Patents

Literature

106results about How to "Increase flow itinerary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

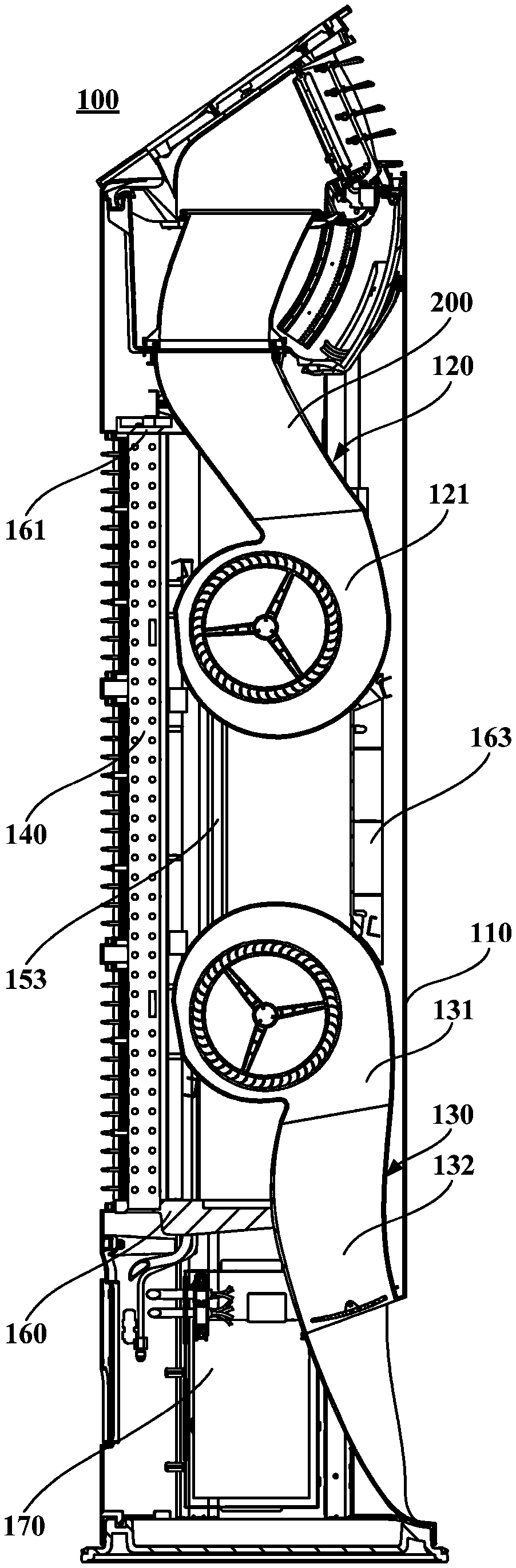

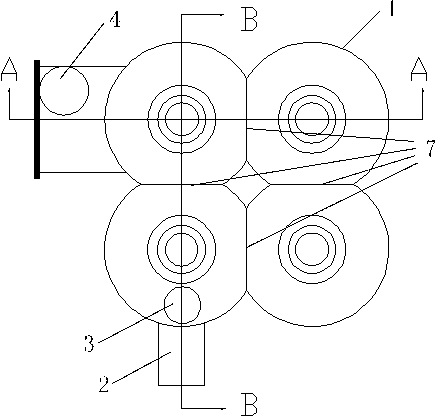

Air supply assembly, and indoor unit with same, for cabinet air conditioner

ActiveCN108534232AIncrease flow itinerarySpeed up the flowLighting and heating apparatusHeating and ventilation casings/coversImpellerEngineering

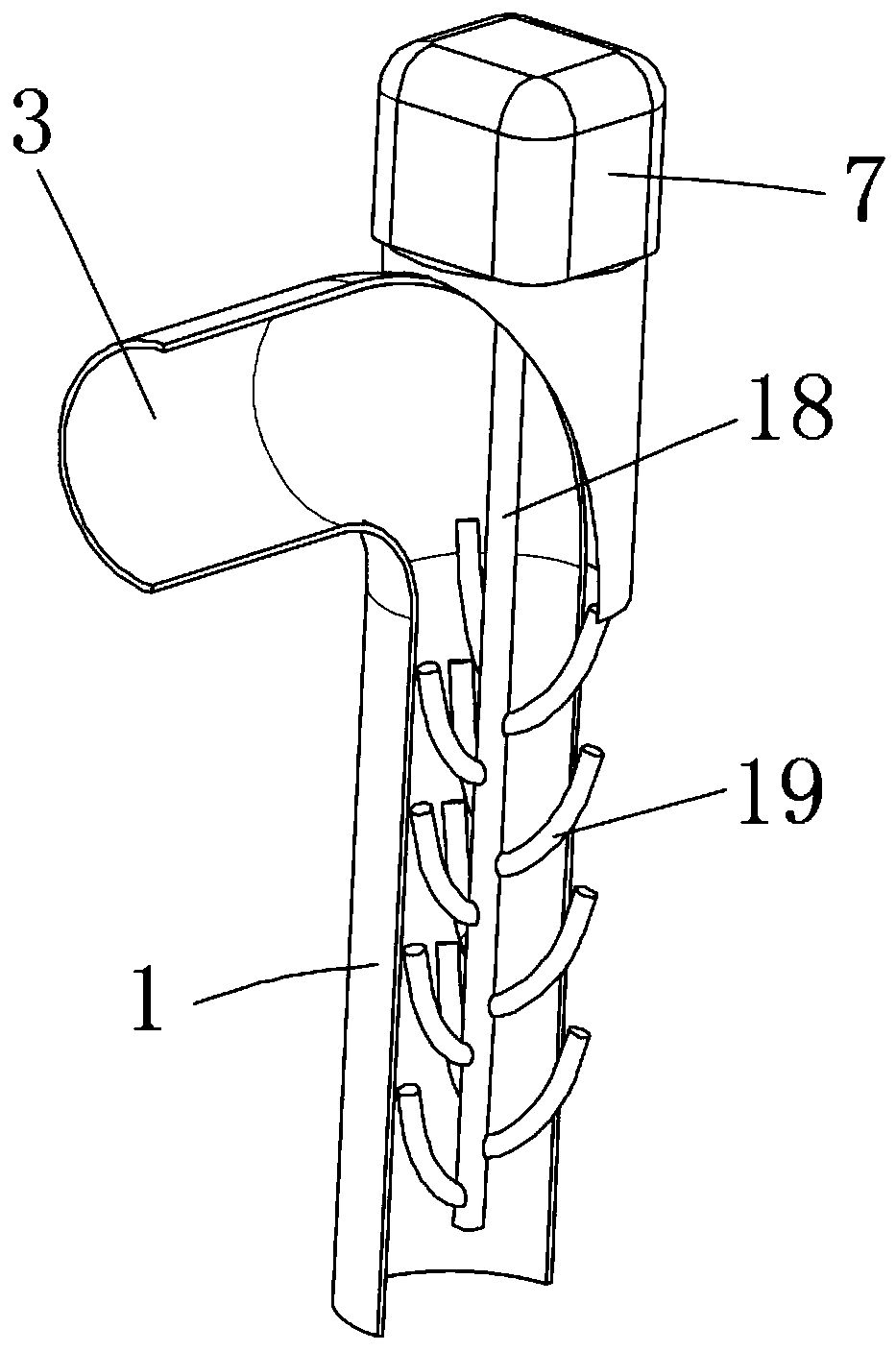

The invention provides an air supply assembly. The air supply assembly comprises a centrifugal fan and an air guide member used for guiding and conveying the airflow blown out from the centrifugal fanto an indoor environment. The outlet section of the centrifugal fan is located at the front side of the volute tongue section of the centrifugal fan. The air guide member defines a flow guide air channel extending in a direction departing from an impeller of the centrifugal fan from an air outlet port of the fan, and the forward sidewall and the backward sidewall of the flow guide air channel areconfigured to extend along a front convex curve and a rear convex curve separately; the two transversal sidewalls of the flow guide air channel are configured to extend in the vertical direction; andeach of the front convex curve and the rear convex curve is a curve bulged backwards. The flow guide air channel comprises a diffusion section extending in a manner of gradually expanding from each axial edge of the air outlet port of the fan, and a flow stabilization section extending in a manner of gradually shrinking from the extending end of each diffusion section, and lower noise is achieved, and the flow speed difference value of the airflow blown out from the centre and the edge of an air outlet port of the flow guide air channel is low, so that good user experience is achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

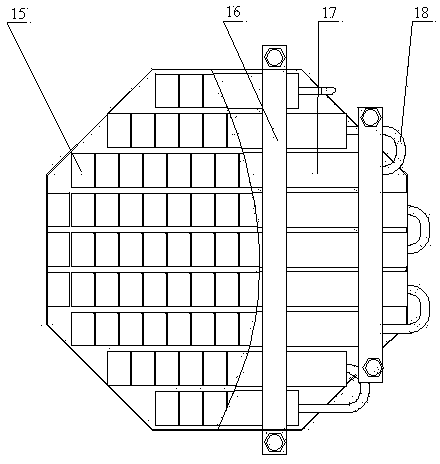

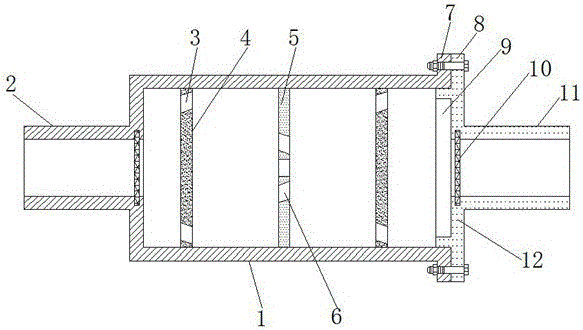

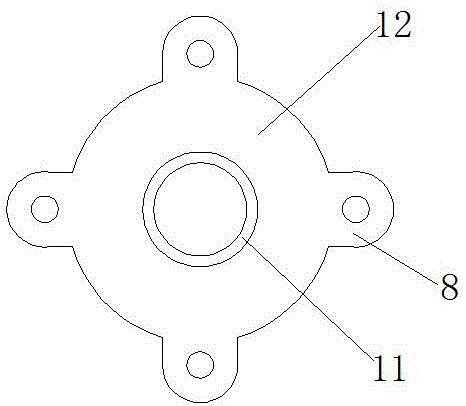

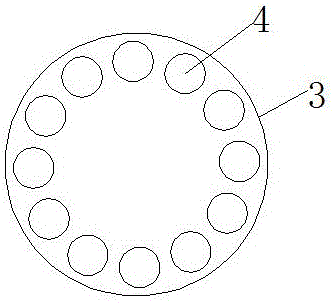

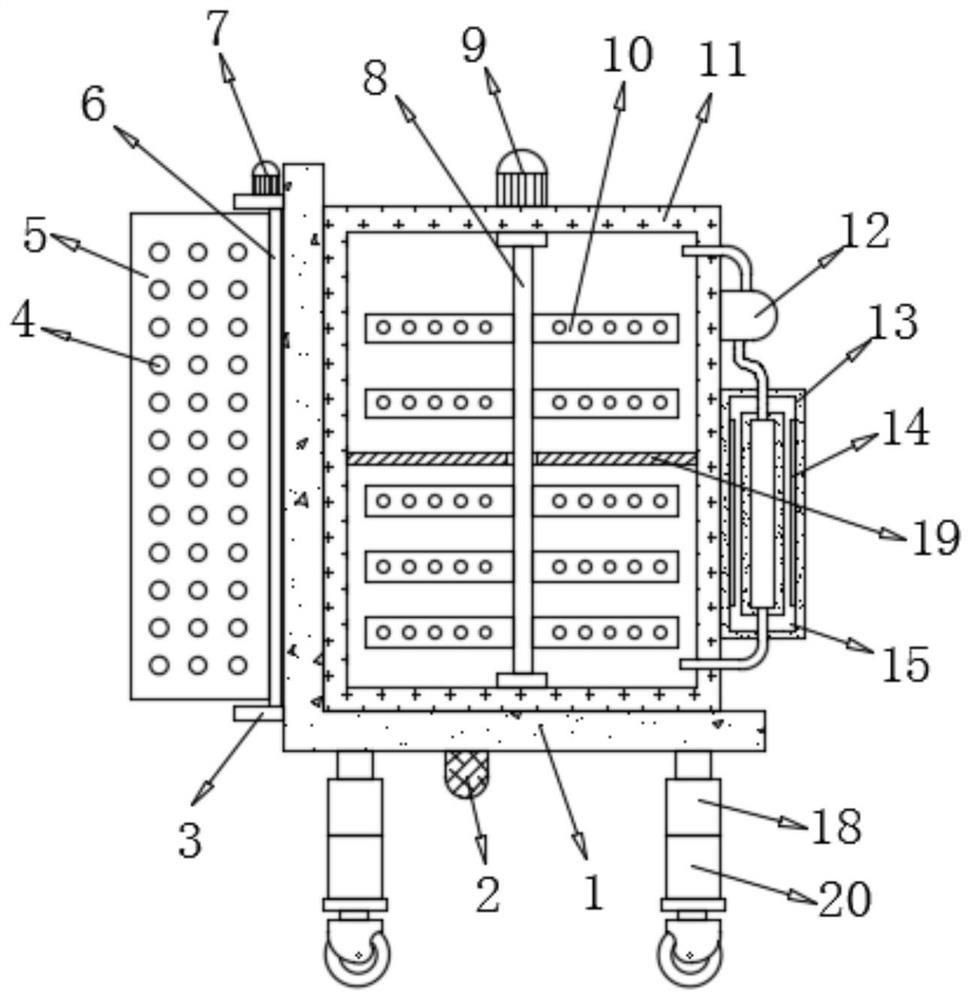

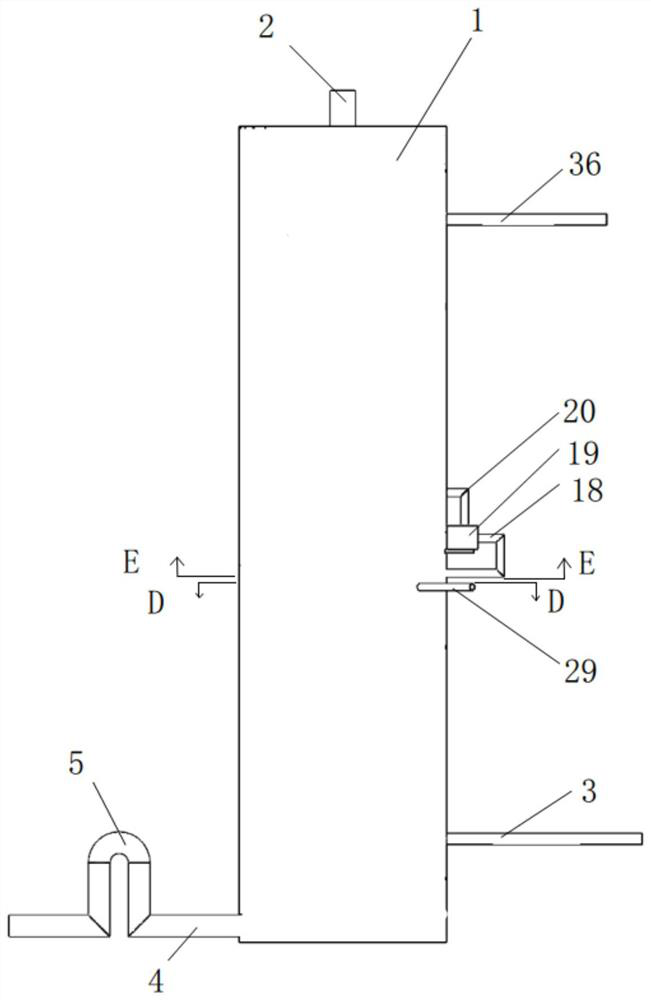

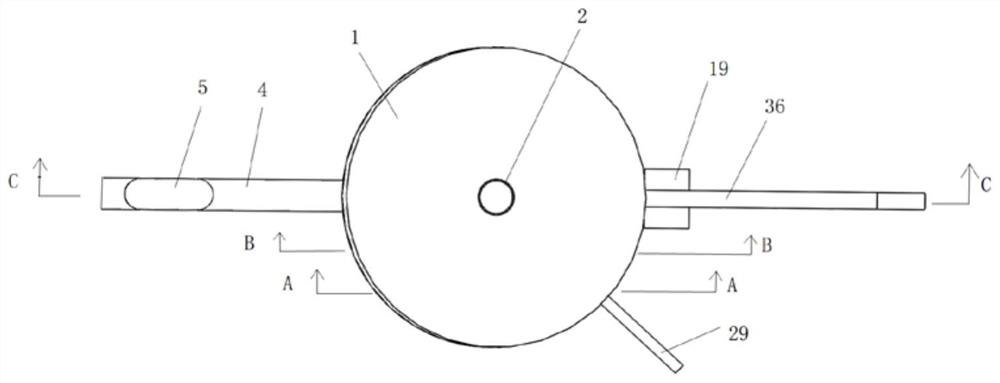

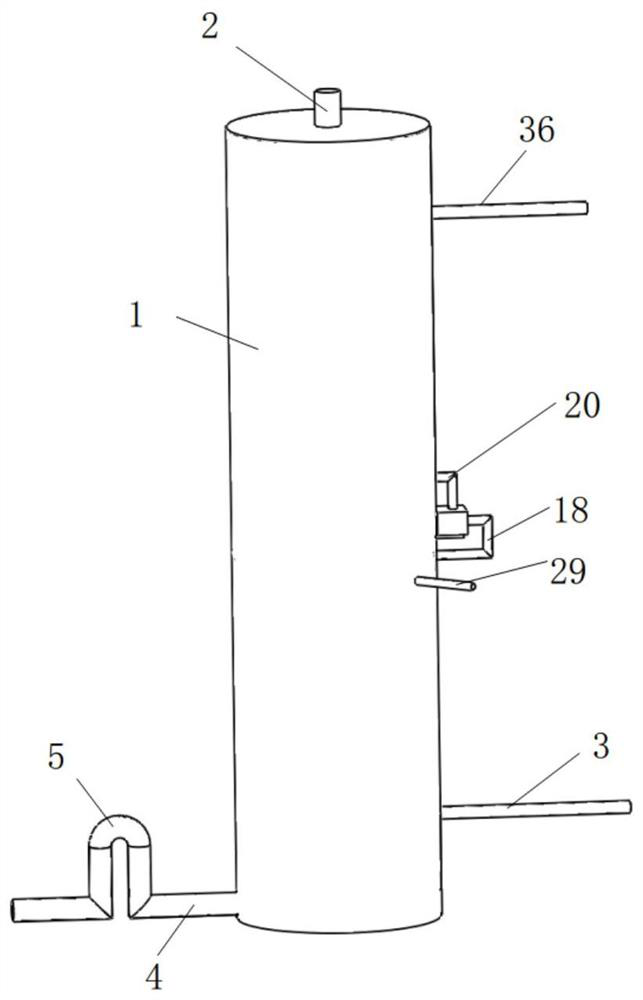

Temperature difference power generation device and vehicle-mounted tail gas waste heat temperature difference power generation system

InactiveCN103904949AIncrease profitImprove power generation efficiencyInternal combustion piston enginesExhaust apparatusTemperature differenceEngineering

