Spiral heat exchanger and manufacturing method thereof

A technology of heat exchanger and spiral, applied in the field of spiral heat exchanger and its manufacturing method, can solve the problems of high maintenance frequency, large flow resistance, unsuitable gaseous fluid heat exchange, etc., and achieve the effect of low maintenance frequency and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

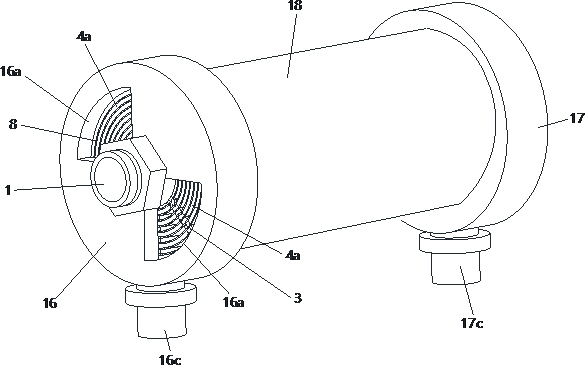

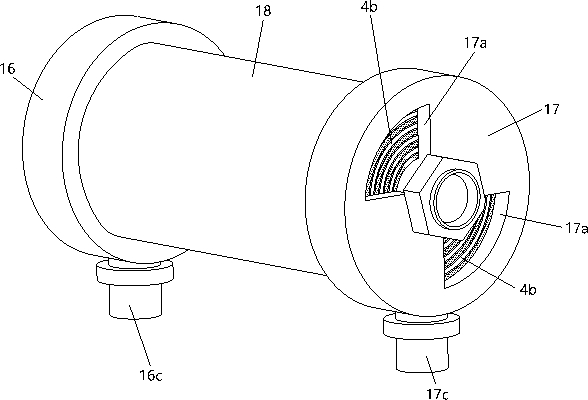

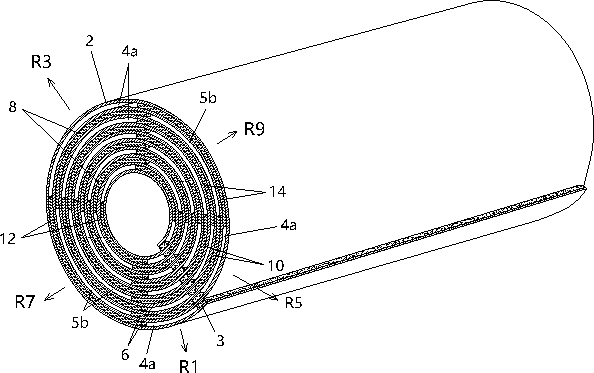

[0113]inFigure 8 withPicture 9 In this case, the area outside of the seventh radial direction R7 of each cold fluid outlet 5b is all blocked by the first baffle 6 to obtain a large enough hot fluid collection area. The area outside the sixth radial direction R6 of each hot fluid outlet 4b is all blocked by the second baffle 7 to obtain a sufficiently large cold fluid collection area. The area of each cold fluid inlet 5a outside the second radial direction R2 is completely blocked by the sixth baffle 11 to obtain a sufficiently large hot fluid collection area. The area outside the first radial direction R1 of each hot fluid inlet 4a is all blocked by the seventh stopper 12 to obtain a sufficiently large cold fluid collection area.

[0114]inimage 3 withFigure 4 In the first embodiment shown, each of the above-mentioned barriers, namely the first barrier 6, the second barrier 7, the third barrier 8, the fourth barrier 9, the fifth barrier 10, and the sixth barrier The barrier bars 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com