Patents

Literature

177results about How to "Automate work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

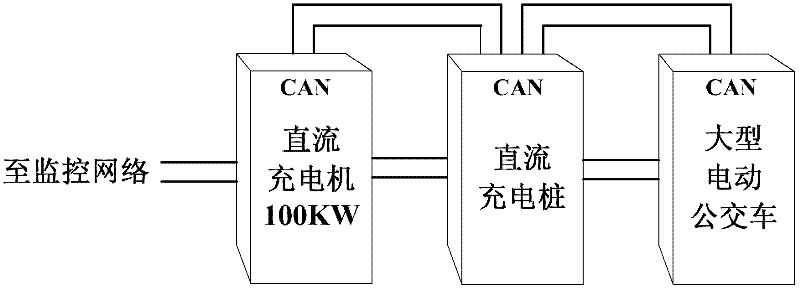

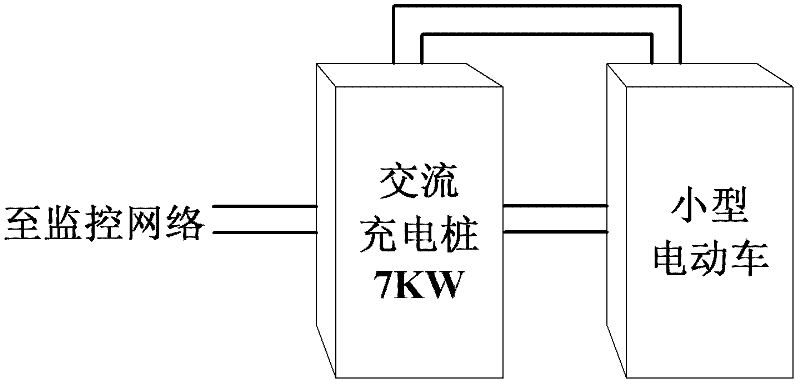

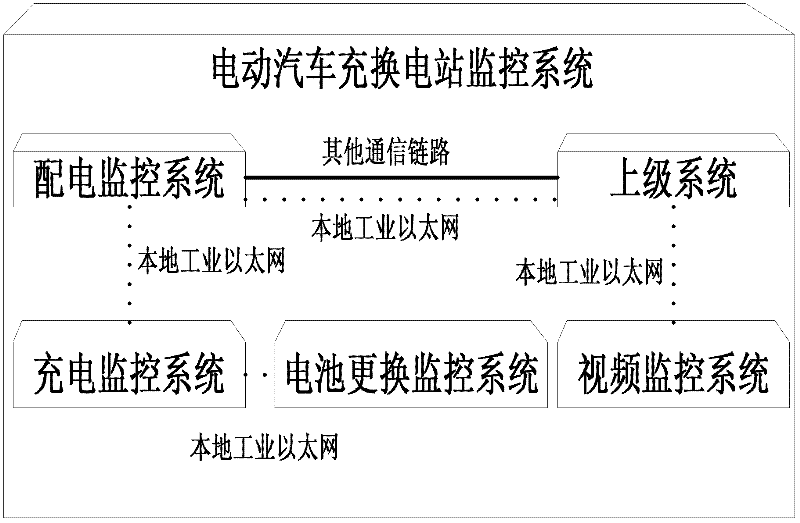

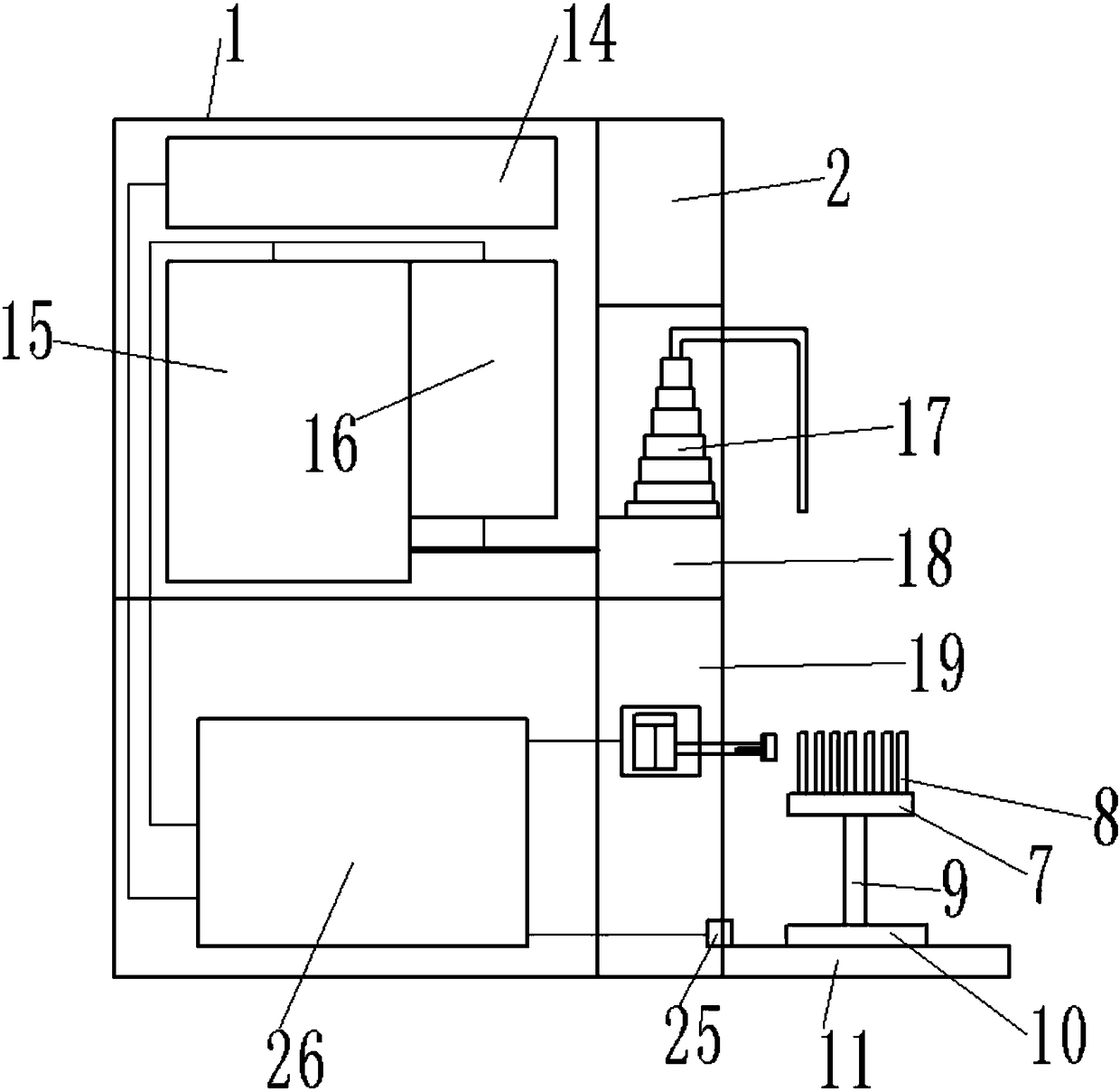

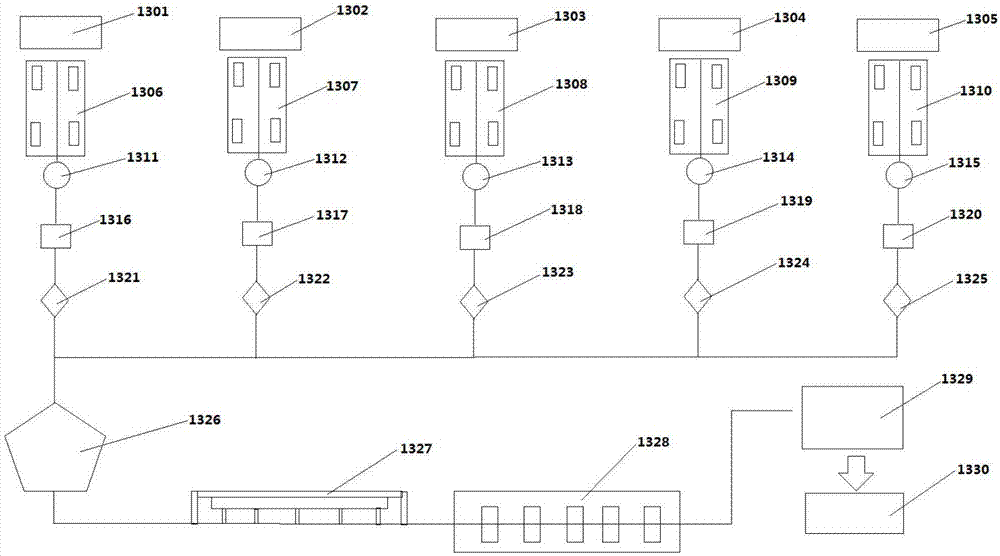

Monitoring system for electric automobile battery charging and replacing station

InactiveCN102315677ASolve the monitoring problem of compatible charging and swapping of large and small carsMeet the requirementsBatteries circuit arrangementsClosed circuit television systemsVideo monitoringDistribution power system

The invention relates to a monitoring system for an electric automobile battery charging and replacing station. The system comprises a superior system, an electricity distribution monitoring system, a charging monitoring system, a battery replacement monitoring system and a video monitoring system; a monitoring work station, a server, a printer, an electricity distribution system communication management machine and an electricity utilization information collecting terminal are connected with a network exchanger of the charging monitoring system through a local industrial Ethernet; a network exchanger of the electricity distribution monitoring system is connected with a communication gateway of the superior system through the local industrial Ethernet; an intelligent communication terminal of the battery replacement monitoring system is connected with the network exchanger of the charging monitoring system through the local industrial Ethernet; and a video server of the video monitoring system is connected with the communication gateway of the superior system through the local industrial Ethernet. The system can meet the requirement of electric energy complement of large commercial vehicles and small passenger vehicles and can realize omnibearing, effective and real-time monitoring on the battery charging and replacing of electric automobiles.

Owner:CHINA ELECTRIC POWER RES INST +1

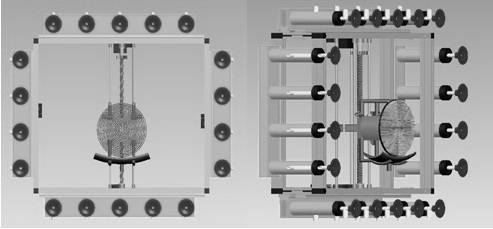

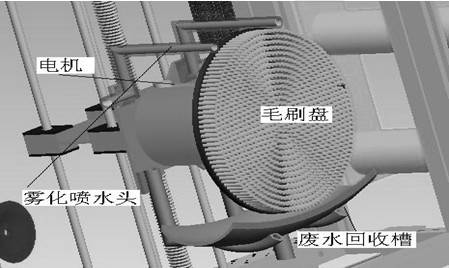

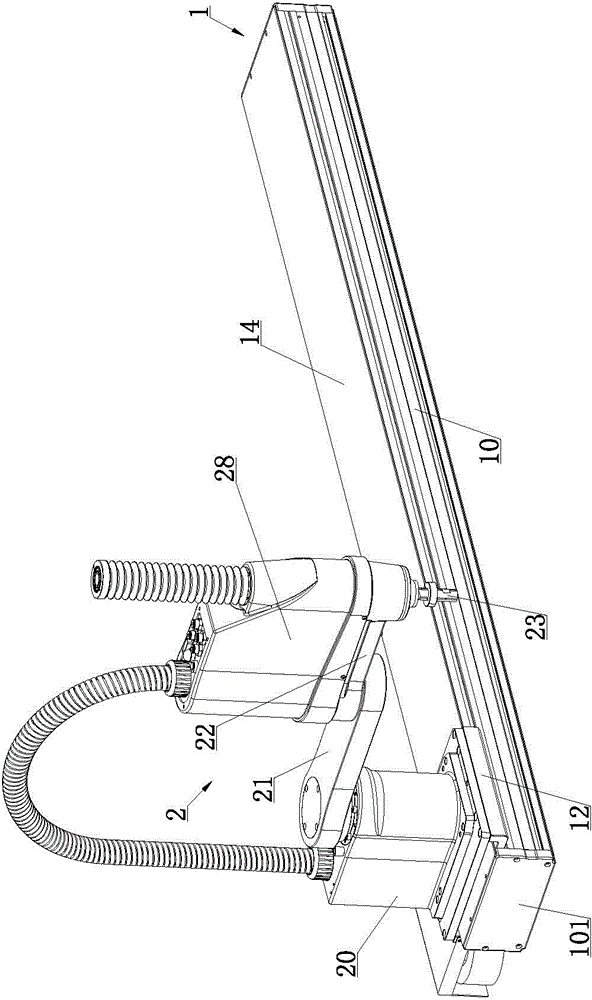

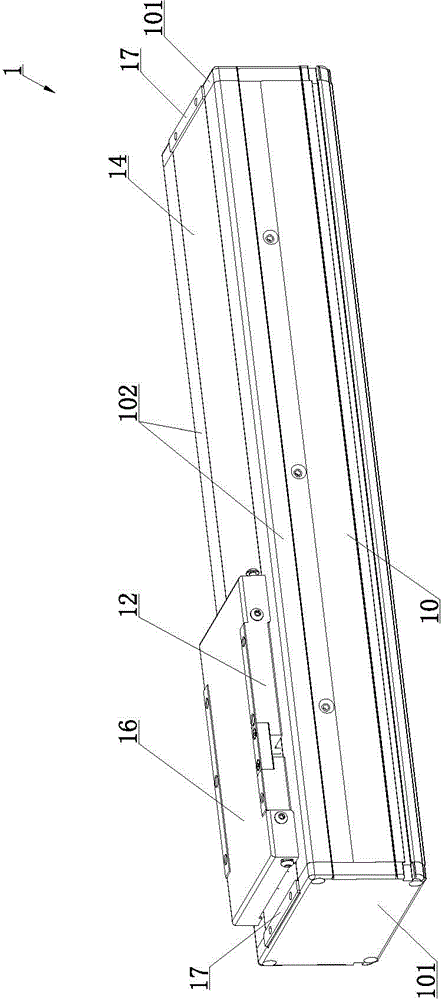

Automated glass scrubber

InactiveCN102657492AReduce quality problemsReduce riskWindow cleanersReciprocating motionAgricultural engineering

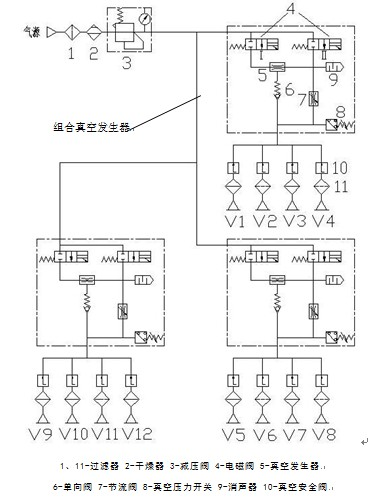

The applied invention relates to research and design of an automated glass scrubber and belongs to an environmentally-friendly glass scrubber device. By changing the traditional cleaning way, automation of work is realized, and the labor intensity of manpower and the risk degree of high-altitude work are reduced. The device adopts a framework and guide track type structure, and a framework can be spliced to be suitable for glass in different areas. Pneumatic powerful sucking discs are arranged on the periphery of the framework for fixing the framework, and a rotatable scrubbing mechanism is arranged at the middle of the framework. A water fog spray nozzle, a rotary brush and a rubber scraping strip are arranged from top to bottom, wherein the spray nozzle is used for spraying an atomized washing liquid, the brush can plays a powerful cleaning role, and the rubber scraping strip below the brush is close to the glass for scraping off the washing liquid on the glass. The mechanical can perform regular reciprocating motion in the framework for realizing repeated scrubbing. The whole process is controlled by a program set in an intelligent interface board, no-man control is realized, and the degree of automation is higher.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