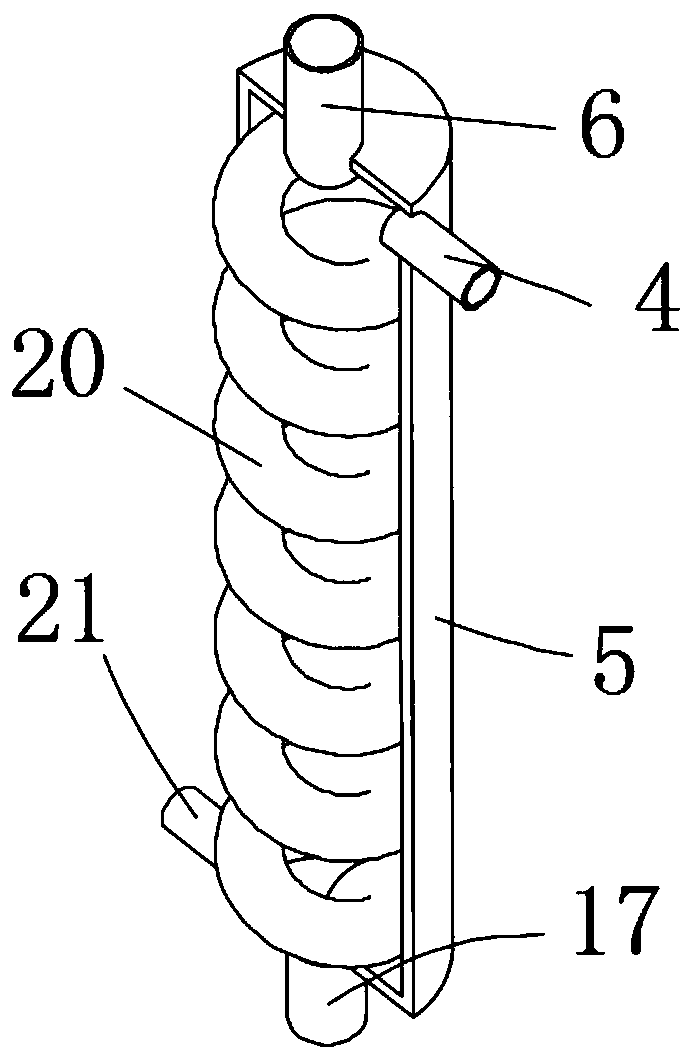

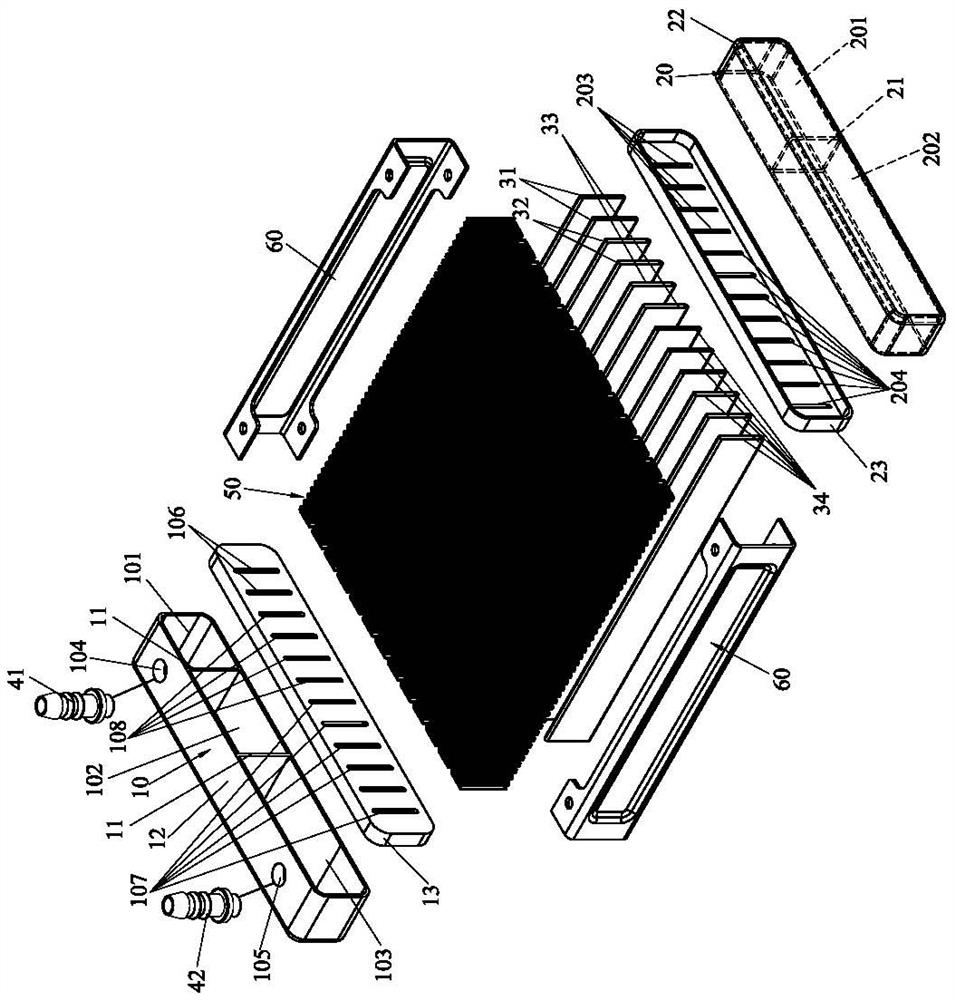

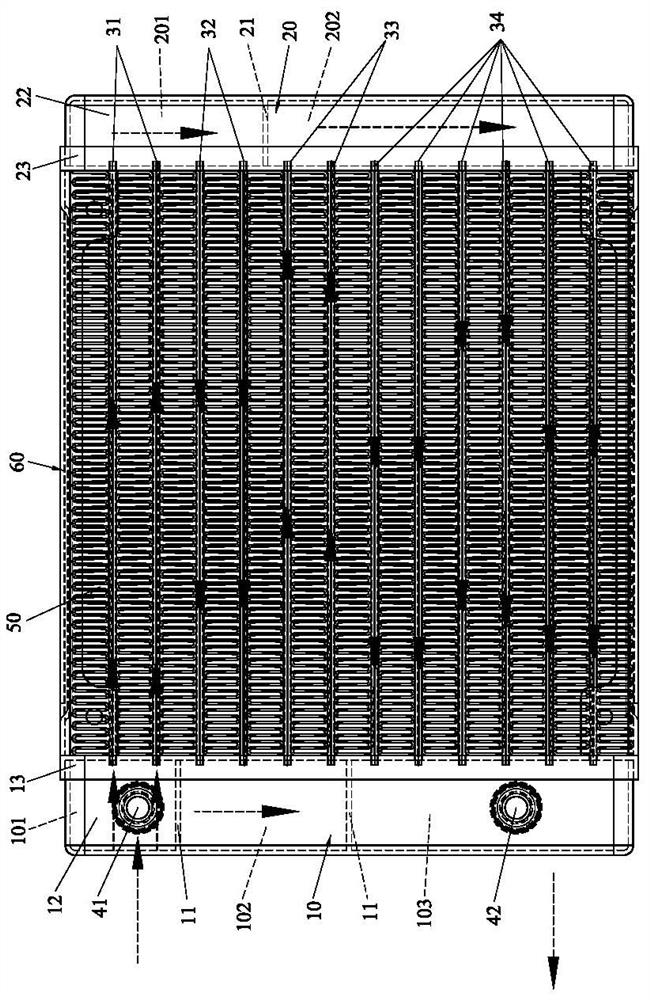

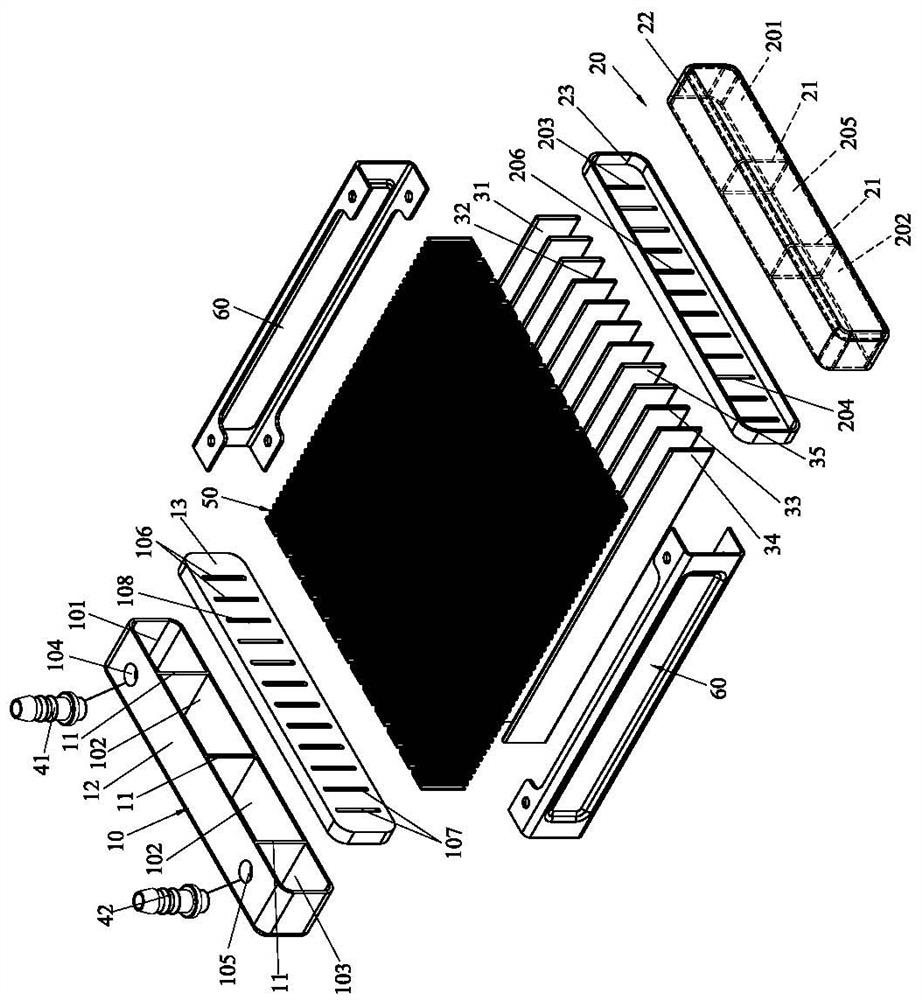

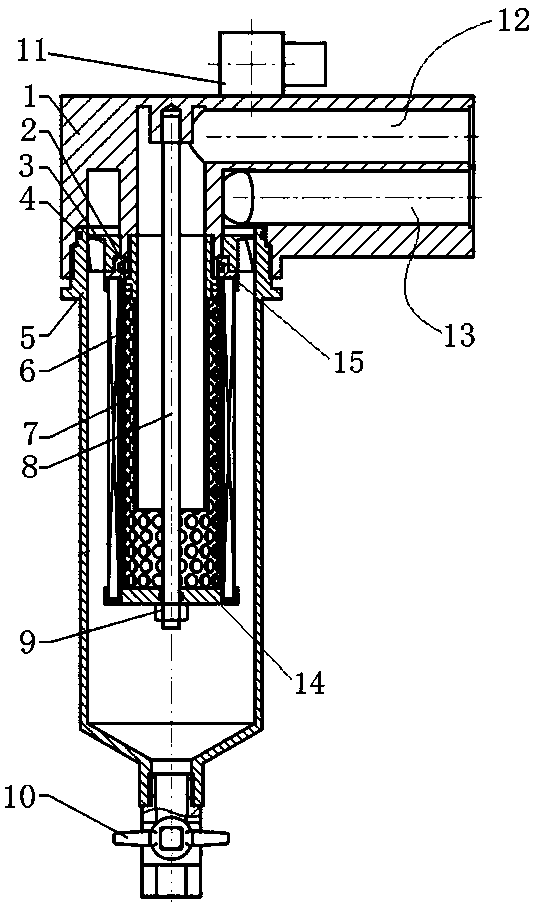

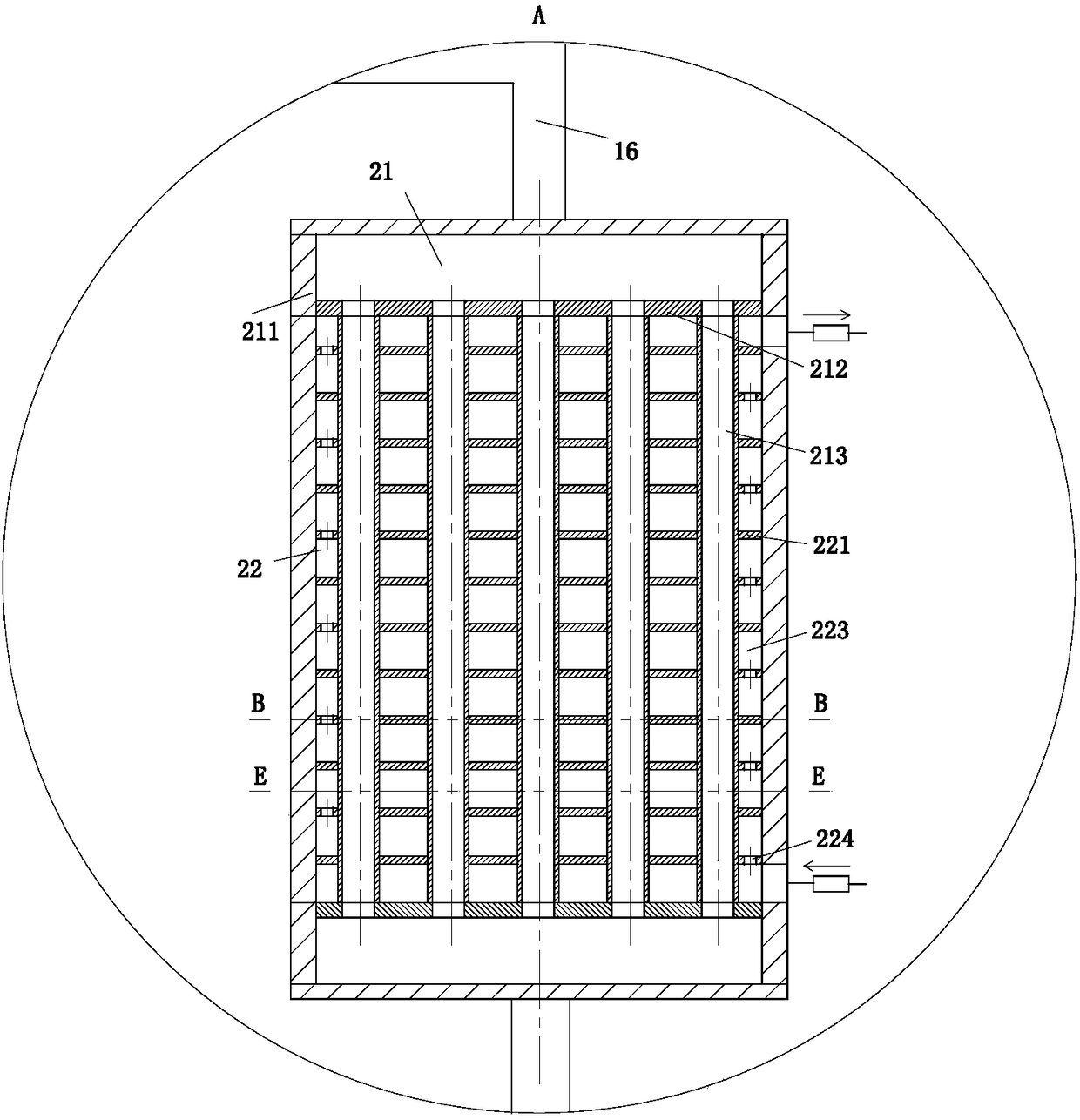

The invention discloses a temperature difference power generation device which comprises a tail gas tank, a cooling water tank assembly, a temperature difference power generation module assembly and a clamping plate. The two ends of the tail gas tank are provided with an intake manifold and an exhaust manifold respectively, and the tail gas tank comprises a gas tank body, a shunt fin, a flow guide fin and an afflux fin; the two ends of the cooling water tank assembly are provided with a water inlet manifold and a water outlet manifold respectively, the cooling water tank assembly comprises multiple cooling water tanks, and each cooling water tank comprises a water tank body and a flow guide plate; the hot end of the temperature difference power generation module assembly is attached to the two sides of the tail gas tank, the cold end of the temperature difference power generation module assembly is attached to one side of the cooling water tank assembly, and the temperature difference power generation module assembly comprises multiple temperature difference power generation modules; the clamping plate is arranged outside the cooling water tank assembly, and the two ends of the clamping plate are locked through bolts. The structure of the temperature difference power generation device is optimized and improved, power generation efficiency is improved, and the aim of improving the energy utilization rate is achieved.

Owner:WUHAN UNIV OF TECH

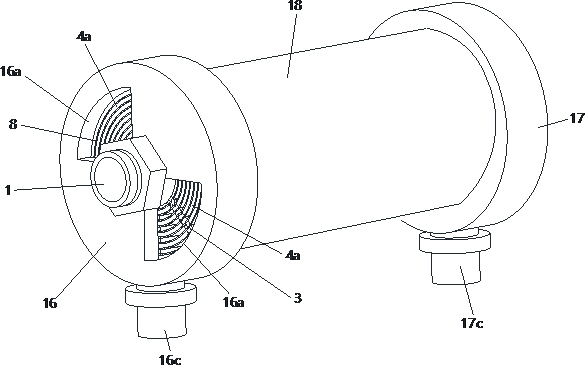

Horizontal oil heating hollow blade bearing reaction kettle

ActiveCN103230762APlay the role of mixing materialsIncrease heat transfer areaChemical/physical/physico-chemical stationary reactorsPressure vessels for chemical processHeating effectEngineering

The invention provides a horizontal oil heating hollow blade bearing reaction kettle, and is used for solving the problem in the prior art that the heating effect is bad when heat conduction oil is used for heating viscous materials. The reaction kettle comprises a reaction kettle barrel which is horizontally arranged, wherein the reaction kettle barrel is internally provided with a hollow shaft, a plurality of hollow blades communicated with the hollow shaft are fixed on the hollow shaft, and an oil inlet end and an oil outlet end are respectively arranged at both ends of the hollow shaft; an upper jacket positioned on the outer surface is fixed at the upper half part of the reaction kettle barrel, and an upper cavity is formed between the upper half part of the reaction kettle barrel and the upper jacket; a lower barrel positioned on the inner surface is fixed at the lower half part of the reaction kettle barrel, a lower jacket is arranged at the part of the reaction kettle barrel positioned under the lower barrel, and a lower cavity is formed between the lower barrel and the lower jacket; the lower jacket is provided with an oil inlet; a cavity opening communicating the upper cavity and the lower cavity is formed in the reaction kettle barrel; and the upper jacket is provided with an oil outlet. Through a double heating manner of the jackets and the hollow blades, the reaction kettle greatly improves the heating efficiency, and the hollow blades can achieve the effect of stirring materials; and the reaction kettle is suitable for viscous materials.

