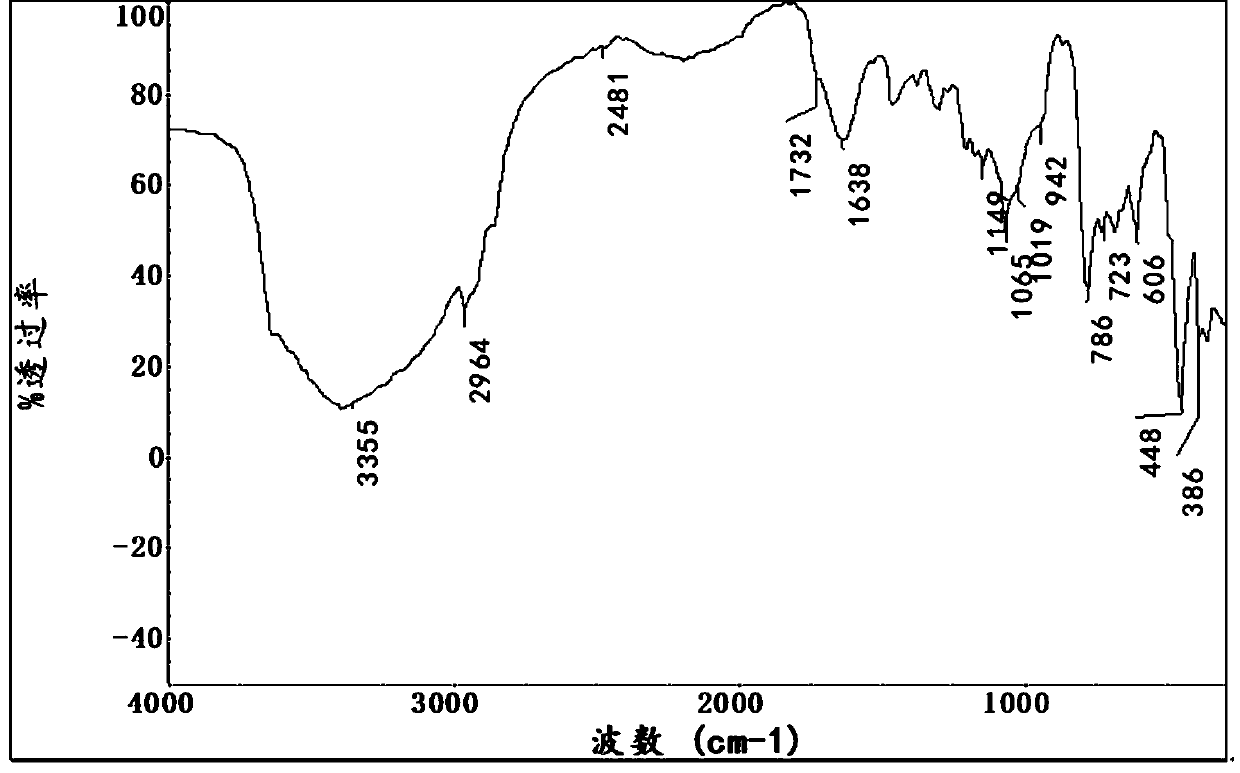

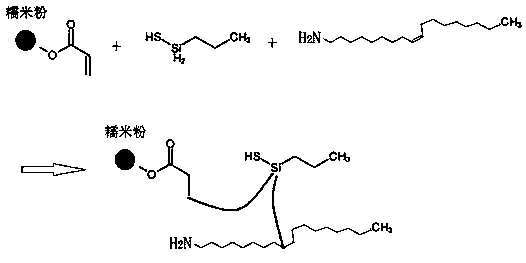

Dicyandiamide black slag resource utilization treatment process

InactiveCN111573706AImprove performanceGood molding effectMacromolecular adhesive additivesCalcium carbideSlagLime kiln

The invention relates to the field of environmental protection, in particular to a dicyandiamide black slag resource utilization treatment process. The invention provides a method for resource utilization of dicyandiamide black slag. According to the invention, a large amount of dicyandiamide black slag can be treated and resource utilization is realized. The method comprises the following steps:firstly, improving the content of calcium carbonate in dicyandiamide black slag through screening and winnowing; then providing a modified glutinous rice pulp inorganic adhesive and adding a quality improving agent to enable formed waste residues to meet the production strength requirement of a lime kiln, and carbonizing and calcining to prepare an active calcium oxide finished product with a highcalcium oxide content, a low impurity content, a loose structure and high activity. The active calcium oxide finished product can be used in a process for producing dicyandiamide from calcium carbideto achieve the purpose of cyclic utilization; according to the method, a large amount of dicyandiamide black slag can be treated with high quality, the environment can be protected, resources can berecycled, and the method has high economic value.

Owner:东阳市琰安建筑工程有限公司

Tunnel kiln for calcining petroleum coke and method for calcining petroleum coke by using tunnel kiln

InactiveCN102628647AImprove insulation effectThe effect of stable pressureCoke ovensChemical industryTunnel kilnGraphite electrode

The invention provides a tunnel kiln for calcining petroleum coke and a method for calcining the petroleum coke by using the tunnel kiln. Automatic doors are arranged respectively at two ends of the kiln, an automatic inner door is arranged inside the kiln, gradually widened and gradually narrowed tunnel steps are arranged inside the kiln, and a gas boaster communicating with a volatile region, a heating-up region and a high-temperature region respectively is arranged outside the kiln. Petroleum coke raw materials are loaded into a bowl tool, are carried into the tunnel kiln by a kiln car, and are sent out of the kiln after passing through a preheating section, a calcination section and a cooling section. The Petroleum coke raw materials are fed into the calcination section after the dehydration processing in the preheating section, the calcination time in the heating-up region, the high-temperature region and a constant high temperature region is 320-640 minutes, wherein the temperature in the high-temperature region is in the range form 1050 DEG C to 1600 DEG C, and the pressure born by the calcination section is 5-10 Pa. Raw material volatile gases in the volatile region are introduced into the heating-up region and the high-temperature region after a calcination temperature is reached, the ratio of natural gas to air quantity is 1:3, and the calcination time in the volatile region is 80-160 minutes. By using the invention, product performance can be improved, high quality raw materials can be provided for producing high power and ultra high power graphite electrodes, and energy saving as well as low production cost can be achieved.

Owner:吉林市亿成石油焦有限公司

Compression calcining type oil shale dry-distillation system

PendingCN107298982AImprove retort efficiencyImprove oil recoveryIndirect heating destructive distillationSpecial form destructive distillationSand blastingHeat energy

The invention discloses a compression calcining type oil shale dry distillation system, which comprises a crushing device, a compression classification device, a sandblasting dry distillation device, a filter, an oil gas separation device, an oil gas dust collector, and an oil collection device connected in sequence, wherein: compression classification The device includes sequentially connected capsule-type grading compression chambers, fixed mesh screens, and first-stage dry distillation and calcining chambers. The capsule-type grading compression chambers are equipped with vertically telescopic power sources, telescopic sleeves, and automatic recovery devices. The outlet of small grains of oil shale passes through The conveying pipe transports the small particle oil shale to the sandblasting and retorting device, and the sandblasting and retorting device includes a vertical sandblasting section and a secondary calcining device; the primary retorting and calcining chamber is also connected to the secondary calcining device. The dry distillation system of the present invention compresses and grades oil shale according to particle size, and is accompanied by sandblasting in the second stage of calcination, and heat energy can be shared between the two stages of calcination. It is a highly efficient, low-loss graded dry distillation system for calcination.

