Patents

Literature

45results about How to "Realize water recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

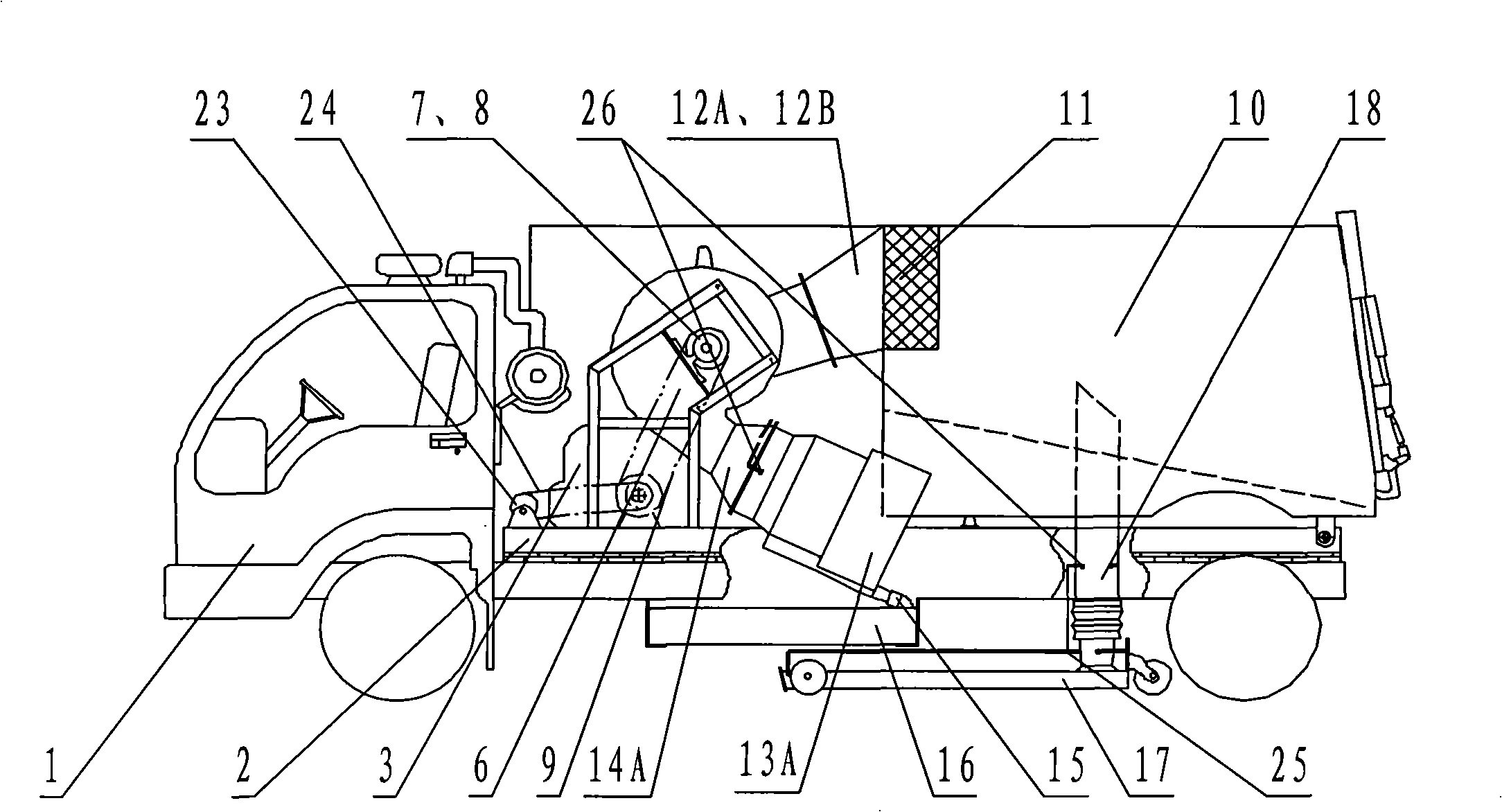

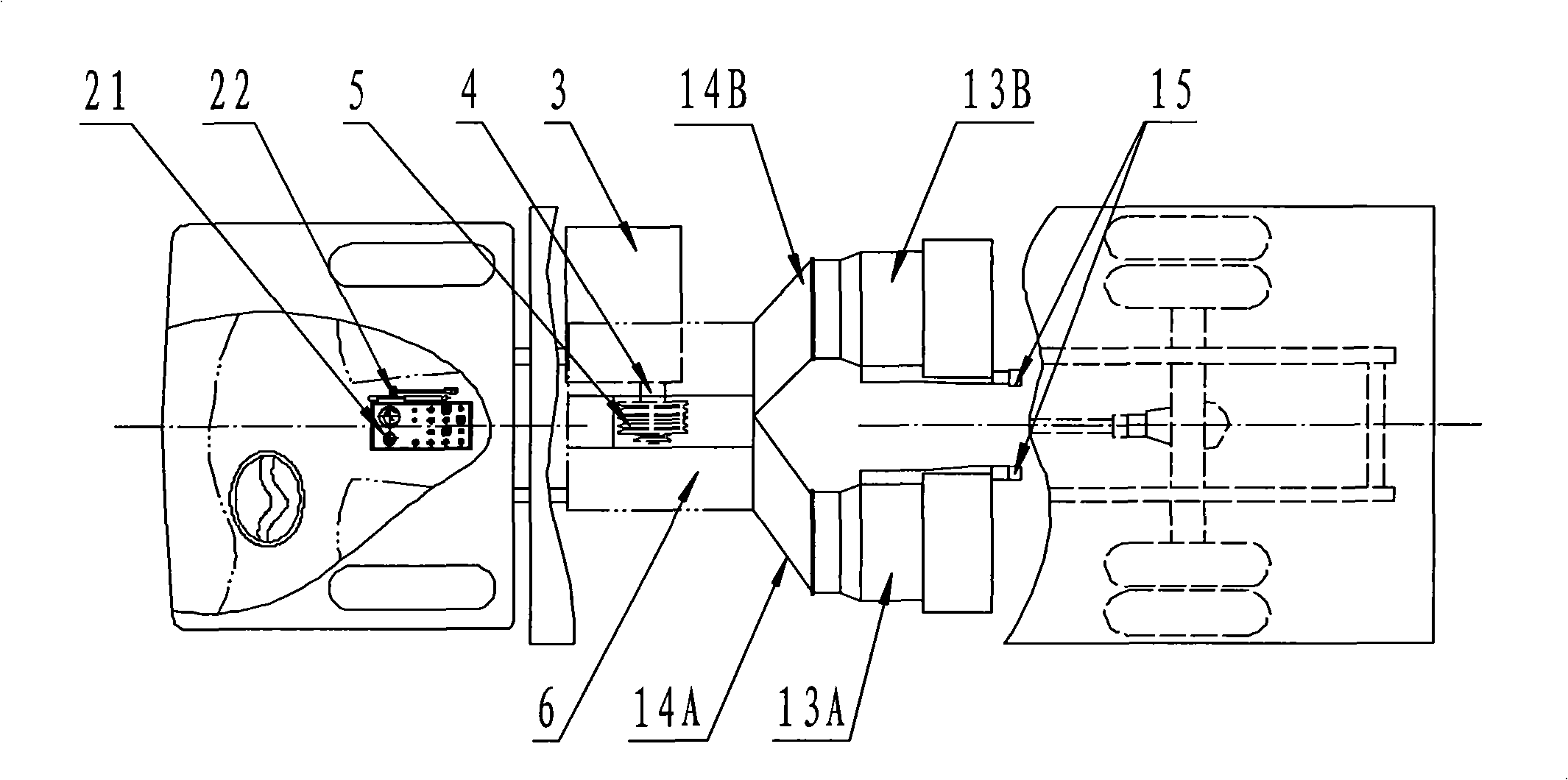

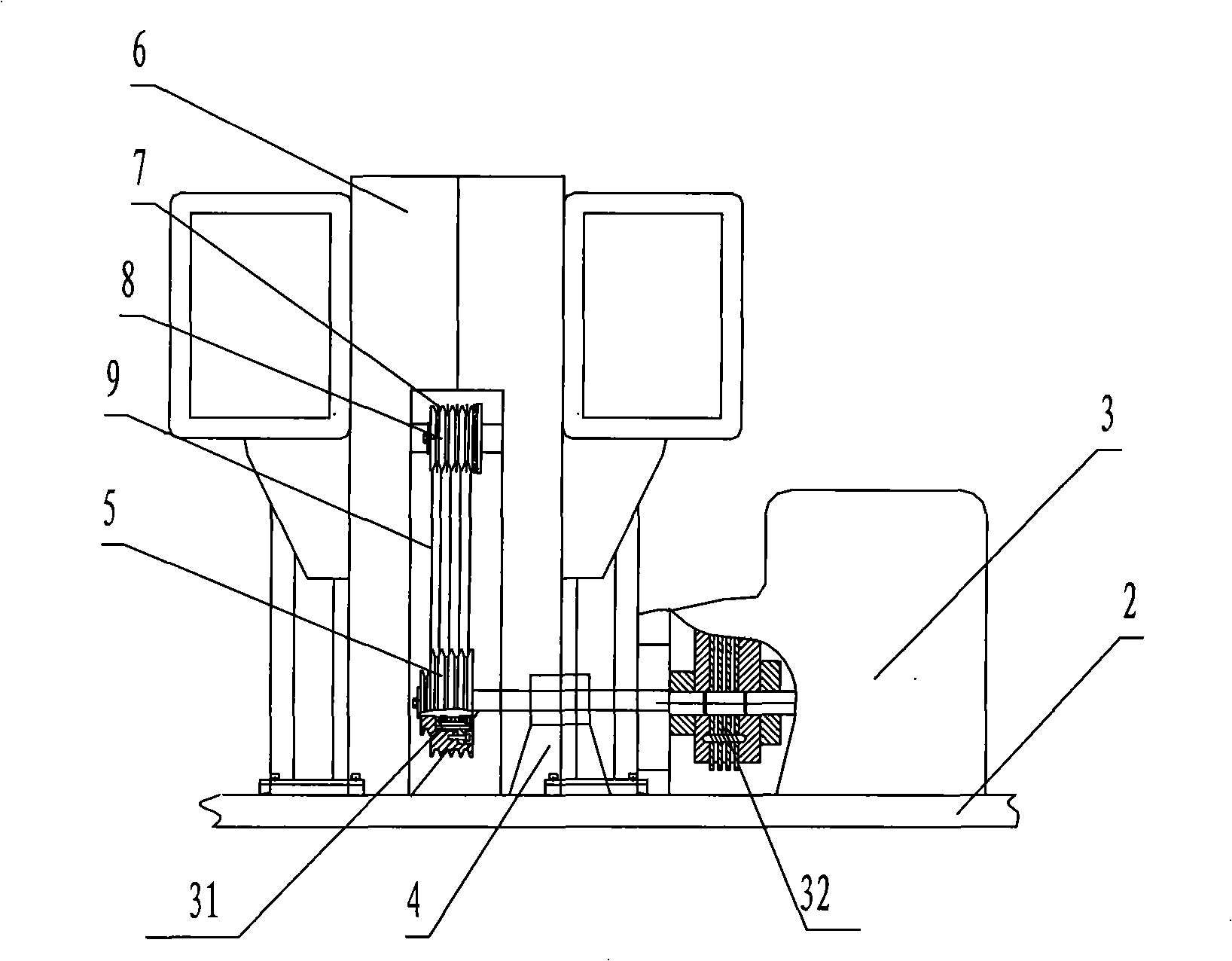

Dry and wet two-purpose road sweeper

InactiveCN101349043ASolve the icingSolve the problem of not being able to spray waterRoad cleaningVehicle frameRoad sweeper

The invention relates to a dry-wet dual purpose road sweeper, which comprises a vehicle frame as well as an auxiliary engine, a garbage bin, a suction fan, a chuck and dust removers which are arranged on the vehicle frame, wherein the chuck is arranged at the lower part of the vehicle frame and is connected to a garbage inlet of the garbage bin through a suction tube, the suction fan is connected with an air outlet of the garbage bin through an air duct, an air vent of the suction fan is connected with the dust removers, the auxiliary engine drives the suction fan, the suction fan is a double suction fan which is respectively communicated with the wet type diagonal flow dust removers. The road sweeper remedies the disadvantages that a suction sweeping road sweeper widely used on the market fails to be normally used in winter and is easy to spray ash and fly dust, and a suction road sweeper fails to perform wet operation and has poor sweeping efficiency and high use cost. The dry-wet dual purpose road sweeper uses a technology that the dry operation and the wet operation can both be performed, the design of the double suction fan with ultra-strong suction, and a unique wet type diagonal flow dust removal technology, and is the all-weather road sweeper.

Owner:江苏飞球专用车制造有限公司

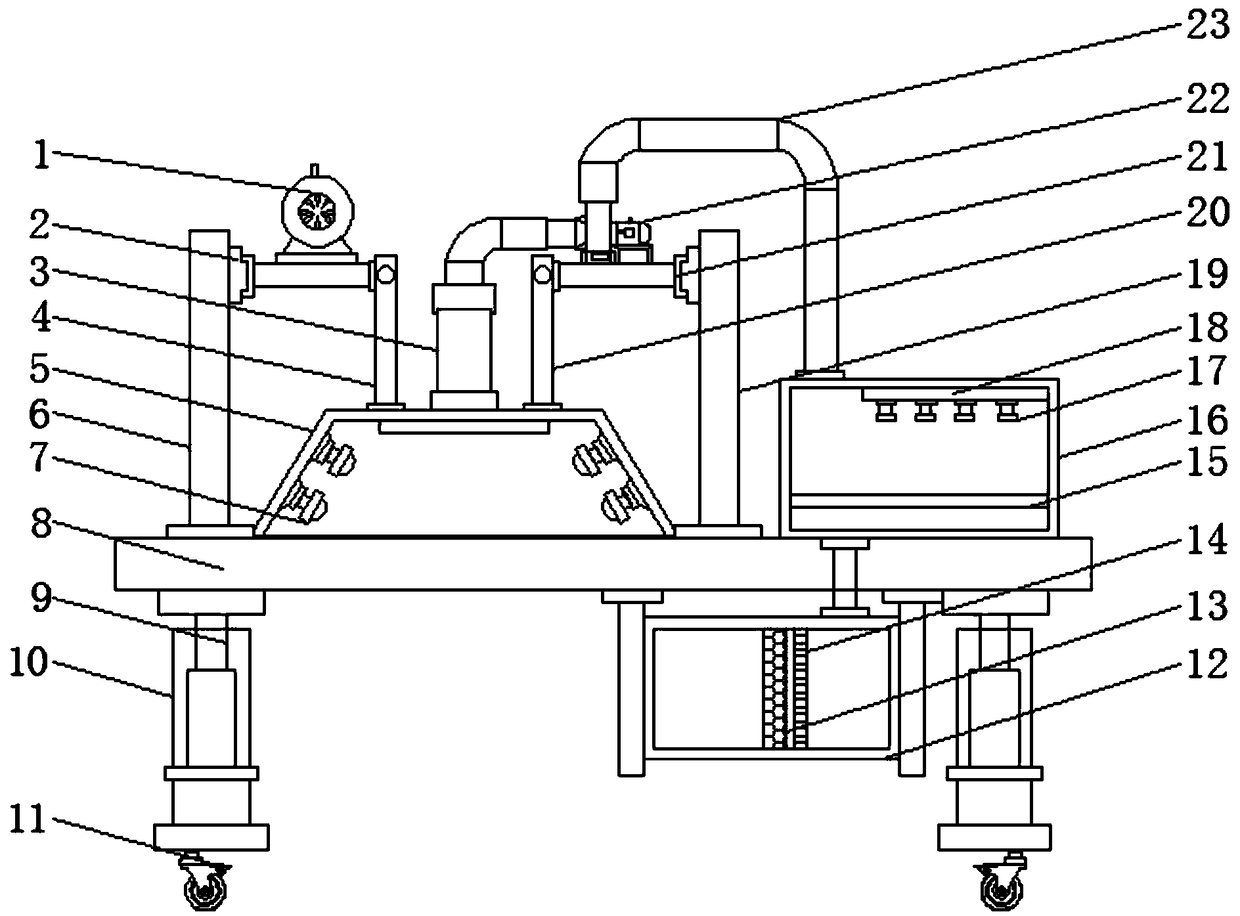

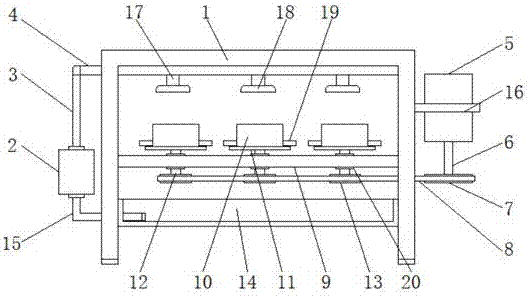

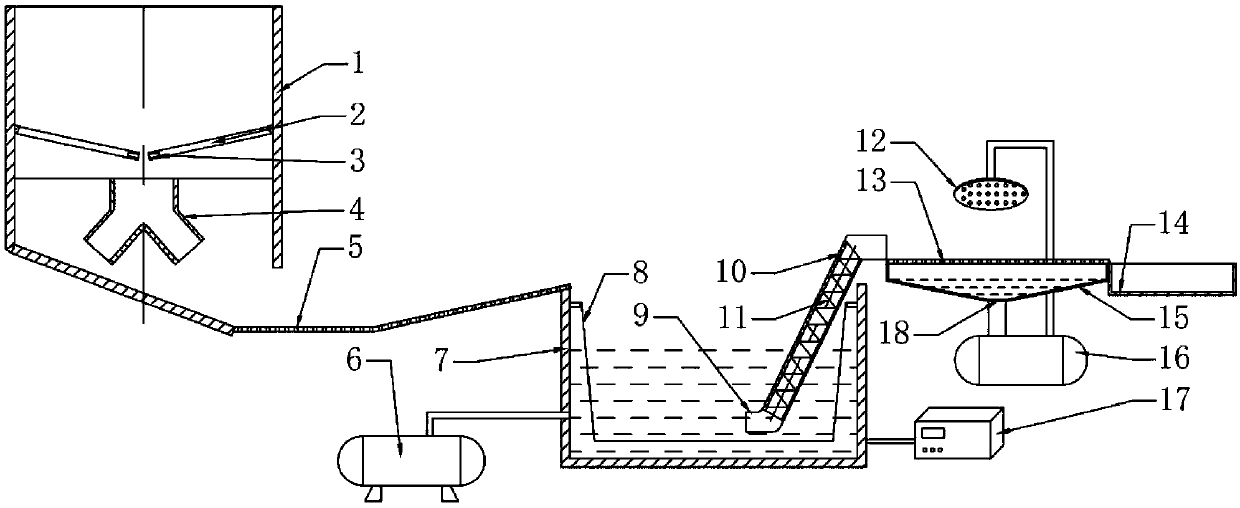

Dust blowing device for spinning machine

InactiveCN108607854AImprove production qualityGood for collection and cleaningUsing liquid separation agentTreatment involving filtrationEngineeringWater tanks

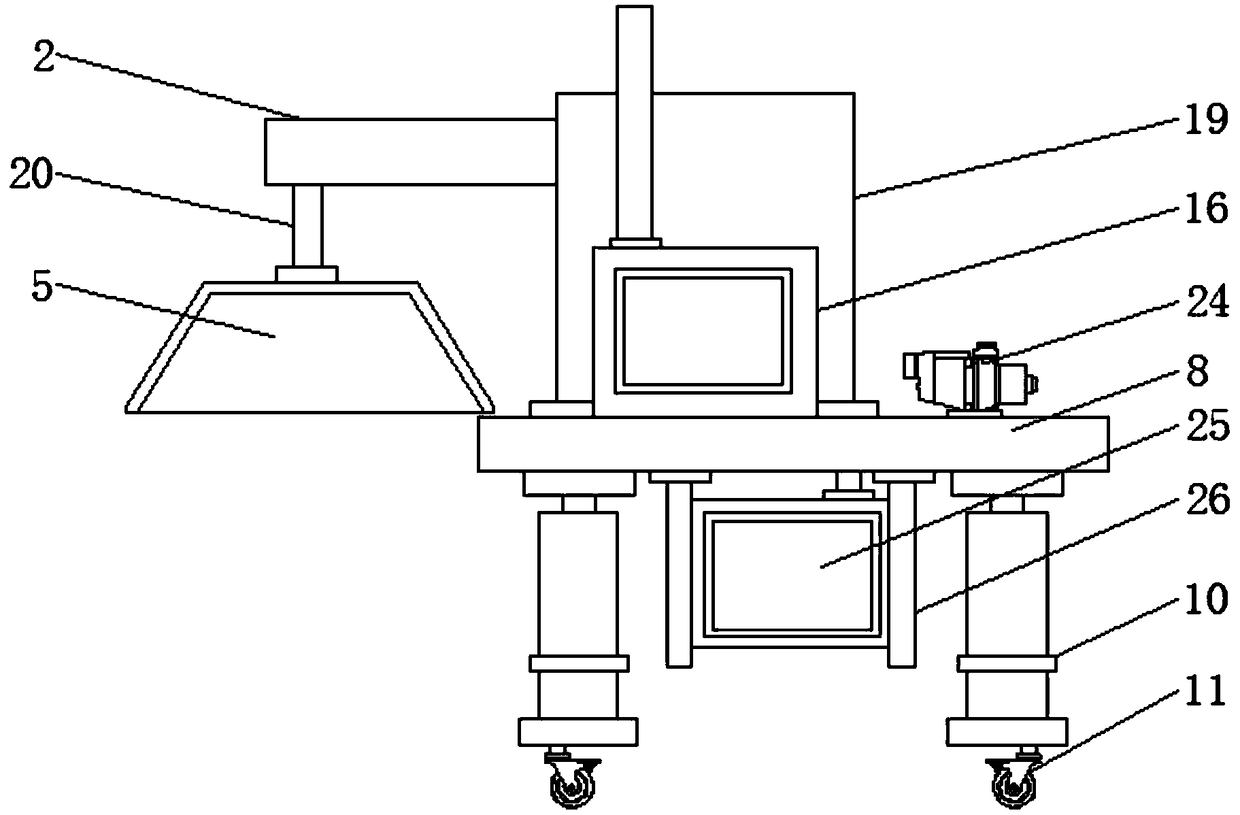

The invention discloses a dust blowing device for a spinning machine. The dust blowing device comprises a dust blowing cover, supporting stand columns, a circulation water tank and a dust collecting box. The output ends of hydraulic telescopic rods penetrate the top ends of the supporting stand columns and are horizontally provided with an installing platform. An installing frame is arranged at one end of the bottom end of the installing platform. The circulation water tank is arranged in the installing frame. The end, away from the installing frame, of the top end of the installing platform is vertically provided with a first vertical plate 6. The dust blowing cover is arranged at the bottom ends of a second installing frame and a first installing frame. Two dust blowing sprayers are arranged on the inner wall of each of the two sides of the dust blowing cover. The dust collecting box is arranged at the top end of the installing platform part on the side, away from the first verticalplate 6, of a first vertical plate 19. According to the dust blowing device, rapid dust blowing can be achieved, meanwhile, flying dust is collected in an air pumping manner, thread residues, flock and dust generated in the spinning process can be rapidly and effectively removed, and the production quality can be effectively improved.