Owner:青岛量子元基环保科技有限公司

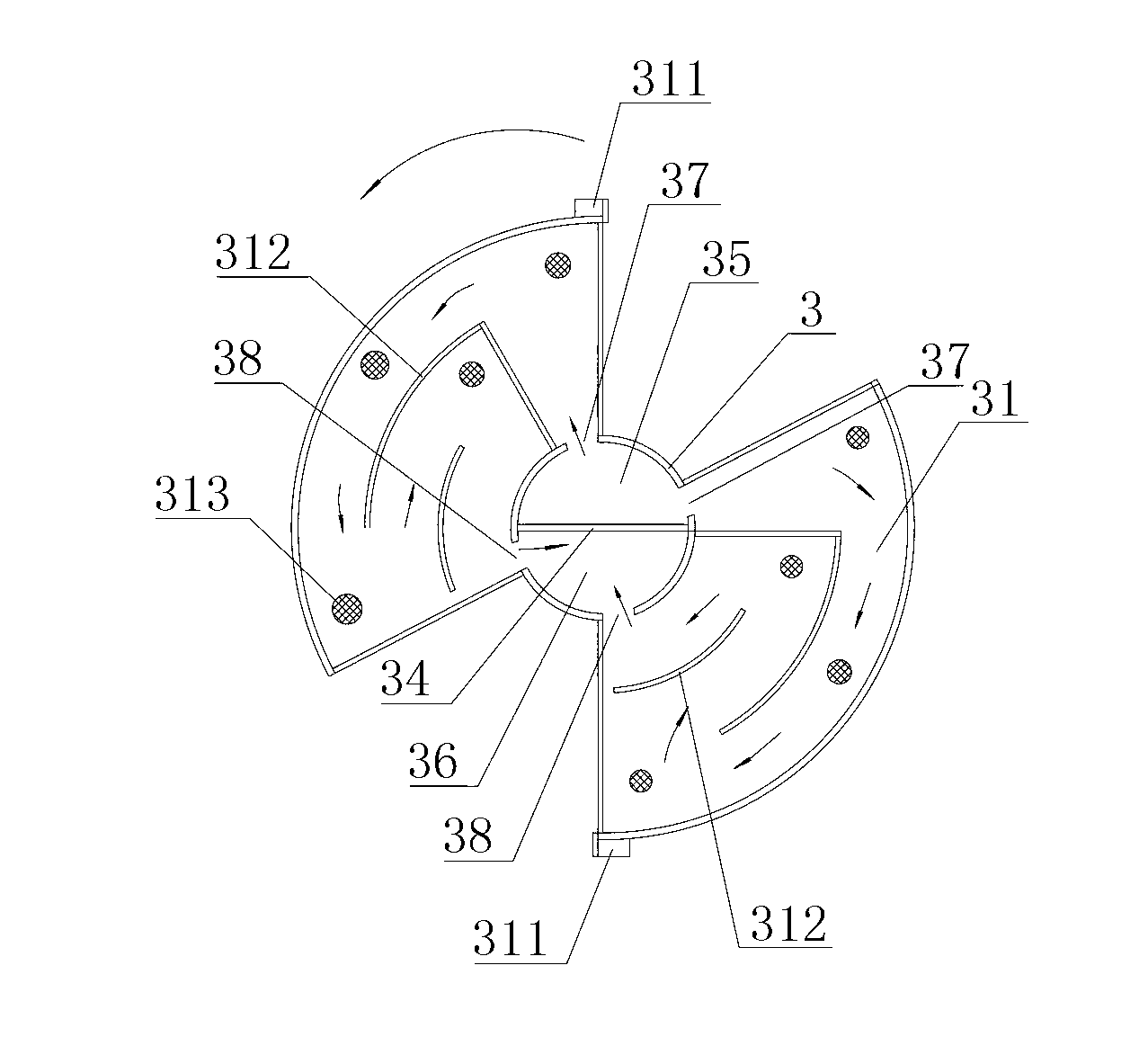

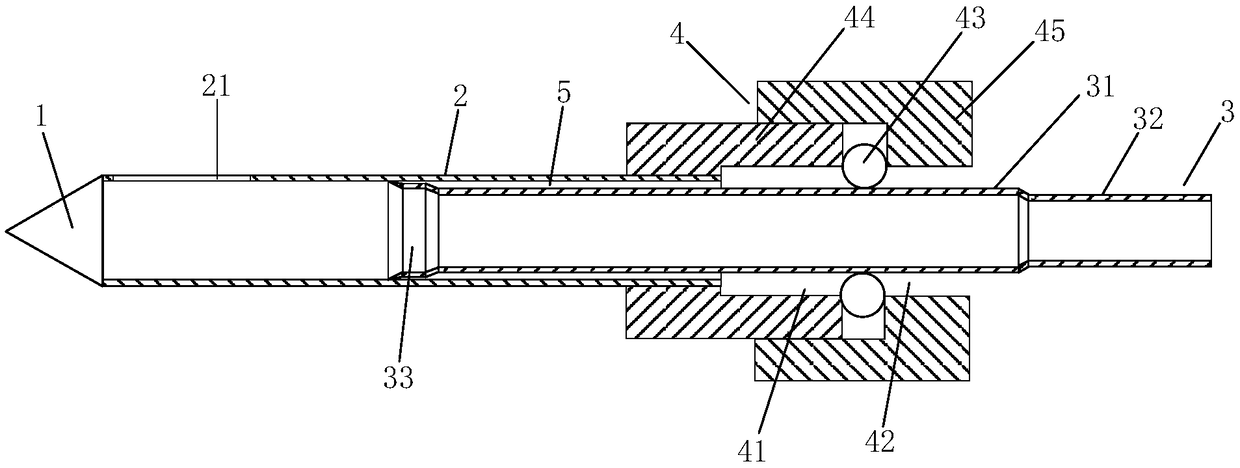

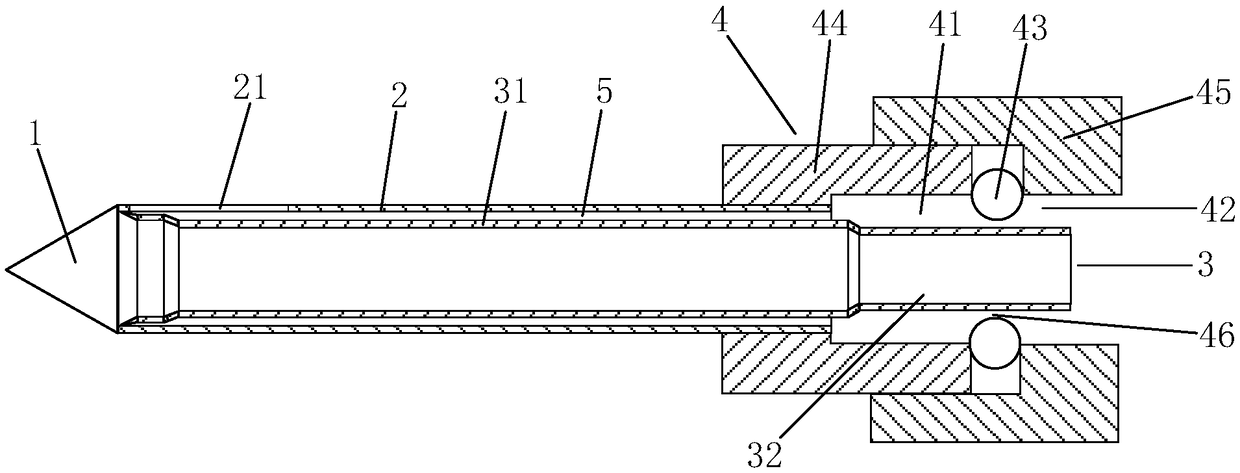

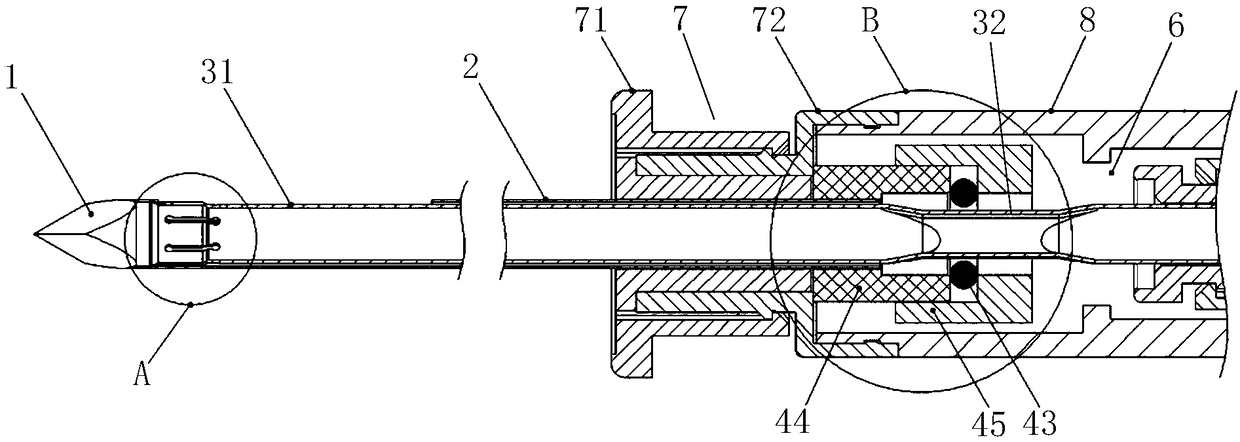

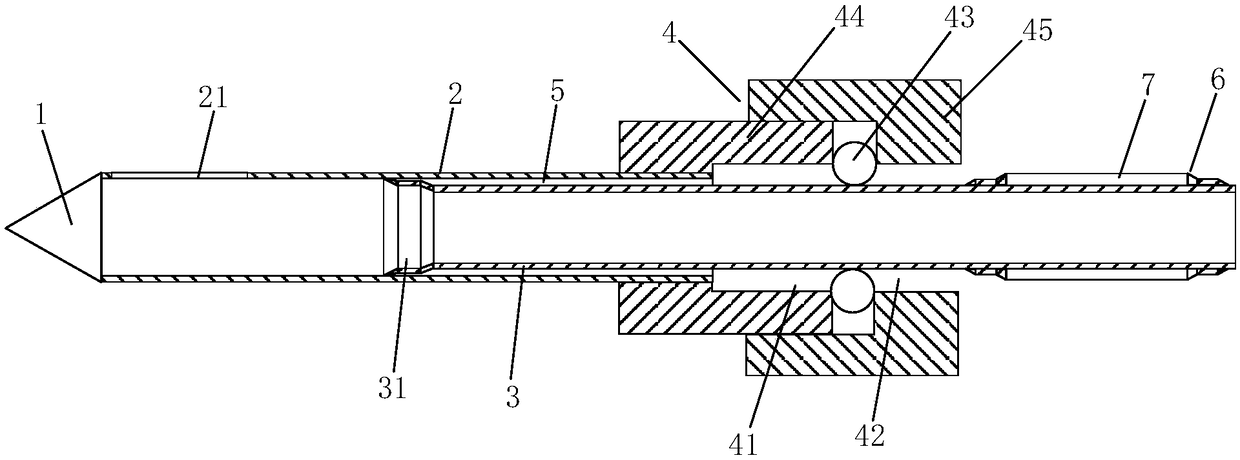

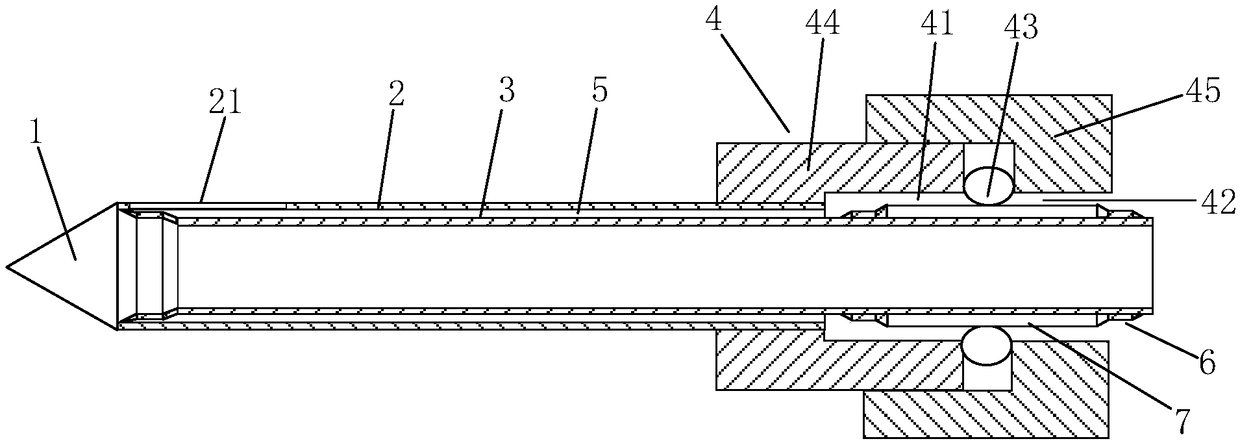

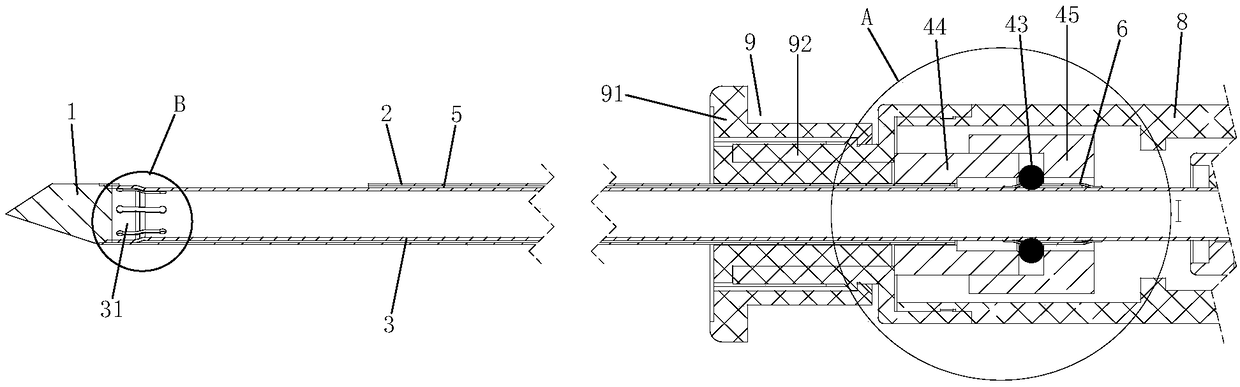

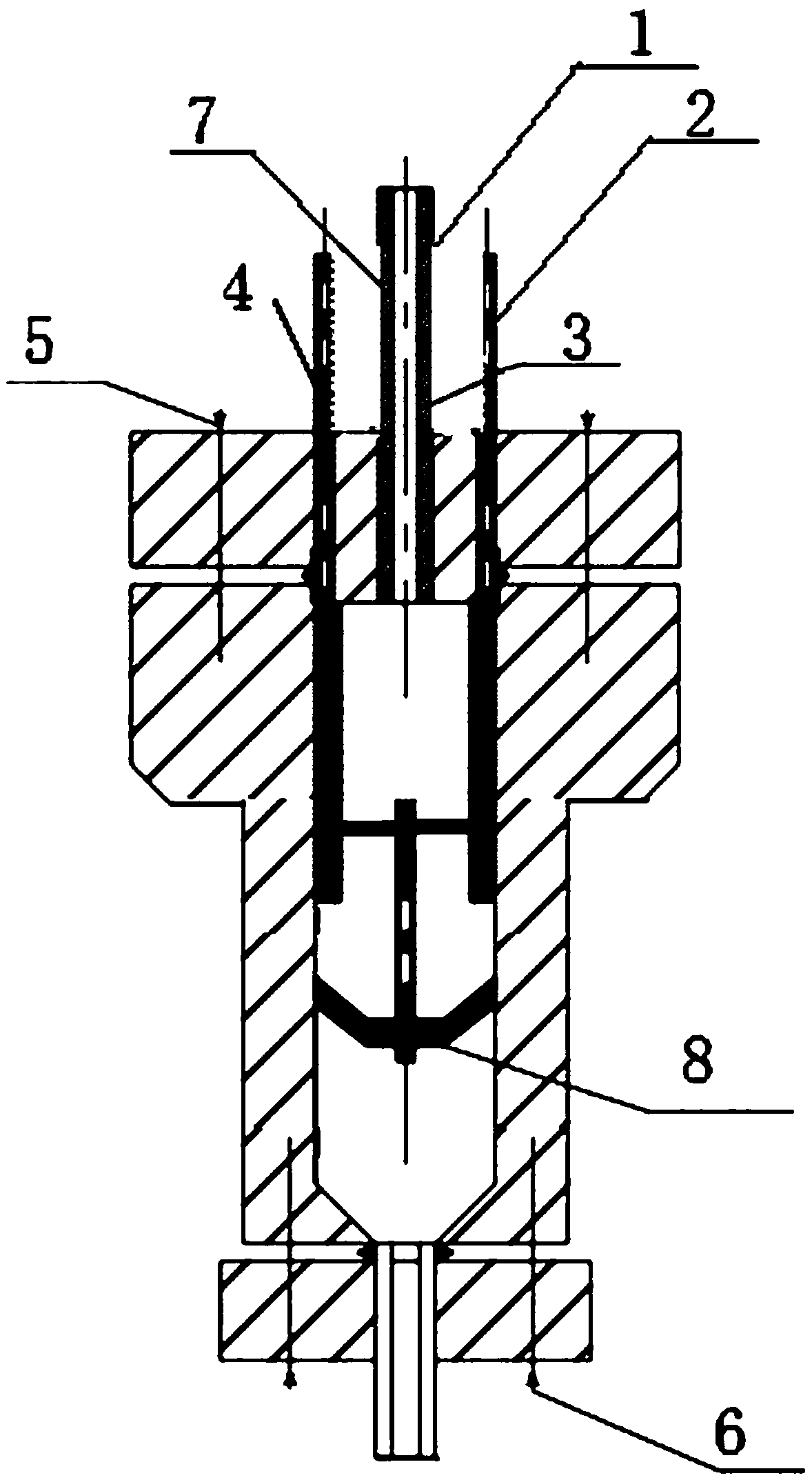

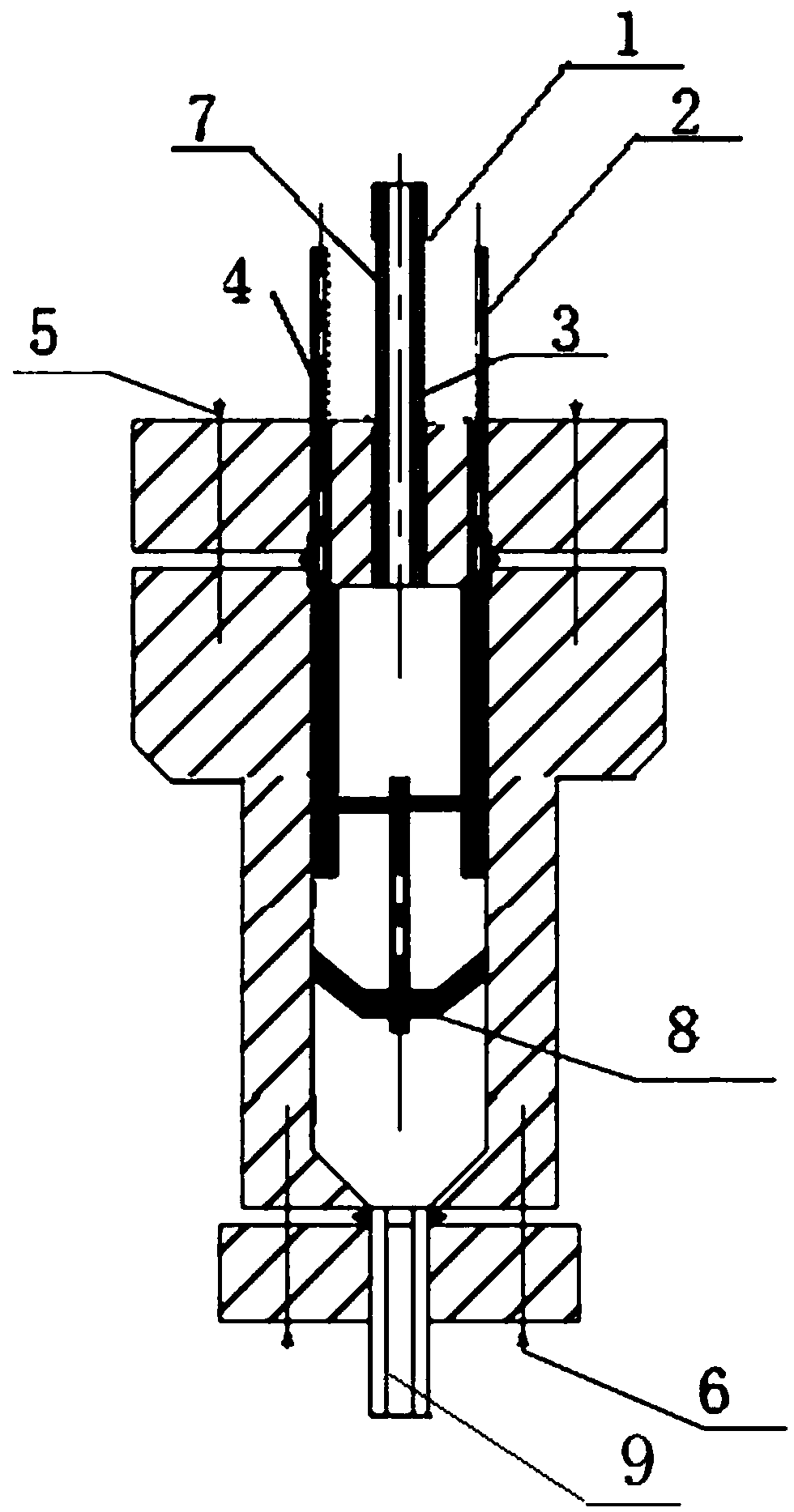

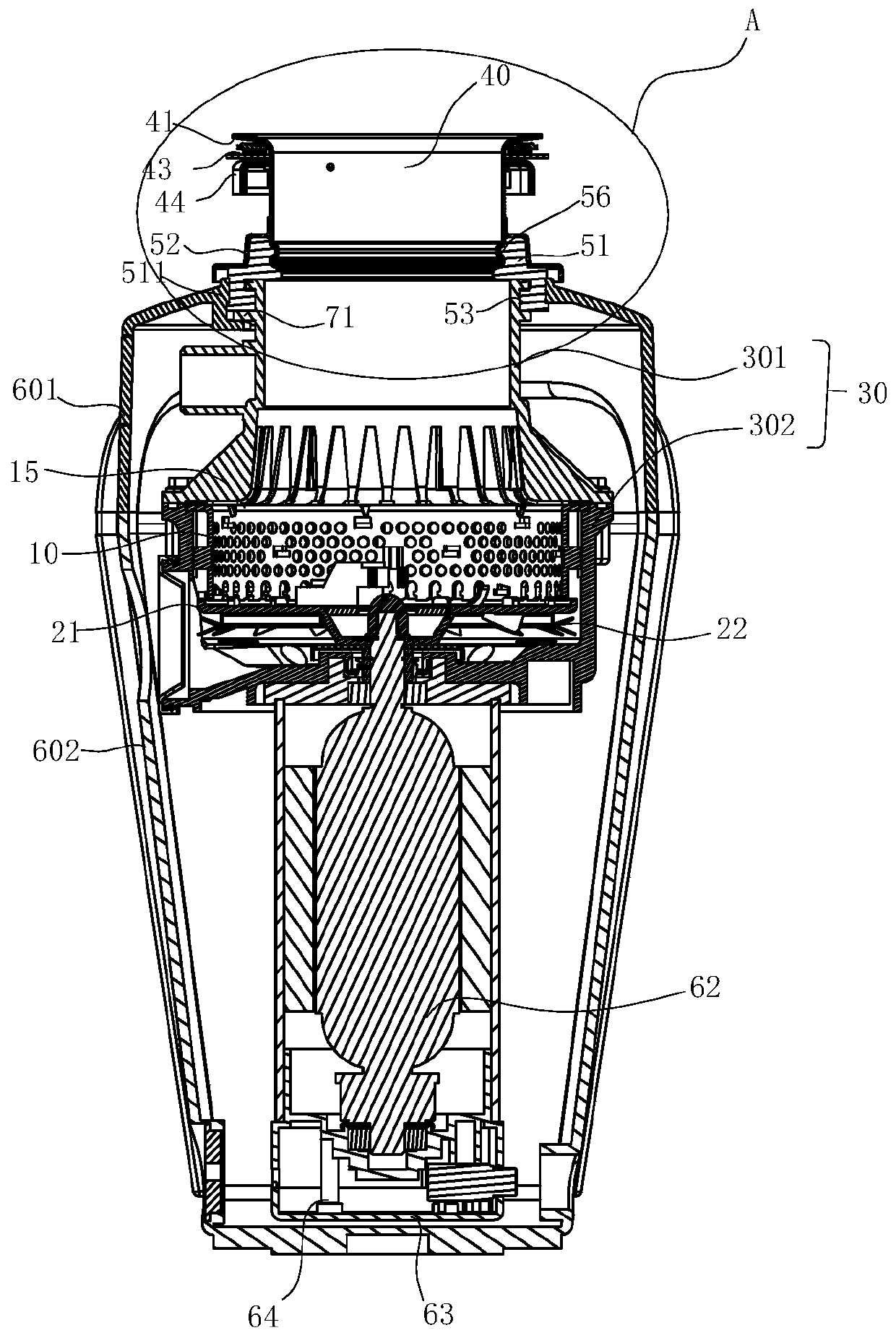

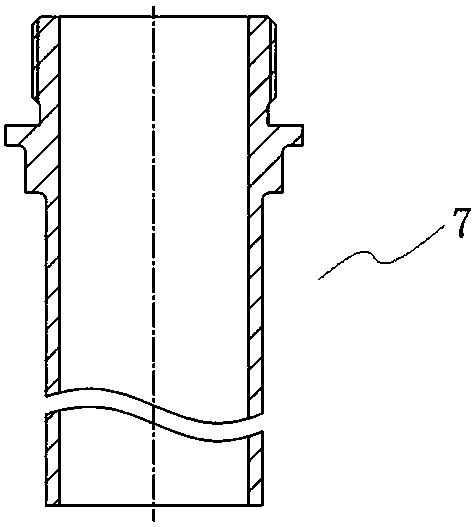

Biopsy rotary cutting device

ActiveCN109330632AEfficient suctionGood suction strengthSurgical needlesVaccination/ovulation diagnosticsUltimate tensile strengthBiopsy

The invention provides a biopsy rotary cutting device, which comprises a dynamic sealing structure arranged on the outer side of an inner cutter tube; the dynamic sealing structure forms a cavity outside the inner cutter pipe; the inner cutter pipe comprises a first pipe section and a second pipe section, wherein the outer diameter of the second pipe section is smaller than the outer diameter of the first pipe section; a sealing ring is arranged in the dynamic sealing structure; the cavity comprises a first cavity and a second cavity; when the inner cutter pipe moves to a first position alongthe axial direction of the inner cutter pipe, the sealing ring is positioned at the outer side of the second pipe section; an inter-cavity gap is formed between the sealing ring and the second pipe section so as to communicate the first cavity and the second cavity. According to the biopsy rotary cutting device, the atmosphere can be introduced to form the circulating airflow with better suction strength; the circulating airflow can more efficiently send the rotary-cut tissue of the corresponding position to a sample collector at the rear end, so that the sample yield is effectively improved.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

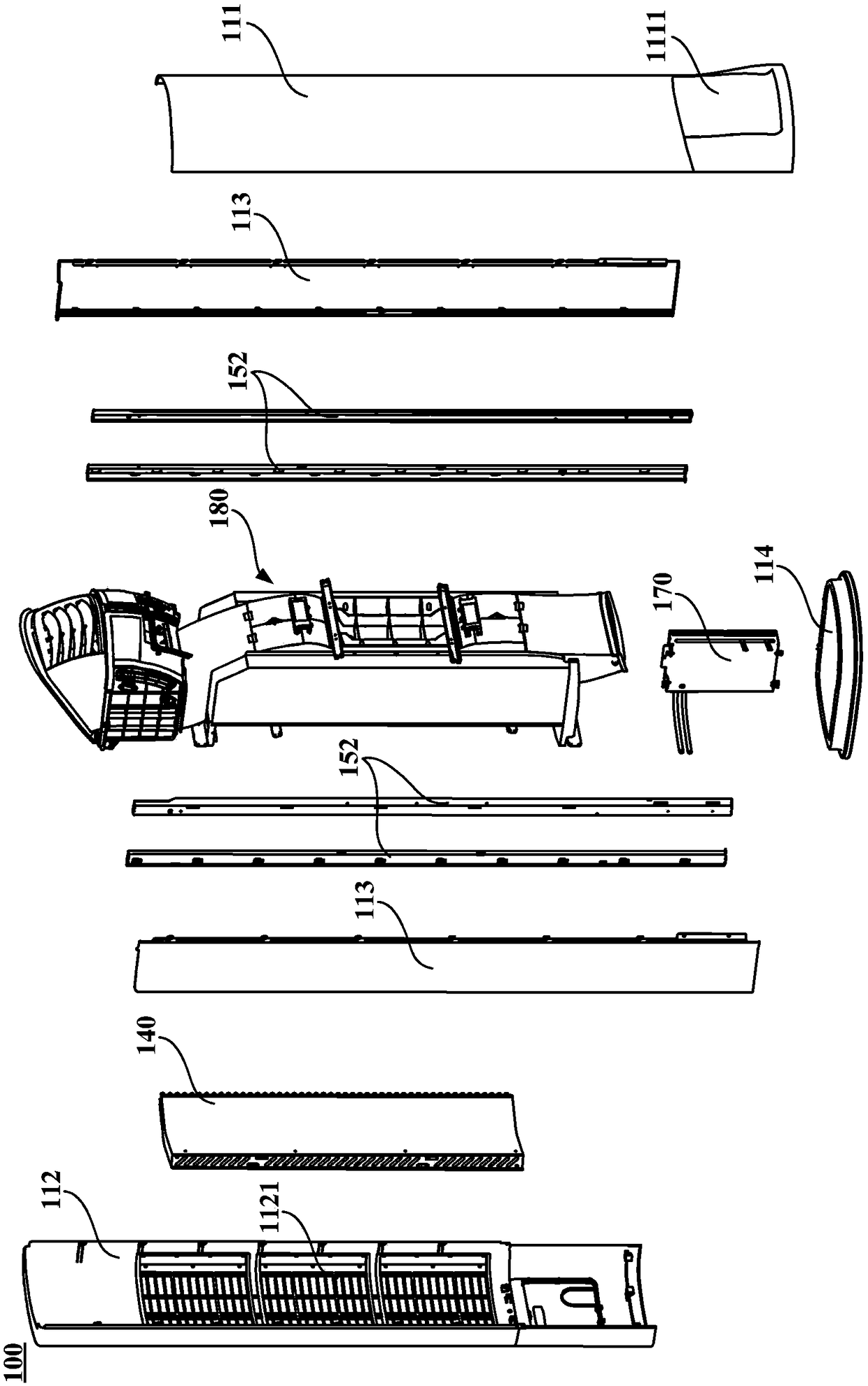

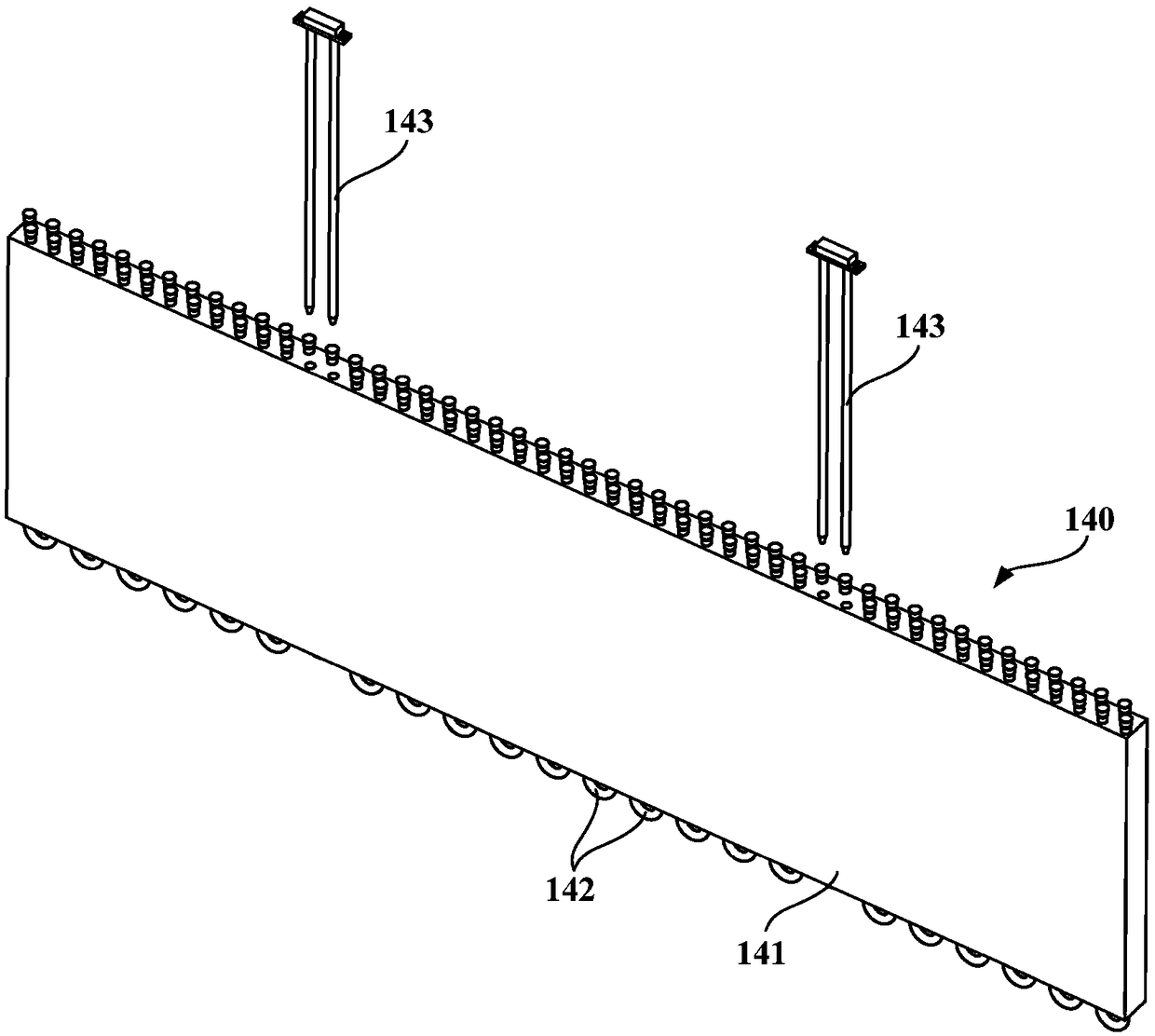

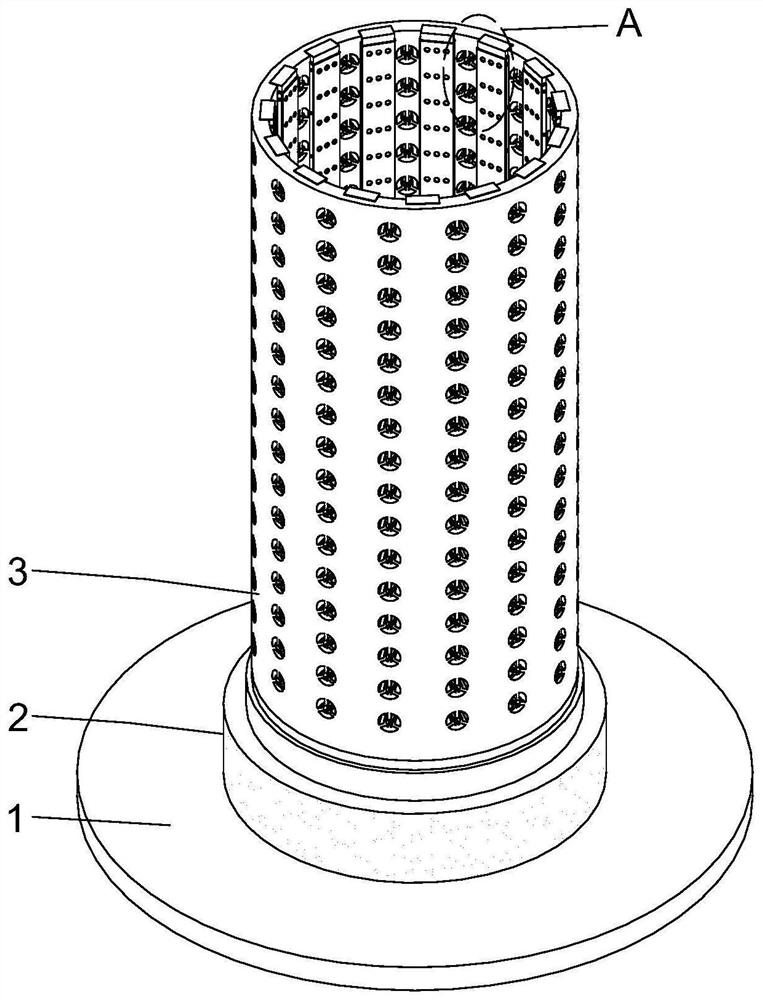

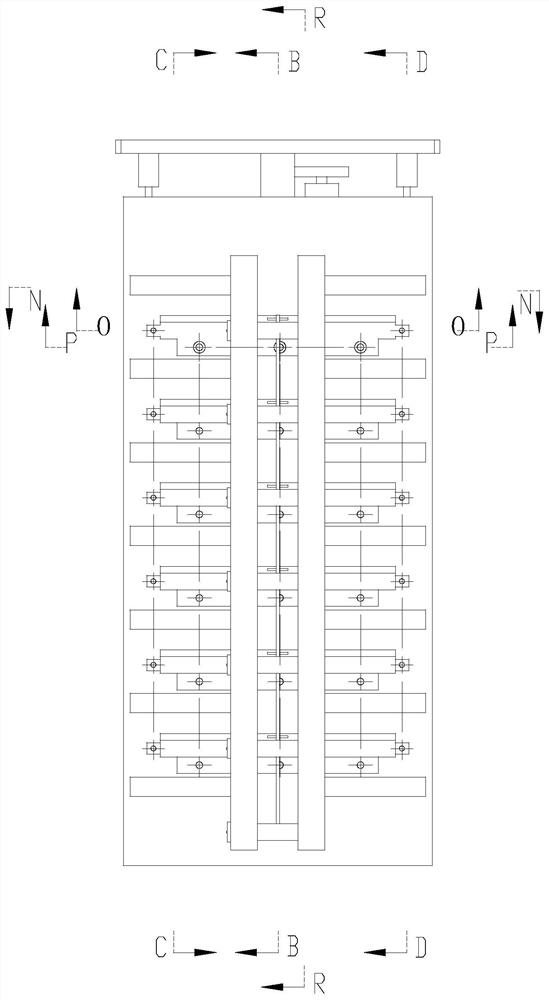

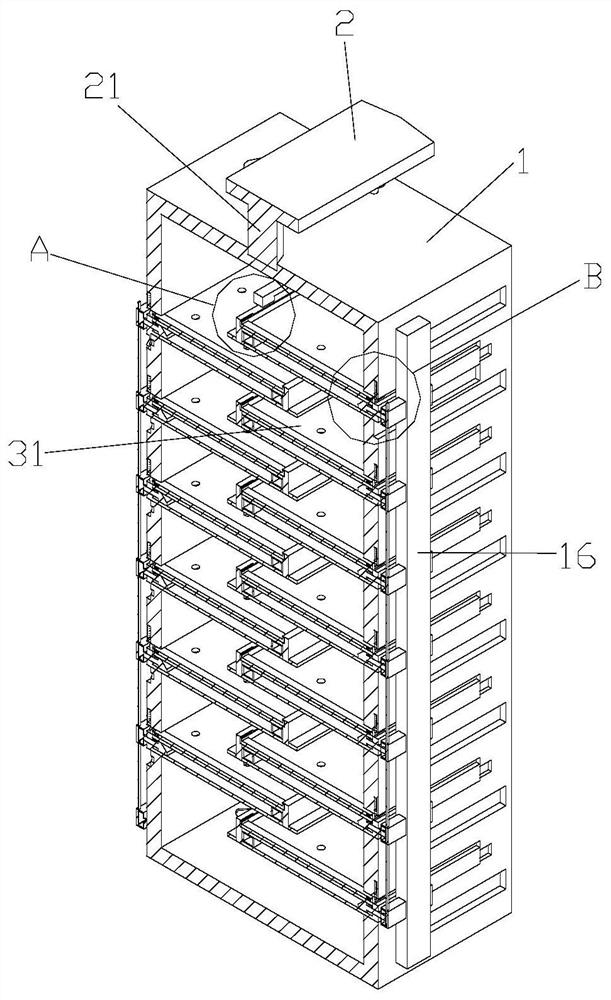

Cabinet type air conditioner indoor unit

ActiveCN108709250AIncrease air volumeIncrease the air intake areaCondensate preventionHeating and ventilation casings/coversAir volumeEngineering

The invention provides a cabinet type air conditioner indoor unit which comprises a case provided with a case air inlet and at least one case air outlet, at least one air feeding assembly arranged inthe case and provided with a centrifugal fan, an indoor heat exchanger arranged on an air inlet path between the case air inlet and the air feeding assembly, and at least one group of electric heatingpipes. The indoor heat exchanger comprises refrigerant heat exchange pipes and a fin group extending along the vertical direction and provided with multiple pipe inserting holes; and the refrigerantheat exchange pipes penetrate through part of pipe inserting holes so as to be fixedly connected with the fin group. The at least one group of electric heating pipes penetrate through the other part of pipe inserting holes so as to be fixedly connected with the fin group. According to the cabinet type air conditioner indoor unit provided by the invention, the original pipe inserting holes of the indoor heat exchanger are used for installing the electric heating pipes, so that no extra space is occupied, the air inlet area is larger, the air resistance is small, and the air feeding amount of the air feeding assembly is further improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

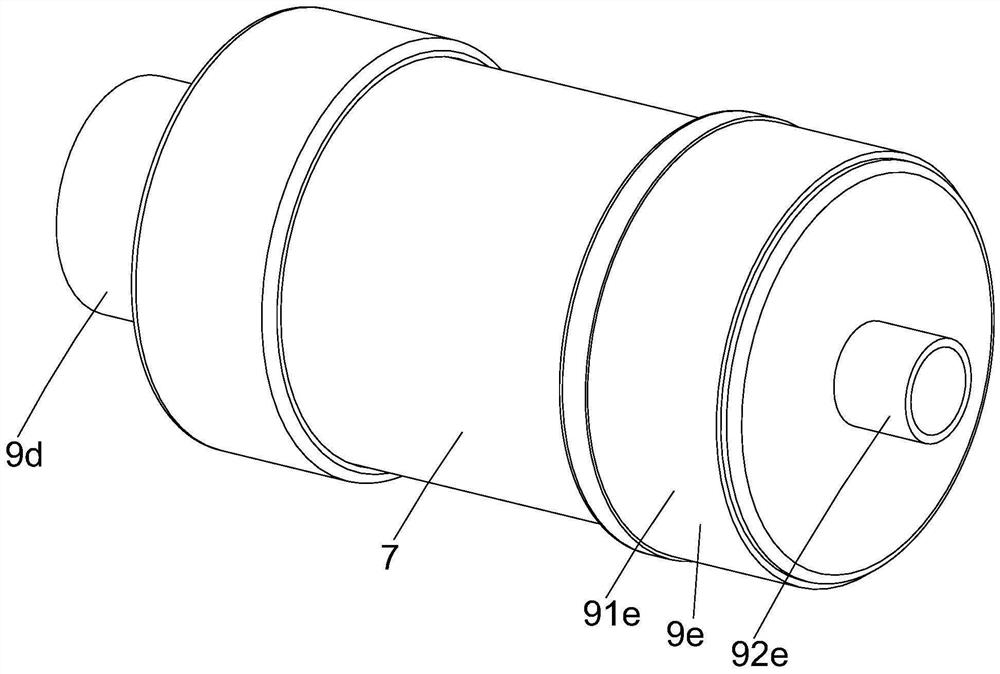

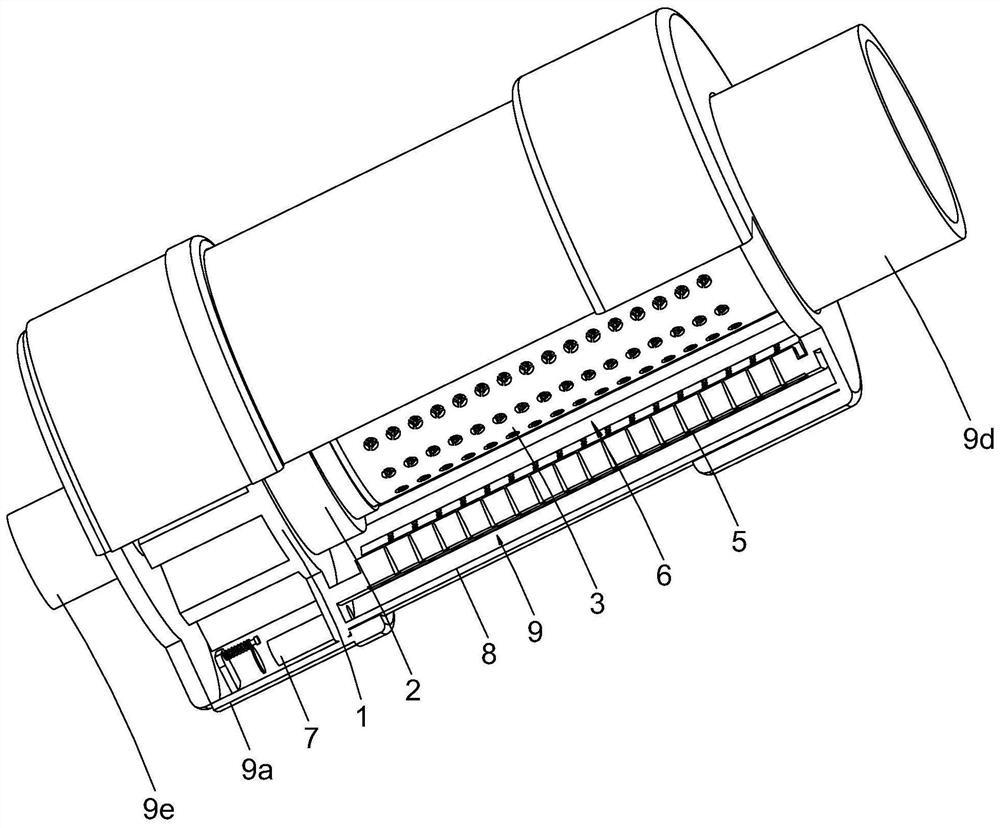

Biopsy rotary cutting device

PendingCN109330633AIncrease flow itineraryImprove delivery efficiencySurgical needlesVaccination/ovulation diagnosticsRing blockEngineering

The invention provides a biopsy rotary cutting device, which comprises a dynamic sealing structure arranged on the outer side of an inner cutter tube; the dynamic sealing structure forms a cavity outside the inner cutter pipe; a sealing ring is arranged in the dynamic sealing structure; the cavity comprises a first cavity and a second cavity; an auxiliary pipe is arranged outside the inner cutterpipe; the auxiliary pipe is provided with a circulation structure; when the inner cutter tube moves to a first position along the axial direction of the inner cutter tube, the sealing ring is positioned at the outer side of the auxiliary tube, and the first cavity and the second cavity are communicated through the circulation structure; when the inner cutter tube moves to a second position along the axial direction of the inner cutter tube, the sealing ring is positioned at the outer side of the inner cutter tube, and the sealing ring blocks the first cavity and the second cavity. According tothe biopsy rotary cutting device, the atmosphere can be introduced to form the circulating airflow with better suction strength; the circulating airflow can more efficiently send the rotary-cut tissue of the corresponding position to a sample collector at the rear end, so that the sample yield is effectively improved.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

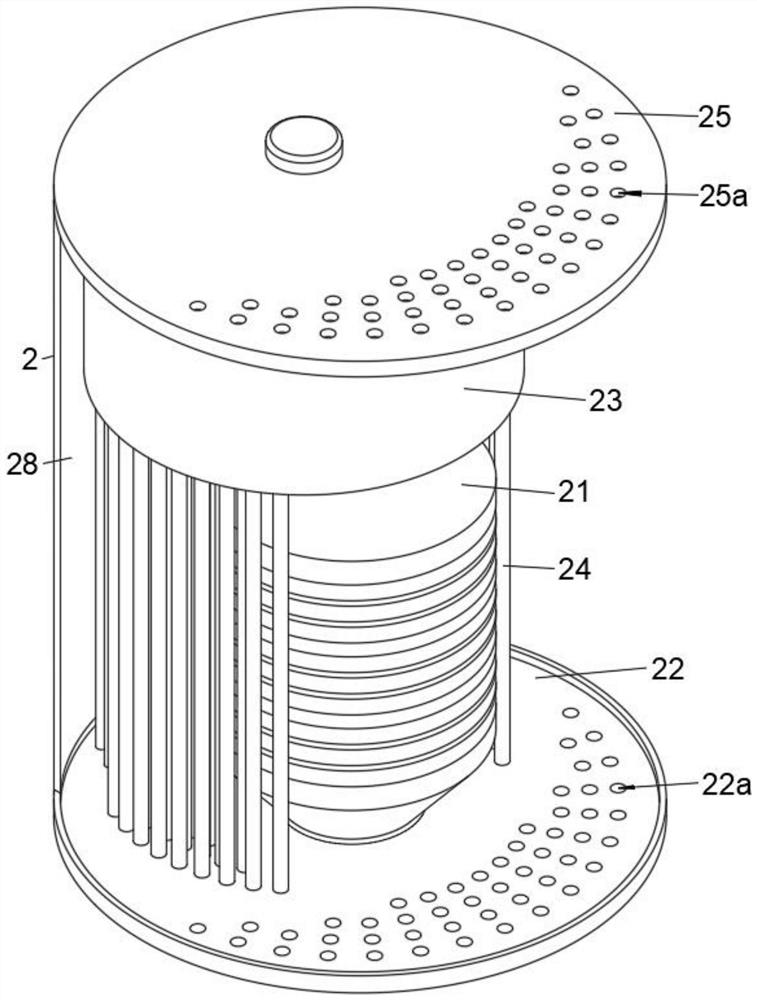

Compressor air filter element

InactiveCN112065694AEffective secondary filtrationImprove adsorption capacityPositive displacement pump componentsPumpsFiberAir filter

The invention relates to the technical field of compressor accessories, in particular to a compressor air filter element. The compressor air filter element comprises a mounting plate, an inner container filter element piece, an outer container filter element piece and a shell. The inner container filter element piece is mounted in the mounting plate through a connecting seat. The outer container filter element piece is erected in the mounting plate and is fixedly mounted on the mounting plate through the shell, and the outer container filter element piece and the inner container filter elementpiece are sleeved with the shell and are arranged with the same axis as the shell. Because of protruding hollow blocks arranged in the inner container filter element piece, on one hand, the flow speed of air discharged out of filtration pores is slowed down, and on the other hand, secondary filtration is carried out on part of air to enable the part of air to be filtered better. Because of an extension mechanism, the flowing travel of the air is prolonged, and under the action of centrifugal force, the air in each layer of gap of a spiral piece diffuses more powerfully and further, the filtering efficiency of a filtering pipe is improved, and the dust suction force of carbon fiber sheets in the protruding hollow blocks is effectively increased.

