Patents

Literature

42results about How to "Achieving a shattering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

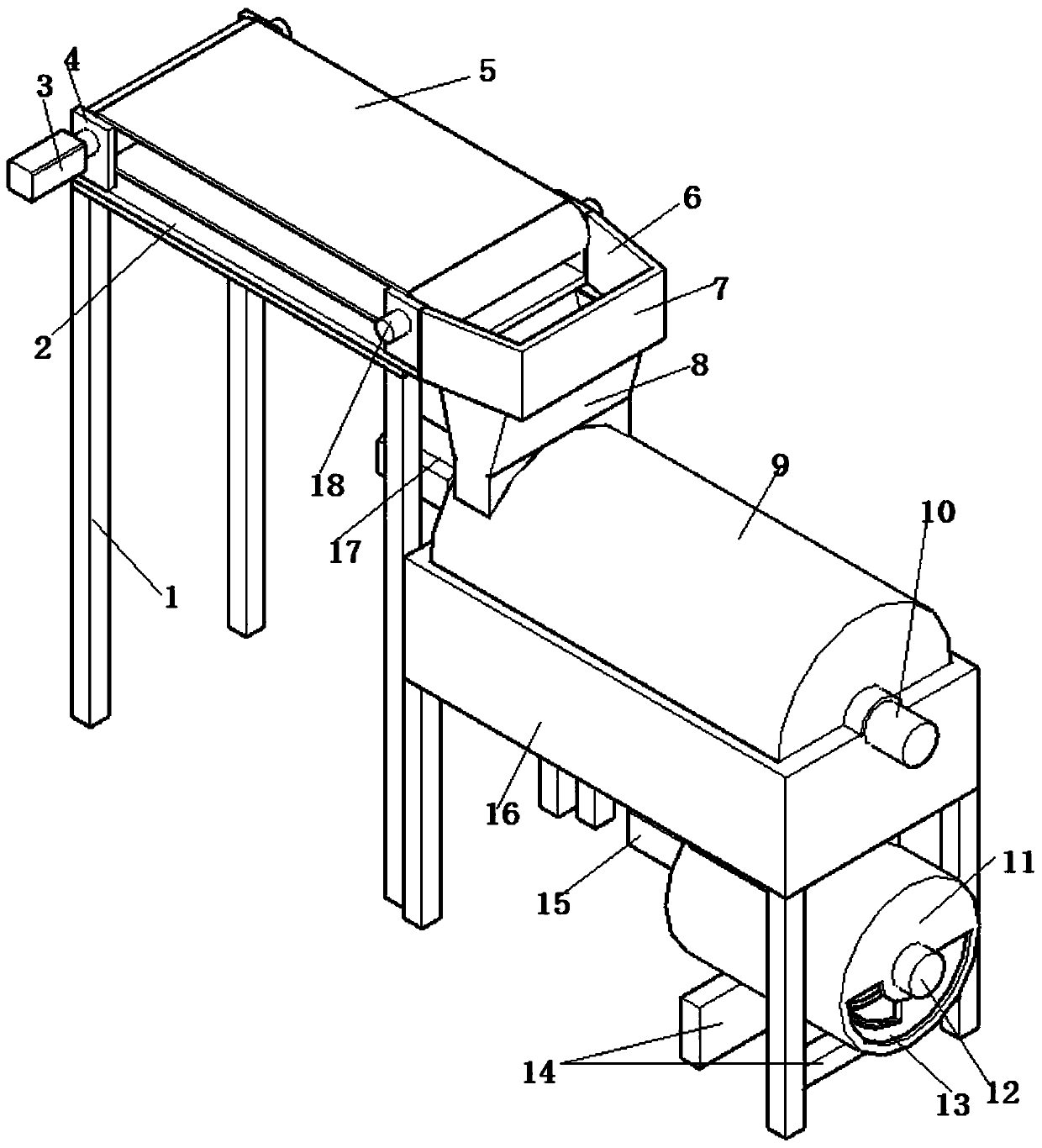

Straw stubble smashing and returning machine

InactiveCN107667671ASimple structureSimple and fast operationLoadersCrop conditionersTransmitted powerAgricultural engineering

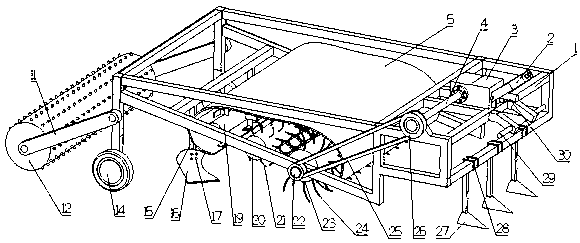

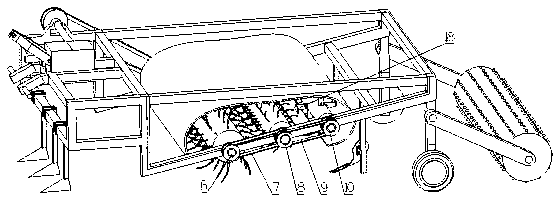

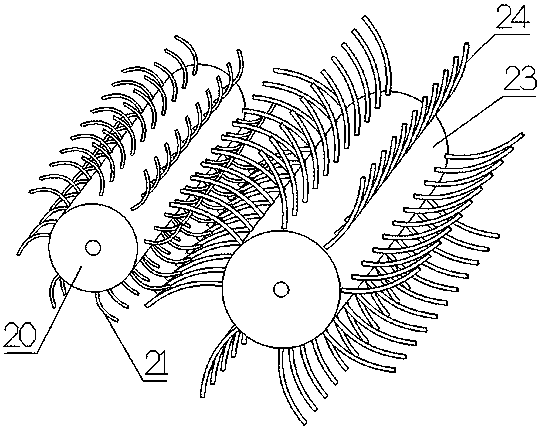

The invention relates to a straw stubble smashing and returning machine. The machine comprises a rack, a power transmission system, a wedge-shaped ditching shovel, a picking and smashing mechanism anda covering and pressing system, wherein the power transmission system is located on the upper portion of the front end of the rack, the wedge-shaped ditching shovel is located on the lower portion ofthe front end of the rack, the picking and smashing mechanism is located in the middle of the rack, and the covering and pressing system is located on the rear portion of the rack; a whole machine power device transmits power to the picking and smashing mechanism and the covering and pressing system through the power transmission system, straw stubbles excavated by the wedge-shaped ditching shovel are picked up and smashed through the picking and smashing mechanism, and finally the straw stubbles are turned over and returned to the field through the covering and pressing system. The machine is simple in structure, easy and convenient to operate, economical, applicable and suitable for smashing and returning of the straw stubbles. The front wedge-shaped ditching shovel can be used for excavating the stubbles, the rear picking and smashing mechanism can pick up the straw stubbles, the smashing function can be achieved, then the smashed stubbles are turned over and buried in soil, and then the land is leveled and compacted.

Owner:KUNMING UNIV OF SCI & TECH

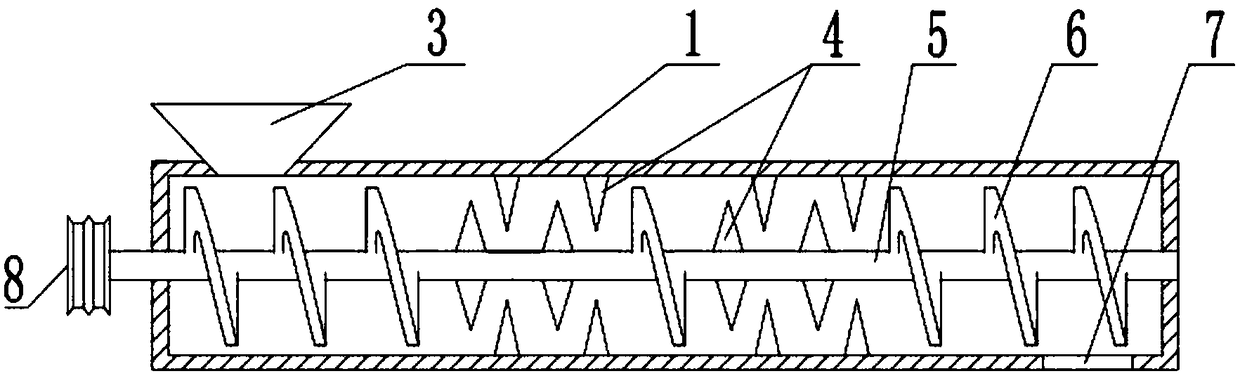

Low-dust type garbage treatment, extrusion and cake formation device

The invention discloses a low-dust type garbage treatment, extrusion and cake formation device. The low-dust type garbage treatment, extrusion and cake formation device comprises a crushing mechanismfor crushing garbage and a molding mechanism for extruding and molding the garbage, wherein the crushing mechanism comprises a crushing barrel; a rotary shaft, which is coaxial with the crushing barrel, is arranged in the crushing barrel; a plurality of sections of spiral blades are fixed at the outer part of the rotary shaft; the adjacent blades are separated by a plurality of metal-made cones; an inner wall of the crushing barrel is also provided with cones which are staggered with the positions of the cones. The low-dust type garbage treatment, extrusion and cake formation device disclosedby the invention has the beneficial effects that the cones with relative positions can be used for tearing and crushing garbage to realize the garbage crushing effect; the cones and the blades, whichare arranged at intervals, are used for repeatedly crushing for a plurality of times, so that the garbage is extruded and molded after being treated in advance, so that a garbage storage space is saved and the subsequent treatment of the garbage is convenient to realize.