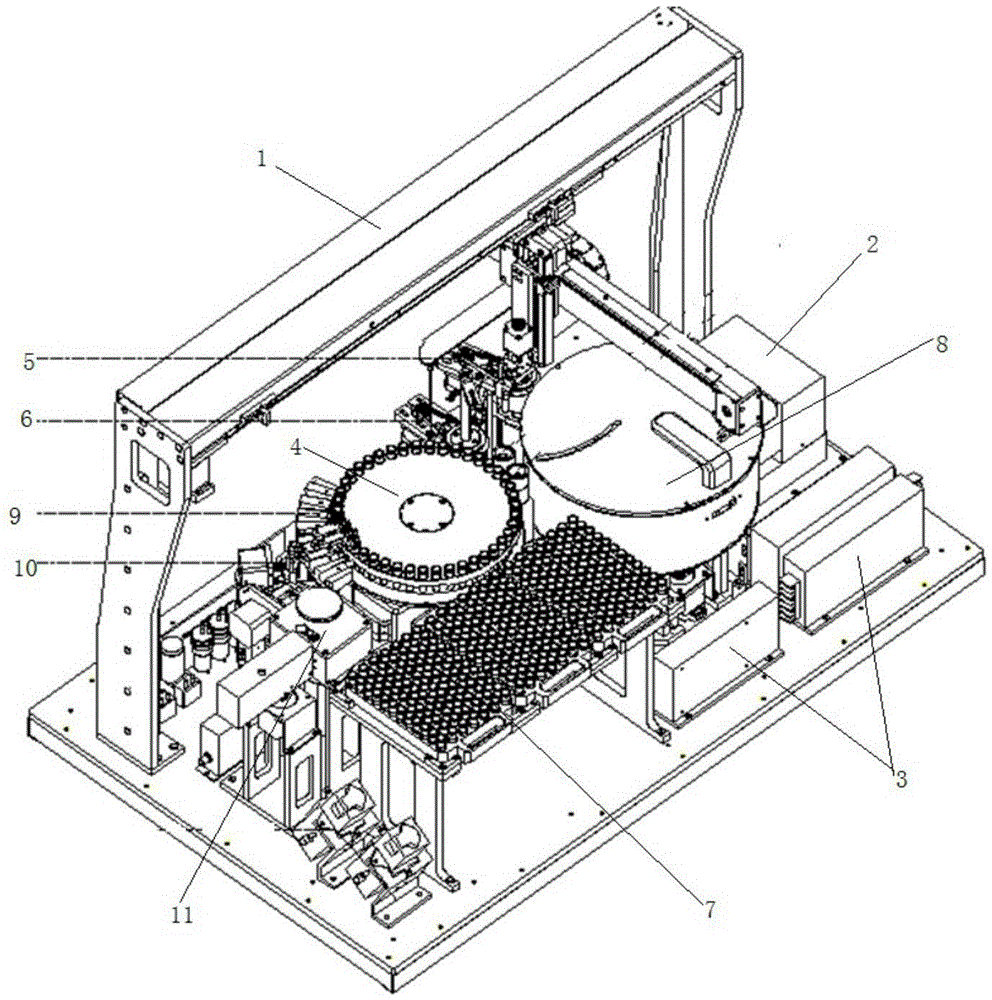

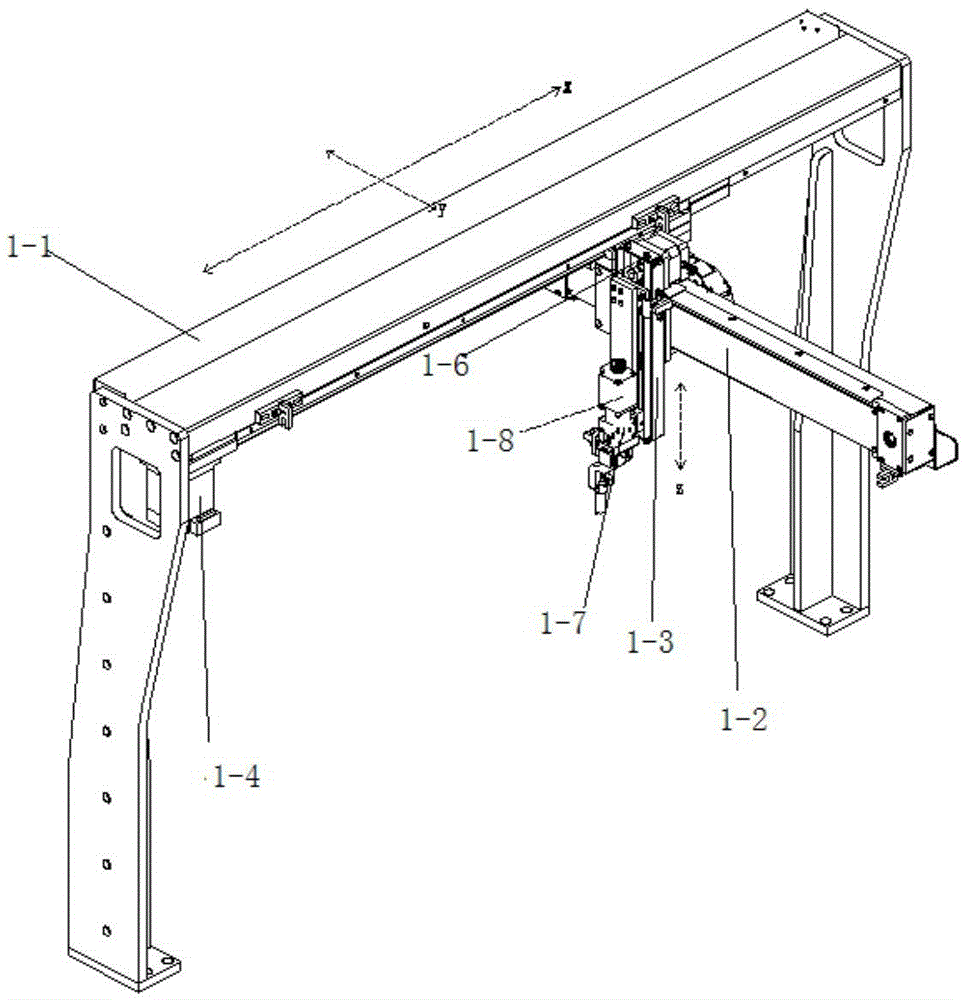

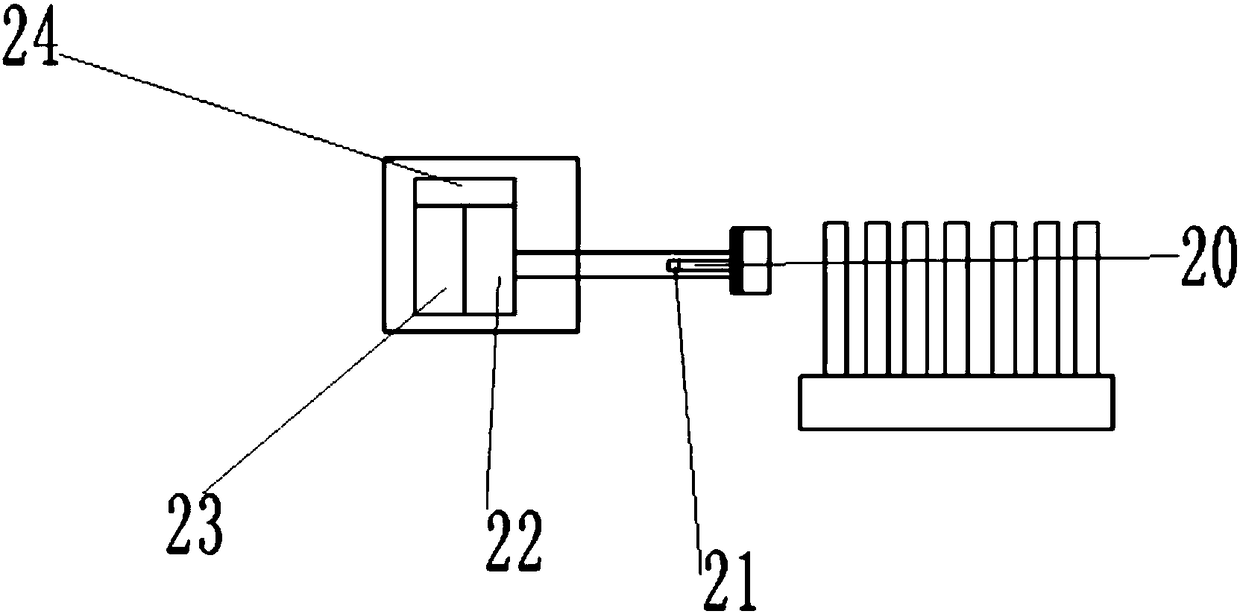

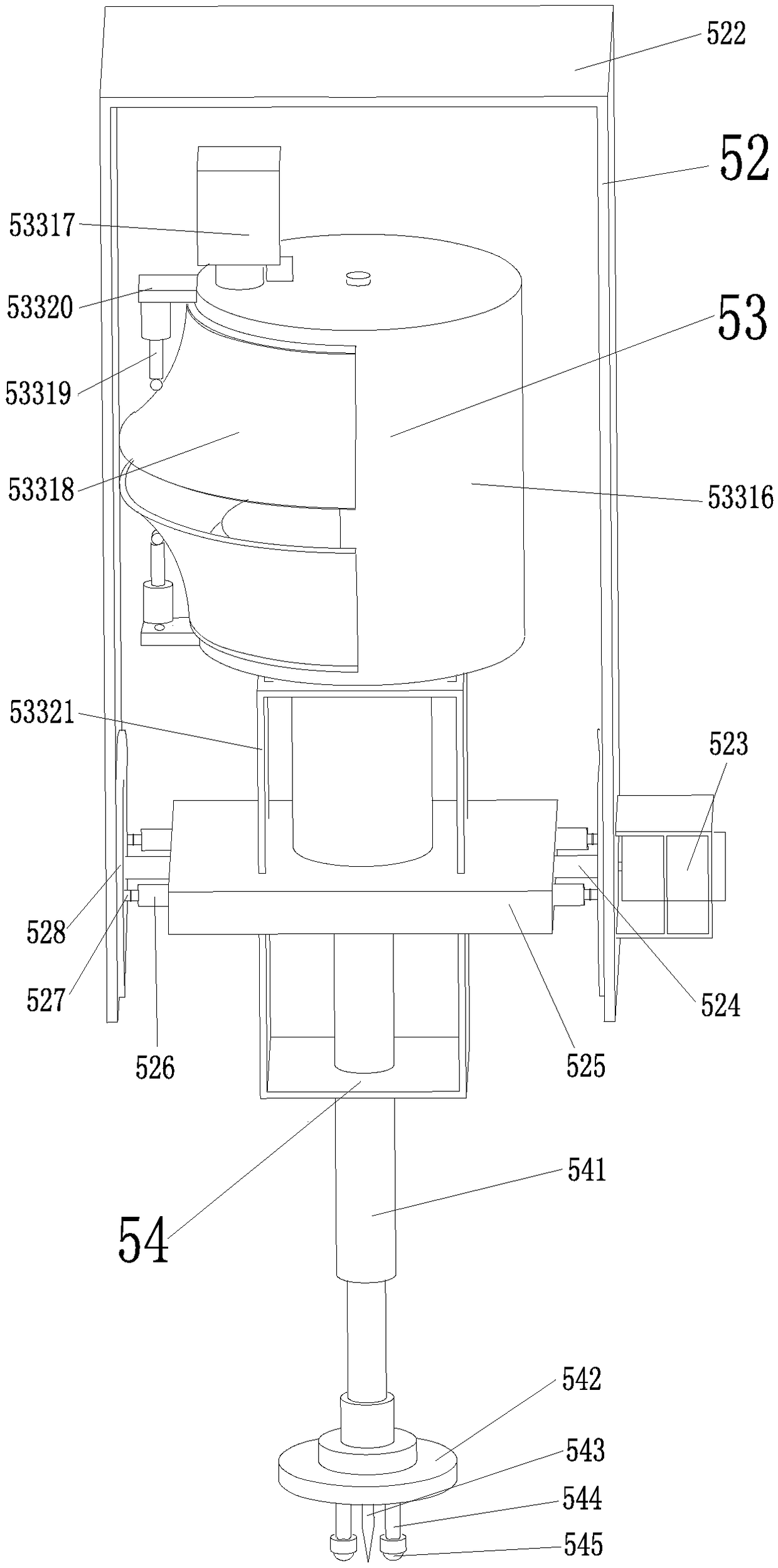

Full-automatic chemiluminiscence tester

ActiveCN105628687AImprove detection efficiencyAvoid errorsChemiluminescene/bioluminescenceEngineeringRefrigeration

The invention discloses a full-automatic chemiluminiscence tester and belongs to the field of chemiluminiscence testing.The full-automatic chemiluminiscence tester comprises a mechanical arm module, a refrigeration module, a power module, a reagent sample disk, a sampling needle component, a stirring component, a reaction cup frame, an incubation device, a magnetic separation component, a washing station component and a measuring room.Full-automatic management is achieved for mixing, reacting, incubating, magnetic separating, detecting and other procedures of a sample to be tested, the detection efficiency is improved, and operation errors are reduced.

Owner:NANJING NORMAN BIOLOGICAL TECH

Beancurd billet automatic production system

InactiveCN102018178ALow costReduce manufacturing costCheese manufactureFood shapingManufacturing engineeringCircular disc

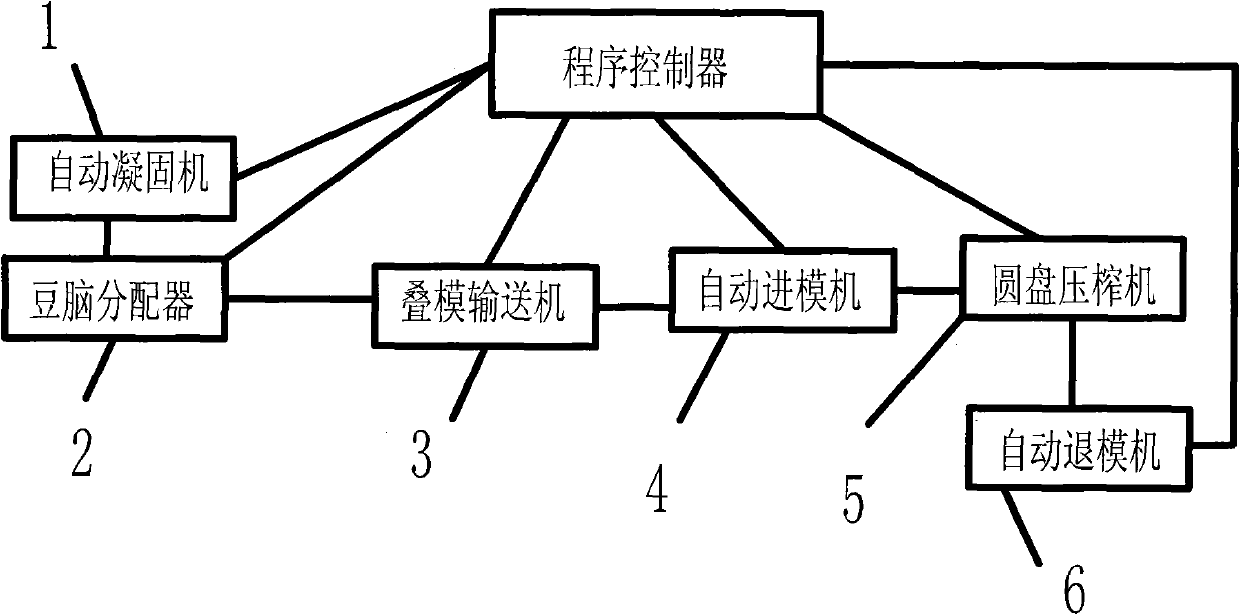

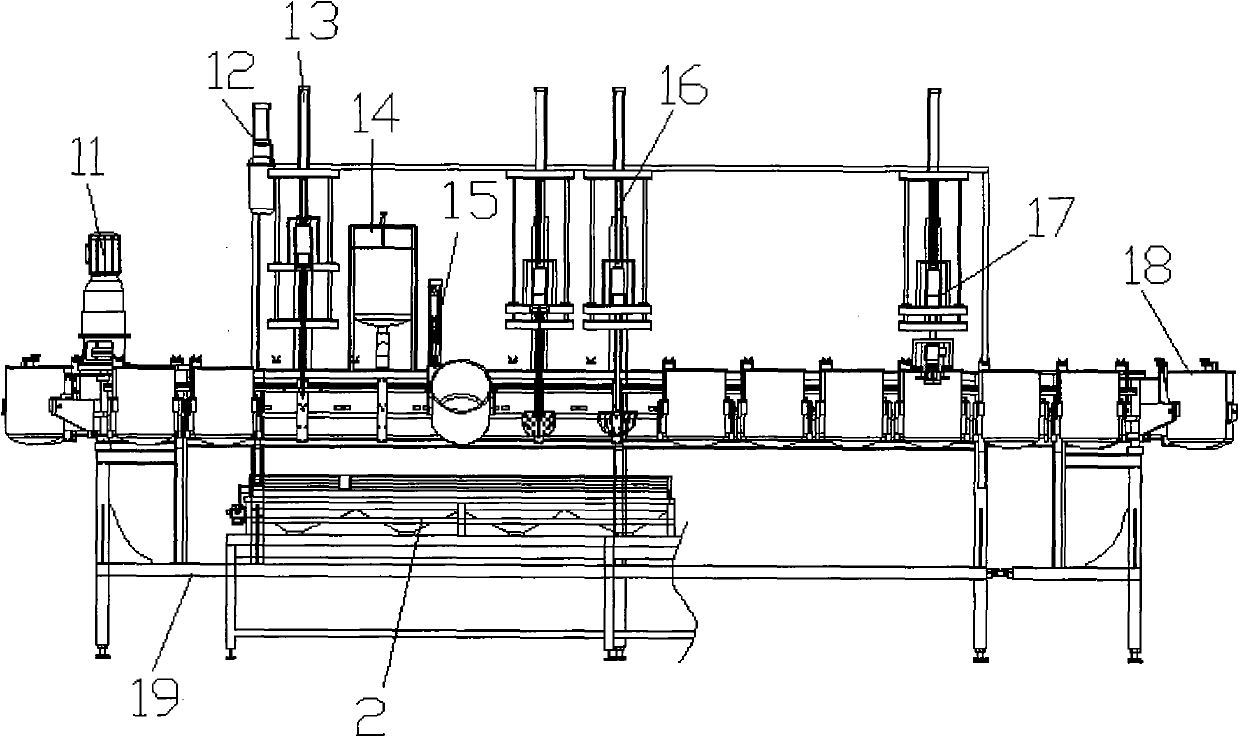

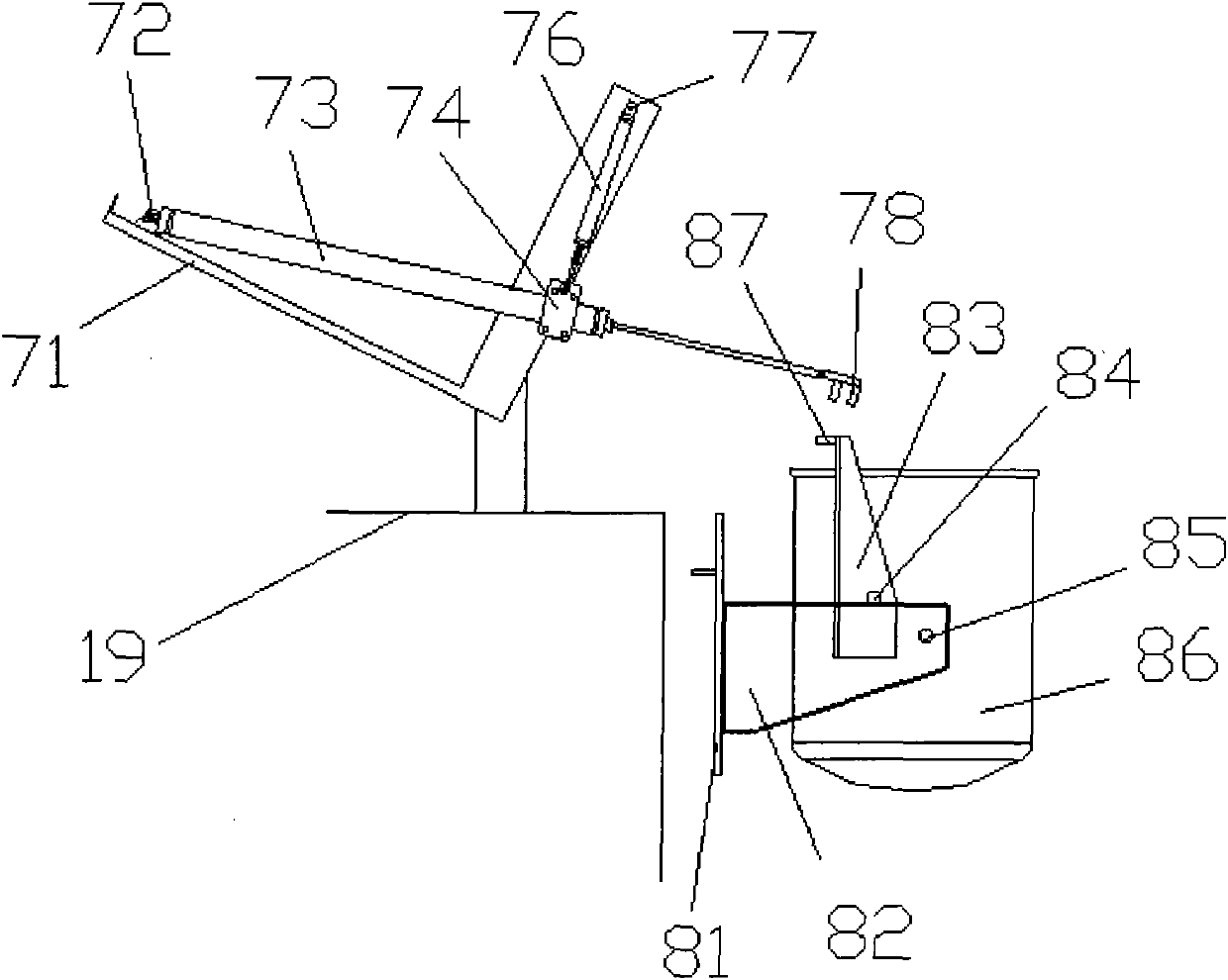

The invention discloses a beancurd billet automatic production system which comprises an automatic congealing machine, an uncongealed beancurd distributor, a stack mold conveyer, an automatic mold feeder, a disc squeezer, an automatic mold discharging machine and a program controller, wherein the uncongealed beancurd distributor is arranged below the automatic congealing machine, the uncongealed beancurd distributor and the automatic mold feeder are arranged at two ends of the stack mold conveyer, the automatic mold feeder and the automatic mold discharging machine are arranged at the periphery of the disc squeezer, and the automatic congealing machine, the uncongealed beancurd distributor, the stack mold conveyer, the automatic mold feeder, the disc squeezer and the automatic mold discharging machine are all connected with the program controller. Under the control of the program controller, the beancurd billet automatic production system realizes automated and continuous working process without manual operation, thereby reducing labor cost and production cost, greatly improving production efficiency and sanitary conditions; moreover, the process flow of the beancurd billet automatic production system can be set in advance according to different kinds of bean products and different production processes.

Owner:BEIJING LUOKE MACHINERY

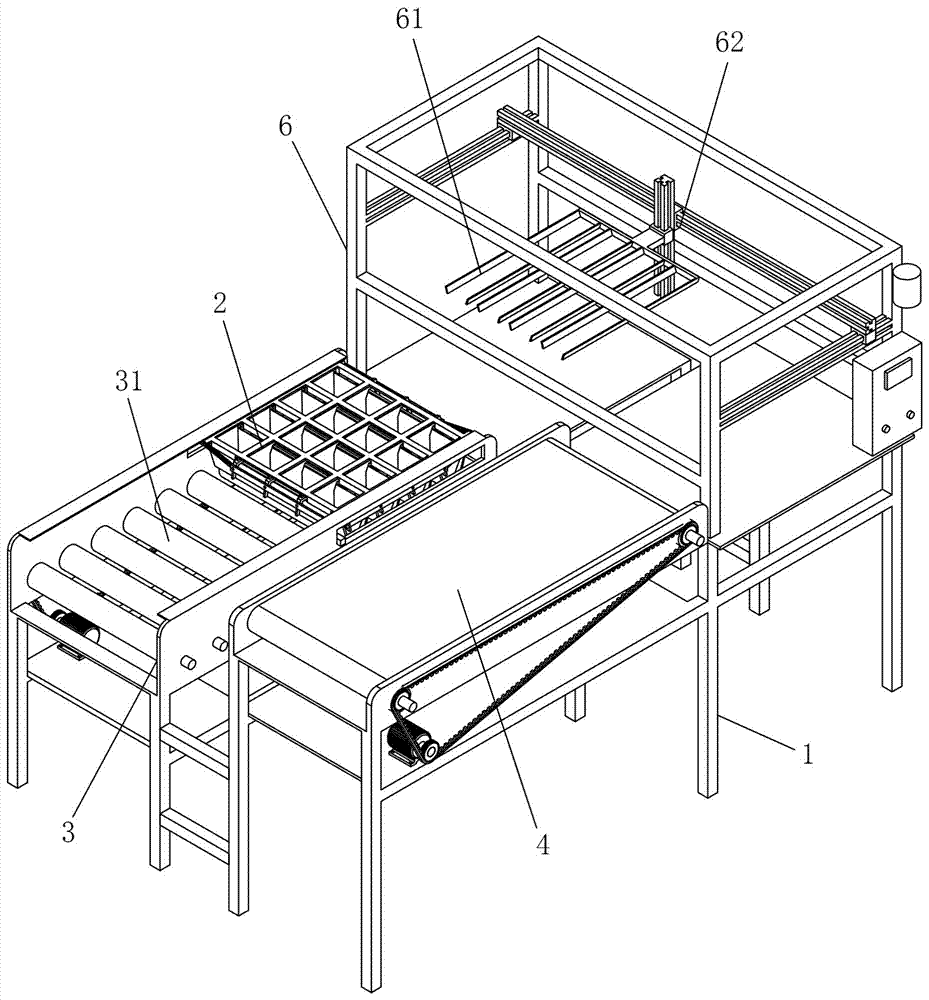

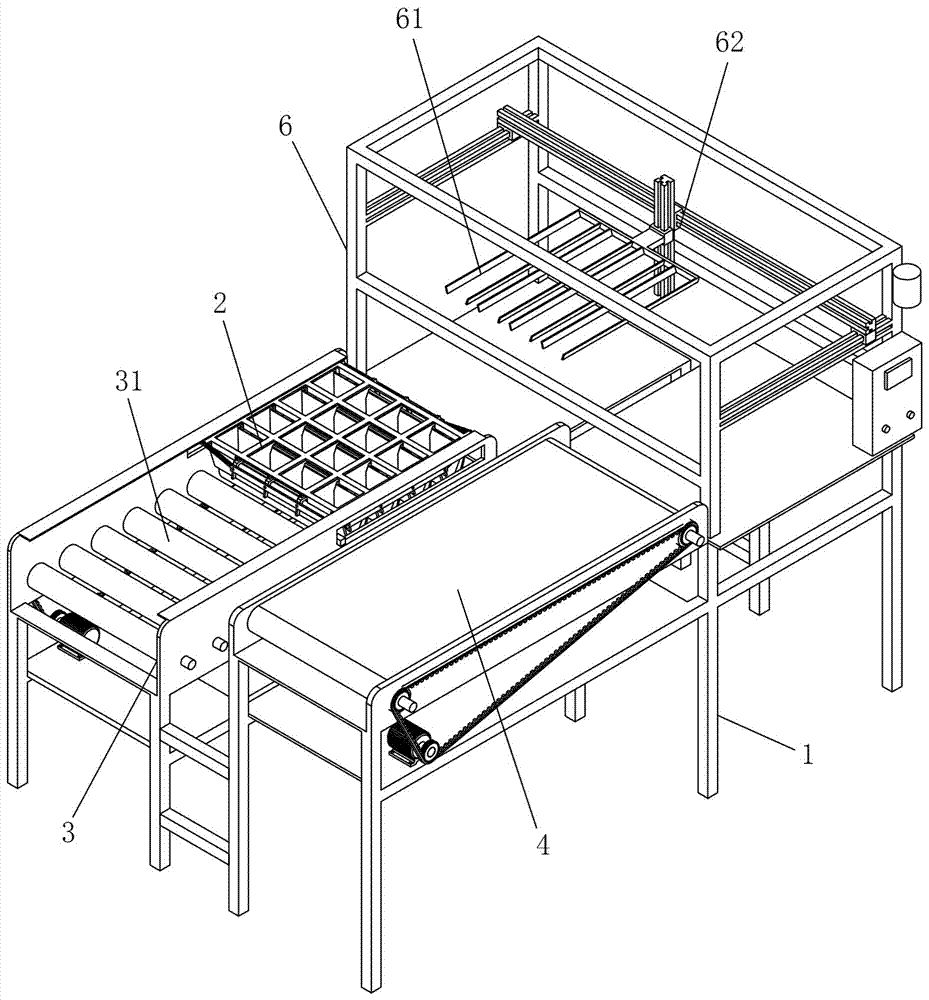

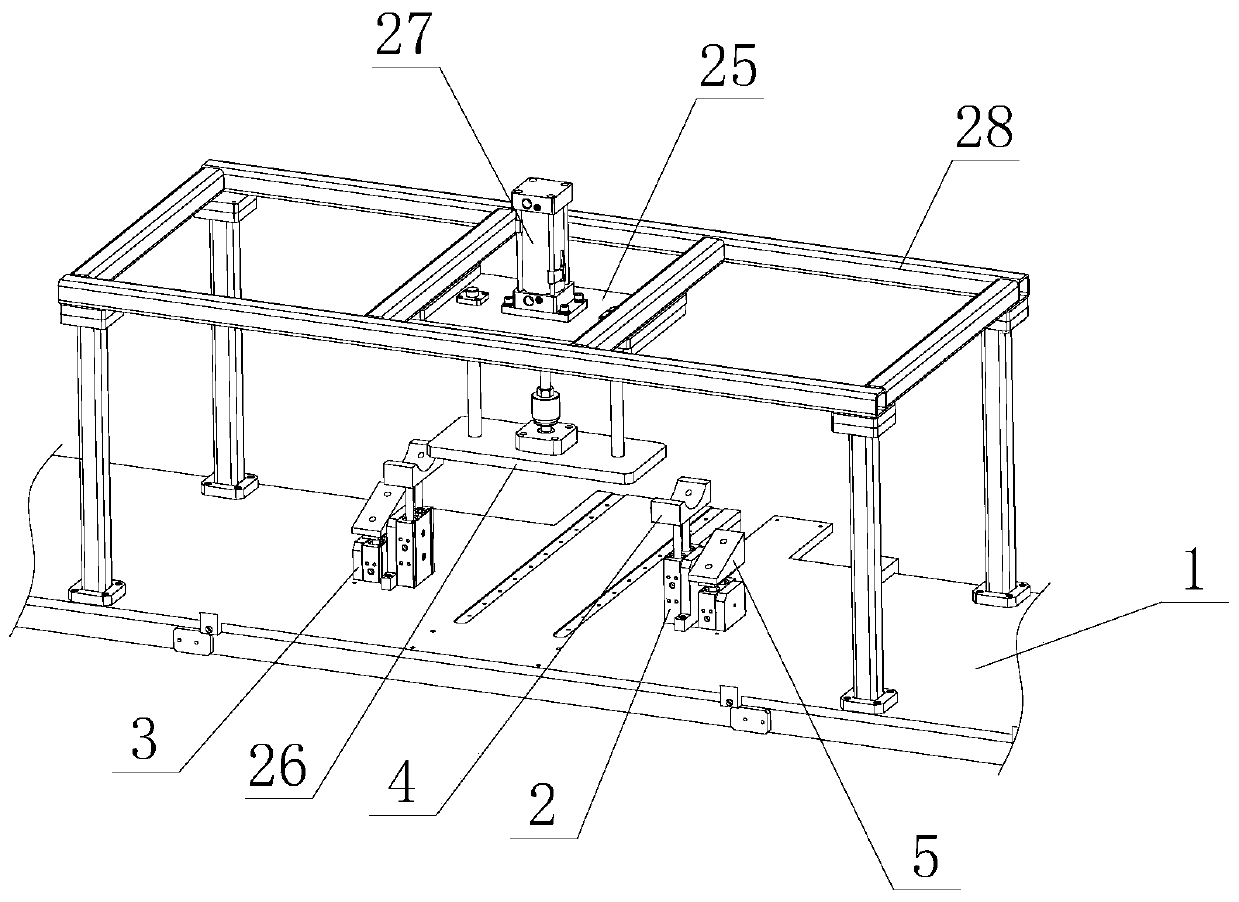

Pot seedling taking and transmitting device

ActiveCN106973600AReduce manual labor intensityImprove transplanting efficiencyTransplantingEngineering

The invention discloses a pot seedling taking and transmitting device, which comprises a rack and a seedling disc having a plurality of through hole-type pot holes; the rack is provided with a seedling disc input mechanism for transmitting the seedling disc and a pot seedling output mechanism for transmitting the pot seedling; a seedling ejecting mechanism is disposed below the seedling disc input mechanism for ejecting the pot seedling out of the pot holes; and a pot seedling delivery mechanism is further mounted on the rack for delivering the ejected pot seedling to the pot seedling output mechanism. The pot seedling taking and transmitting device can perform automatic seedling taking and transmitting, reduce manual labor intensity, and improve transplanting efficiency.