Owner:胡单

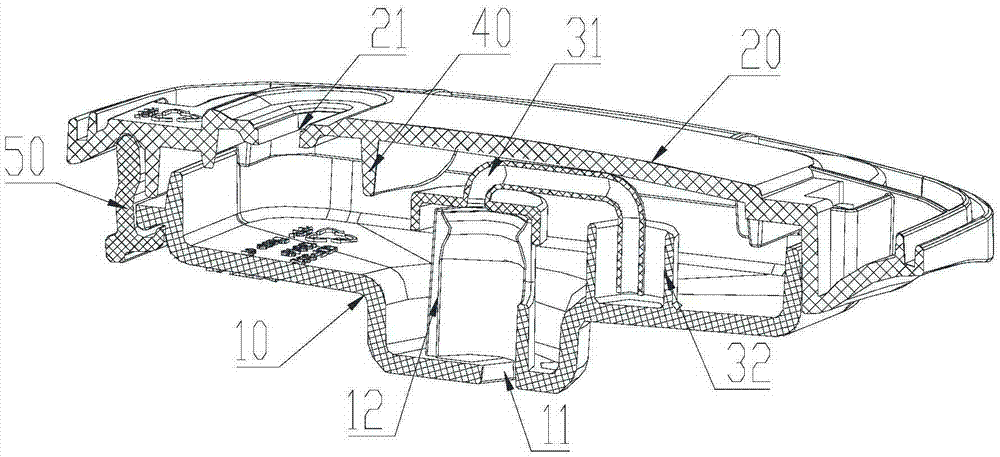

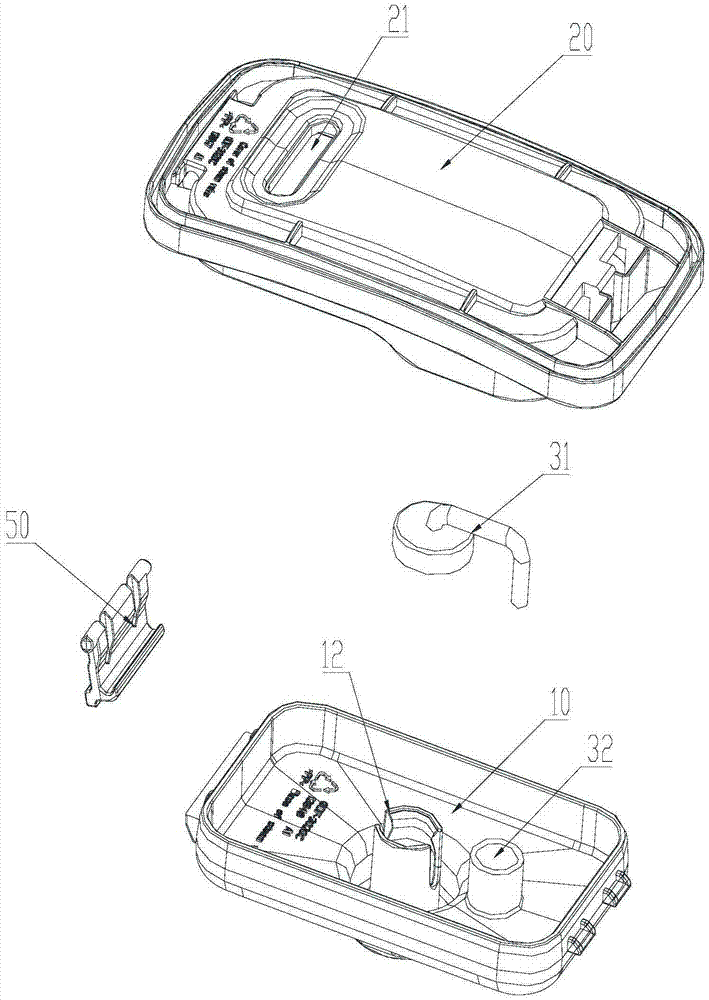

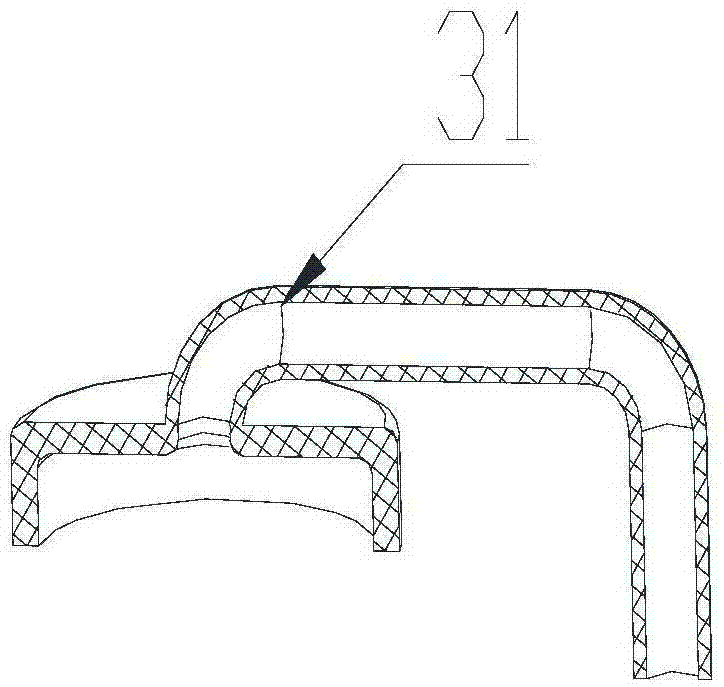

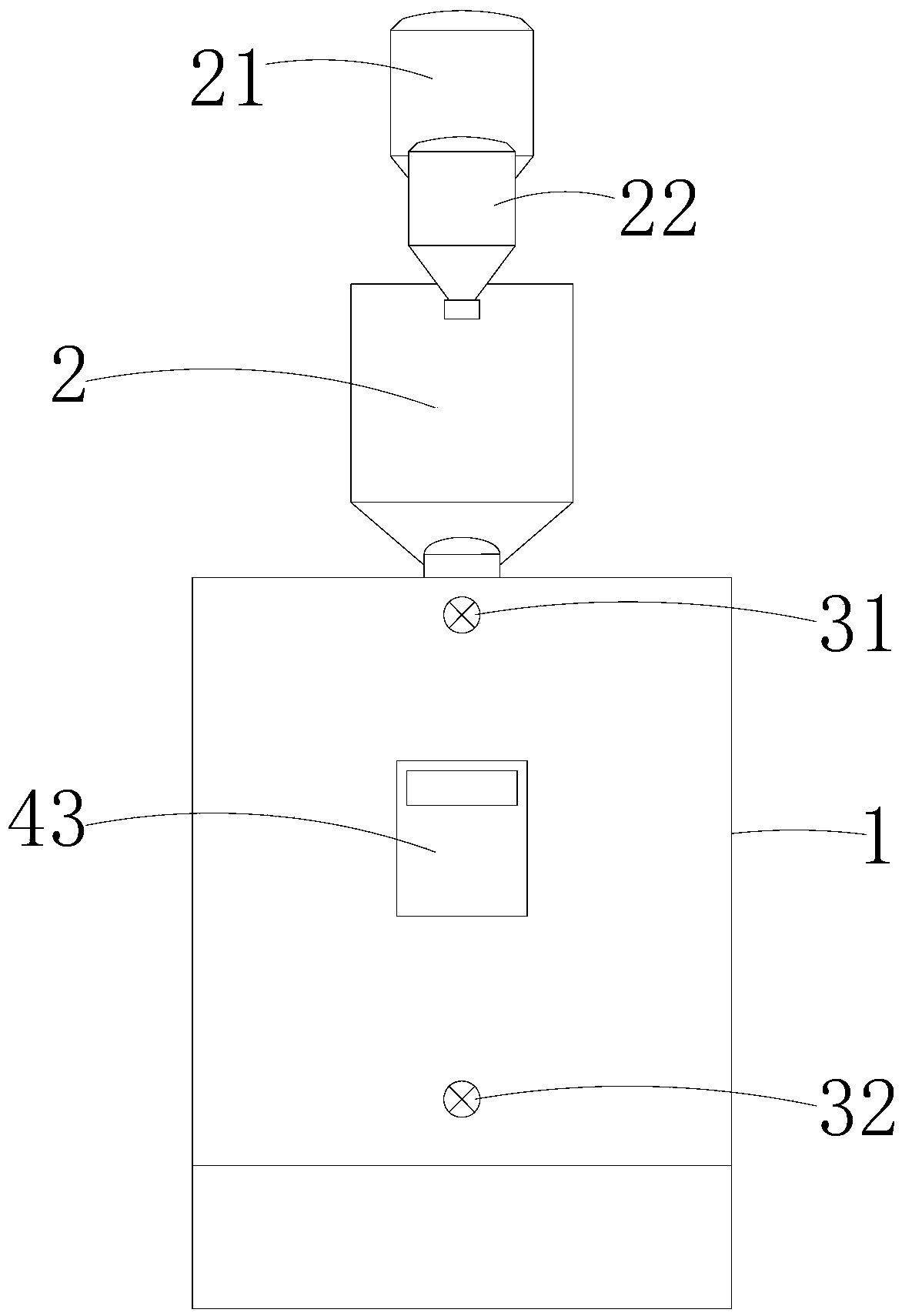

Steam valve and electric rice cooker

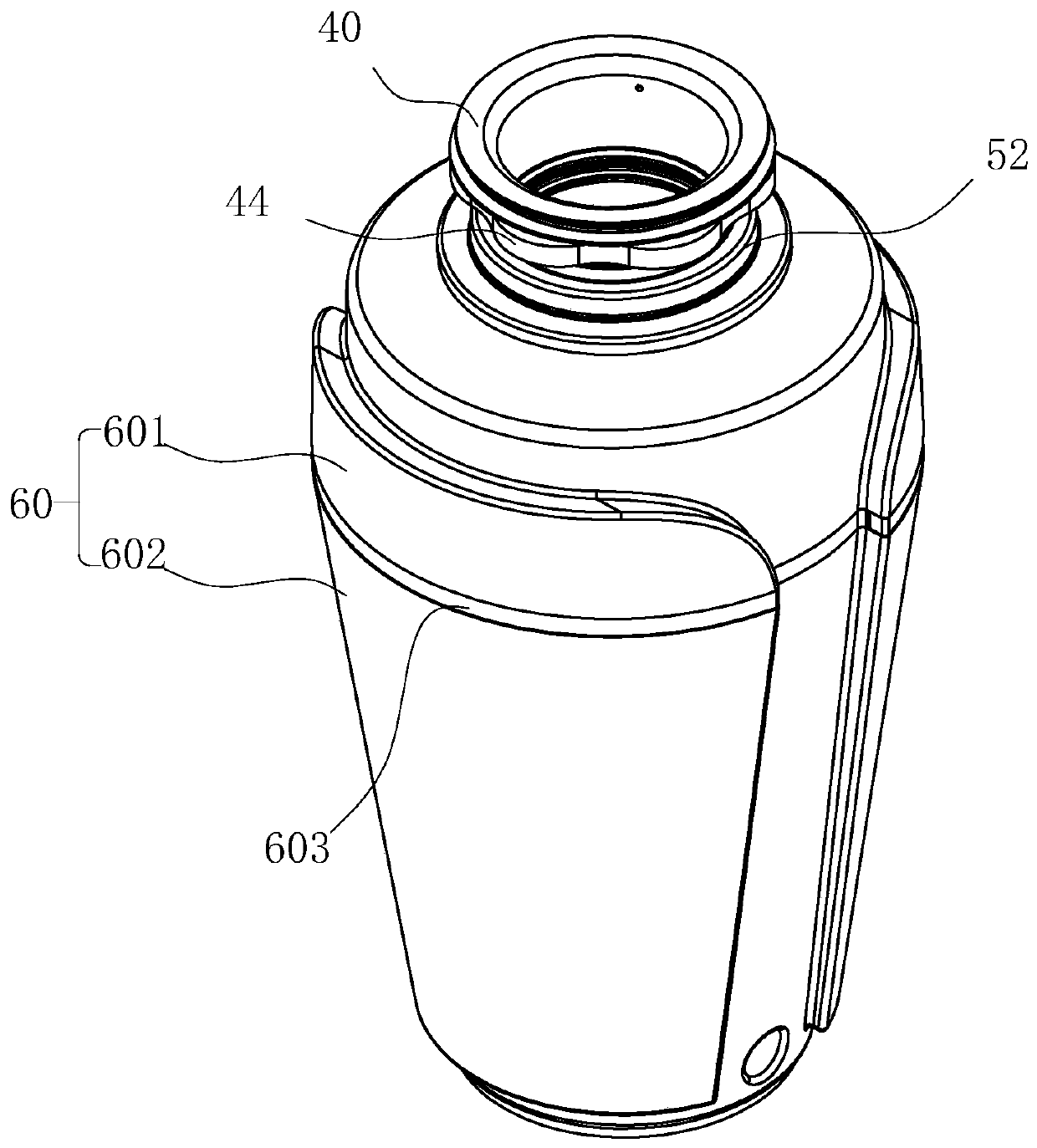

InactiveCN106859323AImprove spill resistanceIncrease flow itineraryBoiling over preventionEngineeringValve seat

The invention provides a steam valve and an electric rice cooker. According to the steam valve of the present invention, it comprises a steam valve seat and a steam valve cover. The steam valve seat is provided with a steam inlet, and the steam valve cover is provided with a steam outlet. The diversion component guides the gas entering from the steam inlet away from the steam outlet. According to the steam valve and the electric rice cooker of the present invention, by setting a guide assembly on the steam valve, the guide assembly guides the airflow entering from the steam inlet to a distance away from the steam outlet to increase the air flow between the steam valve seat and the steam valve cover. The flow stroke enhances the anti-spill effect of the steam valve.

Owner:GREE ELECTRIC APPLIANCES INC

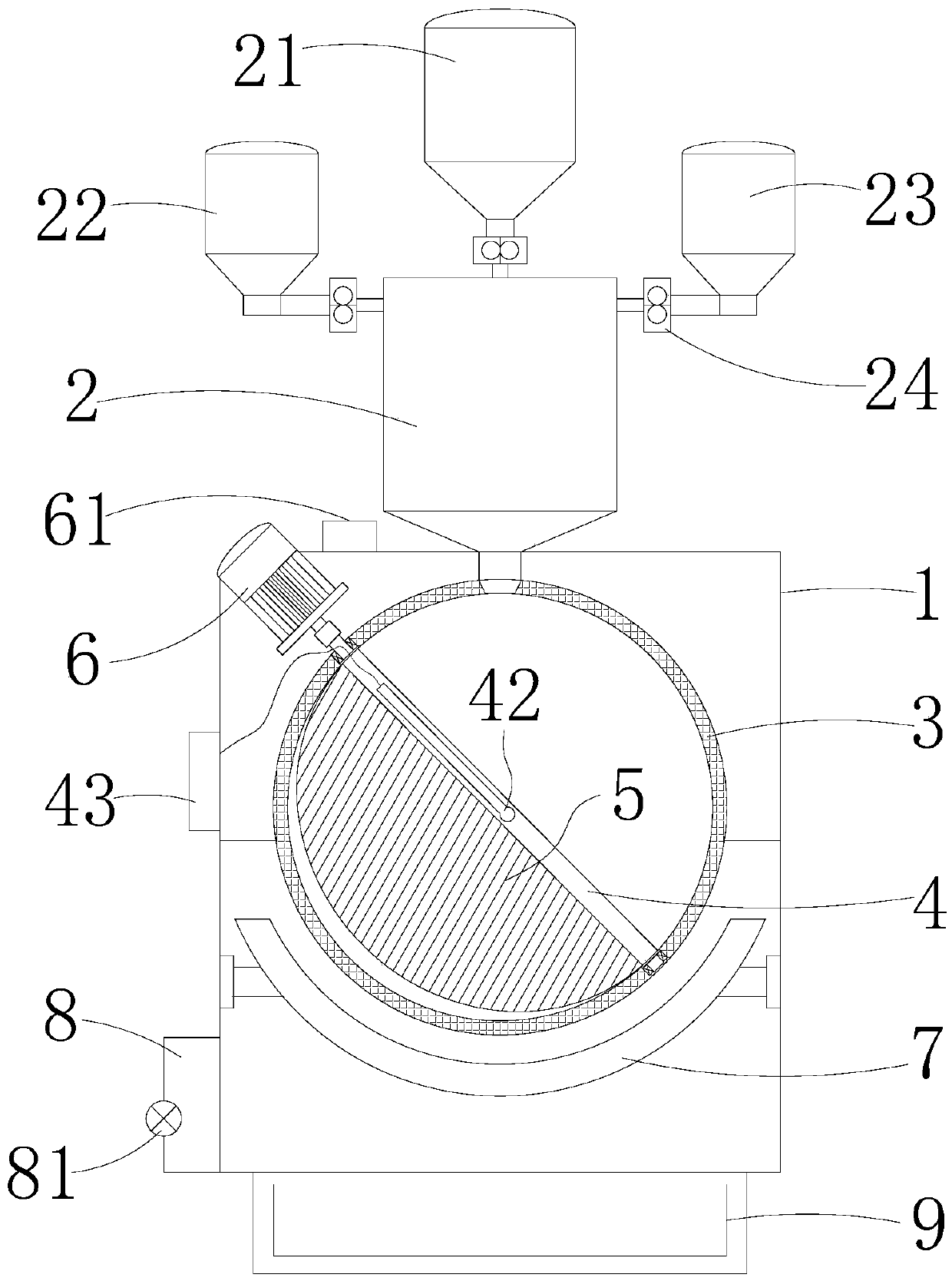

Gelatin melting device with controllable gelatin solution viscosity

ActiveCN105498605AViscosity is easy to controlReasonable structureTransportation and packagingMixer accessoriesElectricityCombustion

The invention discloses a gelatin melting device with controllable gelatin solution viscosity. The gelatin melting device comprises a furnace body, a static stirring device, a spherical heating furnace, a rotating rod, a viscometer, a semicircular stirring plate, a motor, a combustion grate, an air supply device and a collection box, wherein the static stirring device is fixedly mounted at the upper end of the furnace body; a gelatin charging barrel, a pure water charging barrel and an auxiliary charging barrel are mounted on the static stirring device; a metering pump is connected between the static stirring device and each of the gelatin charging barrel, the pure water charging barrel and the auxiliary charging barrel; the spherical heating furnace is mounted in the furnace body; the rotating rod is obliquely mounted in a cavity of the spherical heating furnace; the semicircular stirring plate is fixedly connected with the rotating rod; the viscometer is fixedly connected onto the rotating rod and electrically connected with a viscosity indicator; the combustion grate is mounted below the spherical heating furnace; the air supply device is mounted on the side edge of the lower end of the furnace body. The gelatin melting device is simple in structure and realizes the effects that the viscosity of a pharmaceutical gelatin solution is controllable and a gelatin dipping forming effect is improved.

Owner:ZHEJIANG SHICHENG CAPSULE CO LTD

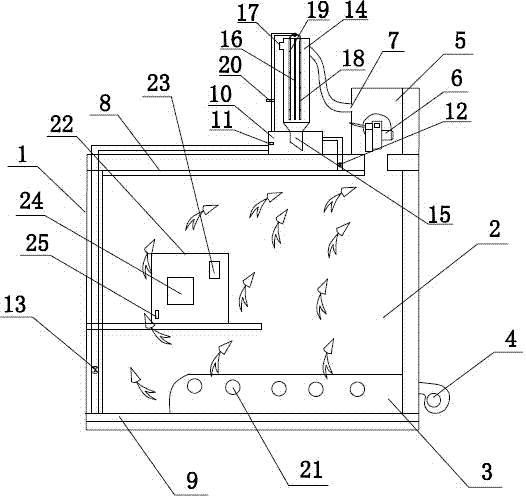

Hot cleaning furnace with dual purification treatment

InactiveCN104329947AIncrease flow itineraryIncrease the itineraryIncreasing energy efficiencyWaste heat treatmentSuspended particlesCombustion chamber

The invention discloses a hot cleaning furnace with dual purification treatment. The hot cleaning furnace comprises a furnace body, wherein a first combustion chamber is arranged at the bottom of the furnace body and a second combustion chamber with a smoke exhausting opening is arranged at the top of the furnace body; each of the inner part of the furnace body and the inner part of the second combustion chamber is provided with a temperature sensor; the smoke exhausting opening is provided with a waste gas purification device; the furnace body is provided with a spraying system; the spraying system comprises a spraying pipe, a circulating water groove and a water tank; the water tank is internally provided with a water level monitor. The hot cleaning furnace with the dual purification treatment is reasonable in structure design; the waste gas purification device is arranged and is used for carrying out purification treatment on high-temperature gas; an atomization high-pressure nozzle is used for washing suspended particles in the gas and a baffle is used for increasing a gas flowing route so that gas and solids, which have different specific gravities, can be separated in the route; the secondary purification treatment of the waste gas is realized and the environmental pollution is reduced; the first combustion chamber with an arch-shaped structure is arranged so that the rapid rising of the temperature in the furnace is realized, so that the treatment time is shortened and the energy consumption is saved; an electric cabinet is arranged so that automatic work is convenient to realize and the operation is easy.

Owner:浙江德立自动化装备股份有限公司

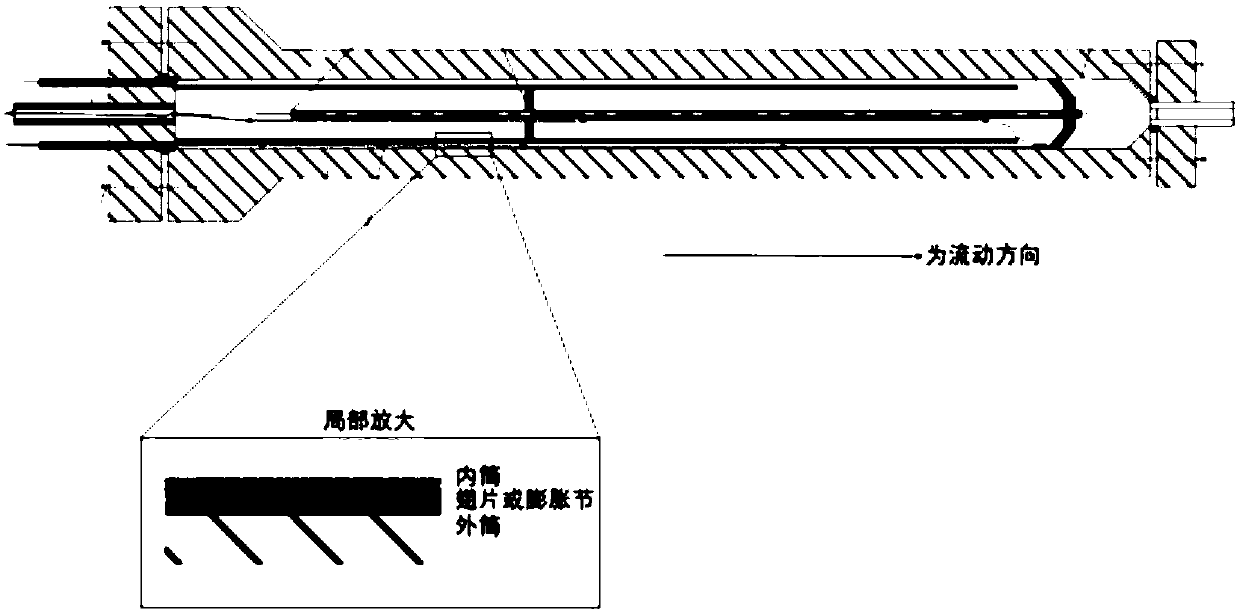

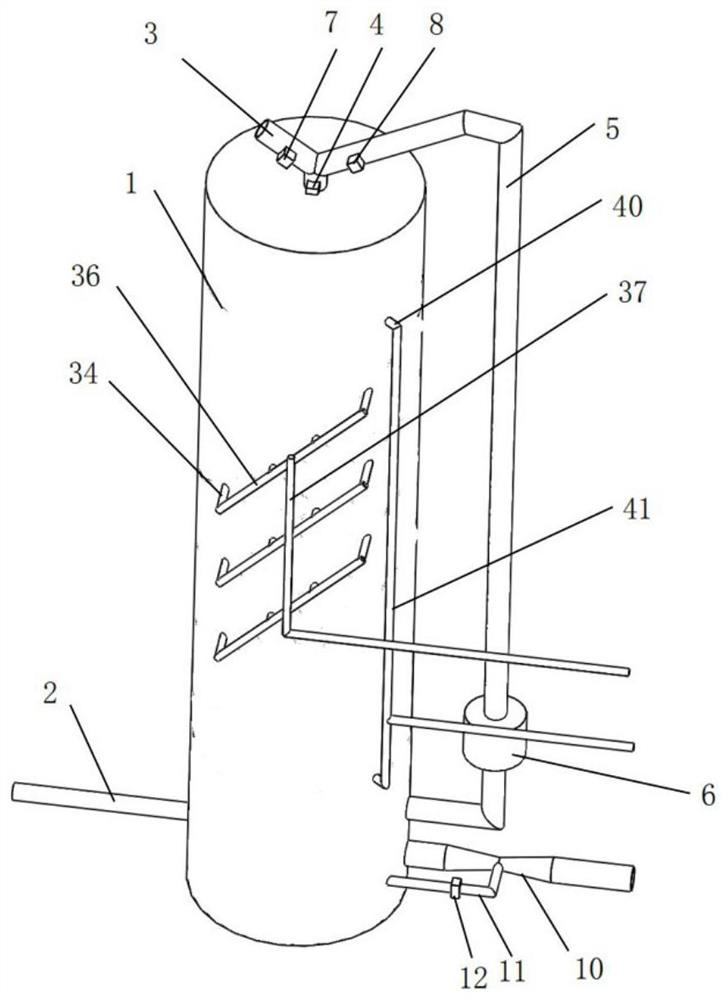

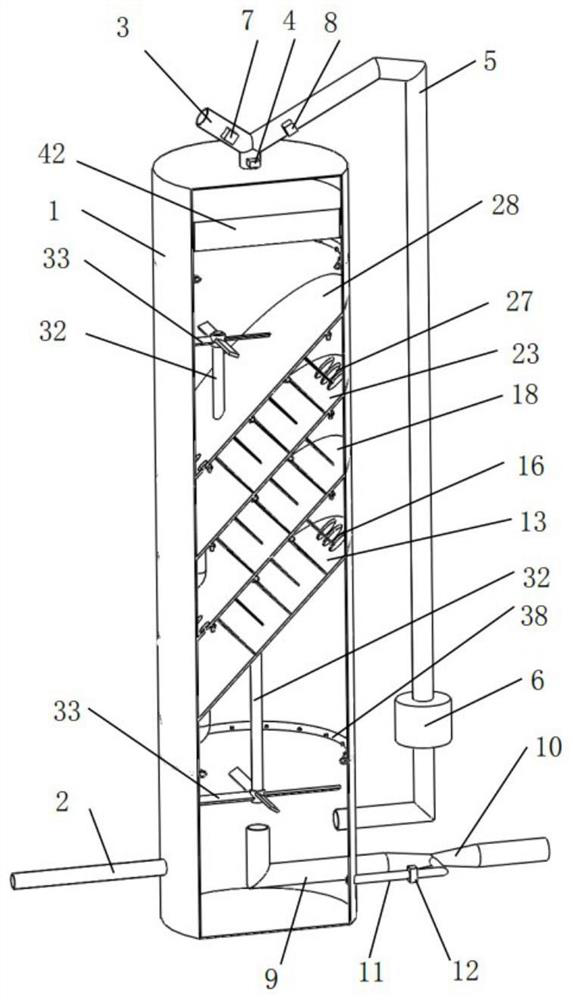

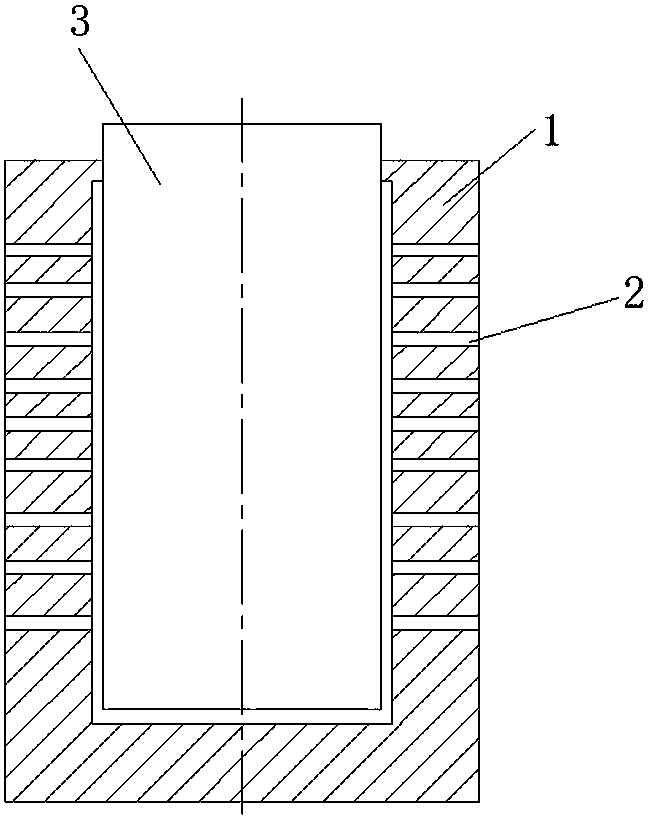

Pipe type supercritical water oxidization reactor and supercritical water oxidization system and method

ActiveCN109592774AIncrease flow itinerarySimple processWater/sewage treatment apparatusWater/sewage treatment by oxidationEngineeringExpansion joint

The invention provides a pipe type supercritical water oxidization reactor and a supercritical water oxidization system and method. The pipe type supercritical water oxidization reactor comprises an inner barrel and an outer barrel; the outer barrel sleeves the outer part of the inner barrel; a material inlet is arranged between the inner barrel and the outer barrel; a material outlet is formed inthe top of the inner barrel and a working medium flows in from the gap between the inner barrel and the outer barrel and flows out from the top of the inner barrel; and a fin or an expansion joint isadditionally arranged in the gap between the inner barrel and the outer barrel, so that the turbulent flow is increased, a flow path is lengthened and the heat exchange is reinforced.

