Chimney cleaning machine

A technology for cleaning machines and chimneys, applied in the fields of solid residue removal, combustion product treatment, combustion methods, etc., to achieve the effects of high practicability, low cost, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

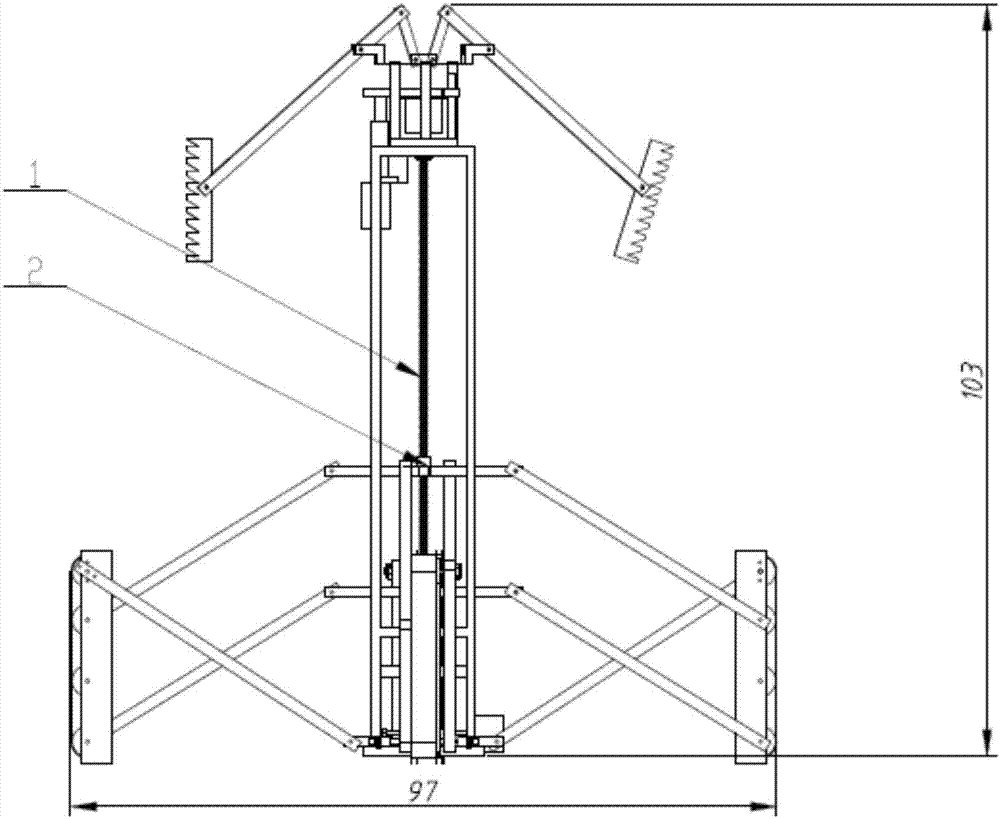

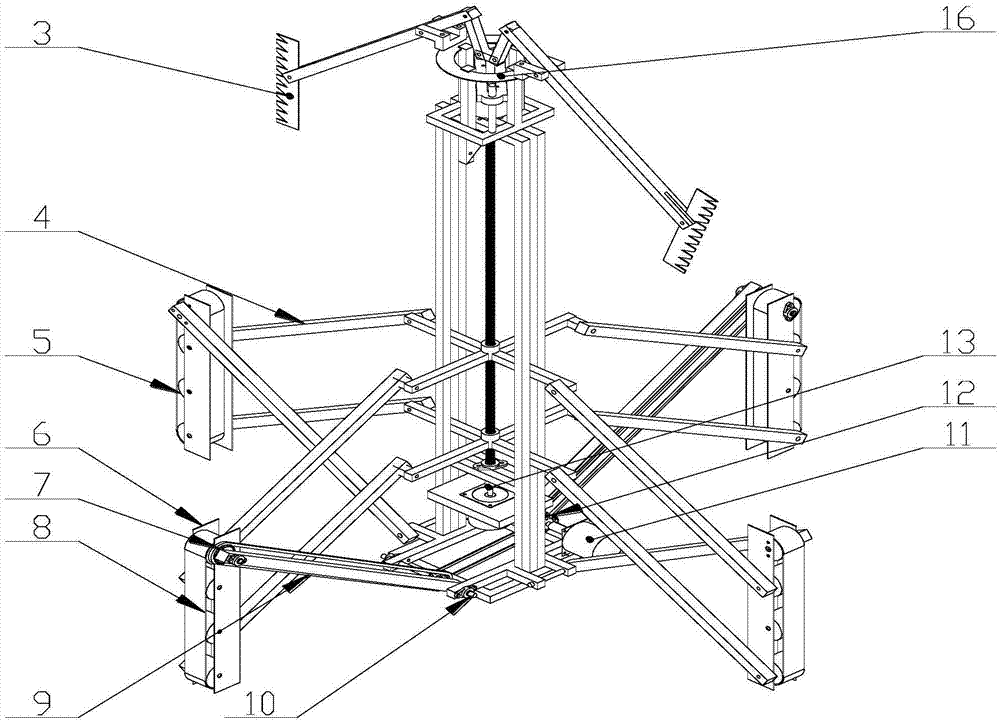

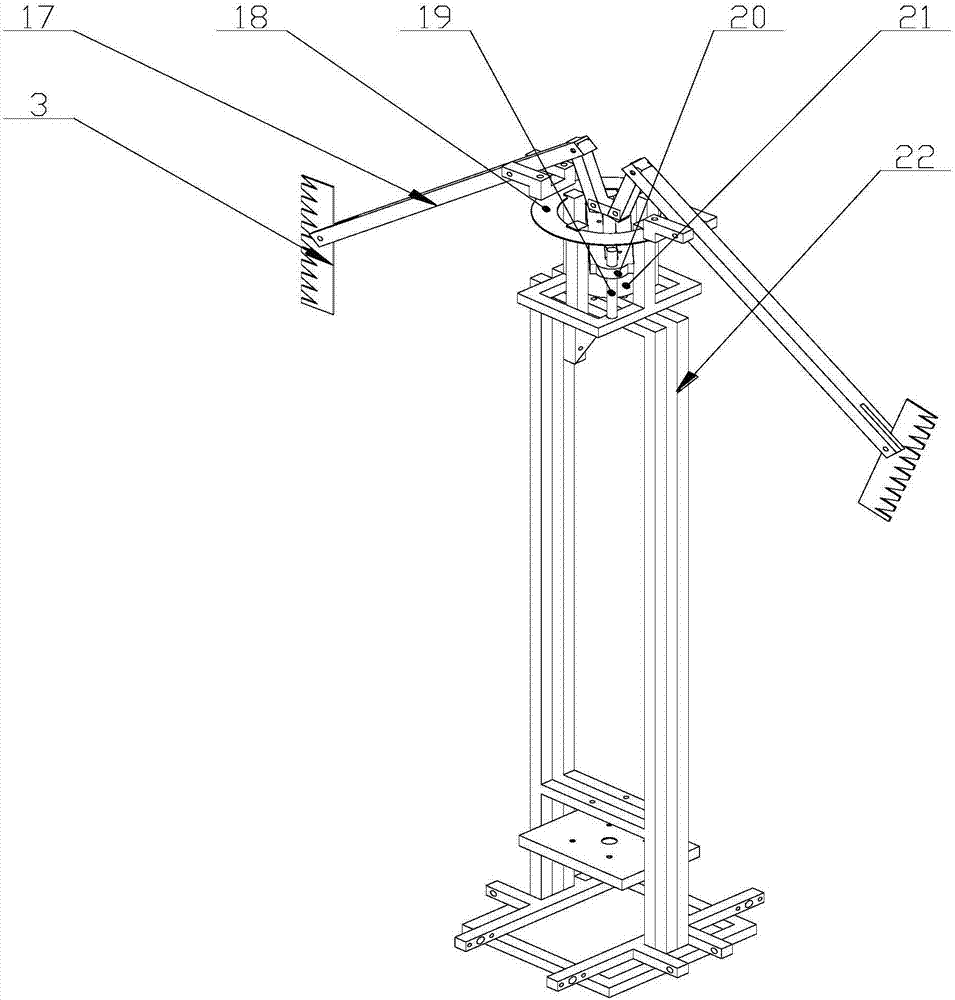

[0027] As described in the background art, at present, the cleaning of the inner wall of a small chimney mainly uses manpower, and a person boards the chimney and uses tools such as brooms and irons to clean it. Not only is it difficult to ensure safety, but it is time-consuming, laborious, inefficient, and difficult to clean up. However, the existing flue cleaning equipment can only clean the kitchen flue and large central air-conditioning pipes in the horizontal direction, and there are dead ends in the cleaning method, so this chimney cleaning machine can solve the problem that the current small chimneys are difficult to clean.

[0028] The invention adopts a four-bar linkage mechanism, which can adapt to the inner walls of chimneys of different sizes, and is very universal; and uses pressure sensors to control the retraction and retraction of the support rods to realize automatic bonding to the inner wall of the chimney, so as to successfully complete the chimneys of differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com