Owner:JIANGSU PENGFEI GROUP

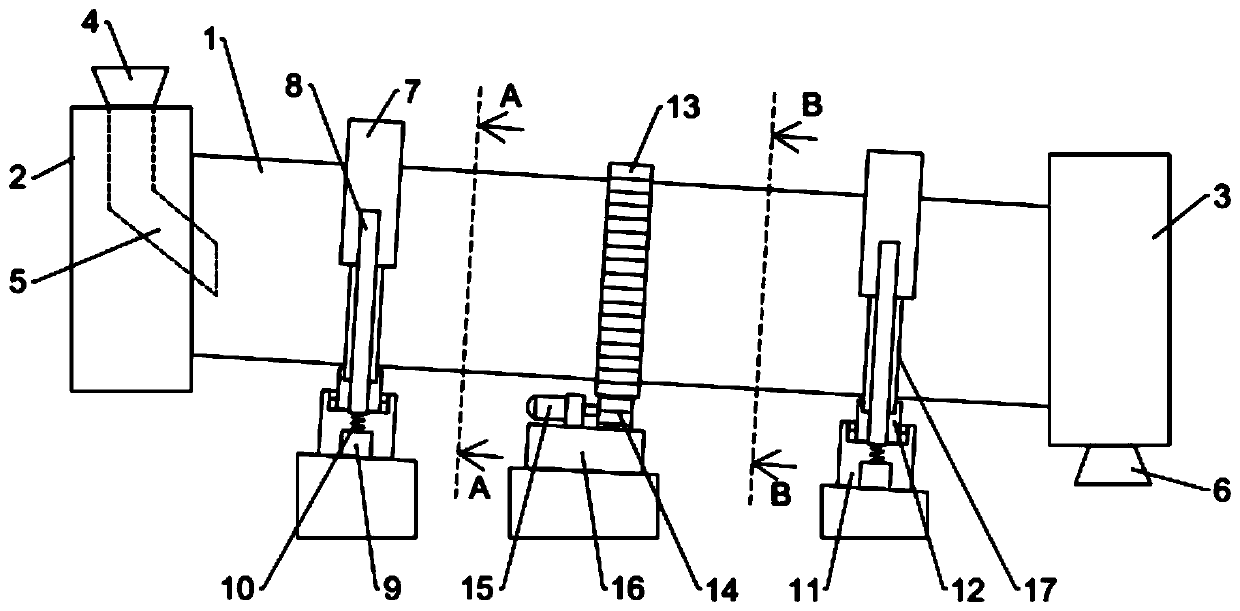

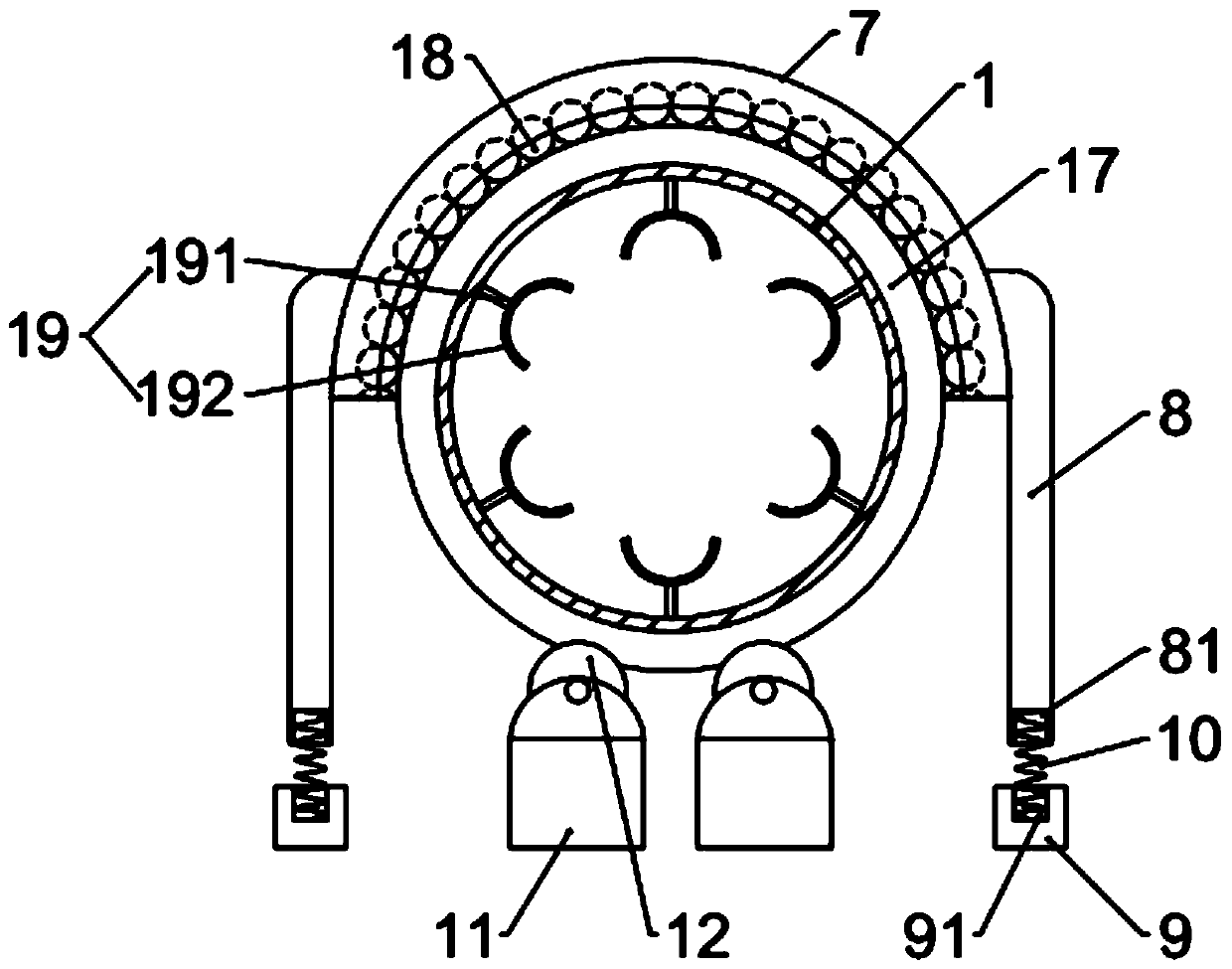

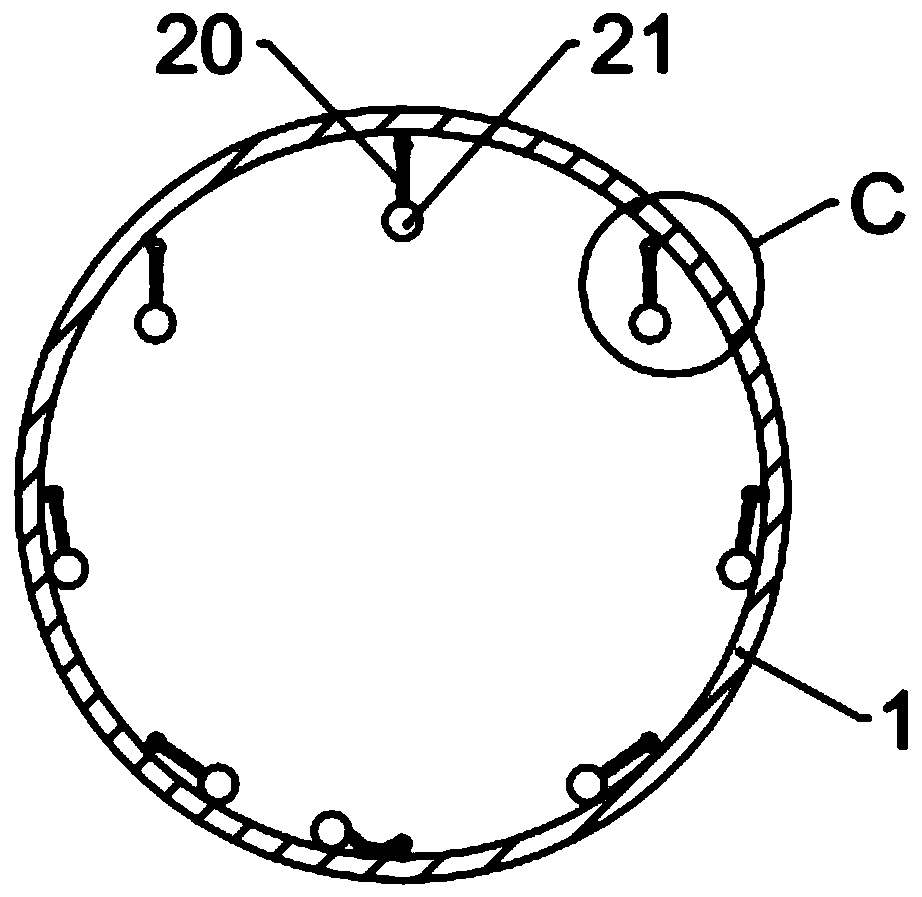

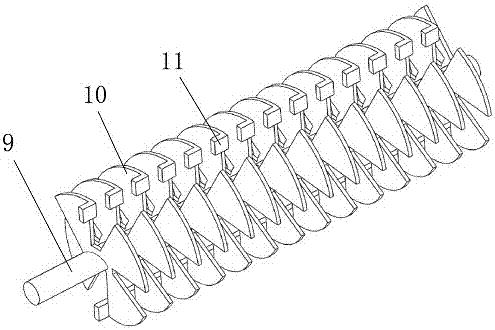

Rotary kiln for producing petroleum coke

PendingCN109827425AReduce shakingReduce the impactRotary drum furnacesPetroleum cokeMechanical engineering

The invention provides a rotary kiln for producing petroleum coke. The rotary kiln comprises a barrel body. Multiple wheel belts are arranged outside the barrel body in a sleeving manner and fixedly connected. A limiting housing is arranged on the upper half of each wheel belt in a housing manner. Each limiting housing is internally provided with multiple rolling wheels which are sequentially arranged into a semicircle. The rolling wheels are in rolling connection with the upper halves of the wheel belts. Support pillars are fixedly connected to the outer wall of each limiting housing, whereinthe support pillars are symmetrically arranged at the two sides of the barrel body. A shock absorption spring is connected to the bottom of each support pillar. A base is connected to the bottom of each shock absorption spring. A mixing mechanism and a beating mechanism are alternately arranged inside the barrel body in the axial direction. The mixing mechanism is composed of multiple mixing components which are uniformly distributed in the circumferential direction. Each mixing component comprises a support plate and a mixing plate, wherein each support plate is fixedly connected with the inner wall of the barrel body, and each mixing plate is fixedly connected with the corresponding support plate. The beating mechanism comprises multiple chains and beating balls, wherein the chains areuniformly distributed in the circumferential direction, and the beating balls are fixedly connected with the chains. According to the rotary kiln, when the barrel body rotates, the shaking degree is low; the service life is long; calcination raw materials are not likely to adhere to the inner wall of the barrel body; the energy consumption is lowered; and the production efficiency is high.

Owner:镇江东亚碳素焦化有限公司

Method and device for microwave calcination of uranium chemical concentrate

The invention relates to a method and device for microwave calcination of a uranium chemical concentrate, and belongs to the technical field of microwave metallurgy. The method comprises leading the uranium chemical concentrate into high-temperature waste heat flue gas for preheating the cold uranium chemical concentrate, and performing three segments of calcination. The device is composed of a microwave generator, a spiral stirring device, a microwave control device, a temperature measuring device and a flue gas circulation purifying system. According to the method, industrial continuous production is realized; the high-temperature waste heat flue gas is fully utilized; and self-circulation treatment is implemented. The uranium chemical concentrate can be directly and fast heated; the heat loss of the material is reduced; and the energy utilization rate is increased. The uniformity of the product is improved; emission of harmful impurities and gas is avoided; and clean production is realized. The device is high in equipment automation degree and strong in controllability.