Owner:SHANDONG UNIV

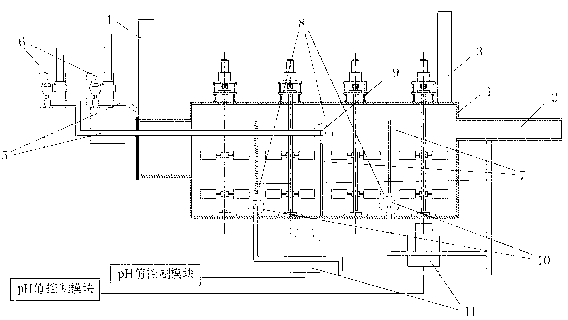

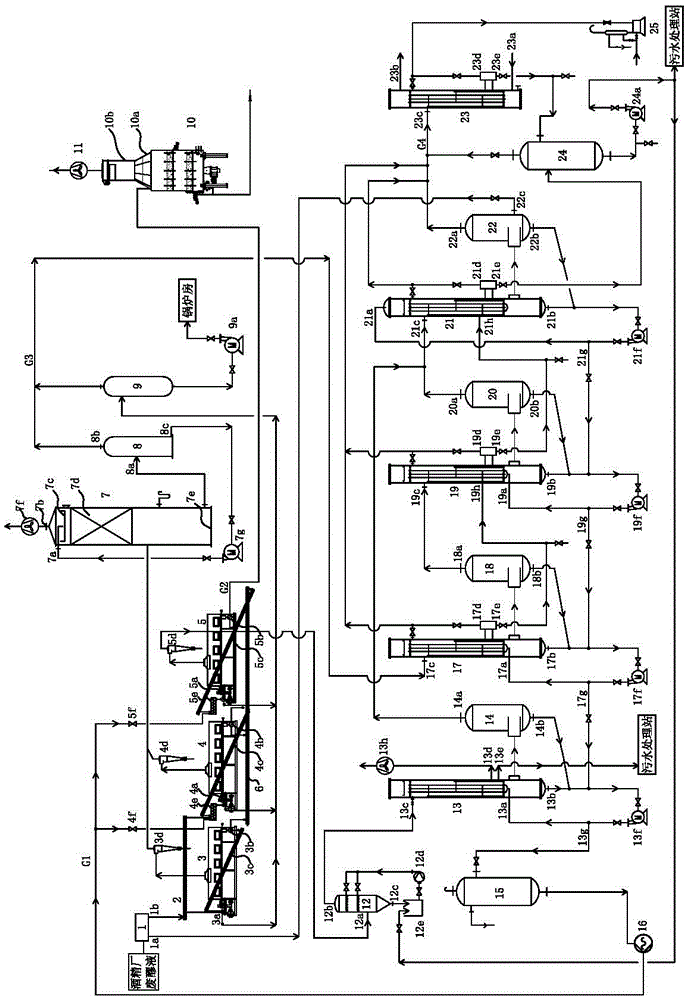

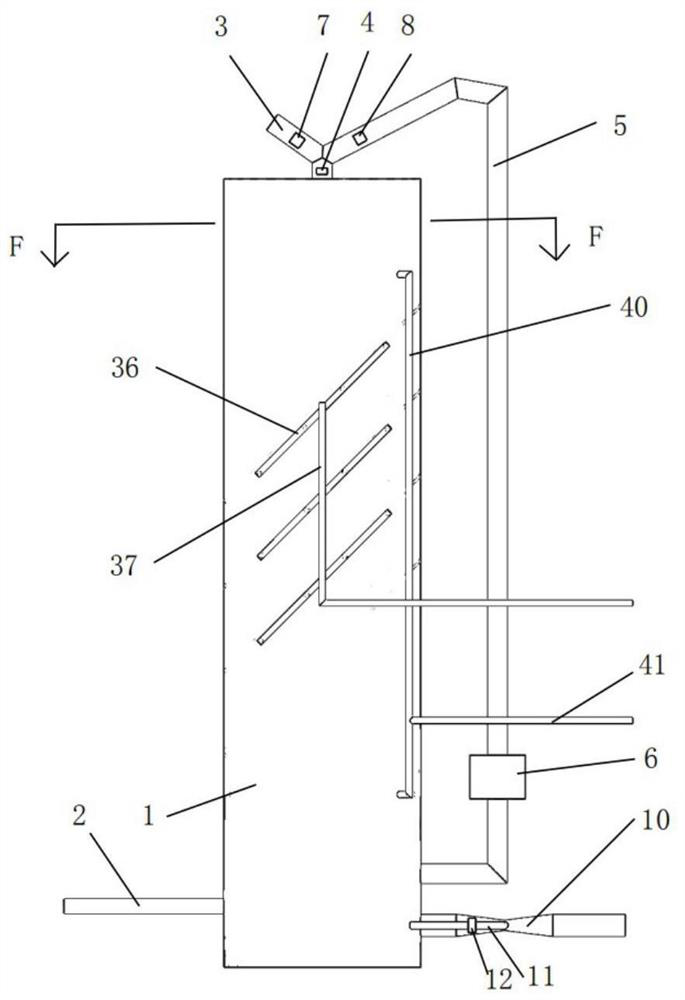

Progressive stoving neutralization reaction device and method

InactiveCN103266184AIncrease flow itineraryImprove uniformityPurification by oxidation/reductionPurification using alkaline earth metal compoundsReaction layerPh control

The invention aims to provide a progressive stoving neutralization reaction device, comprising a box body, an exhaust port, a tube diffuser, a stove tail tube, a lime milk adding tube, an ash adding actuator, more than one separator and a pH control device, wherein the box body is internally divided into more than two reaction layers by the separator in the horizontal direction; and the pH control device is used for detecting the pH of mixed sugarcane juice in the box body and controlling the dosage of the lime milk according to pH information, thus keeping the pH value of the mixed sugarcane juice stable. The invention also provides a stoving neutralization reaction method, wherein pH detection and control are performed on the sugarcane juice in reaction through the pH control device, so that the pH of the sugarcane juice after reaction is kept in a predetermined range. The progressive stoving neutralization reaction device and method provided by the invention have the characteristics that the pH of the sugarcane juice is regulated and controlled in sections and the reaction efficiency of the neutralization reaction is enhanced through a stirring device, so that the pH of the sugar juice is stabilized, the cleaning efficiency is improved and the reaction time is prolonged; and therefore, the device and the method play an important role in improving the product quality and the sugar yield of a sugar refinery.

Owner:南宁苏格尔科技有限公司

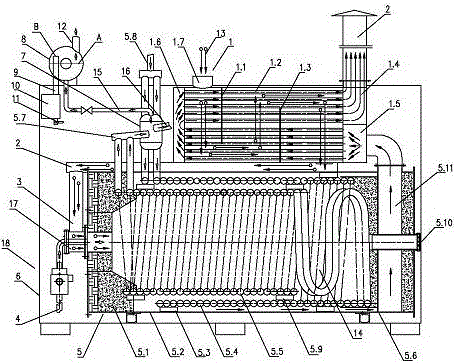

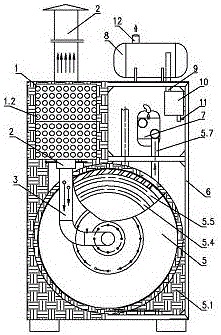

Fuel gas mold temperature controller

InactiveCN106382746ARealize automatic adjustmentEasy to controlFuel supply regulationStorage heatersOil temperatureEnergy conversion efficiency

The invention discloses a fuel gas mold temperature controller. The fuel gas mold temperature controller comprises a rack and a heat conduction oil furnace. A smoke heat recoverer is arranged on the rack which is above the heat conduction oil furnace. One end of the smoke heat recoverer is connected with a smoke chamber and a smoke guiding-in chamber in a sealed mode, and a smoke reversing chamber is arranged at the other end of the smoke heat recoverer in a sealed mode. A plurality of thread smoke tubes are arranged in the smoke heat recoverer in parallel. An oil-gas separation tank and an oil overflowing tank are arranged on the rack which is above the heat conduction oil furnace. The oil-gas separation tank is located below the oil overflowing tank. The oil-gas separation tank is communicated with a coiled tube through an oil outlet tube, the oil outlet tube is arranged on one side of the oil-gas separation tank, a separation tank oil outlet tube is arranged on the other side of the oil-gas separation tank, and the oil-gas separation tank is communicated with the oil overflowing tank. The rack is further provided with an oil temperature control device. The fuel gas mold temperature controller has the benefits that the smoke heat conversion efficiency is good, oil-gas separation is sufficient and thorough, and the oil temperature control is stable and high in precision.

Owner:DONGTAI SANCANG ENERGY SAVING BOILER

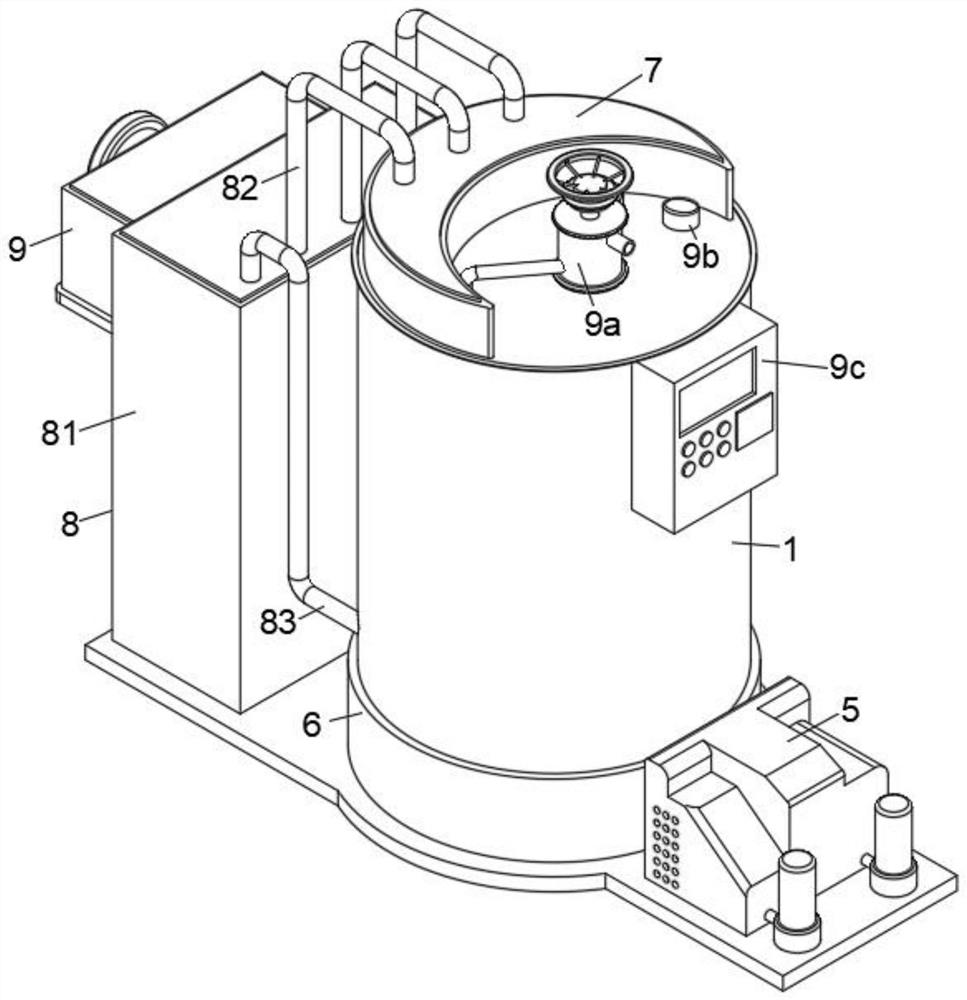

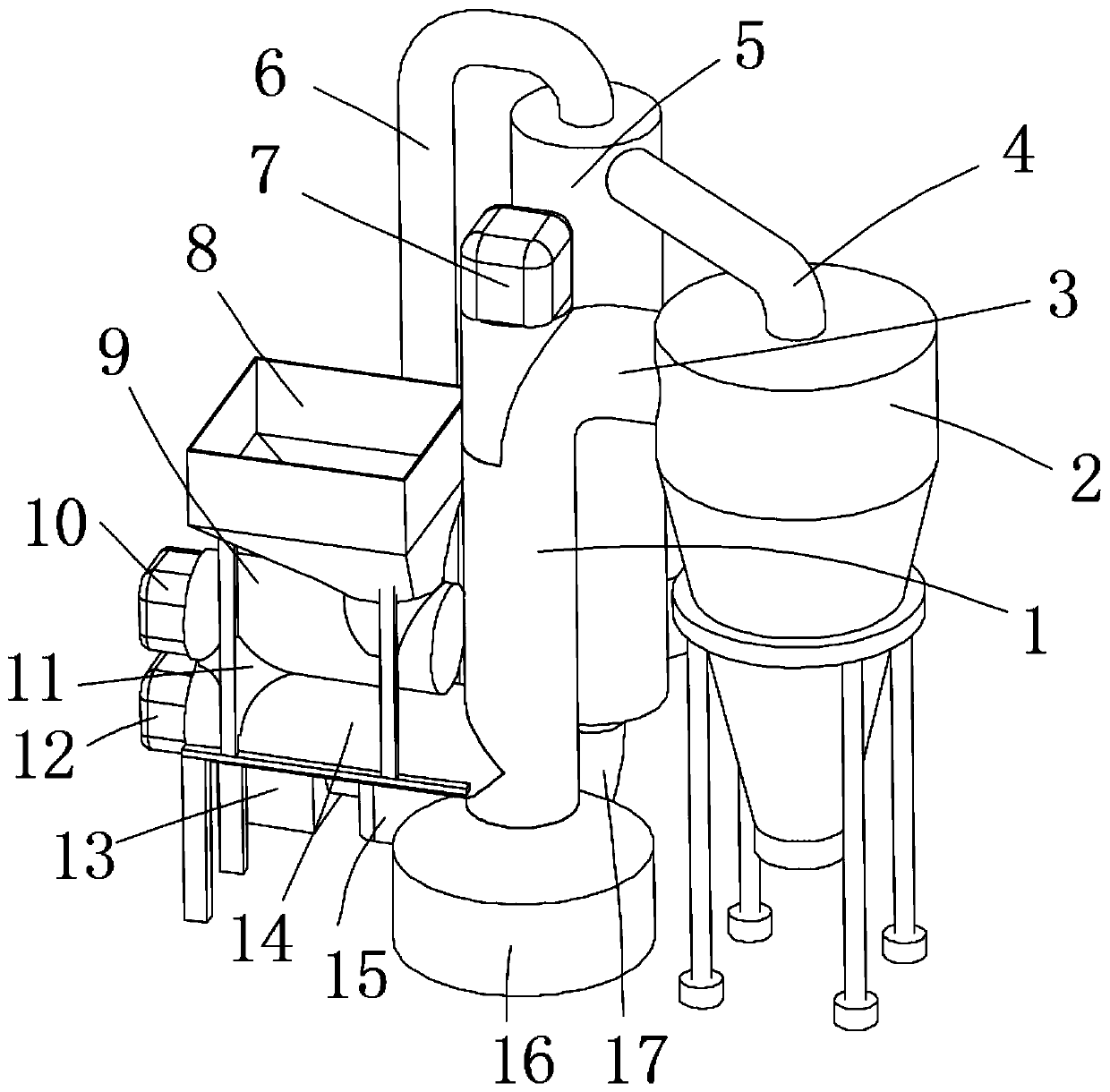

System for evaporation and concentration by using waste heat of dryer

ActiveCN106110685AImprove qualityQuality improvementEvaporators with heating coilsDrying solid materialsEvaporationTower

The invention relates to a system for evaporation and concentration by using waste heat of a dryer. The system comprises a first tube bank dryer, a second tube bank dryer and a third tube bank dryer which successively heat materials in series, the exhaust gas outlets of the tube bank dryers are respectively connected with the air inlets of a first cyclone dust collector, a second cyclone dust collector and a third cyclone dust collector, the air outlets of the first cyclone dust collector and the second cyclone dust collector are connected with the air inlet of a waste heat absorption tower, the air outlet in the top of the waste heat absorption tower is connected with the inlet of an absorption tower exhaust fan, a filler layer is arranged at the upper part of an inner cavity of the waste heat absorption tower, a liquid distributing tray is arranged above the filler layer, a water collecting tray is arranged at the bottom of the waste heat absorption tower, the drainage outlet in the bottom of the water collecting tray is connected with the inlet in the middle of a waste heat flash tank, the waste heat flash tank steam outlet in the top of the waste heat flash tank is connected with a flash steam pipe, the bottom of the waste heat flash tank is connected with the inlet of an absorption tower circulating pump, and the outlet of the absorption tower circulating pump is connected with a water replenishing pipe in the center of the liquid distributing tray. The system for the evaporation and concentration by using the waste heat of the dryer disclosed by the invention is high in utilization rate of the waste heat and good in concentration effect.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

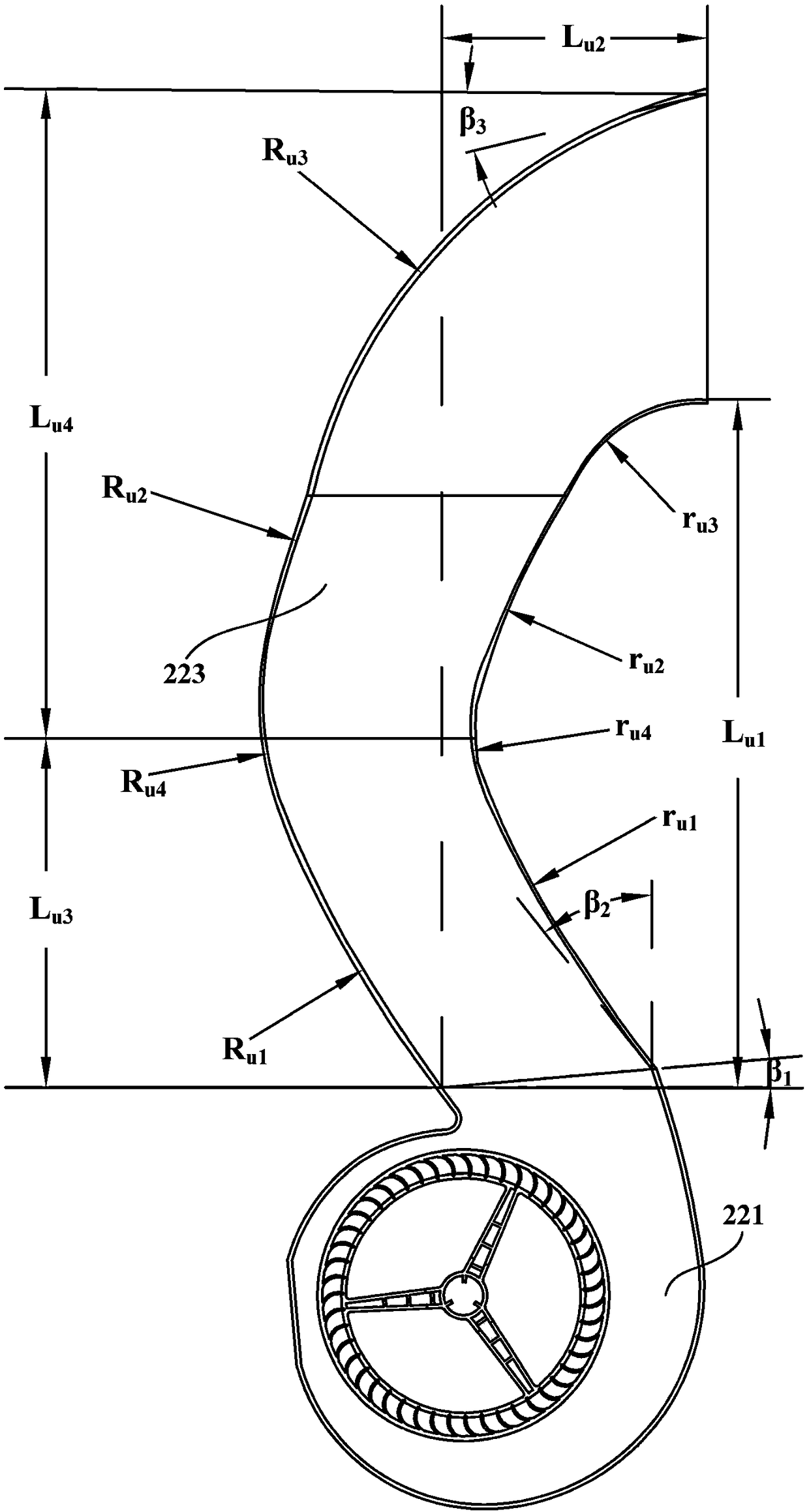

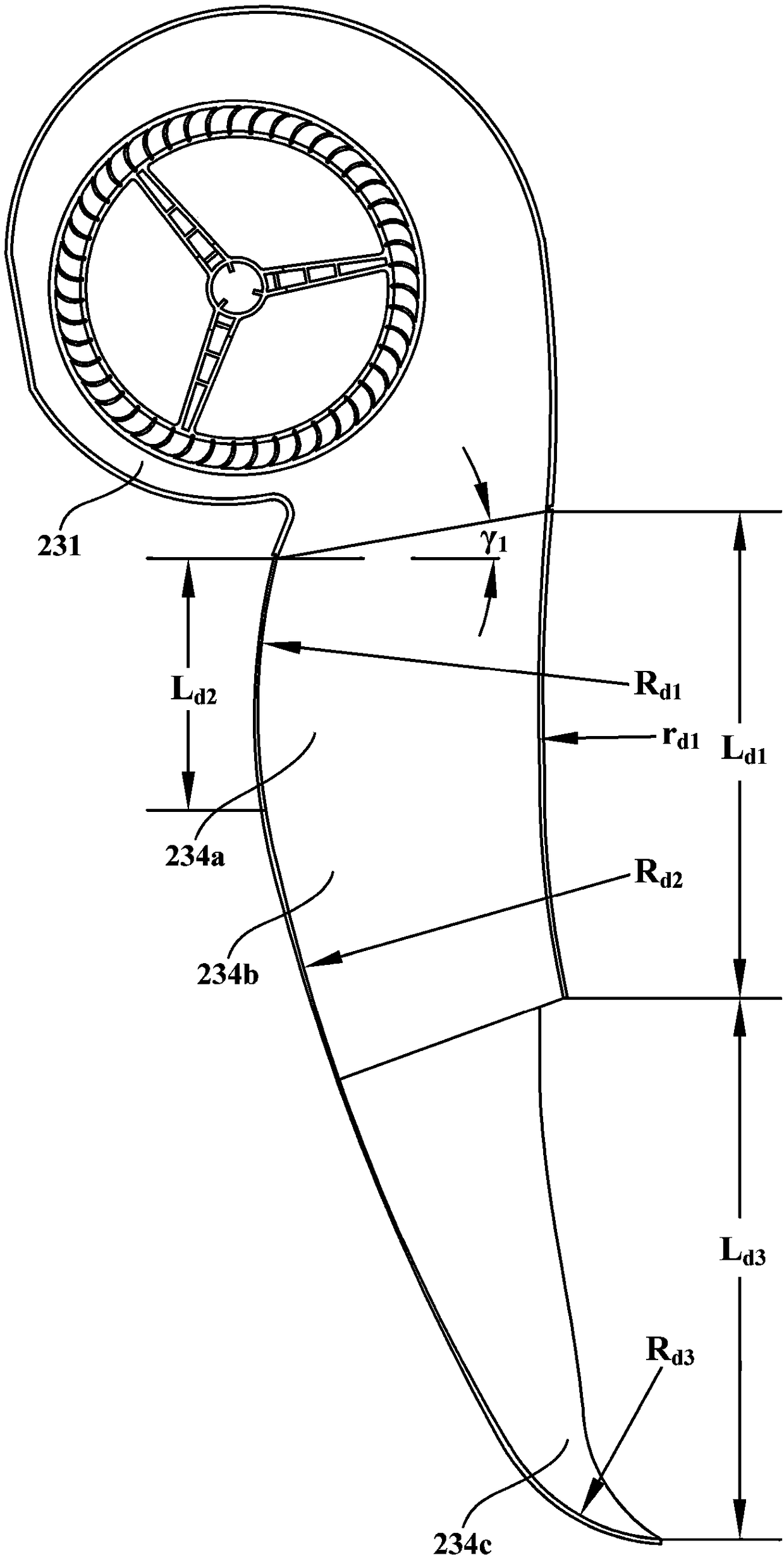

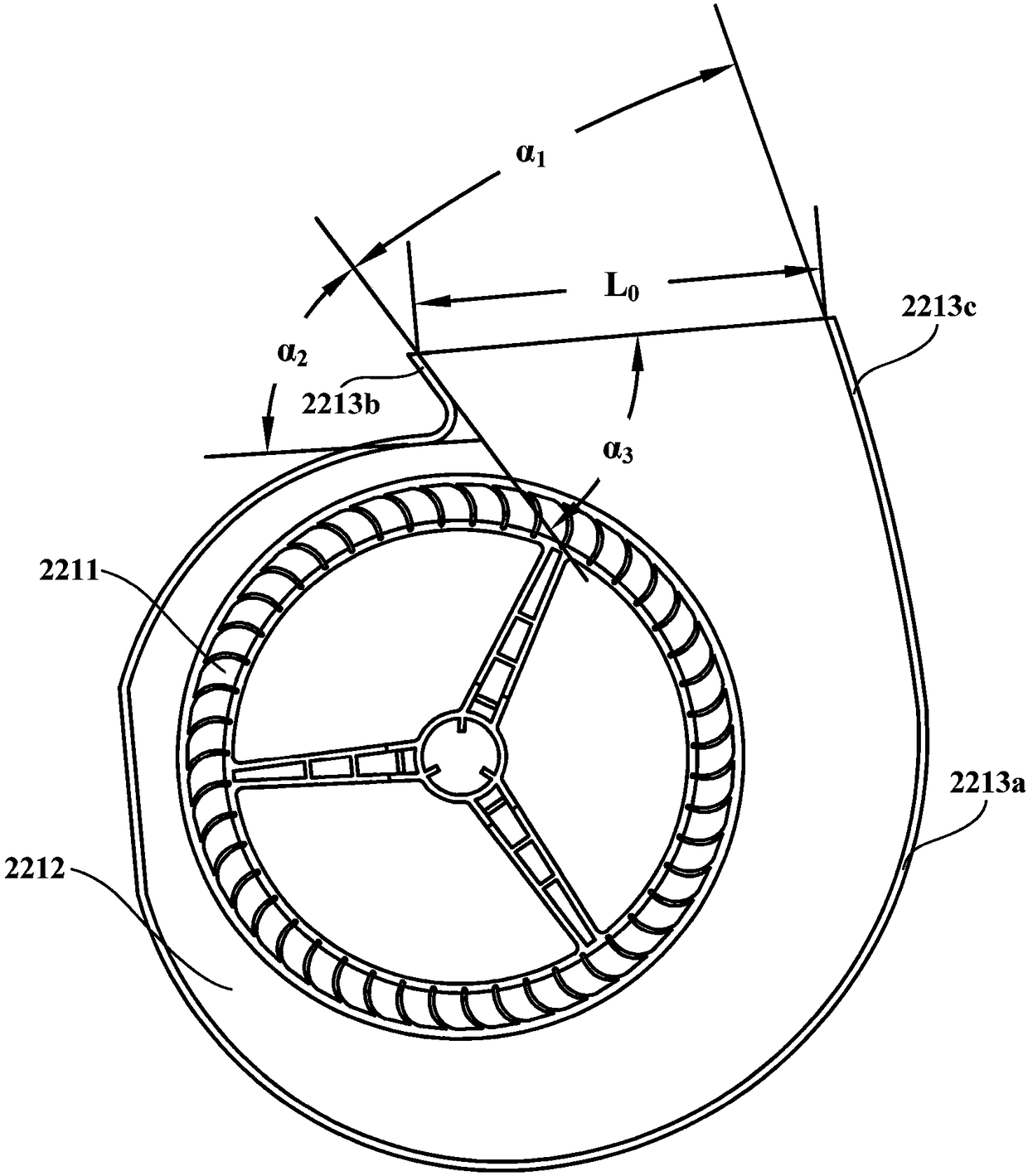

Air supply assembly and cabinet type air conditioning indoor unit comprising same