Owner:郝会杰

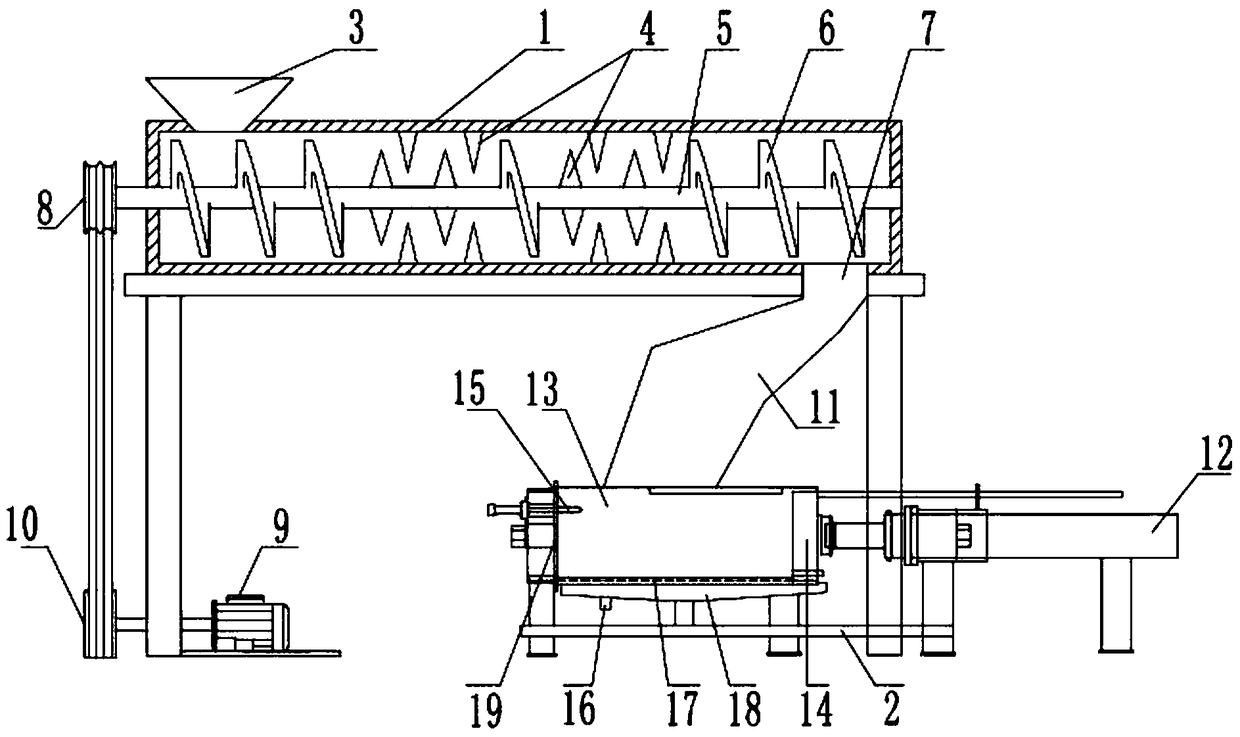

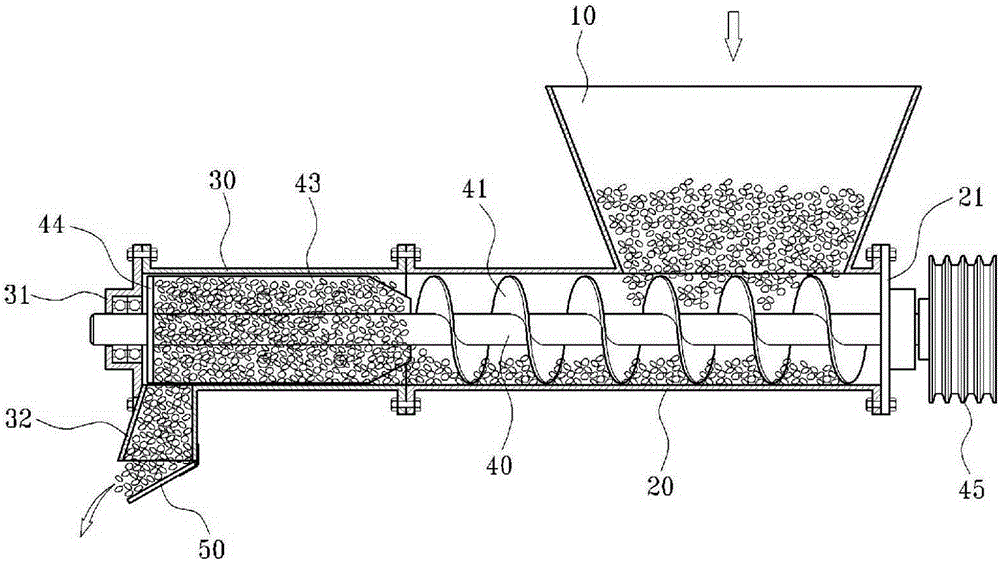

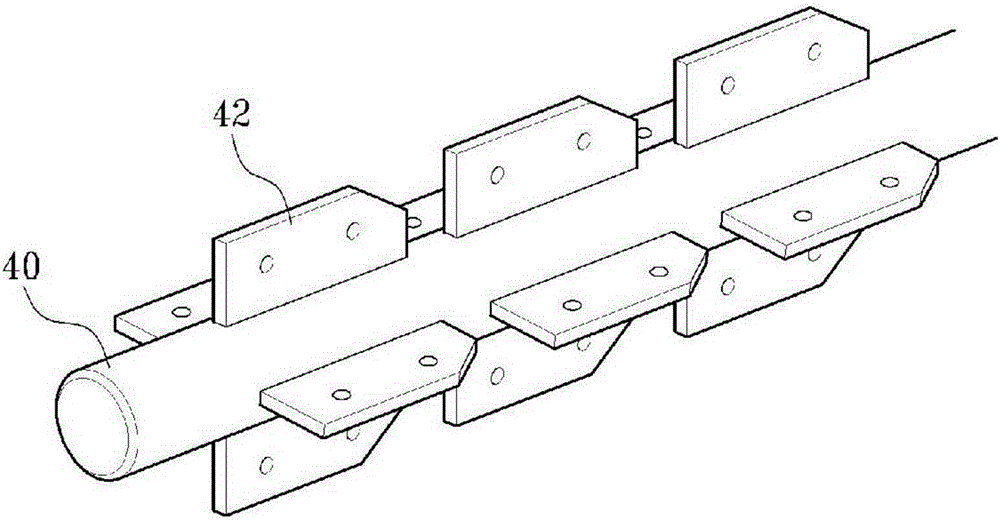

Particle shaping equipment

ActiveCN102755857APrevent adhesion formationBreak up fullyGranulation in stationary drums/troughsEngineeringSilicon

The invention discloses particle shaping equipment, which is arranged between particle forming equipment and cooling equipment and comprises a trough and a stirring device, wherein the trough is used for receiving a solid material led out by the particle forming equipment and is provided with a feed port and a discharge port; and the stirring device is used for scattering the solid material and conveying the solid material to the discharge port, is arranged in the trough and comprises at least two helical stirring paddles which are arranged in the trough in parallel. According to the particle shaping equipment, the solid material can be effectively prevented from being adhered into large blocks due to rapid cooling, cooling and subsequent sieving and crushing are easy, and the particle quality of inorganic silicon is improved.