Owner:JIANGSU BEILIN TEXTILE CO LTD

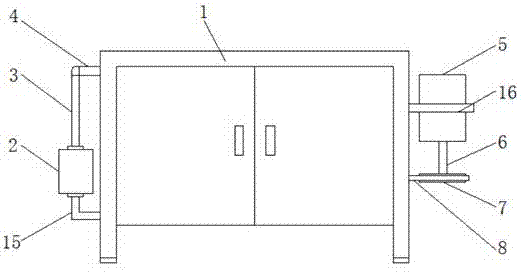

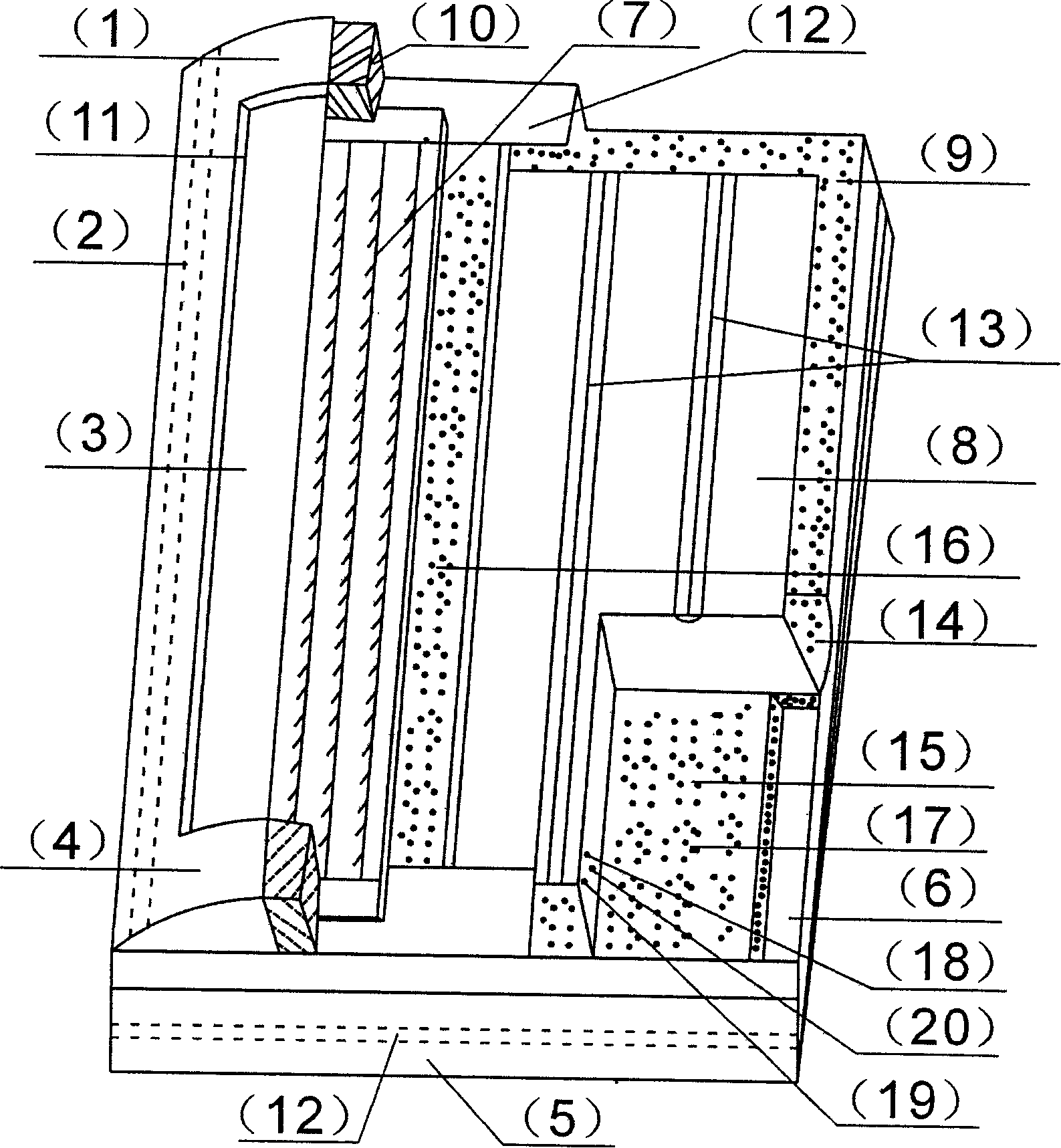

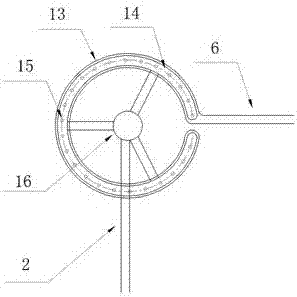

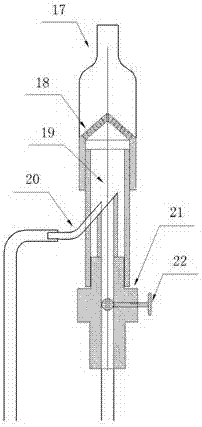

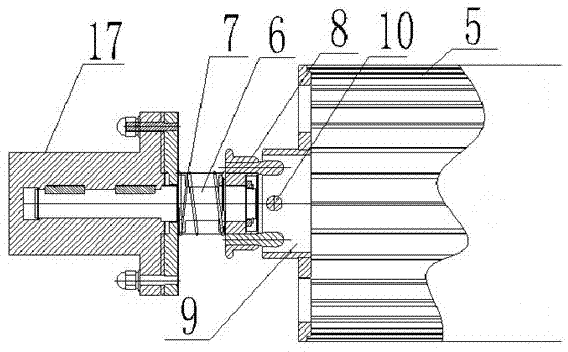

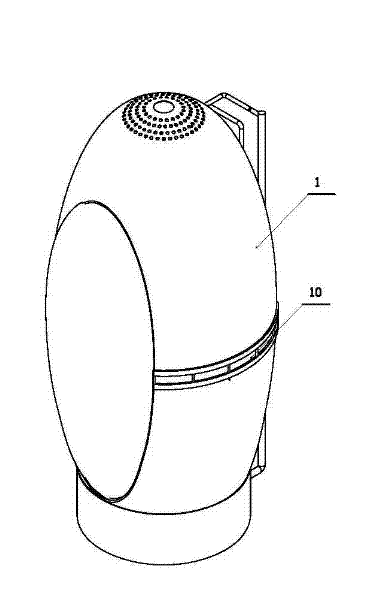

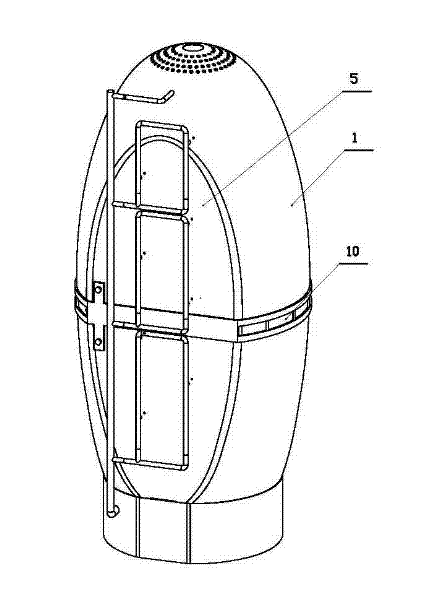

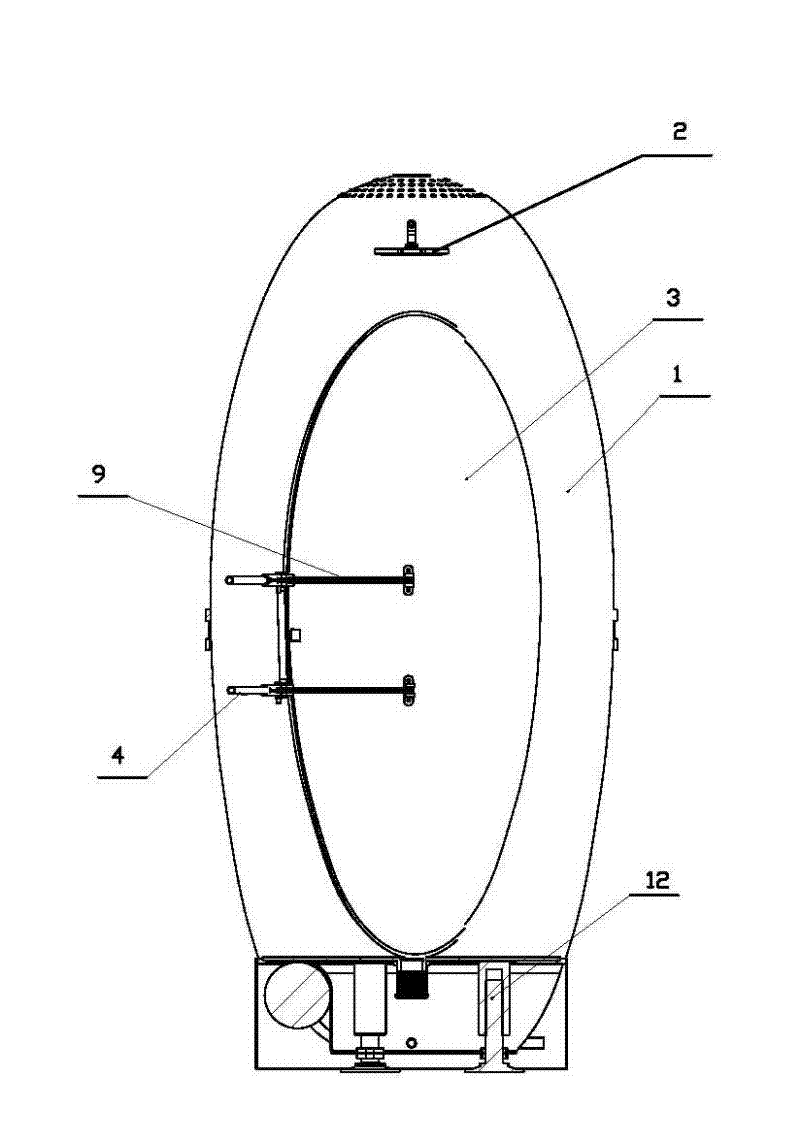

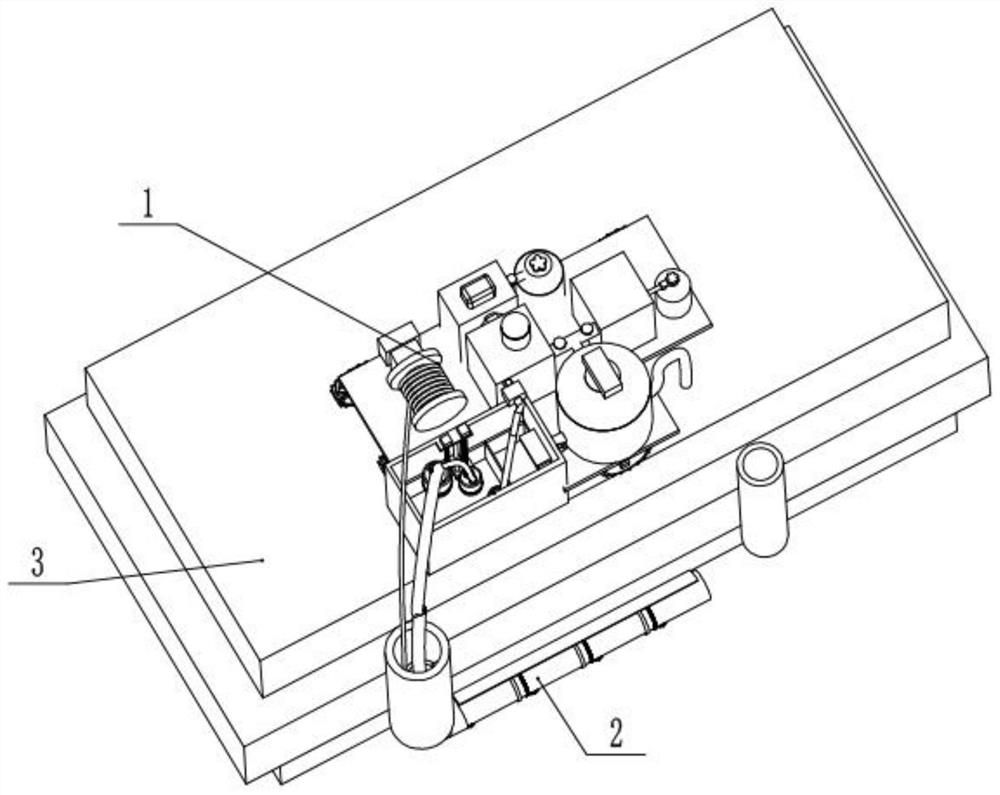

Bathing machine

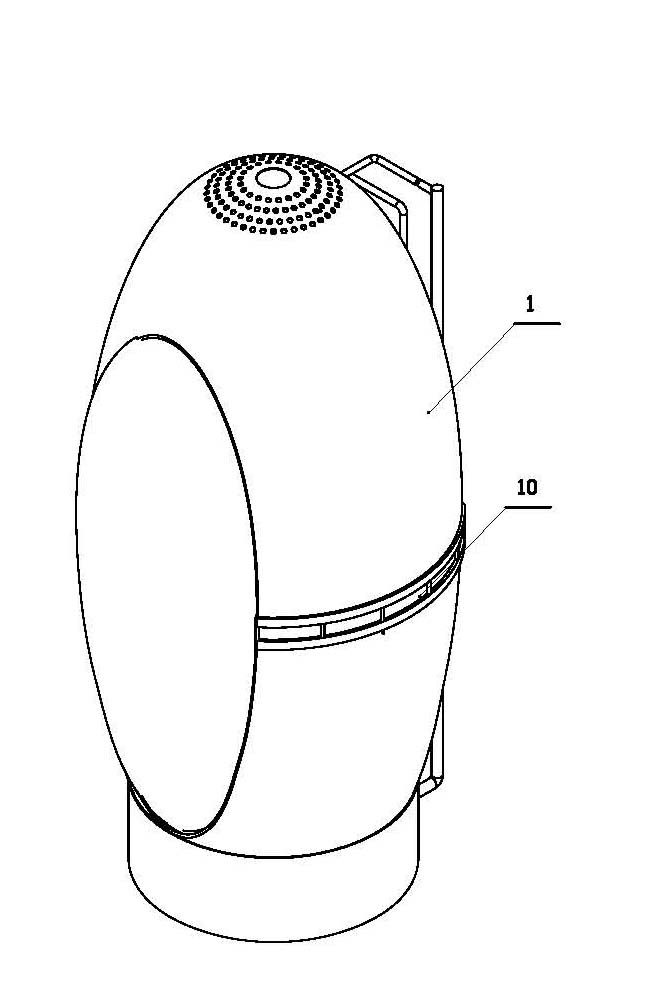

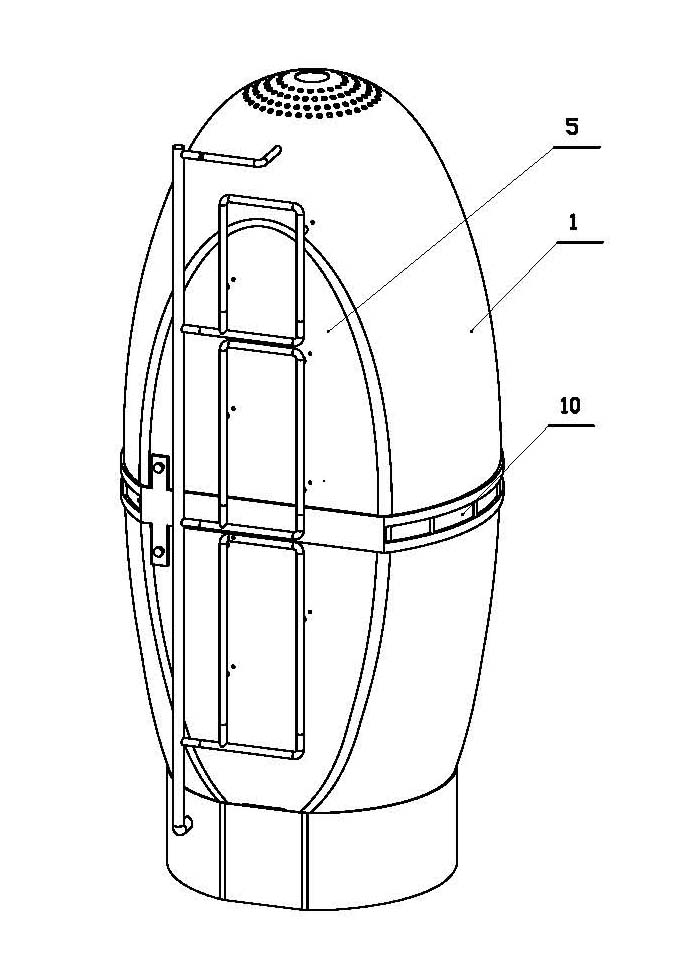

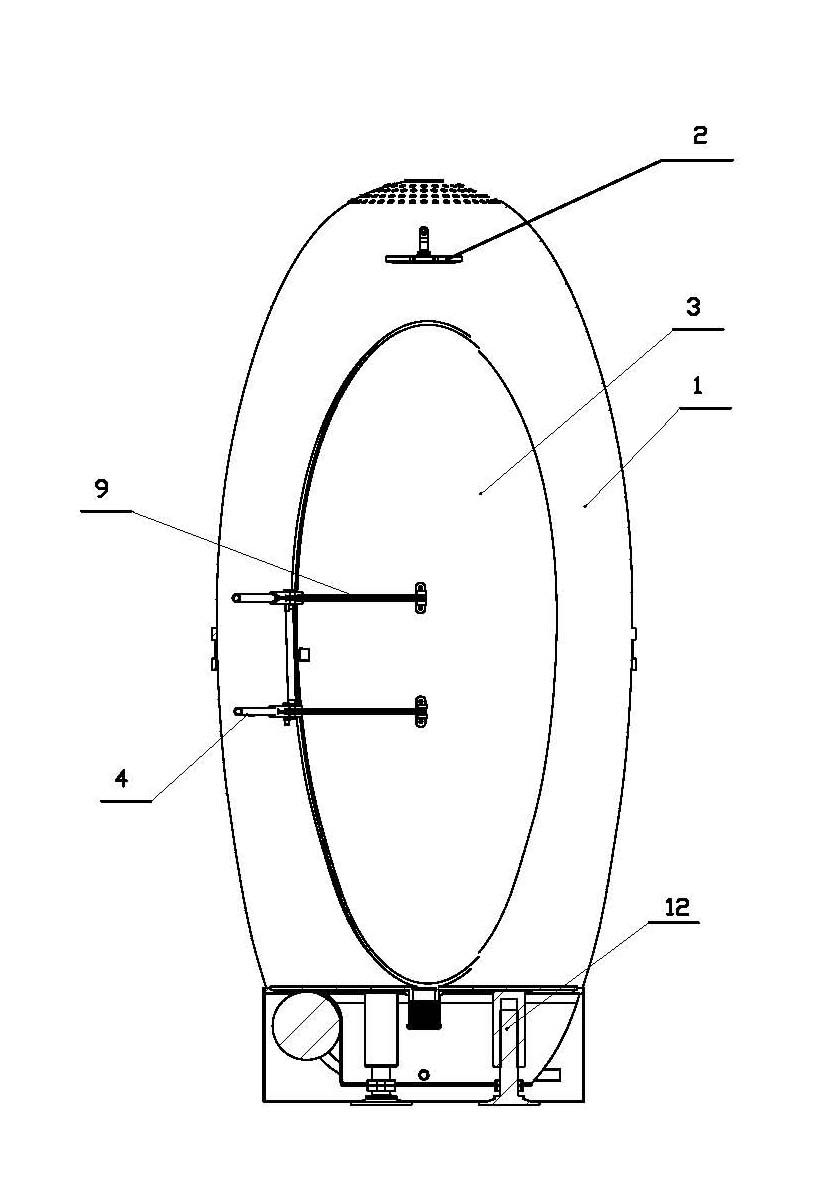

The invention relates to a device for bathing, in particular to a bathing machine which comprises a shell and a sprayer installed in the shell, wherein the shell is provided with a door opening, and the door opening is provided with a door body. The bathing machine is characterized in that the shell is in the shape of an eggshell, the door opening is arranged at the front end of the shell, the back end of the shell is provided with a back plate, the inner side of the shell is fixedly provided with a sliding track, the back end of the sliding track is fixedly connected to the back plate, the front end of the sliding track extends to the door opening of the shell, the front end of the sliding track is provided with a fastener body, and the shell is fixedly provided with a fastener sleeve matched with the fastener body; and the sliding track is provided with a sliding block, the sliding block is fixedly connected with a support bar, and the top end of the support bar is hinged on the door body. The bathing machine uses less water, can realize cyclic water utilization and automatic bathing, has the bathtub function for bathing, and occupies less space.