Owner:HUNAN AGRICULTURAL UNIV

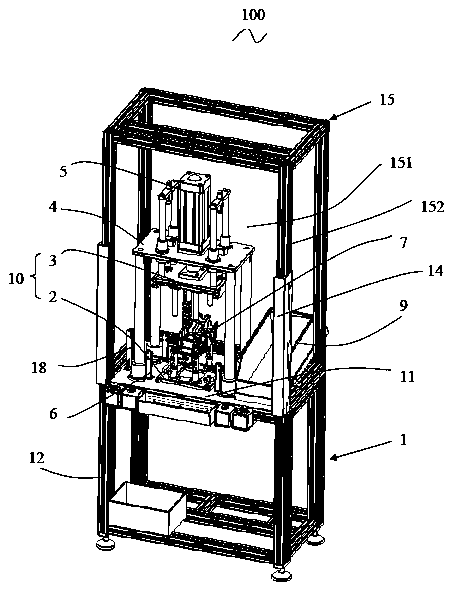

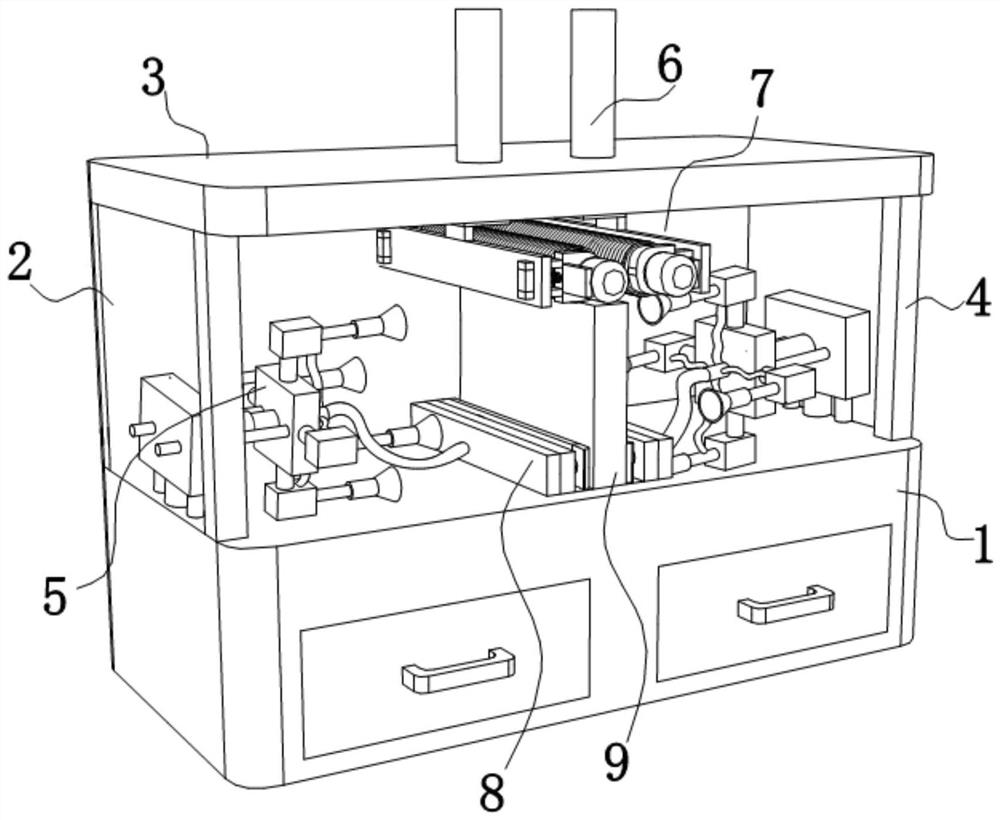

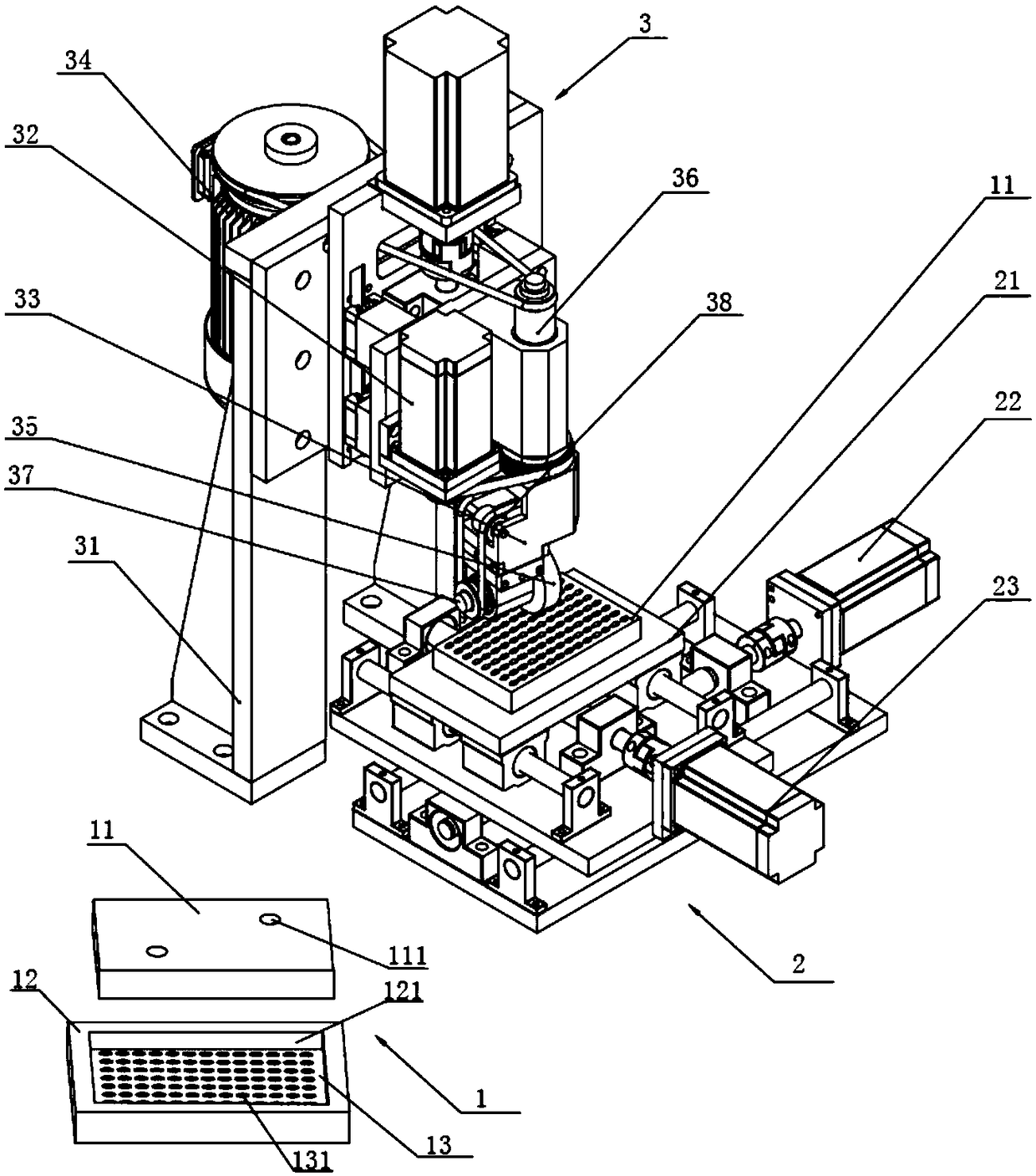

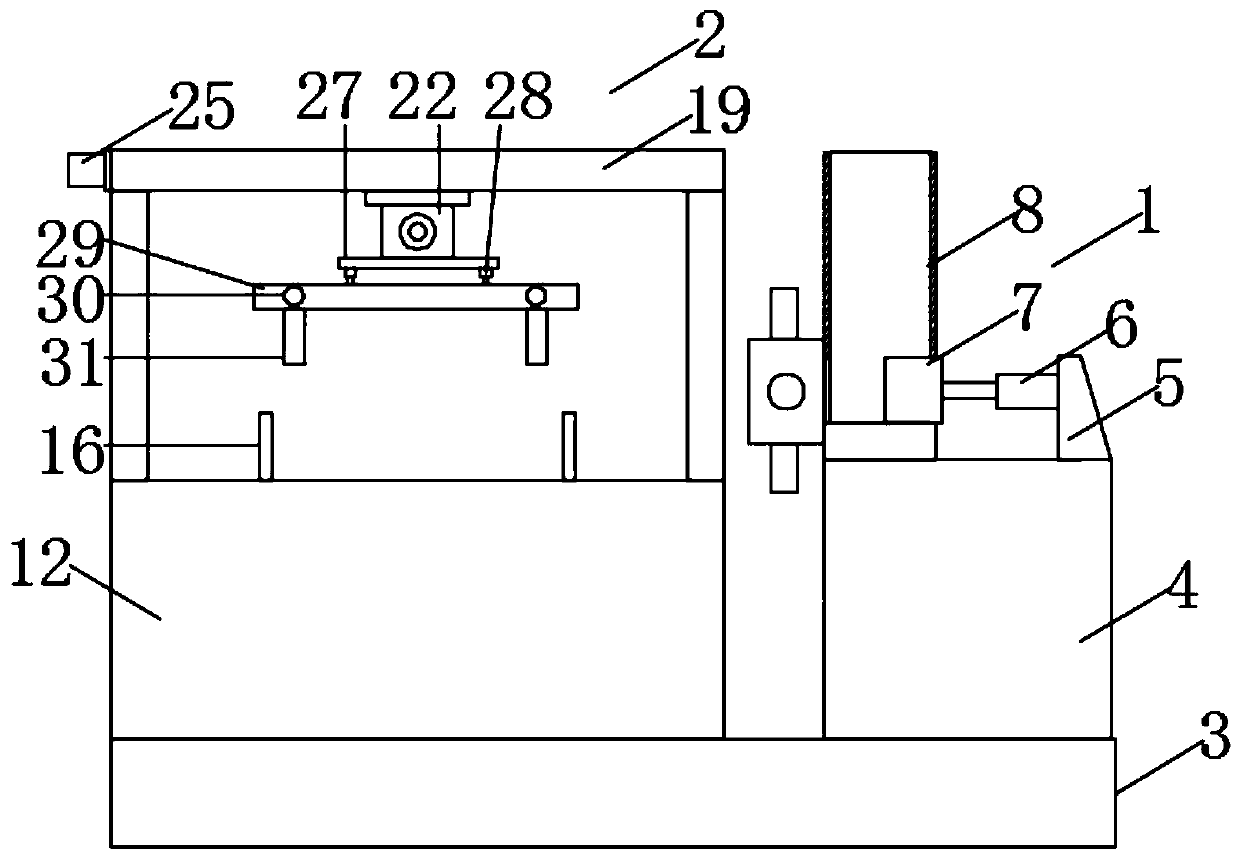

Shifter assembling device

InactiveCN103846650AFast and accurate press fitImprove the protective effectMetal working apparatusMetal-working hand toolsGratingMechanical engineering

The invention relates to a shifter assembling device. The shifter assembling device is used for pressing a bush inside a workpiece and comprises a workbench, a lower clamp arranged on the workbench, an upper clamp which is arranged above the lower clamp and matched with the lower clamp, an anti-leakage detecting device arranged on one side of the lower clamp, a workpiece detecting device for detecting the workpiece, a travel frame which is arranged on the workbench and used for fixing the upper clamp, a driving device which is arranged on the travel frame and used for driving the upper clamp to move vertically, a cover which is arranged on the workbench and encloses the upper clamp and the lower clamp, and a safe optical grating arranged on the cover. The lower clamp comprises a support column, an elastic piece arranged on the support column, a fastening column which is arranged on the elastic piece and used for fixing the bush, and a case which is arranged around the fastening column and used for fixing the workpiece, wherein the fastening column protrudes out of the case.

Owner:SIP GOLDWAY TECH

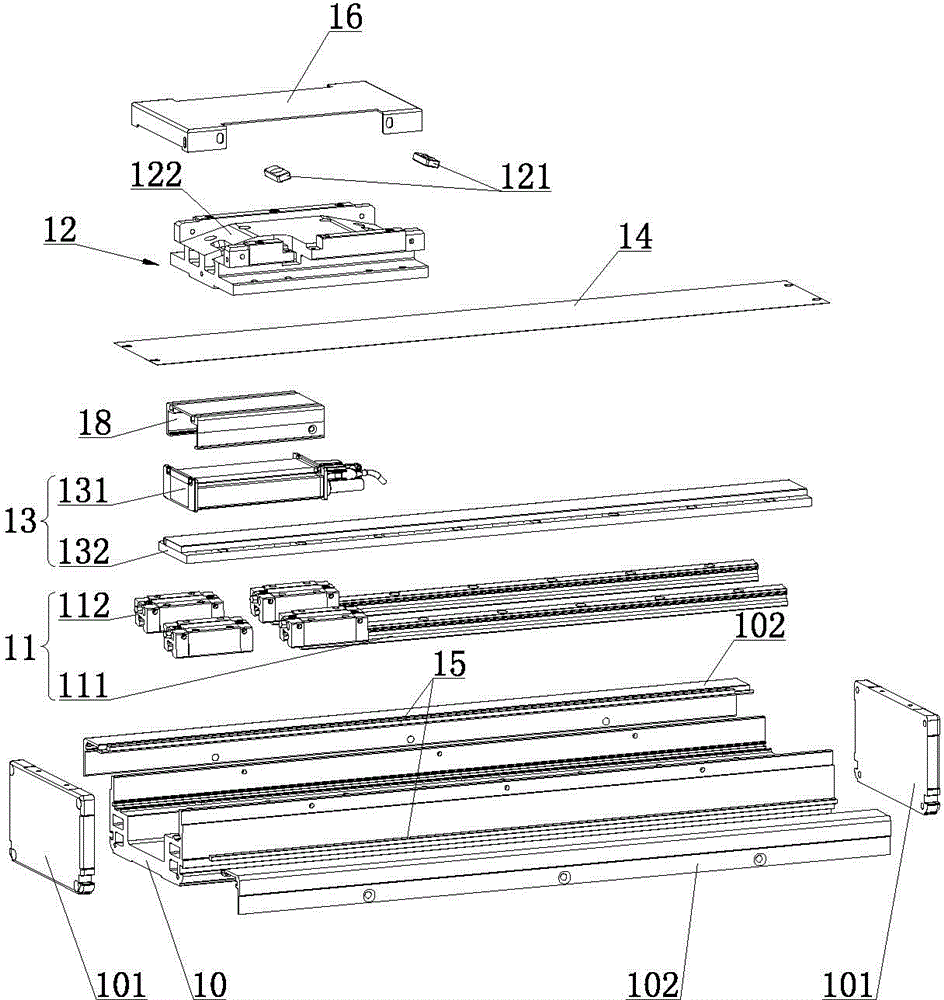

High-speed robot for production assembly line system

ActiveCN104440906AAutomate workProgramme-controlled manipulatorAssembly machinesPhysicsElectric machinery

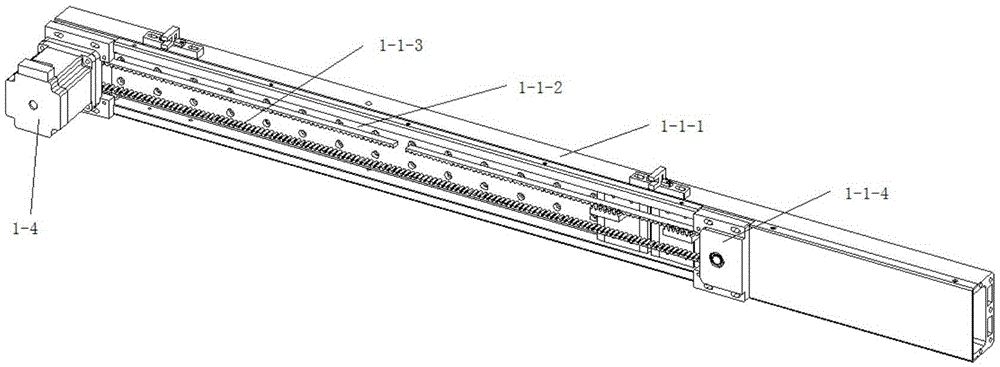

The invention relates to the field of robots, in particular to a high-speed robot for a production assembly line system. The high-speed robot comprises a single-axis mechanical hand, wherein the single-axis mechanical hand comprises a work sliding table and a linear motor for driving the work sliding table to move linearly, the work sliding table is connected with a four-axis mechanical hand, and the four-axis mechanical hand comprises a lead screw and a driving device for driving the lead screw to do four-freedom-degree motion. When the robot is applied to the flow production line, a clamp can be installed on the lead screw, and the four-axis mechanical hand controls the lead screw to do four-freedom-degree motion and can freely control an accessory clamped by the clamp to be assembled, put, taken and the like; the single-axis mechanical hand drives the whole four-axis mechanical hand to move linearly, the linear motor is used as the driving device for the single-axis mechanical hand and can efficiently and accurately control the work sliding table to move, then the work sliding table drives the whole four-axis mechanical hand to move, and therefore the automatic work of the whole flow production line is achieved.

Owner:东莞市智赢智能装备有限公司

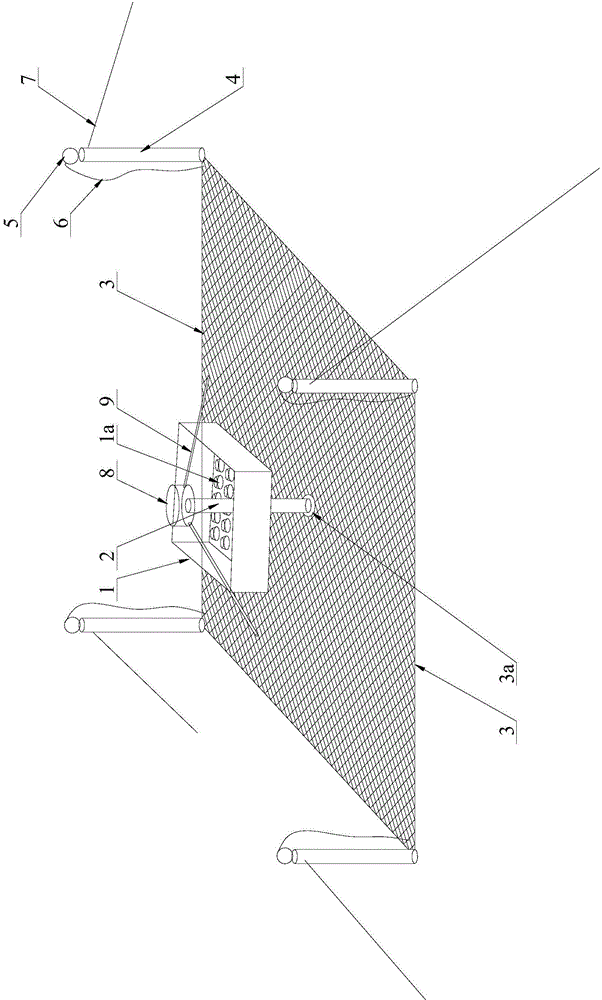

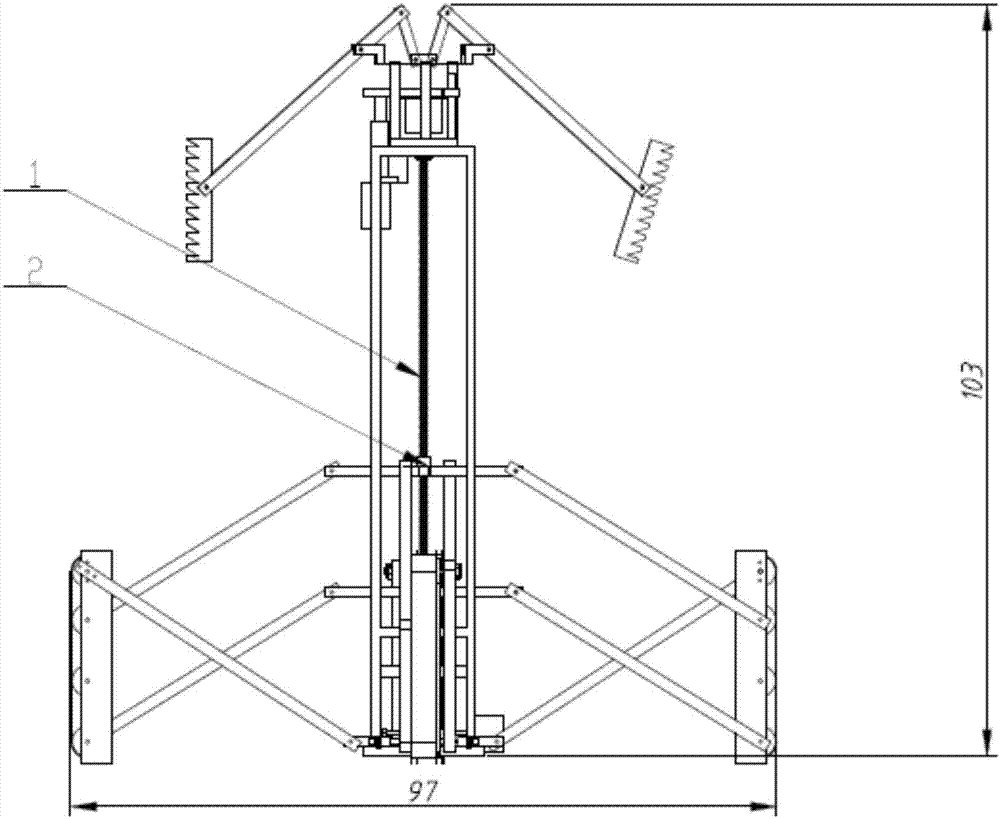

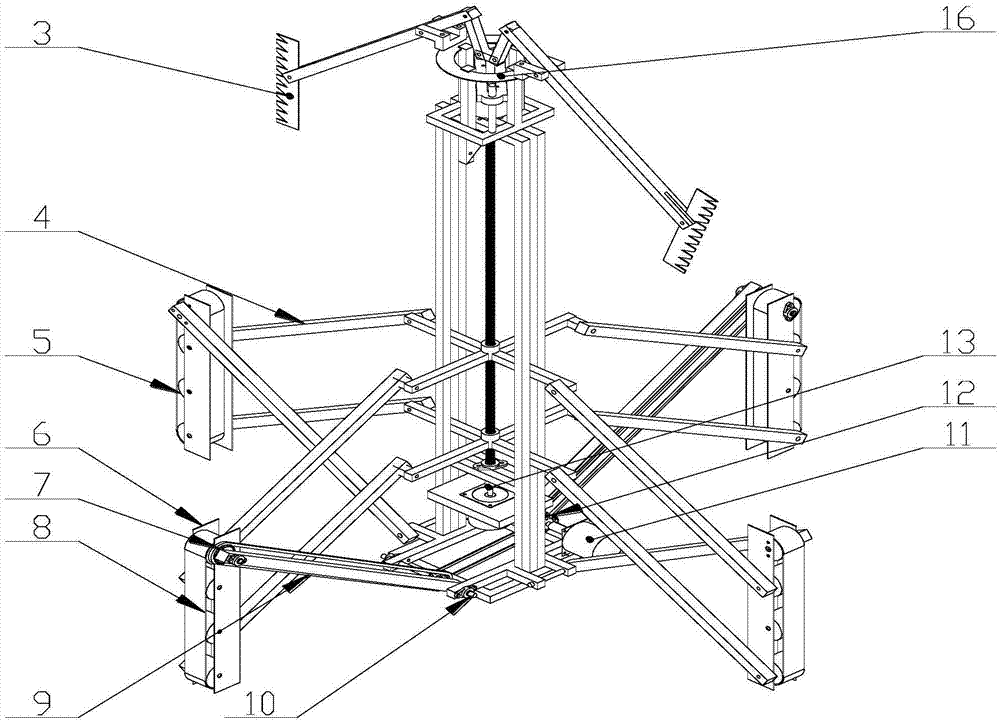

Fixation type automatic live fish gathering and catching device used for large water surface culturing

ActiveCN104604815AReduce human inputImprove harvesting efficiencyClimate change adaptationPisciculture and aquariaEngineeringWater area

The invention discloses a fixation type automatic live fish gathering and catching device used for large water surface culturing. The fixation type automatic live fish gathering and catching device comprises a fish gathering box, a center stand column, a net, a bait throwing system and a net expanding system. The center stand column is arranged in a culturing water region, the upper end of the center stand column penetrates out of the water surface, the fish gathering box is a box with an opening in the top and is provided with one-way channels through which live fishes enter the box, the fish gathering box is installed on the center stand column, the lower portion of the fish gathering box is soaked in water, the upper portion of the fish gathering box is located above the water surface, the net is provided with a center through hole, and the center stand column is sleeved with the center through hole in the net. The bait throwing system can throw baits into the water region where the net is located, and the net expanding system can drive the net to ascend or descend along the center stand column. The baits can be thrown through the bait throwing system so that the live fishes can enter the water region where the net is located; the net ascends through the net expanding system to force the live fishes to enter the fish gathering box through the one-way channels, the live fishes are gathered and caught, and the fixation type automatic live fish gathering and catching device is suitable for gathering and catching the cultured fishes on the large water surface in a quantitative mode, and guarantees the survival rate of the gathered and caught fishes.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Aluminum alloy metal part grinding and polishing device

ActiveCN112775777AEffectively fixedEasy to polishGrinding carriagesGrinding drivesStructural engineeringMechanical engineering

The invention belongs to the technical field of aluminum alloy machining equipment, and discloses an aluminum alloy metal part grinding and polishing device which comprises a grinding table and an aluminum alloy plate. Two symmetrically-distributed fixing assemblies are arranged at the top of the grinding table. Each fixing assembly comprises a first hydraulic rod, wherein the mounting end of the first hydraulic rod is arranged at the top of the grinding table, a fixing plate is arranged at the output end of the first hydraulic rod, a first electric telescopic rod is arranged on one side of the fixing plate, a first moving plate is arranged at the output end of the first electric telescopic rod, second electric telescopic rods are arranged on the end face of the periphery of the first moving plate, second moving plates are arranged at the other ends of the second electric telescopic rods, first air guide pipes are arranged at one ends of the second moving plates, and suckers are arranged at the other ends of the first air guide pipes. According to the aluminum alloy plate polishing device, through the arrangement of a polishing assembly, the fixing assemblies and a containing plate, the two side faces of an aluminum alloy plate can be ground at a time, the aluminum alloy plate can be ground and pre-cleaned, and the grinding precision is controlled.