Owner:山东龙港硅业科技有限公司

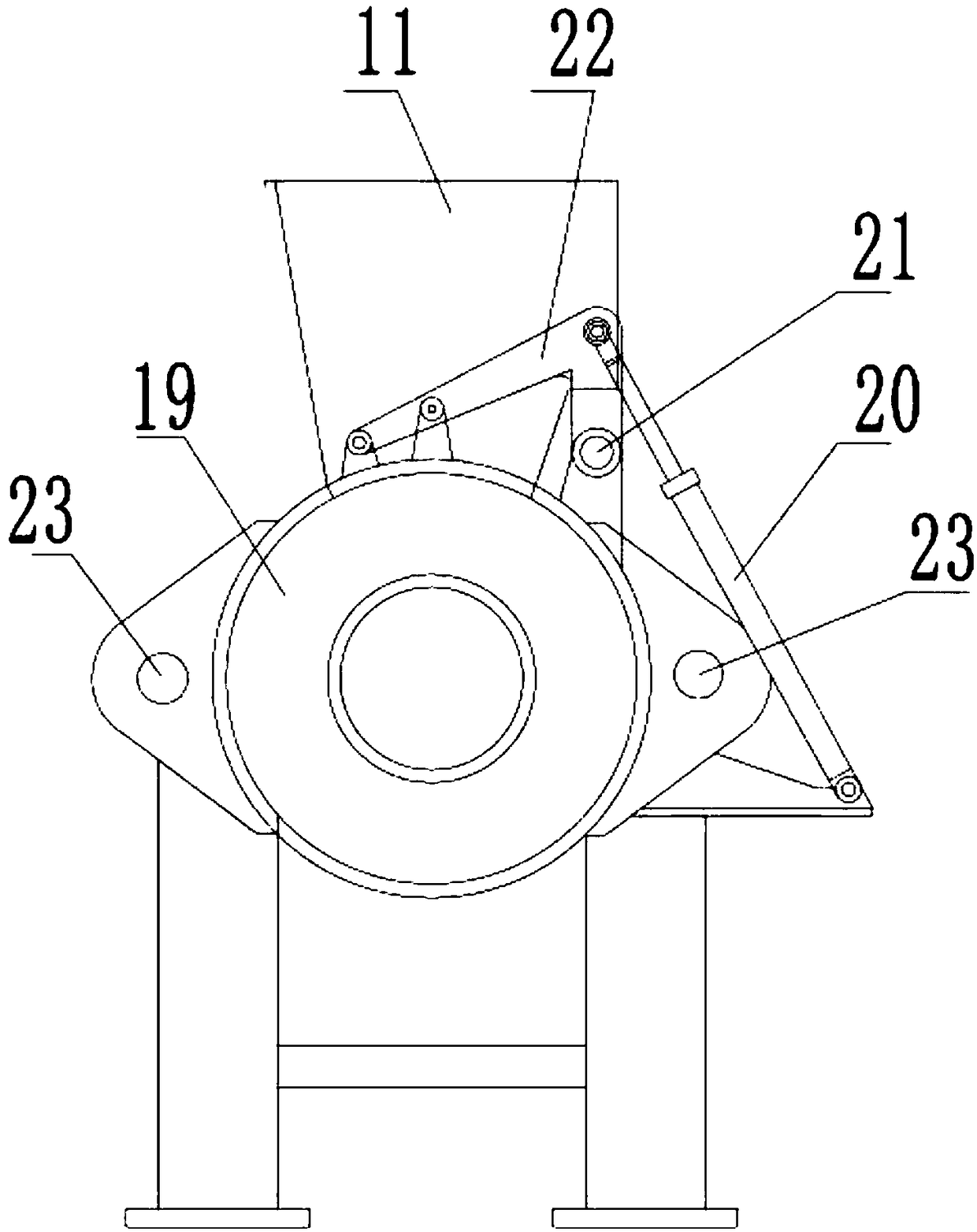

Crushing and vibrating type shell-removing and seed-taking device of camellia oleifera fruits for agricultural production

ActiveCN107668734AReasonable structureInnovative designFatty-oils/fats productionHuskingCamellia oleiferaDrive shaft

The invention discloses a crushing and vibrating type shell-removing and seed-taking device of camellia oleifera fruits for agricultural production. The crushing and vibrating type shell-removing andseed-taking device comprises a box body, wherein a drive box is mounted on the middle part of the right side of the box body; a drive shaft is mounted inside the drive box; a drive gear is mounted onthe middle part of the front end of the drive shaft; a spur rack is meshed with the drive gear; a first guide rod is mounted at the left end of the spur rack; a vibration frame is connected to the left end of the first guide rod; a second guide rod is connected to the middle part of the left end of the vibration frame; a guide block is connected to the middle part of the left end of the second guide rod; an air blowing cylinder is arranged on the outer side of the piston; a supporting plate is fixedly connected to the lower end of the air blowing cylinder; a heating box is fixed to the middlepart of the lower end of the supporting plate; an air blowing cavity is formed in the left end of the inner wall of the box body; air nozzles are uniformly mounted on the middle part of the right endof the air blowing cavity; a waist-shaped groove is formed in the middle part of the upper end, the front end and the rear end of the box body; and a rotating shaft is mounted on the middle part of the waist-shaped groove. Through the adoption of the crushing and vibrating type shell-removing and seed-taking device disclosed by the invention, the crushing of the camellia oleifera fruits in different sizes and the effective separation of seeds from shells are achieved, and the effects of removing shells and taking seeds are improved.

Owner:江西齐云山油茶科技有限公司

Equipment used for crushing and compressing stainless steel and aluminium materials of security windows

PendingCN112547770AAchieve compressionAchieve the effect of automatic crushing assistanceSolid waste disposalTransportation and packagingStructural engineeringSS - Stainless steel

The invention relates to equipment used for crushing and compressing, in particular to equipment used for crushing and compressing stainless steel and aluminium materials of security windows. The provided equipment used for crushing and compressing the stainless steel and aluminium materials of the security windows is simple and convenient to operate and high in automation degree, and integrates crushing and compressing. The equipment used for crushing and compressing the stainless steel and aluminium materials of the security windows comprises a floor, a pushing rod, a compressing mechanism,a crushing mechanism and an automatic crushing assisting mechanism, wherein an air cylinder is installed on the floor; the pushing rod is arranged at the top of the air cylinder; the compressing mechanism is arranged on the floor, and the compressing mechanism is connected with the pushing rod; the crushing mechanism is arranged on the floor, and the crushing mechanism is connected with the compressing mechanism; and the automatic crushing assisting mechanism is arranged on the floor, and both the compressing mechanism and the crushing mechanism are connected with the automatic crushing assisting mechanism. According to the equipment used for crushing and compressing the stainless steel and aluminium materials of the security windows, the pushing rod is driven by the air cylinder to move downwards, so that a compressor is driven to move downwards, and compressing effects of the compressor on the aluminium materials are achieved.

