Calcium oxide and calcium hydroxide preparation methods and calcination device for preparation of calcium oxide

Calcium oxide and calcination technology, which is applied in the field of calcination equipment for preparing calcium oxide, calcium oxide, and calcium hydroxide preparation methods, can solve problems such as energy consumption that is not considered, and achieve the effects of reducing energy consumption for calcination and improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

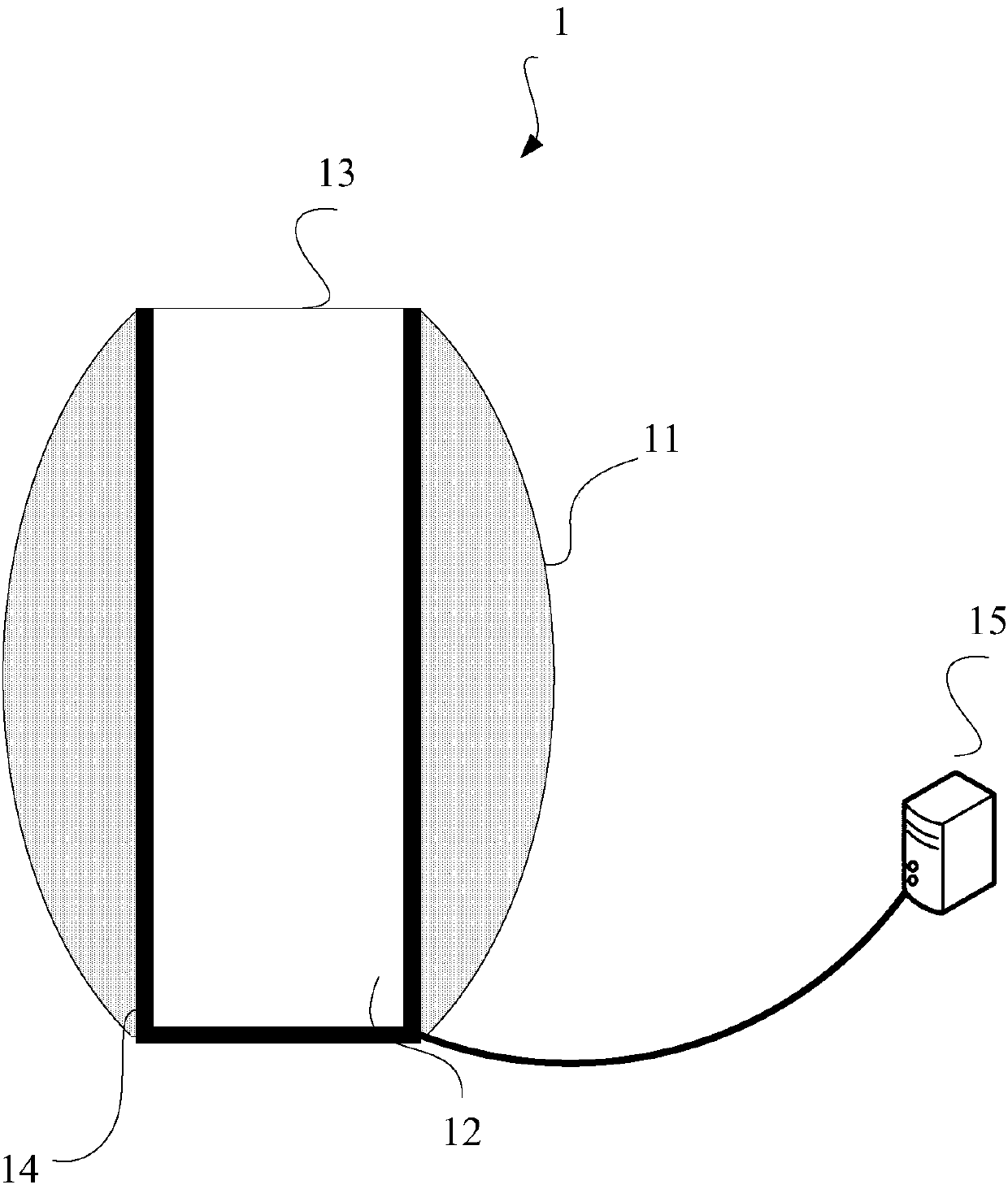

[0042] In order to solve the problem in the prior art that only a single calcination temperature is provided when calcining calcium carbonate, which leads to serious waste of heat in some calcination stages that do not need this temperature, this embodiment provides a new calcium oxide preparation scheme, The preparation method of calcium oxide and the calcining equipment for preparing calcium oxide will be introduced below. see first figure 1 A schematic cross-sectional view of the shown calcining equipment:

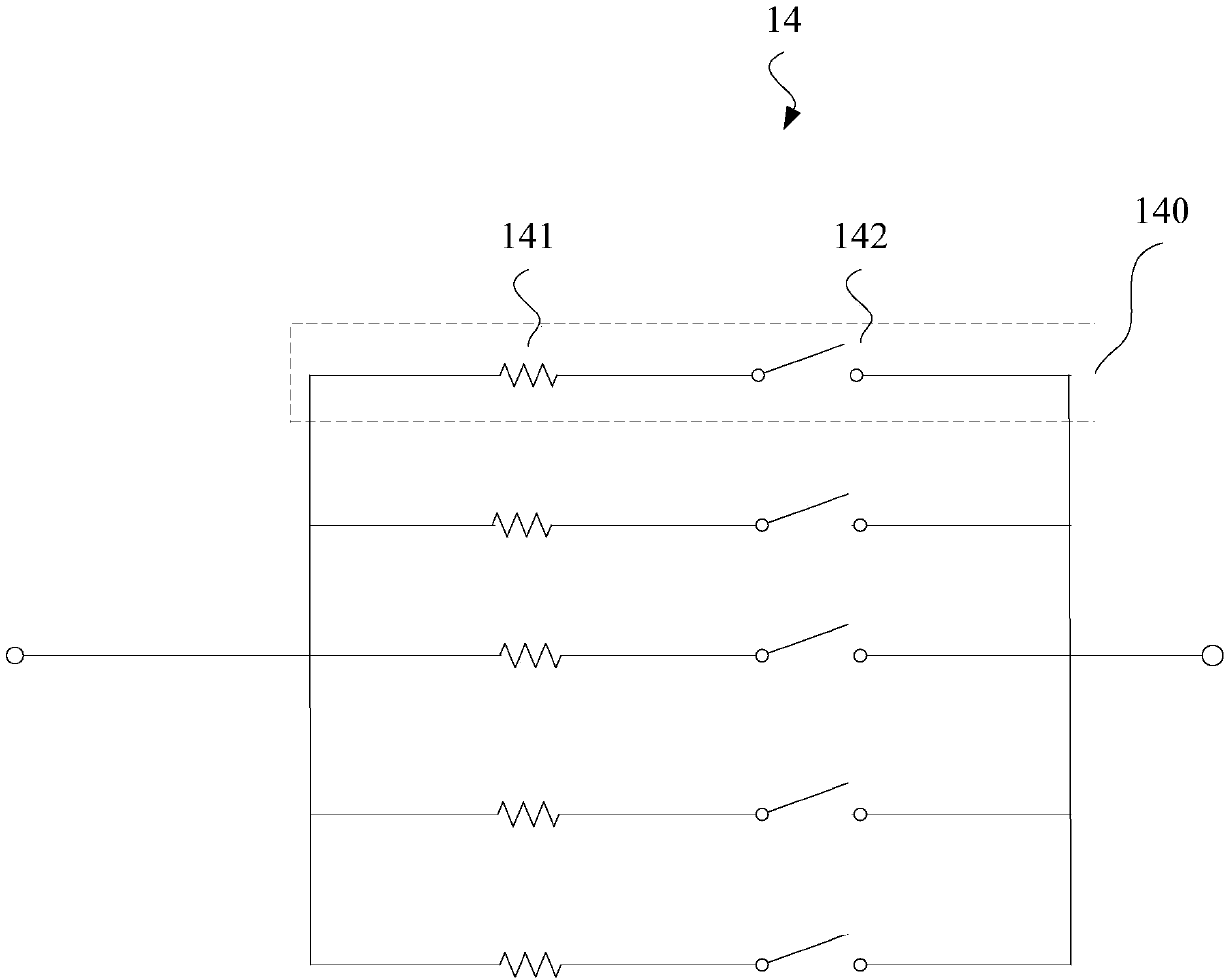

[0043] Calcination equipment 1 comprises equipment body 11, and there is hollow chamber inside this equipment body 11, and this chamber is exactly calcining chamber 12, and is provided with feed inlet 13 on equipment body 11, and feed inlet 13 communicates with equipment body 11 exterior and The calcining chamber 12 is used for transporting the raw material to be calcined from the outside of the equipment body 11 to the calcining chamber 12 . The raw material to be ca...