Owner:JIANGXI DONGYANG ALUMINUM CO LTD

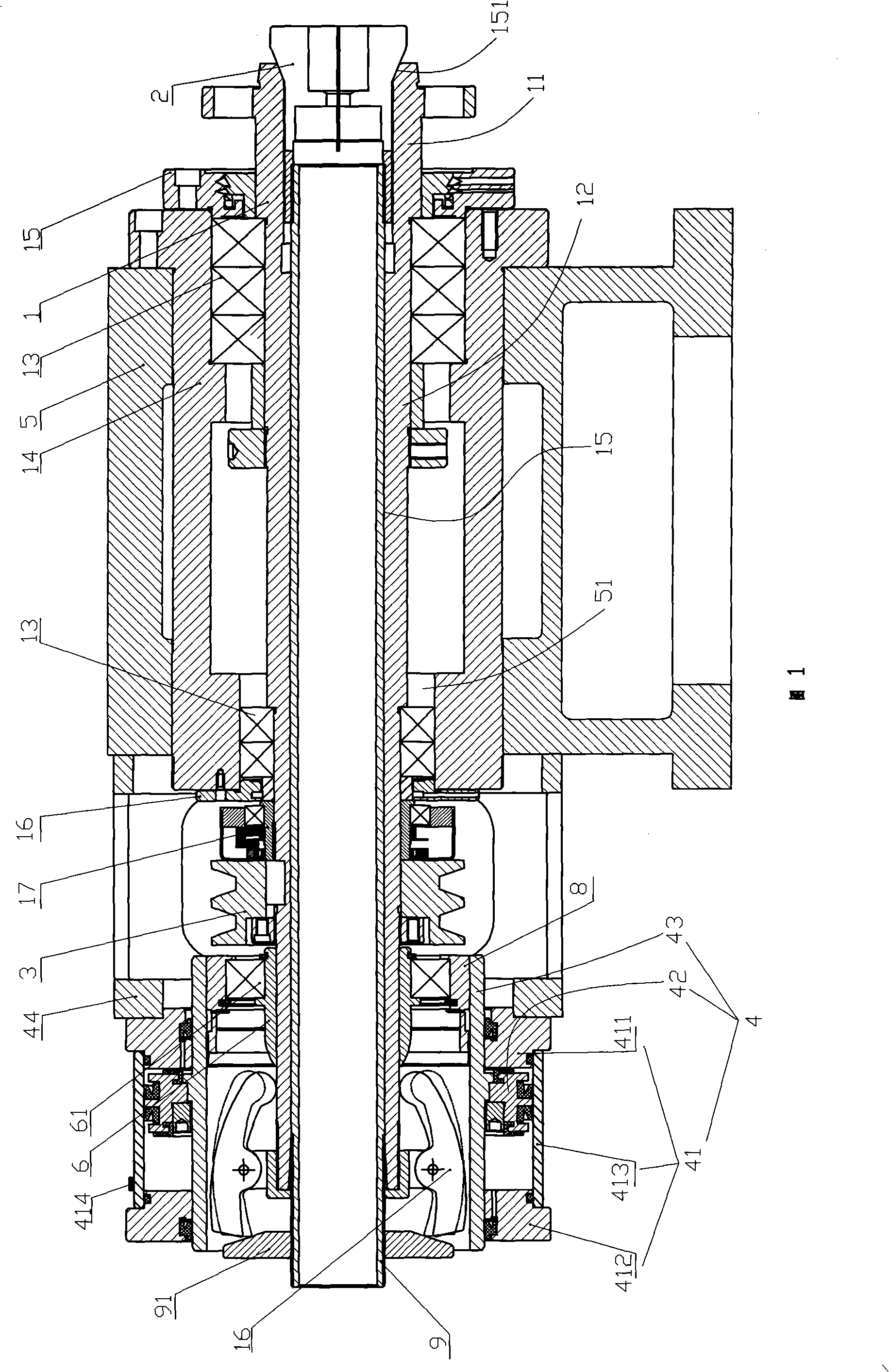

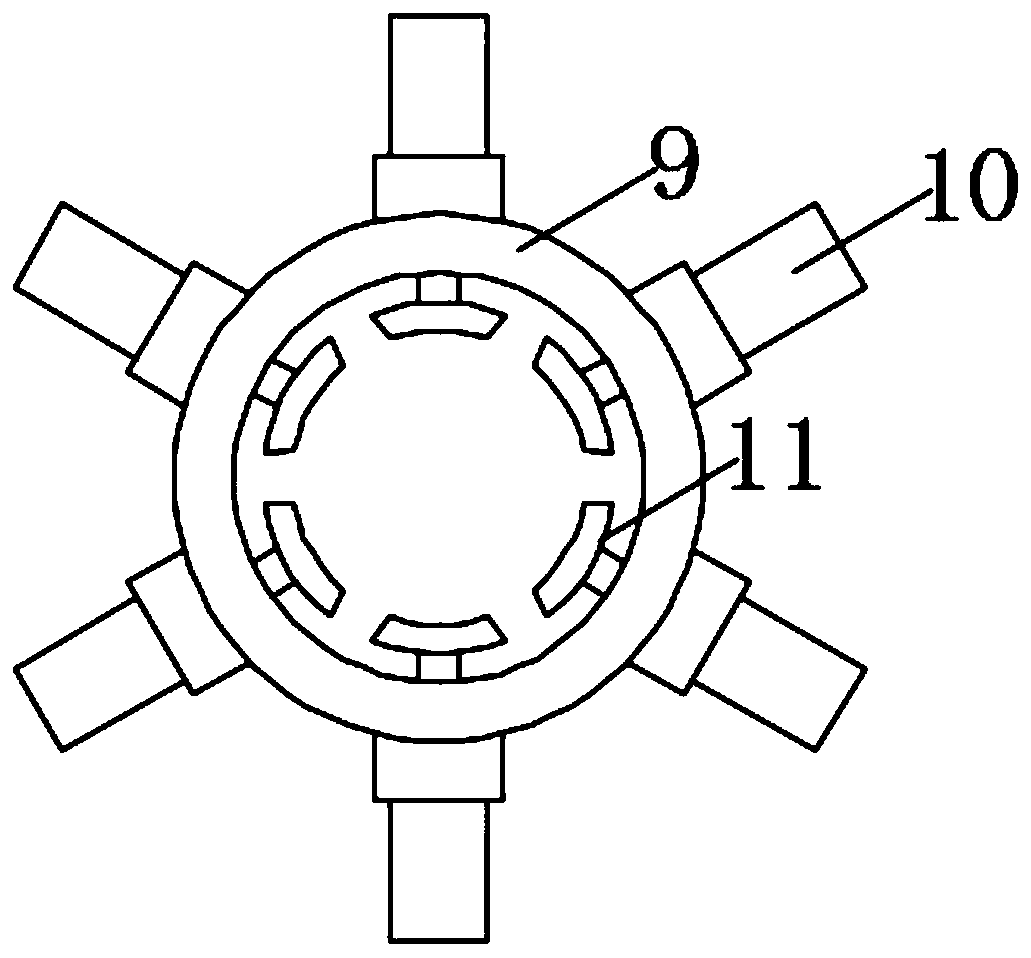

Intelligent clamping device of numerically controlled machine tool

InactiveCN101337328AAutomate workPositioning apparatusMetal-working holdersNumerical controlScrew thread

The invention discloses an intelligent clamping device of a numerical control machine tool. The entire device comprises a rotating main shaft, a clamping chuck, a belt pulley and a piston cylinder, wherein the rotating main shaft comprises a head and a body, wherein the front section of the body is movably connected with a shaft sleeve and positioned in a mounting hole of a tool head; the belt pulley is mounted at the middle section of the body of the main shaft; the rear section thereof is connected with the piston cylinder; an inner hole of the rotating main shaft is a straight through-hole; the clamping chuck is mounted in an opening at the front end of the straight through-hole; the rear part of the clamping chuck is connected with a pull pipe; the pull pipe extends from the inner hole of the main shaft backwards into the piston cylinder; an inclination disk is connectedly arranged at the tail end of the pull pipe; a three-jaw structure is arranged at the tail end of the rotating main shaft in a thread connection manner and can form a movable fit with the inclination disk. By structurally adopting the electromechanical integration design, the clamping device has the advantages of low manufacture cost, as well as convenient, practical, quick and labor-saving clamping of the clamping chuck; meanwhile, the clamping force can be directly measured in the clamping process, so that the clamping device is favorable for operators to use.

Owner:郭文龙

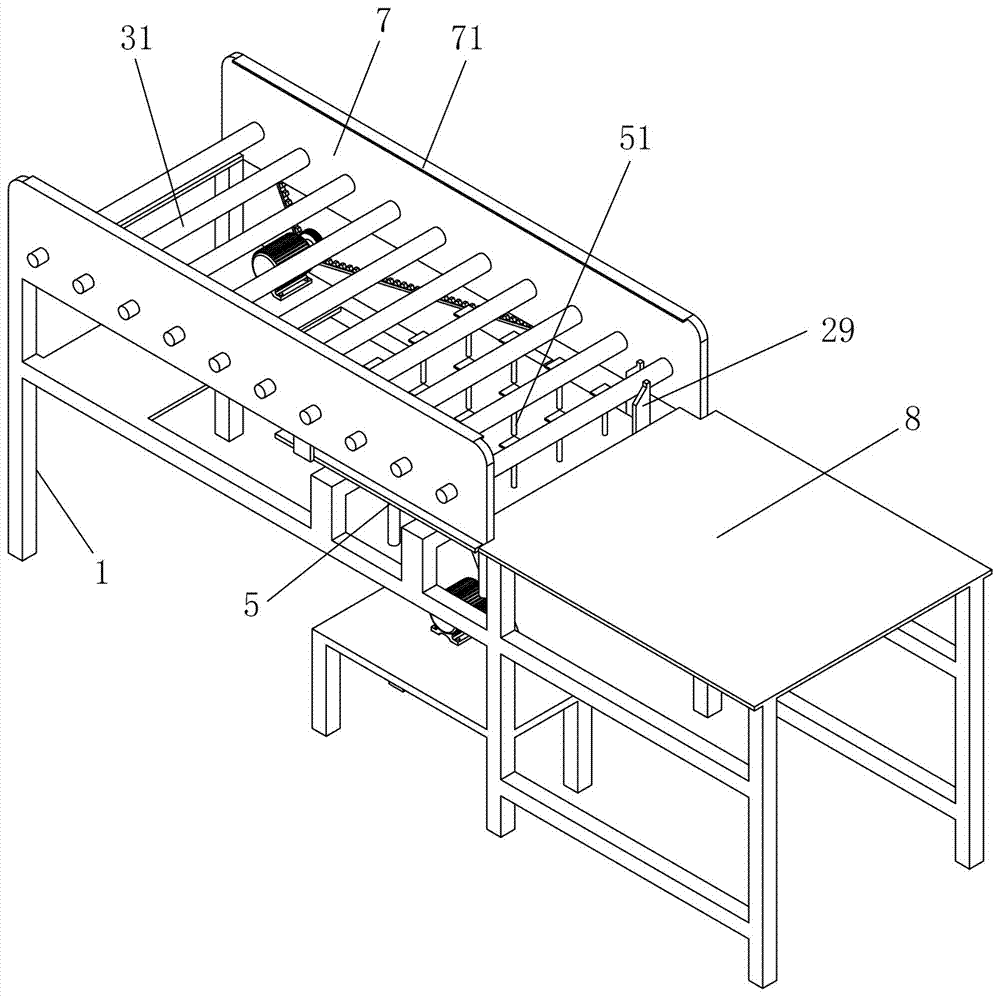

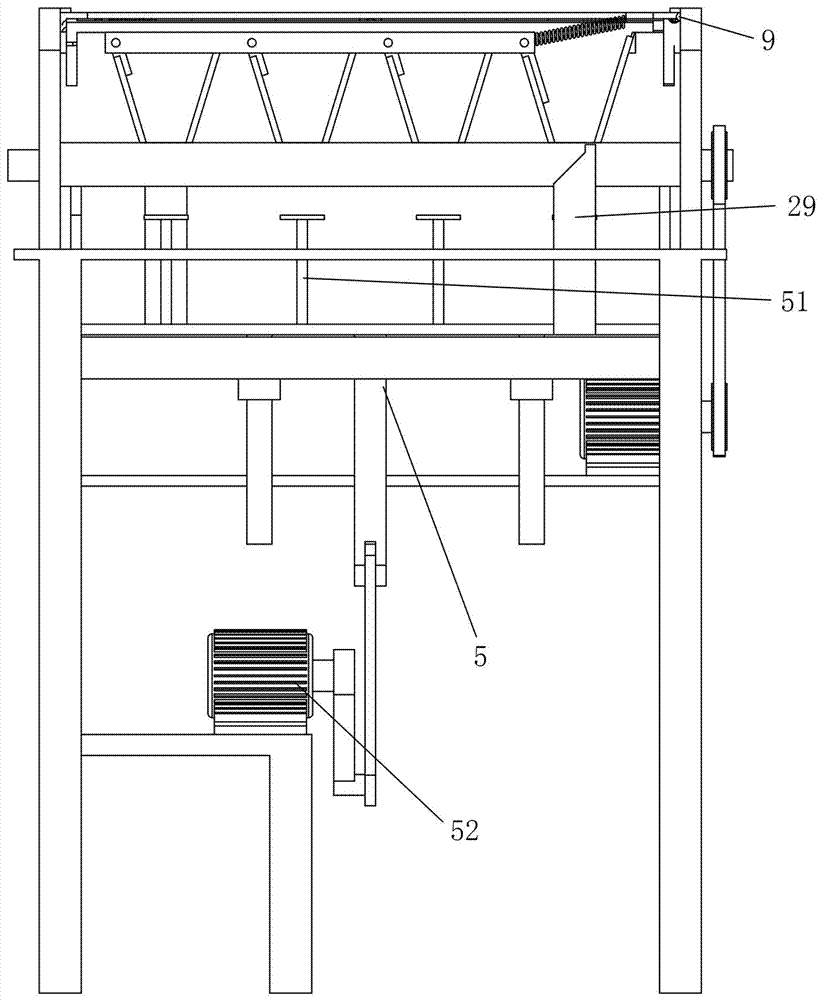

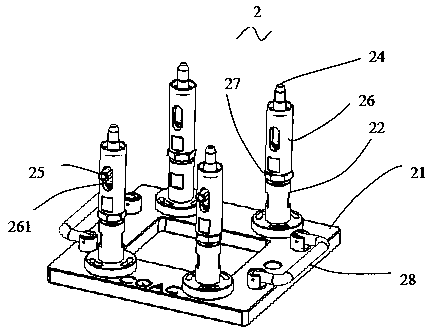

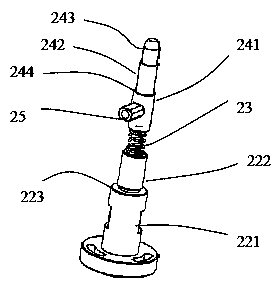

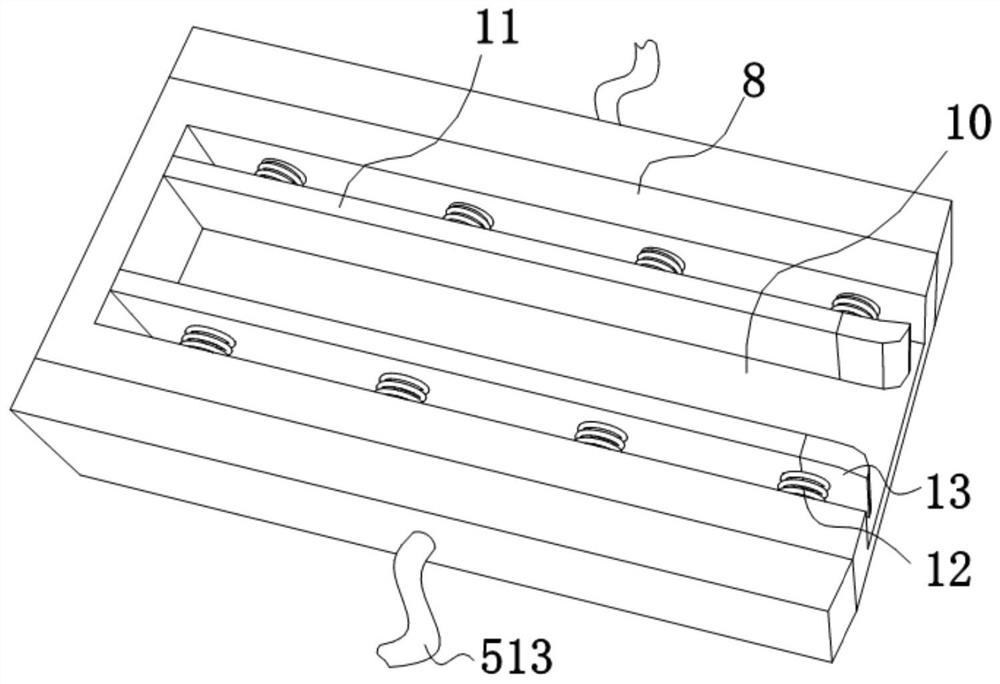

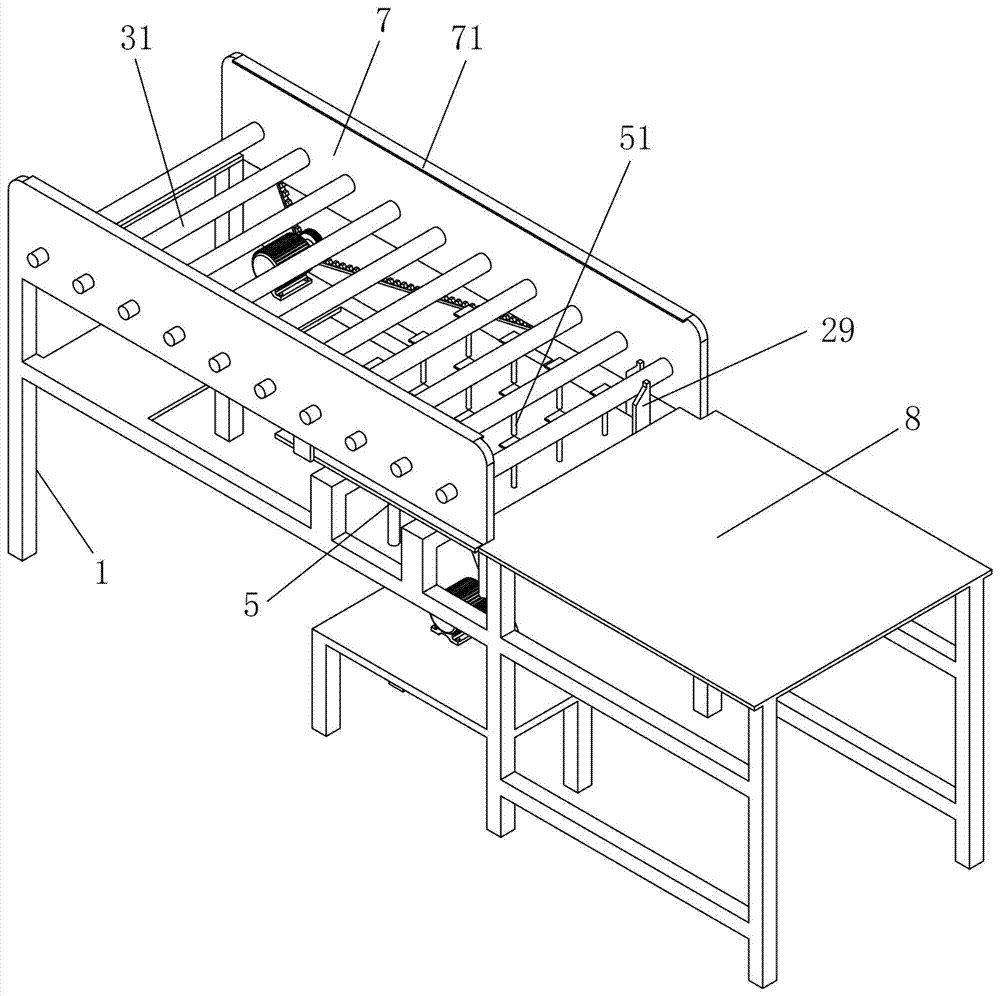

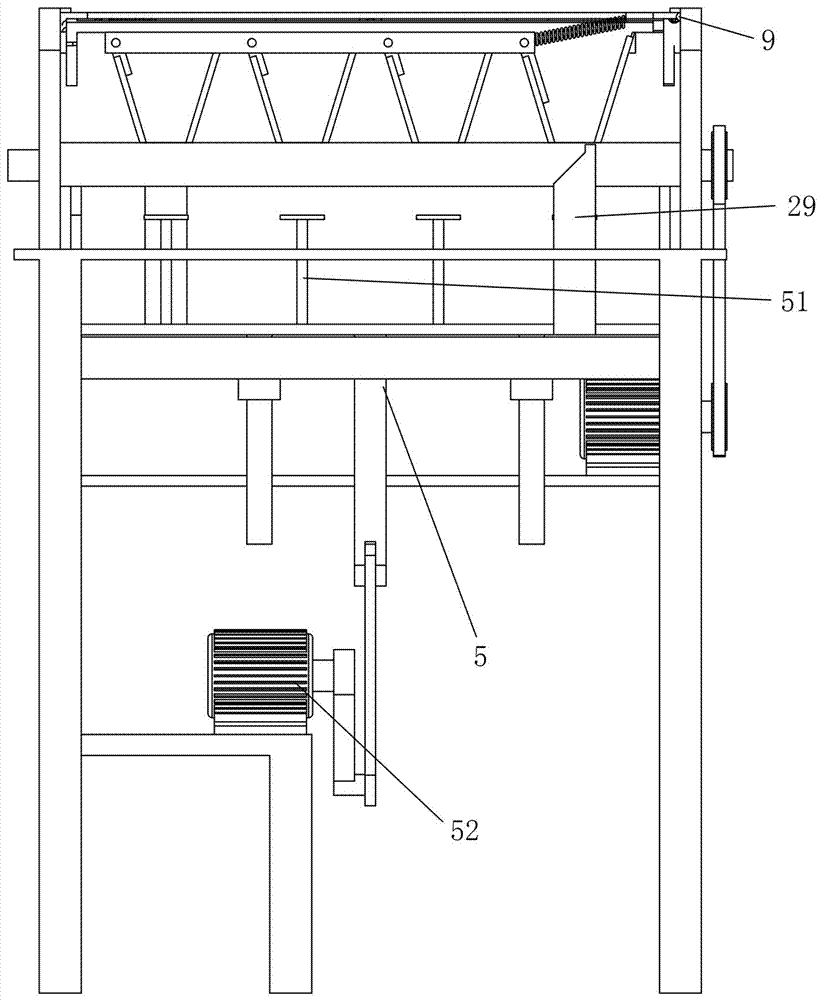

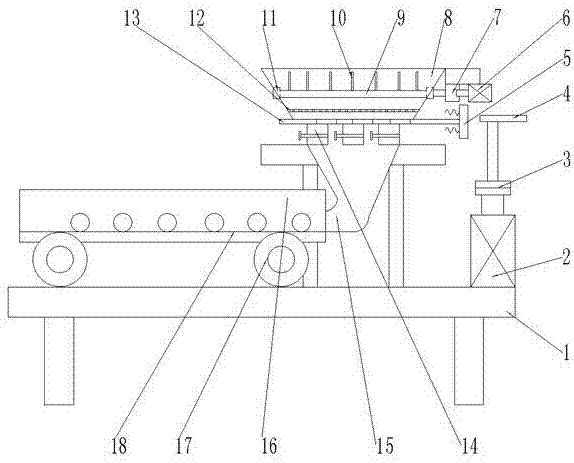

Pot seedling tray-removing device

The invention discloses a pot seedling tray-removing device. The tray-removing device comprises a rack and a seedling tray with a plurality of through hole type pot holes; a seedling tray input mechanism for conveying the seedling tray is installed on the rack, a seedling ejecting mechanism for ejecting the pot seedling from the pot hole is arranged below the seedling tray input mechanism; the seedling ejecting mechanism comprises ejector pins which have the consistent number with the pot hole of the seedling tray and are corresponding to the pot holes one to one, and a first lifting driving part installed on the rack and used for driving all ejector rods to synchronously lift. The pot seedling tray-removing device is capable of realizing the automatic tray removing of the pot seedling, and has the advantages of being simple and compact in structure, stable and reliable in work, easy to control, convenient for assembling and maintaining.

