A flue gas treatment system and method for integrated ammonia desulfurization and PM2.5 removal

A technology of flue gas and ammonia method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles to achieve the effects of improving governance effects, reducing operating costs and floor space, and preventing ammonia from escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

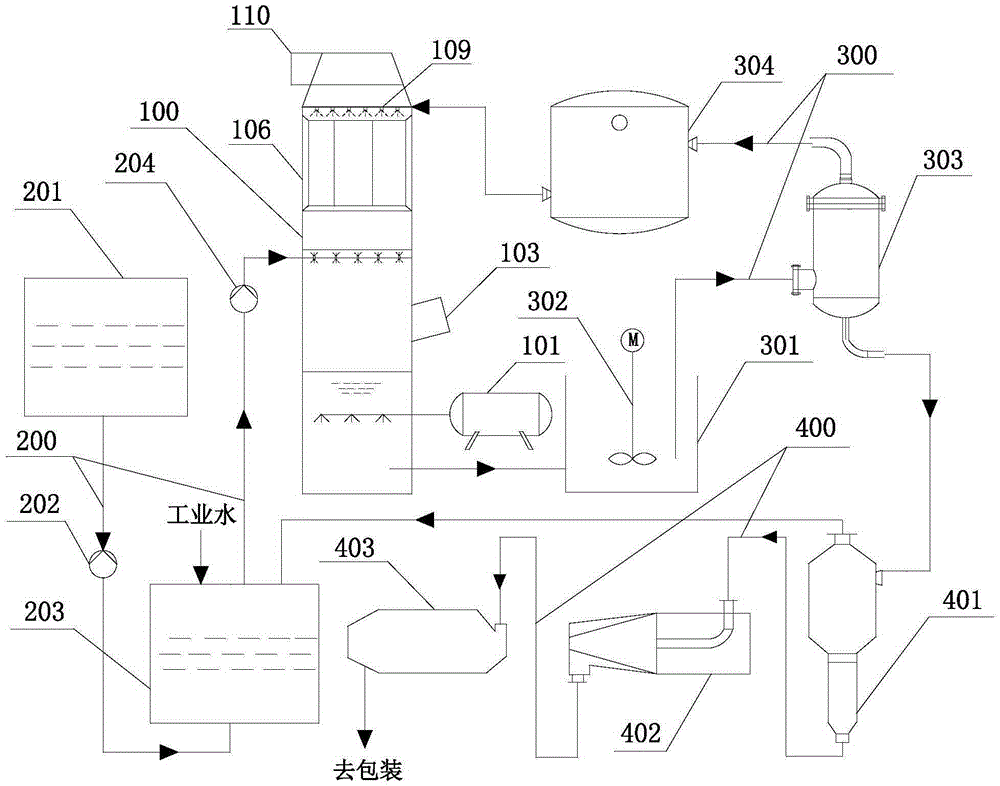

[0050] figure 1 It is a structural schematic diagram of the flue gas treatment system for ammonia method integrated desulfurization and PM2.5 removal of the present invention. Such as figure 1 As shown, a kind of flue gas treatment system with integrated ammonia desulfurization and PM2.5 removal proposed in this embodiment includes:

[0051] Flue gas integrated treatment tower 100 for ammonia wet desulfurization and integrated removal of PM2.5,

[0052] Ammonia removal agent pulping and slurry supply system 200 for preparation and supply of ammonia desulfurization agent,

[0053] A water circulation system 300 for maintaining the process water balance of the flue gas treatment system, and

[0054] A by-product preparation system 400 for recycling by-products of ammonia desulfurization.

[0055] Such as figure 1 As shown, the ammonia remover pulping and slurry supply system 200 is connected to the flue gas integrated treatment tower 100, and the ammonia remover slurry is t...

Embodiment 2

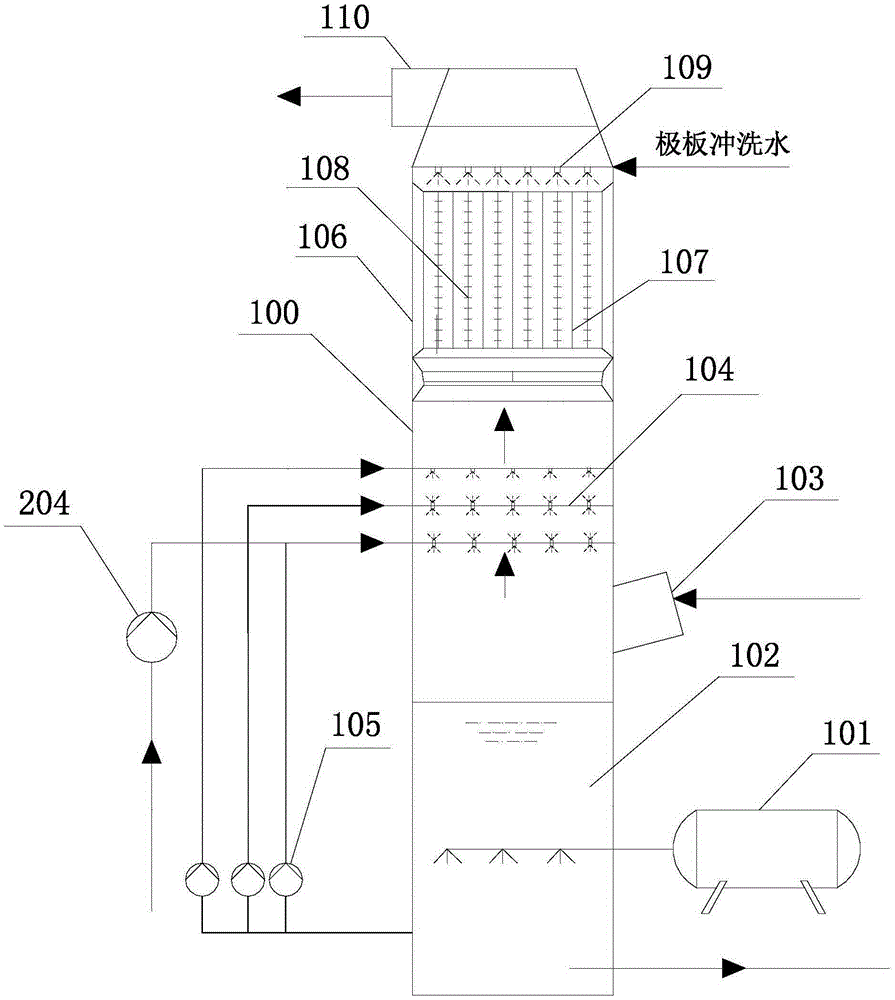

[0065] This example proposes a flue gas treatment method with integrated ammonia desulfurization and PM2.5 removal, using the flue gas treatment system with ammonia integrated desulfurization and PM2.5 removal in Example 1 for flue gas purification treatment, combined with figure 1 and figure 2 shown, including the following steps:

[0066] Step 1, ammonia removal agent preparation stage: the ammonia removal agent stock solution stored in the ammonia storage tank 201 is transported by the ammonia distribution pump 202 to the ammonia distribution tank 203, and the ammonia removal agent is prepared according to the set ratio with industrial water , and then sent to the ammonia removal agent spraying device 104 by the ammonia supply pump 204.

[0067] Step 2, ammonia method synergistic desulfurization and PM2.5 removal stage: the flue gas to be treated is introduced from the flue gas inlet 103 into the flue gas integrated treatment tower 100, and the upward flue gas is sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com