Embodiment 2

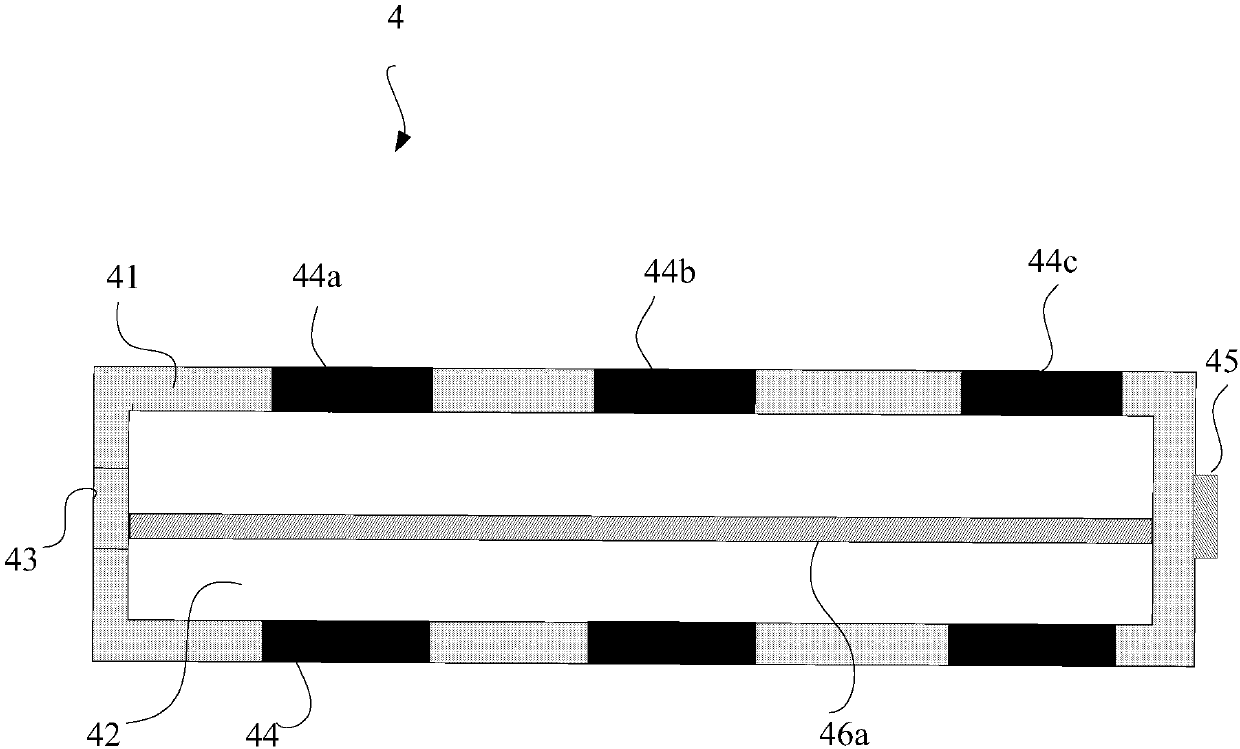

[0065] In order to make the advantages and details of the calcium oxide preparation method more clear, this embodiment will continue to introduce the process and required equipment for the preparation of calcium oxide, please refer to Figure 4 :

[0066] The calcining equipment 4 provided in this embodiment includes a device body 41, a calcining chamber 42, a feed inlet 43, a heating device 44, and a control device 45, but it is different from the calcining device in the embodiment in that the calcining device in this embodiment There is more than one heating device, and these heating devices 44 can provide suitable calcining temperatures to the calcium source to be calcined in the calcining chamber 42 at different calcining stages. It can be understood that the heating devices corresponding to each calcination stage can be completely different, but two or more calcination stages can share the same heating device.

[0067] It is assumed that in an example of this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com