Owner:HUNAN AGRICULTURAL UNIV

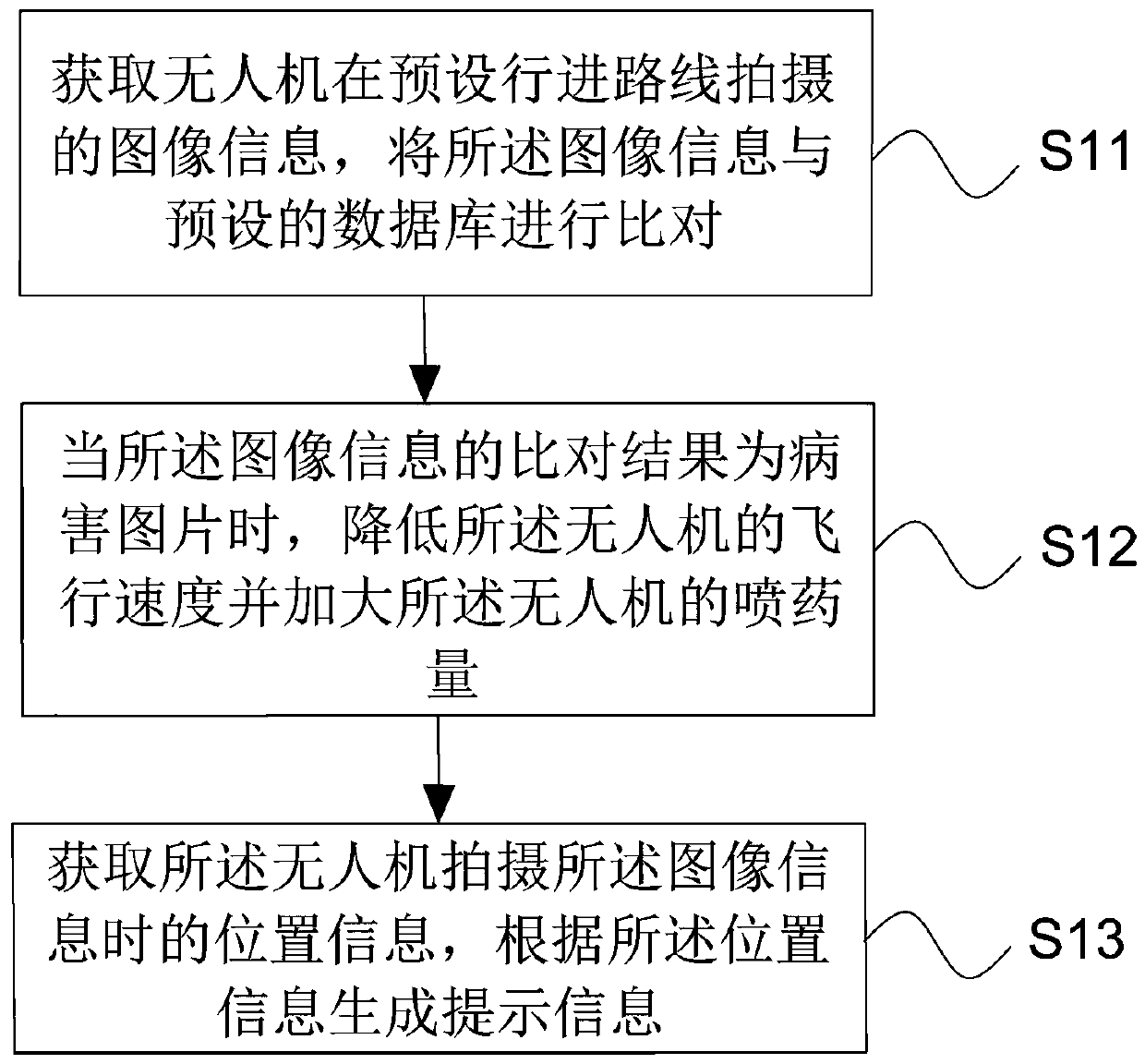

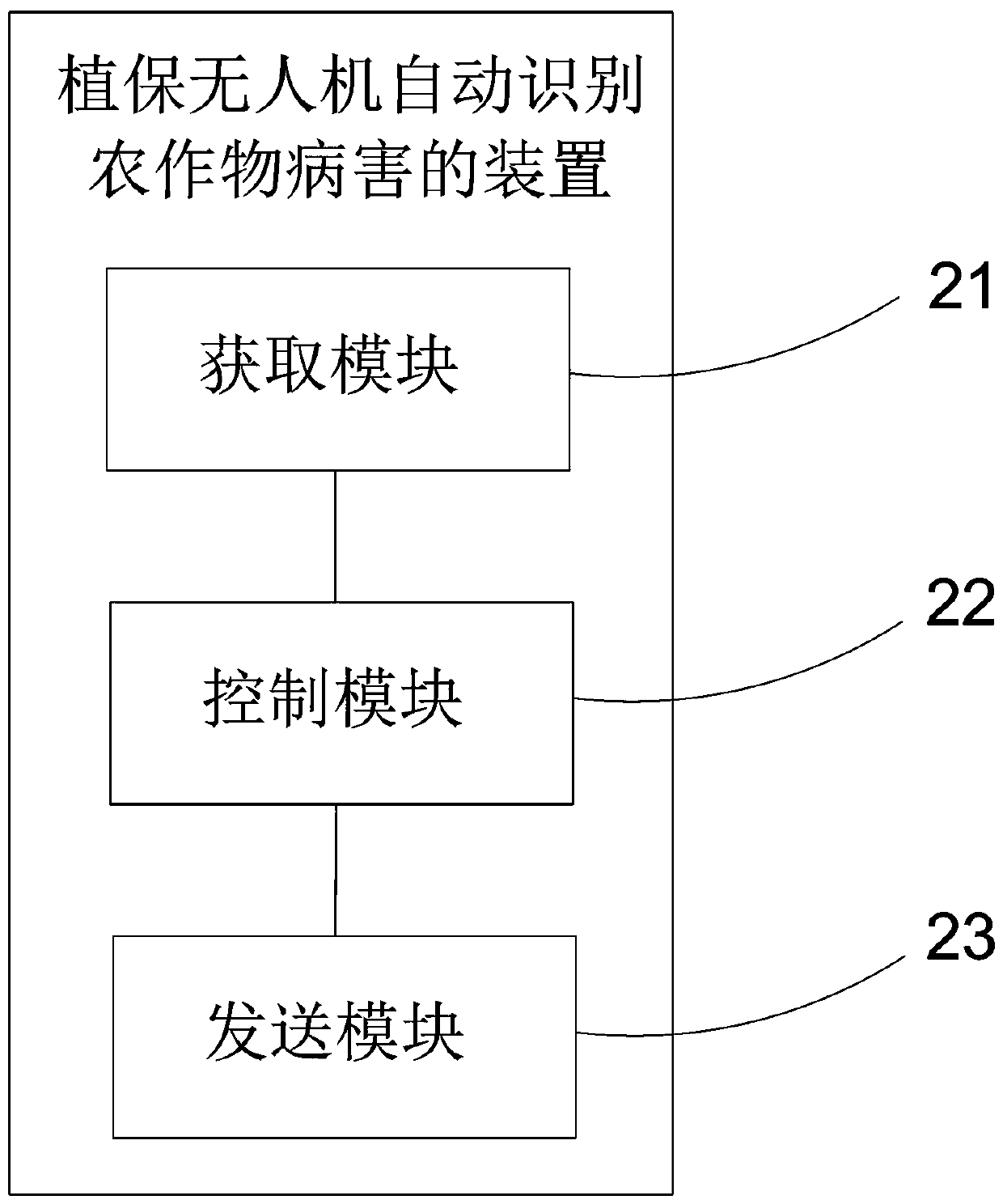

Method and device for automatically identifying crop diseases by plant protection unmanned aerial vehicle

InactiveCN110162087ASlow flightAchieve autonomyPosition/course control in three dimensionsInsect pestComputer vision

The invention discloses a method for automatically identifying crop diseases by a plant protection unmanned aerial vehicle. The method comprises the following steps that: obtaining image information shot by the unmanned aerial vehicle on a preset proceeding route, and comparing the image information with a preset database; when the comparison result of the image information is a disease picture, reducing the flight speed of the unmanned aerial vehicle, and increasing the pesticide spraying amount of the unmanned aerial vehicle; and obtaining position information when the unmanned aerial vehicle shots the image information, and according to the position information, generating prompt information. The invention also relates to a device for automatically identifying crop diseases by the plantprotection unmanned aerial vehicle. The unmanned aerial vehicle is controlled to reduce the flight speed and increase the pesticide spraying amount, and pesticide spraying intensity is enlarged for crops on the positions of plant diseases and insect pests so as to reduce plant diseases and insect pests.

Owner:安徽舒州生态农业科技股份有限公司

Multifunctional detector used for blood detection and blood detection method thereof

InactiveCN108593943AShorten visit timeEffectively provide work efficiencyPreparing sample for investigationTransverse planeWorkload

The invention discloses a multifunctional detector used for blood detection and a blood detection method thereof. The multifunctional detector comprises a main body, a paper-out apparatus, a detectionapparatus, a marking apparatus, a detection marking port, a position sensor, a printer, a blood routine detector, a blood smearing instrument, and a processor, the paper-out apparatus is arranged ata front transverse plane of the top of the main body, the detection apparatus is positioned below the paper-out apparatus, the marking apparatus is positioned below the detection apparatus, a pedestalis arranged at the bottom of the front transverse plane of the main body, the blood smearing instrument is arranged at a rear part of the detection apparatus, the blood routine detector is arranged at the rear part of the blood smearing instrument, and the processor is positioned at the rear part of the marking apparatus. The multifunctional detector has the advantages of simple structure and lowcost, and is suitable for various hospitals, is simple in operation, can effectively reduce the workload of medical workers, and saves the medical worker time and patient clinic time.

Owner:WEIFANG UNIV OF SCI & TECH

Chimney cleaning machine

The invention discloses a chimney cleaning machine, which is formed by a control part, a transmission part, a support part and a cleaning part. The whole frame is formed by welding and bolting squarepipes, so that not only can the strength requirement of the whole mechanism be met, but also the weight is reduced. The control part mainly depends on a single chip microcomputer to control a motor, and support rods of the support part are stretched out and drawn back through the control of a pressure sensor and a relay, so that the automatic work of the chimney cleaning machine is realized. The transmission part is formed by a sprocket chain, a screw rod and a gear. The support part adopts a four-connecting-rod structure so as to ensure the foldability and the stability of the support part, and a caterpillar is adopted at the tail end of the support part, so that a friction force between the support part and a tube wall is increased, and a climbing function of the chimney cleaning machineclimbing on an inner wall of a chimney is realized.

Owner:QINGDAO UNIV

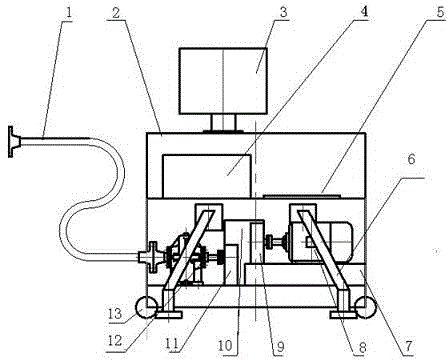

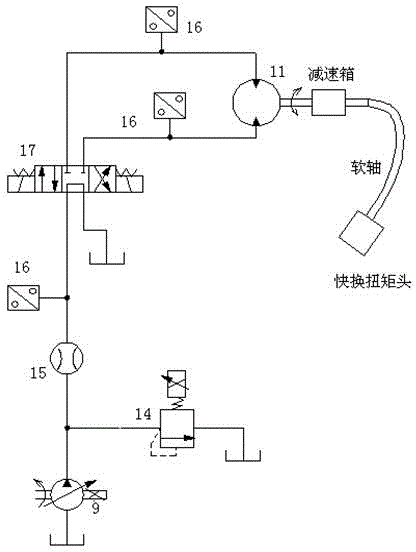

Fastening member assembling machine capable of automatically controlling various torque values

InactiveCN104148927ARealize fastening workStable replacementMetal working apparatusAutomatic controlTorque transmission

The invention discloses a fastening member assembling machine capable of automatically controlling various torque values. The fastening member assembling machine is characterized in that the fastening member assembling machine is movable and can be pushed to move on the ground, a power portion and a torque sleeve for receiving torque are flexibly connected, a torque transmission joint is replaceable, a flexible shaft for torque transmission and a replaceable fastening bolt head can change into different operation positions at any time, and torque received by each bolt can be automatically stored in a computer after reaching a fixed value and can automatically correspond to management project requirements along with a computer program; the fastening member assembling machine comprises a mechanical portion, a hydraulic portion and a control portion, and the mechanical portion comprises a torque wrench actuating device, a moving trolley, a rack, a speed reducing device, a hydraulic power damping device and a control portion damping device. The fastening member assembling machine is wide in application range, can perform precise-torque-value fastening on various bolts and can record and trace data in real time.

Owner:JIUJIANG UNIVERSITY

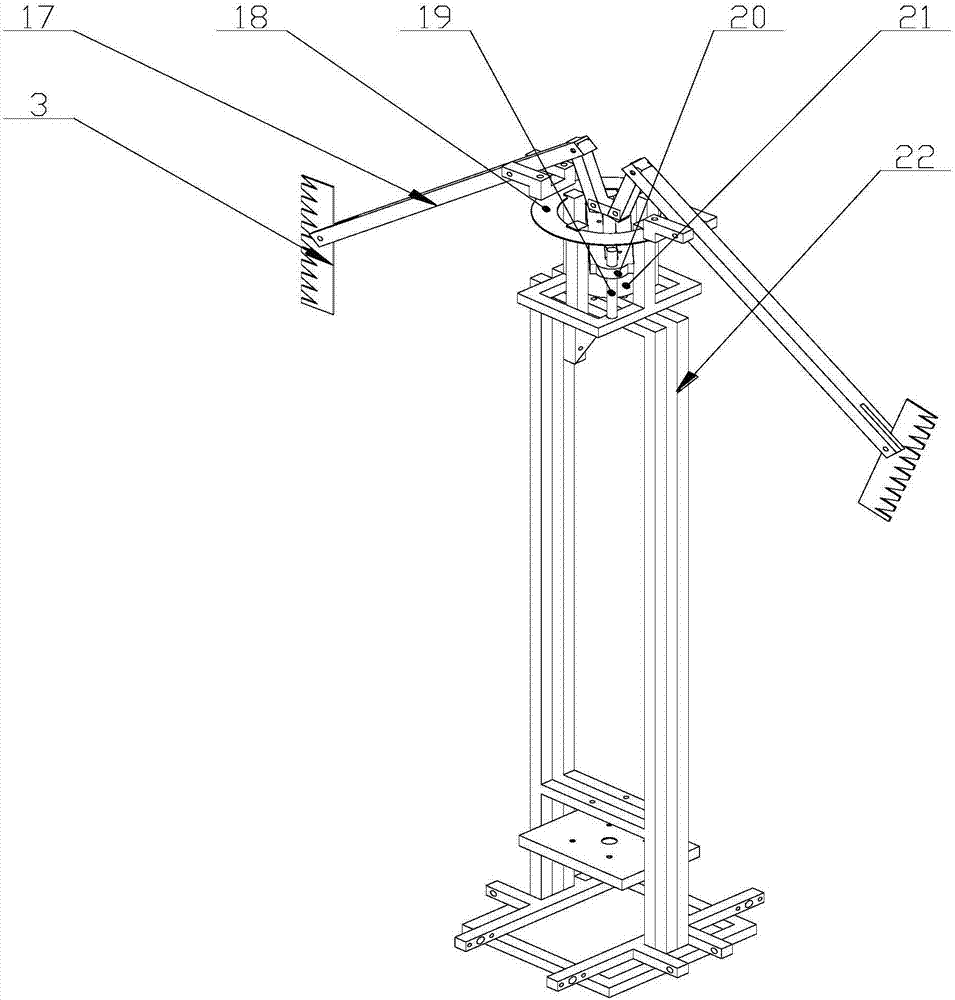

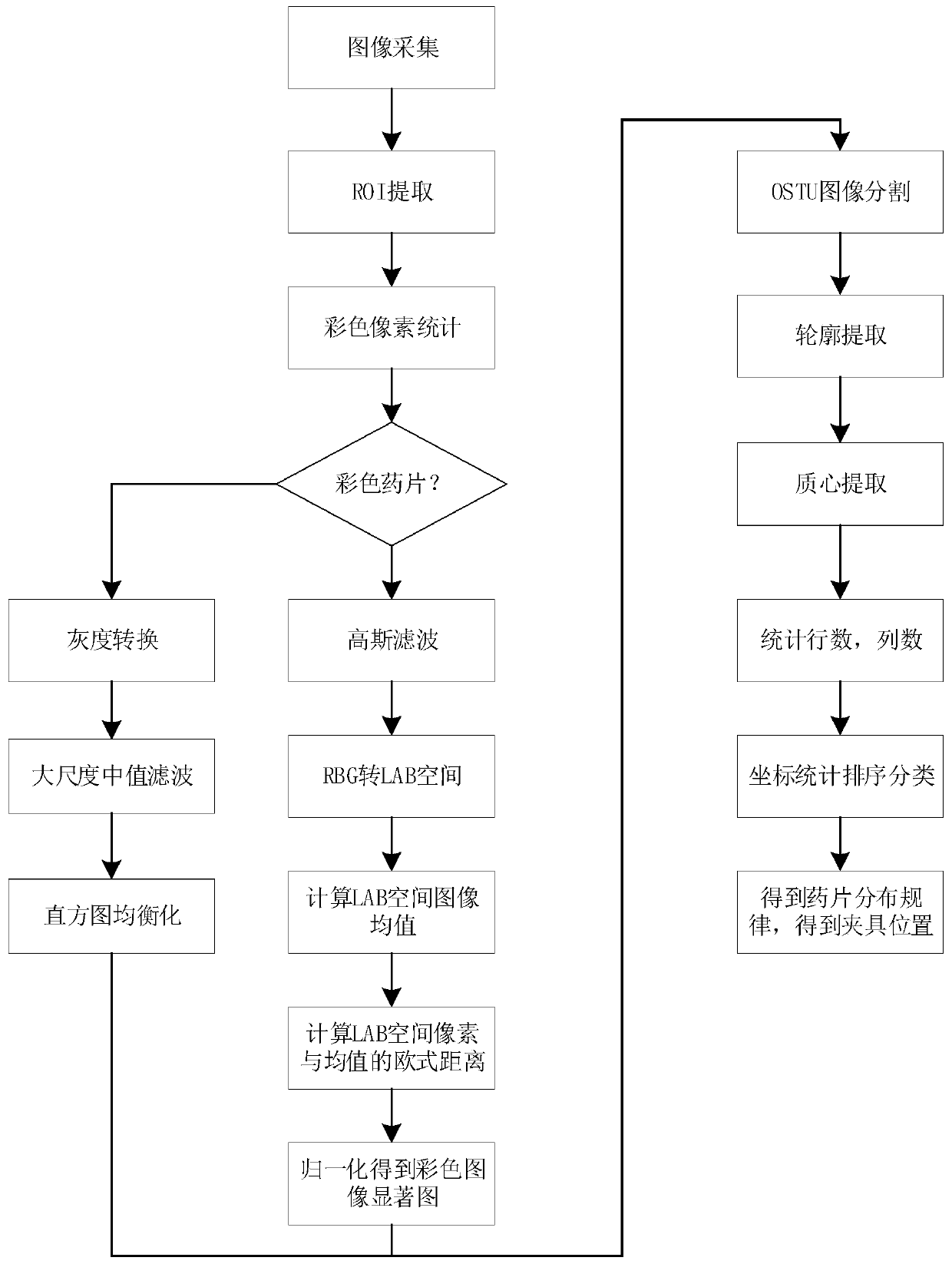

Aluminum/aluminum blister packaging tablet recognition and positioning method based on machine vision

ActiveCN110032946AAutomate workAchieve positioningCharacter and pattern recognitionPattern recognitionLab color space

The invention discloses an aluminum / aluminum blister packaging tablet recognition and positioning method based on machine vision. Tablets are automatically recognized and positioned through words. Themethod comprises the steps of image acquisition, ROI extraction, color pixel statistics, saliency object (tablet) extraction, tablet contour recognition, contour centroid extraction, coordinate sorting, clamp position positioning and the like. Through the steps, aluminum / aluminum blister packaging tablets of different specifications can be adaptively identified, the quantitative output of the positions of the tablets is realized, and the production efficiency of the medicine stripping machine is improved. According to the method for carrying out tablet detection by utilizing machine vision, the automatic work of a medicine peeling machine can be realized, the colored and white tablets classified by statistical information are used for identification, and various working condition requirements can be flexibly met. And finally, an LAB color space frequency domain method is used for extracting the visual saliency object, so that the recognition and positioning of the color tablets can beefficiently achieved.

