Automatic sampler

A prototype and automatic technology, applied in the direction of sampling devices, etc., can solve the problems of low degree of automation, unfriendly staff personal safety, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

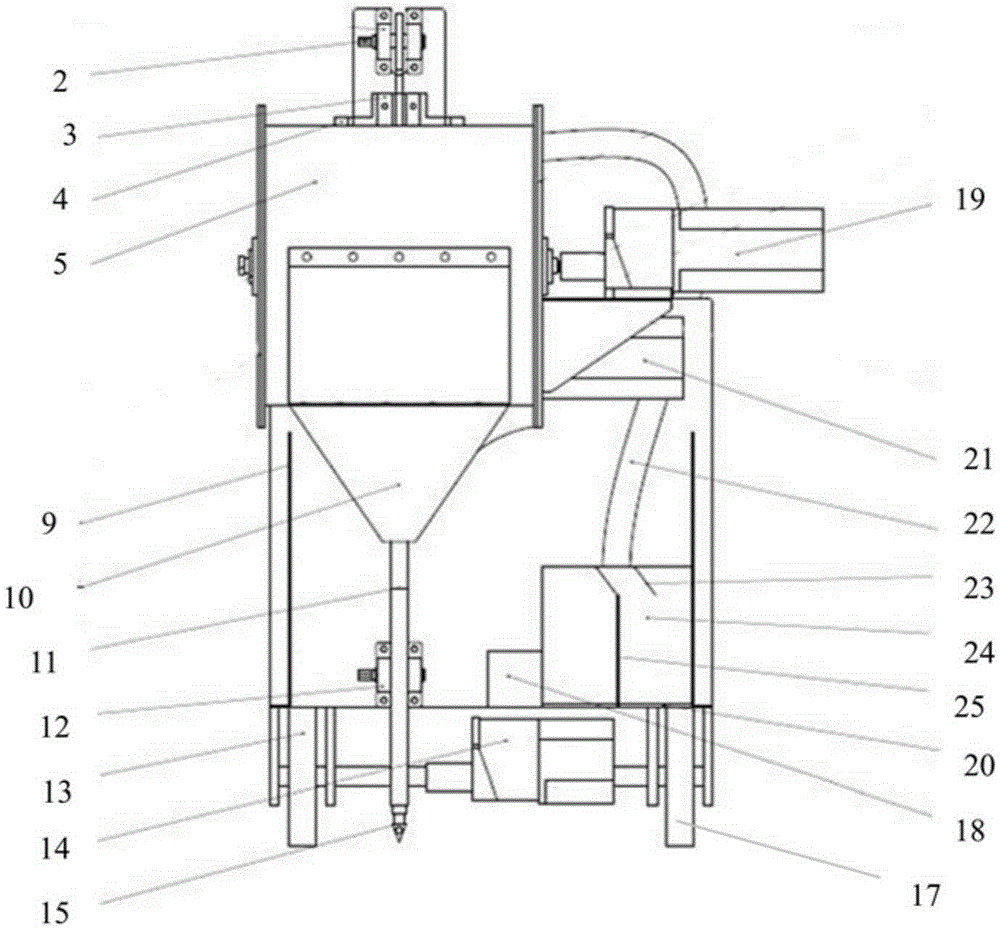

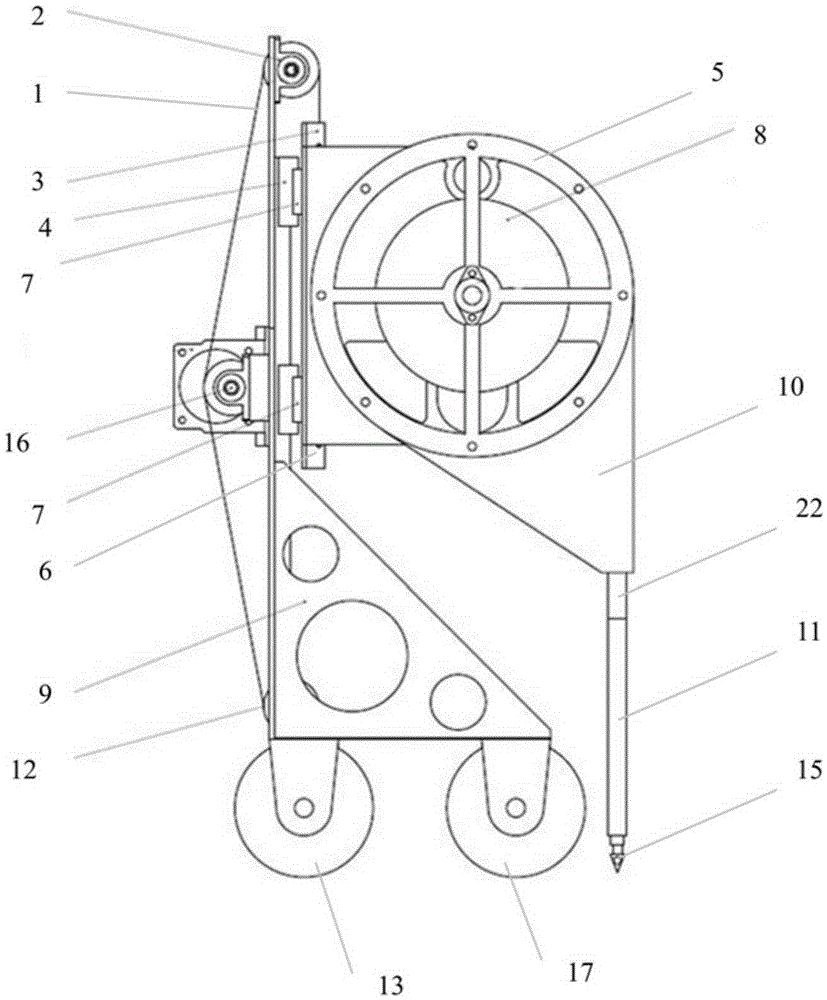

[0022] An automatic cutting machine of the present invention will be further described in conjunction with specific embodiments below.

[0023] like Figure 1-2 As shown, an automatic sample cutting machine includes a support 9, a feeding mechanism, a sample cutting mechanism and a walking mechanism. On the feeding mechanism, the hose 22 is wound and arranged on the outer periphery of the sampling mechanism, one end of the hose 22 communicates with the material, and the other end of the hose 22 communicates with the material collection device, and the material collection device In communication with the blower 18, the material collection device can be disposed on the support 9 in a tiltable manner, and the running mechanism is arranged at the lower part of the support 9, and the running mechanism and the material collection device are connected to the same control system. Like this, because blower fan 18 is connected with material collection device, the rotation of the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com