Purification formaldehyde inner wall water-resisting putty

A technology for water-resistant putty and interior walls, applied in the direction of filling slurry, etc., can solve the problem that the effect of photon excitation cannot be observed, and achieve the effect of high strength, avoiding easy agglomeration and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The formula of formaldehyde-removing putty for interior walls is as follows in parts by weight:

[0028] 150 parts of 42.5 white cement

[0029] 325 mesh heavy calcium 217 parts

[0030] 500 mesh heavy calcium 600 parts

[0031] Available in disperse rubber powder 5 parts

[0032] Cellulose ether 5 parts

[0033] 3 parts starch ether

[0034] Nano titanium dioxide 10 parts

[0035] Molecular sieve 10 parts

[0036] The cellulose ether is methyl B-grade hydroxyethyl cellulose ether, and the nano-titanium dioxide used is anatase type, with a specific surface area of 70-120m 2 , the average particle size is 20±5nm, and the molecular sieve particle size is 150 mesh.

[0037] The preparation method of purifying formaldehyde interior wall water-resistant putty: its specific steps are:

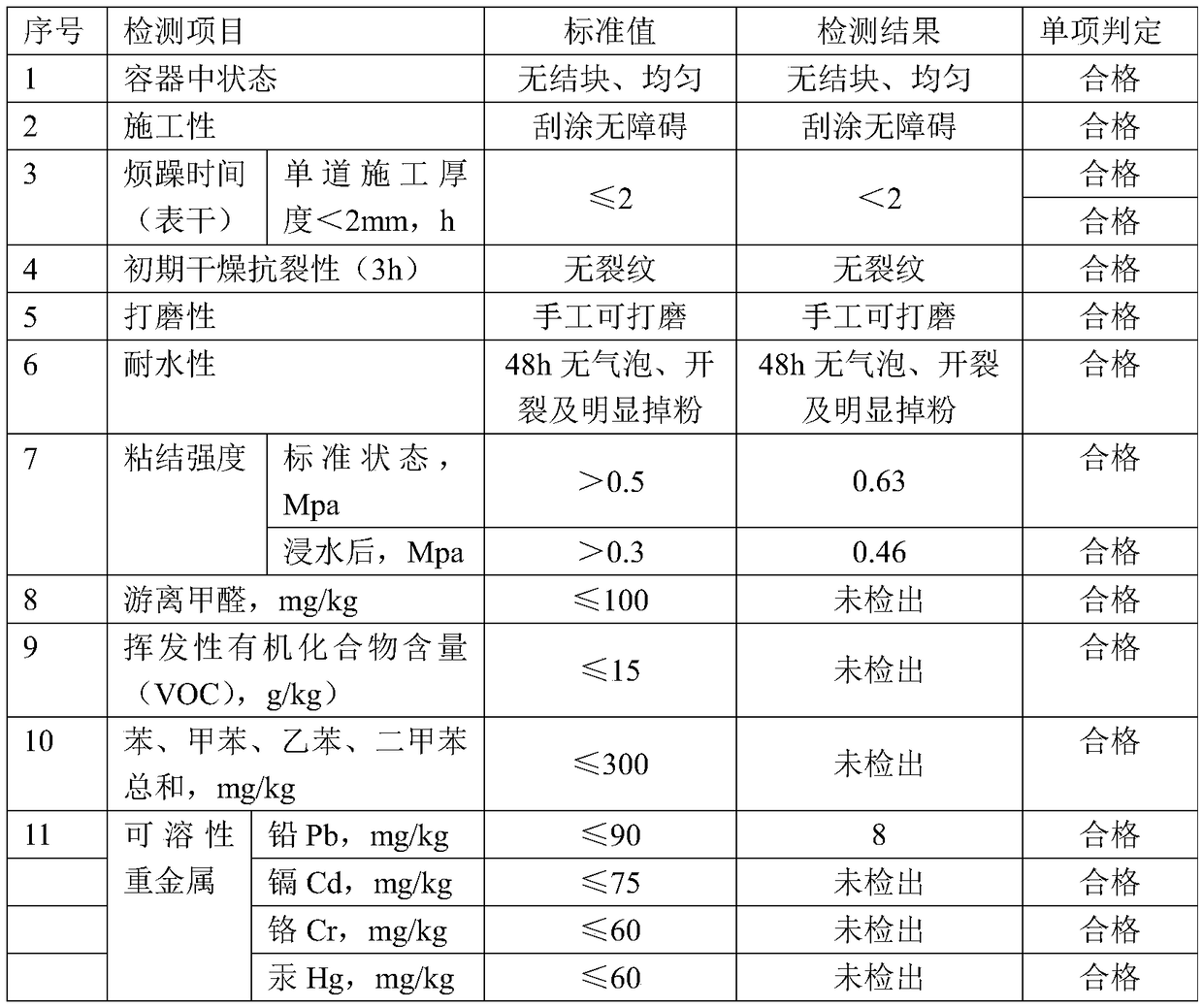

[0038] The test results of the prepared formaldehyde-free interior wall water-resistant putty are as follows: 100 parts of white cement, 217 parts of 325-mesh heavy calcium, 300 part...

Embodiment 2

[0045] The formula of formaldehyde-removing putty for interior walls is as follows in parts by weight:

[0046]150 parts of 42.5 white cement

[0047] 325 mesh heavy calcium 217 parts

[0048] 500 mesh heavy calcium 600 parts

[0049] Available in disperse rubber powder 5 parts

[0050] Cellulose ether 5 parts

[0051] 3 parts starch ether

[0052] Nano titanium dioxide 10 parts

[0053] Formaldehyde remover 20 parts

[0054] The formaldehyde remover is a molecular sieve compound doped with titanium dioxide;

[0055] The preparation method of the formaldehyde remover: the specific steps are: adding the molecular sieve into the titanyl sulfate aqueous solution and soaking for 120 minutes, after filtering, raising the temperature to 200°C in the air at a heating rate of 5°C / min, and staying there for 1.5 hours, Then in an oxygen-depleted atmosphere, the temperature was raised to 420°C at a rate of 15°C / min, and stayed for 1.5 hours to obtain a molecular sieve loaded with ...

Embodiment 3

[0059] The formula of formaldehyde-removing putty for interior walls is as follows in parts by weight:

[0060] 150 parts of 42.5 white cement

[0061] 325 mesh heavy calcium 217 parts

[0062] 500 mesh heavy calcium 600 parts

[0063] Available in disperse rubber powder 5 parts

[0064] Cellulose ether 5 parts

[0065] 3 parts starch ether

[0066] Nano titanium dioxide 10 parts

[0067] Formaldehyde remover 20 parts

[0068] The formaldehyde remover is a molecular sieve compound doped with titanium dioxide;

[0069] The preparation method of the formaldehyde remover: the specific steps are: adding the molecular sieve into the titanyl sulfate aqueous solution and soaking for 120 minutes, after filtering, raising the temperature to 200°C in the air at a heating rate of 5°C / min, and staying there for 1.5 hours, Then raise the temperature to 420°C at a rate of 15°C / min in an oxygen-poor atmosphere, and stay there for 1.5 hours to obtain a molecular sieve loaded with titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com