Owner:XI AN JIAOTONG UNIV

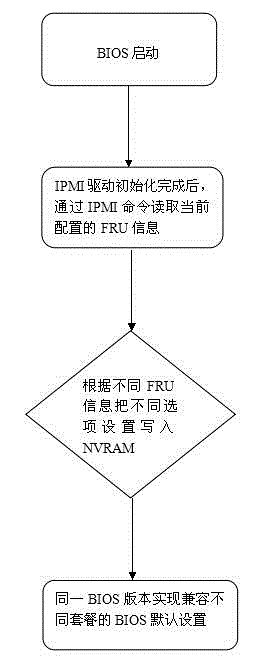

Method of server for automatically setting BIOS default values

The invention provides a method of server for automatically setting BIOS default values, relating to the technical field of computer server firmware. By reading information on product package in BMC FRU information, a BIOS default value matching a current product is set. By writing the default value into NVRAM for storage, products set by multiple different default values can be compatible to one edition. The method of server for automatically setting BIOS default values has following beneficial effects: automation work of a server system is achieved; one edition is compatible to configuration requirements of multiple systems; and the method is easy and highly-efficient and helps to save resources for research and development and raise production efficiency.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

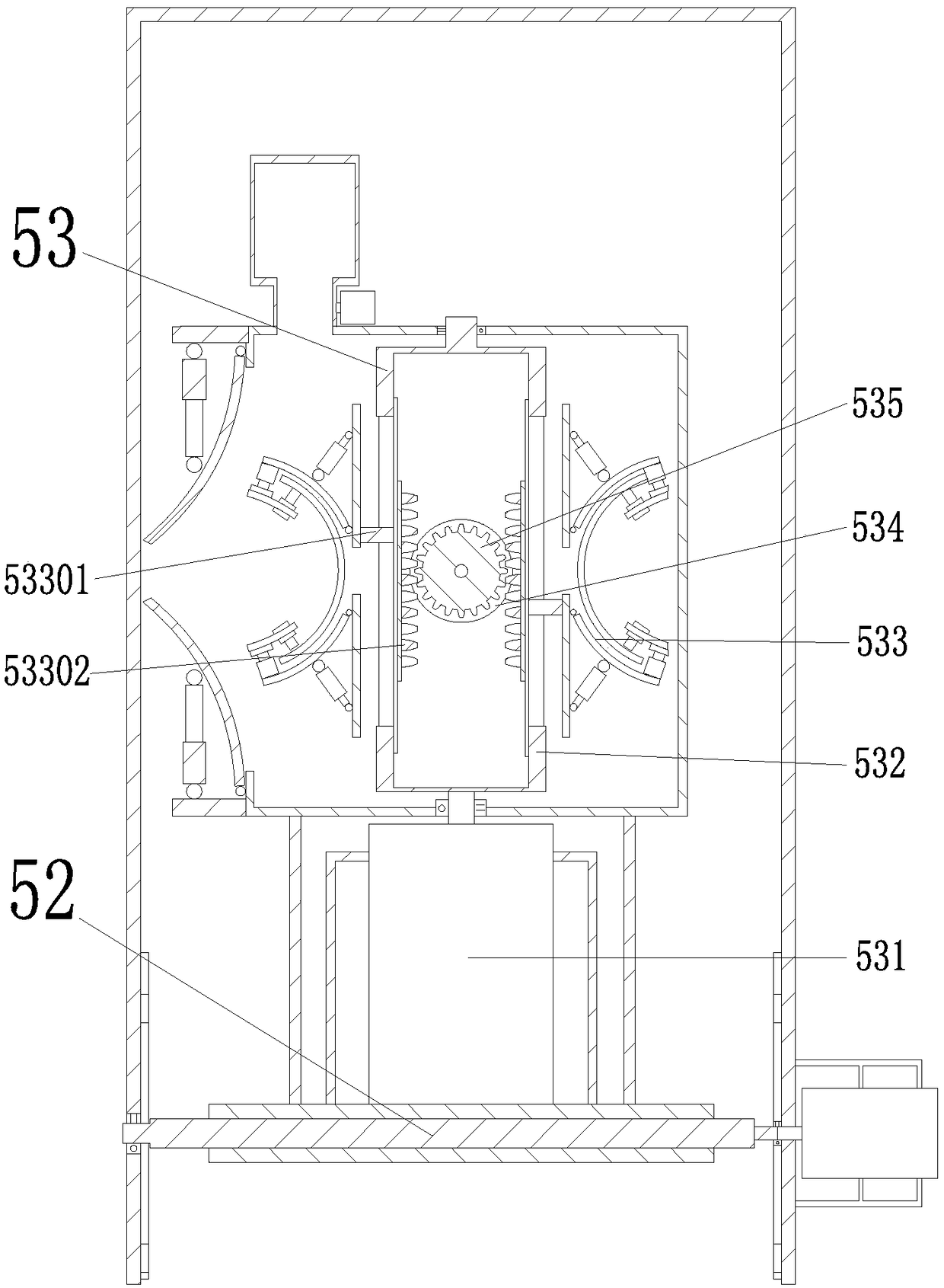

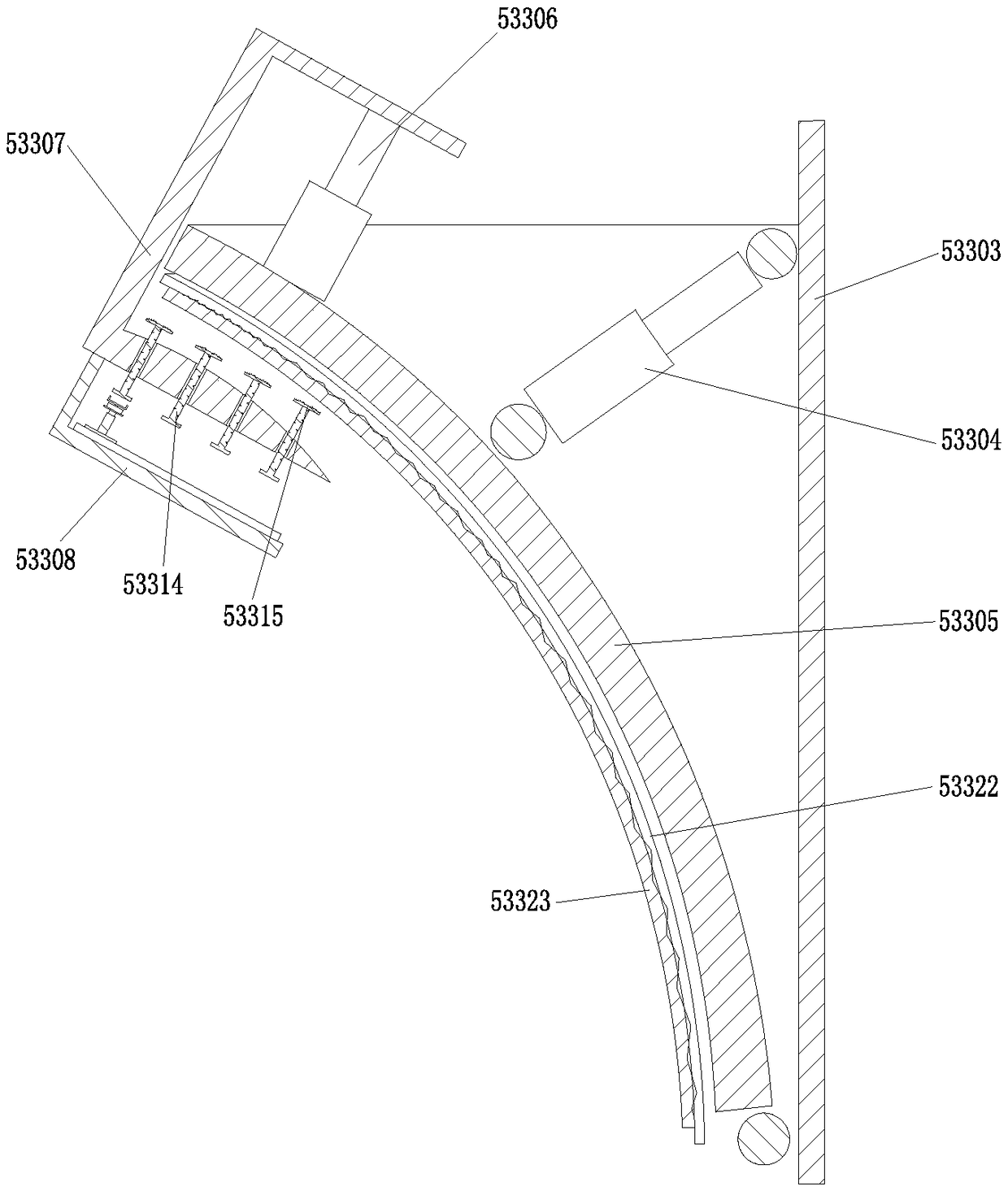

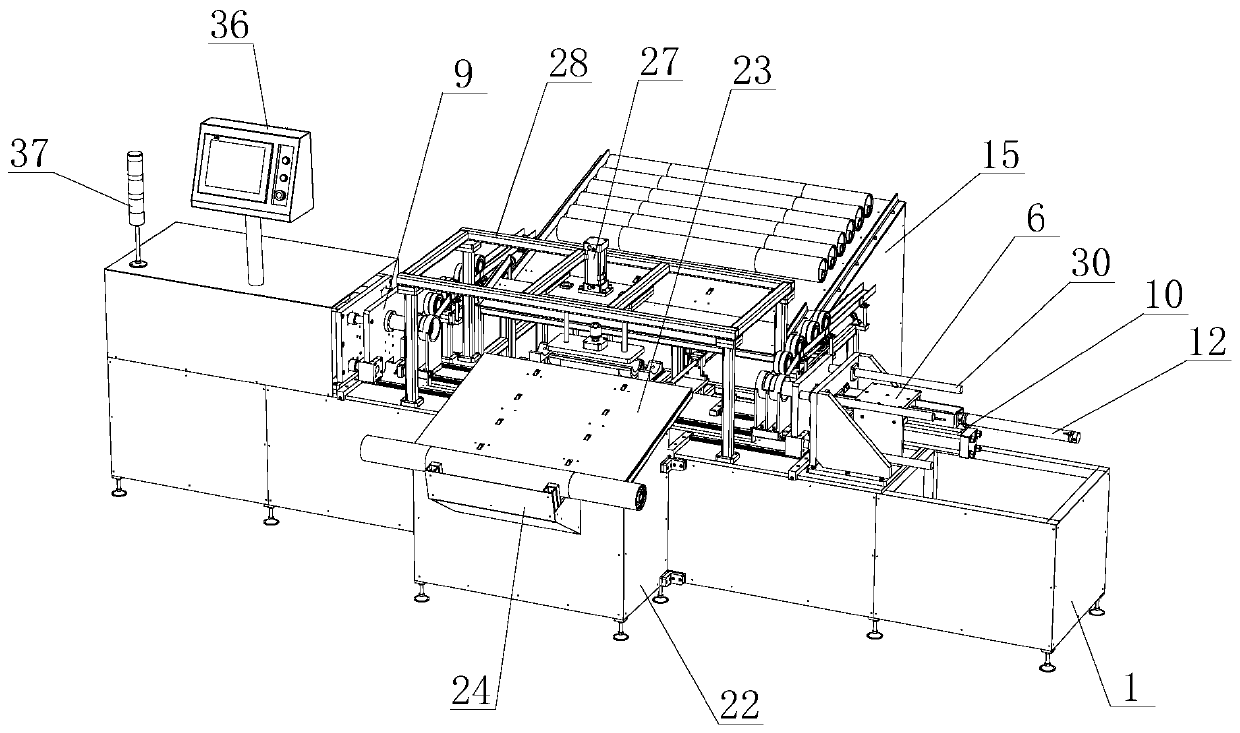

Tempered glass machining system and tempered glass machining method thereof

ActiveCN109049348AReduce labor intensityDecrease productivityEdge grinding machinesGrinding wheel securing apparatusEngineeringMachining system

The invention relates to a tempered glass machining system and a tempered glass machining method thereof. The tempered glass machining system comprises a supporting executing mechanism, a grinding executing mechanism and a cutting executing mechanism, the grinding executing mechanism is installed on the upper side of the bottom end of the supporting executing mechanism, the cutting executing mechanism is installed on the lower side of the bottom end of the supporting executing mechanism, the supporting executing mechanism drives the grinding executing mechanism and the cutting executing mechanism to move to a designated position, edge grinding machining is performed on tempered glass by the grinding executing mechanism, and cutting machining is performed on the tempered glass by the cutting executing mechanism. Manual operation is not needed in the machining process, so that breakage of the tempered glass caused by misoperation is avoided, the labor intensity of workers is reduced, theworking efficiency is improved, and the function of performing cutting and edge grinding machining continuously at the same station in the deep machining process of the tempered glass can be realized.

Owner:SHANDONG FANGDING SAFETY GLASS TECH CO LTD

Semi-automatic patterning machine

The invention belongs to the technical field of gold jewelry processing and particularly relates to a semi-automatic patterning machine. The semi-automatic patterning machine comprises a workpiece fixing mechanism, a feeding mechanism and a patterning mechanism, wherein the workpiece fixing mechanism comprises a patterning piece fixing plate, an external positioning plate and a mould plate; the feeding mechanism comprises a worktable, an X-axis servo motor and a Y-axis servo motor; the patterning mechanism comprises a patterning frame which is provided with a rotating cutter driven by a C-axisservo motor, the rotating cutter is provided with a patterning cutting disk driven by a driving motor, and the patterning cutting disk is provided with a cutting blade. The semi-automatic patterningmachine is simple in structure and easy to operate and can achieve scale and semi-automatic jewelry piece feeding during which time and labor can be saved; the servo motors drive the worktable to moveand further to achieve automatic patterning operation on jewelry pieces, thereby greatly improving the production efficiency and achieve uniform patterning and stable quality.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD

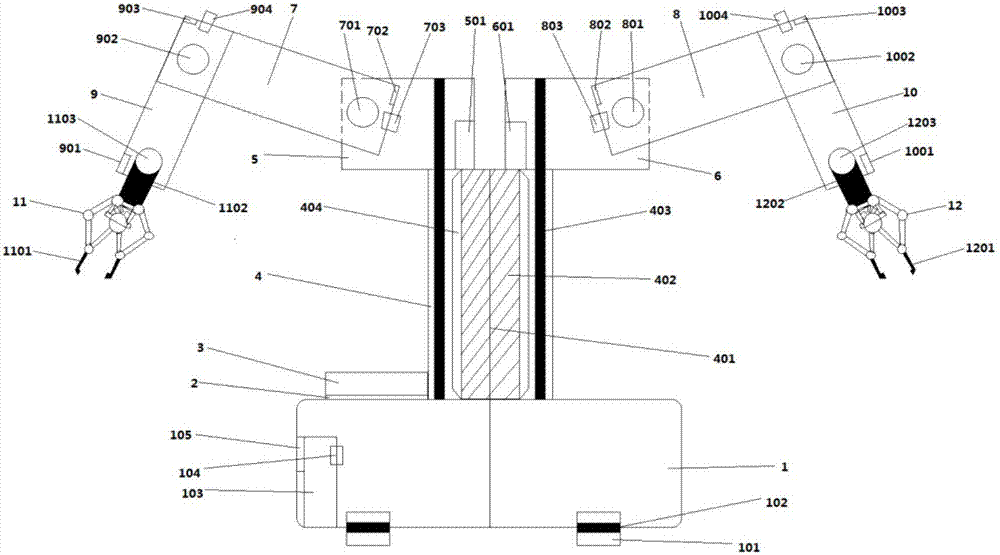

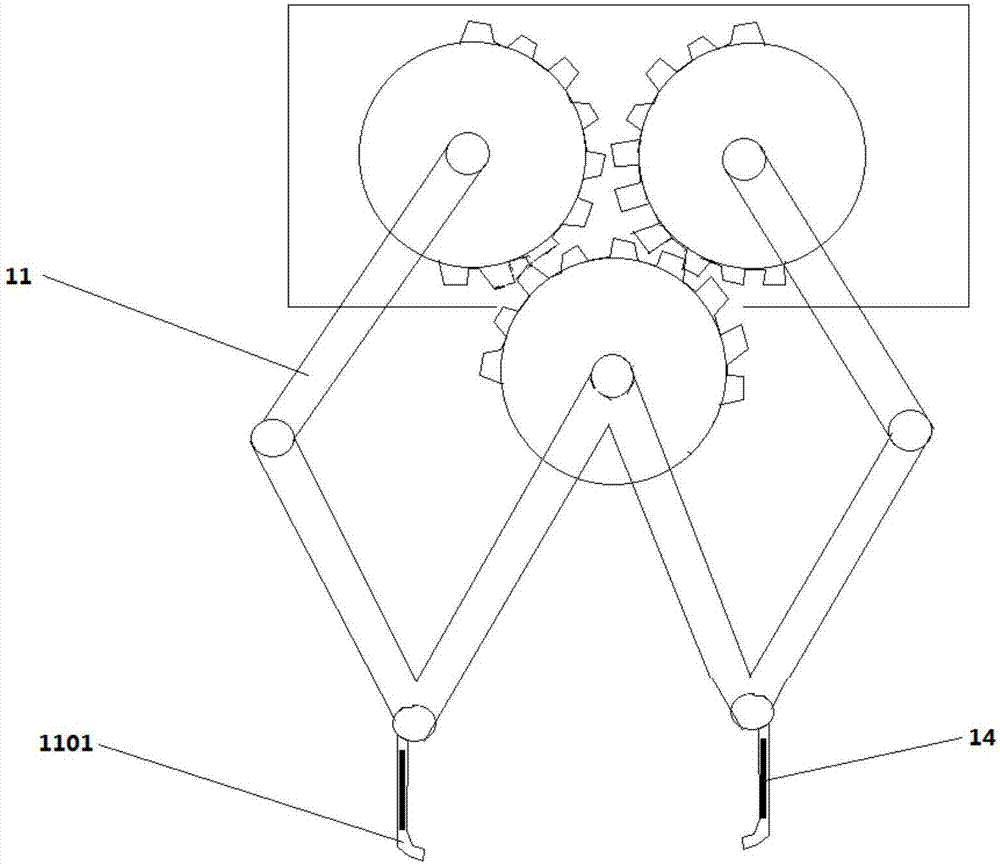

Heavy manipulator device for production line machining

ActiveCN107457771AGuarantee the safety of lifeReasonable structureProgramme-controlled manipulatorGripping headsProduction lineEngineering

The invention discloses a heavy manipulator device for production line machining. The device mainly comprises a base, a driving motor mounting plate, a driving motor, a stand column, a left rotating arm base, a right rotating arm base, a left large arm, a right large arm, a left small arm, a right small arm, a left parallel jaw and a right parallel jaw; the driving motor mounting plate is positioned on the upper surface of the base; the driving motor is mounted on the driving motor mounting plate; the stand column is mounted on the base; one end of the left rotating arm base is mounted on the stand column, and the other end is connected with the left large arm; the other end of the left large arm is connected with the left small arm; the other end of the left small arm is connected with the left parallel jaw; one end of the right rotating arm base is mounted on the stand column, and the other end is connected with the right large arm; the other end of the right large arm is connected with the right small arm; and the other end of the right small arm is connected with the right parallel jaw. The device uses a modernization technology for realizing automatic work, guarantees the life safety of workers, and improves the working efficiency.

Owner:LINYI UNIVERSITY

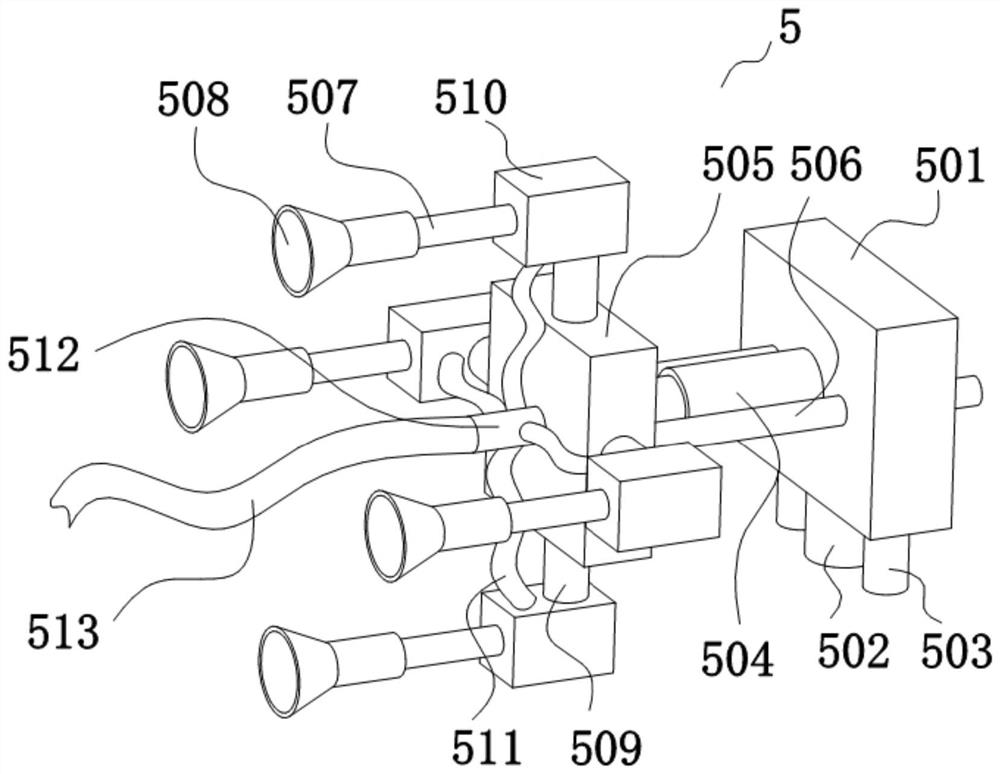

Clamping and pressing device for pipe connection

InactiveCN110052544ARealize automatic loading and unloadingAutomate workMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention discloses a clamping and pressing device for pipe connection. The clamping and pressing device for pipe connection comprises a clamping and pressing mechanism, a feeding mechanism and afixed base. The feeding mechanism is arranged at one end of the top of the fixed base. The clamping and pressing mechanism is arranged at the end, far away from the feeding mechanism, of the top of the fixed base. The clamping and pressing mechanism is composed of a fixed platform, a fixed block, a feed cylinder, a feeding push block, a storage sliding chute, a clamping and pressing ring, hydraulic cylinders and clamping and pressing blocks. One end of the top of the fixed base is fixedly connected with the fixed platform. The clamping and pressing device for pipe connection realizes automaticfeeding and discharging of pipes through the feeding mechanism, a second motor and a first motor. The structural flexibility of the clamping and pressing device is greatly improved. The labor intensity of workers is reduced. Automated operation of the clamping and pressing device is realized. The clamping and pressing device for pipe connection can conduct automatic feeding on sockets of the pipes through the storage sliding chute and the feeding push block without manual adding. The machining process of pipe clamping and pressing is shortened. The working efficiency of the pipe clamping andpressing is improved.