Owner:王踵先

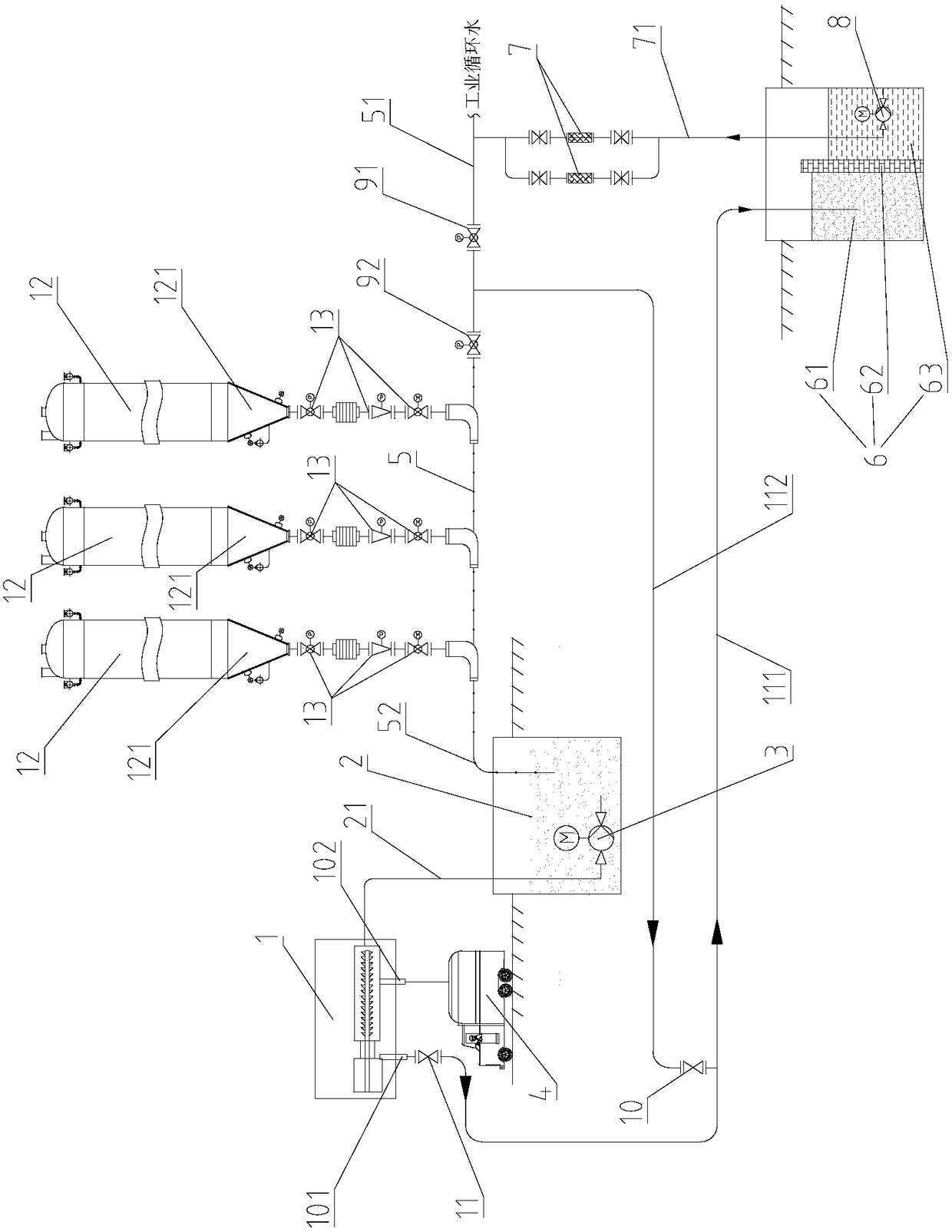

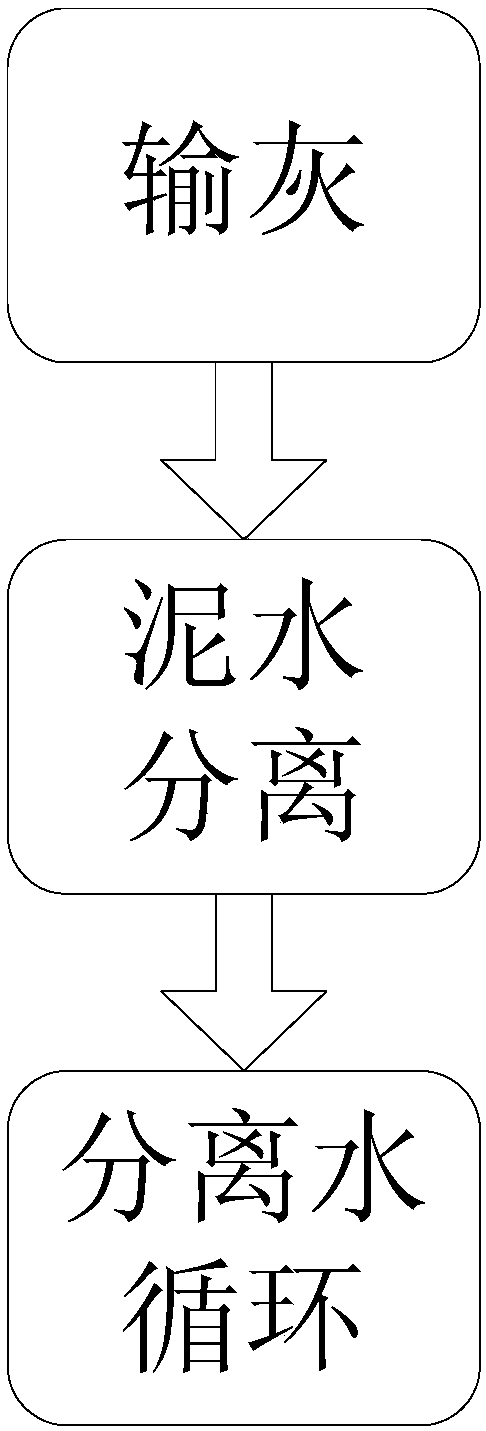

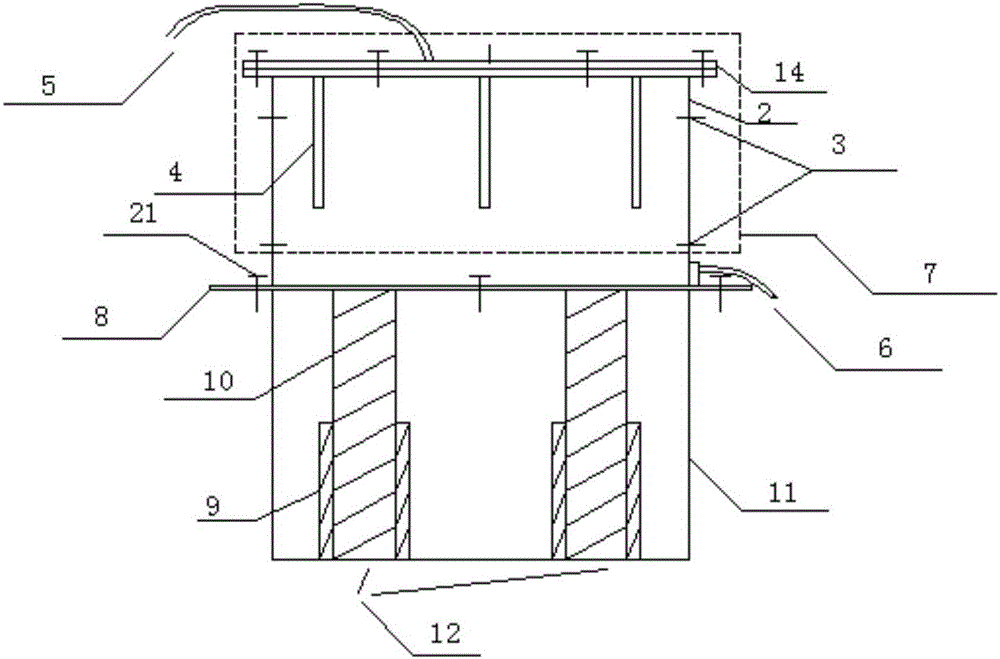

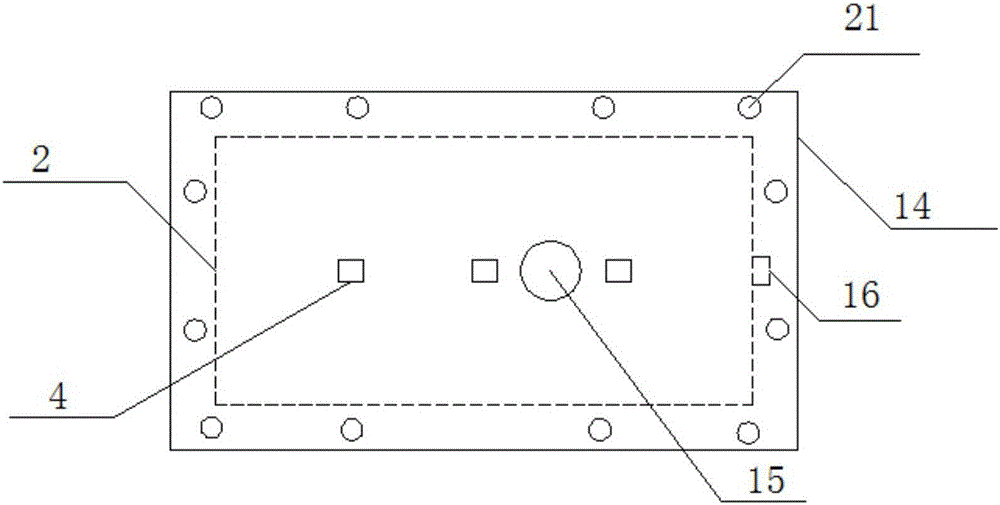

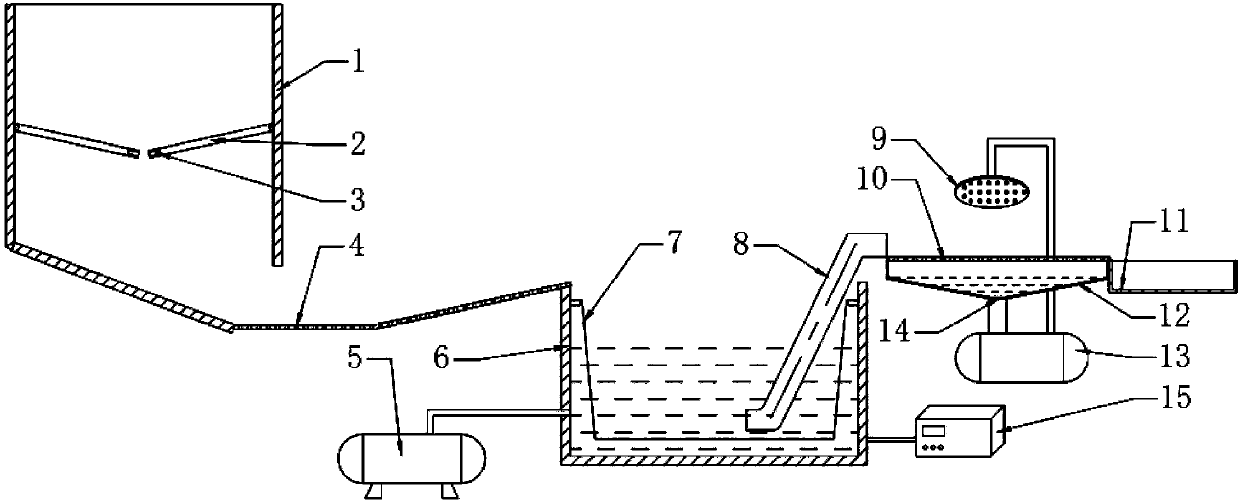

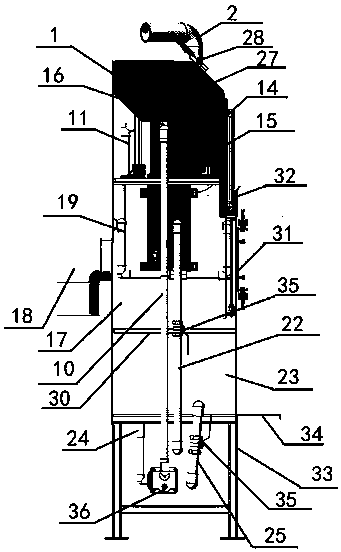

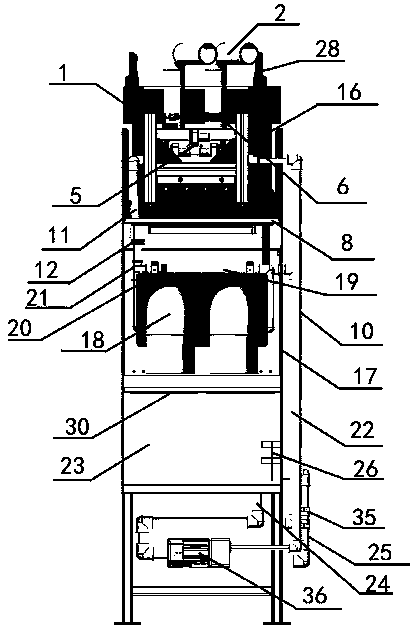

Dust removal ash conveying device and method for blast furnace

PendingCN108116892AEasy to separateAvoid cloggingWater/sewage treatment by centrifugal separationDispersed particle filtrationPollutionBlast furnace

The invention provides dust removal ash conveying device and method for a blast furnace. According to the dust removal ash conveying device for the blast furnace, a plurality of dust removers are connected to an ash conveying pipeline in parallel, and the first end of the ash conveying pipeline is connected with an industrial cyclic water pipeline; a mud sump is connected to the second end of theash conveying pipeline, and a first mud pump is arranged in the mud sump; a mud-water separation mechanism is connected with the first mud pump through a mud conveying pipeline, and the mud-water separation mechanism is provided with a water outlet and a mud outlet; and a water recovery mechanism comprises a sedimentation tank and a second mud pump located in the sedimentation tank, the sedimentation tank is connected with the water outlet of the mud-water separation mechanism through a water outlet pipeline, and the second mud pump is connected with the first end of the ash conveying pipelinethrough a recovery pipeline. According to the dust removal ash conveying device and method for the blast furnace, furnace ash is conveyed in a manner of mixing industrial cyclic water with the furnace ash, so that blockage of the ash conveying pipeline can be avoided, and flying dust and pollution are avoided; moreover, the cyclic water in mud can be separated well; and the dust removal ash conveying device and method for the blast furnace are safe and environment-friendly, high in ash conveying efficiency, low in cost, and capable of realizing cyclic use of water.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

