Garbage treating device

A technology of garbage disposer and cutter head, which is applied to indoor sanitary pipe installations, water supply installations, buildings, etc., can solve the problems of insufficient time for effective cutting, blockage of sewer pipes, difficult treatment, etc., and achieve the effect of increasing the flow stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

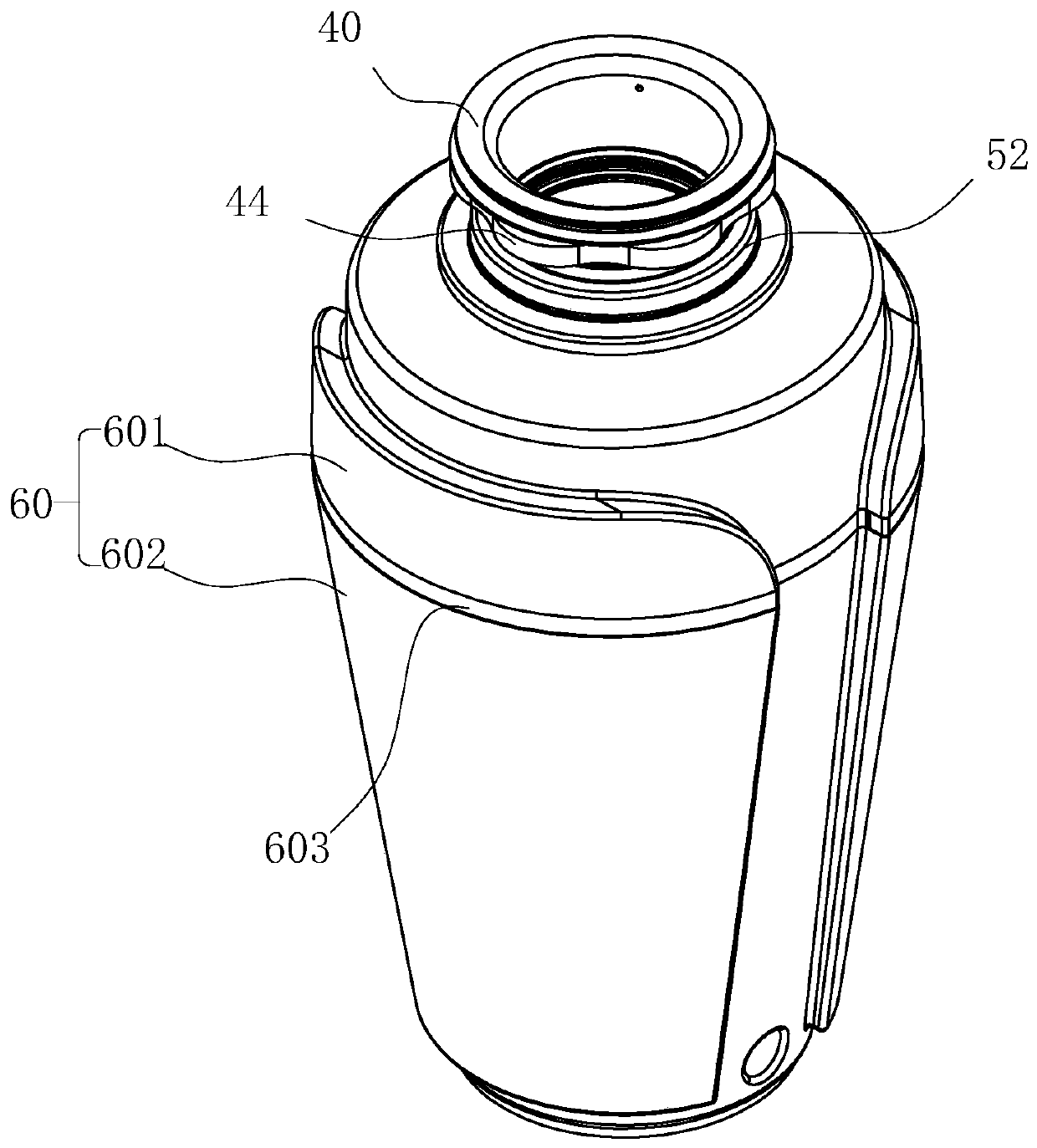

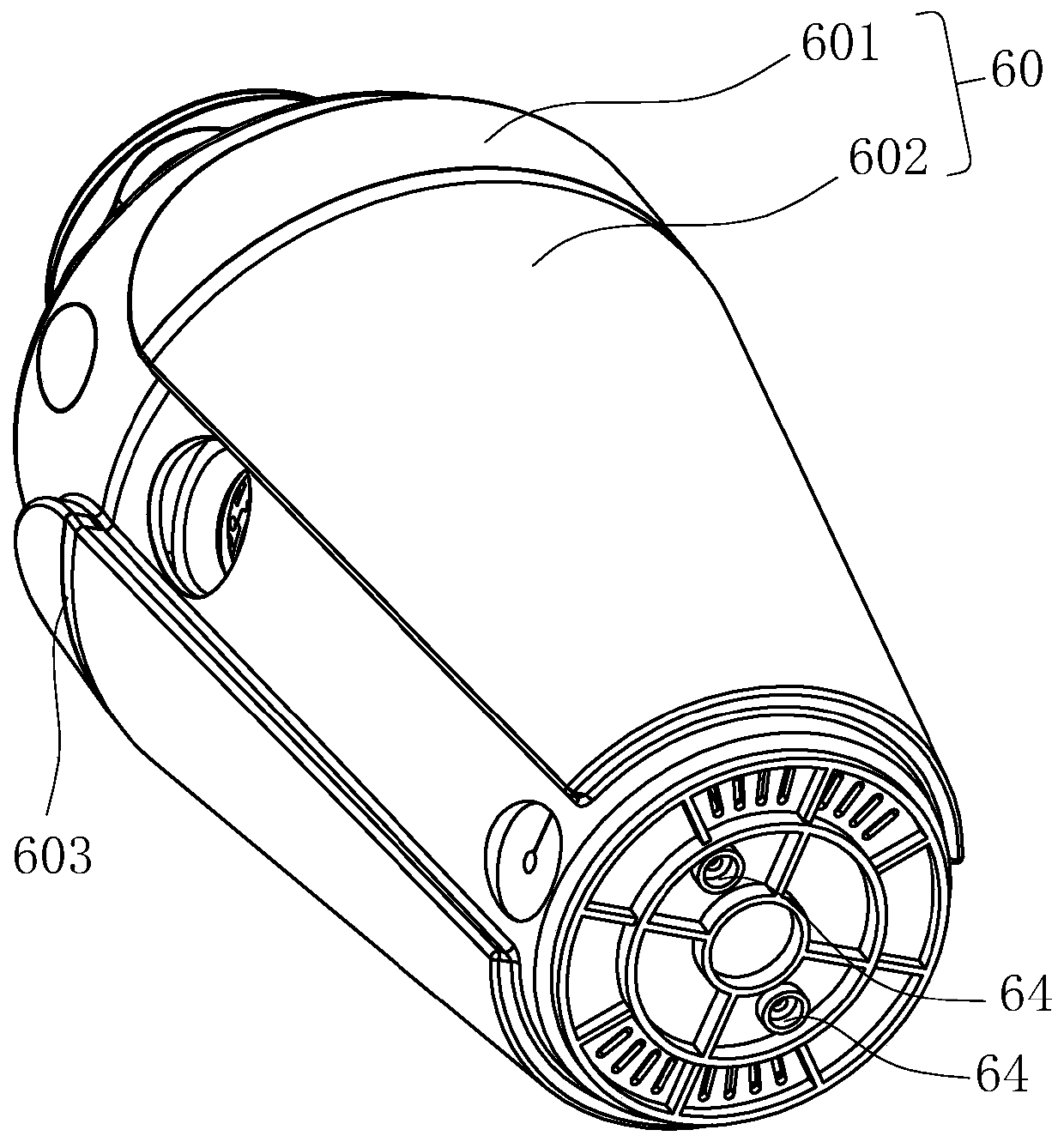