Owner:侯仪丽

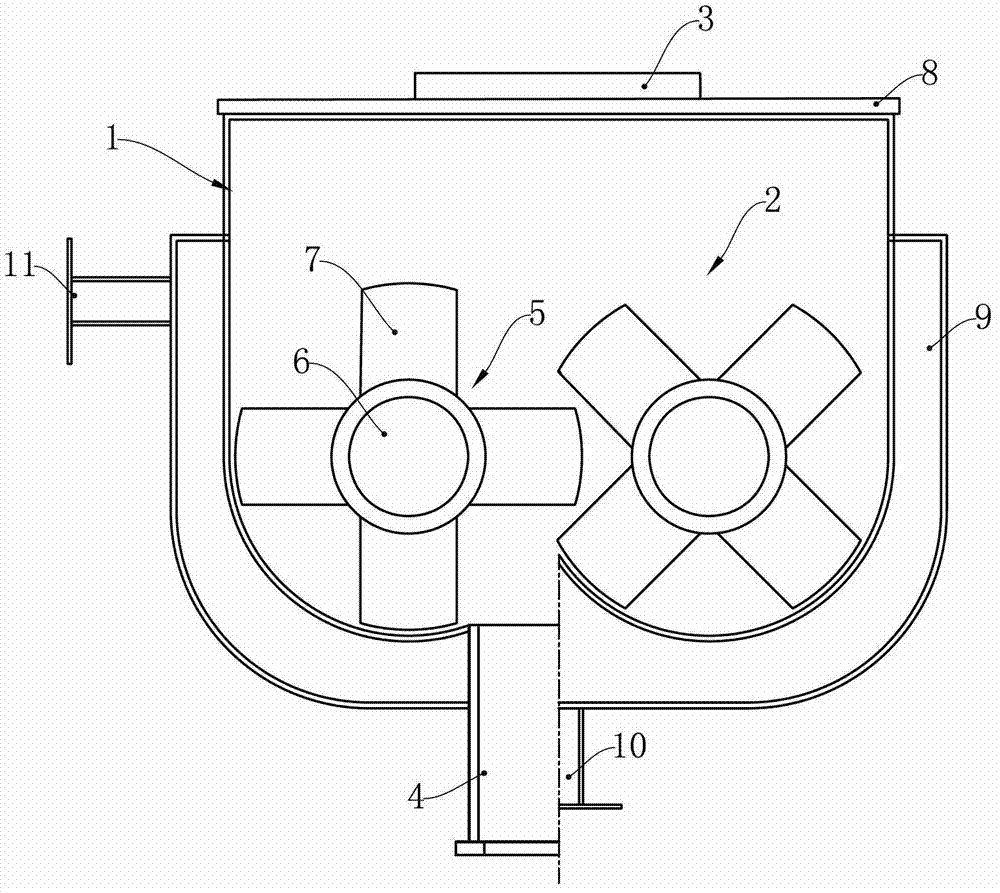

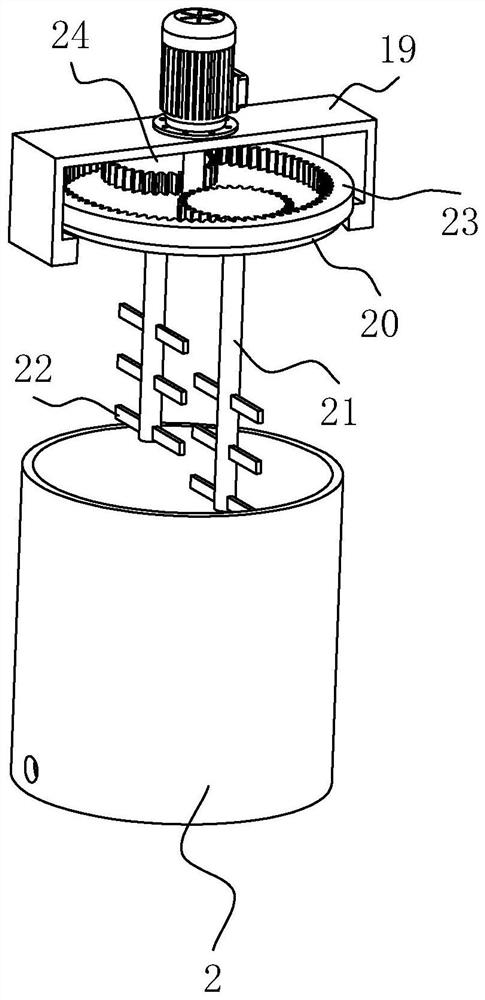

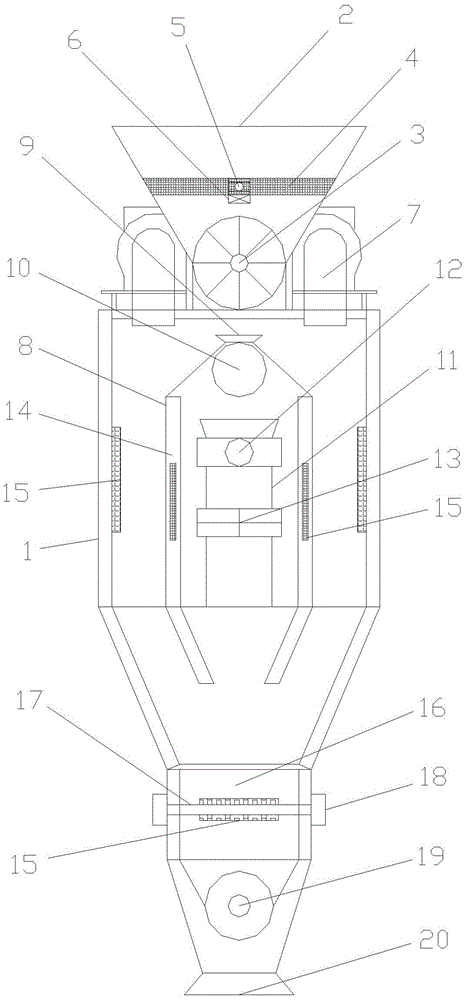

Solid material fermentation device

InactiveCN107828638ASlow down the flowAchieve preliminary dryingBioreactor/fermenter combinationsBiological substance pretreatmentsThermal insulationAgricultural engineering

The invention discloses a solid material fermentation device. The solid material fermentation device comprises a housing, a flow guide mechanism, and a stirring column; the periphery of the external wall of the housing is sleeved by a thermal insulation sleeve; a thermal insulation chamber is formed between the housing and the thermal insulation sleeve; a plurality of heating sheets are arranged in the thermal insulation sleeve at intervals; the flow guide mechanism comprises a first steel plate, a second steel plate, a first heating plate, and a second heating plate which are arranged in thehousing via clamping; a first flow guide assembly is fixedly arranged on the first steel plate; a second flow guide assembly is fixedly arranged on the second steel plate; a first heating assembly isfixedly arranged on the first heating plate; a second heating assembly is fixedly arranged on the second heating plate; the stirring column is horizontally provided with a plurality of transverse columns; rotating shafts are vertically arranged on the transverse columns downward; the bottom end of each rotating shaft is provided with a rotating disc; the periphery of each rotating disc is providedwith a plurality of stirring blades at equal intervals; the upper edge of each stirring blade is of a curved knife edge structure, and the lower edge of each stirring blade is of a linear knife edgestructure. The solid material fermentation device is capable of realizing full stirring, and achieving excellent stirring effect, and high inoculation rate.

Owner:广西南宁秀珀生物科技有限公司

Sewer pipeline filter having automatic crushing function

The invention discloses a sewer pipeline filter having an automatic crushing function. The sewer pipeline filter comprises a filter cartridge main body (1) and a bottom cover (2) which is provided with filter holes (3), wherein a waterproofing box (4) and a crushing mechanism which is arranged in the waterproofing box (4) are fixedly arranged at the bottom of the bottom cover (2); the crushing mechanism comprises a battery (9), a micro controller (5), a wireless signal receiver (6), a motor (7) and rotary vanes (8); the micro controller (5) and the motor (7) are connected; a rotating shaft of the motor (7) extends out of the waterproofing box (4) and is fixedly connected to the center of the rotary vanes (8); and signals, which are received by the wireless signal receiver (6), are transmitted to the micro controller(5), and a rotating shaft of the motor (7) is rotated by virtue of the micro controller (5), so that the rotary vanes (8) are rotated in a pipeline. According to the sewer pipeline filter disclosed by the invention, the rotary vanes can get into direct contact with large sundries entering the bottom cover to crush the large sundries, so that an effect of crushing is achieved and the volume of the sundries is diminished; therefore, pipeline blockage due to accumulation of the sundries in a pipeline is prevented from occurring easily.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

Granular medicine crushing equipment for endocrinology department

ActiveCN113385249AAutomatic grinding effectRealize the effect of automatic feedingOral administration deviceGrain treatmentsEndocrinology departmentPharmacy medicine

The invention relates to crushing equipment, in particular to granular medicine crushing equipment for the endocrinology department. The granular medicine crushing equipment for the endocrinology department aims at achieving the technical effects that automatic discharging can be achieved, and tablets can be automatically ground. The granular medicine crushing equipment for the endocrinology department comprises supporting frames, a first outer frame, a first fixing column, an air cylinder, cutting knives and first springs, wherein the supporting frames are symmetrically arranged on the first outer frame; the first fixing column is arranged on one side of the first outer frame; the air cylinder is arranged on the first fixing column; the cutting knives are arranged on the two sides of the first outer frame in a sliding mode, and the air cylinders are connected with the adjacent cutting knives; and the first springs are connected between the cutting knives and the first outer frame. According to the equipment, the effects that automatic discharging can be achieved, and tablets can be automatically ground are achieved; and the cutting knives on the front side and the rear side move towards the inner side, so that the effect of automatically crushing the tablets can be achieved.

Owner:QINGDAO CENT HOSPITAL

Straw smashing device

PendingCN114210403AEffective shreddingAvoid mixingCrop conditionersMowersDraft animalsAgricultural engineering

The invention discloses a straw smashing device, and belongs to the technical field of straw treatment.The straw smashing device comprises a smashing box, two first rotating shafts are rotationally connected between the front wall and the rear wall of the smashing box, smashing rollers are fixedly connected to the outer walls of the first rotating shafts, and a conveying cylinder is fixedly connected to the right wall of the smashing box; the right wall of the smashing box and the left wall of the conveying cylinder are provided with communicated material returning openings, and the left wall of the smashing box is hinged to a filtering screen plate extending to the material returning openings. According to the scheme, smashed straw can be screened through the filtering sieve plate, the follow-up straw smashing effect and quality are improved, the straw which is not smashed completely above the filtering sieve plate can enter the conveying cylinder, the driving mechanism and the linkage mechanism are matched to drive the spiral conveying blade to rotate so that the straw can be conveyed upwards, and therefore the straw smashing effect is improved. And finally, the straw falls into the smashing box again to be smashed, complete smashing of the straw can be achieved, the situation that the straw which is completely smashed is doped in the finally-smashed straw is greatly avoided, and meanwhile subsequent livestock can eat the straw conveniently.

