Aluminum/aluminum blister packaging tablet recognition and positioning method based on machine vision

A blister packaging, machine vision technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of laborious, low efficiency, etc., to achieve identification and positioning, efficient identification and positioning, and automatic work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

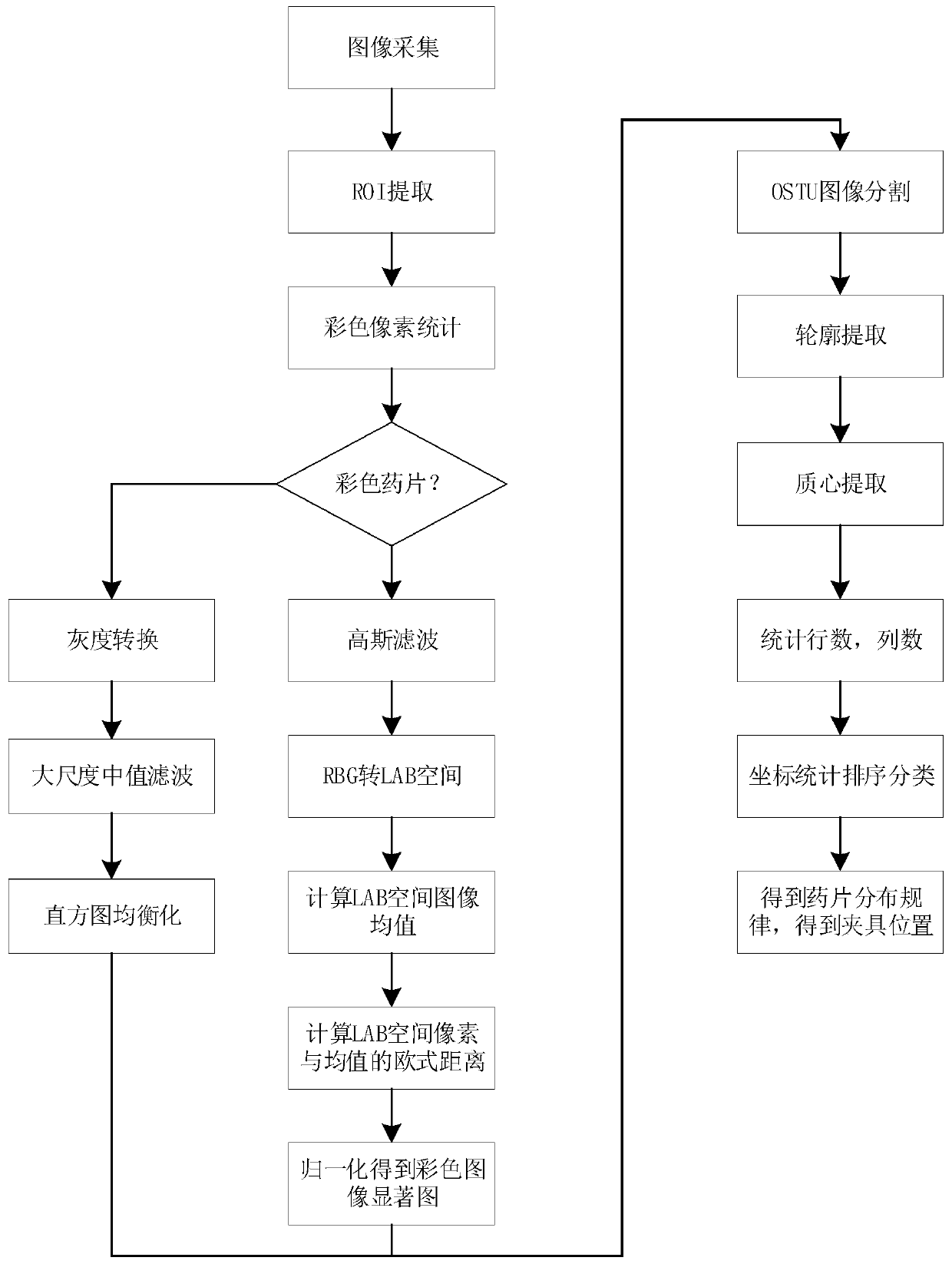

[0059] The present embodiment is described with colored tablet, as figure 1 shown, including the following steps:

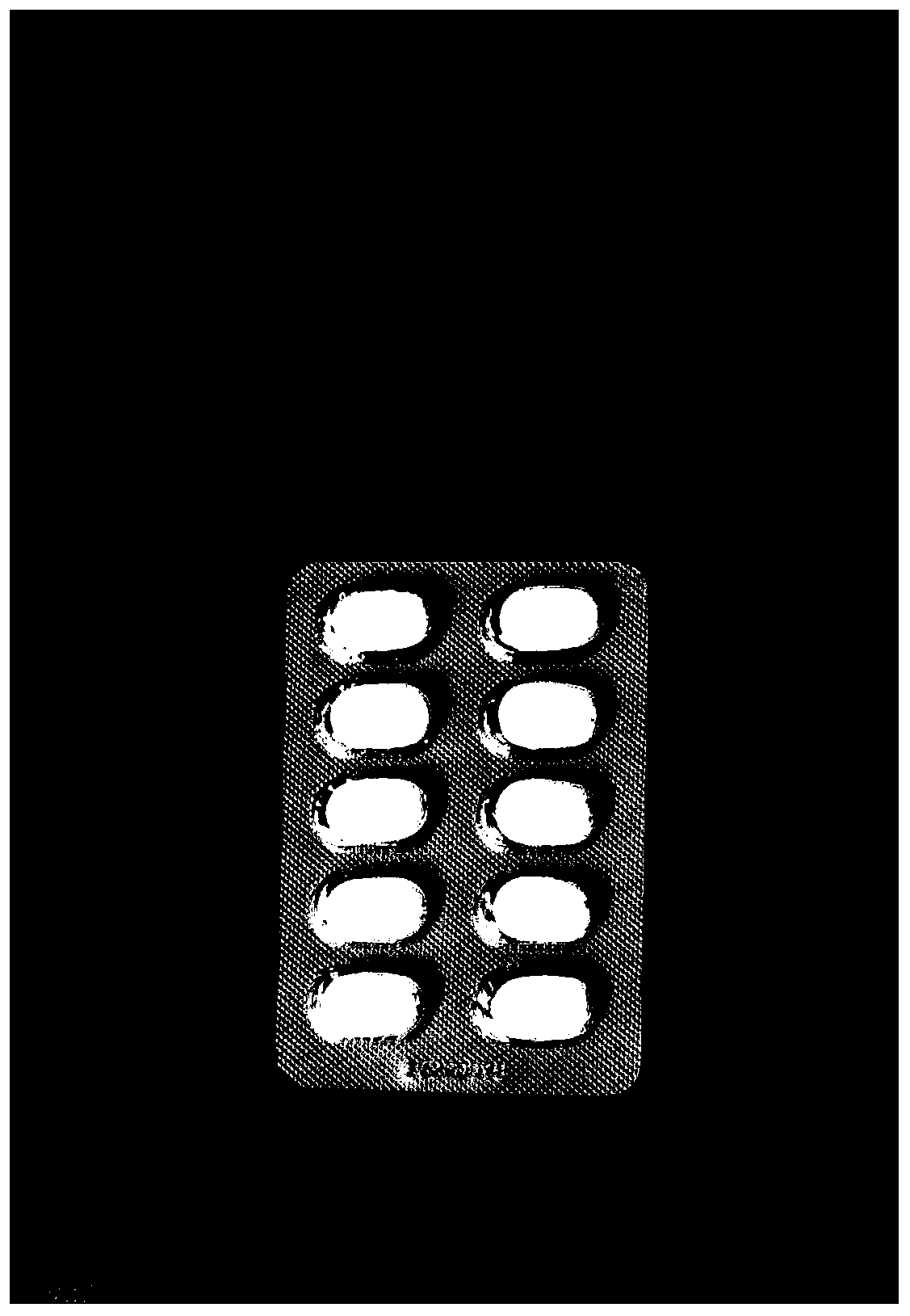

[0060] Step 1: Image acquisition is required. The image acquisition uses a 5-megapixel industrial camera. The industrial camera is vertically arranged directly above the drug stripping machine station. It is illuminated by fluorescent lamps and the illumination is kept uniform; the aluminum / aluminum blister packaging drug is removed in the field of view of the camera. There is no debris outside the board, the edge of the aluminum / aluminum blister package is parallel to the field of view of the camera, and the background is black to ensure uniform lighting, clear images, and strong contrast. See the results figure 2 .

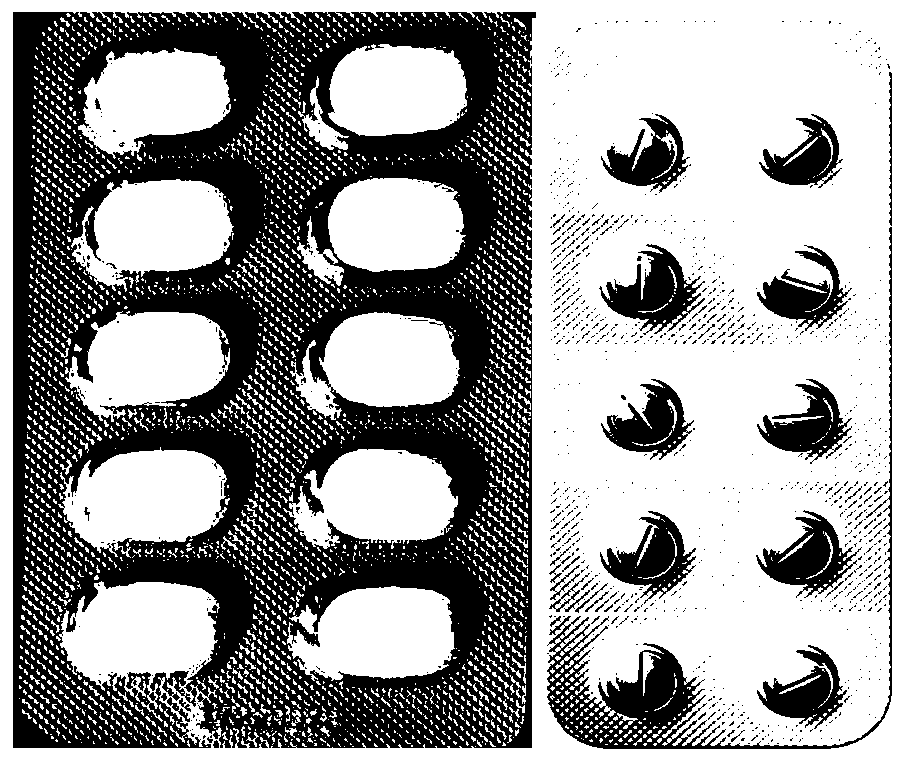

[0061] Step 2: Perform region-of-interest extraction to segment the aluminum-plastic blister pack medicine board from the camera's field of view. First, the color image needs to be converted to a grayscale image according to formula 1.

[0062]...

Embodiment 2

[0087] Embodiment 2: For white medicines, step 4 has the following differences. White medicines are similar in color to aluminum-plastic packaging, and it is difficult to judge visual significance, but image segmentation can be better achieved by using histogram equalization.

[0088] First, use formula 1 to convert the image grayscale;

[0089] In order to eliminate the influence of the texture of the aluminum-plastic package, a large-scale median filter is performed on a digital image sequence X j (-∞<j<∞) When filtering, firstly define an L window whose length is odd, L=2N+1, N is a positive integer. Assuming that at a certain moment, the signal samples in the window are X(i—N),...,X(i),...,X(i+N), where X(i) is the signal at the center of the window sample value. After the L signal sample values are arranged in ascending order, the median value, the sample value at i, is defined as the output value of the median filter.

[0090] Histogram equalization is to modify the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com