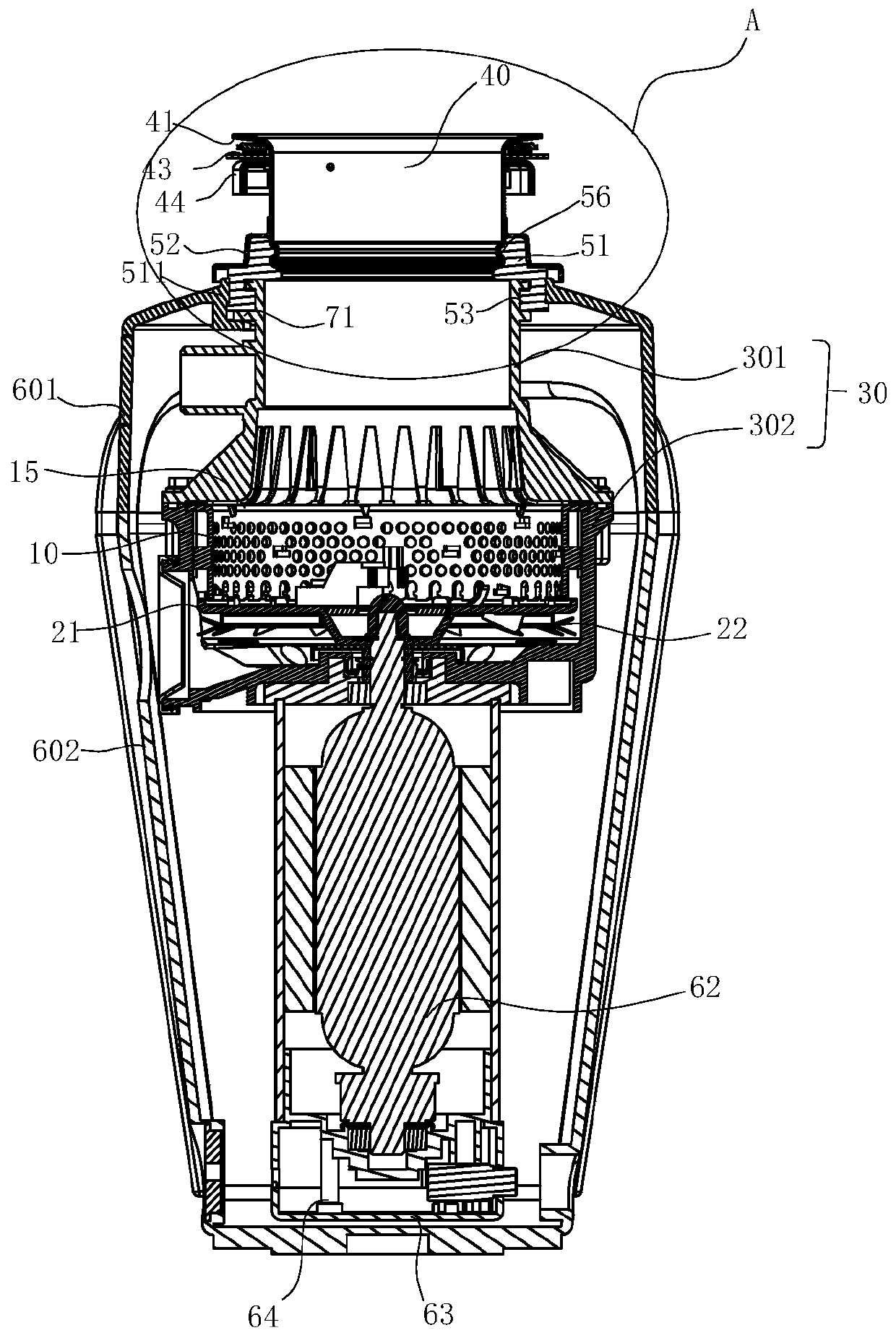

[0042] see Figure 1-Figure 3 , a kind of garbage disposer, connected at the drain at the bottom of the water tank 61, for grinding the food residues washed down from the downpipe 40 connected to the drain at the drain of the tank 61.

[0043] see Figure 1-Figure 17 The garbage disposer includes a casing 60, a grinding part and a motor drive part located in the casing 60, the grinding part includes a working cavity 30 and a grinding mechanism provided in the working cavity 30, the upper port of the working cavity 30 and the downpipe 40 connection, the grinding mechanism includes a cutterhead assembly 20 and a grinding ring 10 that is covered above the cutterhead assembly 20, wherein the motor drive part is located below the working cavity 30, and the output shaft of the motor 62 of the motor drive part passes through the working chamber. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com