Owner:王秀丹

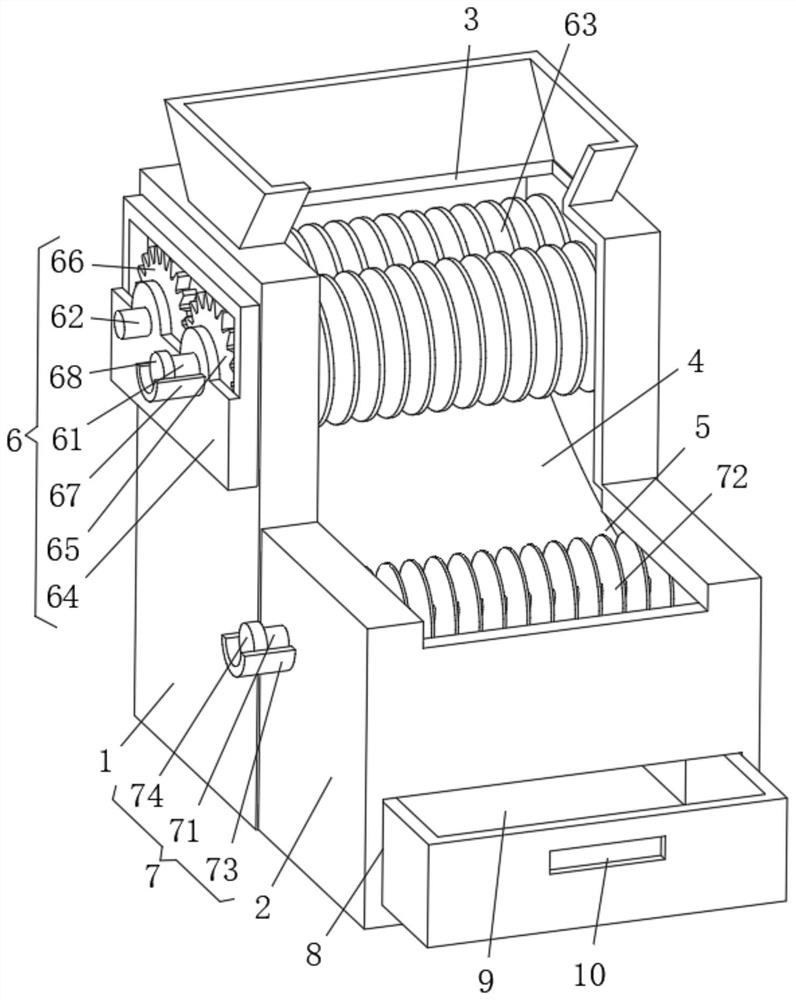

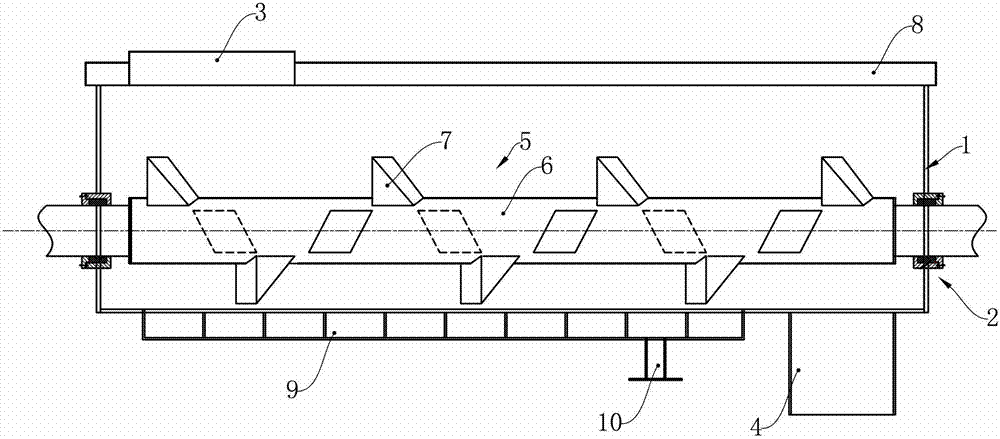

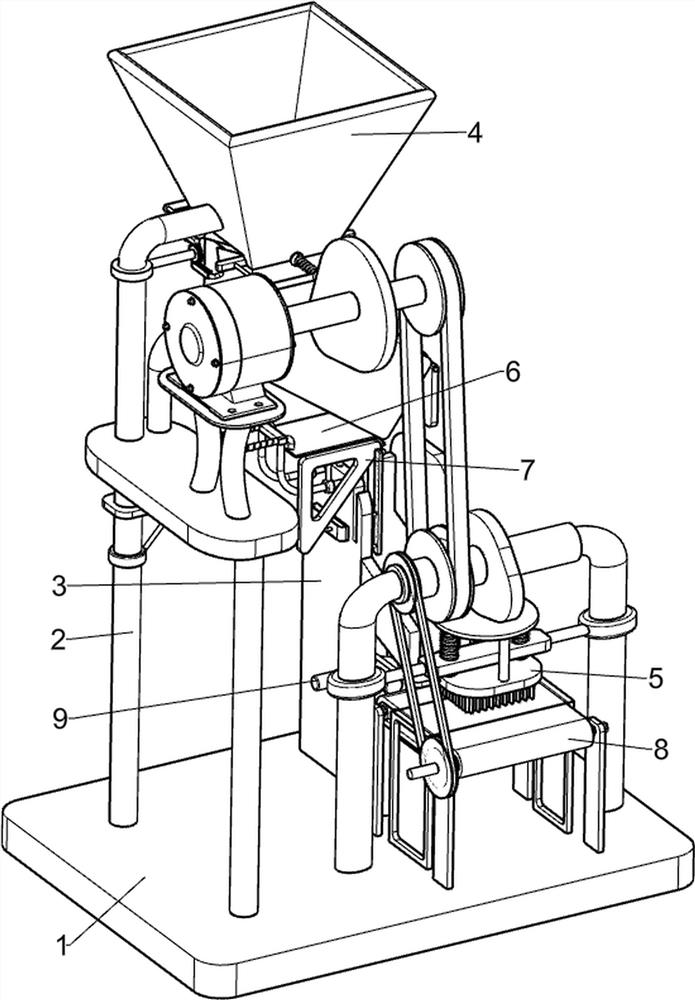

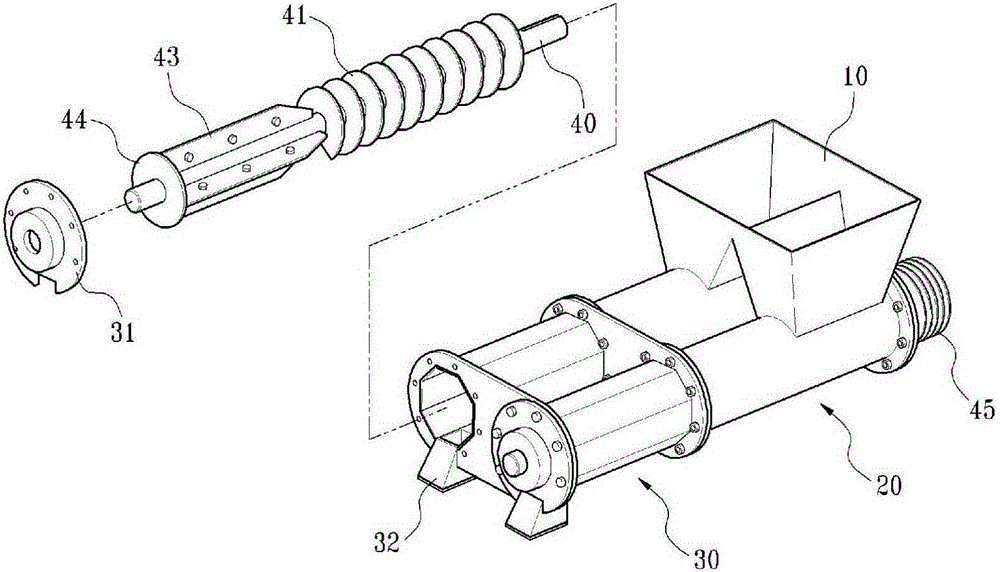

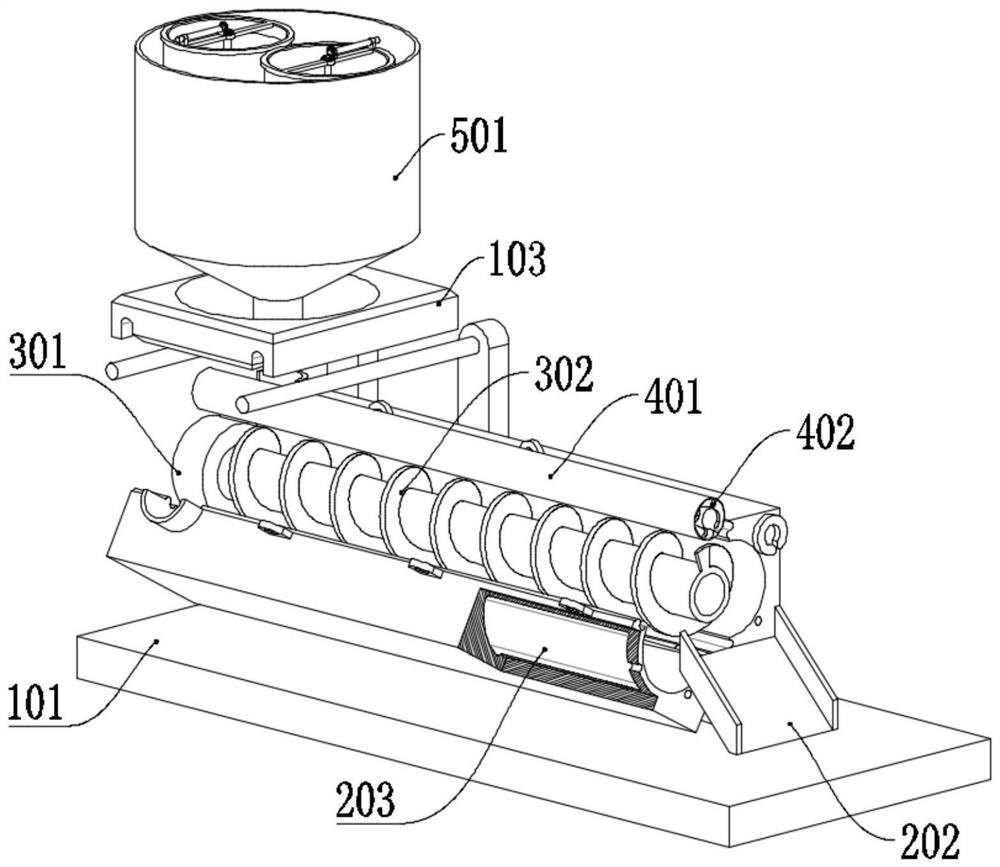

Offcut recycling and crushing device for wood-plastic floor production

InactiveCN111054494AAchieving a shattering effectEasy dischargeGrain treatmentsElectric machineStructural engineering

The invention discloses an offcut recycling and crushing device for wood-plastic floor production. The device includes a bracket, the top of the bracket is equipped with a loading conveying mechanism,the end of which is equipped with a protection assembly, a crushing cylinder fixed by a mounting frame is arranged below the protection assembly, a crushing propelling mechanism driven by a motor a is arranged in the crushing cylinder, a discharging connecting pipe is connected to the tail end at the top of the crushing cylinder, and the bottom of the discharging connecting pipe is communicated with a discharging mechanism. During use, offcut is placed on a conveyor belt, a motor b drives a conveying roller to enable the conveyor belt to convey, the offcut enters the cylinder from a feeding hopper, the motor a drives a rotating shaft to rotate so as to drive a spiral propeller a and a smashing cutter to rotate, thus realizing the effect of material pushing and crushing at the same time, particles meeting the particle size requirement enter a discharging connecting pipe from a sieve plate and then enter a discharging cylinder, and a motor c drives a spiral propeller b to discharge theparticles from a discharging port.