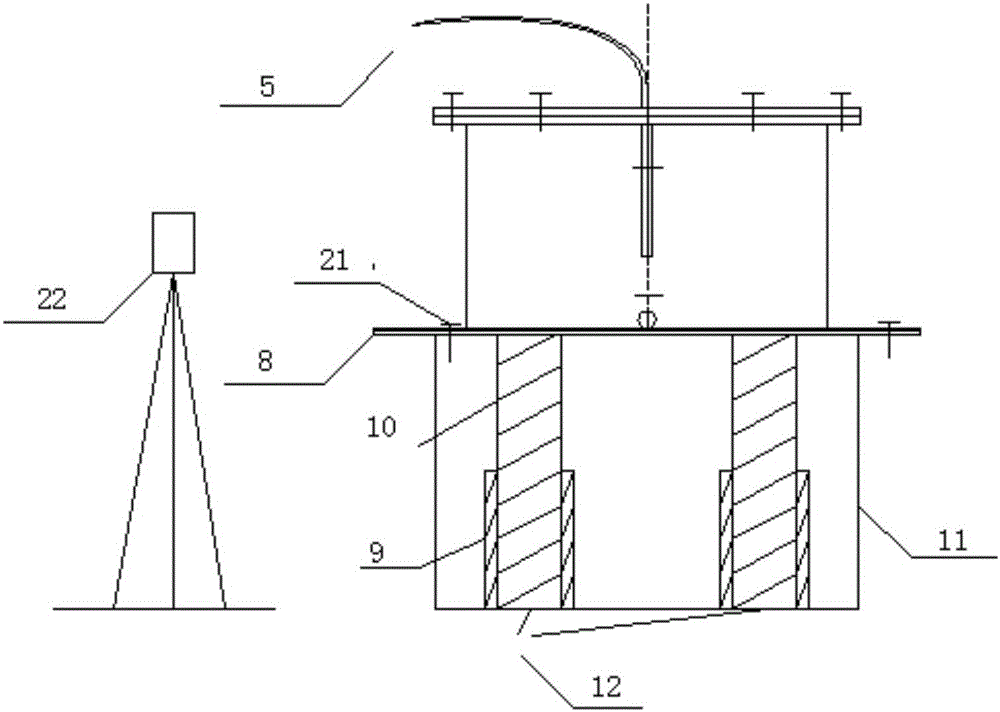

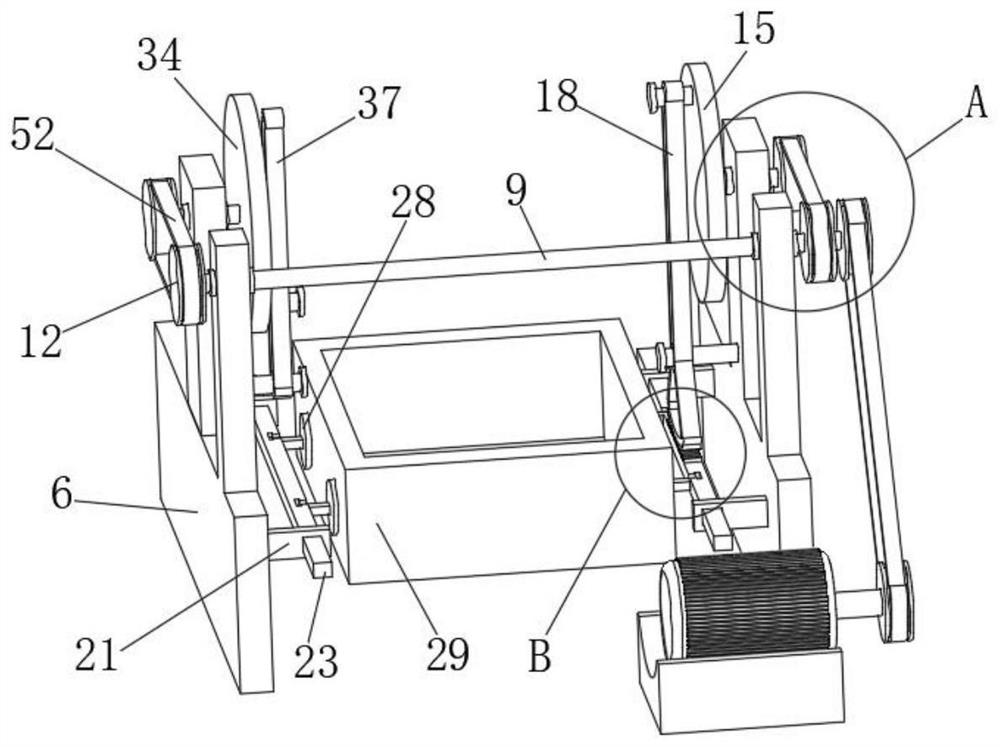

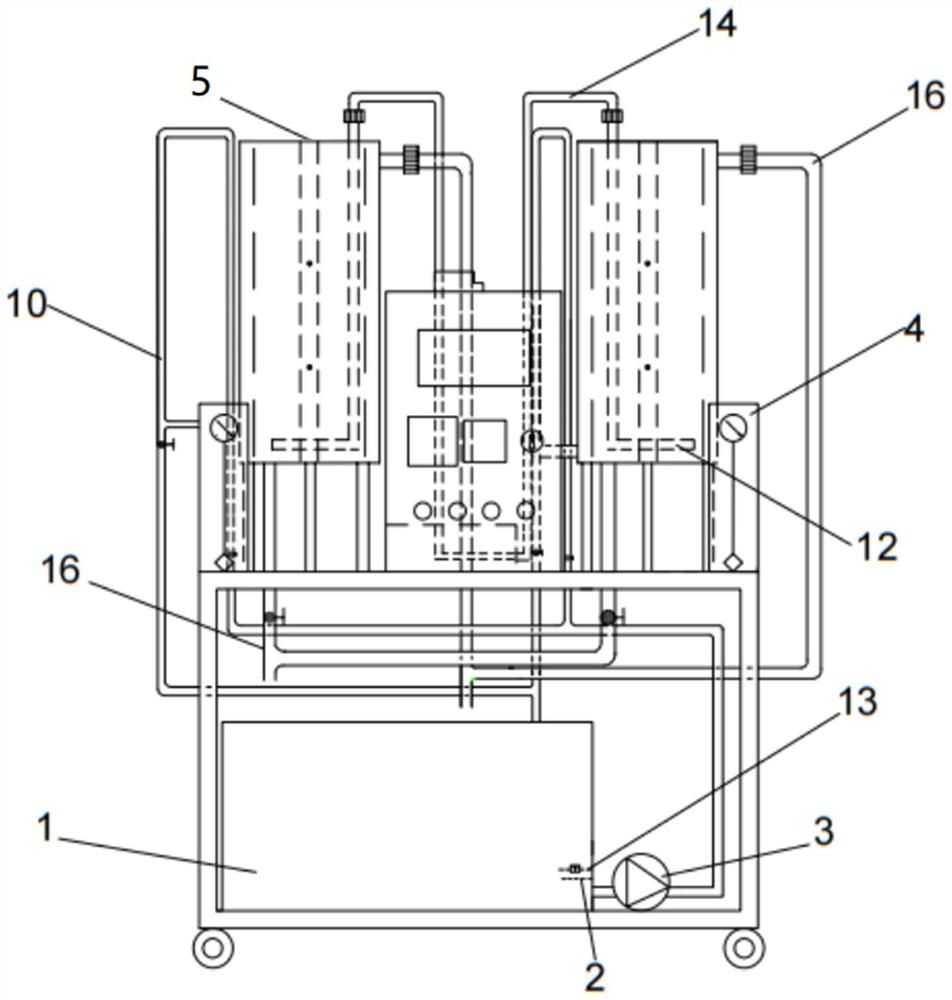

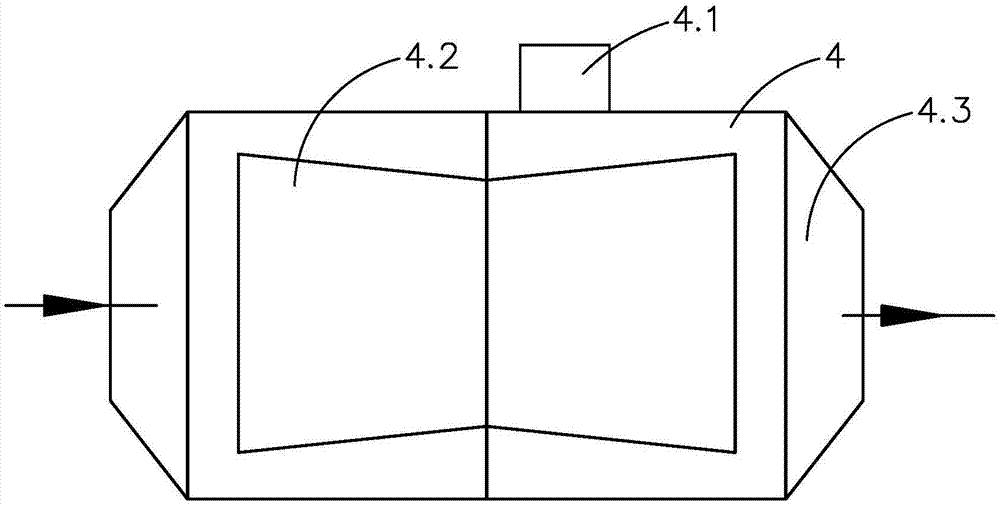

Liquid tank sloshing experiment integration device and using method thereof

The invention discloses a liquid tank sloshing experiment integration device, which is characterized by comprising a control system, a liquid tank, a water inlet system, a water outlet system, and a data acquisition device, wherein the liquid tank is arranged above a motion platform; and the control system is respectively connected with the water inlet system, the water outlet system, the data acquisition device and the motion platform. According to the liquid tank sloshing experiment device with a compact structure, convenient assembly and disassembly, reliable connection, stable operation, strong practicability and realized integration, a motor system, the water inlet and outlet system, the data acquisition device and a high-speed camera are controlled through a single chip microcomputer, motion of three degrees of freedom of the liquid tank is controlled through the motor system, different carrier rates of the liquid tank are controlled through the water inlet and outlet system, pressure and wave heights at different positions are recorded through the data acquisition system, each process is coordinated for operation, the integrated experiment is realized, and as the water inlet and outlet system is connected with an underwater reservoir, circulating water use is realized, and the device is green.

Owner:HOHAI UNIV

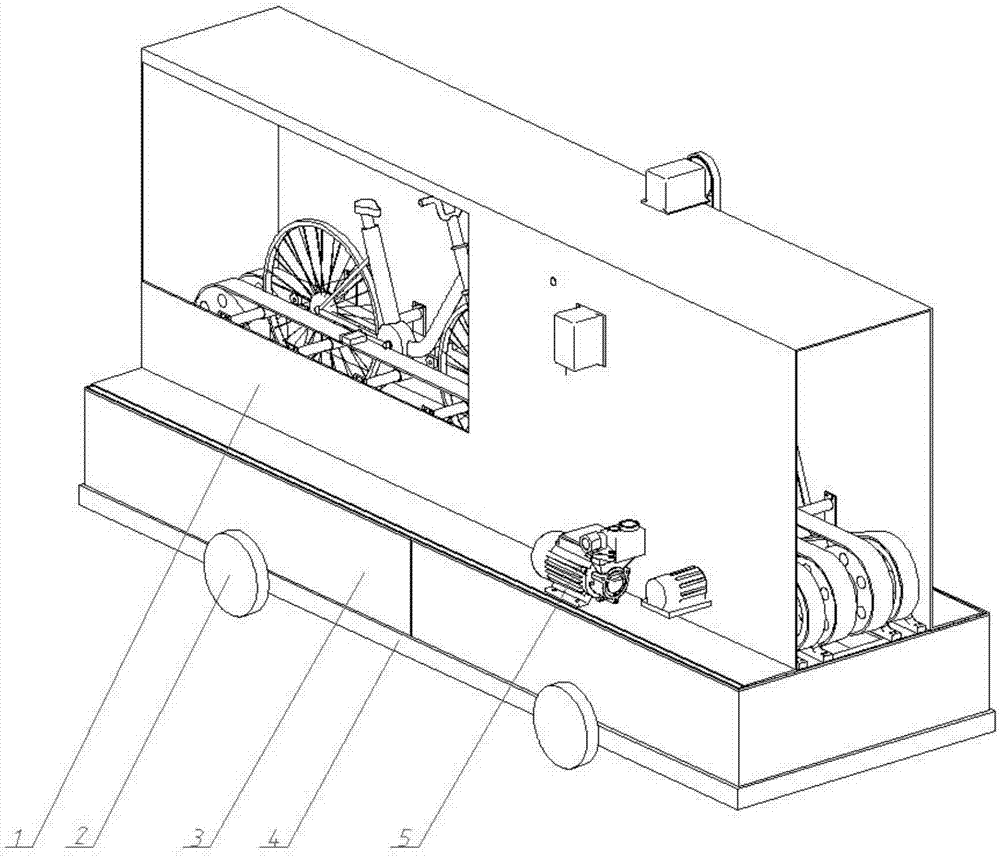

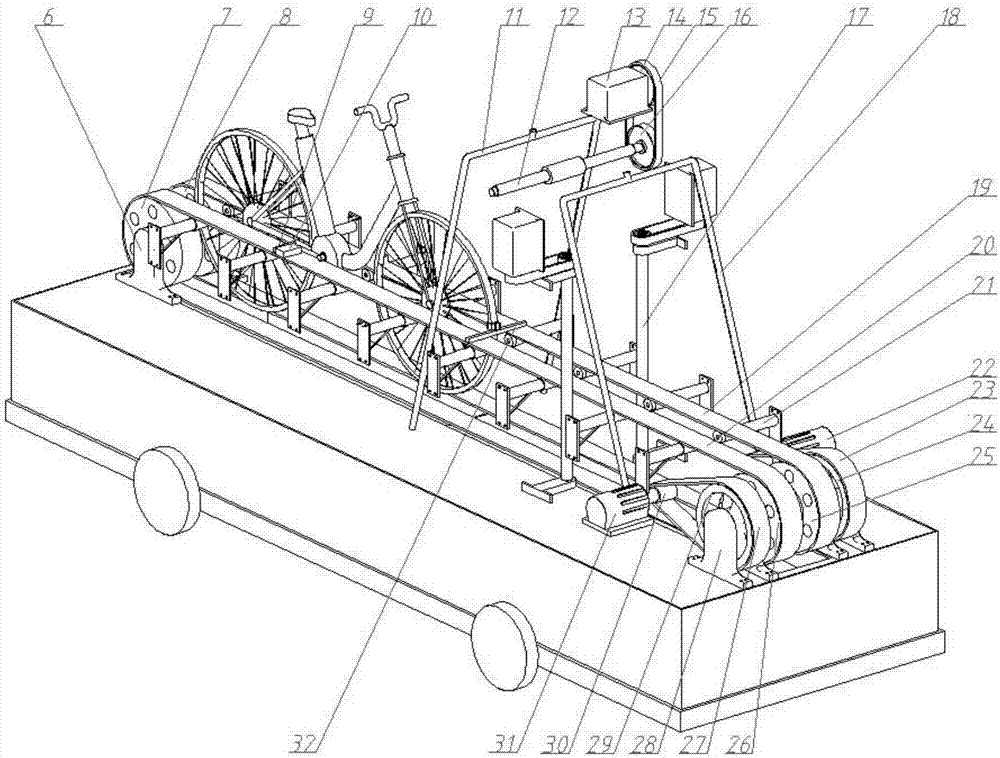

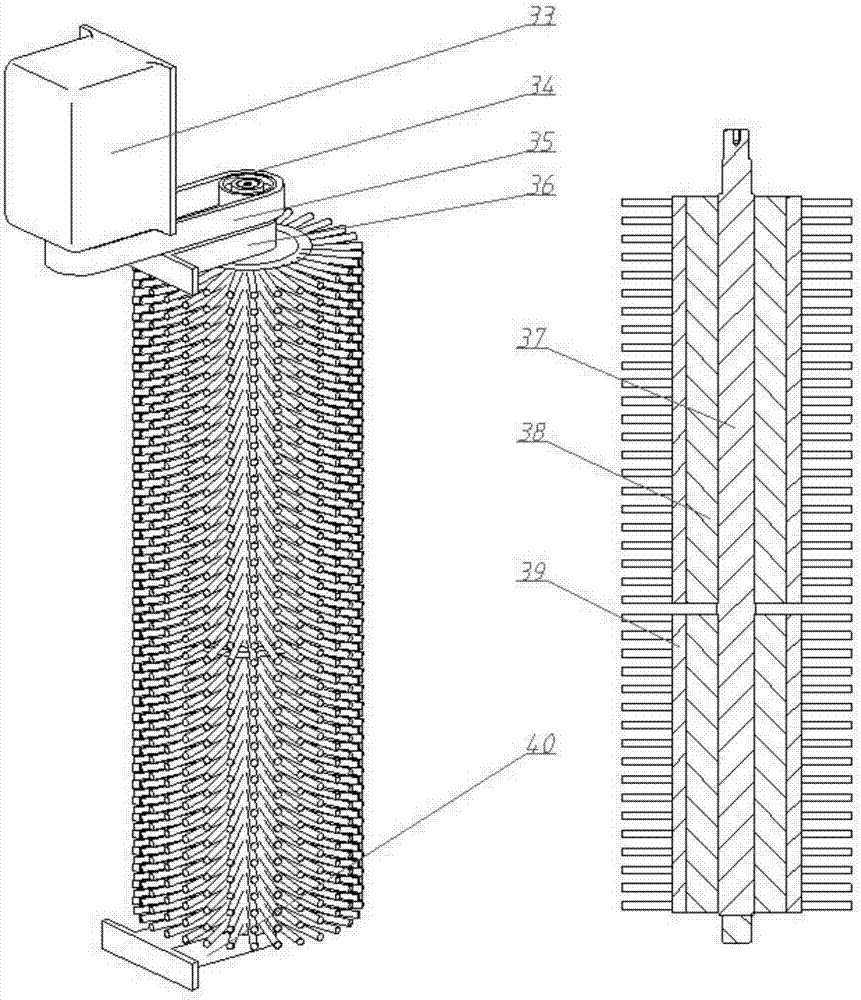

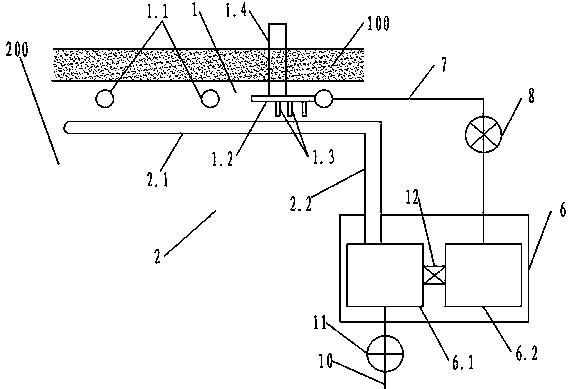

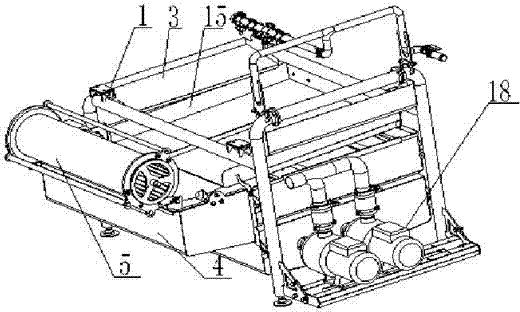

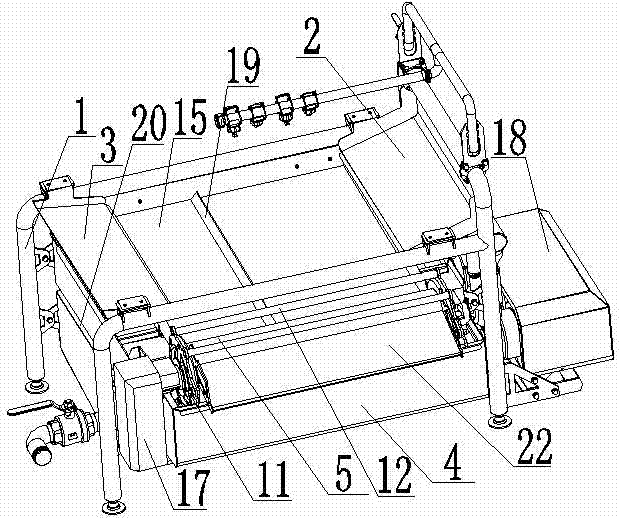

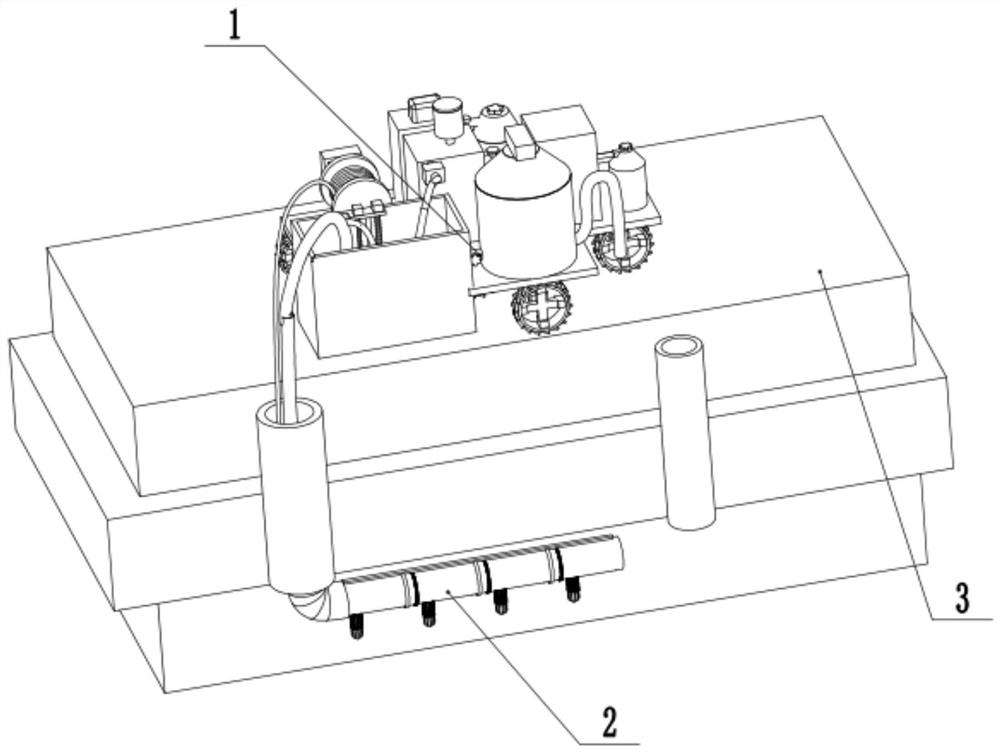

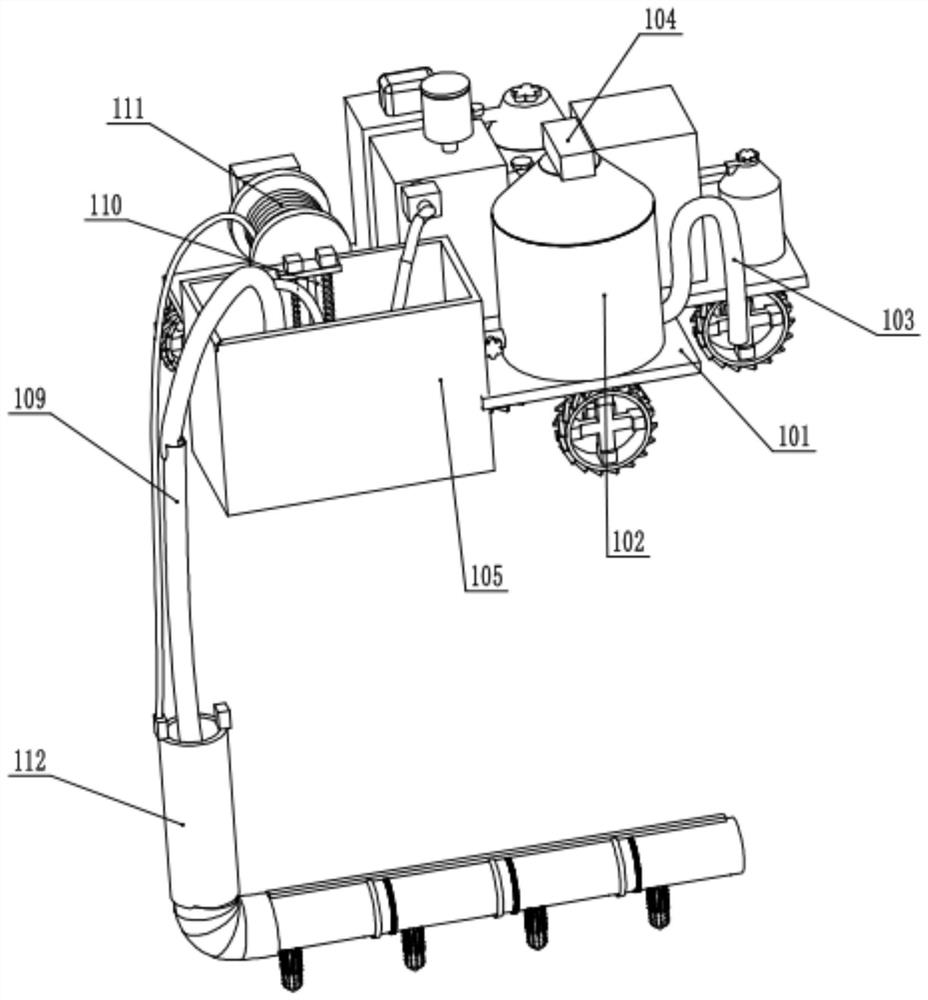

Automatic cleaning device of public bicycles on city road

PendingCN106915335AAchieve fixationPrevent rotationCleaning apparatus for vehicle exteriorsEngineeringElectrical and Electronics engineering

The invention discloses an automatic cleaning device of public bicycles on a city road. According to the automatic cleaning device of the public bicycles on the city road, the problems that in the prior art, bicycles are low in operation efficiency and poor in cleaning effect are solved, and the effects that cleaning efficiency is high, water for a machine is recycled, and manual labor is relieved are achieved. According to the scheme of the automatic cleaning device of the public bicycles on the city road, the automatic cleaning device of the public bicycles on the city road comprises a base and a side hairbrush; a spray mechanism is arranged on the base, one side of the spray mechanism is provided with a bicycle scrubbing mechanism which comprises a support, and the bicycle is arranged on one side of the support; and the top of the support is provided with a horizontally or obliquely arranged top hair brush which can rotate to clean the upper half portion of a bicycle body of the bicycle, and the side hairbrush is vertically arranged or obliquely arranged and can rotate to clean the lower half portion of the bicycle body of the bicycle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