Owner:KUNMING UNIV OF SCI & TECH

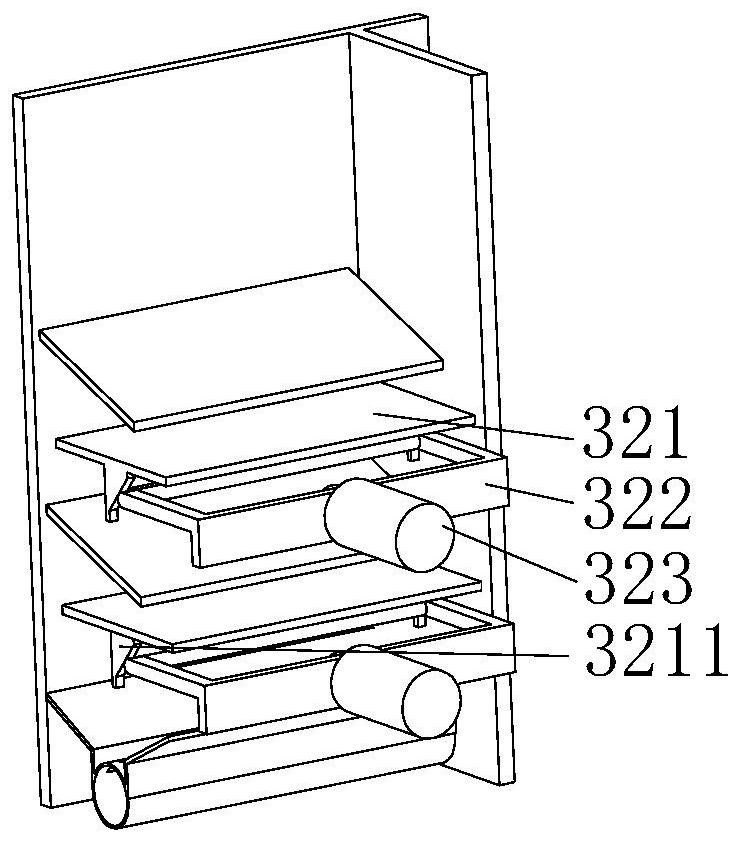

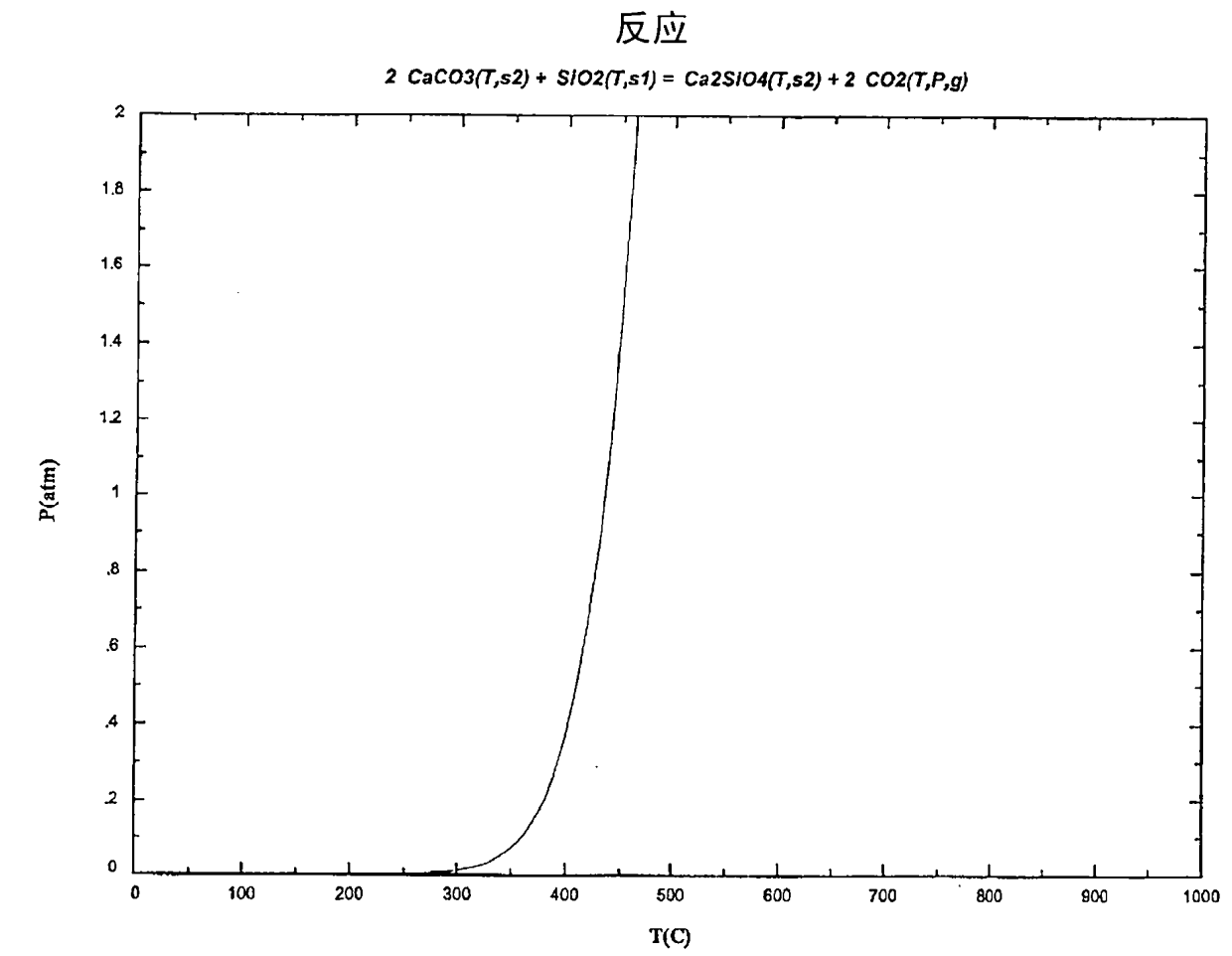

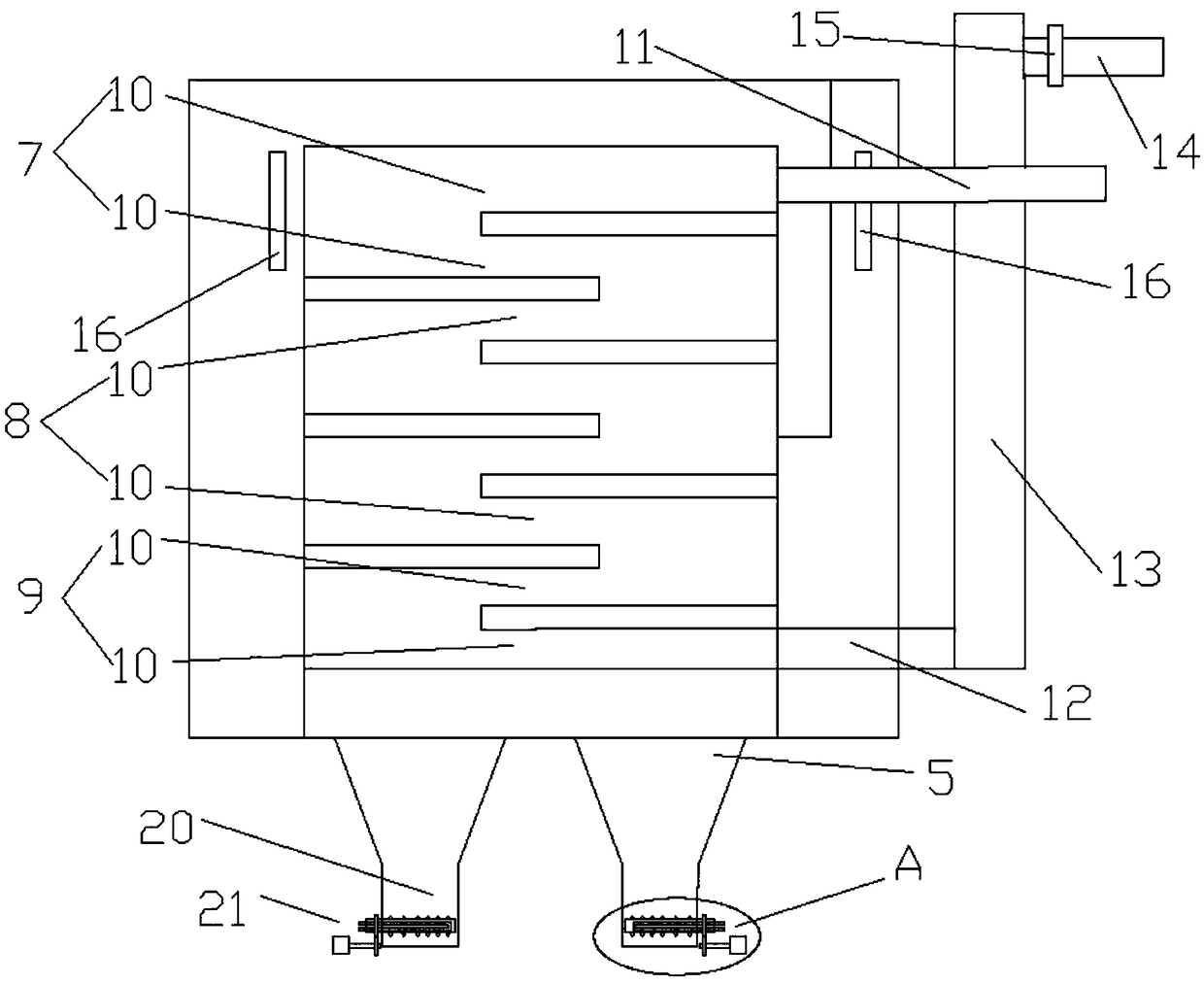

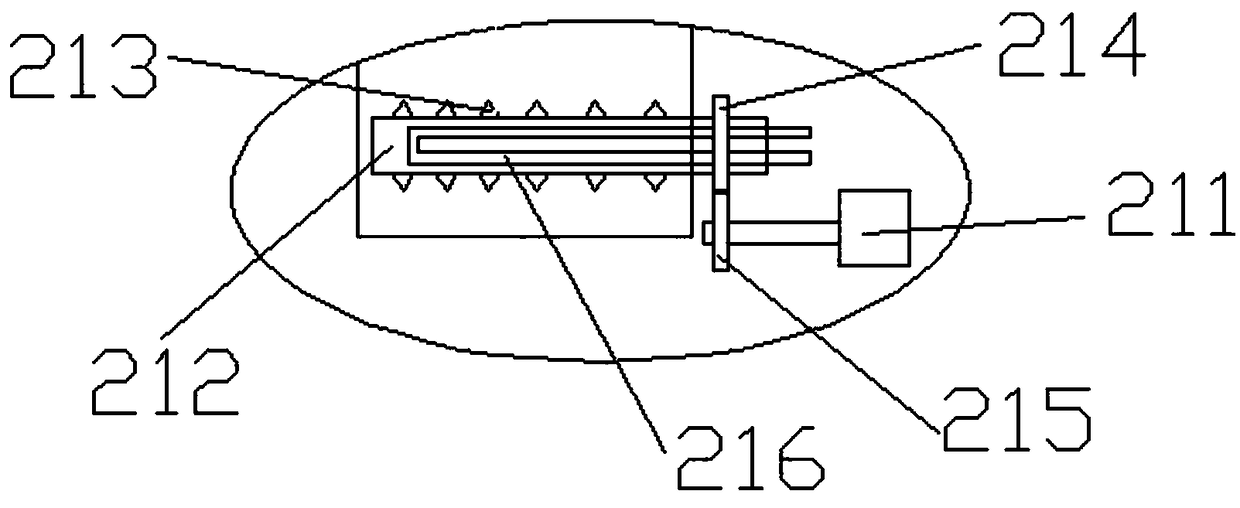

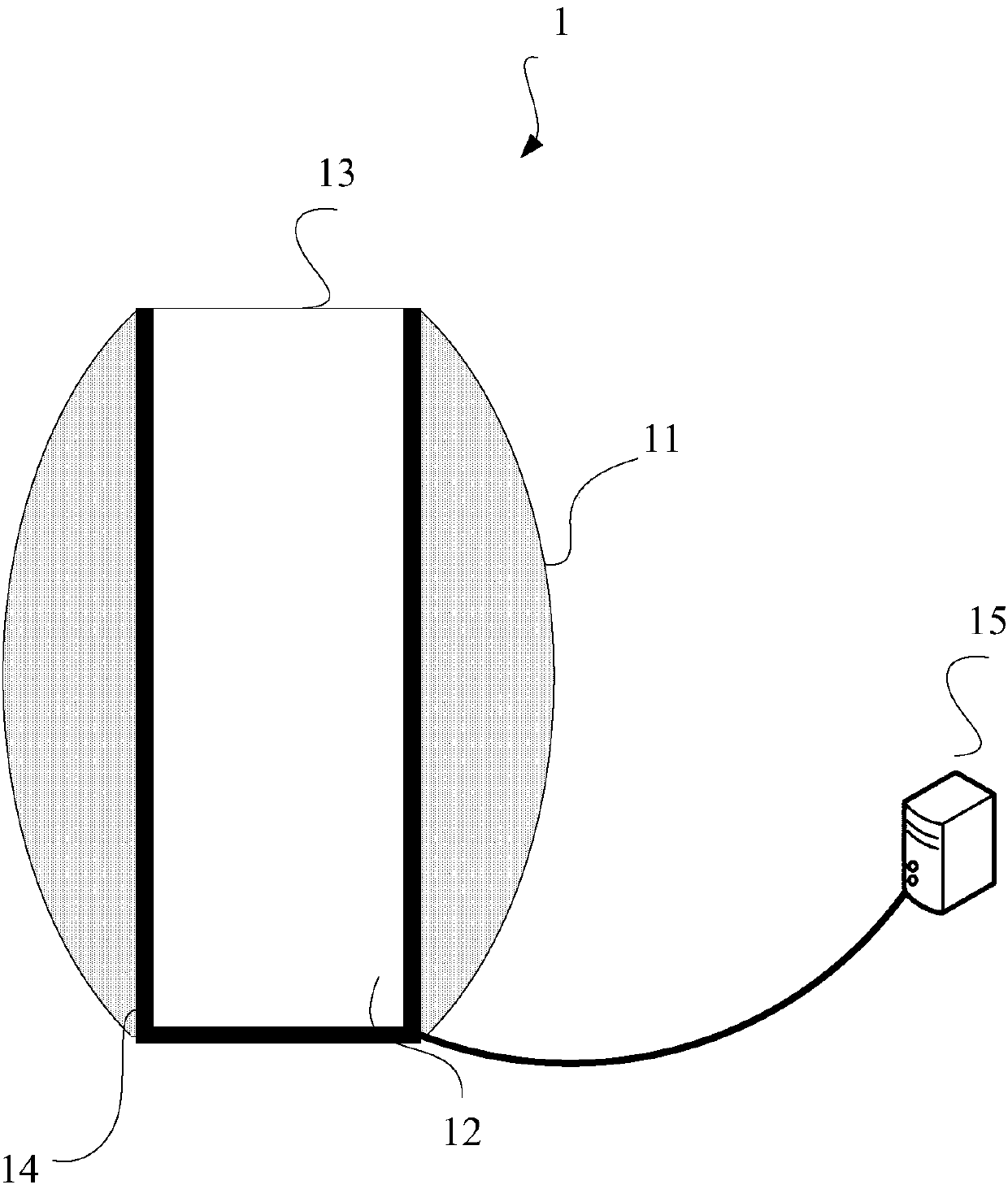

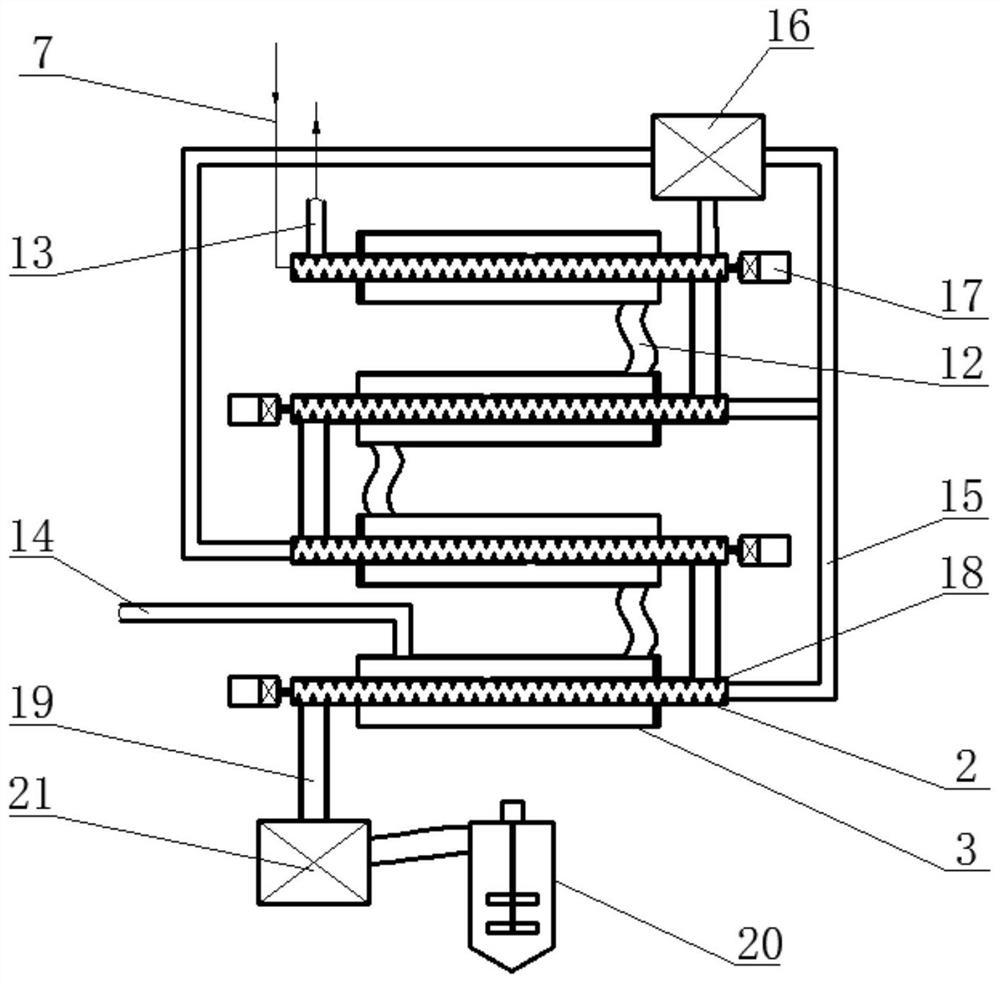

Calcium oxide and calcium hydroxide preparation methods and calcination device for preparation of calcium oxide

The embodiment of the invention provides calcium oxide and calcium hydroxide preparation methods and a calcination device for preparation of calcium oxide; a calcium source is added into a calcinationchamber in the calcination device via a feed port of the calcination device; a heating device of the calcination device is used for three-or-more-section continuous segmented calcination on the calcium source in the calcination chamber to obtain calcium oxide. Because the calcination device of the embodiment performs three-or-more-section periodic calcination on the calcium carbonate-rich calciumsource according to actual demand of calcining calcium carbonate to transform into calcium oxide, the corresponding calcination temperatures are provided for the calcium source according to the calcination stages, and a heat demand rule for calcium carbonate calcination preparation of calcium oxide is met. Therefore, calcium carbonate is guaranteed to be fully calcined, calcium oxide with relatively high yield and purity is prepared, the heat provided by the heating device can be guaranteed to be fully utilized and basically not be wasted, the utilization rate of the heat is increased and theenergy consumption of calcination is reduced.