Owner:陈特

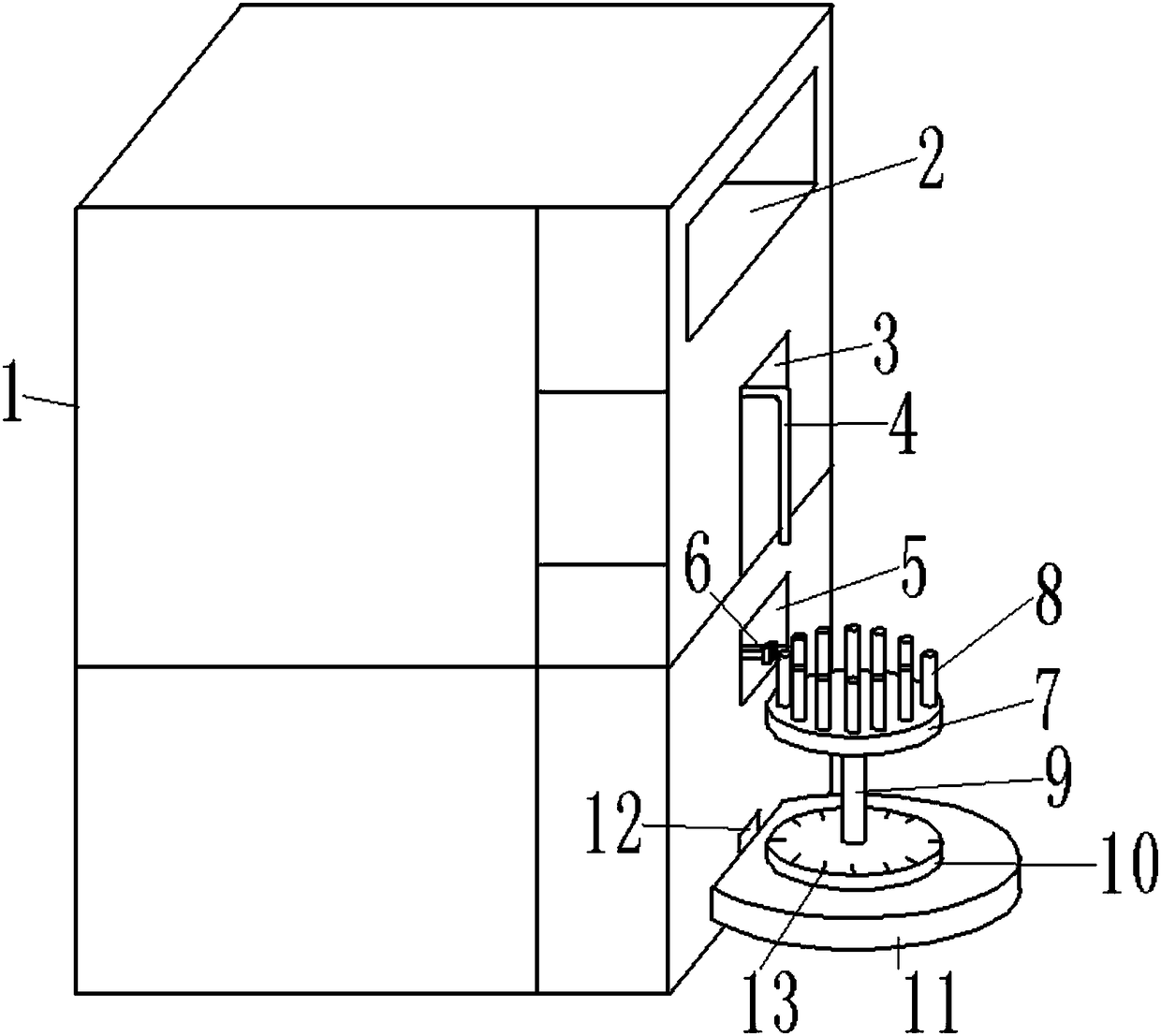

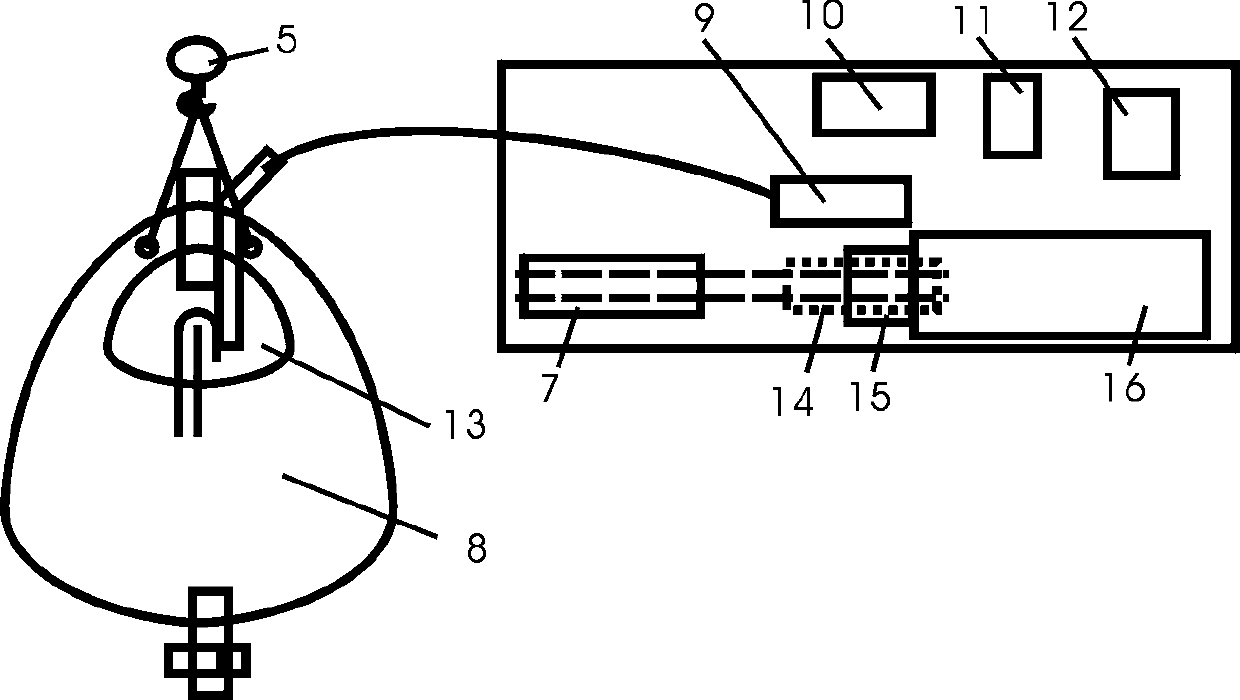

Automatic sampler

InactiveCN105300735AEasy to operateImprove collection efficiencyWithdrawing sample devicesEngineeringControl system

The invention discloses an automatic sampler which comprises a bracket, a feeding mechanism, a sampling mechanism and a traveling mechanism, wherein the feeding mechanism is slidably connected with the bracket in the vertical direction; the sampling mechanism is rotationally connected to the feeding mechanism; a hose is wound at the periphery of the sampling mechanism; one end of the hose is communicated with materials; the other end of the hose is communicated with a material collection device; the material collection device is communicated with a fan and is arranged on the bracket in an inclinable manner; and the traveling mechanism is arranged on the lower part of the bracket and is connected with the material collection device and the same control system. Automatic operation is realized, manual action is avoided, the sampling speed is high, the efficiency is high, the personal safety of an operator is guaranteed, the working efficiency is improved, and the manual cost is saved.

Owner:HUNAN INST OF METROLOGY & TEST

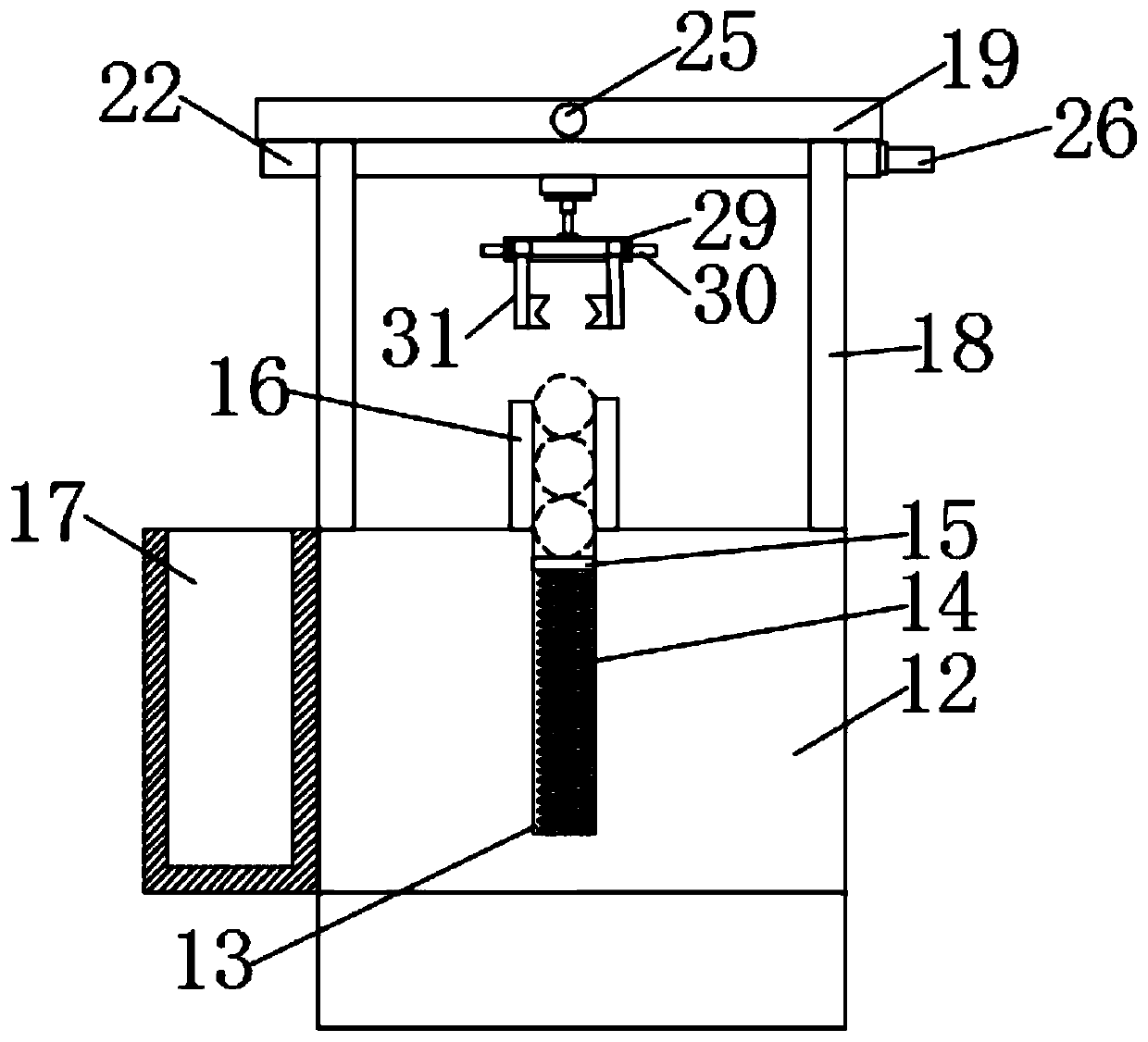

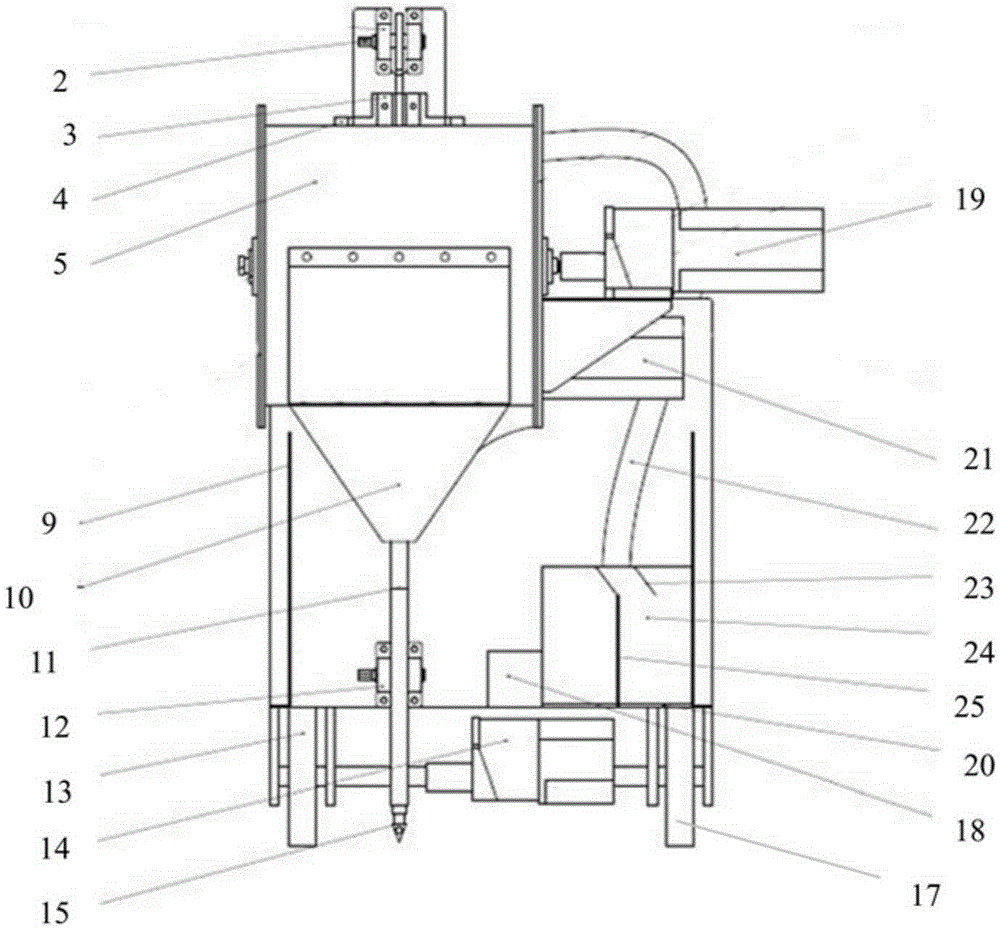

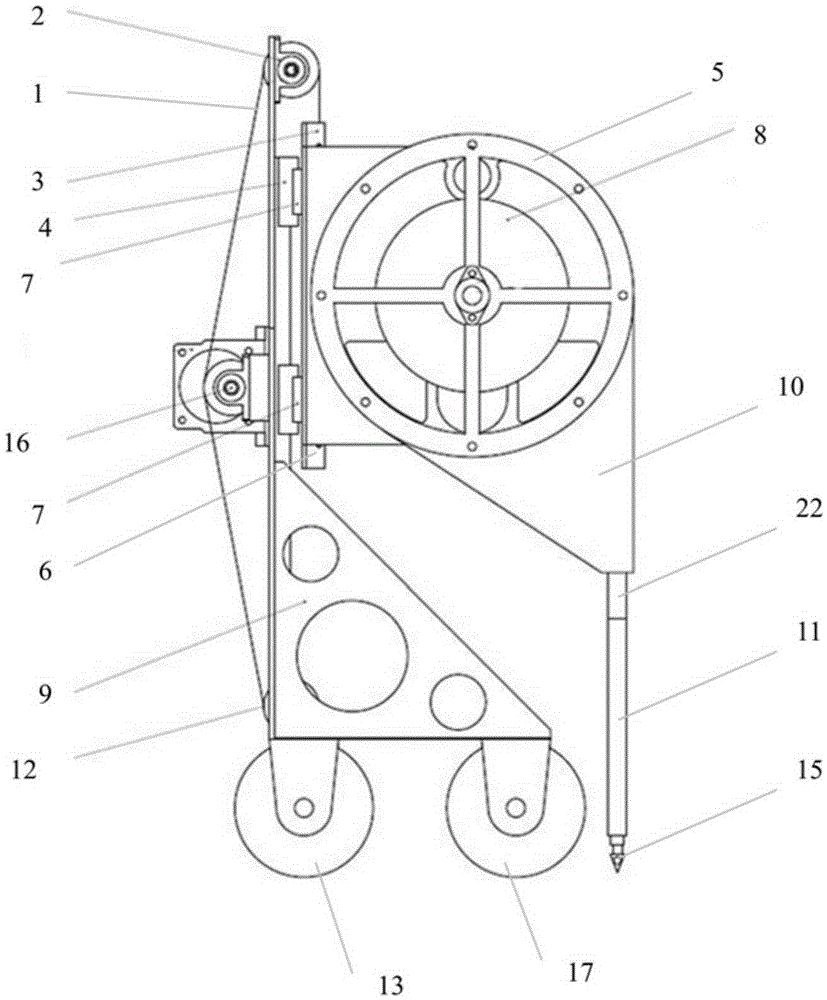

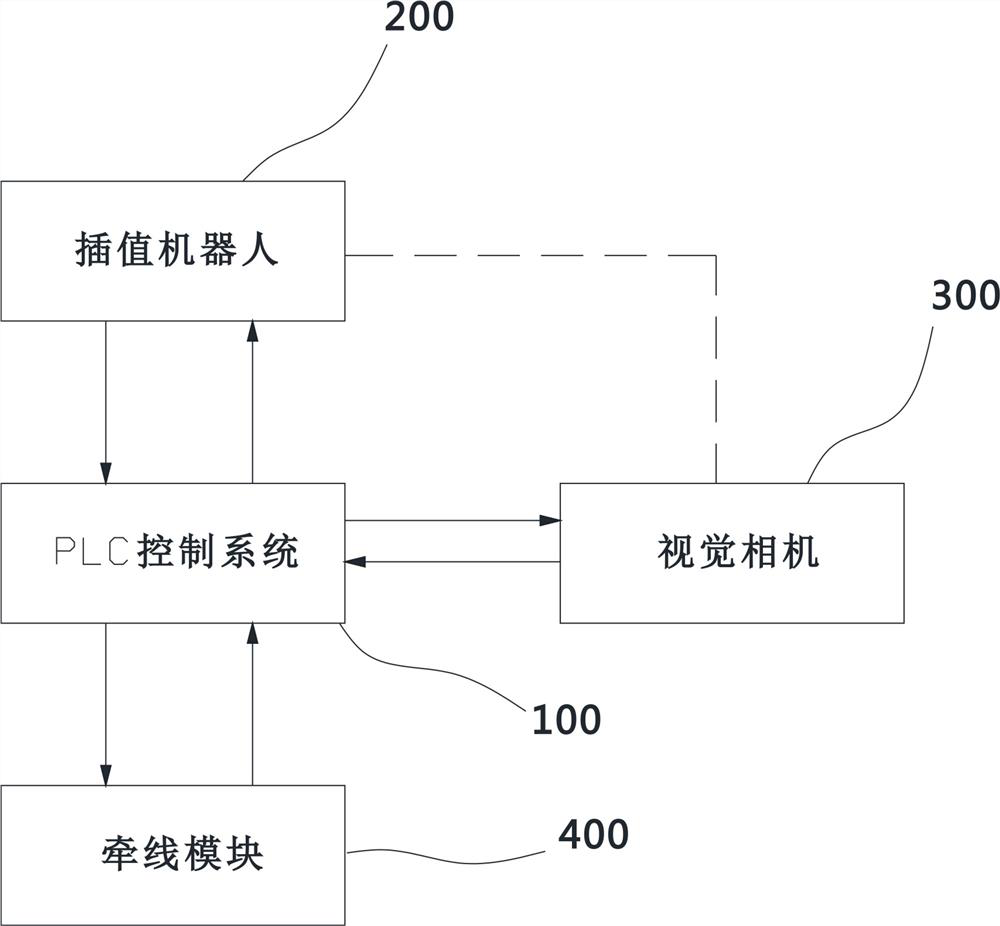

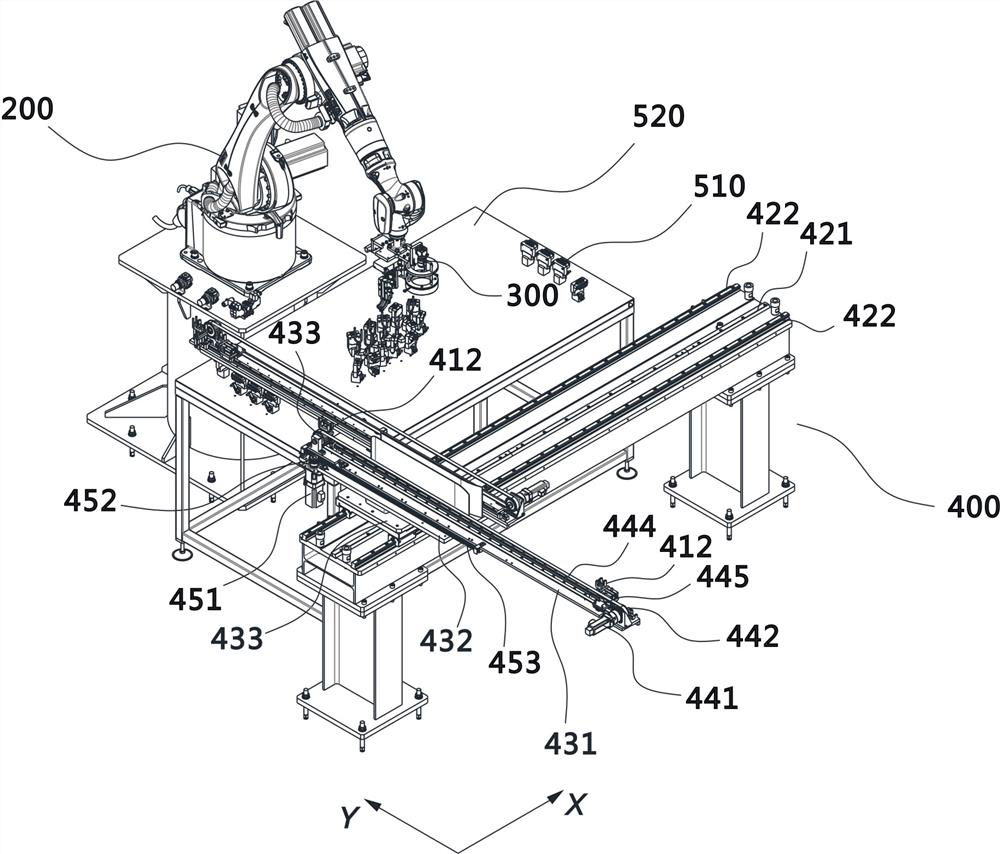

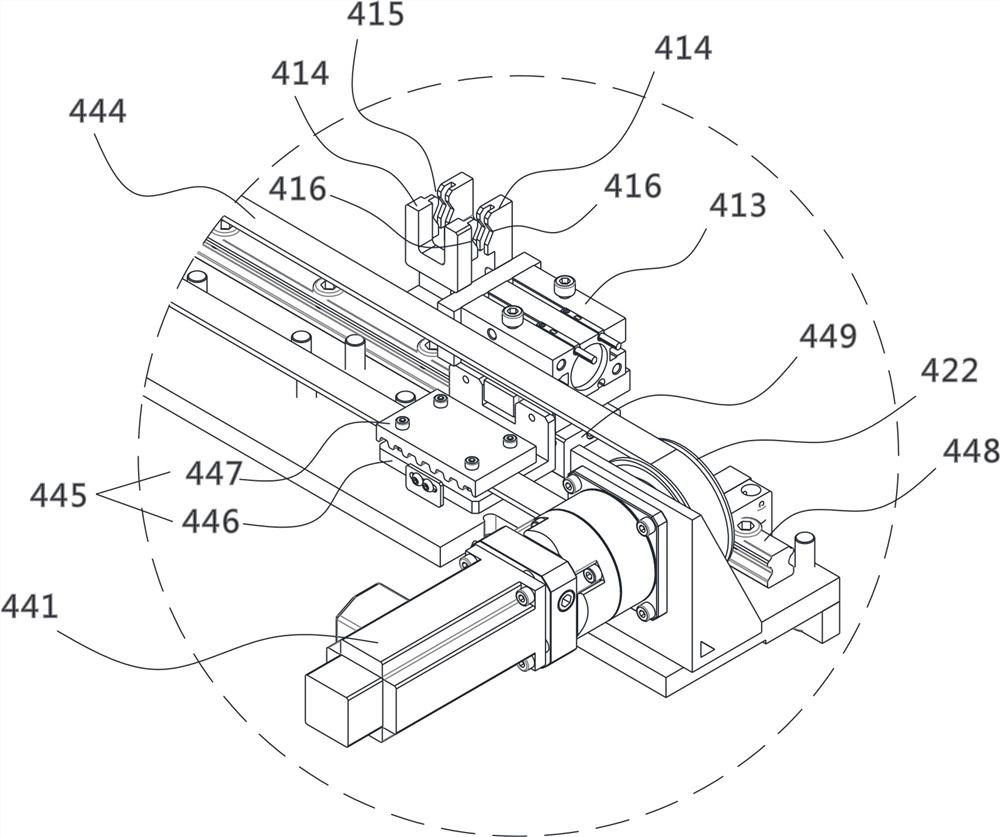

Automatic wire harness implantation system, method and controller

ActiveCN112290344AAccurate implantationEfficient transplantingVehicle connectorsContact member assembly/disassemblyControl systemMechanical engineering

The invention discloses an automatic wire harness implantation system and method and a controller to implant a wire of a wire harness into a connector. The implantation system comprises: a PLC controlsystem, an implantation robot and a visual camera; the visual camera is used for acquiring image information of at least one connector and acquiring first position information and first rotation angle information of the connector according to the image information; and the PLC control system is used for controlling the implantation robot to insert the terminal of the wire into the corresponding insertion hole of the connector according to the first position information and the first rotation angle information of the connector. The implantation method comprises the following steps: A, acquiring first position information and first rotation angle information of the connector; and B, according to the first position information and the first rotation angle information of the connector, controlling the implantation robot to insert the terminal of the wire into a corresponding insertion hole of the connector. According to the invention, automatic work of wire harness implantation is realized, and the implantation work of the wire terminals can be precisely carried out.

Owner:季华科技有限公司

Recovery system for wet noodles ends

InactiveCN104286069AReduce wasteReduce manufacturing costDough shaping and cutting apparatusPulp and paper industryConveyor belt

The present invention discloses a recovery system for wet noodles ends. The recovery system comprises a cutting machine located in front of drying equipment, a noodles end collection device provided beneath the cutting machine, a conveyor belt provided beneath the noodles end collection device, a stirring machine arranged at one end of the conveyor belt, and a motor used to drive the conveyor belt. The recovery system for wet noodles ends provided by the present invention adjusts the wet noodles to a proper length so as to make the ends of noodles neat before a drying process, so that when dried noodles are cut to a fixed length, the generated dry noodles ends are significantly reduced. The cut-off wet noodles ends can be recovered by the collection device, the conveyor and the stirring machine for further utilization, so that wasted raw materials and production costs are effectively reduced. The recovery system for wet noodles ends provided by the present invention can realize automated work without manual operation.