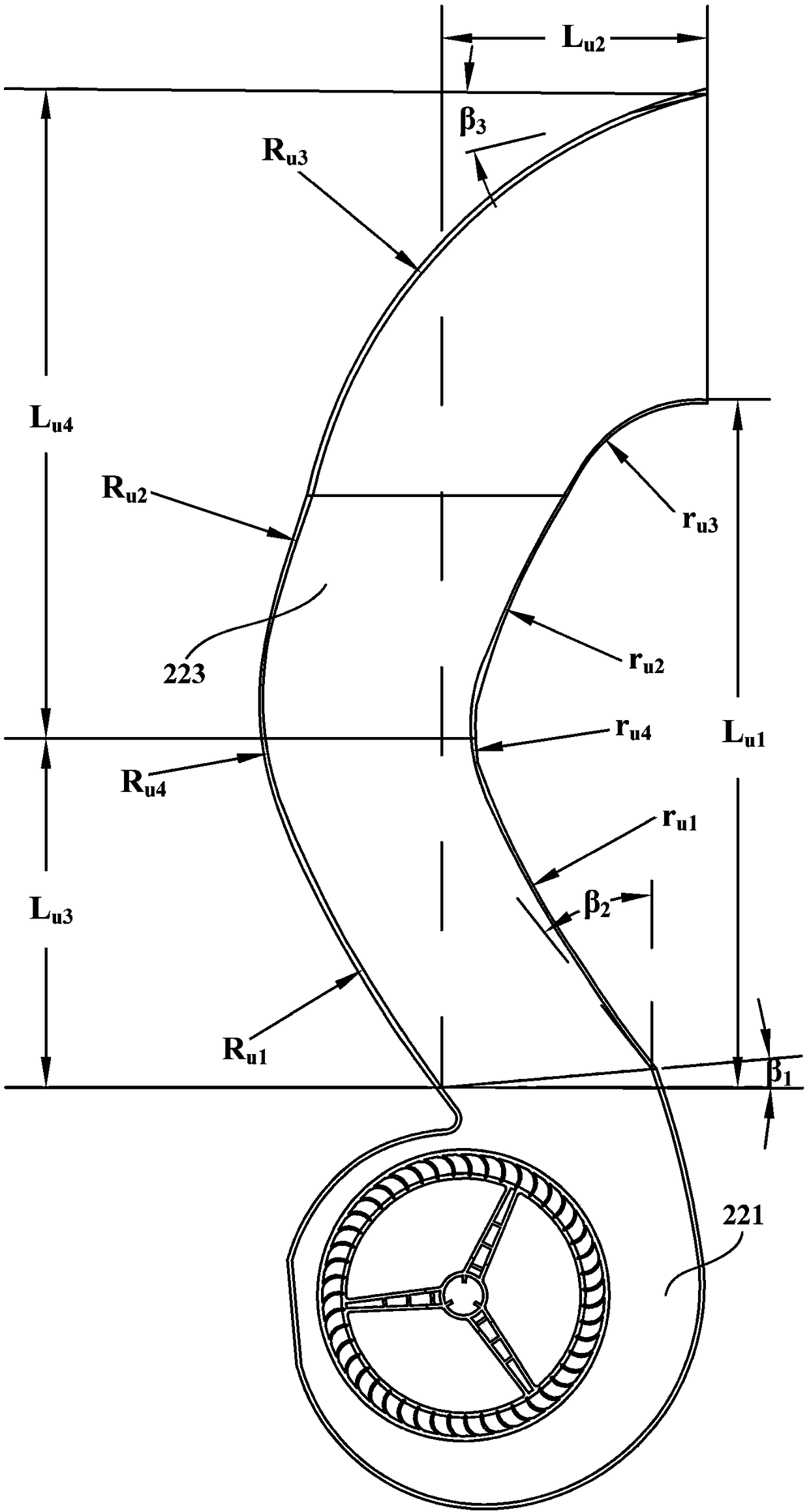

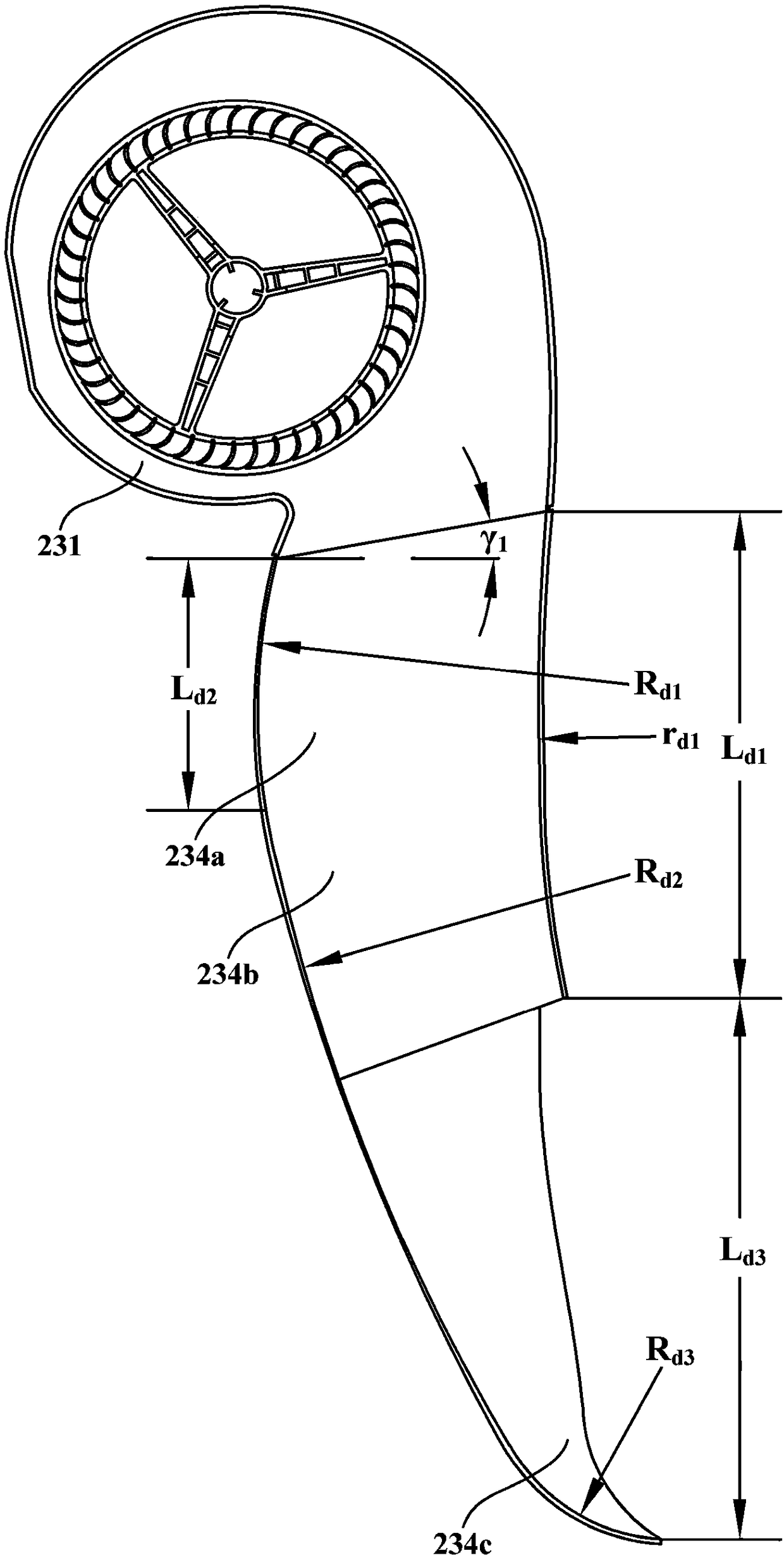

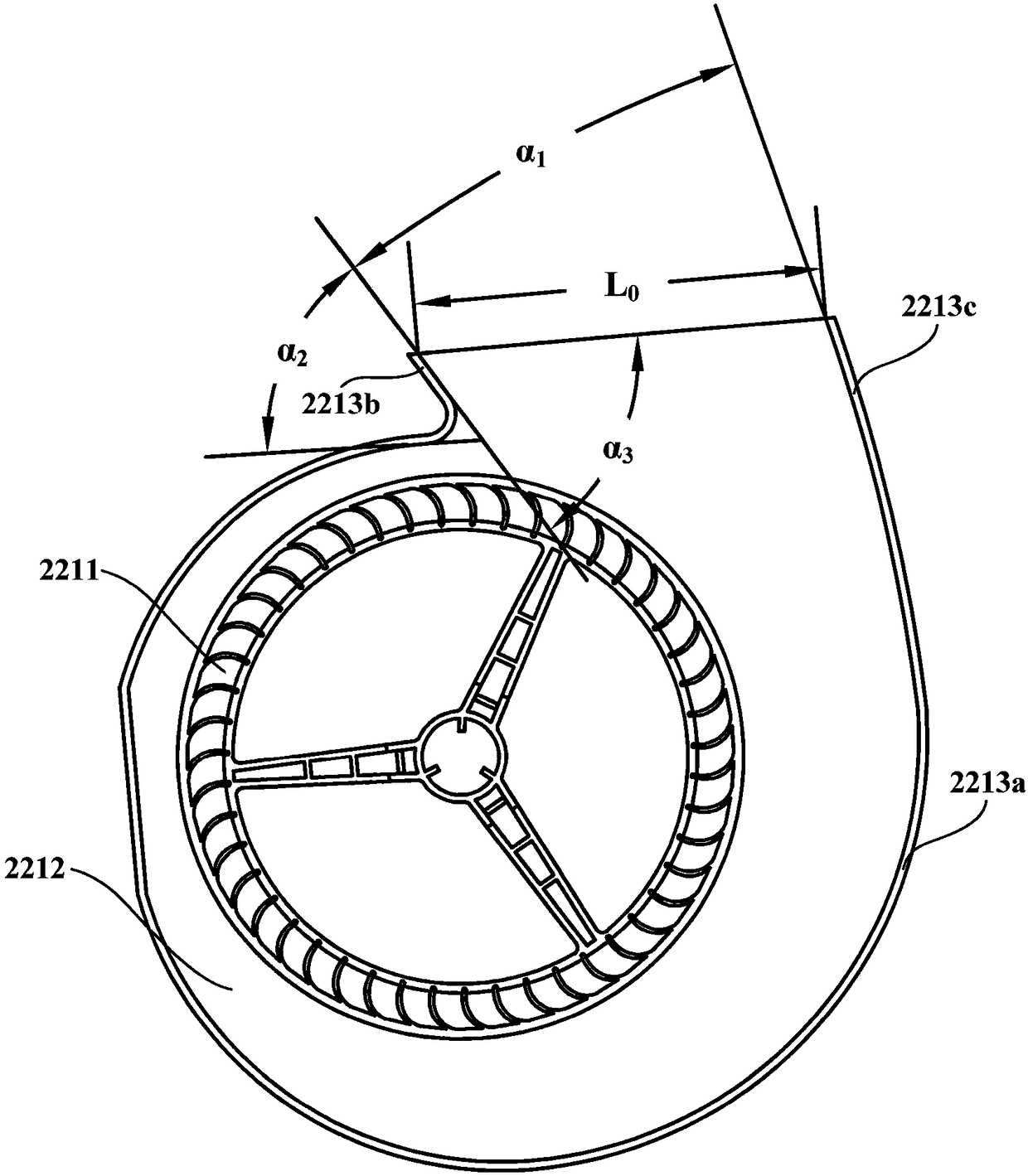

PendingCN108533511AIncrease flow itinerarySpeed up the flowPump componentsLighting and heating apparatusImpellerAirflow

The invention provides an air supply assembly. The air supply assembly comprises a centrifugal fan and an air guide component used for guiding and conveying airflow blown out of the centrifugal fan to the indoor environment. According to the air supply assembly, an outlet section of the centrifugal fan is located on the front side of a volute tongue section of the centrifugal fan, the air guide component defines a flow guide air duct extending from a fan air outlet to the direction away from an impeller of the centrifugal fan, the forward side wall and the backward side wall of the flow guideair duct are arranged to extend along a front convex curve group and a rear convex curve group respectively, the two transverse side walls of the flow guide air duct are arranged to extend in the vertical direction, a front convex curve and a rear convex curve are curves which protrude backwards and can prolong the flow stroke of air in the flow guide air duct, so that the air blown out of the centrifugal fan is fully mixed in the flow guide air duct, meanwhile, flowing of the air is smooth, lower noise is achieved, the flow velocity difference value between airflow blown out from the centerof an air outlet of the flow guide air duct and airflow blown out from the edge of the flow guide air duct is small, and good user experience is achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Automobile exhaust filtering device

ActiveCN105971691AEvenly distributedIncrease flow itineraryExhaust apparatusSilencing apparatusEngineeringFilter effect

The invention discloses an automobile exhaust filtering device which comprises a shell. An air inlet pipe is installed at the left end of the shell. An end cover is arranged at the right end of the shell. A connecting pipe is integrally formed on the left side face of the end cover. A thread is formed on the surface of the connecting pipe. The connecting pipe is connected with the right end of the inner surface of the shell through the thread. First convex lugs are evenly distributed at the right end of the outer surface of the shell. Second convex lugs matched with the first convex lugs are arranged on the end cover. The first convex lugs and the second convex lugs are connected through bolts. An exhaust pipe is installed in the middle of the right side face of the end cover. According to the automobile exhaust filtering device, first diffluence holes in a first partition plate and second diffluence holes in a second partition plate are matched so that gas entering the shell can be subjected to diffluence, and the flowing stroke of exhaust gas inside the shell is increased; due to the fact that the first diffluence holes are formed around the first partition plate at equal intervals, exhaust diffluence is uniform, and the filtering effect is improved.

Owner:WUXI YONGYI PRECISION CASTING

Industrial waste gas circulation integrated treatment device

InactiveCN111821834AReasonable structural designCompact structureGas treatmentDispersed particle separationRefluxExhaust fumes

The present invention discloses an industrial waste gas circulation integrated treatment device, which comprises: a detection circulation reflux member, which comprises a shell, a detection reflux member and a waste gas pretreatment member, and the detection reflux member and the waste gas pretreatment member are arranged on the shell; an extended-range turbulent flow part comprises a first extended-range part, a second extended-range part, a third extended-range part, a fourth extended-range part and a turbulent flow part, the first extended-range part, the second extended-range part, the third extended-range part and the fourth extended-range part are all arranged on the shell, and the turbulent flow part is arranged on the first extended-range part and the fourth extended-range part; adesulfurization and denitrification part comprises an atomizing part and a spraying part, the atomizing part is arranged on the extended-range turbulent flow part, and the spraying part is arranged onthe shell. According to the invention, the waste gas motion stroke can be obviously increased, the waste gas desulfurization and denitrification efficiency can be obviously improved, the desulfurization and denitrification liquid consumption is obviously reduced, and the desulfurization and denitrification cost is reduced.

Owner:苏州仕净科技股份有限公司

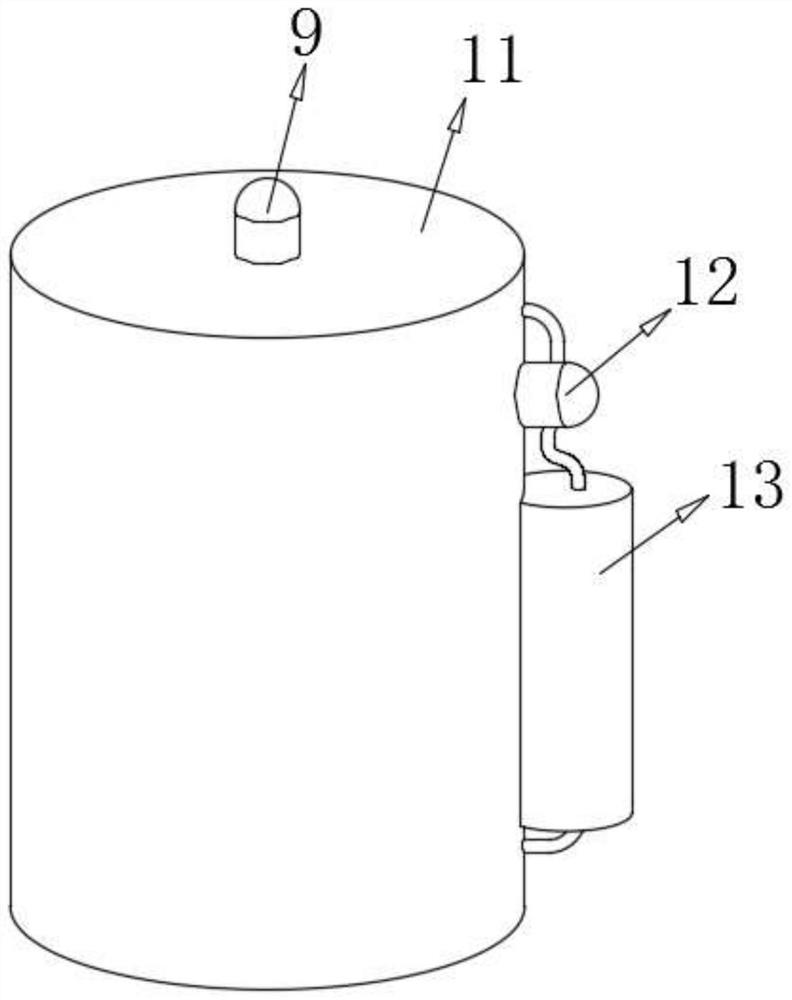

Three-return-stroke vertical gas boiler

PendingCN111998329AIncrease flow itineraryIncrease the areaSteam boilersFeed-water heatersThermodynamicsBoiler furnace

The invention relates to the technical field of boilers, and particularly relates to a three-return-stroke vertical gas boiler. The three-return-stroke vertical gas boiler comprises a shell, a returnstroke assembly and a preheater. The return stroke assembly used for driving smoke to return multiple times so as to improve smoke heat utilization is installed in the shell. The preheater used for utilizing waste heat of smoke exhausted from the interior and the exterior of the shell and the shell are installed on a boiler base side by side. According to the three-return-stroke vertical gas boiler, a vertical framework is adopted in the gas boiler, a short smoke pipe and a long smoke pipe are distributed on the two sides of a corrugated boiler furnace, and therefore the heating temperature ofwater liquid in the short smoke pipe side is higher than that of water liquid in the long smoke pipe side, the water liquid at the short smoke pipe is diffused towards the position above the water liquid in the long smoke pipe, and the water liquid at the long smoke pipe is diffused towards the position below the water liquid in the short smoke pipe to form convection; and due to the fact that the water liquid on the two sides of the corrugated boiler furnace constantly carries out convection to form water liquid inner circulation, the temperature difference of the water liquid on the two sides in the gas boiler is small, the steam generation speed is higher, and the heating efficiency of the boiler is improved.

Owner:金文应

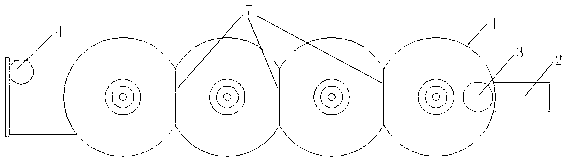

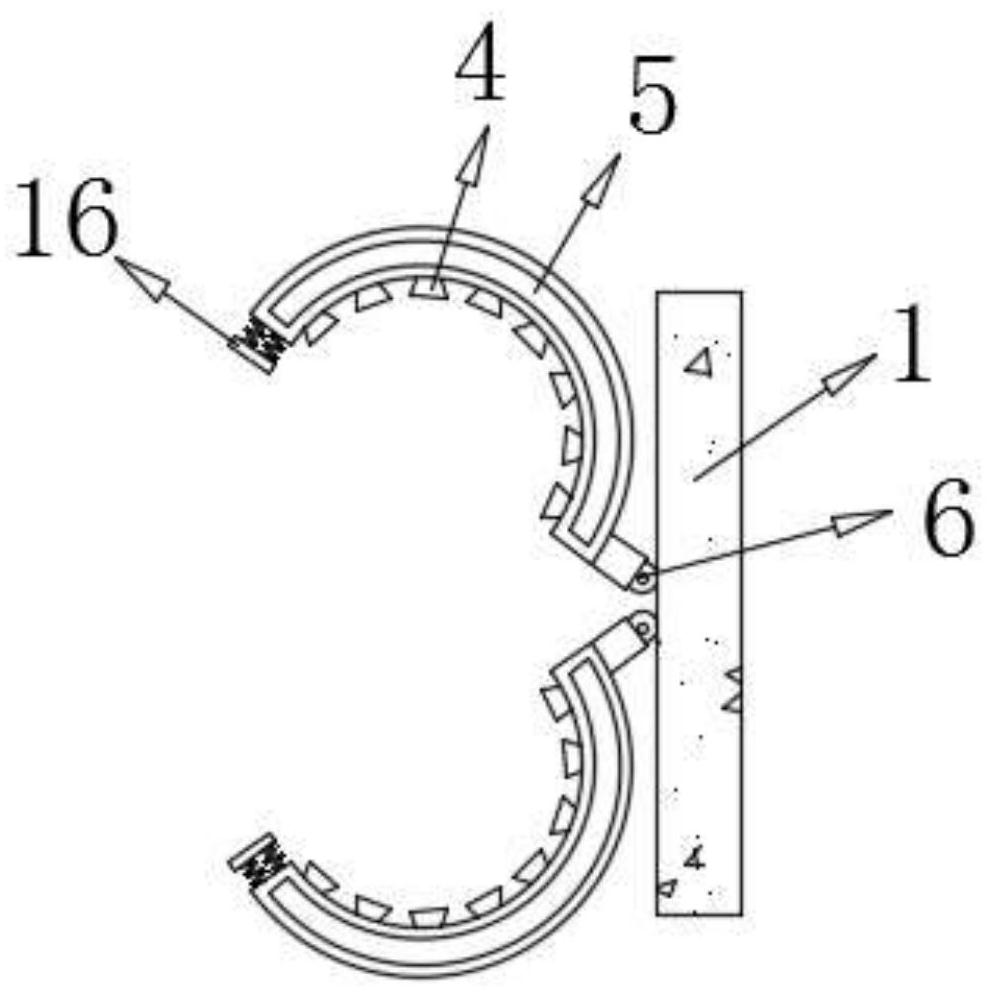

Tree trunk whitewashing device for garden

InactiveCN112452594AWhite evenlyPrevent mis-sprayingLiquid spraying apparatusPlant protectionTree trunkAgricultural engineering

The invention discloses a tree trunk whitewashing device for a garden. The tree trunk whitewashing device comprises a movable seat with an L-shaped cross section, wherein the top of the movable seat is connected with a material storage barrel through a bolt; the bottom of the movable seat is connected with a first conveying pump through a bolt; a stirring mechanism is arranged in the material storage barrel; the top and the bottom of one side of the movable seat are connected with mounting plates correspondingly through bolts; and one side of one mounting plate is connected with a rotary motorthrough bolts. According to the tree trunk whitewashing device disclosed by the invention, a stirring motor drives a rotary rod and a stirring paddle to stir and uniformly mix a whitewashing agent; the movable seat is pushed to move so that a tree trunk is located between two movable plates; the rotary motor drives the two movable plates to rotate around a rotary shaft and cover an outer wall ofthe tree trunk in a buckling manner; the first conveying pump is used for pumping the whitewashing agent in the material storage barrel into the movable plates and spraying the whitewashing agent through a spraying nozzle to uniformly whitewash the tree trunk; and the tree trunk whitewashing device is convenient and efficient, and the circumstance that the whitewashing agent is sprayed onto clothes by mistake in a spraying process is avoided.

Owner:薛晶

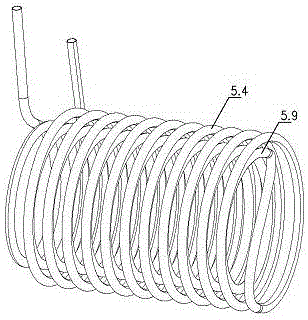

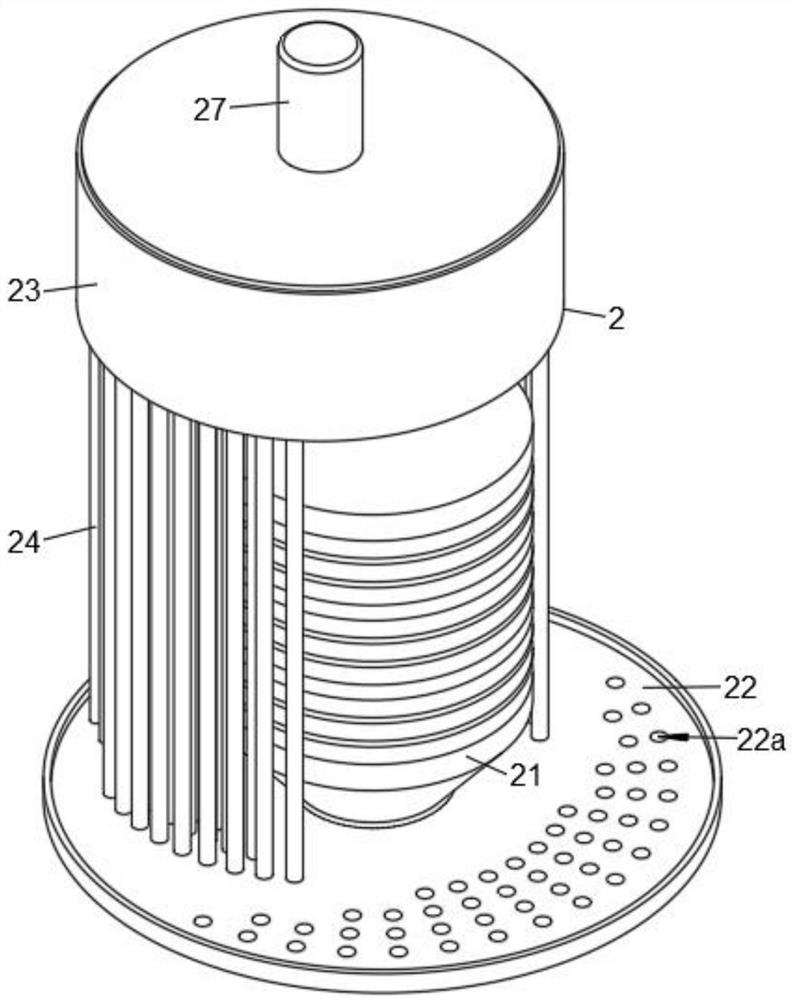

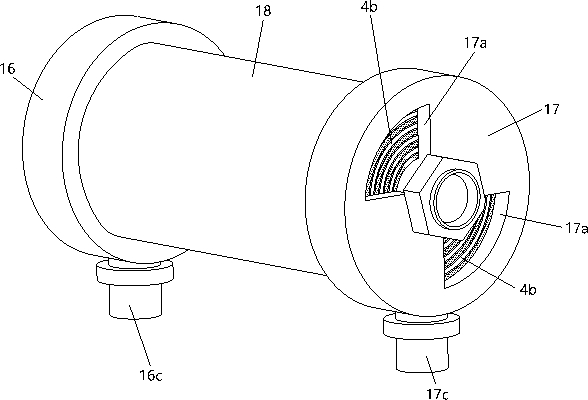

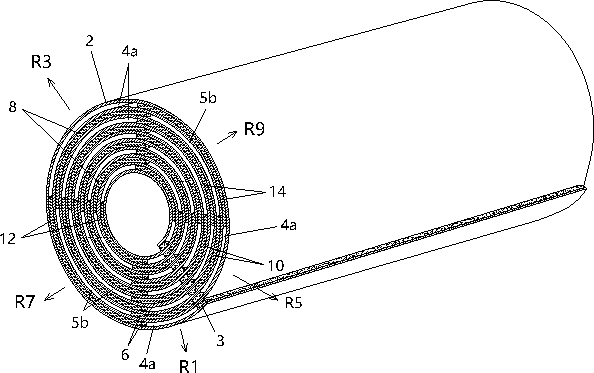

Spiral heat exchanger and manufacturing method thereof

ActiveCN112179182ALow flow resistanceEasy to importHeat exchanger casingsStationary plate conduit assembliesEngineeringMechanical engineering

The invention relates to a spiral heat exchanger and a manufacturing method thereof. The spiral heat exchanger comprises a mandrel with the axis extending leftwards and rightwards and heat conductionthin strips spirally wound around the periphery of the mandrel by at least three circles. The heat conduction thin strips of any two adjacent ring layers are spaced by a certain distance, blocking ribs extending left and right are arranged between the heat conduction thin strips of any two adjacent ring layers in a supporting mode, all the blocking ribs are sequentially arranged in the radial direction of the mandrel, so that a plurality of hot fluid flow channel and a plurality of cold fluid flow channels alternately arranged in the radial direction of the mandrel are formed, each cold fluidoutlet is provided with a first barrier strip for partially blocking the cold fluid outlet, each hot fluid outlet is provided with a second barrier strip for partially blocking the hot fluid outlet, the first barrier strips are sequentially arranged in the first radial direction, and the second barrier strips are sequentially arranged in the second radial direction. The spiral heat exchanger is compact and ingenious in structure, small in flow resistance, large in heat exchange area, high in heat exchange efficiency and quite suitable for gas-gas heat exchange and gas-liquid heat exchange.

