Automatic feeding type ultrasonic decontamination equipment

An automatic feeding, ultrasonic technology, applied in water/sewage treatment, water/sludge/sewage treatment, conveyor objects, etc., can solve the problems of impurities and pesticide residues that are difficult to clean up, product quality decline, and raw materials are easily damaged. , to achieve the effect of saving labor costs, reducing labor costs, improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

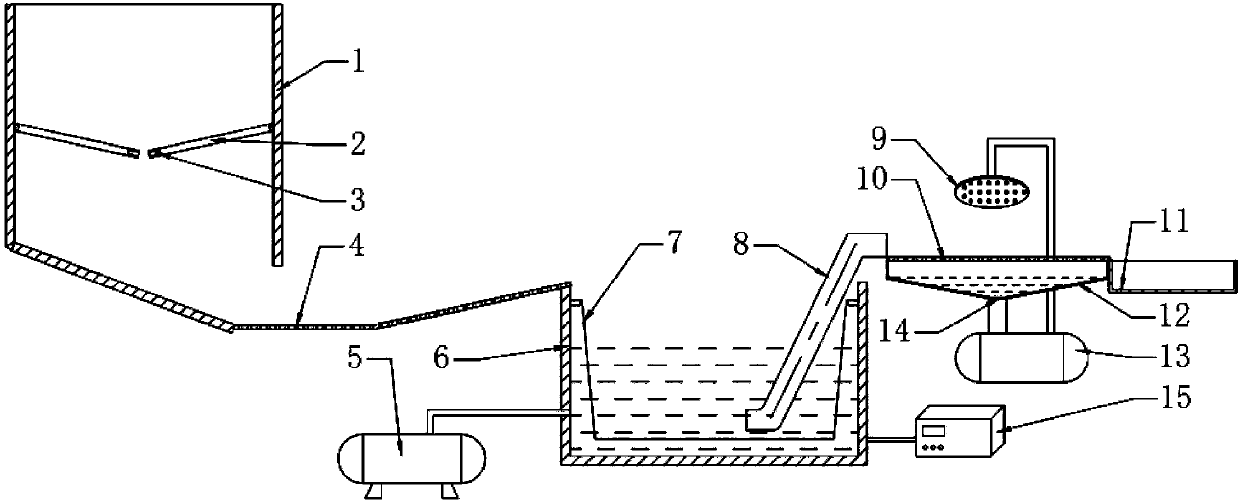

[0022] Combine below figure 1 The present invention will be described in detail.

[0023] An automatic feeding ultrasonic decontamination equipment, including an automatic feeder 1, a pair of openable and closable weighing plates 2 are installed in the automatic feeder, and the outlet below the automatic feeder 1 is provided with The first conveyor belt 4, the discharge end of the first conveyor belt 4 is equipped with a decontamination tank 6, which is characterized in that a raw material basket 7 with a distance between the bottom and the bottom of the decontamination tank 6 is installed in the decontamination tank 6 , the lower right side of the decontamination tank 6 is connected with an ultrasonic generator 15, the lower left side of the decontamination tank 6 is connected with an air pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com