Owner:深圳市天橙宝投资发展有限公司

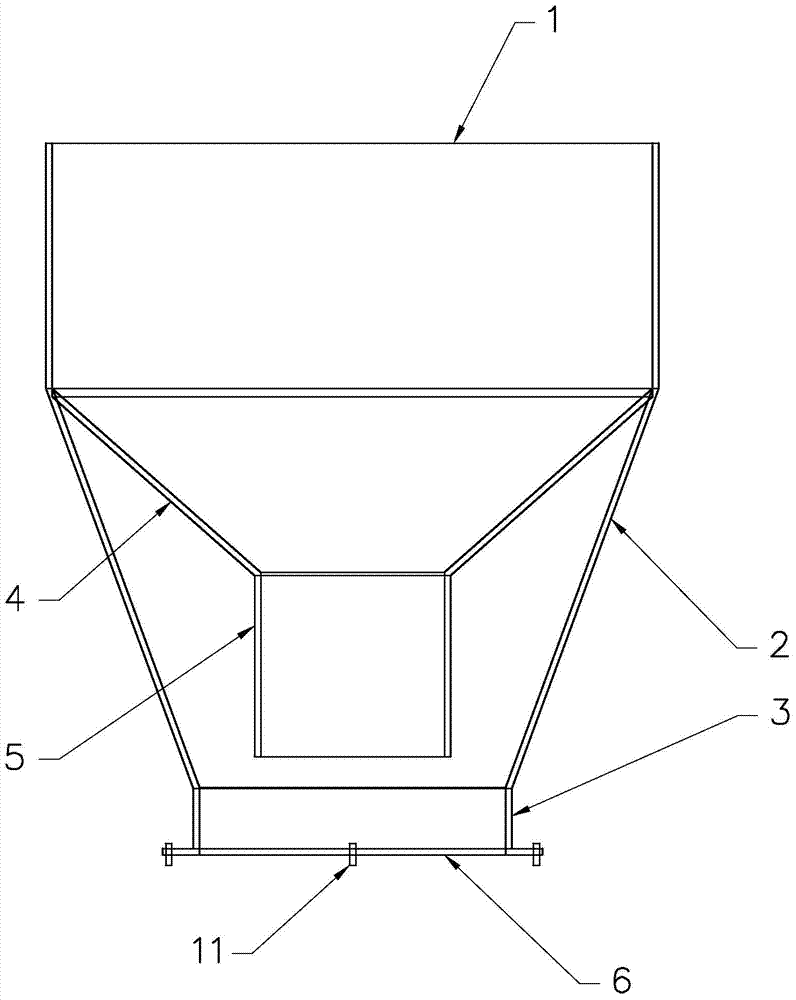

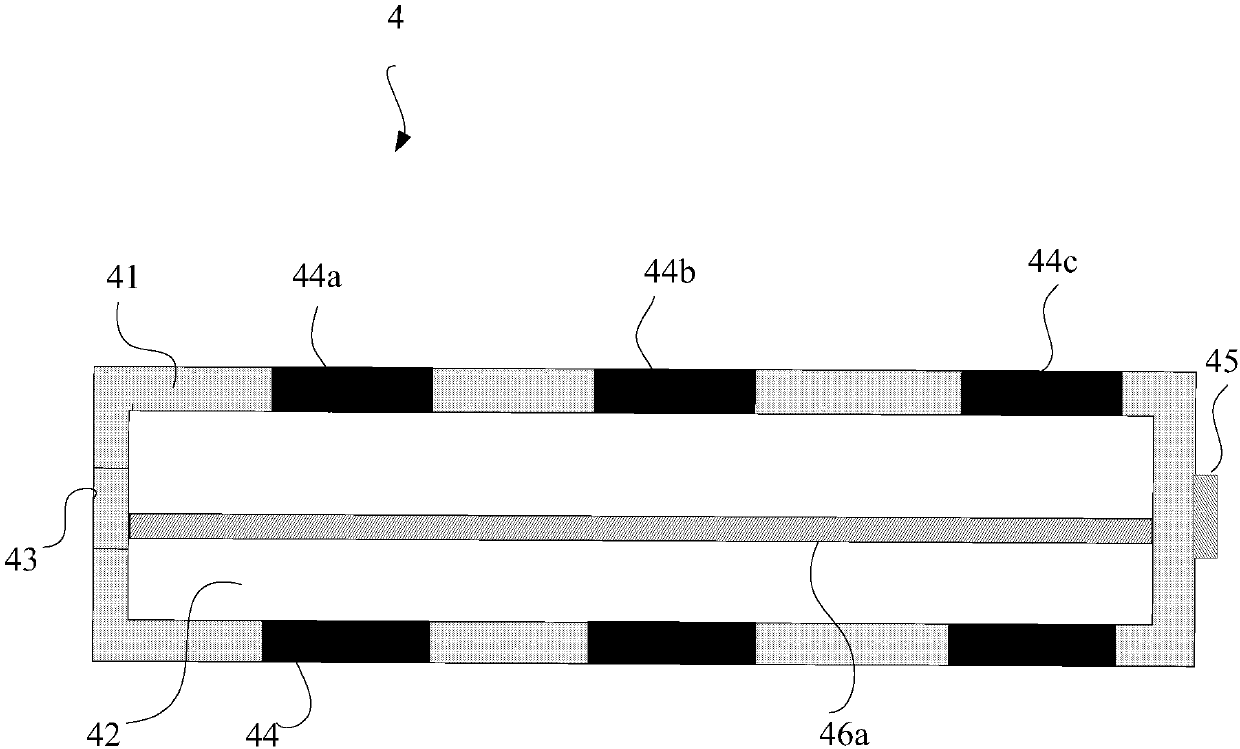

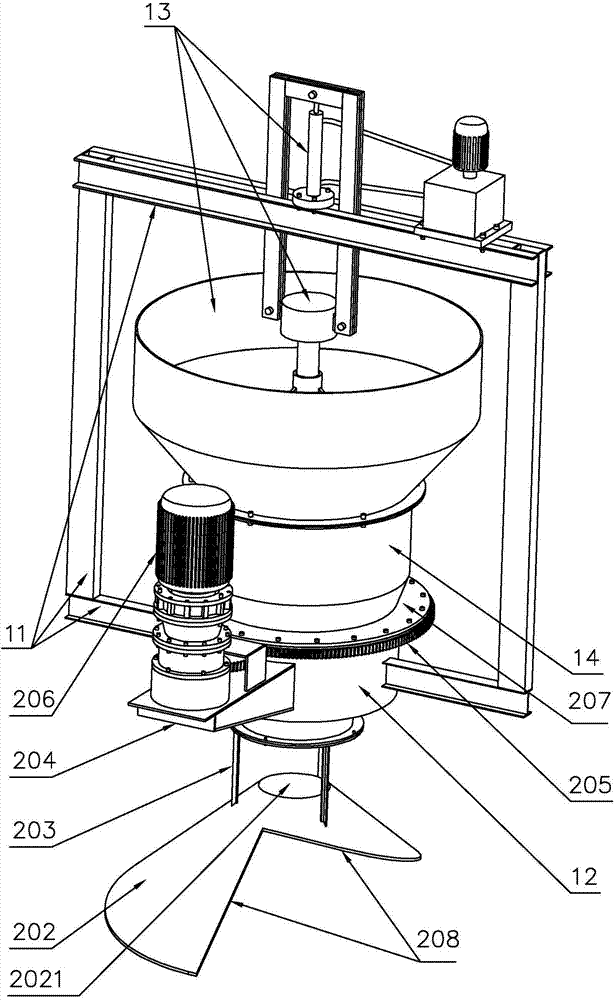

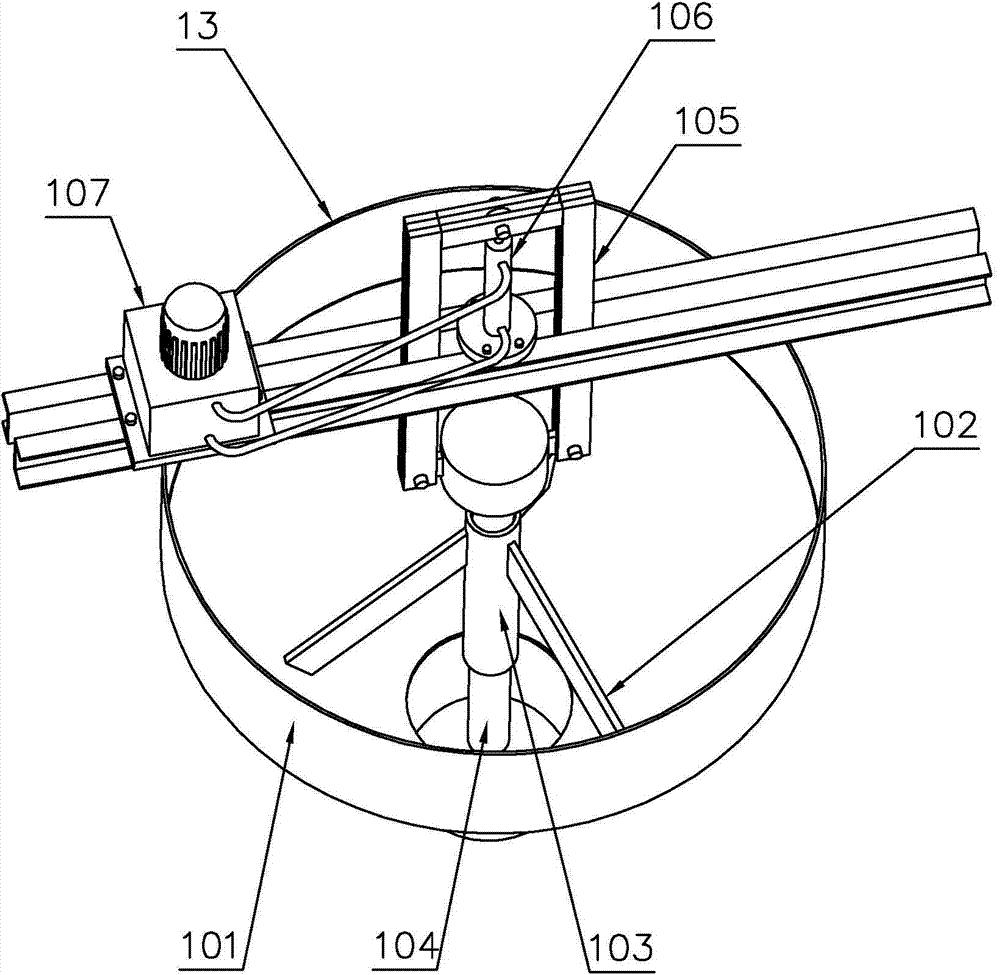

Novel mixing distributor for kiln

The invention discloses a novel mixing distributor for a kiln. The mixing distributor comprises a frame, a base, a mixing mechanism and a distributing mechanism, wherein the frame is arranged on two sides of the base; a support seat is arranged on one side of the base; a motor is arranged above the support seat; the distributing mechanism comprises a distributing hopper, a distributing device and connecting rods; the mixing mechanism is arranged above the distributing mechanism and comprises a mixing hopper and stirring blades; a shaft sleeve is arranged in the center of the mixing hopper; the stirring blades are arranged on the side wall of the shaft sleeve; a discharge opening is formed in the center of the bottom of the mixing hopper; a lifting shaft is arranged in the center of the shaft sleeve; a bracket is arranged on two sides of the lifting shaft; an oil cylinder is arranged in the center of the bracket; the bottom of the oil cylinder is arranged on the frame; a hydraulic tank is arranged on one side of the oil cylinder; and a bottom cover is arranged at the bottom of the lifting shaft. Through the novel mixing distributor for the kiln, materials are mixed uniformly, distributed consistently and calcined fully in the lime kiln, and the efficient and reasonable production of the lime kiln is realized.

Owner:刘建轻

Method for producing feed-grade tricalcium phosphate by utilizing low-calorific-value tail gas

PendingCN111377423AReduce processing costsFacilitate the decomposition and defluorinationDrying solid materials with heatEnergy inputExhaust gasChemistry

The invention discloses a method for producing feed-grade tricalcium phosphate by utilizing low-calorific-value tail gas. The method comprises the following steps: (1) burning ground phosphate rock byutilizing the low-calorific-value tail gas and drying; (2) mixing and ball milling; (3) performing disc granulation; (4) calcining and defluorinating the low-calorific-value tail gas; (5) air heat storage and temperature rise; (5) cooling, crushing and sieving; (6) circularly crushing and screening, and ball-milling a semi-finished product; (7) screening and removing iron; and (8) packaging products. The method has the following advantages: (1) the raw material components and the particle size range of the ground phosphate rock are specified; (2) low-calorific-value tail gas combustion is fully utilized for heat storage and temperature rise of combustion-supporting air; (3) a low-calorific-value tail gas combustion technology and a co-combustion technology are fully utilized; (4) steam isadded in the calcining process to promote decomposition and defluorination of the phosphate ore; and (5) saturated steam and superheated steam are produced by fully utilizing calcined tail gas, so that energy is saved, and energy consumption and production cost are reduced. The method is very suitable for being popularized and used in enterprises producing feed-grade tricalcium phosphate products.

Owner:WENGFU (GRP) CO LTD

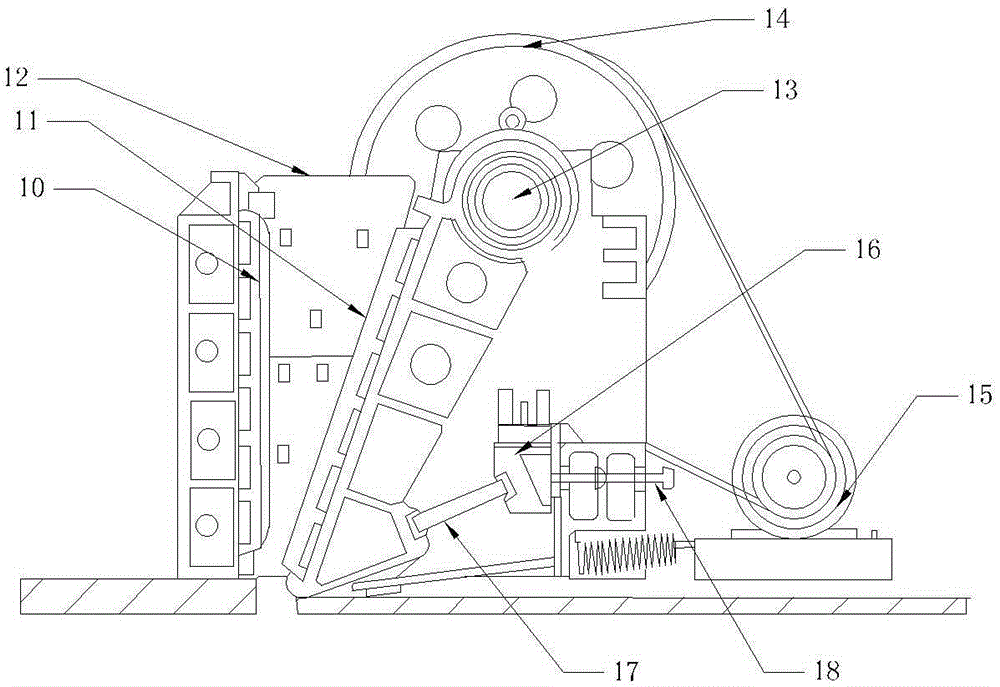

Smashing and calcining device for lead waste

ActiveCN105331798AGuaranteed uptimeUniform particle sizeProcess efficiency improvementBrickCombustion

The invention discloses a smashing and calcining device for lead waste. The device comprises a breaking device, a smashing device and a calcining device. The breaking device and the calcining device are located above and below the smashing device respectively. A discharge outlet of the breaking device is in butt connection with a feed inlet of the smashing device. The smashing device and the calcining device are connected through a pipeline. The calcining device comprises a calcining furnace, and a combustion assembly and a distribution assembly which are arranged in the calcining furnace. A layer of refractory bricks are arranged on the inner wall of the calcining furnace, and a furnace door of the calcining furnace is arranged at the bottom. The distribution assembly in a conical shape is arranged on the upper portion of the combustion assembly. According to the smashing and calcining device for the lead waste, the lead waste is sufficiently calcined, fuel consumption is small, and consumed time is short.