Owner:SHANGHAI XINGYE MATERIALS TECH CO LTD

Raw material drying device for solid toilet cleaner production

ActiveCN110940166AWell mixedImprove drying effectDrying gas arrangementsDrying machines with non-progressive movementsElectric machineryProcess engineering

The invention belongs to the technical field of toilet cleaner production, in particular to a raw material drying device for solid toilet cleaner production. In view of the problems that the existingdrying device cannot enable hot air and materials to be fully mixed, the following scheme is put forward: the device comprises a drying cylinder, a bent end is arranged at the top of the drying cylinder, the inner wall of the top of the drying cylinder is connected with a stirring shaft through a bearing, a stirring rod is arranged on the outer wall of the side face of the stirring shaft, a stirring motor is arranged on the outer wall of the top of the drying cylinder, an output shaft of the stirring motor is connected to the outer wall of the top of the stirring shaft through a coupler, a heating cylinder is fixedly connected to the outer wall of the bottom end of the drying cylinder, and an air guide pipe is inserted into the outer wall of one side of the heating cylinder. By means of the drying device, upward-moving powdery raw materials and hot air can be stirred and then fully mixed, the drying effect is improved, the materials can be prevented from adhering to the stirring rod, air in the drying cylinder can be prevented from being exhausted from a feeding hopper, and the air heating effect is improved.

Owner:株洲蓝海包装有限公司

Garbage treating device

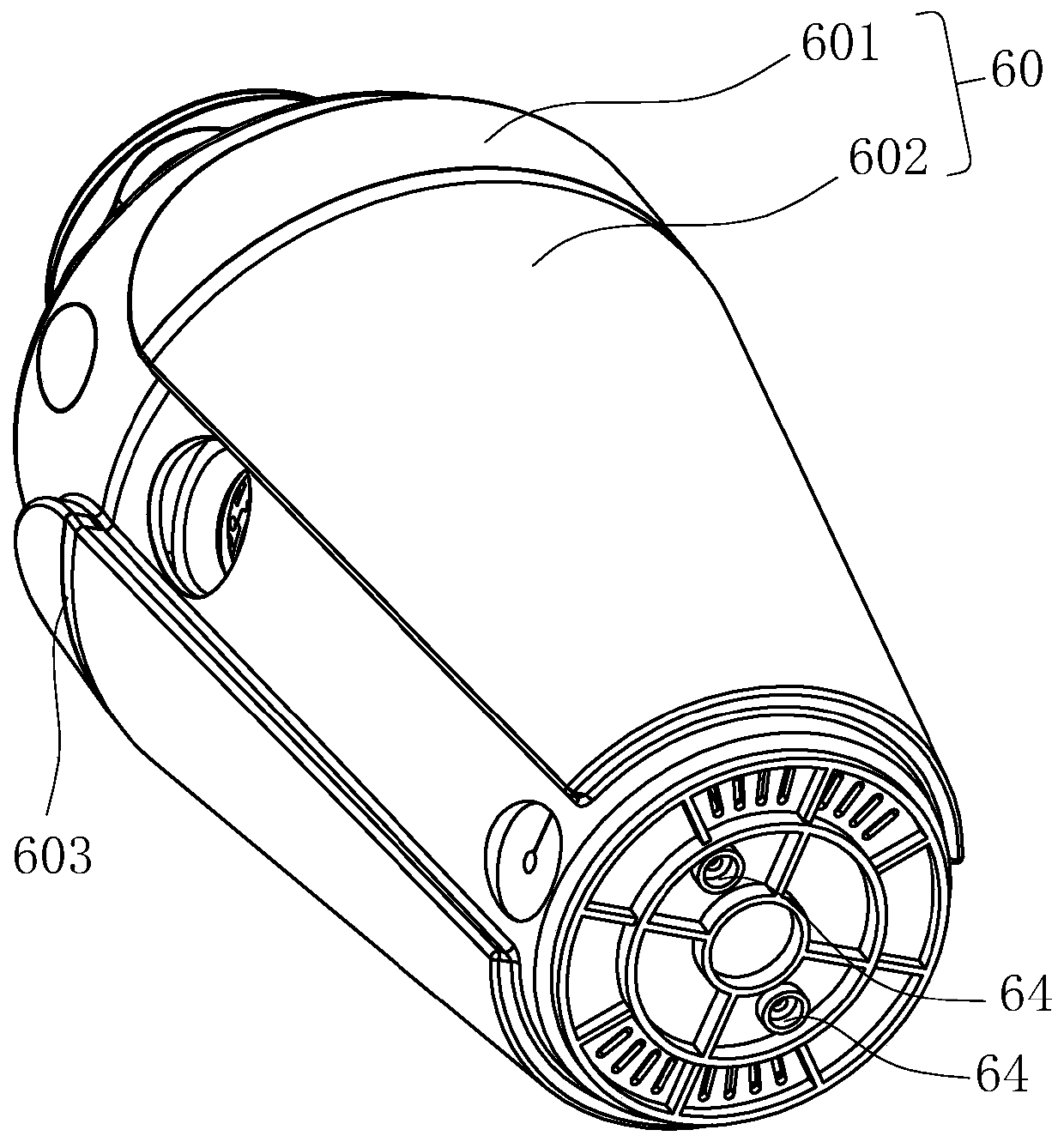

PendingCN110528642AIncrease flow itineraryAchieving a shattering effectDomestic plumbingDISC assemblyFlange

The invention relates to a garbage treating device which comprises a grinding mechanism and a working cavity used for storing the grinding mechanism. The grinding mechanism comprises a grinding ring and a cutter disc assembly which is arranged below the grinding ring and rotates relative to the grinding ring. The cutter disc assembly comprises a cutter disc. The outer edge of the cutter disc is turn over upwards to form a first ring-shaped flange. The lower edge of the grinding ring is matched with the first ring-shaped flange in an inserting manner. A channel for garbage to flow through is formed between the grinding ring and the first ring-shaped flange. Multiple slots are formed in the lower edge of the grinding ring at intervals in the circumferential direction. First cutting teeth arearranged on the inner wall of each slot. Multiple second cutting teeth extending upwards are further arranged on the first ring-shaped flange at intervals in the circumferential direction. The secondcutting teeth can form cutting match with the first cutting teeth in the rotating process of the cutter disc. The garbage treating device can effectively prolong the stroke of the food garbage chopping process, and then the chopping effect is improved effectively.

Owner:宁波亿盛电机有限公司

Environment-friendly industrial waste gas purification device

ActiveCN112807974ANew Design IdeasReasonable structureDispersed particle separationExhaust fumesProcess engineering

The invention discloses an environment-friendly industrial waste gas purification device, which comprises: a shell; a waste gas conveying piece comprising a waste gas conveying header pipe and a first bubble crushing turbulent flow piece, wherein the waste gas conveying header pipe and the first bubble crushing turbulent flow piece are both arranged on the shell; a first spraying piece comprising a partition plate, a primary spraying branch pipe, a primary spraying pipe, a primary spraying head, a primary spraying header pipe, a booster water pump and a booster water suction pipe; a spraying piece comprising a waste gas relay pipe, an extended mixing pipe, a spraying branch pipe, a spraying pipe, a spraying head and a spraying header pipe, wherein the waste gas relay pipe is arranged on the partition plate; and a second spraying piece comprising a second bubble crushing turbulence piece, a spraying support frame, a secondary spraying branch pipe, a secondary spraying head, a secondary spraying header pipe and a demister. The environment-friendly industrial waste gas purification device is novel in design thought, reasonable in structure, small in occupied area, reasonable in waste gas desulfurization and denitrification process, high in desulfurization and denitrification efficiency, low in desulfurization and denitrification liquid consumption and low in production cost.

Owner:苏州仕净科技股份有限公司

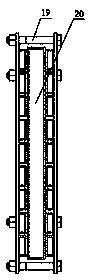

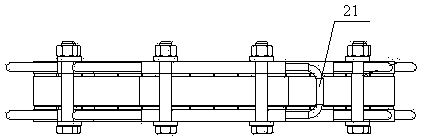

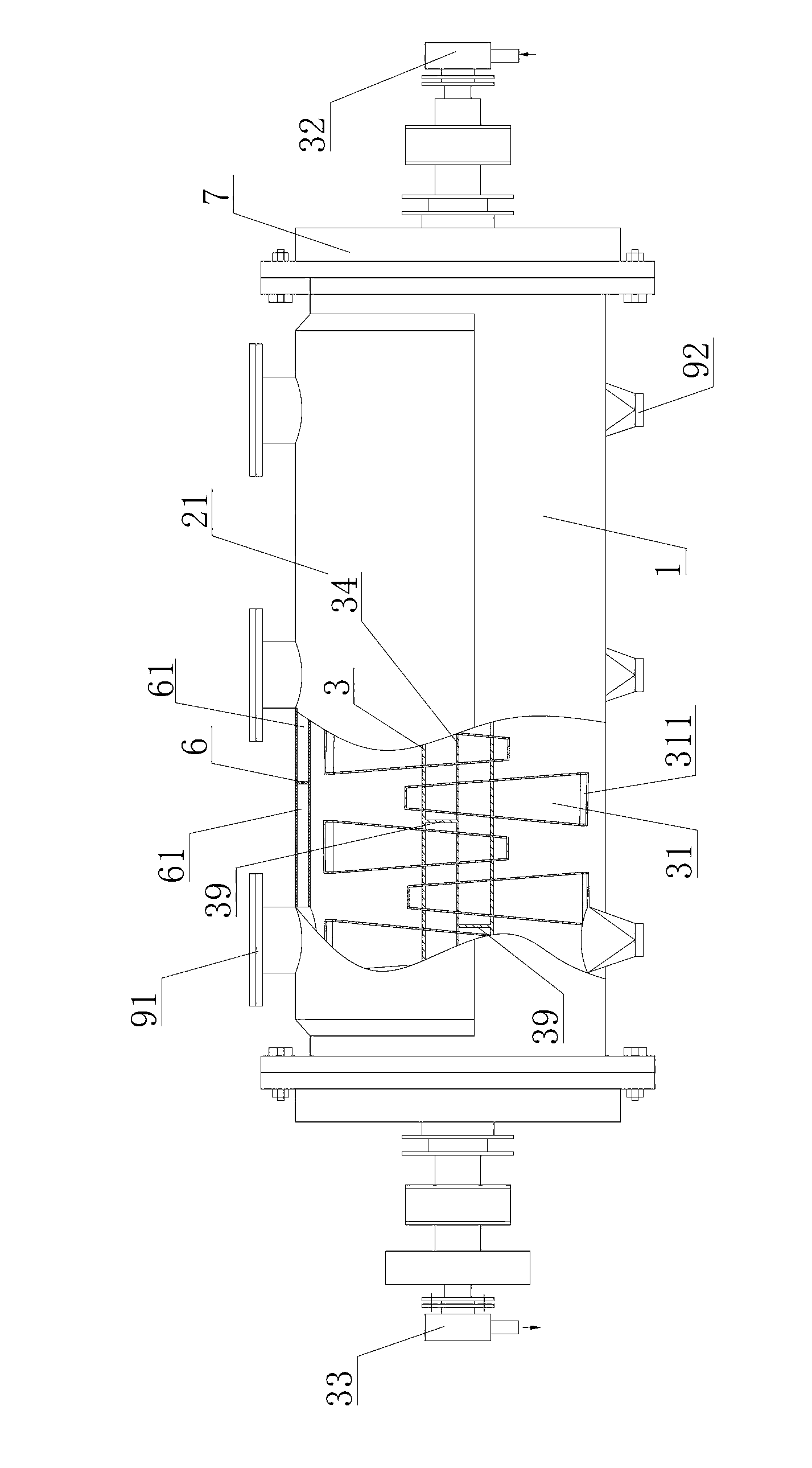

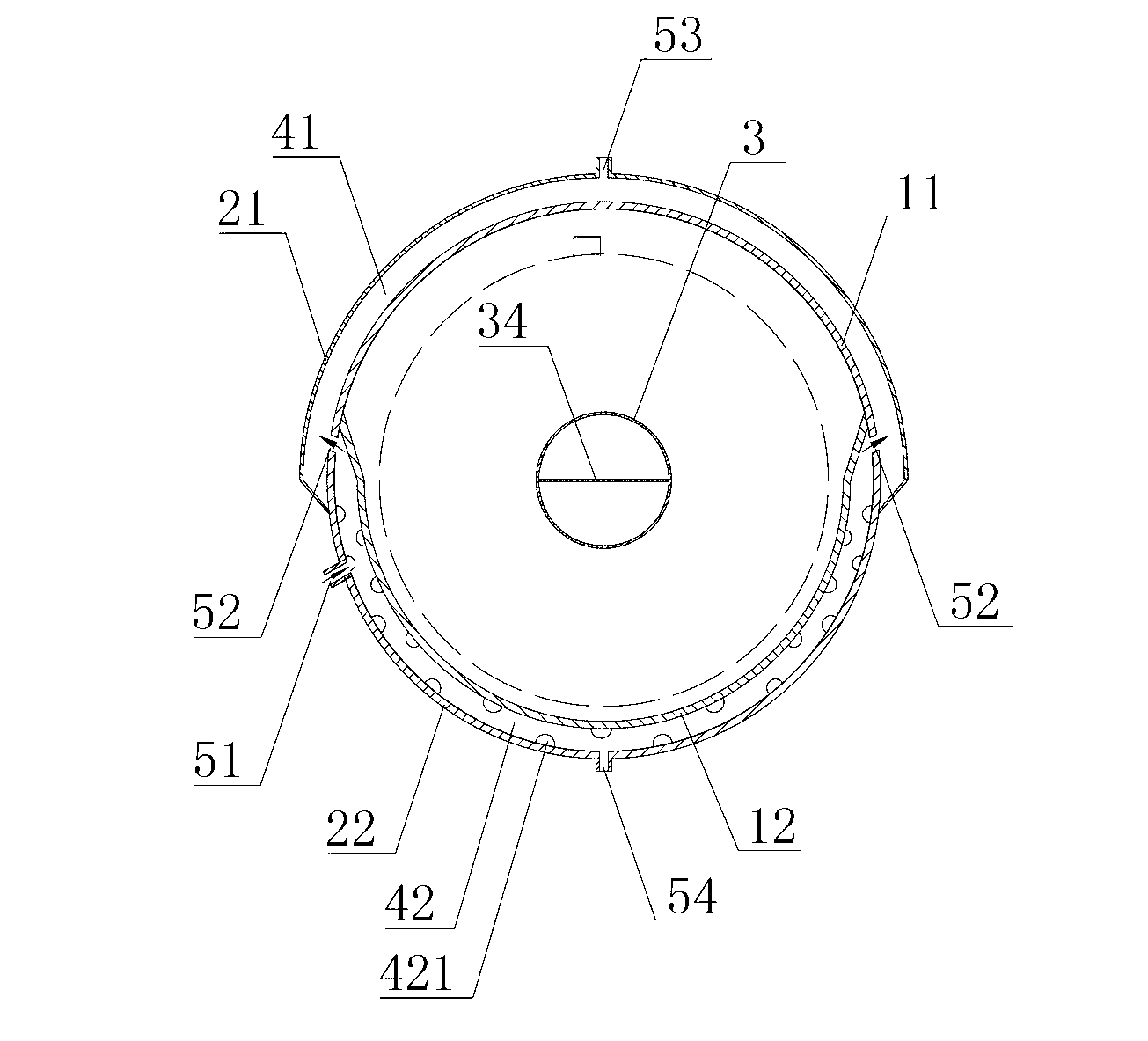

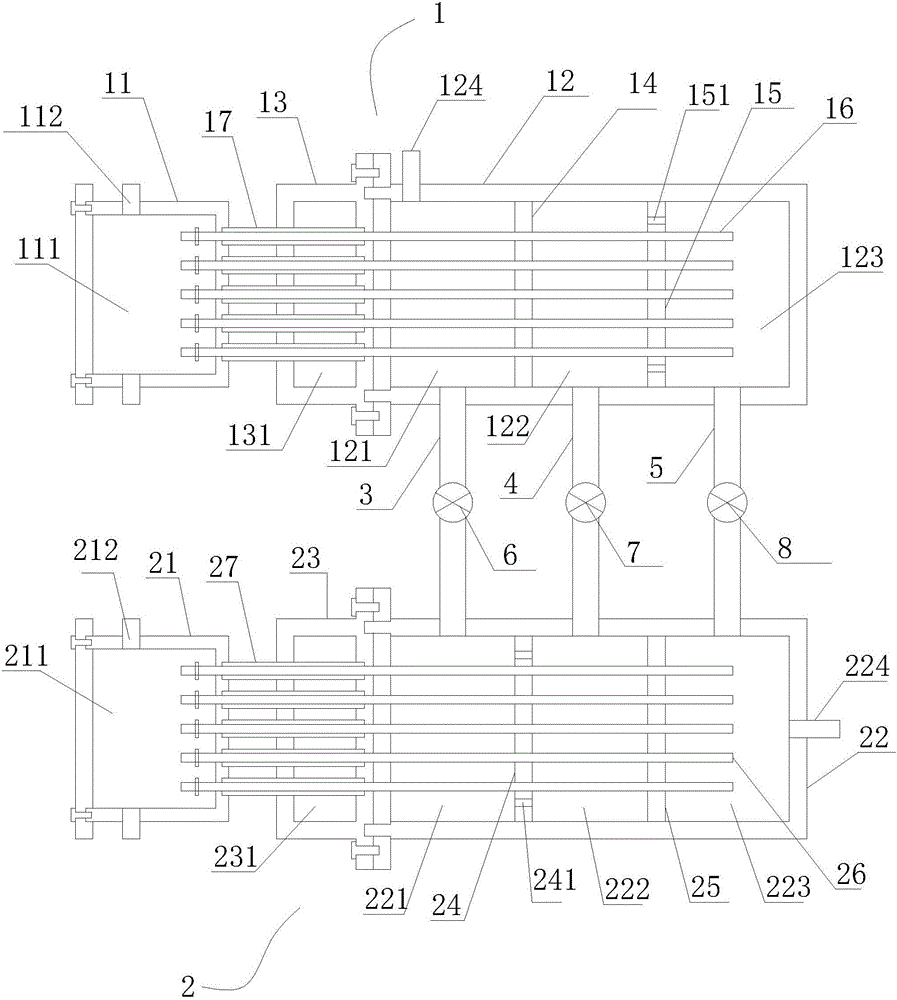

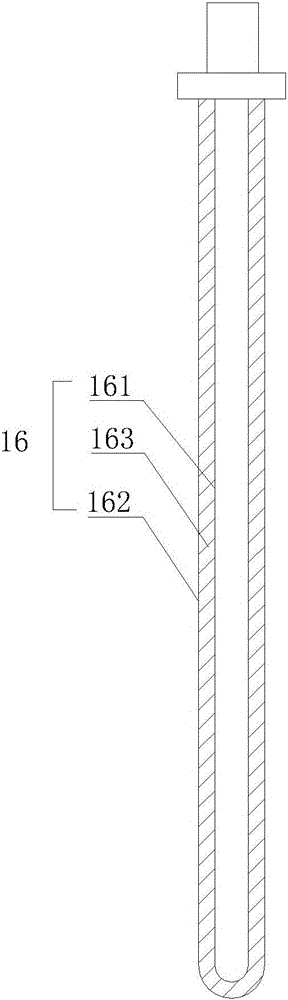

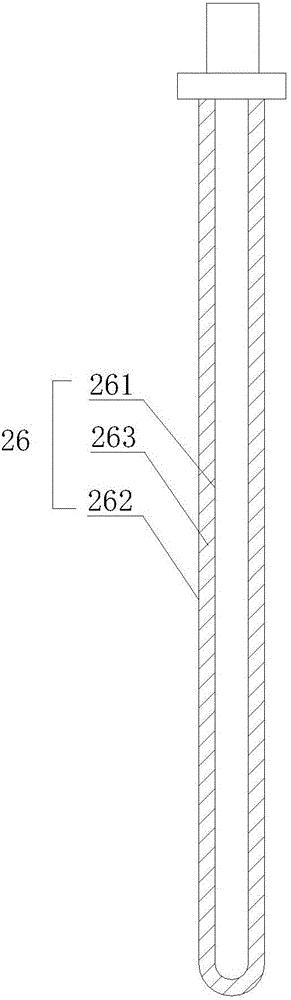

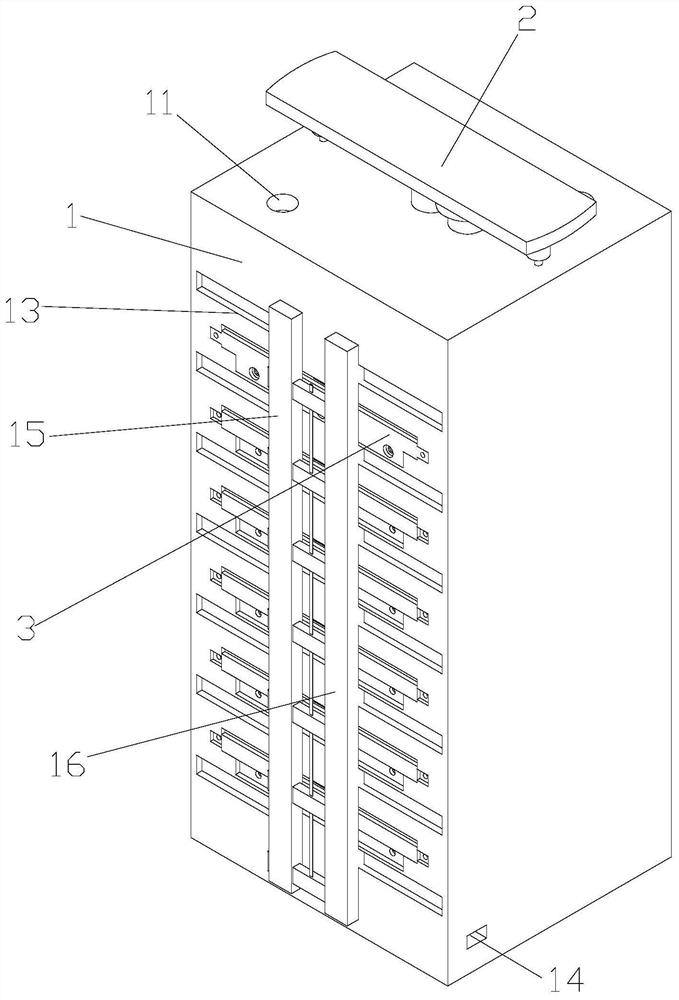

Combined explosion-proof electric heater

The invention provides a combined explosion-proof electric heater. The combined explosion-proof electric heater comprises a first heater, a second heater, a first connecting pipe, a second connecting pipe and a third connecting pipe, wherein the first heater comprises a first explosion-proof terminal box, a first container body, and a first container cover, wherein a first heating cavity of the first heater is divided into a first chamber, a second chamber and a third chamber by a first partition plate and a second partition plate; the second heater comprises a second explosion-proof terminal box, a second container body, and a second container cover; a second heating cavity of the second heater is divided into a fourth chamber, a fifth chamber and a sixth chamber by a third partition plate and a fourth partition plate; two ends of the first connecting pipe separately communicate with the first chamber and the fourth chamber; two ends of the second connecting pipe separately communicate with the second chamber and the fifth chamber; and two ends of the third connecting pipe separately communicate with the third chamber and the sixth chamber. According to the combined explosion-proof electric heater disclosed by the invention, the flowing stroke of fluid is extended, and the heating time of the fluid is prolonged, so that the fluid can be sufficiently heated, and the heating effect is improved.

Owner:安徽易众电气科技有限公司

A high-efficiency continuous vacuum stripping system for removing dioxane

ActiveCN112169363BReduce energy consumptionEfficient removalOrganic chemistryOrganic compound preparationTowerMechanical engineering

The invention discloses a high-efficiency continuous vacuum stripping system for removing dioxane, which comprises a stripping tower and trays arranged in the stripping tower, a heating module is arranged in the stripping tower, and The top of the stripping tower is provided with a liquid inlet and a gas outlet, the bottom of the stripping tower is provided with a liquid outlet, and the side wall of the stripping tower is provided with a plurality of first mounting grooves matched with the trays, The tray is installed in the first installation groove, and the stripper is provided with a first fixing rod and a second fixing rod for fixing the tray in the first installation groove; A second installation groove is provided on the tower plate, and a top plate is rotatably connected to the inner wall of the second installation groove, and a first through hole is arranged on the top plate, and a hole corresponding to the first through hole is arranged on the tower plate. Corresponding to the second through hole, the diameter of the second through hole is larger than that of the first through hole.