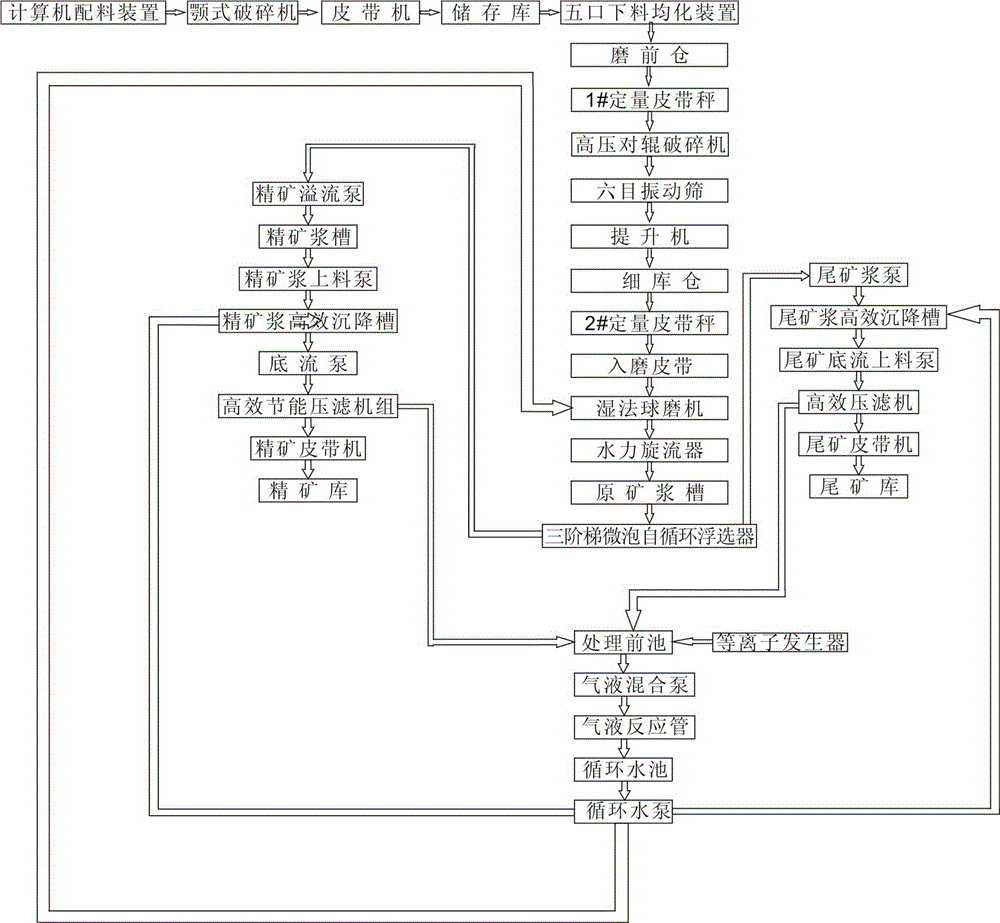

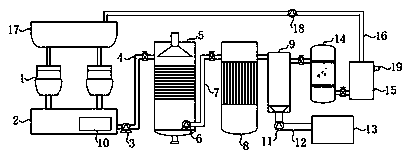

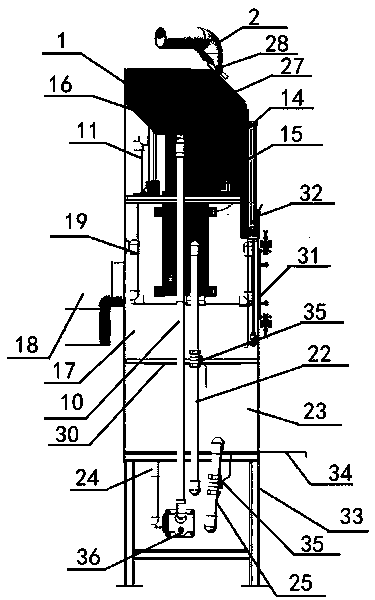

Independently constructed benefication complete equipment for annually producing bauxite with 200,000 tons

InactiveCN102744147AReduce power consumptionRealize water recyclingFlotationGrain treatmentsEngineeringCrusher

The invention relates to independently constructed benefication complete equipment for annually producing bauxite with 200,000 tons. The independently constructed benefication complete equipment is composed of main parts including a computer batching device, a jaw crusher, a belt conveyor, a storage storehouse, a five-hole blanking homogenizing device, a front grinding storehouse, a 1# quantitative belt weigher, a high-pressure double-roller crusher, a six-mesh vibration screen, a hoister, a fine ore storehouse, a 2# quantitative belt weigher, a grinding entering belt, a wet ball mill, a hydrocyclone, an original ore pulp tank, a three-step micro-foam self-circulating floatation selector, a finished ore overflow type pump, a finished ore pulp tank, a finished ore pulp charging pump, a finished ore pulp high-efficiency sedimentation tank, an underflow pump, a high-efficiency energy-conservation filter pressing unit, a finished ore belt conveyor, a finished ore storehouse, a tailing ore pulp pump, a tailing ore pulp high-efficiency sedimentation tank, a tailing ore underflow charging pump, a high-efficiency filter presser, a tailing ore belt conveyor, a front tailing ore storehouse processing pool, a gas-liquid mixing pump, a gas-liquid reaction pipe, a circulation water pool, a circulation water pump and the like. According to the equipment, the benefication efficiency is greatly improved; simultaneously, the loss is also effectively reduced; the whole equipment forms a self-circulating system; and the zero release is realized.

Owner:HENAN DONGDA TECH CO LTD

Fruit-and-vegetable cultivating frame saving water resources

The invention discloses a fruit-and-vegetable cultivating frame saving water resources. The fruit-and-vegetable cultivating frame comprises a fixing frame, a water pump is arranged on one side face ofthe fixing frame, a first water delivering pipe is fixedly communicated to the top of the water pump, a second water delivering pipe is fixedly communicated to the end, away from the water pump, of the first water delivering pipe, the end, away from the first water delivering pipe, of the second water delivering pipe penetrates through the outer surface of the fixing frame and extends inside thefixing frame, the top of the second water delivering pipe is fixedly connected with the inner top wall of the fixing frame, a stepper motor is arranged on the side face, away form the water pump, of the fixing frame, a rotating rod is fixedly connected to the output end of the stepper motor, the end, away from the stepper motor, of the rotating rod is sleeved with a first gear, the inner wall of the first gear is fixedly connected with the outer surface of the rotating rod, and the outer surface of the first gear is sleeved with a rack. The fruit-and-vegetable cultivating frame saving the water resources has the advantages that the structure is simple, the photic angles of fruits and vegetables can be adjusted, and water recycling is achieved.

Owner:WUXI IGROWTHS TECH CO LTD

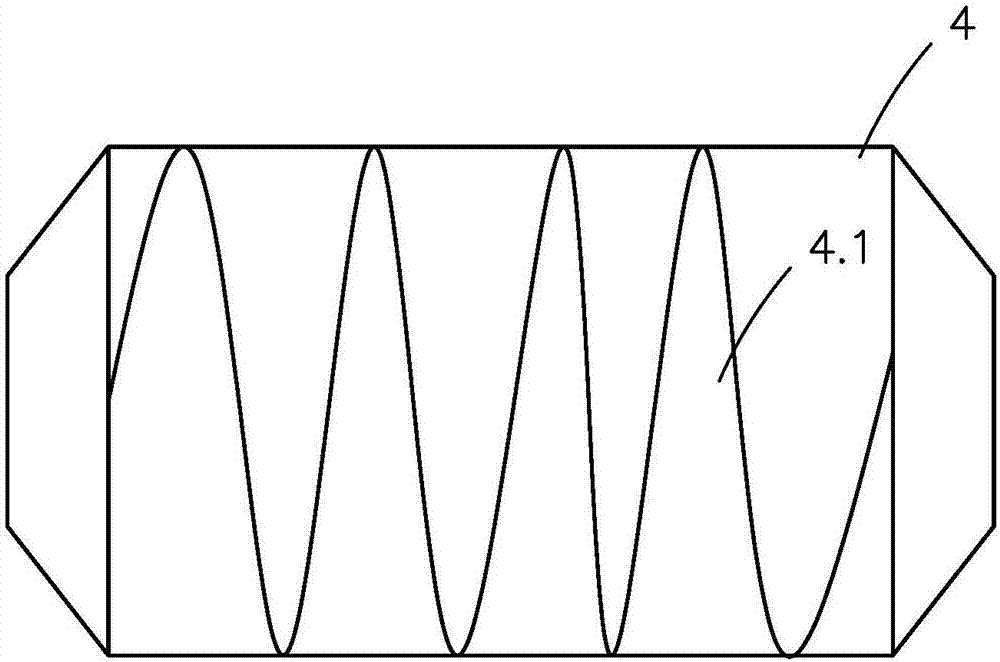

Guide rail processing cooling apparatus

InactiveCN109269220AEasy to useRealize water recyclingLighting and heating apparatusCooling fluid circulationWater resourcesEngineering

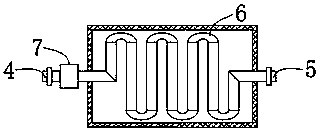

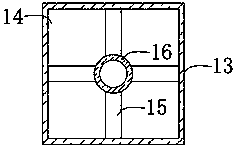

The invention discloses a guide rail processing cooling apparatus, comprising a base. A housing is fixedly mounted above the base; a water tank is arranged inside the housing; an inflow pipe and a drain pipe are arranged at the left and right ends of the water tank respectively; an S-shaped coil is fixedly mounted in the water tank; the outflow pipe is fixedly connected to the right top of the water tank; the other end of the outflow pipe is fixedly connected with a first water pipe; the other end of the first water pipe is connected with the inflow end of a water pump; the outflow end of thewater pump is connected with a second water pipe; a first outflow pipe is fixedly mounted at the bottom of the second water pipe; a workbench is arranged in the housing; a rectangular cavity is arranged in the workbench. The cooperation of the water tank, the S-shaped coil, the water pump, the first outflow pipe, the rectangular cavity, a discharge pipe and a collection bucket helps cool a guide rail and recycle water, thereby saving water resources and greatly improving working efficiency.

Owner:CHUZHOU OUBOTE ELECTRONICS MFG

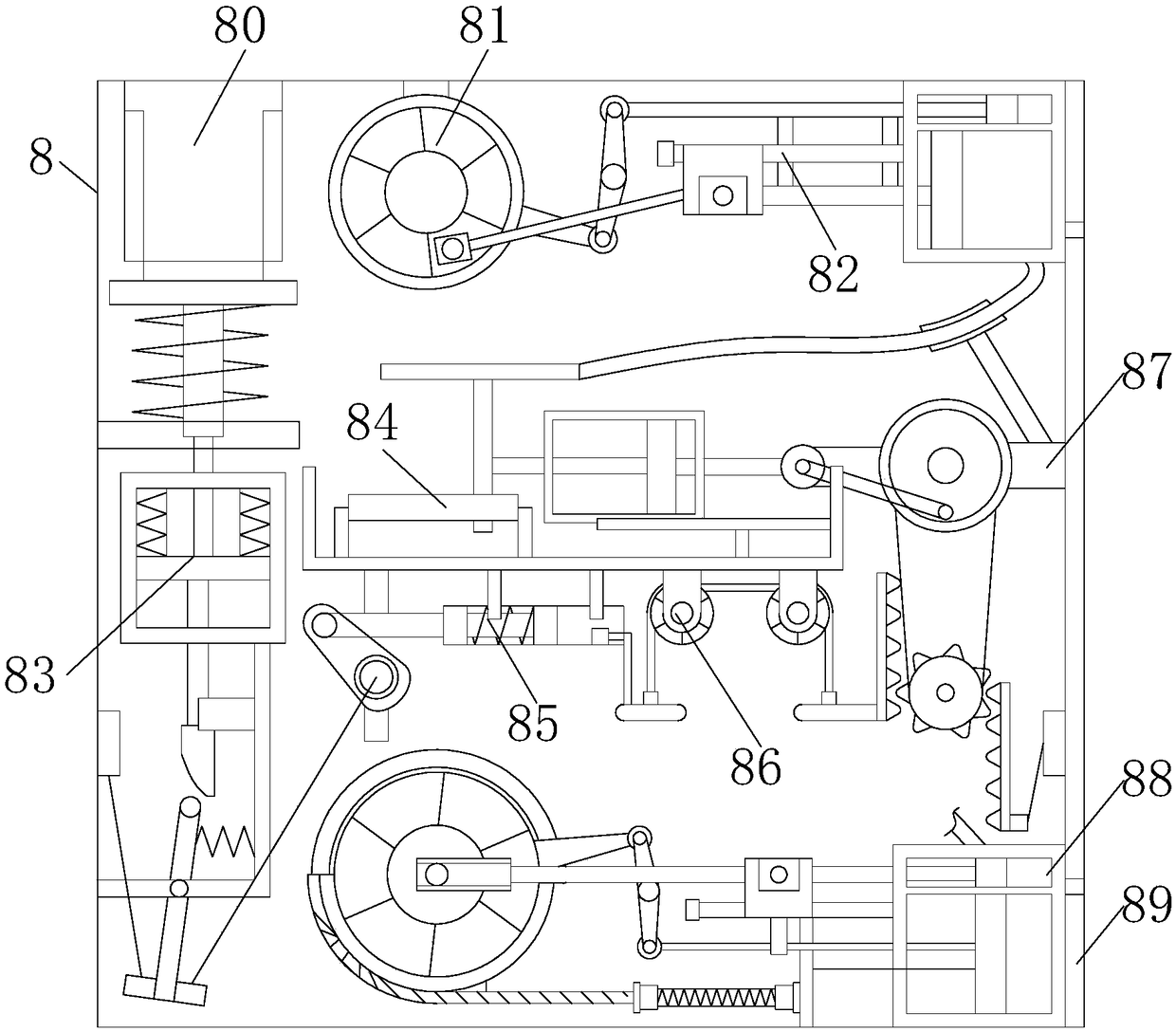

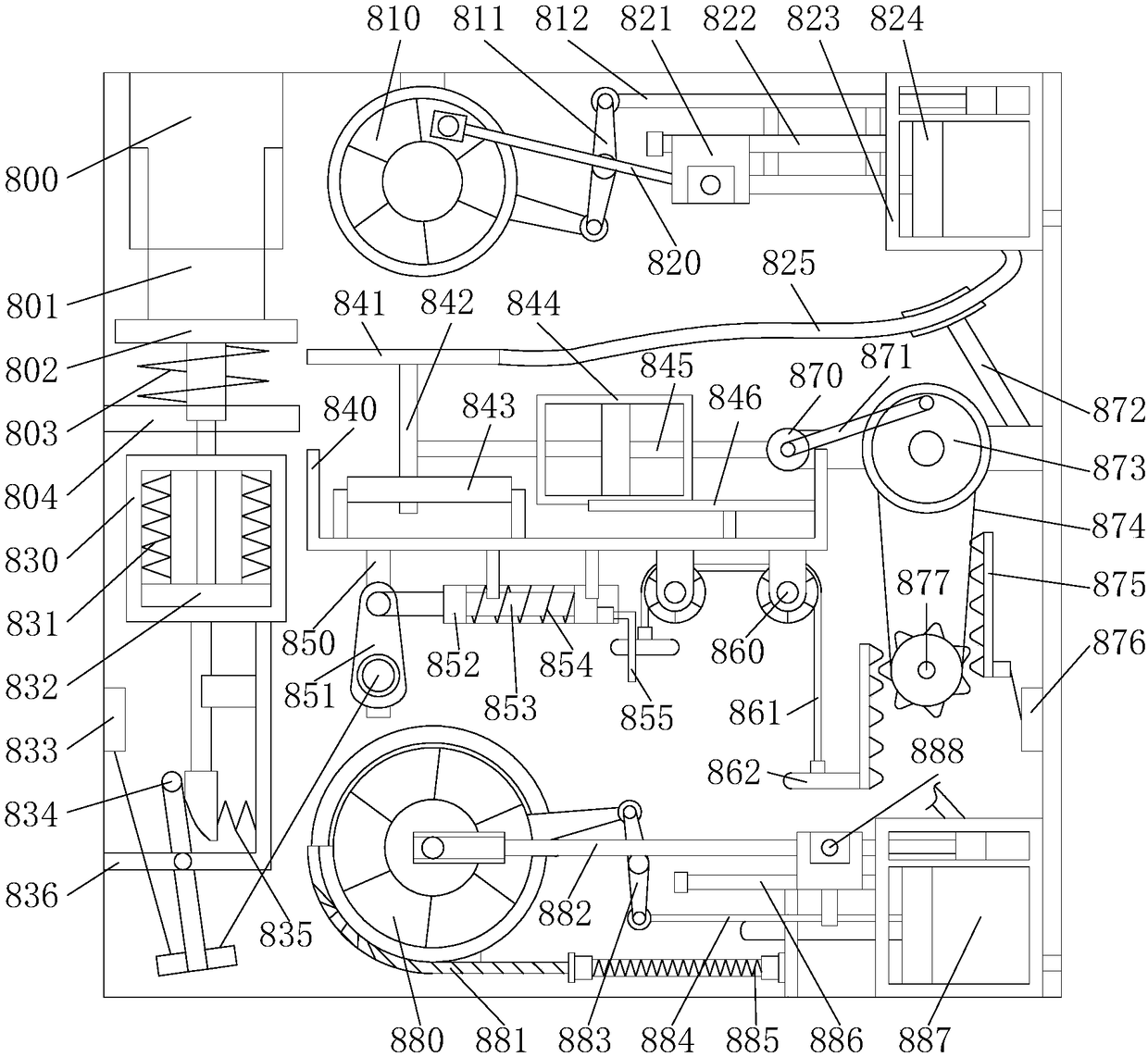

Bean cleaning device and bean product processing method

InactiveCN112586770AReduce manufacturing costFully cleanedCleaning using liquidsFood treatmentSoybean productReciprocating motion

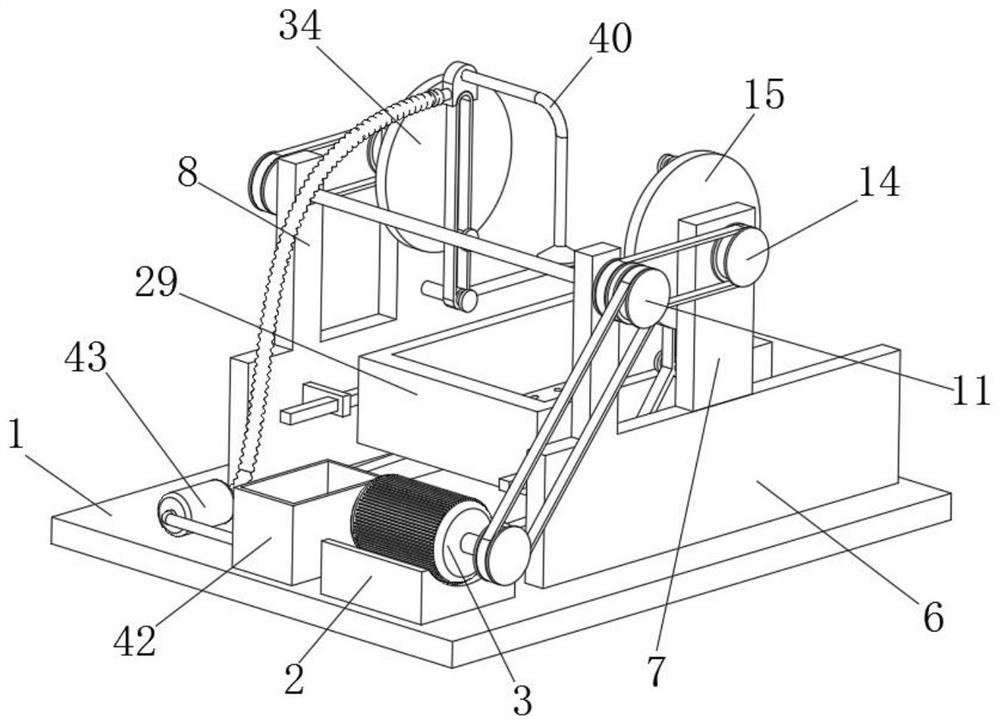

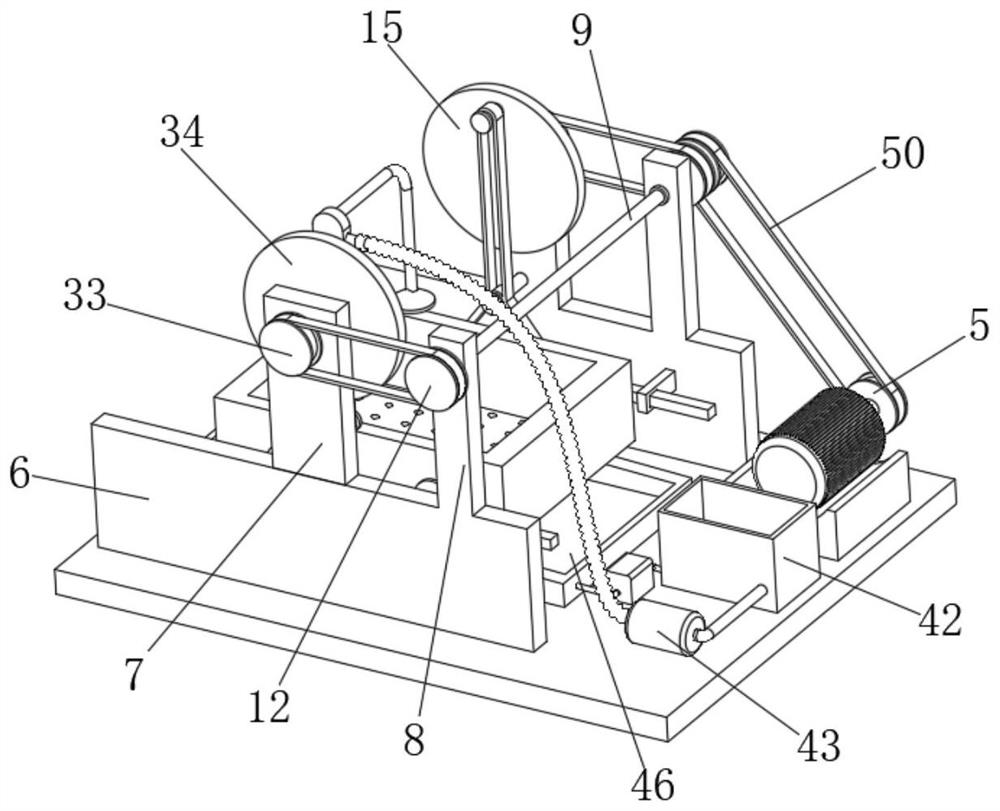

The invention relates to the technical field of bean cleaning devices, and discloses a bean cleaning device and a bean product processing method. A first belt wheel drives a third belt wheel to rotatethrough a first transmission belt, a swing disc enables a first connecting column and a first limiting block to rotate, an arc-shaped rack plate swings leftwards and rightwards on engaged rack blocks, two sliding rods slide leftwards and rightwards in limiting holes, the sliding rods drive a swing box to do reciprocating motion through T-shaped blocks, and soybeans continuously roll over, so thatuniform cleaning of the soybeans is achieved; and a second belt wheel drives a fourth belt wheel to rotate through a second transmission belt, the fourth belt wheel further enables a second rotatingshaft to rotate, a cleaning disc rotates, a rectangular frame rotates on a second connecting column and another limiting column, and a connecting pipe, a cleaning pipe and a multi-hole spray head aredriven to rotate through a convex block, so that the soybeans are fully cleaned, and the cleaning speed of the soybeans is increased.