Owner:贵州融晟环保科技有限公司

Mixing type lime kiln with raw material graded treatment function

The invention relates to the field of production of lime and particularly relates to a mixing type lime kiln with a raw material graded treatment function. The mixing type lime kiln comprises a kiln body, wherein a material distributing mechanism is arranged in the kiln body, at least two layers of mutually-parallel material distributing plates are arranged in the material distributing mechanism,a plurality of through holes for enabling raw materials to pass through are formed in the material distributing plates, the through holes in adjacent two material distributing plates are lessened gradually from the top of the material distributing mechanism to the bottom of the material distributing mechanism, the material distributing mechanism is connected with a driving mechanism, and the driving mechanism drives the material distributing mechanism to rotate. The raw materials can be dispersed on different material distributing plates according to different sizes, the proceeding of a calcination process is accelerated, and the consumption of fuel is lowered; and meanwhile, the driving mechanism is further arranged to drive the material distributing mechanism to rotate, thus, relative positions between the fuel and limestone are changed during the rotation of the raw materials in the material distributing mechanism in the calcination process, the proceeding of the calcination processis further accelerated, the production efficiency of the lime kiln is increased, and then, resource expenditure is reduced, so that the mixing type lime kiln has the effects of high yield and energysaving.

Owner:四川马氏窑技术发展有限公司

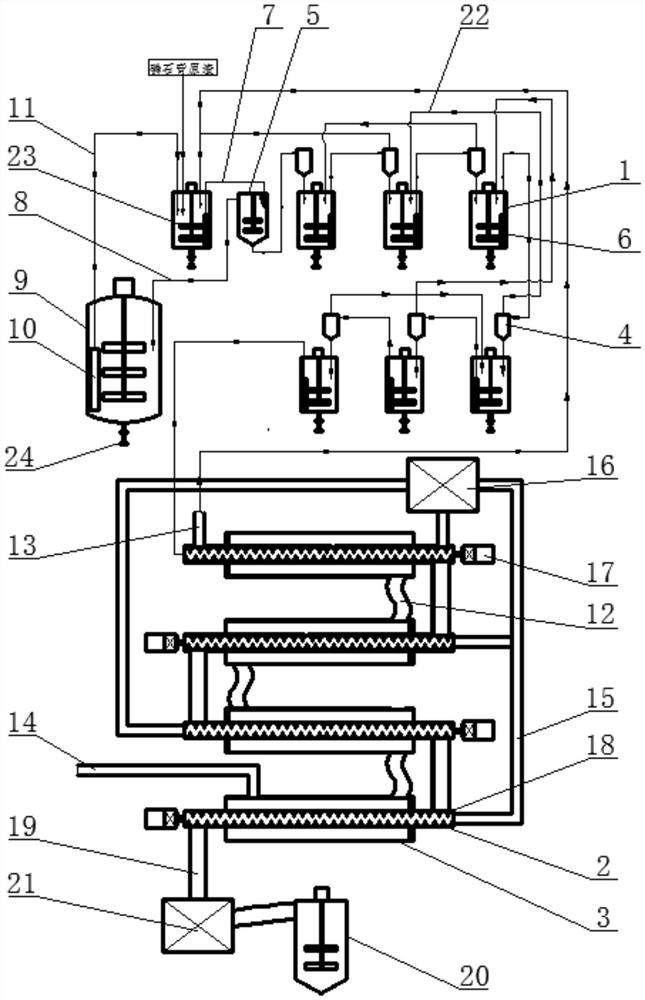

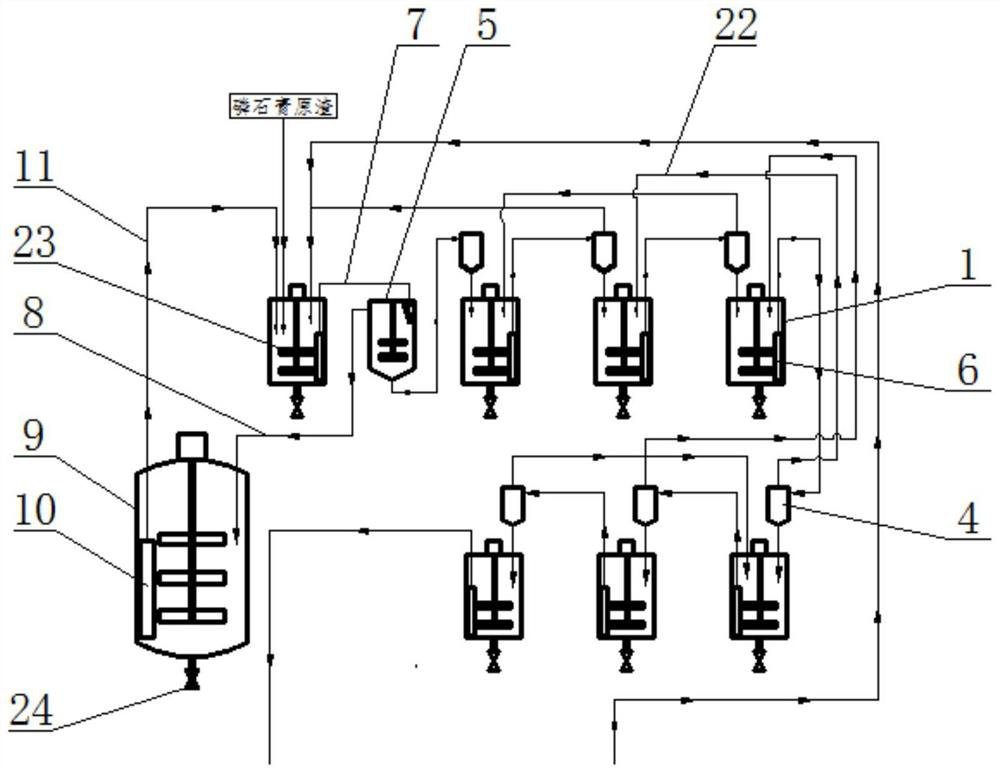

Full-cycle comprehensive utilization integrated complete production line for ardealite and by-products of ardealite

The invention provides a phosphogypsum and by-product full-cycle comprehensive utilization integrated set production line, which comprises purification tanks, calcining cylinders and a heat exchange cylinder, the calcining cylinders are connected in series end to end, a solid-liquid separator is further arranged between two adjacent purification tanks, a thickener is further arranged between the first purification tank and the first solid-liquid separator, and the other solid-liquid separator is arranged between the second purification tank and the second solid-liquid separator. A slurry pump is arranged in the purification tank, the slurry pump respectively extends into the thickener and the next solid-liquid separator through feeding pipes and is connected with the head end of the first calcining cylinder, the upper part of the thickener extends into the synthesis tower through a purification liquid pipe, a reflux pump is arranged in the synthesis tower and is connected with a reflux water pipe, the first heat exchange cylinder is further connected with a steam condensing pipe, and the steam condensing pipe is connected with the condensing pipe. And the tail end of the backflow water pipe and the tail end of the steam condensing pipe extend into the first purification tank. By adopting the technical scheme provided by the invention, by-products such as purified liquid, steam condensate and the like generated in the treatment process of the industrial gypsum raw slag are reasonably and effectively recycled, so that the effective utilization rate of resources is improved, and the pollution to the environment is avoided.

Owner:GUIZHOU LANTU NEW MATERIALS

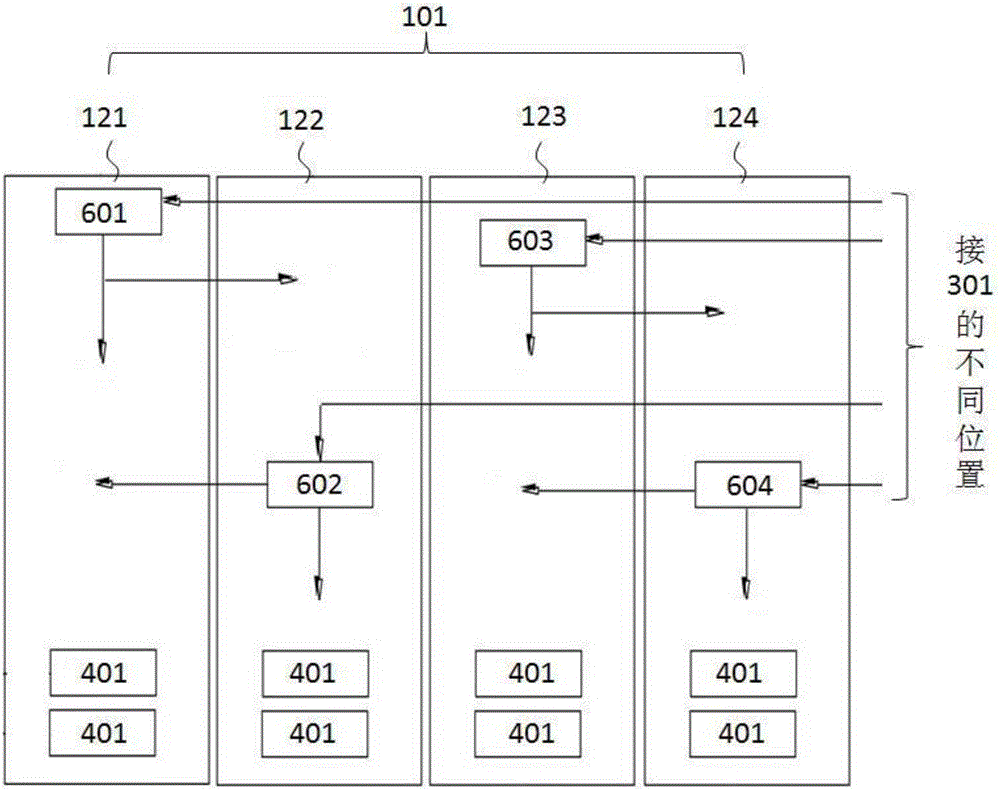

Furnace device and method utilizing furnace device to manufacture sintered bricks

ActiveCN105973007AReduce consumptionEasy to dryCharge composition/stateDrying gas arrangementsTunnel kilnBrick

The invention provides a furnace device and a method utilizing the furnace device to manufacture sintered bricks. The furnace device comprises drying kilns, tunnel kilns, ventilation channels and centrifugal fans, wherein the drying kilns communicate with the tunnel kilns through the ventilation channels; and the centrifugal fans are connected with the ventilation channels, and are used for enabling hot air in the tunnel kilns to enter the drying kilns through the ventilation channels. According to the furnace device and the method, the centrifugal fans can extract hot air in the tunnel kilns and feed the hot air into the drying kilns to dry green bricks, so that the energy consumption during the brick manufacturing process is greatly reduced; when the device is utilized to manufacture the sintered bricks, the temperature of the tunnel kilns is increased to 700 to 1000 DEG C, the green bricks are fed into the drying kilns from inlets of the drying kilns to outlets of the drying kilns, and then enter the tunnel kilns from inlet of the tunnel kilns to outlets of the tunnel kilns, and the sintered bricks are obtained; the method fully utilizes the structural characteristics of the furnace device, only the tunnel kilns require to be heated, and the drying kilns do not require to be heated, so that the energy consumption is low, and the method is simple and quick; and besides, the strength of the manufactured sintered bricks is high.