Owner:ANHUI YOUSHENGMEI NEW MATERIAL TECH CO LTD

Industrial sludge recycling harmless treatment device and method

InactiveCN112062438AFirmly connectedEasy inspection and maintenanceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeProcess engineering

The invention provides an industrial sludge recycling harmless treatment device and method. The industrial sludge recycling harmless treatment device comprises a sludge taking cylinder and a recyclingbin, the top of the recycling bin is connected with a rotating cover plate through a connecting rotating shaft, an air drying sterilization box is arranged at the bottom of the recycling bin, and a first guide rail and a second guide rail are arranged on the right side face of the recycling bin; the right side face of the first guide rail and the right side face of the second guide rail are in contact fit with the left side face of a first motor bottom plate, a first motor is arranged on the right side face of the first motor bottom plate, and a power shaft is arranged at the right side poweroutput end of the first motor. The right end of the power shaft is fixedly connected with the left side face of the sludge taking cylinder through a middle connecting block, and a top control box isfixed to the upper surface of the interior of the sludge taking cylinder. According to the technical scheme, the technical problems that in the prior art, the automatic intelligent sludge taking capacity is not achieved, and industrial sludge cannot be filtered, recycled, air-dried, smashed, sterilized and the like are effectively solved, and application and popularization are facilitated.

Owner:长沙如洋环保科技有限公司

Raw material block crushing device

ActiveCN109046540AEvenly crushedAchieving a shattering effectGrain treatmentsHydraulic cylinderElectric machinery

The invention discloses a raw material block crushing device. The raw material block crushing device comprises a main hydraulic cylinder, a hollow crushing box, a crushing device, a transmission device and an ejecting device; two material outlets are formed in the side wall of the hollow crushing box; the crushing device comprises a rotating motor, an upper hollow crushing disc and a lower crushing plate; the transmission device comprises an inverted U-shaped rod, a U-shaped hinging rod, a transmission straight rod and a T-shaped pushing rod; the rotating motor is fixedly arranged on the inverted U-shaped rod; the upper end of the T-shaped pushing rod penetrates through a through hole; a circular plate pushing block is arranged at the upper end of the T-shaped pushing rod; a first rotatingshaft is arranged in the U-shaped hinging rod; symmetric U-shaped hinging seats are arranged at the two ends of the bottom of the T-shaped pushing rod; second rotating shafts are arranged in the U-shaped hinging seats; the ejecting device comprises a sub hydraulic cylinder; and a material pushing plate is arranged at the tail end of a telescopic rod of the sub hydraulic cylinder. According to theraw material block crushing device, the structure is simple, raw material blocks can be initially crushed, block-shaped raw materials are changed into powders, and the powder mixing difficulty in thelater period can be reduced.

Owner:WUHU KANGQI PHARMA

Medical infusion tube smashing treatment device

PendingCN113058971AAchieving a shattering effectRealize intermittent feeding effectSolid waste disposalMagnetic separationSurgeryBiomedical engineering

The invention relates to a smashing treatment device, in particular to a medical infusion tube smashing treatment device. The medical infusion tube smashing treatment device is good in control effect and capable of achieving automatic cutting-off and automatic smashing. The medical infusion tube smashing treatment device comprises a bottom plate, a guide frame, a cutting assembly and a cutting assembly, wherein a first supporting frame is arranged on the left side of the bottom plate, the guide frame is arranged at the right part of the rear side of the bottom plate, the cutting assembly is arranged on the upper portion of the first supporting frame, and the smashing assembly is arranged on the right portion of the front side of the bottom plate. According to the medical infusion tube smashing treatment device, a second cam is in contact fit with a tool rest, so that the tool rest is driven to move downwards, then a second tool is driven to move downwards, a first spring is compressed, the second tool crushes an infusion tube on a workbench, and the crushing effect is achieved.

Owner:赖仕萌

Glass crusher

InactiveCN105233946APush each otherAchieving a shattering effectGlass recyclingGrain treatmentsGlass chipCrusher

The invention discloses a glass producing device and particularly relates to a glass crusher. The glass crusher comprises a shell and a rotating shaft rotationally connected into the shell. The rotating shaft is provided with spiral auger knifes and stirring blades. The shell comprises first cavities for containing the spiral auger knifes and second cavities for containing the stirring blades. The first cavities are provided with feeding hoppers. The second cavities are provided with discharging hoppers. The inner section of the second cavities is a regular hexagon and the second cavities correspond to the stirring blades in number. By means of the glass crusher, the technical defect that in the prior art, strip-shaped glass sheets exist and block follow-up conveying is overcome, glass can be broken completely, and strip-shaped glass sheets are prevented.