Owner:ZHONGJIANG YANSHI GRAIN & OIL FOOD

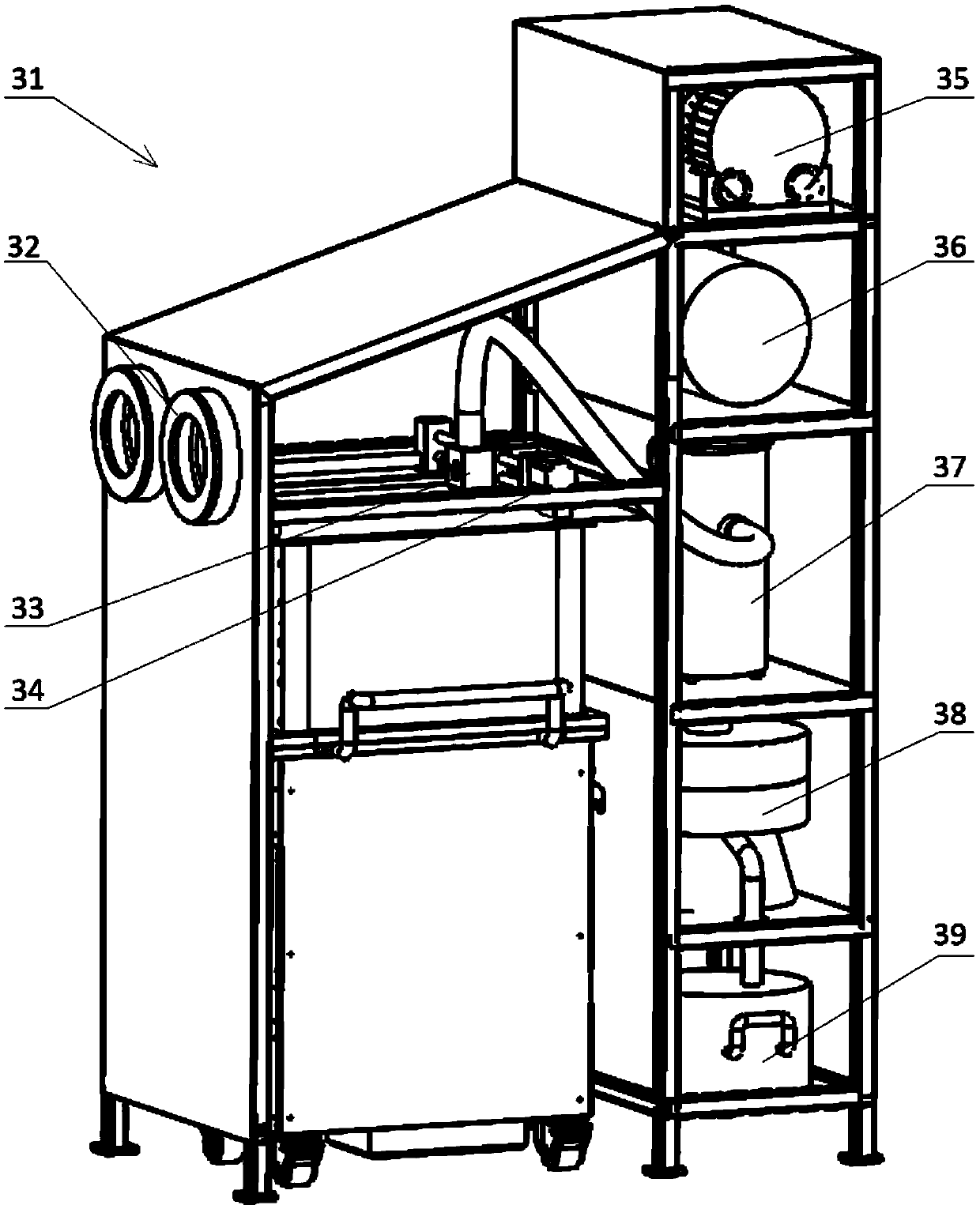

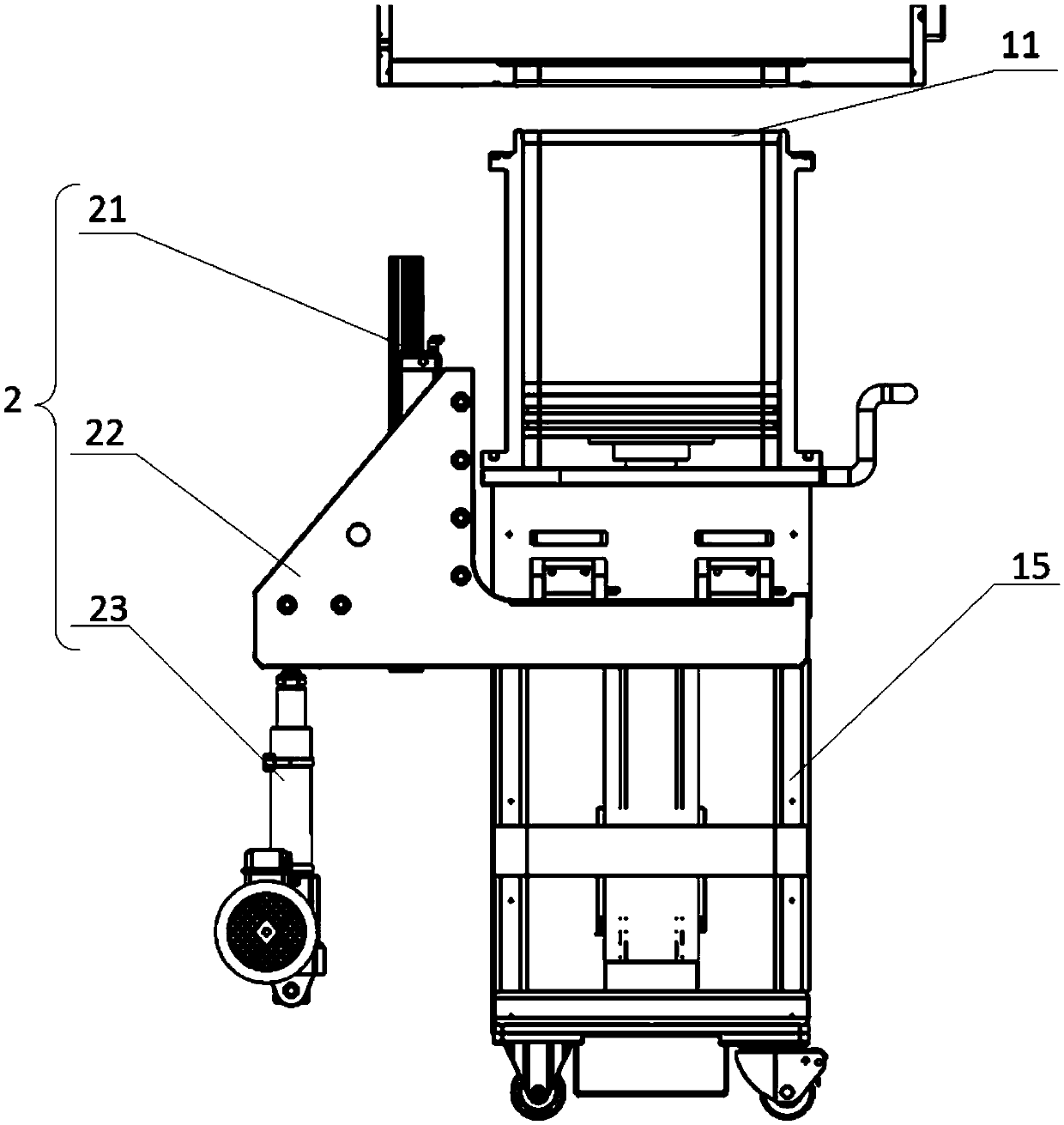

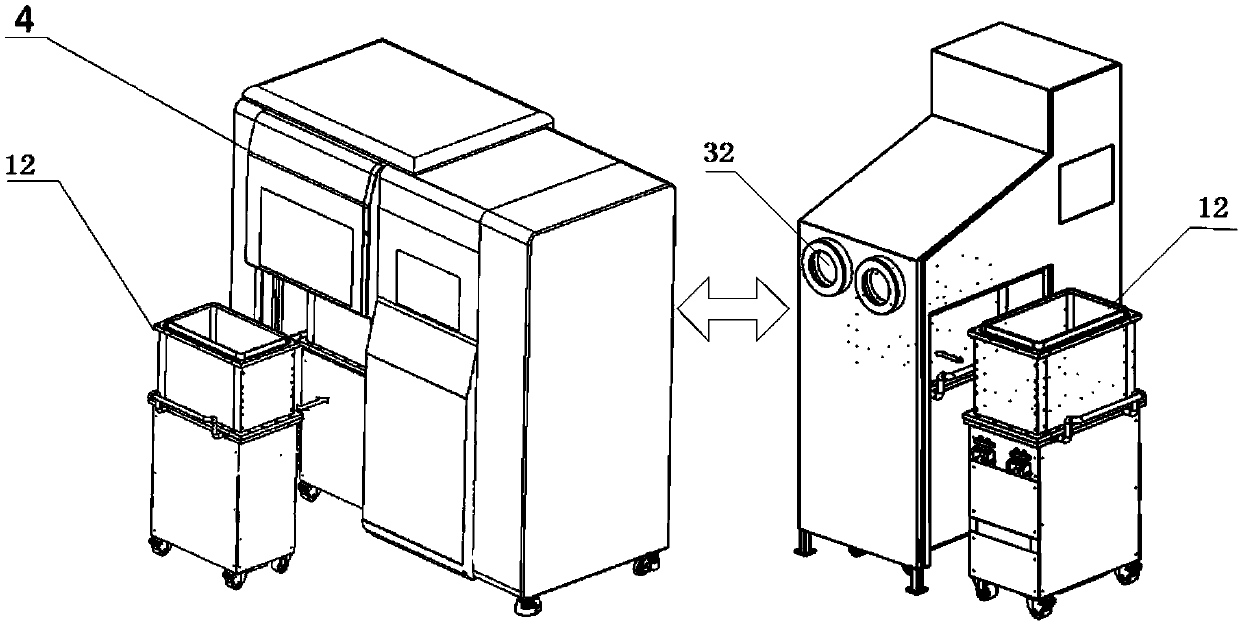

Automatic powder recycling device

PendingCN109550950AAvoid contactImprove securityAdditive manufacturing apparatusDispersed particle separationEngineeringAir blower

The invention discloses an automatic powder recycling device which comprises a box body. The box comprises a left box body and a right box body, the left box body is a glove box with no bottom plate,a movable forming cylinder mechanism is placed in the glove box, the right box body is a powder recycling box, an air blower, a filter, a cyclone separator, a vibration screen and a powder collectionbottle which are in pipeline connection are sequentially arranged inside the right box body from top to bottom, the side wall of the upper portion of the glove box is provided with two windows where arms can stretch, and rubber gloves are installed in the windows correspondingly. The movable forming cylinder mechanism carries a forming cylinder to move between machining equipment and the powder recycling device, and operators do not need to make contact with a large amount of powder for operation; in the powder removing process, the glove box is adopted to prevent powder from making contact with operators; all the devices in the powder recycling box are connected through a sealing pipeline, automatic powder screening is carried out in the whole process, and equipment using safety is improved.

Owner:SOUTH CHINA UNIV OF TECH

Feeding device for biscuit production

InactiveCN107539799AVolume controlAvoid easy jammingLarge containersLoading/unloadingDrive shaftCoupling

The invention discloses a feeding device for biscuit production, which comprises a bottom plate, a first motor is welded on the top side of the bottom plate, a coupling is welded on the output shaft of the first motor, and the coupling is far away from One side of the first motor is welded with a cam through a connecting rod, the top of the middle position of the bottom plate is welded with a support frame, and the top of the support frame is connected with a storage box by bolts, and the inner walls of both sides of the storage box are welded There is a bearing, a transmission shaft is plugged into the inner wall of the bearing, a governor is welded on the end of the transmission shaft away from the material storage box, a second motor is welded on the end of the governor away from the bearing, the transmission shaft Stirring blades are connected by bolts on the outer wall. The invention completely avoids the jamming phenomenon easily caused when a large amount of materials pour into the feed inlet, has simple overall structure, convenient processing and manufacturing, low production cost, can realize automatic work, and achieves a desired effect.

Owner:顾亚明

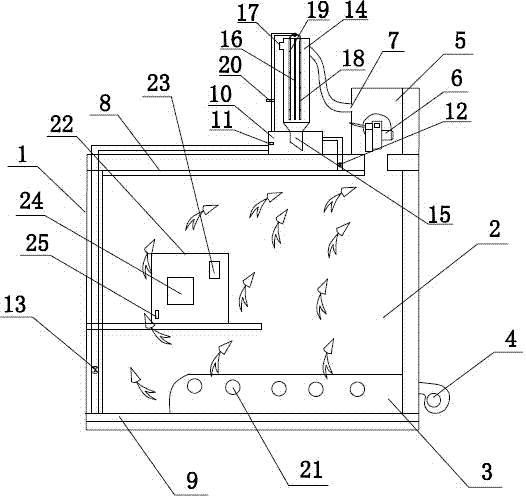

Hot cleaning furnace with dual purification treatment

InactiveCN104329947AIncrease flow itineraryIncrease the itineraryIncreasing energy efficiencyWaste heat treatmentSuspended particlesCombustion chamber

The invention discloses a hot cleaning furnace with dual purification treatment. The hot cleaning furnace comprises a furnace body, wherein a first combustion chamber is arranged at the bottom of the furnace body and a second combustion chamber with a smoke exhausting opening is arranged at the top of the furnace body; each of the inner part of the furnace body and the inner part of the second combustion chamber is provided with a temperature sensor; the smoke exhausting opening is provided with a waste gas purification device; the furnace body is provided with a spraying system; the spraying system comprises a spraying pipe, a circulating water groove and a water tank; the water tank is internally provided with a water level monitor. The hot cleaning furnace with the dual purification treatment is reasonable in structure design; the waste gas purification device is arranged and is used for carrying out purification treatment on high-temperature gas; an atomization high-pressure nozzle is used for washing suspended particles in the gas and a baffle is used for increasing a gas flowing route so that gas and solids, which have different specific gravities, can be separated in the route; the secondary purification treatment of the waste gas is realized and the environmental pollution is reduced; the first combustion chamber with an arch-shaped structure is arranged so that the rapid rising of the temperature in the furnace is realized, so that the treatment time is shortened and the energy consumption is saved; an electric cabinet is arranged so that automatic work is convenient to realize and the operation is easy.

Owner:浙江德立自动化装备股份有限公司

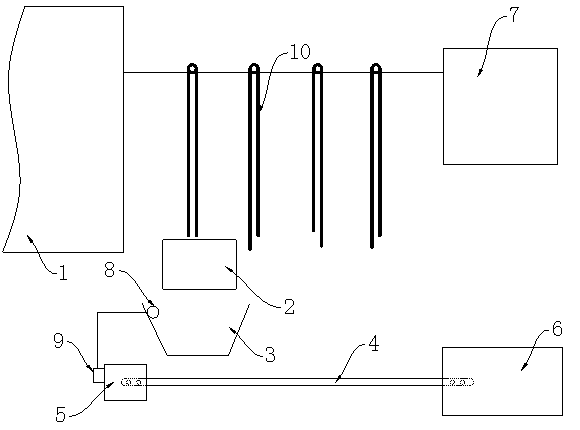

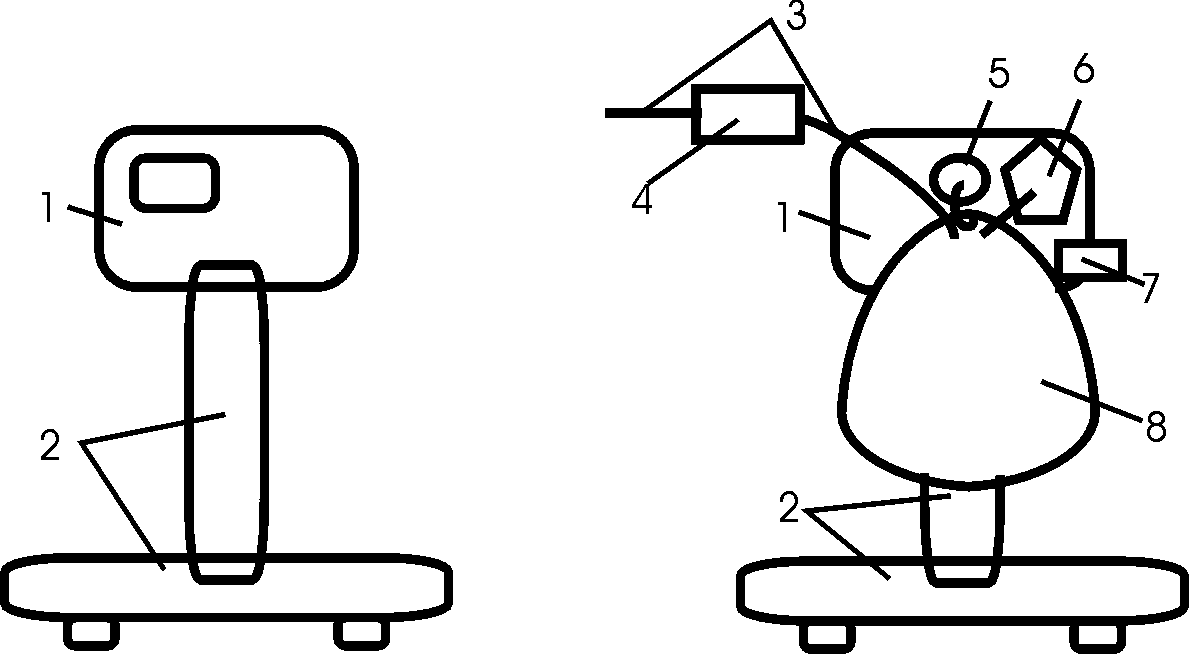

Full-automatic dynamic urine monitoring system

InactiveCN107782884AReal-time monitoring of urinationReal-time monitoring of biochemical indicatorsTransmission systemsSensorsDynamic monitoringBiochemical markers

The invention discloses a full-automatic dynamic urine monitoring system, belongs to urine test items and relates to a set of bedside urine monitoring system and technology capable of automatically monitoring catheterization patients, used for monitoring urine output and biochemical urine indexes of the patients and performing bladder smooth muscle training. The system adopts multiple technologiesand products involving urine dipstick, dipstick storage bin box, acquisition, transfer and location, retaining fresh primary and secondary urine bags of the urine, bladder smooth muscle training, urine sample extraction and injection, accurately weighing urination, converting accurate urine volume by urine specific gravity and recording, urine detection to acquire biochemical indexes and urine specific gravity, local data storage and wireless / wired batch timed transmission, or reception of instructions to complete specified operations, one-step parameter setting and automatic and continuous operation. A host controls all subsystems to monitor urination and biochemical urine indexes in real time to complete functions which cannot be realized in the traditional method. The aims of eliminating multiple interference sources, avoiding personal errors, reducing manual operations and preventing pollution to operators are achieved, and an automated unmanned operation is really realized.

Owner:XIAN LAN MING MEDICAL TECH CO LTD

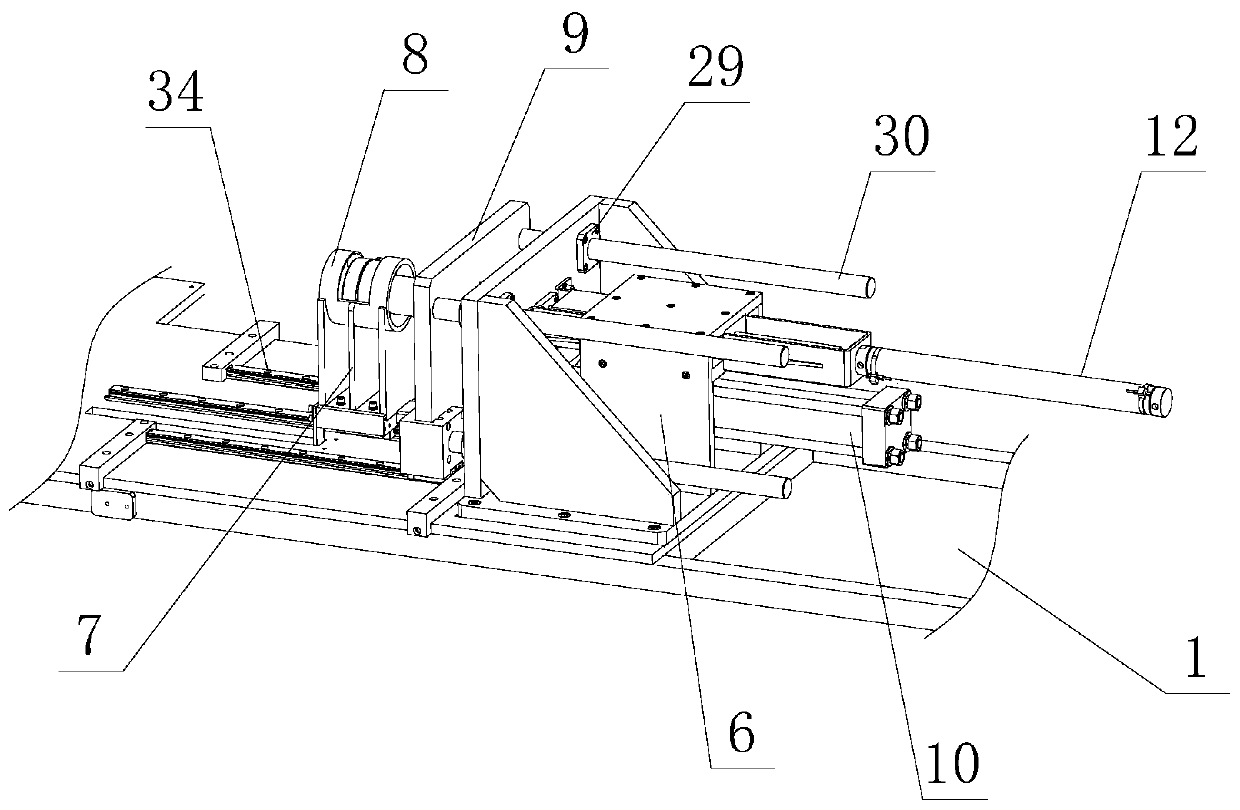

Horizontal bearing press-in equipment

PendingCN110860878AAutomate workIncrease productivityMetal working apparatusMaterial resourcesStructural engineering

The invention relates to horizontal bearing press-in equipment. The horizontal bearing press-in equipment comprises a rack, wherein a press bearing mechanism is arranged on the rack, a product discharging mechanism and a roller feeding mechanism are arranged on the front side and the rear side of the rack respectively, bearing feeding mechanisms are arranged on the two sides of the roller feedingmechanism respectively, the press bearing mechanism comprises a transposition assembly and two press-in assemblies, the transposition assembly comprises two oppositely arranged lifting units, each lifting units comprises a first top lift turbine and a second top lift turbine, a roller supporting block and a pushing block; each press-in assembly comprises a fixed seat, a slidable placing frame, a bearing placing sleeve, a push plate, a first jacking cylinder, a supporting shaft and a second jacking cylinder. According to the horizontal bearing press-in equipment, the functions of feeding, assembling and discharging are realized, automatic work is realized, and the production efficiency is improved; the roller, the shaft core and the bearing can be accurately positioned, the assembly effectis guaranteed, and the defective rate of products is reduced; and in a specified range, the operation is simple, manpower and material resources are greatly saved, and the operation safety is improved.

Owner:上海双彩吉智能科技有限公司

Advanced treatment and reuse technology of car wash wastewater

InactiveCN107792970ASolve pollutionGood removal effectFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationActivated carbonElectrolysis

The present invention discloses an advanced treatment and reuse technology of car wash wastewater. The technology comprises the following steps: S1. collecting wastewater to be treated, removing sludge by a grid, and removing oil by an inclined plate; S2. adjusting the pH of the wastewater subjected to sludge and oil removal; S3. performing micro-electrolysis treatment on wastewater after pH adjustment, and conveying the upper-layer wastewater to a unit for downstream treatment process; S4. adjusting the pH of wastewater treated in the step S3, discharging suspended solids and floating flocksin the wastewater to a sludge pool; S5. pumping supernatant wastewater treated in the step S4 to a cyclone filter system for further solid-liquid separation; and S6. enabling wastewater treated by a rotary filter to pass through multi-stage filtration systems such as a micro filtration system, an activated carbon adsorption system, an ultrafiltration system, and a nanofiltration system in sequence, and guaranteeing outgoing water to meet the drinking water standard. The technology has reasonable design and high practicability, can realize automation work, and is simple to operate and suitablefor promotion.

Owner:福瑞莱环保科技(深圳)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com