Owner:常德天厦建材有限公司

Uniform calcining kiln device

InactiveCN107120964AFully calcinedImprove uniformityCharge treatment typeFurnace typesReduction driveCoupling

The invention discloses a uniform calcining kiln device. The uniform calcining kiln device comprises a motor for power of the whole device, a speed reducer used for reducing the rotating speed, a calcining kiln body used for loading materials, a cover used for sealing and a base used for supporting the calcining kiln body. A stirrer is arranged on the calcining kiln body through a bearing. The motor is connected with the speed reducer through a first coupler, the speed reducer is connected with the stirrer through a second coupler, and a discharging hole is formed in the end, far away from the motor, of the calcining kiln body. The uniform calcining kiln device solves the problems that a traditional similar device is not uniform in calcining and low in efficiency, by means of the stirring function of a stirrer structure, continuous mixing operation during calcining is achieved, uniformity of calcining is improved, and the cost is reduced; by means of cooperative work of stirring blocks and stirring blades, the materials are sufficiently calcined more effectively; and the uniform calcining kiln device has the beneficial effects of being high in structural stability and maneuverability and good in calcining effect.

Owner:XIANGZHOU COUNTY INST OF SCI & TECHN INFORMATION

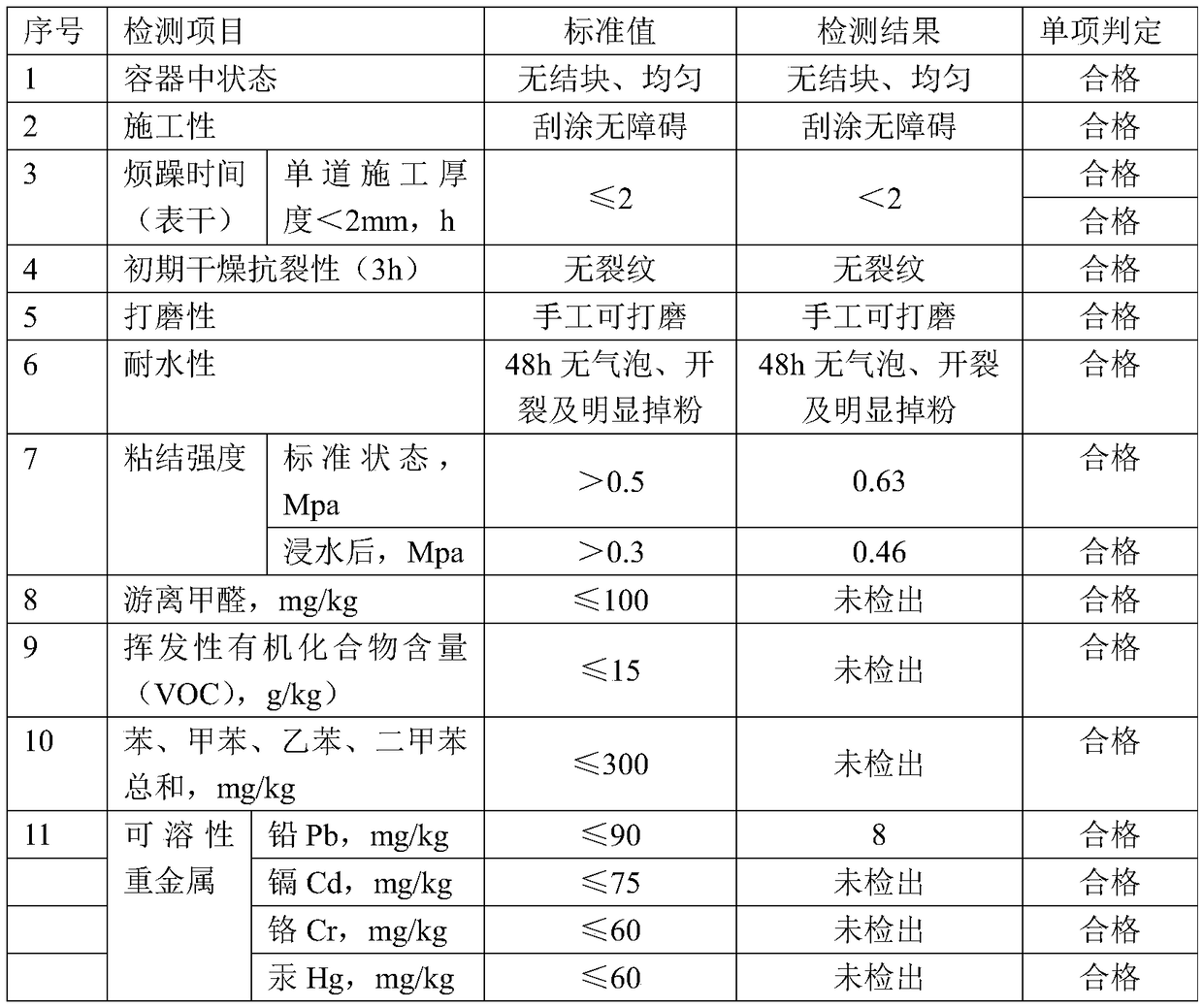

Purification formaldehyde inner wall water-resisting putty

InactiveCN109401415AImprove distribution uniformityAvoid easy reunion problemsFilling pastesCelluloseHazardous substance

The invention relates to purification formaldehyde inner wall water-resisting putty. The purification formaldehyde inner wall water-resisting putty is prepared from the following raw materials in parts by weight: 100 to 200 parts of white cement, 800 parts of heavy calcium, 3 to 6 parts of dispersible rubber powder, 3 to 6 parts of cellulose ether, 3 to 6 parts of starch ether, 5 to 10 parts of nano titanium dioxide, and 5 to 10 parts of molecular sieve. The putty powder has good application property, high strength and good water resistance, and has an absorption and degradation effect for formaldehyde. A porous structure of a molecular sieve contained in the putty powder can absorb the formaldehyde in the air, and can rapidly reduce the content of the formaldehyde in the air, and the contact catalytic effect of the bio-enzyme and the photocatalytic effect of nano titanium dioxide can thoroughly decompose harmful substances such as formaldehyde and TVOC; and by virtue of the absorptionand degradation double effects, the formaldehyde in the air can be rapidly reduced, the formaldehyde pollution can be thoroughly solved, and the purification formaldehyde inner wall water-resisting putty is particularly suitable for the indoor decoration.