Owner:深圳市光华中空玻璃工程有限公司

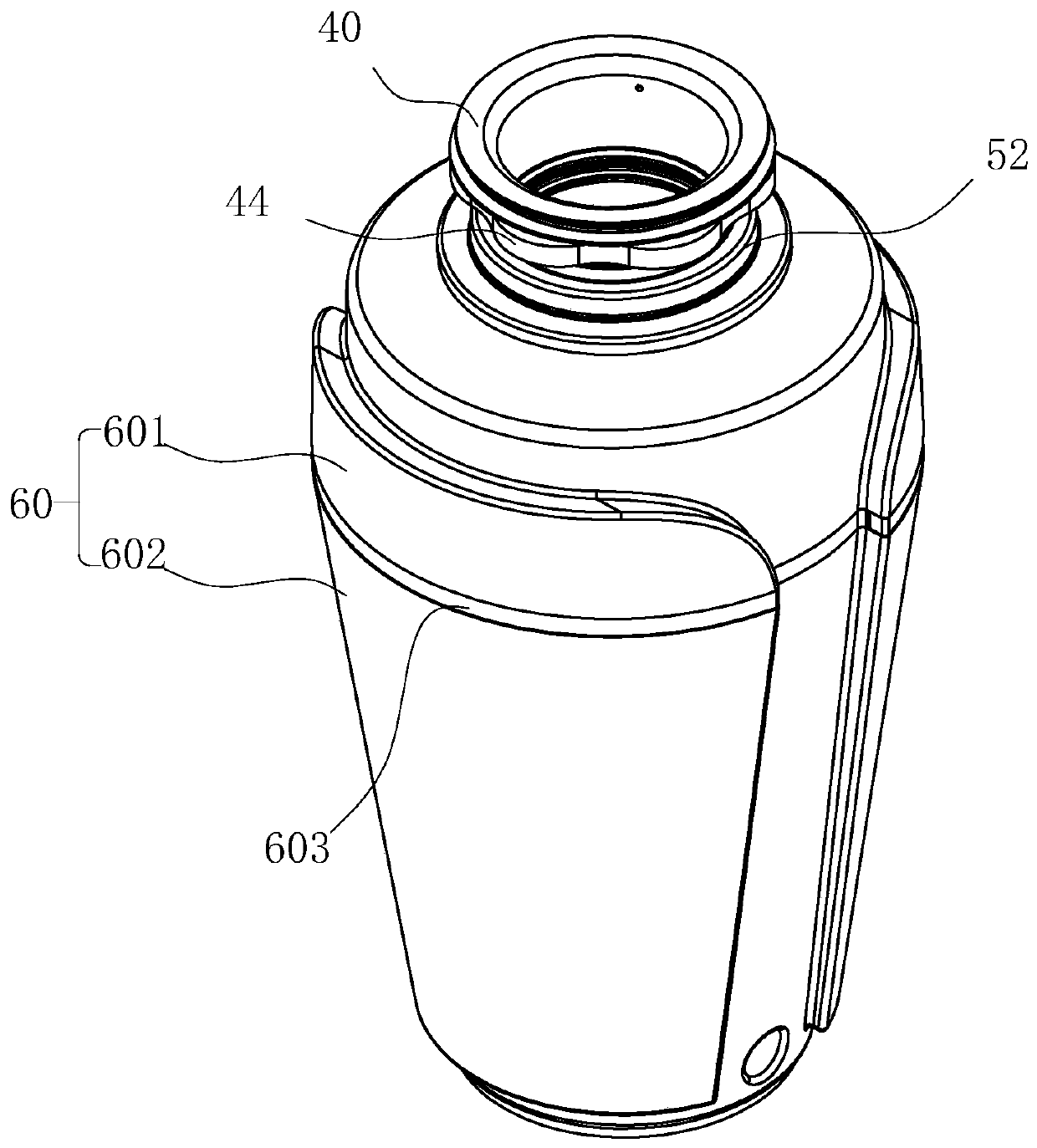

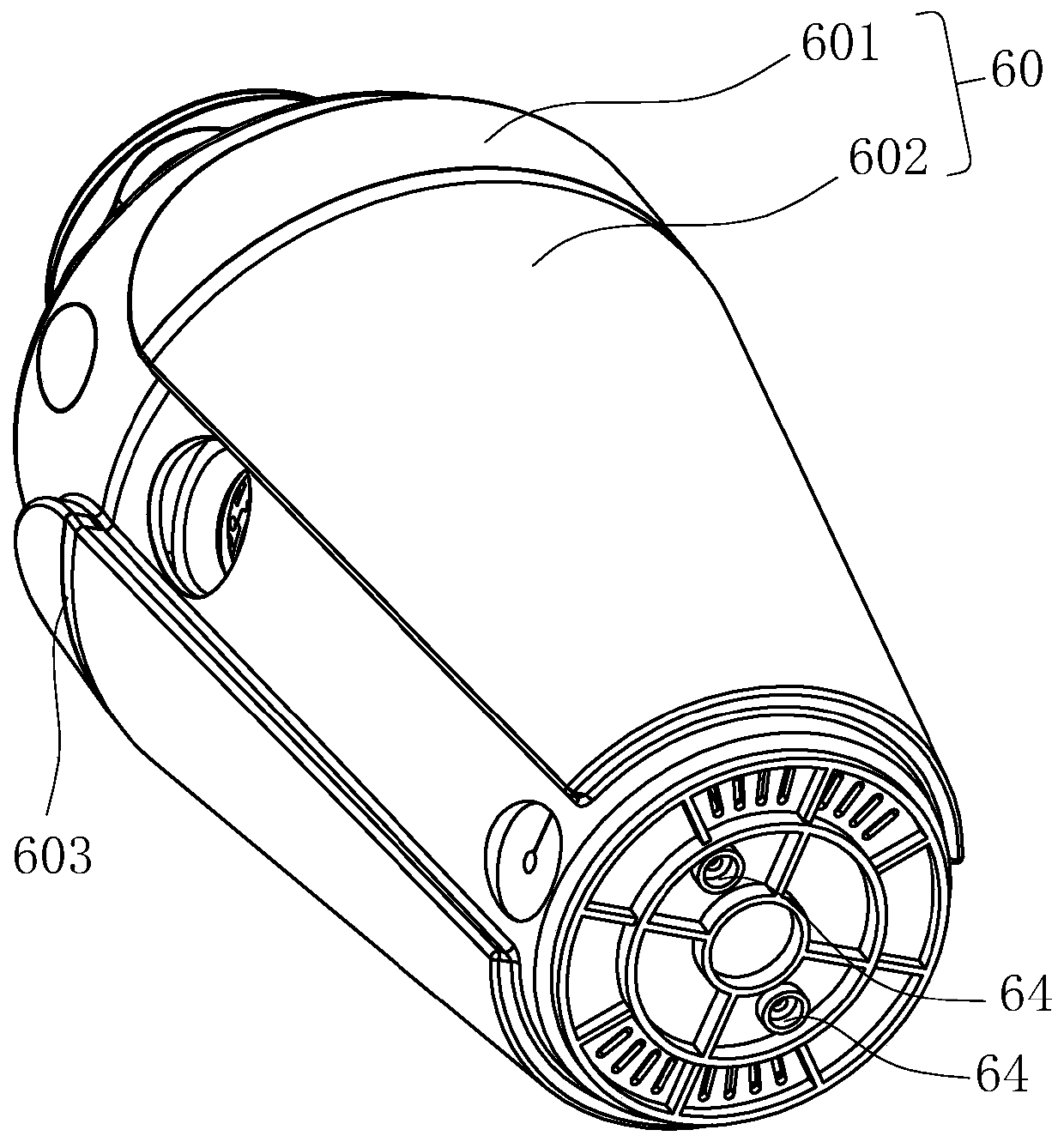

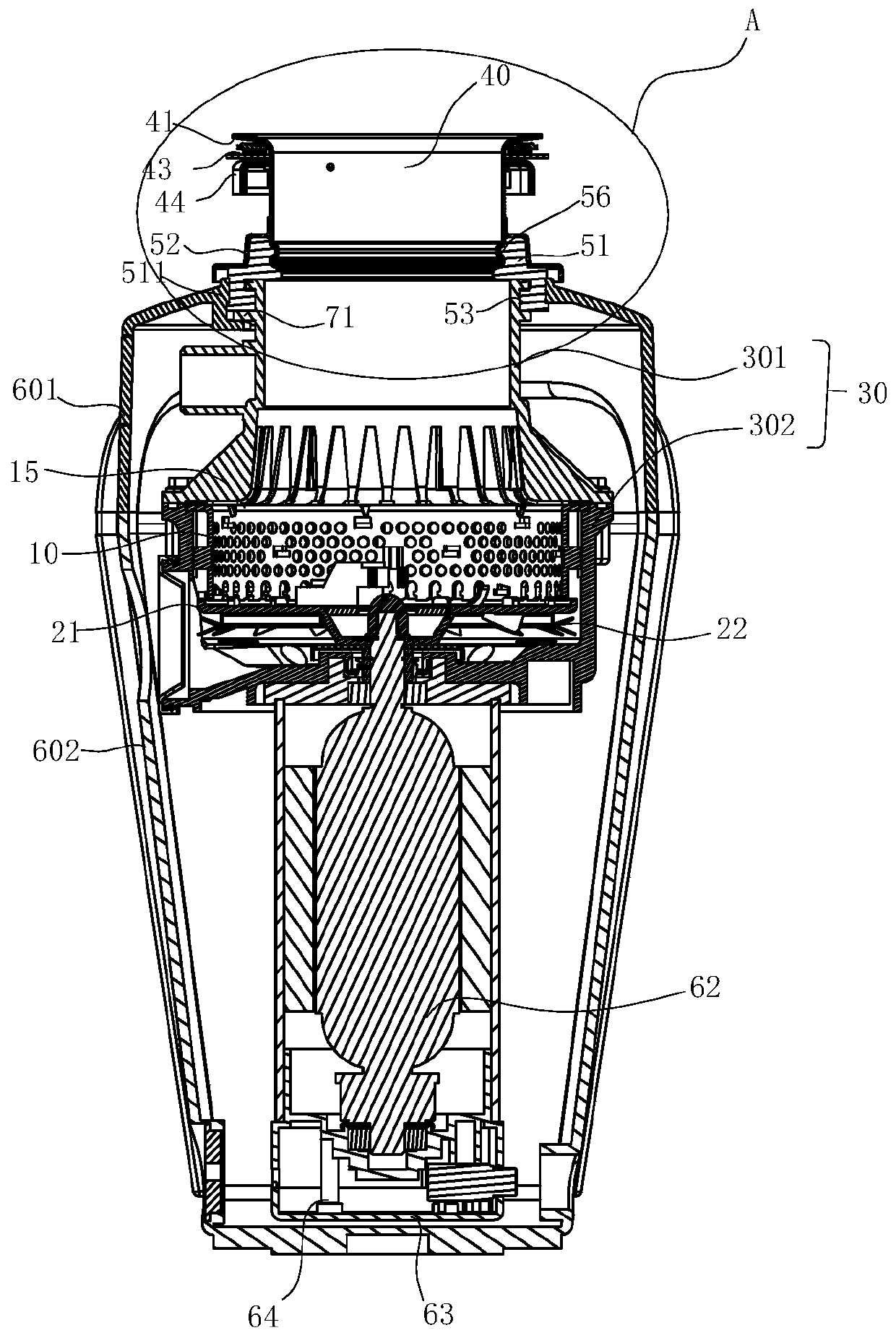

Garbage treating device

PendingCN110528642AIncrease flow itineraryAchieving a shattering effectDomestic plumbingDISC assemblyFlange

The invention relates to a garbage treating device which comprises a grinding mechanism and a working cavity used for storing the grinding mechanism. The grinding mechanism comprises a grinding ring and a cutter disc assembly which is arranged below the grinding ring and rotates relative to the grinding ring. The cutter disc assembly comprises a cutter disc. The outer edge of the cutter disc is turn over upwards to form a first ring-shaped flange. The lower edge of the grinding ring is matched with the first ring-shaped flange in an inserting manner. A channel for garbage to flow through is formed between the grinding ring and the first ring-shaped flange. Multiple slots are formed in the lower edge of the grinding ring at intervals in the circumferential direction. First cutting teeth arearranged on the inner wall of each slot. Multiple second cutting teeth extending upwards are further arranged on the first ring-shaped flange at intervals in the circumferential direction. The secondcutting teeth can form cutting match with the first cutting teeth in the rotating process of the cutter disc. The garbage treating device can effectively prolong the stroke of the food garbage chopping process, and then the chopping effect is improved effectively.