Owner:周阳

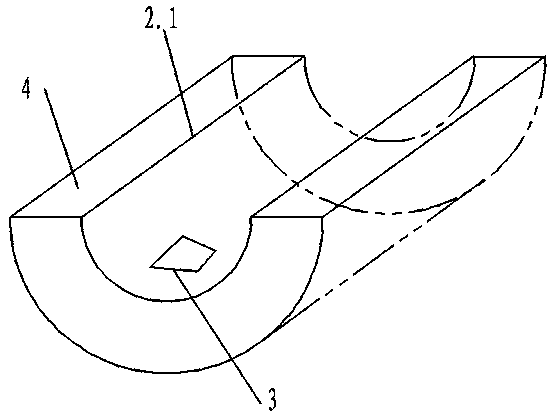

Cooling device in biomass carbonizing furnace

InactiveCN108690645ARealize all-round coolingImprove cooling effectBiofuelsSpecial form destructive distillationCooling effectWater cycling

The invention discloses a cooling device in a biomass carbonizing furnace. The cooling device includes an integrated heat dissipate box, a heat dissipater, a storage bin, a cooling frame bottom trough, a cooling frame upper cover, a cooling frame, a control panel, and an internal cooler. The heat dissipater is installed on the integrated heat dissipate box. The storage bin and the control panel form a vertical structure and are respectively embedded in the integrated heat dissipate box. The cooling frame has a U-shaped structure and is connected to the integrated heat dissipate box to form anintegrated structure. In the cooling device, water is injected into a fixed water injection cylinder so as to drive the device through gravity of water, thus reasonably utilizing the water; the wateris pumped into a water pumping cylinder for spray cooling the furnace completely, so that the device has good cooling effect; finally, the water, after spraying, is pumped into a water circulating storage frame and then is injected into the fixed water injection cylinder again, thereby achieving circulation utilization of water and effectively saving water resources.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Full-automatic fruit and vegetable feeding and washing device

The invention discloses a full-automatic fruit and vegetable feeding and washing device, and belongs to the technical field of processing of foods. The full-automatic fruit and vegetable feeding and washing device comprises an automatic feeding machine, wherein a pair of weighing plates is mounted in the automatic feeding machine; a falling buffering device is arranged under the weighing plates; afirst conveyor belt is arranged at a discharging opening in the lower part of the automatic feeding machine; a sewage removing groove is formed in the discharging end of the first conveyor belt. Thefull-automatic fruit and vegetable feeding and washing device is characterized in that a raw material basket is mounted in the sewage removing groove; a distance is formed between the bottom of the raw material basket and the bottom of the sewage removing groove; an ultrasonic generator is connected to the lower right part of the sewage removing groove; an air pump is connected to the lower left part of the sewage removing groove; a tubular type spiral hoisting machine of which the lower end is pendent extends into the raw material basket; an air outlet of the air pump is formed over against an opening in the lower end of the tubular type spiral hoisting machine; a spiral plate is arranged in the tubular type spiral hoisting machine in an axial direction; and a second conveyor belt is arranged at the upper end of the tubular type spiral hoisting machine. The full-automatic fruit and vegetable feeding and washing device disclosed by the invention is short in raw material washing time and good in washing effects, and the production efficiency and the product quality can be improved.

Owner:CHENGDU JUNSHUO RUIZHI INFORMATION TECH CO LTD

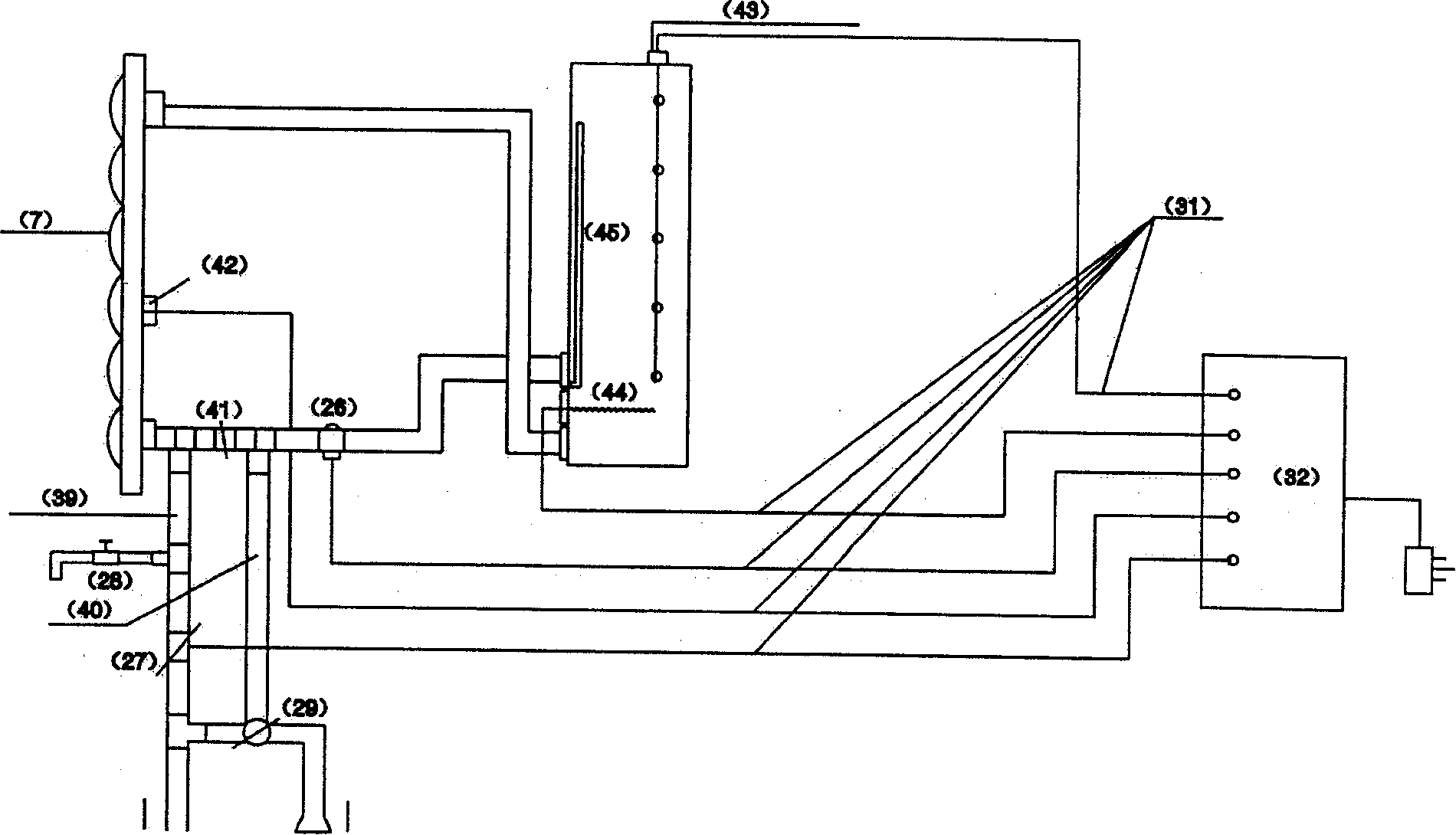

Method and system for improving saline-alkali land on basis of dark pipes and saline-alkali tolerant rice

InactiveCN108668555AAvoid enteringRealize water recyclingSoil-working methodsMicrocontrollerAlkali soil

The invention relates to a method and system for improving saline-alkali land on the basis of dark pipes and saline-alkali tolerant rice. The system comprises a planting soil layer and a salt discharging layer; the saline-alkali tolerant rice is planted on the planting soil layer, and an irrigation pipe net and a dark pipe salt-discharging pipe net are arranged in the salt discharging layer; the dark pipe salt-discharging pipe net comprises a first-level water absorption pipe and a second-level water collection pipe; the irrigation pipe net comprises main irrigation pipes and a branch irrigation pipe, and the branch irrigation pipe is connected to the main irrigation pipes and also connected to droppers or a ground bolt flooding pipe; the second-level water collection pipe is connected toa water tank A in a water treatment tank, the water tank A in the water treatment tank is connected to a water tank B in the water treatment tank through an electromagnetic valve, the water tank B isconnected to a water outlet pipe, an irrigation pump is arranged on the water outlet pipe, the water outlet pipe is connected to the water inlet end of the irrigation pipe net through the irrigation pump, and the water inlet end of the irrigation pipe net is also connected with a fresh water source through the water inlet pipe. A liquid level sensor is arranged in the water tank A, the electromagnetic valve is connected to the output end of a microcontroller, and the signal input end of the microcontroller is connected to the liquid level sensor.

Owner:中天水土治理科技(山东)股份有限公司

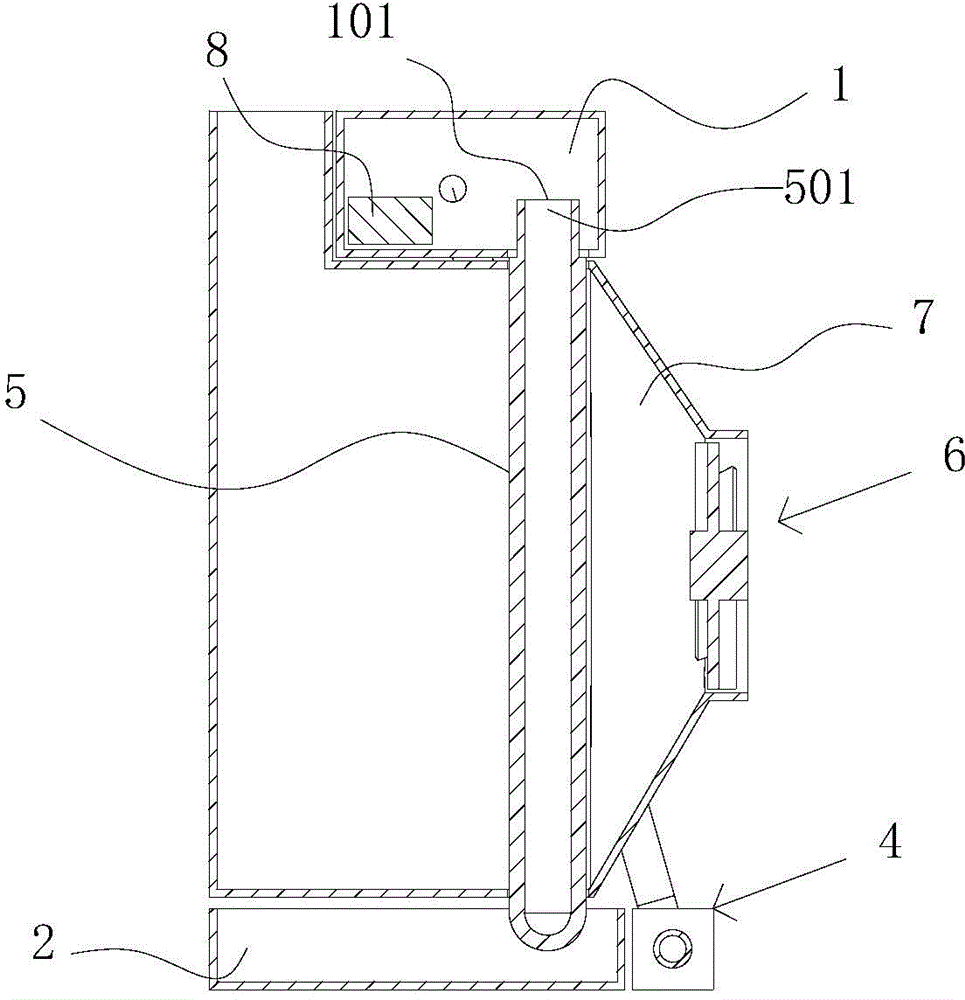

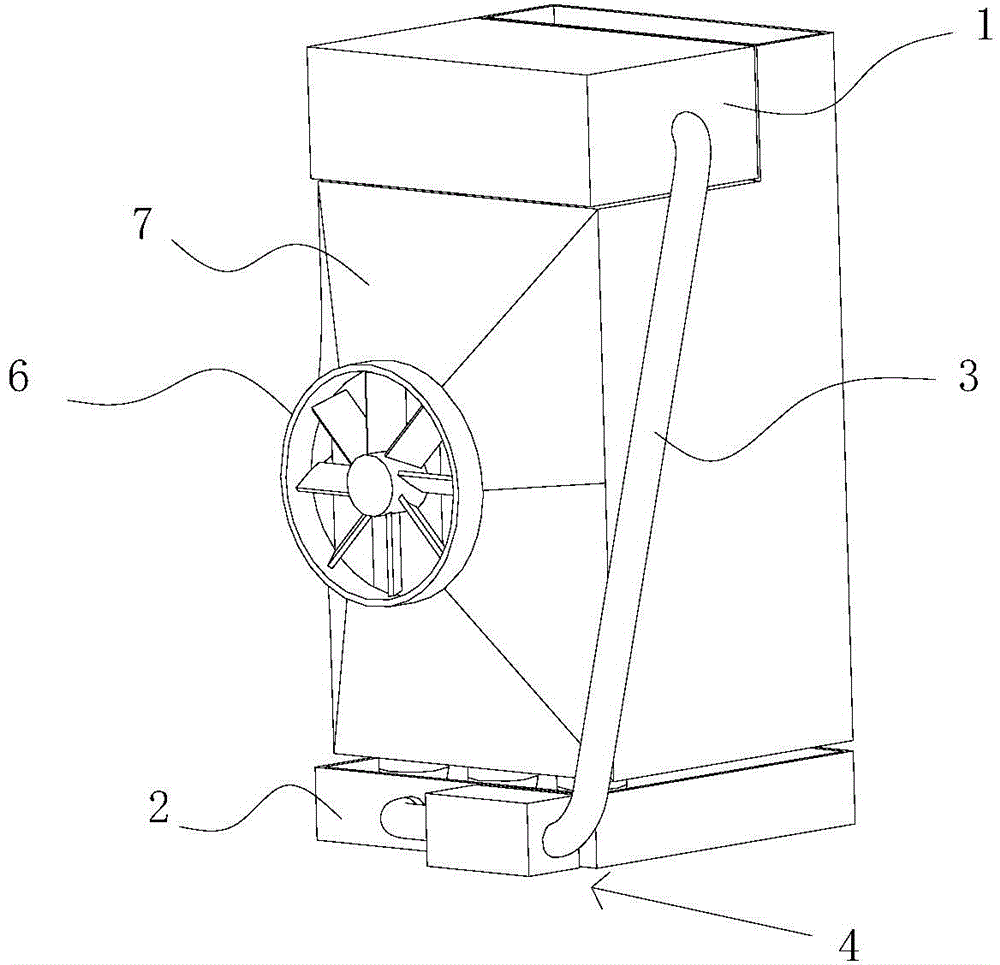

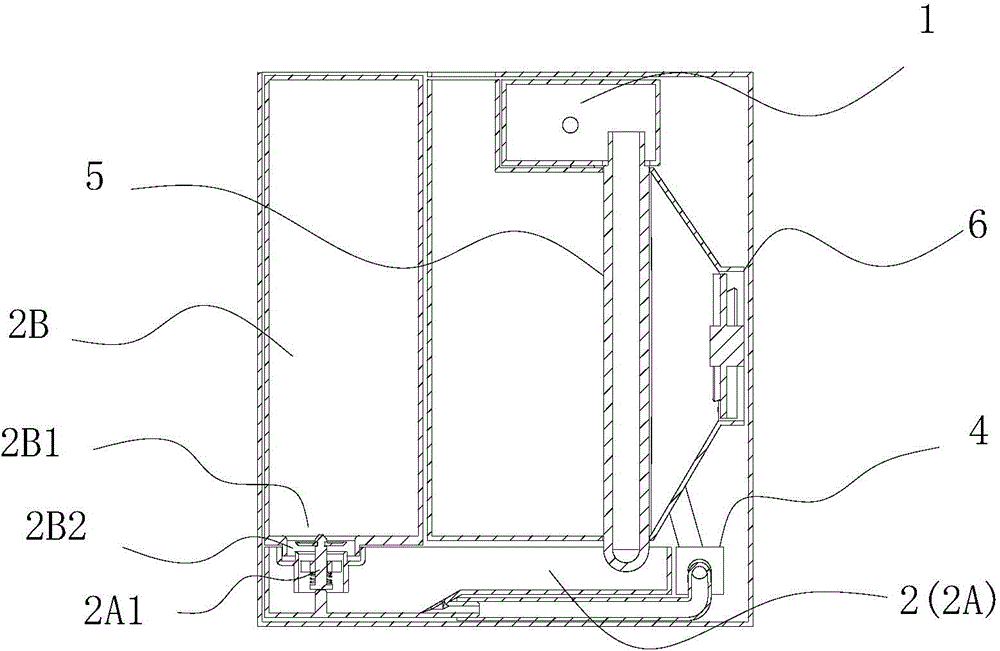

Water circulation type humidifier

InactiveCN104482620AExtension of timeUniform humidification effectLighting and heating apparatusAir humidification systemsIndoor air qualityEngineering

The invention belongs to the field of indoor air quality improving equipment, in particular to a water circulation type humidifier. The water circulation type humidifier comprises an upper buffer arranged above and a lower water reservoir arranged below, wherein a conveying water pipe is arranged between the lower water reservoir and the upper buffer; the conveying water pipe conveys liquid in the lower water reservoir to the upper buffer through a conveying device; a micro-penetrating return pipe is connected between the upper buffer and the lower water reservoir; the outlet of the upper buffer is connected with the upper end inlet of the micro-penetrating return pipe. The water circulation type humidifier further comprises a blowing device, wherein the blowing device generates flowing airflow which flows through the micro-penetrating return pipe; the flowing airflow is mixed with moisture at the surface of the micro-penetrating return pipe and then blows to a target field, thereby achieving the humidifying function; the liquid aggregated at the lower part of the micro-penetrating return pipe returns to the lower water reservoir. Compared with the prior art, the water circulation type humidifier has the advantages of being uniform in humidifying effect, saving resources, and continuously working for long time.

Owner:刘喜祥

Ecological environment-friendly mobile toilet adopting circulating water flushing and processing method

InactiveCN108824580ASave waterEasy to store and clean upSludge treatment by de-watering/drying/thickeningWater closetsCentrifugal pumpUrine

The invention discloses an ecological environment-friendly mobile toilet adopting circulating water flushing and a processing method. The mobile toilet comprises a closestool, wherein an excrement collecting box is connected to the lower side of the closestool via a pipeline; a first centrifugal pump is arranged in an outlet at the right side of the excrement collecting box; the first centrifugalpump is connected to an anaerobic pool via a first pipeline; a first lift pump is arranged at the bottom side of the interior of the anaerobic pool; the first lift pump is connected to a contact oxidation pool via a second pipeline; a urine and feces separating pool is arranged at the right side of the contact oxidation pool; a second lift pump is arranged at the bottom of the urine and feces separating pool; a purifier is connected to the top right side of the urine and feces separating pool via a pipeline; a water storage tank is connected to the right side of the bottom of the purifier viaa pipeline; and the top of the water storage tank is connected to the top of a flushing tank via a water discharge pipeline. The mobile toilet provided by the invention, by defining a multi-stage processing structure by connecting the parts sequentially, can achieve circulating water consumption, save water resource and prevent easy blockage; and a resource utilization rate of excrement is improved.