Owner:上海伟星新材料科技有限公司

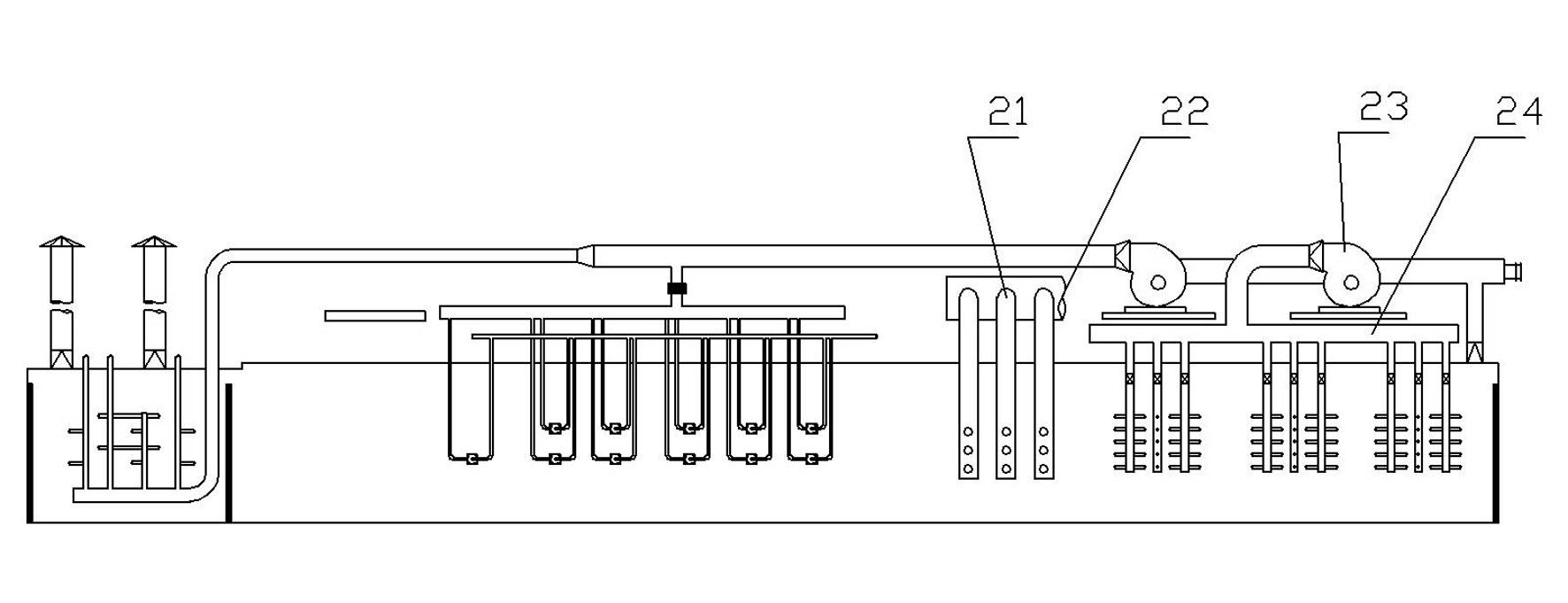

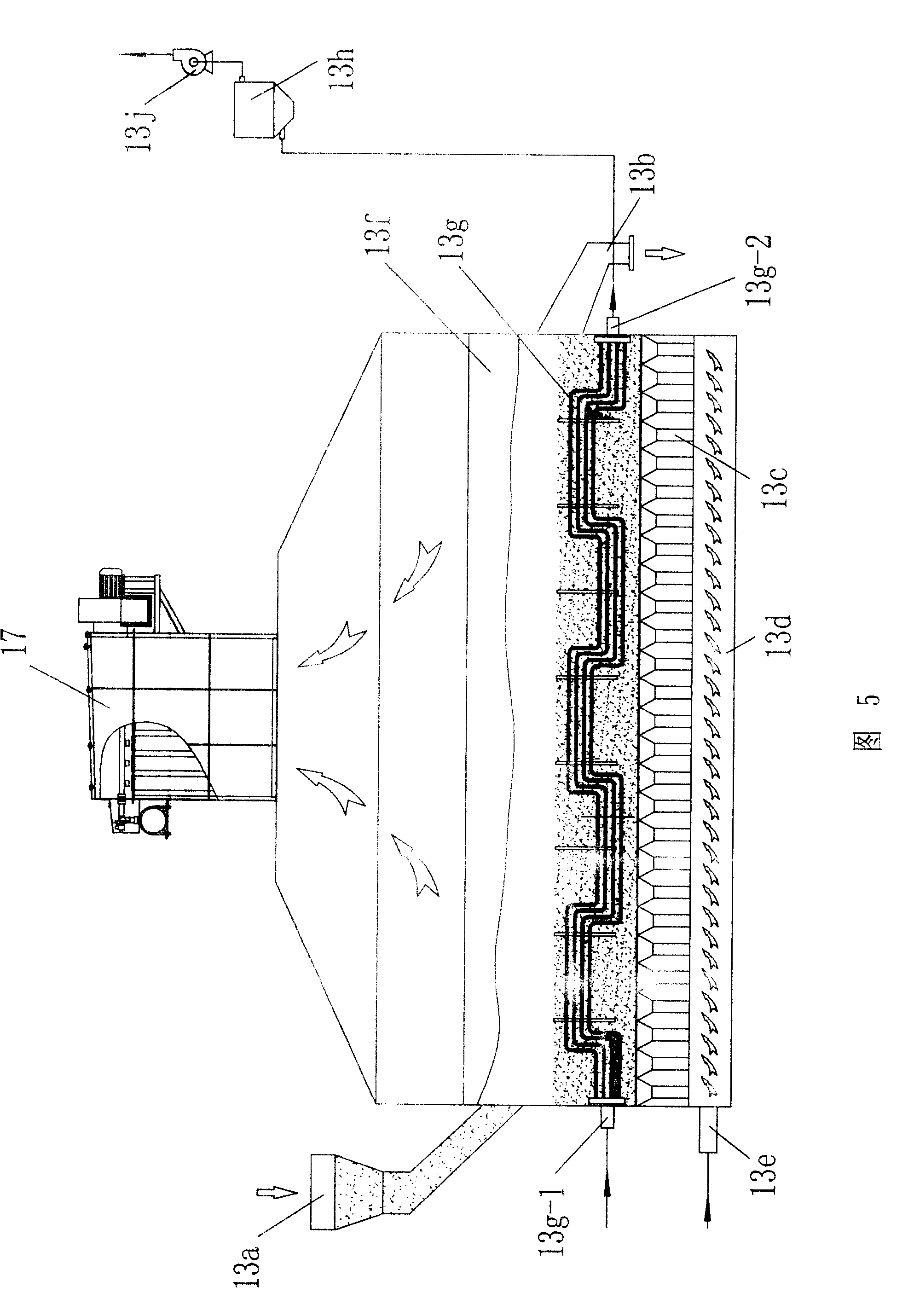

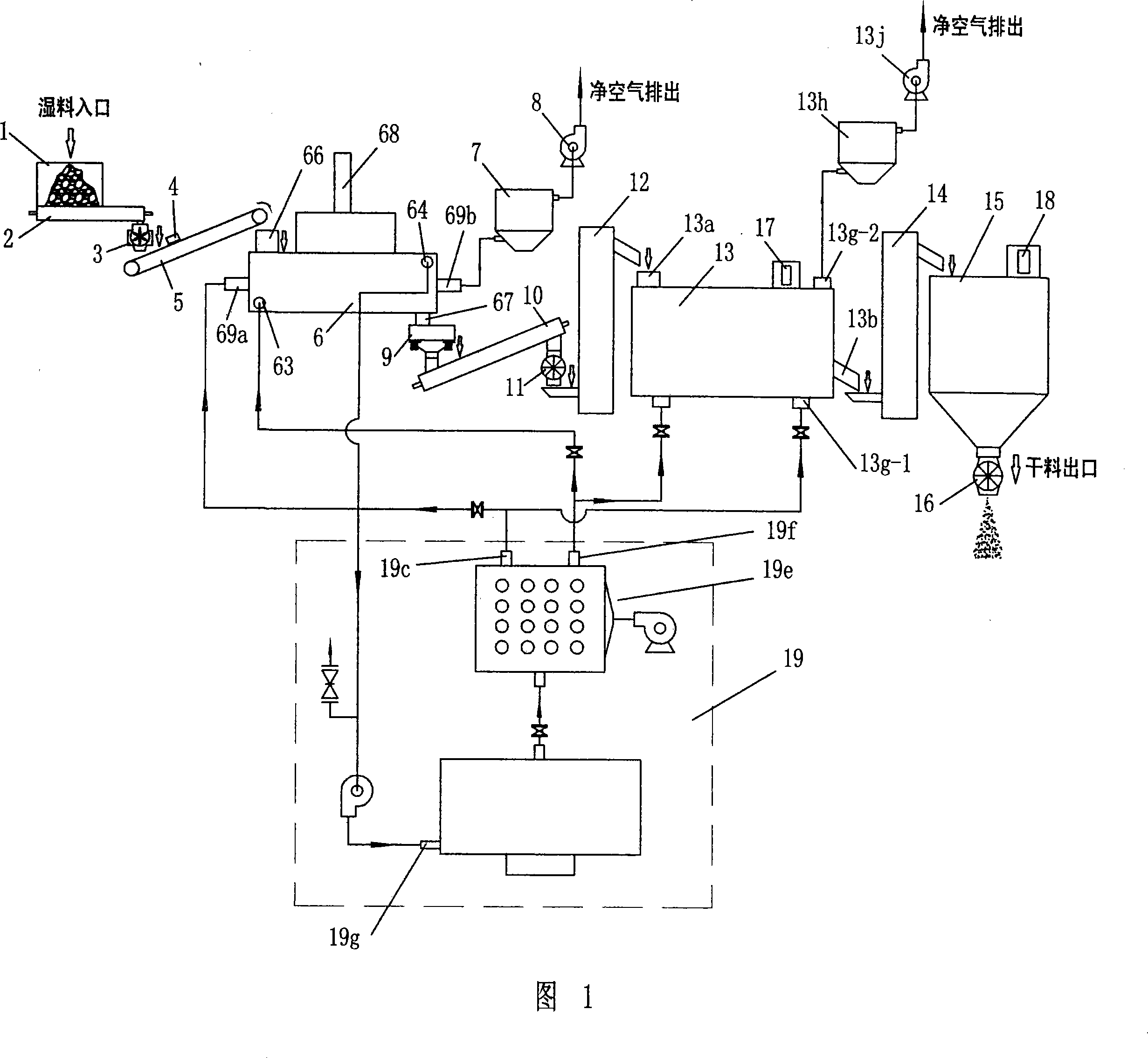

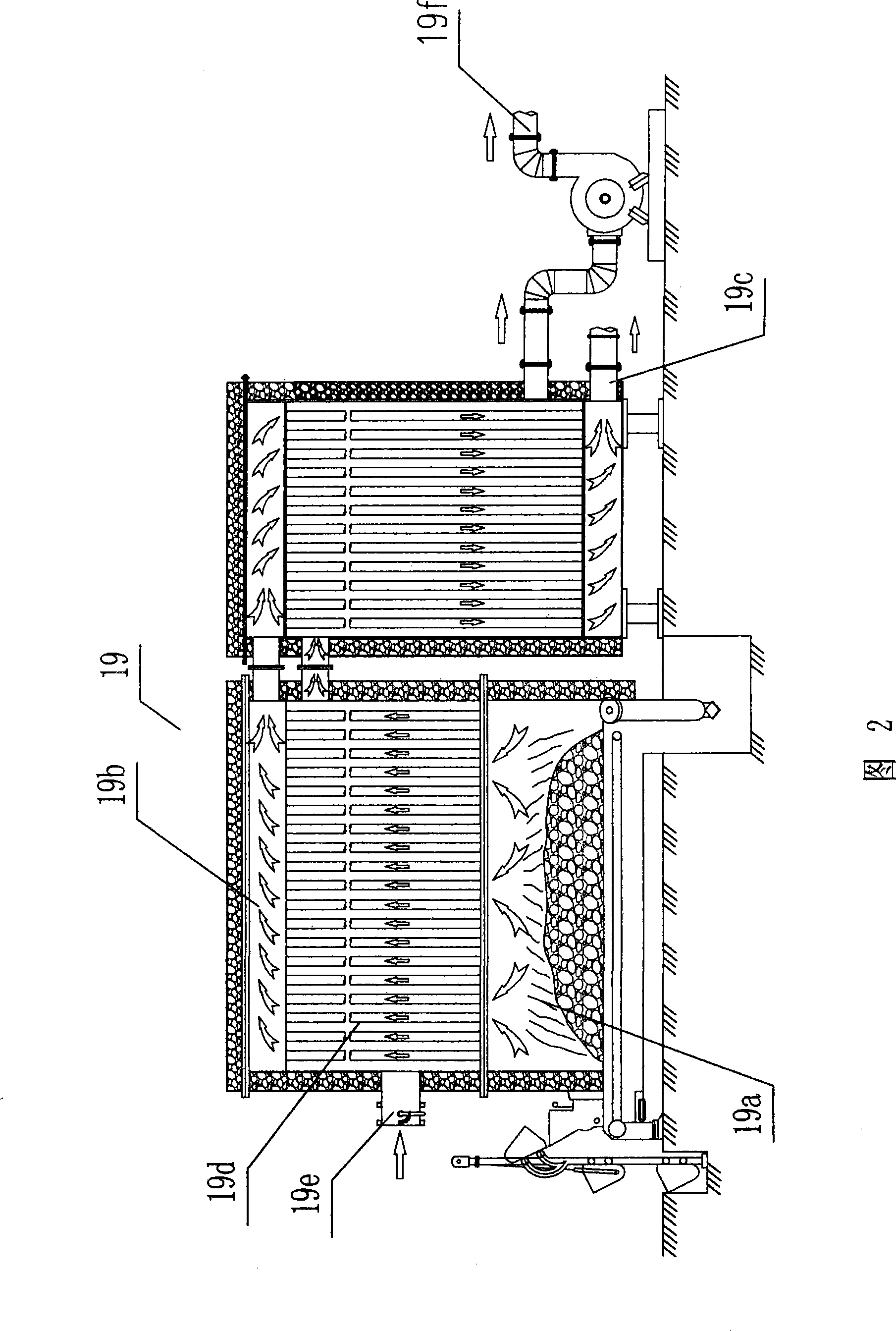

Gypsum calcining system

The invention discloses a system for calcinating plaster and a calcinating method thereof. The system includes a crusher for crushing the plaster material, a plaster drying device for drying the crushed plaster material, an oscillating sieve for sieving the dried plaster material, a calcinatory of a fluid bed for calcinating the sieved plaster material, a storage tower for storing the calcinated plaster as well as a hot air boiler for providing a thermal source for the plaster drying device and the calcinatory of the fluid bed. By adopting the device which first dries and then calcinates in the invention greatly promotes the efficiency and improves the quality of calcinating; besides, by adopting the single storage tower to carry out cooling, the efficiency of the whole system is greatly improved; the crushing and sieving of the plaster material guarantees that the calcinatory of the fluid bed sufficiently calcinates the plaster material, thus facilitating the production quality.

Owner:潍坊天洁环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com