Owner:中轻化工绍兴有限公司

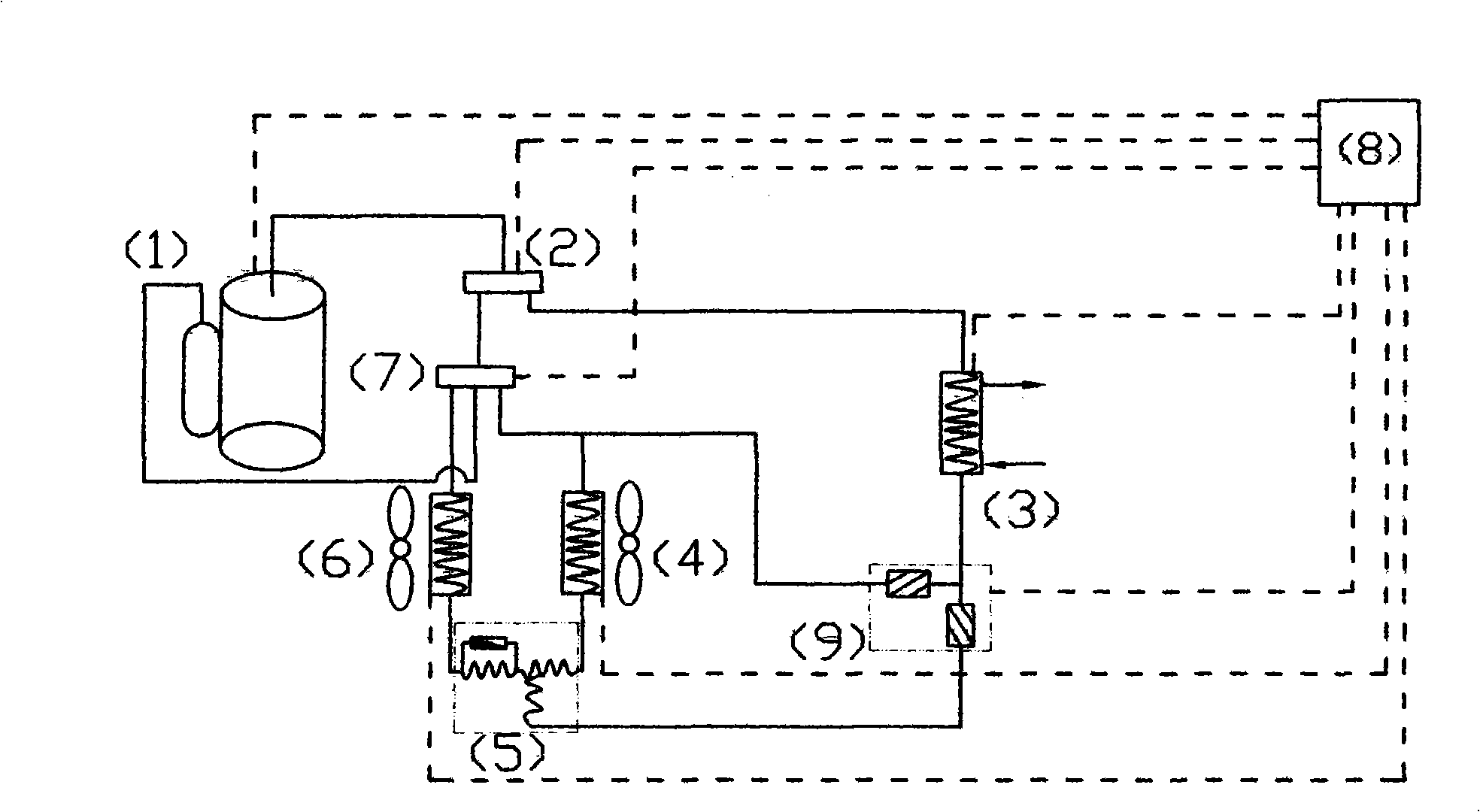

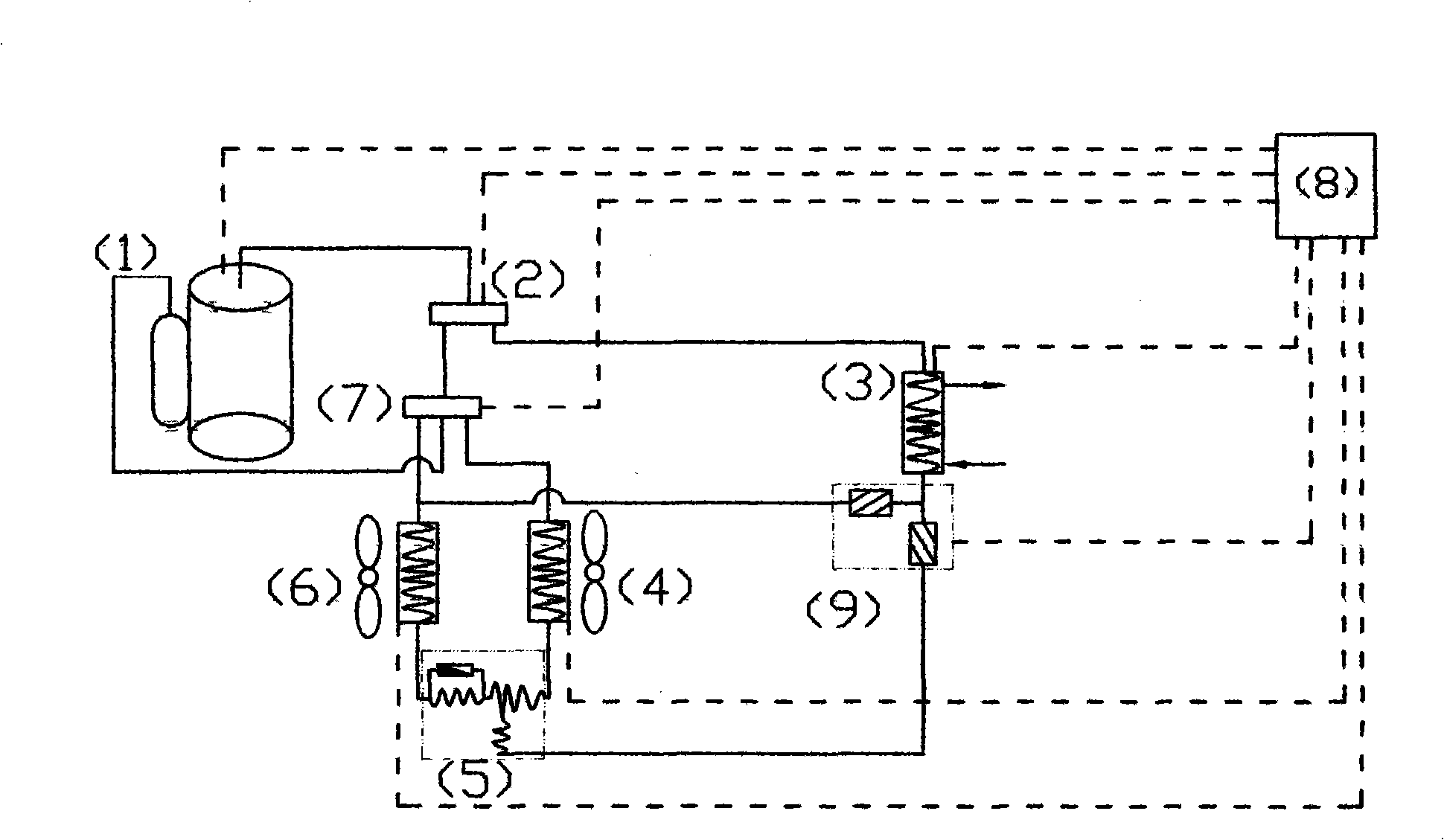

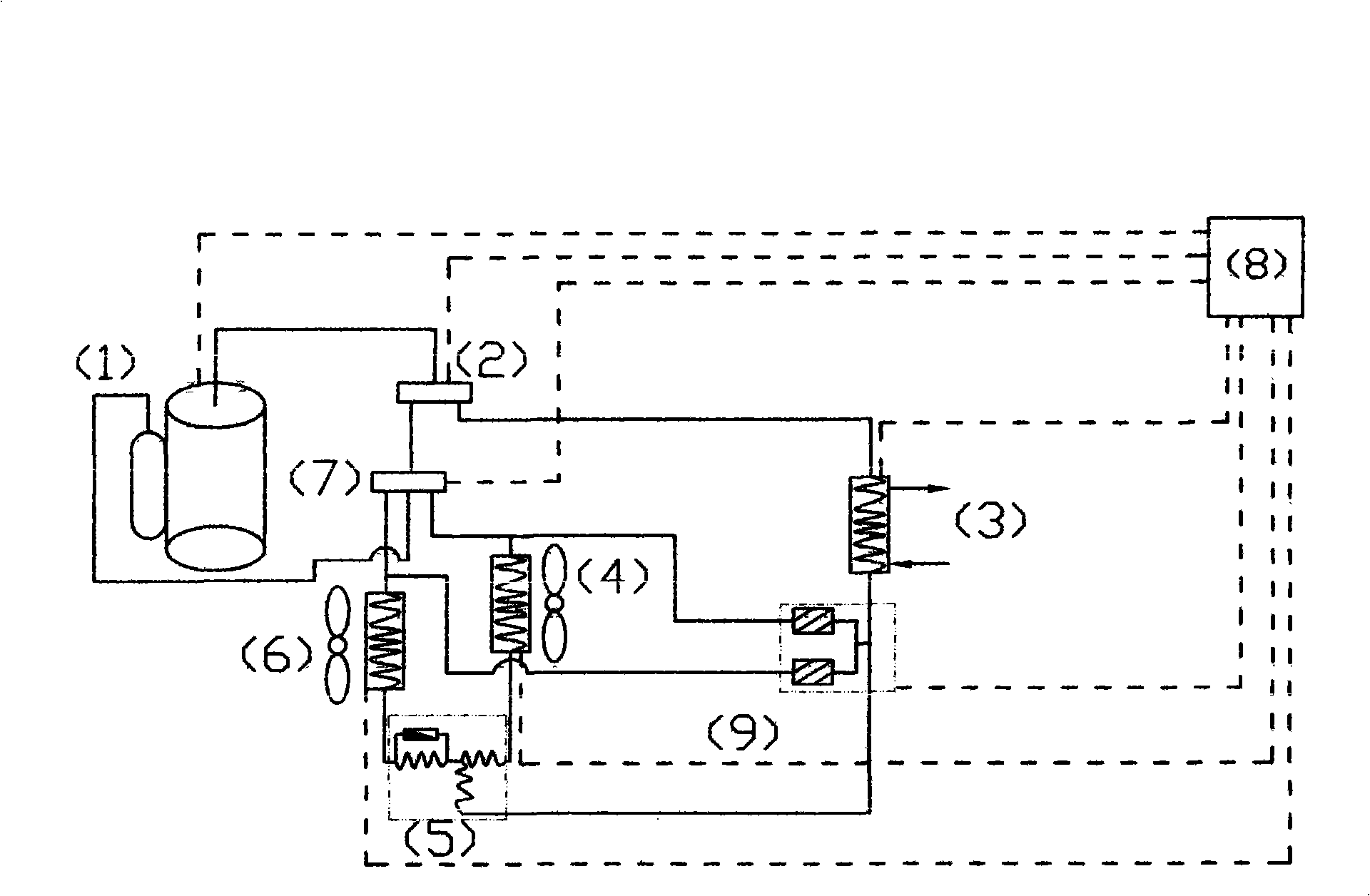

High-efficiency heat pump hot-water air conditioner

InactiveCN101319831ASubstantial performance improvementConsiderable positive effectFluid heatersHeat pumpsEngineeringHigh pressure

The invention relates to a high efficiency heat pump hot water air conditioner, belongs to the heat pump applied technology field, mainly comprising a compressor (1), a gate valve (2), a water condenser (3), an indoor heat exchanger (4), a throttling device (5), an outdoor heat exchanger (6) and a reversing arrangement (7). The outdoor heat exchanger (6) and the reversing arrangement (7) form a refrigerant closed cycle system which is controlled by an electric control device (8). The system is characterized in that the refrigerant outlet of the water condenser (3) is at least separated into two ways by a gate device (9). One way is connected with the throttling device (5), and at least one way is connected with the inlet of high pressure refrigerant of the indoor heat exchanger (4) or the outdoor heat exchanger (6) or at least two other ways are connected with the inlet of high pressure refrigerant of the indoor heat exchanger (4) or the outdoor heat exchanger (6). The high efficiency heat pump hot water air conditioner can realize multiple effects with one device, can supply air conditioning and hot water with high efficiency and energy saving. The speed of the hot water is speed, the performance is stable and the service life is long.

Owner:惠州市思想科技有限公司

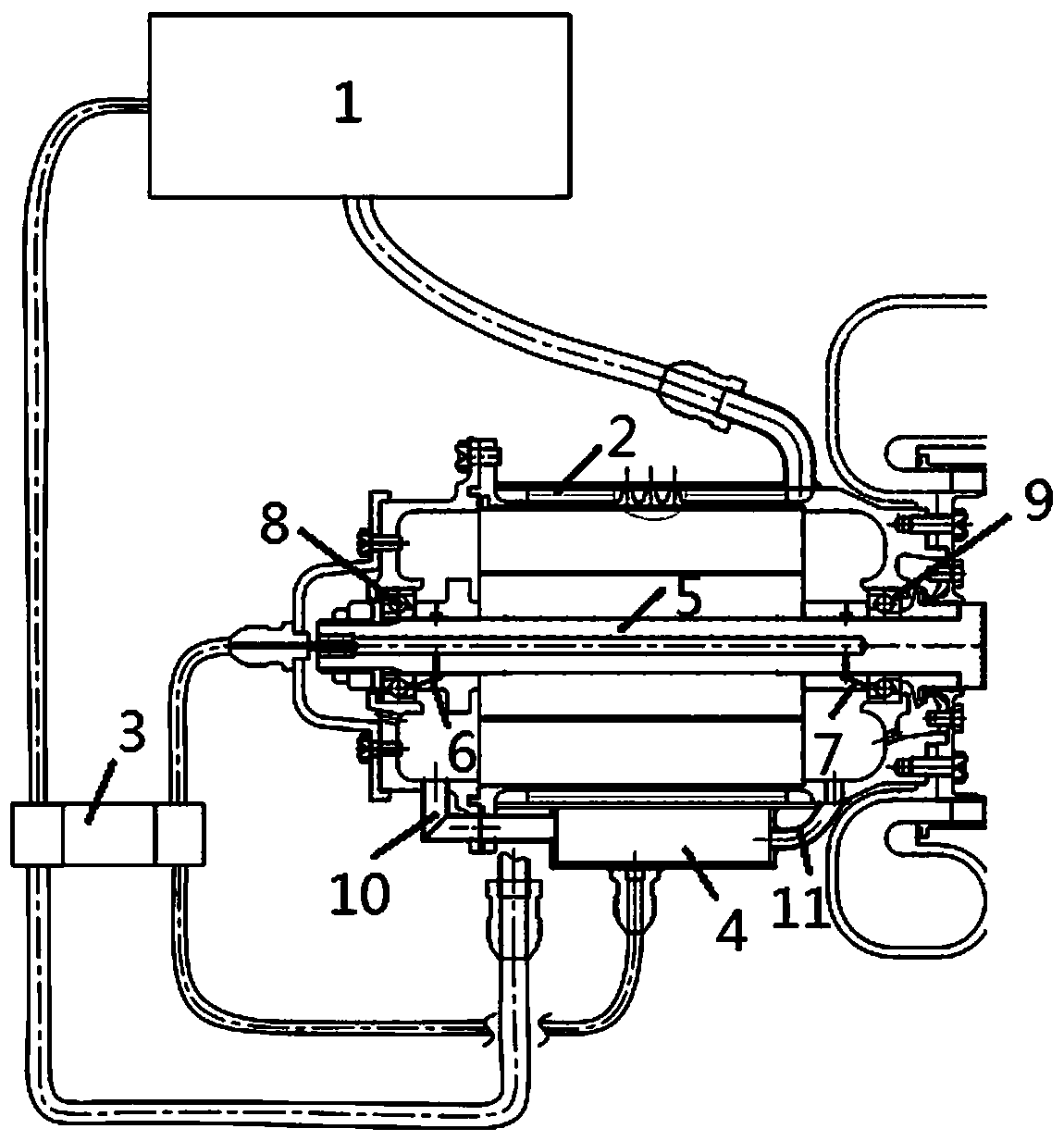

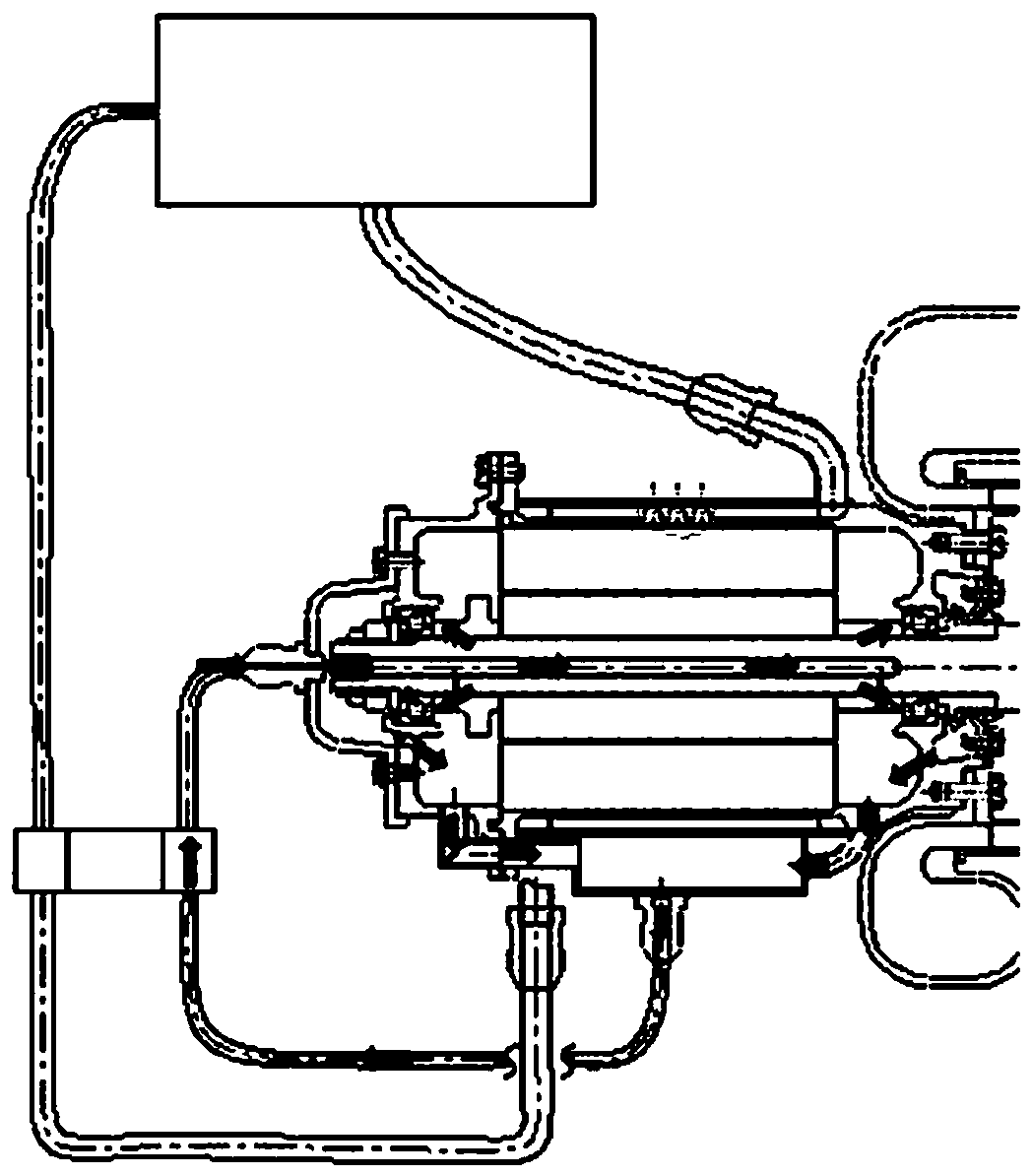

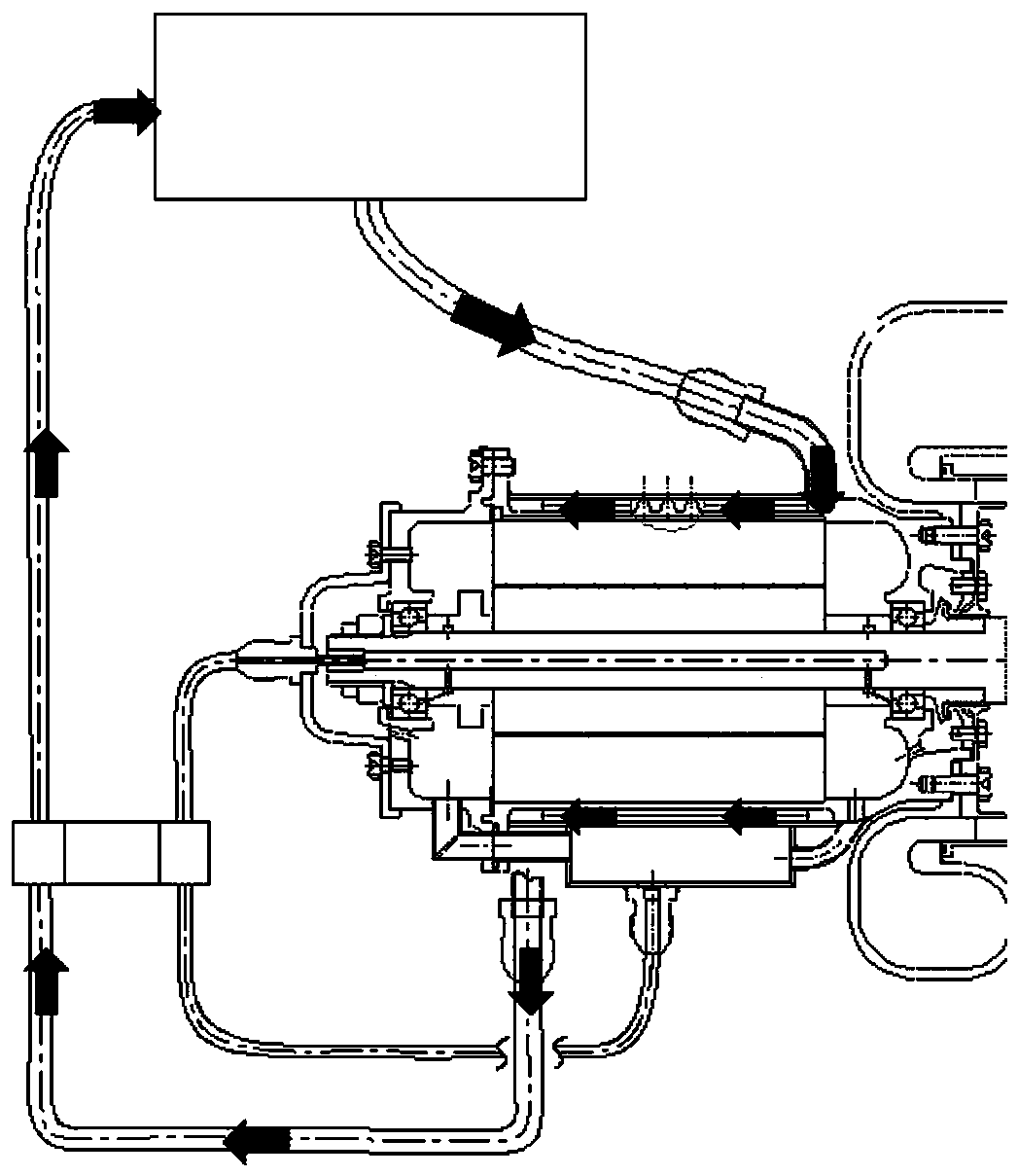

Shaft hole cooling and lubrication system

ActiveCN105162286BImprove cooling effectSimple compositionMagnetic circuit rotating partsCooling/ventillation arrangementFuel tankLubrication

Owner:SHENYANG AEROSPACE XINGUANG GRP

Multi-flow-channel type efficient heat dissipation water cooling row

PendingCN112414164AIncrease flow itineraryFully cool downStationary conduit assembliesHeat exchanger casingsThermodynamicsEngineering

The invention discloses a multi-flow-channel type efficient heat dissipation water cooling row. The multi-flow-channel type efficient heat dissipation water cooling row comprises a flow dividing groove, a water collecting groove, first row pipes, second row pipes, third row pipes and fourth row pipes. The flow dividing groove is made of heat dissipation metal materials, a plurality of first flow dividing water-stop plates are arranged in the flow dividing groove to divide the interior of the flow dividing groove into a water inlet cavity, a transition cavity and a water outlet cavity, and thewater collecting groove is also made of heat dissipation metal materials. A plurality of second flow dividing water-stop plates are arranged in the water collecting groove to divide the interior of the water collecting groove into a first water collecting cavity and a second water collecting cavity, the flow dividing water-stop plates are arranged in the flow dividing groove and the water collecting groove to form a plurality of cavities, and all row pipes are arranged in a matched manner to be communicated with the corresponding cavities. Flow channels in the water cooling row are of a plurality of circuitous structures which are connected in sequence, the flowing stroke of water in the water cooling row is effectively prolonged, the water can be effectively and fully cooled and dissipated, and the overall heat dissipation effect of the water cooling row is very good.

Owner:HUIZHOU HANXU HARDWARE PLASTIC TECH CO LTD

Air filtering unit, railway vehicle and air filter thereof

PendingCN109772077AIncrease flow itineraryImprove filtering effectCombination devicesRailway heating/coolingAir filterFilter material

The invention relates to an air filtering unit, a railway vehicle and an air filter thereof and aims at improving a filtering effect on moisture in air. The air filter for the railway vehicle comprises a shell body, wherein an air feeding channel and an air exhausting channel are arranged on the shell body, a filter core communicated with the air feeding channel is arranged in the shell body, an air exhausting pipe cavity extending in the axial direction is arranged in the filter core, condensing flow guiding pipe is arranged in the air exhausting pipe cavity, the condensing flow guiding pipecomprises an air exhausting opening which is in sealed connection with the air exhausting channel, the condensing flow guiding pipe further comprises an air inlet which extends into the air exhaustingpipe cavity in the axial direction, and the condensing flow guiding pipe further comprises a guiding peripheral face which can guide filtered air to the air inlet and make the air flow to the air exhausting opening from the condensing flow guiding pipe. According to the air filter disclosed by the invention, a flowing journey of air flowing out of a filtering material is increased; in a longer flowing journey, the air can be filtered many times, and moisture can be condensed; thus, the moisture in the air is reduced, and a filtering effect of the filter on the moisture is improved.

Owner:XINXIANG AVIATION IND GROUP

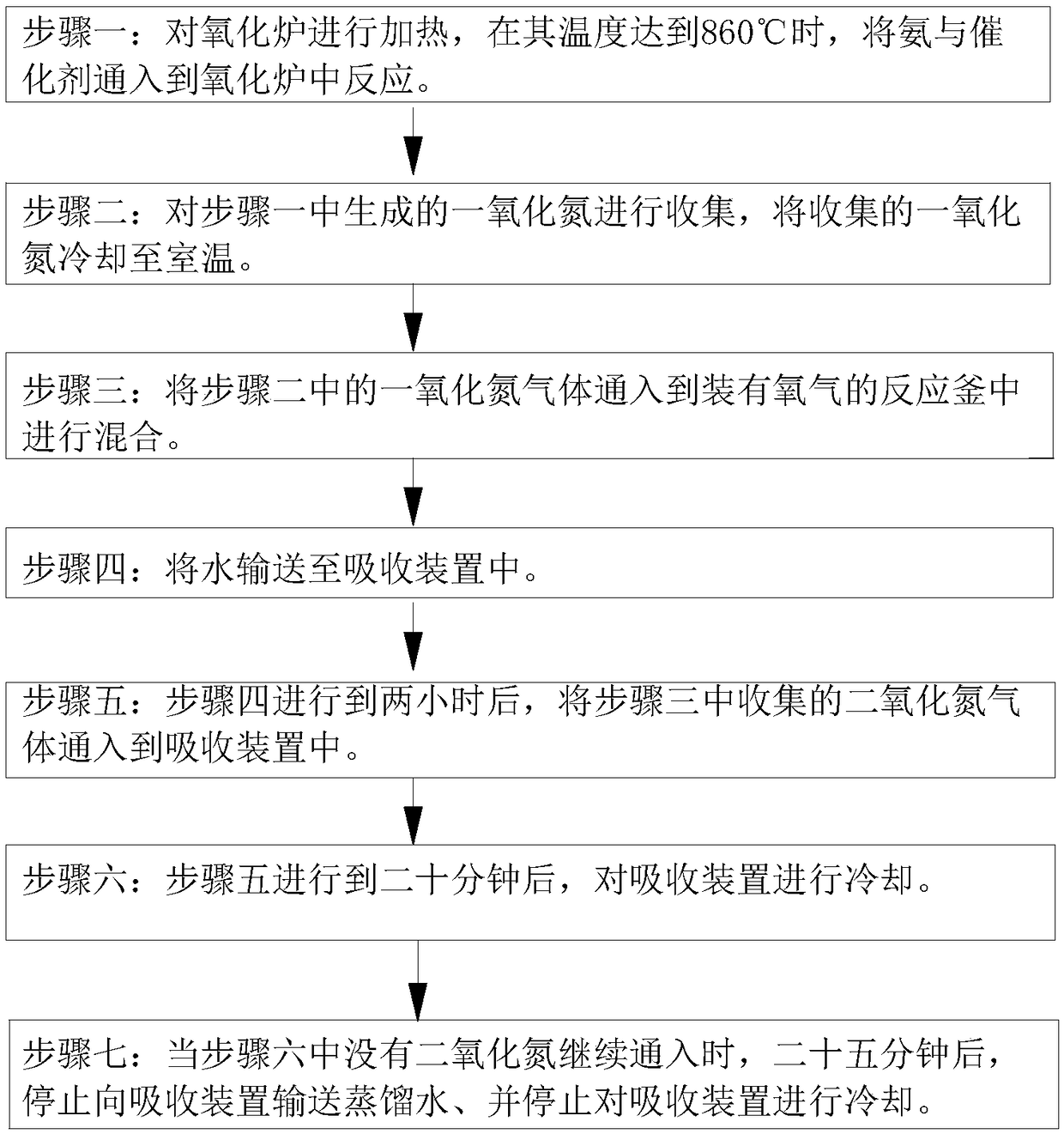

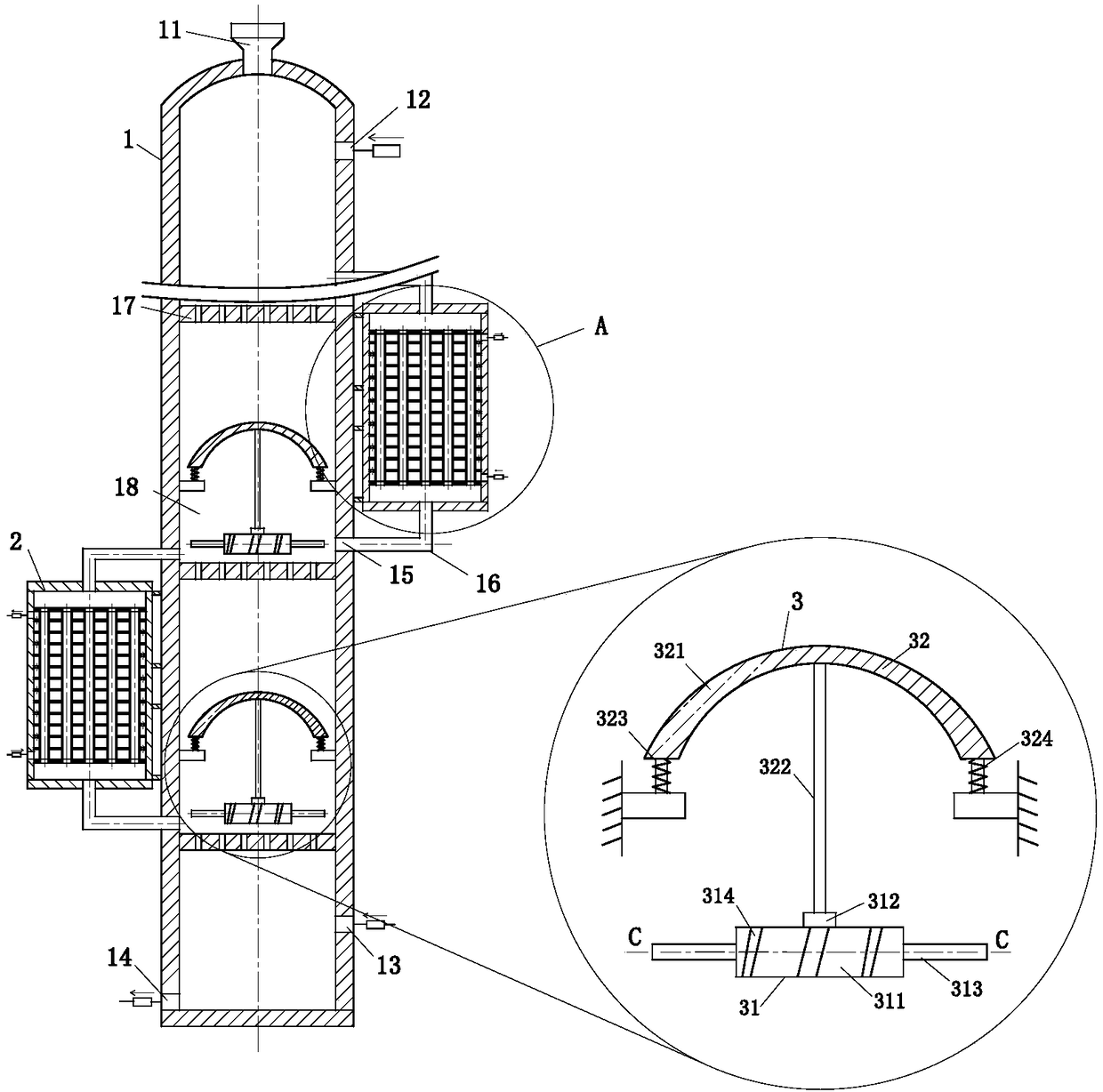

Preparation method for industrial nitric acid

The invention belongs to the technical field of preparation of nitric acid, and in particular relates to a preparation method for industrial nitric acid. The method comprises steps 1 to 7, wherein step 4, step 5 and step 6 cooperate and are used for absorption of nitrogen dioxide by distilled water, and step 7 is used for absorption of nitrogen dioxide when a reaction is finished. Absorption apparatus used in the method comprises an absorption tower, a cooling device and air pressure stirring devices; a sieve plate divides the absorption tower into a plurality of absorption layers, and the interior of each absorption layer is provided with one air pressure stirring device; the exterior of the absorption tower is provided with the cooling device; and each air pressure stirring device comprises one telescopic unit and one stirring unit, and the stirring units are used for breaking bubbles in the absorption layers and accelerating dissolution of a gas. The method provided by the inventionmainly utilizes water to absorb the nitrogen dioxide gas, can improve preparation efficiency of the nitric acid and reduce pollution of the nitrogen dioxide to air.

Owner:东营睿港投资服务有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com