Owner:安徽正风环保设备有限公司

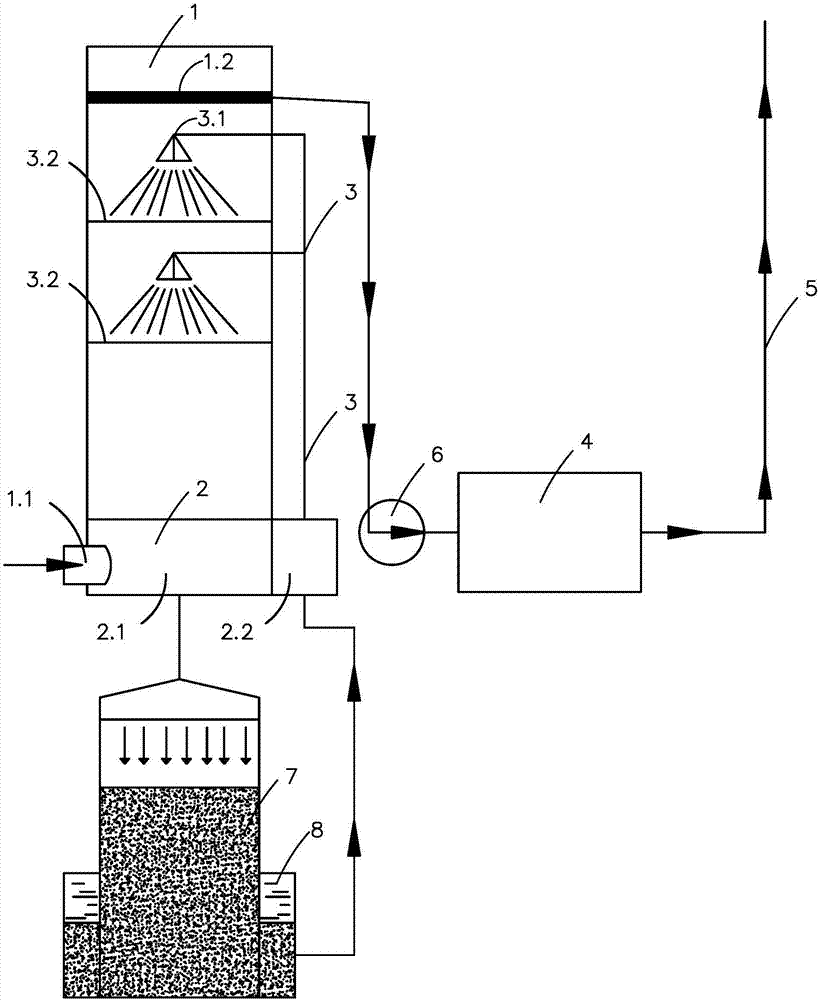

Waste gas multi-process purification system realizing circulation water use

InactiveCN106994289ARealize water recyclingImprove processing efficiencyDispersed particle separationWater/sewage treatmentWater useCooling tower

Owner:成都联咏科技有限公司

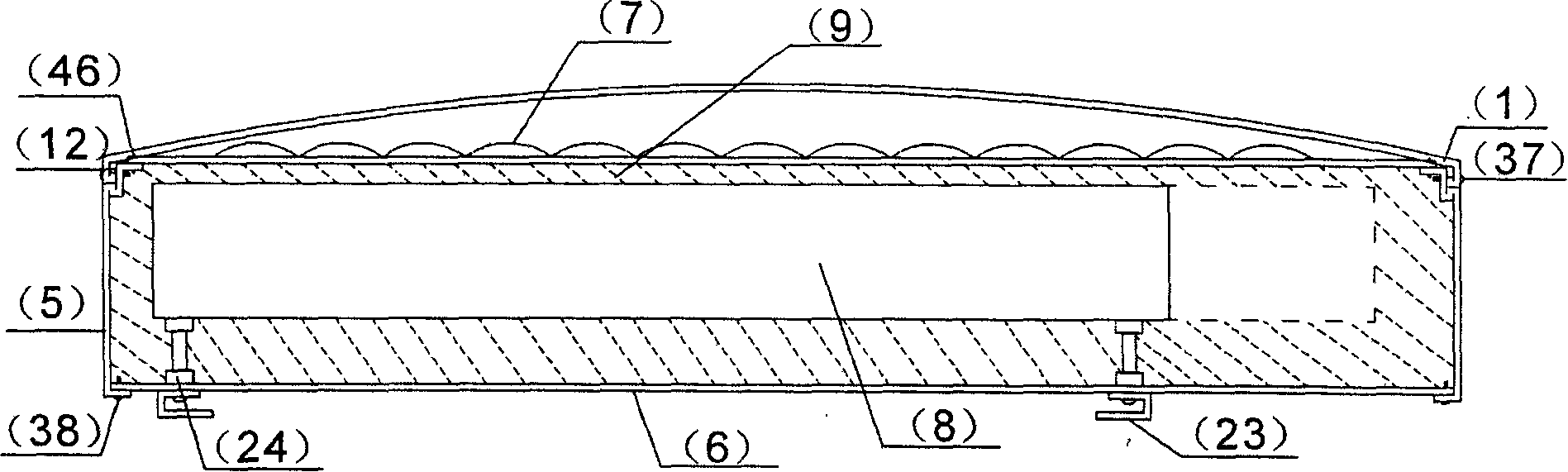

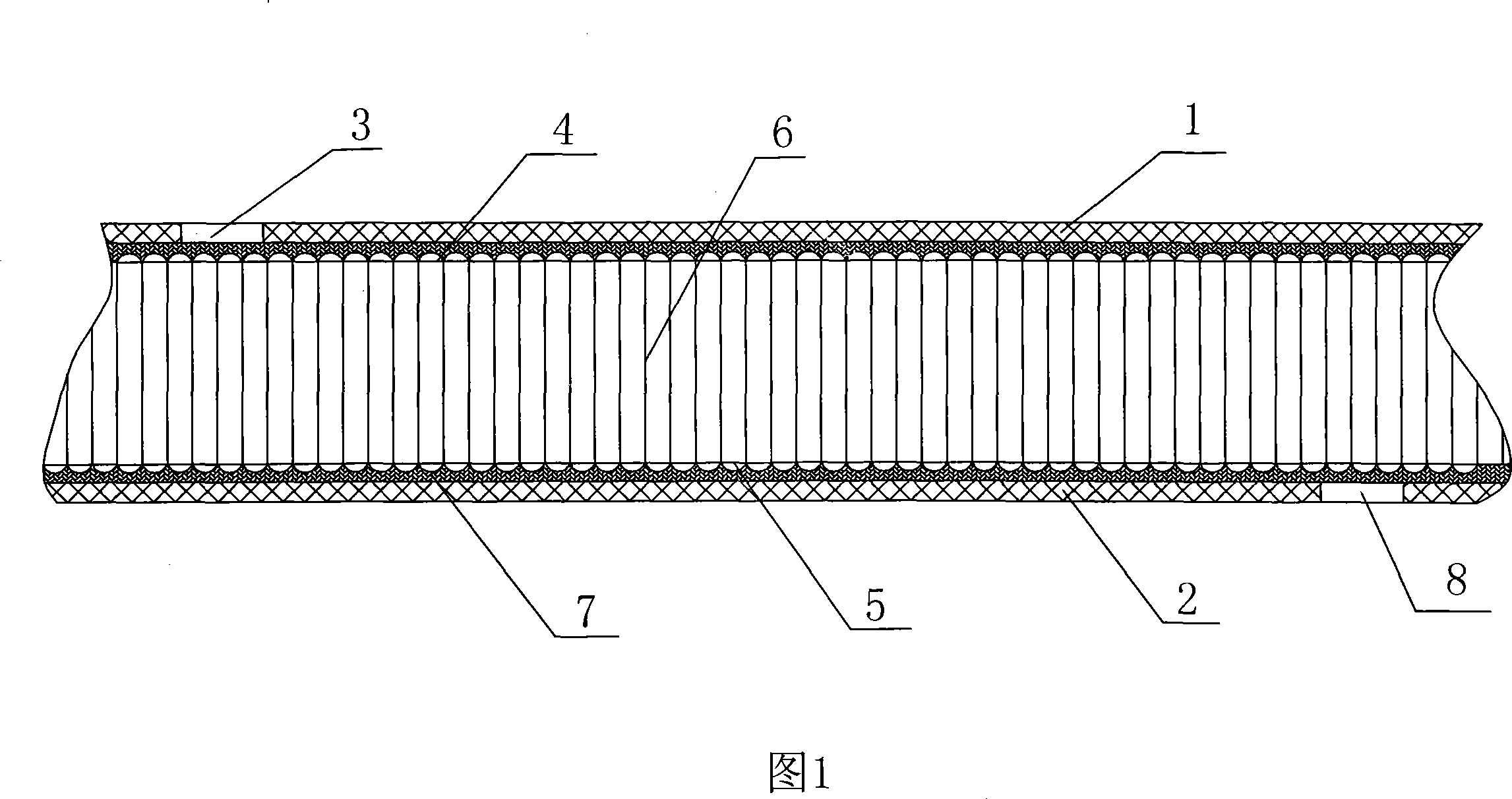

High energy-cumulating integral solar energy water heater

InactiveCN101210743ARealize water recyclingDoes not damage the façade effectSolar heating energySolar heat devicesElectricityWater leakage

A novel energy-concentrated integrated solar water heater is provided, which is quite different from the vacuum tubular type solar water heater, the flat plate solar water heater and integral-type solar water heater, and integrates the functions of the solar water heater and the electrical water heater. The novel solar water heater can be easily installed on southern walls and floors of buildings, without occupying any space indoor; and can normally work all day around in a way that the water is supplemented as being consumed under the electrical heating conditions. The novel solar water heater comprises a special corrugated metal heat-collecting core which can efficiently increase heat-collection area and heat-collection efficiency and increase the heat yield; a quadrate separated water tank which is integrated with a mainframe and installed outdoors. The novel solar water heater has functions of preventing dry burning, stroke, water leakage, power leakage, freezing and heat waste, and is safe to use. The novel solar water heater further comprises an intelligent control system for ensuring functions of temperature stabilization, timing, circulation, water supplementation, water consumption, drainage, time-delay and electrical heating.

Owner:施青

Automatic feeding type ultrasonic decontamination equipment

InactiveCN107811308AWon't hurtShort timeWater/sewage treatmentLoading/unloadingAir pumpConveyor belt

The invention discloses automatic feeding type ultrasonic decontamination equipment and belongs to the technical field of processing of canned foods. The automatic feeding type ultrasonic decontamination equipment comprises an automatic feeder, wherein a first conveyor belt is arranged at a discharge hole below the automatic feeder; a decontamination trough is formed in the discharging end of thefirst conveyor belt; the automatic feeding type ultrasonic decontamination equipment is characterized in that a raw material basket between the bottom of which and the bottom of the decontamination trough a distance is reserved is arranged in the decontamination trough; the right lower part of the decontamination trough is connected with an ultrasonic generator; the left lower part of the decontamination trough is connected with an air pump; a tubular screw elevator of which the lower end is suspended stretches into the raw material basket; an air outlet of the air pump is aligned at an opening in the lower end of the tubular screw elevator; a second conveyor belt is arranged at the upper end of the tubular screw elevator; and a spray header is arranged above the second conveyor belt. Theautomatic feeding type ultrasonic decontamination equipment disclosed by the invention is low in time consumption, excellent in decontamination effect and capable of increasing the production efficiency and product quality.

Owner:CHENGDU JUNSHUO RUIZHI INFORMATION TECH CO LTD

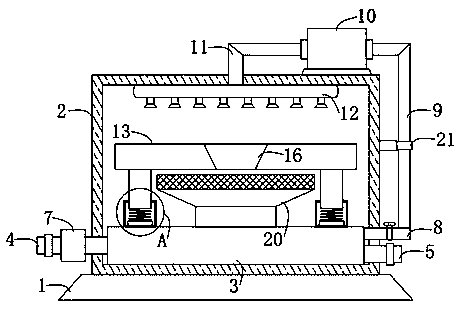

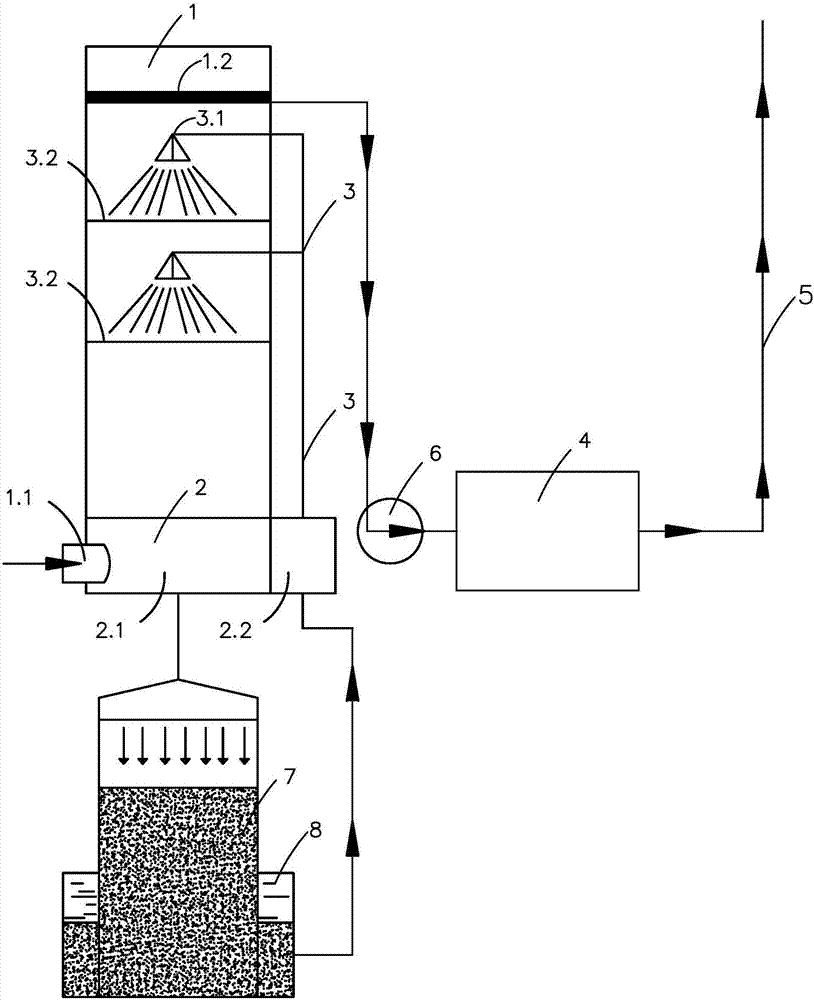

Device for culturing algae at constant temperature and experimental method

PendingCN114703053AEvenly heatedControl light timeBioreactor/fermenter combinationsBiological substance pretreatmentsWater useWater baths

The invention discloses a device for culturing algae at constant temperature and an experimental method, the device comprises a water tank, a transparent culture cylinder, water inlet and outlet equipment, a heating, lighting and air supply structure and the like, and the experimental method comprises the steps 1-5. The culture device designed by the invention adopts a water bath temperature control design concept, and has the advantages of controllable temperature, stable heating and uniform algae heating; according to the transparent culture cylinder and the mounting structure thereof, entering of air pollution particles can be reduced; water used by the heat preservation layer can be recycled by water in the water pool; the main control box is adopted to control the illumination intensity, and the timing device is adopted to control the lamp tube to control the illumination time to achieve the optimal growth condition; by using the design concept of water bath temperature control, the device has the advantages of controllable temperature, stable heating and uniform heating of algae, and redundant water is discharged by the drainage pipeline above the acrylic plate column and enters the water pool again to realize water recycling.

Owner:ANHUI UNIV OF SCI & TECH

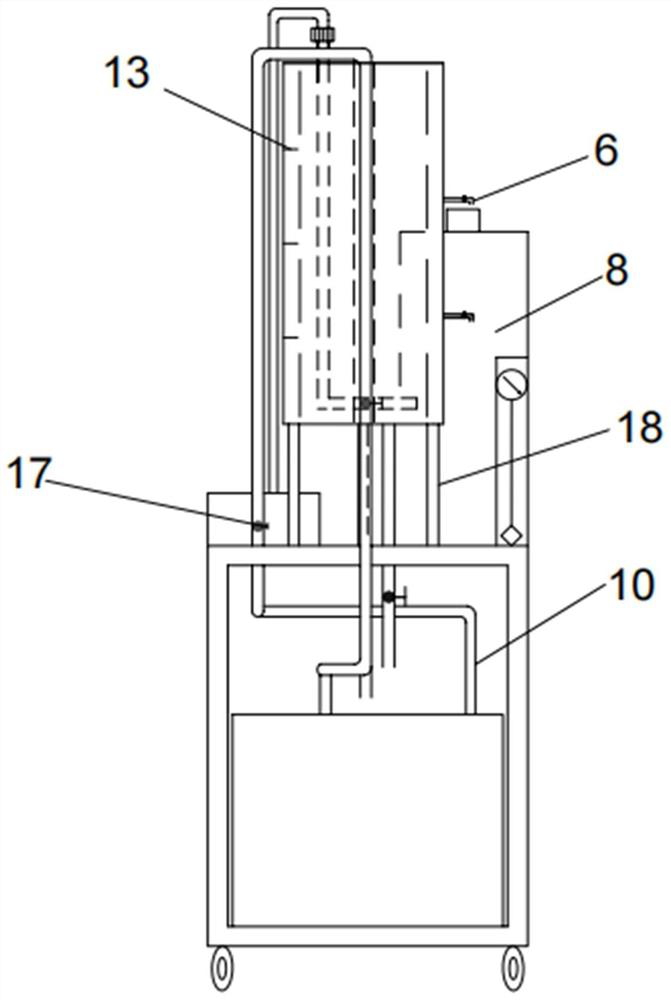

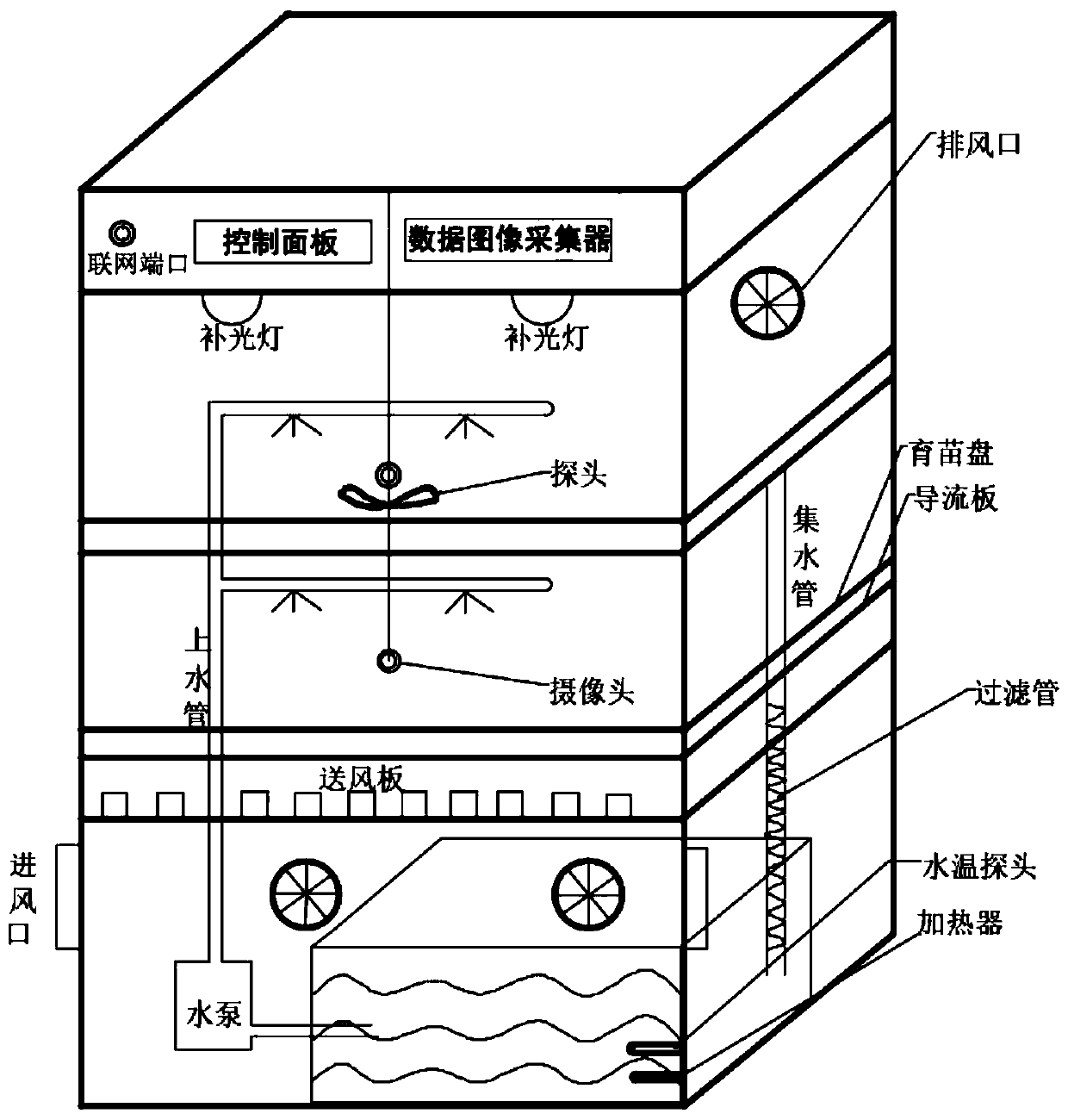

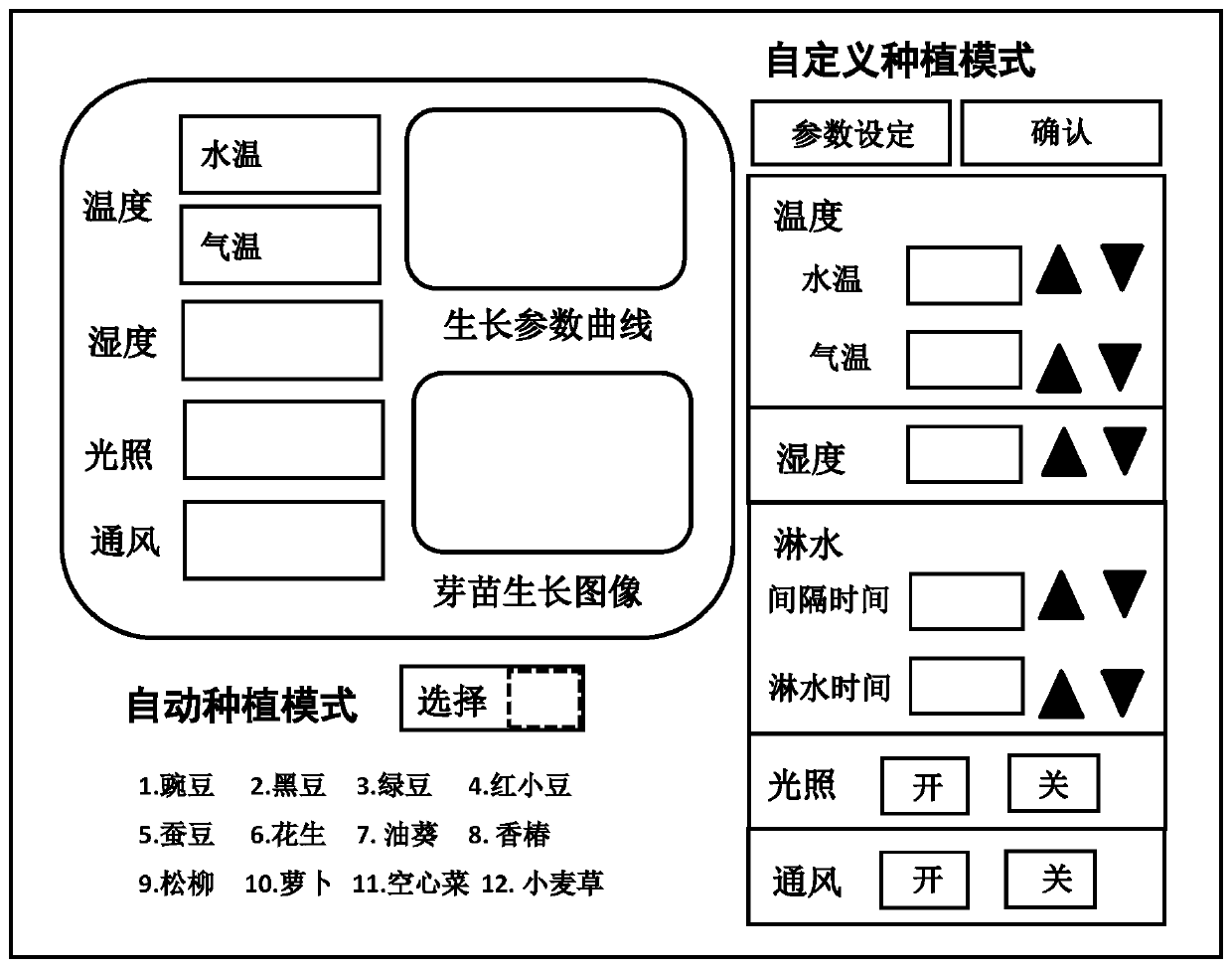

Full-automatic intelligent Internet-connected sprout seedling box

InactiveCN110800595AReal-time monitoring of growthWith intelligent networking functionAgriculture gas emission reductionCultivating equipmentsWater useAgricultural science

