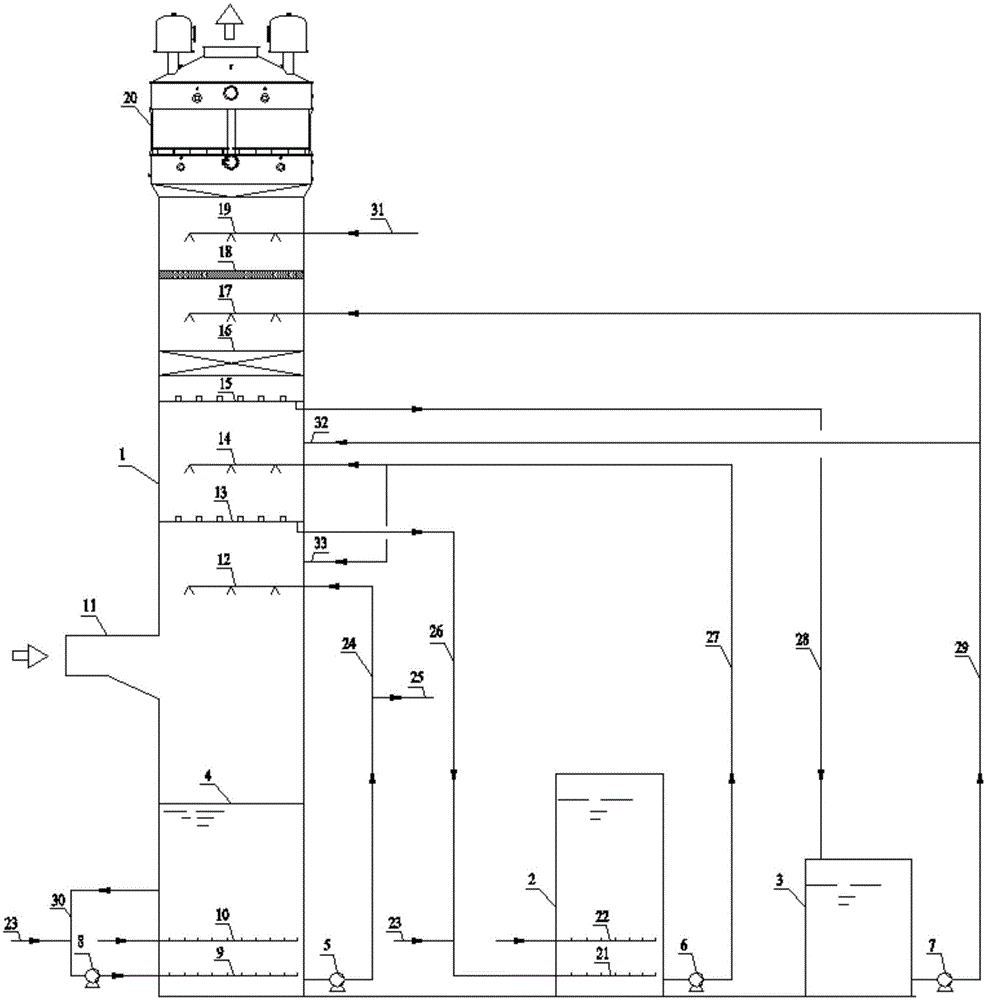

Multi-stage absorbing desulfurizing device by adopting ammonia-ammonium sulfate method

A technology of ammonium sulfate method and desulfurization device, which is applied in the direction of combined device, separation method, and dispersed particle separation, etc., can solve the problems of high aerosol content in flue gas, increased aerosol, and tailing of smoke plume, so as to improve oxidation efficiency, Improve the utilization rate of ammonia, improve the uniformity of distribution and the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

