Multi-cavity baffle type electrolytic milling and grinding complicated machining tool cathode and method

A tool cathode and compound processing technology, which is applied in the field of multi-cavity baffle type electrolytic milling and grinding compound processing tool cathodes, can solve problems such as short circuit workpieces, increased electrolyte pressure, and holes in the processing gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

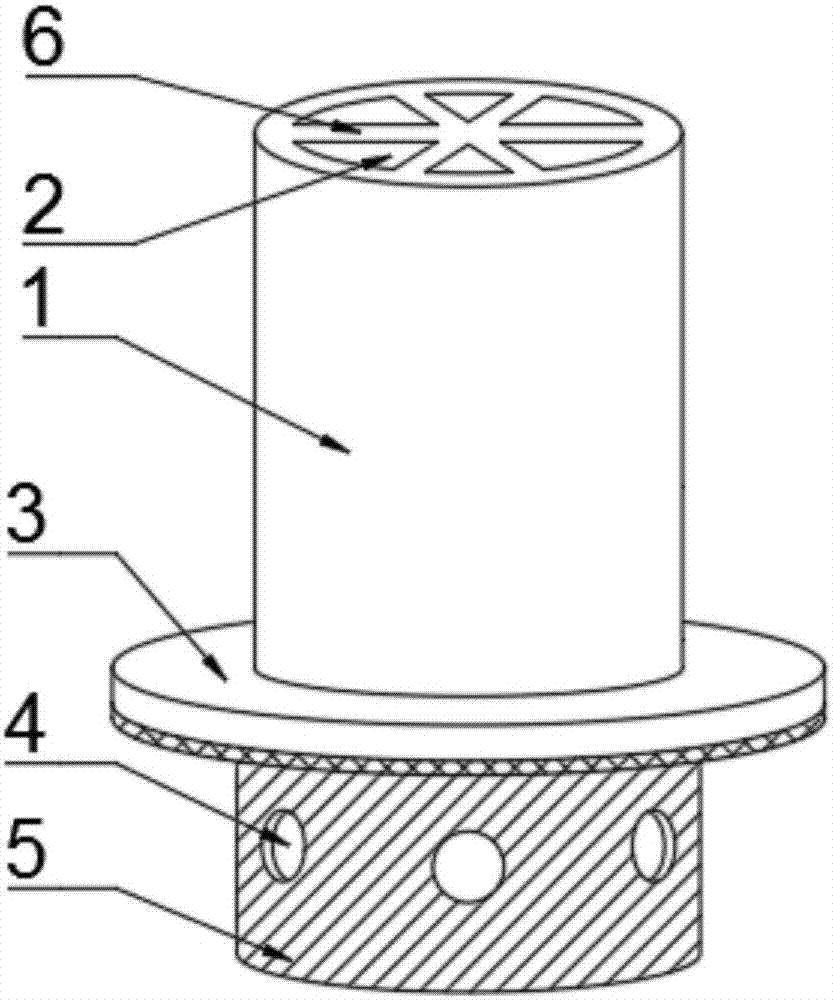

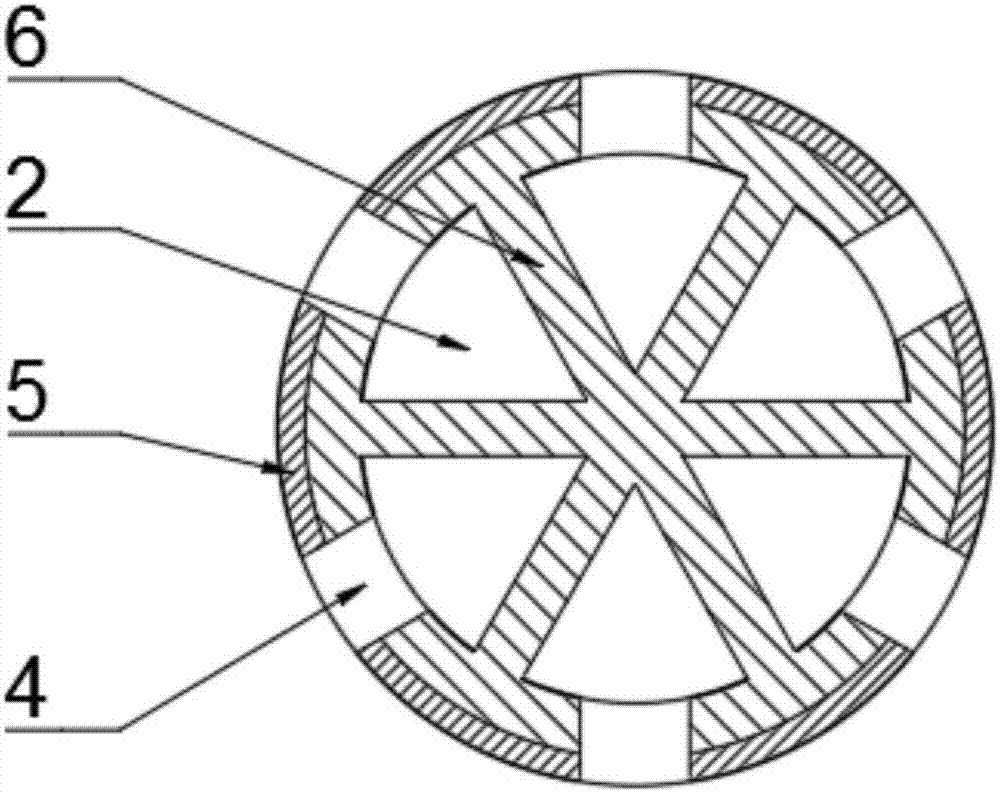

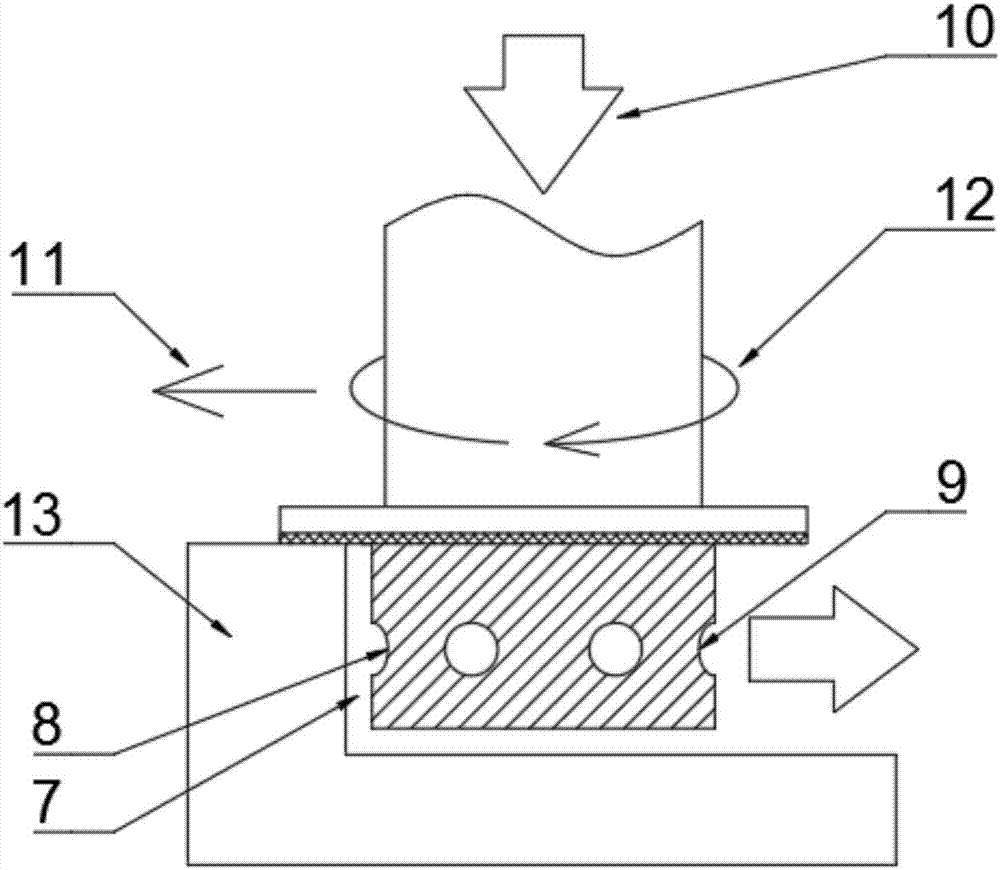

[0026] Such as figure 1 and figure 2 As shown, the cathode of a multi-cavity baffle plate type electrolytic milling and grinding compound processing tool proposed by the present invention includes a tool cathode base 1, the inside of the tool cathode base 1 is a central blind hole, and the cylindrical surface of the lower part of the cathode has an annular baffle 3, uniform Arrange liquid outlet holes 4 and diamond abrasive grain layer (5); it is characterized in that: the above-mentioned central blind hole is evenly divided into several fan-shaped blind hole cavities 2 by several axial partition plates 6; the fan-shaped blind hole cavities 2 divide the above-mentioned outlet The liquid holes 4 are evenly divided into several groups, and each fan-shaped blind hole cavity 2 communicates with a group of liquid outlet holes; the above-mentioned annular baffle 3 is located ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com