The invention discloses a full-automatic intelligent Internet-connected sprout seedling box which is portable and light in structure and suitable for household use. Functionally, the box can automatically control water temperature, automatic water spraying and light supplementing, and has an automatic water filtering function, thereby realizing water recycling; the box can fully meet culture needsof different types of sprouting vegetables, has an intelligent Internet connecting function and can monitor growth conditions of the sprouting vegetables in real time and make timely reminding. The box can meet diversified needs of families on planting of the sprouting vegetables, can produce the sprouting vegetables of various types at the same time, thereby being reassuring and labor-saving, can realize intelligent reminding and enables people to fully experience vegetable planting and harvesting fun.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

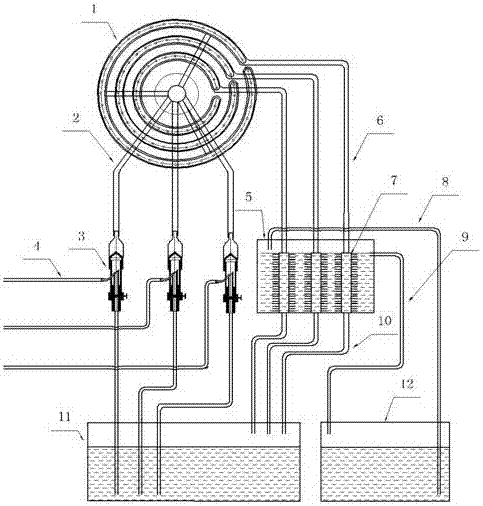

Organic waste gas treatment device for achieving water recycling

InactiveCN106975332AAdequate responseRealize water recyclingDispersed particle separationDecompositionWater circulation

The invention discloses an organic waste gas treatment device for achieving water recycling. An organic waste gas is decomposed and oxidized by using strong oxidability of ozone, meanwhile, rotation stirring blades are arranged in the middle of a cylindrical tower body in a radial manner and are capable of achieving the ozone full react with the organic waste gas while stirring, so that the best purification effect is ensured. Meanwhile, an inner pool of the tower communicates with an outer pool of the tower through a wastewater treatment device, so that wastewater can be reutilized, water recycling of a purification system is achieved, and secondary pollution is reduced.

Owner:成都联咏科技有限公司

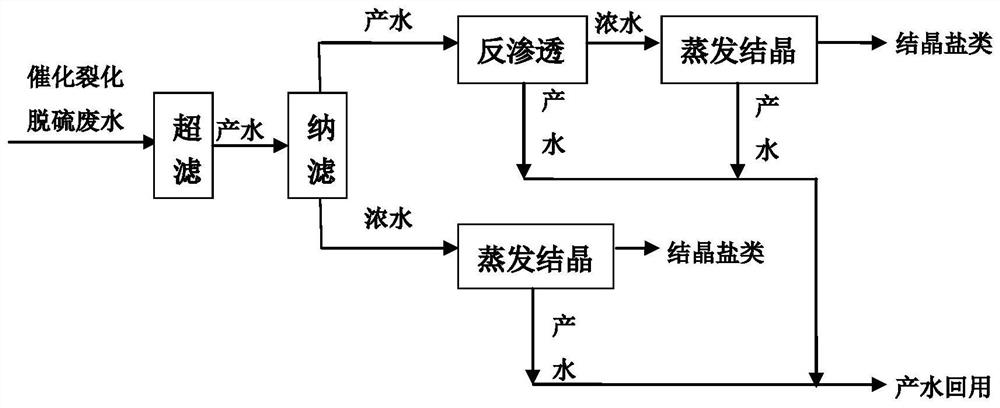

Industrial wastewater treatment system and application thereof

InactiveCN111847742ARealize water recyclingRealize fractional crystallization treatmentWater/sewage treatmentWaste water treatment from gaseous effluentsIndustrial waste waterReverse osmosis

The invention provides an industrial wastewater treatment system. The industrial wastewater treatment system comprises an ultrafiltration device; a nanofiltration device which is connected with the ultrafiltration device; a reverse osmosis device and a first evaporative crystallization device which are respectively connected with the nanofiltration device; and a second evaporative crystallizationdevice which is connected with the reverse osmosis device. The ultrafiltration device, the nanofiltration device, the reverse osmosis device, the first evaporative crystallization device and the second evaporative crystallization device are matched for use, and the respective advantages of each device are fully combined so that the problem that the catalytic cracking flue gas desulfurization wastewater of petrochemical enterprises is difficult to treat is solved, the resource utilization of water resources and salts is effectively realized, and meanwhile, a low-temperature heat source is alsoeffectively utilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

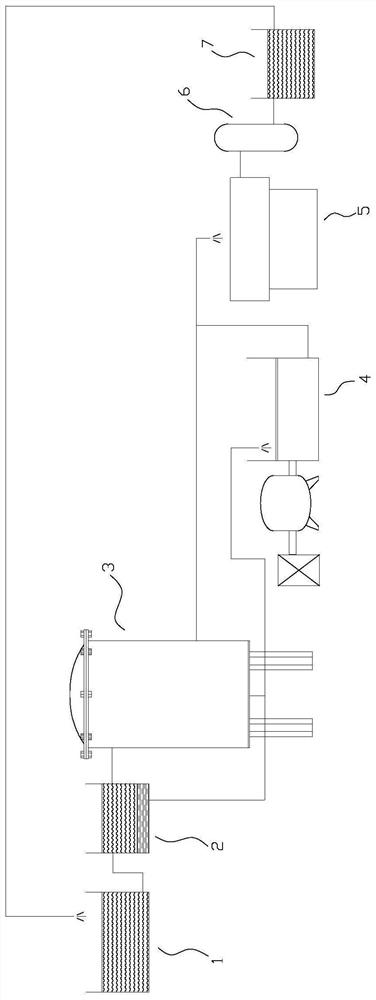

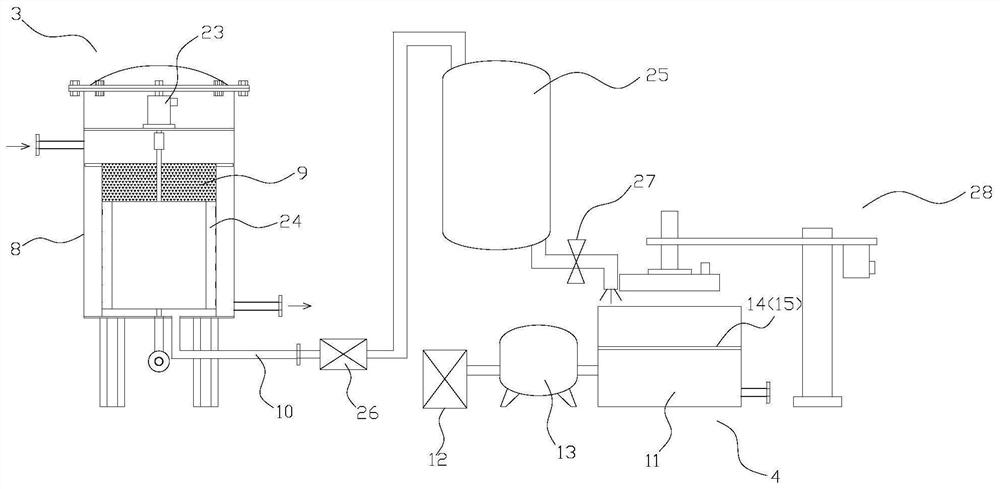

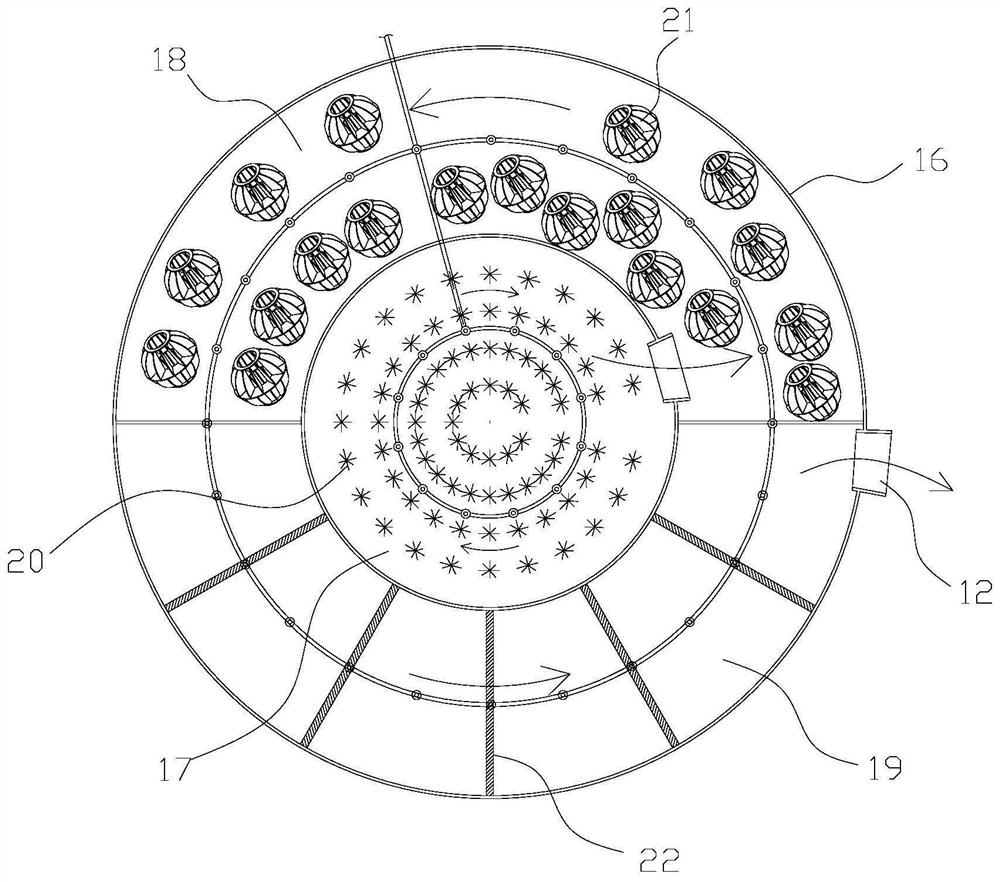

Industrial aquaculture zero-emission resource recycling and purifying system and purifying process thereof

PendingCN112960871AAchieving ectopic repairRealize water recyclingBio-organic fraction processingExcrement fertilisersFiltrationSludge

The invention provides an industrial aquaculture zero-emission resource recycling and purifying system and a purifying process thereof. The purifying system comprises an aquaculture pond, a sediment adjusting pond, a microfiltration device, a vacuum suction filtration device, a three-stage biological purifying device, an ozone ultraviolet reactor and a clean water pond. A water inlet of the precipitation regulating tank is connected with a sludge outlet of the culture pond; a water inlet of the microfiltration device is connected with a water outlet of the precipitation regulating tank; a water inlet of the vacuum suction filtration device is respectively connected with a concentrated solution outlet of the microfiltration device and a precipitation solution outlet of the precipitation regulation tank; a water inlet of the third-stage biological purification device is connected with water outlets of the microfiltration device and the vacuum filtration device; the ozone ultraviolet reactor is connected to a water outlet of the three-stage biological purification device, a water inlet of the clean water tank is connected with a water outlet of the ozone ultraviolet reactor, and a water outlet of the clean water tank is communicated to the culture pond. Fish feces, feed residues and the like can be filtered, dried and separated, and cyclic utilization of culture pond water is achieved in cooperation with ex-situ remediation of biological floccules.

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

Automobile refrigeration seat cushion

InactiveCN101070056AGood comfortGood cooling effectSeat heating/ventillating devicesCushionAerospace engineering

The invention discloses a vehicle cooling cushion. It contains upper and lower rubber cloth with around airproof and waterproof and supporting body between them. The intake opens on the upper or lower rubber cloth. The supporting body is sandwich cloth which is composed of the cloth gluing with the upper and lower rubber cloth. There is vertical sheet of nylon lines between the upper and lower cloth. The two ends of the nylon lines are wholly twined on the cloth. An outlet is opened on the upper or lower underlying surface. The cooling cushion has characteristics of having on collapsing, harmogegathy or slippage and convenient sitting. The water in the cushion can circulate, which has batter radiating effect.

Owner:麦镇荣

Method for recovering caffeine from caffeine refined mother liquor

The invention relates to the technical field of chemical process technologies, in particular to a method for recovering caffeine from caffeine refined mother liquor, and the method is high in caffeine recovery rate and low in process cost. The whole technological process is a physical process, does not involve the processes of solvent extraction, resin adsorption and the like, and is green and environment-friendly. The method comprises the following steps: 1) pretreatment of caffeine refined mother liquor: clarifying and removing impurities from the caffeine refined mother liquor through an ultrafiltration tube type ceramic membrane UF-I ultrafiltration system with the molecular weight of 10000-300000 Dal, and controlling the temperature to be 18-50 DEG C to obtain clarified and transparent caffeine refined mother liquor; (2) decolorizing and desalting the clarified liquid of the caffeine refining mother liquid obtained in the step (1) through an NF-II nanofiltration system, controlling the temperature to be 18-50 DEG C, and adding top washing water which is 5 times of the volume of the concentrated liquid to obtain a decolorized solution with the caffeine yield being greater than or equal to 99%; and (3) carrying out high-temperature concentration on the decolored solution obtained in the step (2) through an NF-III nanofiltration system.

Owner:上海赛奥分离技术工程有限公司

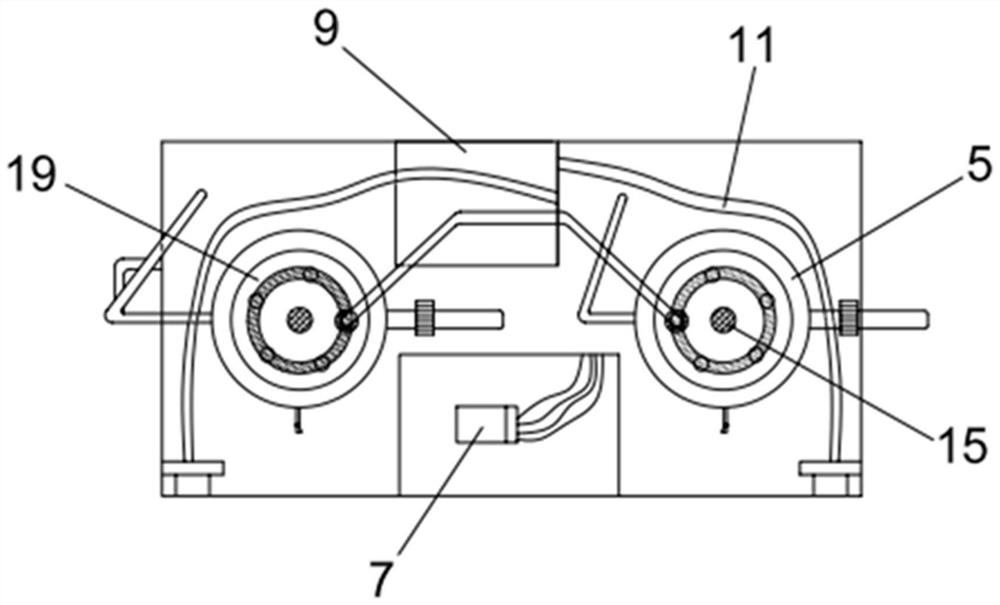

A kind of soft water circulating water cooling mold device for edge milling wheel

A soft water circulating water-cooling mold device for edge-milled wheels comprises annular water mist cooling pipes, water mist generators, a cooling water treatment tank, a cooling water storage tank and a soft water storage tank. Annular U-shaped grooves which are 10.0-12.0 mm deep and 12.0-15.0 mm wide are milled in larger casting wall thickness parts of a top mold and a bottom mold, the annular water mist cooling pipes are inlaid in the grooves, soft water enters water vapor mixing chambers of the water mist generators via water pipe joints under the action of compressed air, and water vapor mixtures are further atomized by conical water mist nozzles, enter water mist outlet joints, enter water mist flow dividers by the aid of connecting pipes and then uniformly enter inner-layer pipes of the annular water mist cooling pipes for circulation by the aid of the water mist flow dividers; the annular water mist cooling pipes absorb heat emitted by molds, water mist is converted into water vapor, and the water vapor carries heat to enter water vapor outlet pipes. The device is high in cooling effect, uniform in cooling and capable of preventing the molds from corroding.

Owner:JIANGSU KAITE AUTO PARTS

Rapid-dismounting type roll cage circulation water tank purification device capable of overturning

The invention relates to a purification device, in particular to a rapid-dismounting type roll cage circulation water tank purification device capable of overturning. The rapid-dismounting type roll cage circulation water tank purification device capable of overturning comprises a support leg, wherein a first water receiving plate and a second water receiving plate are respectively arranged between the two ends of the support leg. The rapid-dismounting type roll cage circulation water tank purification device capable of overturning is characterized in that the lower part of the support leg is connected with a circulating water tank; a roll cage is arranged at one side of the circulating water tank; the roll cage is connected with a rotating shaft; the rotating shaft is provided with a compression spring; a transmission connecting sleeve is arranged on the top of the compression spring; the transmission connecting sleeve is inserted into a transmission hole in the roll cage; the roll cage is provided with a baffle which is inserted and connected with the transmission connecting sleeve; and a slag outlet plate is hung on a roll cage rack. The rapid-dismounting type roll cage circulation water tank purification device capable of overturning has the beneficial effects that impurities such as weeds and sludge in the water can be automatically removed; a middle water receiving hopper can be taken out at any time; meanwhile, a circulation water tank is convenient to clean; and the roll cage can rotate away from the circulation water tank at any time, thus being convenient to clean.

Owner:山东科迈达智能食品装备有限公司

Bathing machine

Owner:王踵先

Multi-channel gasifier for underground coal gasification and gasification method

ActiveCN113027410ASo as not to damagePromote generationConstructionsChemical industrySewageThermodynamics

The invention discloses a multi-channel gasifier for underground coal gasification and a gasification method. The multi-channel gasifier comprises a ground gasification part and an underground gasification part, wherein the ground gasification part comprises an equipment base, a coal gas collecting furnace, a gas outlet pipe, a wastewater purification tank, a gas inlet system and a coal gas purification and hydrogen purification system; the underground gasification part comprises an outer protection pipe, an inner ventilation pipe and a gas injection device; the coal gas collecting furnace is fixedly mounted on the equipment base; the wastewater purification tank is used for filtering and recycling sewage; the gas inlet system is mounted in the wastewater purification tank and stretches into a coal layer from a gas inlet hole through the gas inlet system, so that conditions are provided for coal gas gasification; purified coal gas in the coal gas collecting furnace enters the coal gas purification and hydrogen purification system to be subjected to separation and compression of the coal gas and the work of reacting the coal gas to generate hydrogen; one end of the outer protection pipe is communicated with the gas inlet system; and after the coal gas enters the coal layer, the outer protection pipe is opened and the gas injection device rotates out to inject water mist and air, so that the coal layer reacts and the rapid generation of the coal gas is facilitated.

Owner:天津市地质研究和海洋地质中心 +1

Automatic cleaning and drying device for aluminum alloy machined part

PendingCN110961396AEasy grab toolEasy to useDrying gas arrangementsCleaning using gasesMachine partsWater storage tank

The invention discloses an automatic cleaning and drying device for an aluminum alloy machined part. The device comprises a box body, a hot air pipe is arranged at the top of the box body, the hot airpipe is connected with a hot air blow-drying device, the hot air blow-drying device is provided with an air knife moving device, and a first power cylinder is connected to the air knife moving device; output ports of the air knife moving device and the hot air blow-drying device are correspondingly provided with a product fixing table, the product fixing table is arranged on a mounting table, a high-pressure spraying device is arranged behind the product fixing table, and the high-pressure spraying device is connected with a water inlet pipe and a water pump under a water storage tank; the mounting table is provided with a turnover mechanism, and the turnover mechanism is turned over through a second power cylinder; a self-cleaning box is arranged under the mounting table, a spraying pipeand an air spraying device are arranged in the self-cleaning box, an exhaust pipe is arranged at one side of the self-cleaning box, an access hole is formed in the other side, and a filter screen isarranged at the bottom; and the water storage tank is arranged under the self-cleaning tank and provided with a water outlet and a water drainage hole. Thus, high-pressure cleaning, drying and water recycling of the workpieces are achieved, and self-cleaning of the device is guaranteed.

Owner:GAOYAO LIYUAN DIE CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com