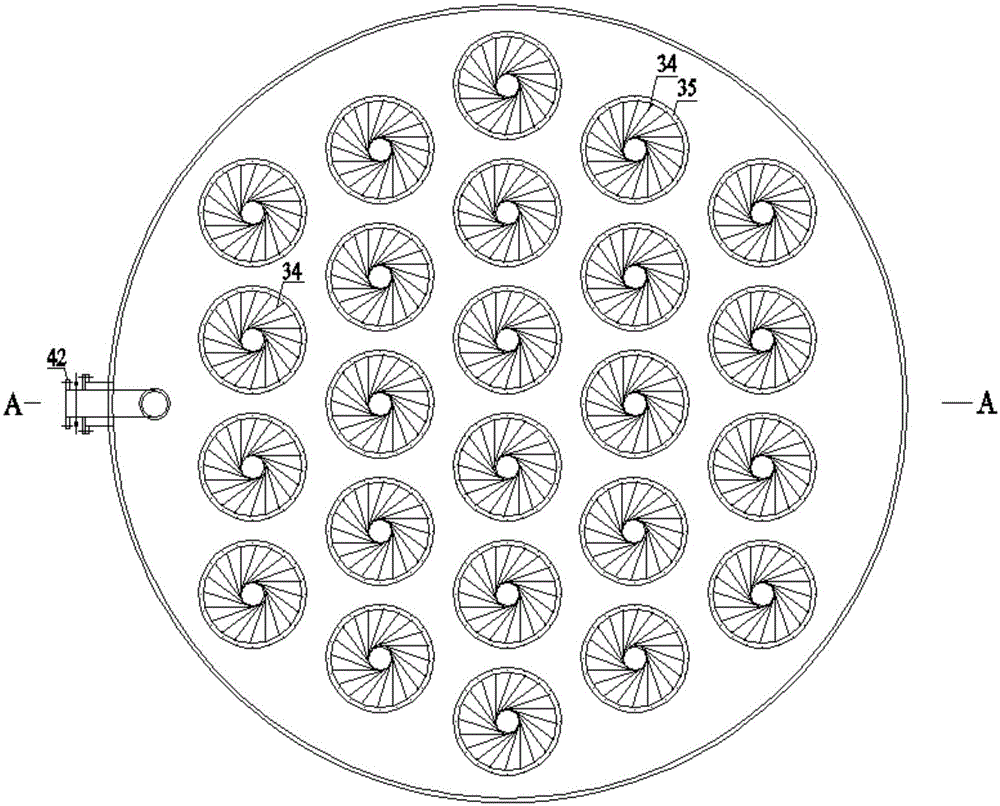

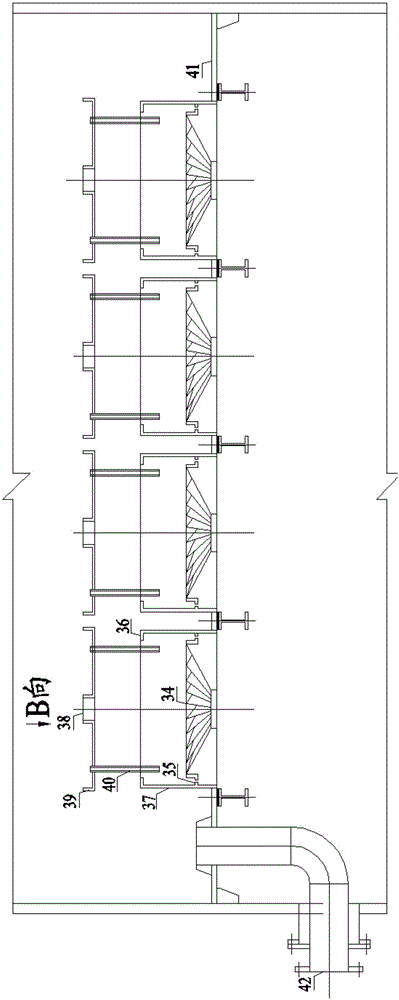

Embodiment 1

[0050]Treat 240t / h pulverized coal boiler flue gas, the flue gas volume is 280000Nm under rated working conditions 3 / h, the raw flue gas temperature at the flue inlet 11 is 125°C, SO 2 Concentration 2500mg / Nm 3 , Dust content 20mg / Nm 3 . The flue gas desulfurization absorption tower 1 is made of carbon steel-lined glass flakes, 32m high and 7.2m in diameter, in which the liquid level of the concentrated slurry circulation tank 4 is controlled at 5.5m~6m, and the jet stirring distribution pipe 9 made of FRP and the absorption tower are arranged below Oxidation air distribution pipe 10, the oxidation air volume is 1800Nm 3 / h. The concentrated pre-absorption section is equipped with a concentrated slurry spray layer 12, the material is 2205 duplex stainless steel, and the flow rate is 400m 3 / h, the spray coverage rate is 150%; above the concentrated slurry spray layer 12, a layer of concentrated pre-absorption backwash layer is set as the backwash spray layer of the absor...

Embodiment 2

[0056] The hierarchical absorption desulfurization device of the ammonia-ammonium sulfate method of embodiment 1 is transformed. During the transformation, only the swirl defogging liquid collector is adjusted, and it is respectively transformed into a device (device A ), the device (device B) that is neither provided with the absorption liquid cyclone demister liquid collector 13 nor the dilute slurry cyclone demist liquid collector 15 is respectively introduced into the flue gas, and the flue gas volume is 270000Nm 3 / h, SO in flue gas 2 Concentration 2000mg / Nm 3 . Compared with device B, the air resistance of device A increased by 180Pa, the amount of ammonium sulfate carried from the concentrated pre-absorption section to the absorption section was reduced from 2t / h to 0.4t / h, and the concentration of the slurry in the absorption section was reduced from 30% to 12%. The total aerosol (dust) content in the net flue gas is increased from 40mg / Nm 3 Reduced to 20mg / Nm 3 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com