Owner:宁波亿盛电机有限公司

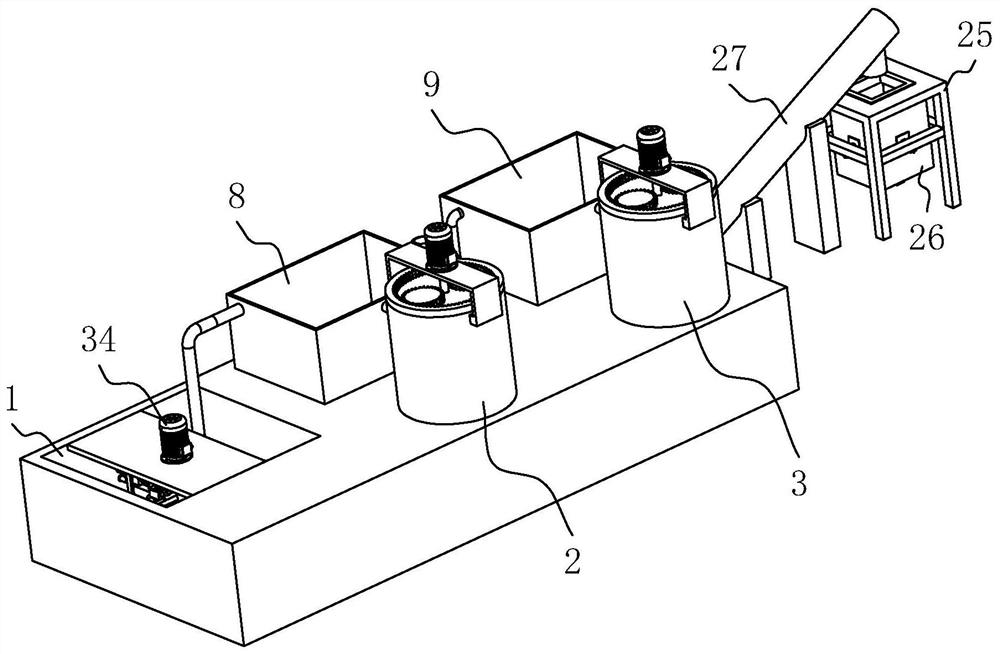

Slurry dewatering and curing construction device and method

ActiveCN112897852AAchieving a shattering effectSludge treatment by de-watering/drying/thickeningFlocculationElectric machinery

The invention relates to a mud dewatering and curing construction device and method and relates to the field of mud treatment. The device comprises a mud pool, an inorganic flocculation pool, an organic flocculation pool and a filtering device. A mud pump is installed in the mud pool, and a smashing rod is rotationally connected to the position, close to the mud pump, of the mud pool; crushing sheets are fixedly connected to the peripheral wall of the crushing rod, and the mud pit is fixedly connected with a first motor for driving the crushing rod to rotate; the mud pit is rotationally connected with a rotating shaft synchronously rotating with the crushing rod, and the rotating shaft is connected with a crushing assembly; the output end of the slurry pump is connected with a first sedimentation tank connected with the inorganic flocculation tank, the first sedimentation tank is connected with a second sedimentation tank connected with the organic flocculation tank, and the second sedimentation tank is connected with the filtering device. The device has the effect of ensuring that the slurry pump normally pumps slurry, it is ensured that the slurry is fully flocculated and agglomerated, and the working efficiency of slurry dehydration and solidification is improved.

Owner:深圳市瑞沃工程有限公司

Potato starch rapid forming equipment for food processing

PendingCN113368995AAchieving a shattering effectRealize the blanking effectSievingScreeningAgricultural sciencePotato starch

The invention relates to forming equipment, in particular to potato starch rapid forming equipment for food processing. The invention provides the potato starch rapid forming equipment for the food processing which is automation in roll, reduction in labor cost and high in powder output. The potato starch rapid forming equipment for the food processing comprises a supporting frame and a smashing mechanism and a first discharging mechanism. The smashing mechanism is arranged in the middle of the supporting frame; the first discharging mechanism is arranged on the upper side of the supporting frame. According to the potato starch rapid forming equipment for the food processing, a straight gear set drives a smashing shaft on the right side to rotate, the smashing shafts on the two sides rotate to smash potato crops, the potato crops are smashed into potato powder, and the smashing effect is achieved; a shifting block rotates to drive a first connecting rod to move upwards, so that a first baffle is driven to move upwards, a first elastic assembly is contracted, then a discharging port of a material box is opened, and due to the fact that the bottom of the material box is inclined, the potato crops can automatically fall into a smashing box, and the discharging effect is achieved.

Owner:万细凤

Bean product fat content detection device convenient to sample

ActiveCN113484481AAchieving a shattering effectFree from pollutionTesting starch susbtancesWithdrawing sample devicesSoybean productMechanical engineering

The invention relates to the technical field of bean product production, and particularly discloses a bean product fat content detection device convenient to sample, which comprises a base and a motor. The top surface of the base is fixedly connected with a support rod, the top of the support rod is fixedly connected with a device main body, and the surface of the device main body is provided with a detection head; the supporting rod is arranged on the base to support the device main body, the motor arranged on the device main body can drive the main rod to rotate, the stirring assembly on the main rod can stir raw materials at the moment, and through cooperation with the round rod and the blade on the main rod, the raw materials can be stirred by the stirring assembly. Cooperating with the round rod and the blade on the main rod, the raw materials can be crushed through the stirring cylinder, the raw materials which are stirred and crushed are directly fed into a detection part through the sampling cylinder, the redundant transfer process is avoided, the effect of conveniently sampling and detecting is achieved, and the effect of protecting the raw materials from being polluted is achieved.

Owner:丽江市质量技术监督综合检测中心

Intelligent crushing device for astaxanthin processing

InactiveCN114308270AEasy to disassembleEasy to installTransportation and packagingHollow article cleaningAstaxanthinEngineering

The invention provides an intelligent crushing device for astaxanthin processing, and relates to the technical field of crushing devices. A discharging assembly is arranged on the mounting device, a discharging structure is rotationally mounted in the discharging assembly, a cooling assembly is arranged in the discharging structure, a mixing device is arranged at the upper end of the left side of the mounting device, the bottom of the mixing device makes contact with the discharging assembly, and the discharging structure is rotationally mounted in the discharging assembly. Firstly, a discharging barrel of the discharging assembly is of a structure capable of being opened in a swinging mode, the interior of the discharging assembly is more convenient to clean, in the process that powder discharged and conveyed by a discharging structure passes through the discharging assembly, the cooling effect on the powder can be achieved through a cooling groove in the discharging assembly, and the problems that common equipment is low in crushing efficiency, and the crushing cost is high are solved. And after high-speed crushing, the temperature of the powder is too high, and residual impurities in equipment after production are difficult to remove.

Owner:云南钰腾生物科技有限公司

Powder spraying three-return dryer unloading hopper

ActiveCN105466203AEasy to controlImprove drying efficiencyDrying solid materialsDrying goods handlingThermal insulationEngineering

The invention discloses a powder spraying three-return dryer unloading hopper. The unloading hopper comprises a hopper body; a feed hopper is arranged at the top end of the hopper body, and is communicated with the hopper body; an impeller distributor is arranged in the connected place of the feed hopper and the hopper body; a heating rod is arranged on the side wall of the hopper body; an embedder is arranged in the hopper body; a material receiving port is formed in the top end of the embedder; a hot air connecting pipe is arranged in the material receiving port; an inner cylinder is arranged below the hot air connecting pipe; a cyclone separator is arranged at the top end; an ultrafine crusher is arranged on the inner cylinder below the cyclone separator; a thermal insulation layer is arranged on the side wall of the embedder; the heating rod is arranged in the thermal insulation layer; a material chamber is formed in the bottom end of the hopper body; a material transmission port is formed in the bottom end of the material chamber; and a conveyor is arranged in the material chamber. The device realizes a preheating effect and a crushing effect of fine particles in the material unloading process, guarantees the unloading progress of wet wood powder materials, prevents the waste, and improves the drying quality of the wet wood powder materials.

Owner:ANHUI DING BEAM BIO ENERGY TECH DEV CO LTD

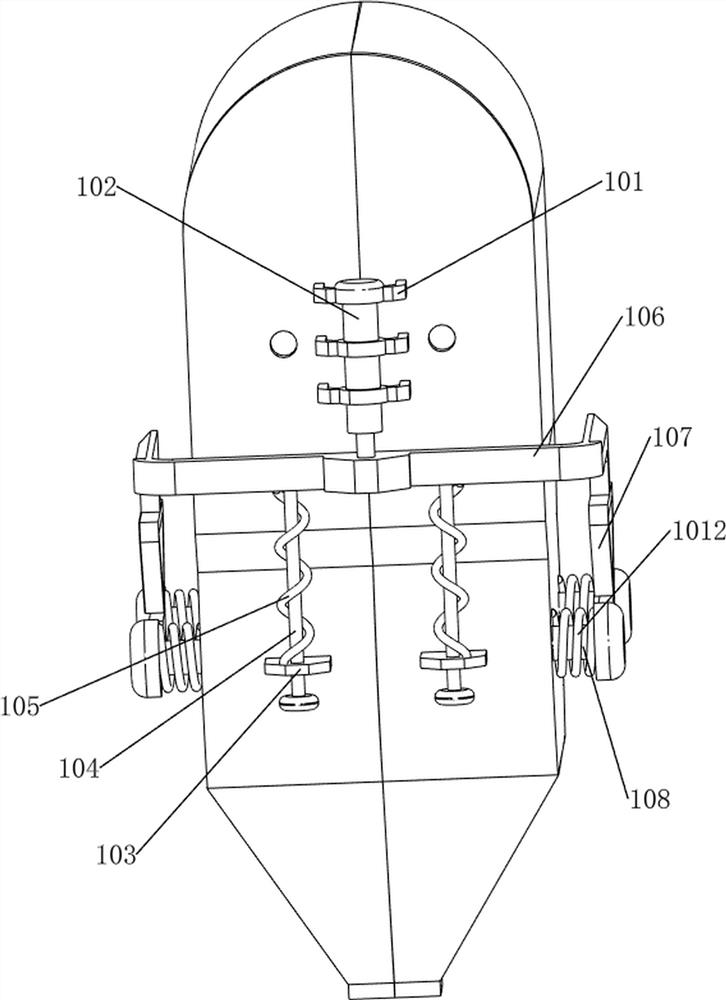

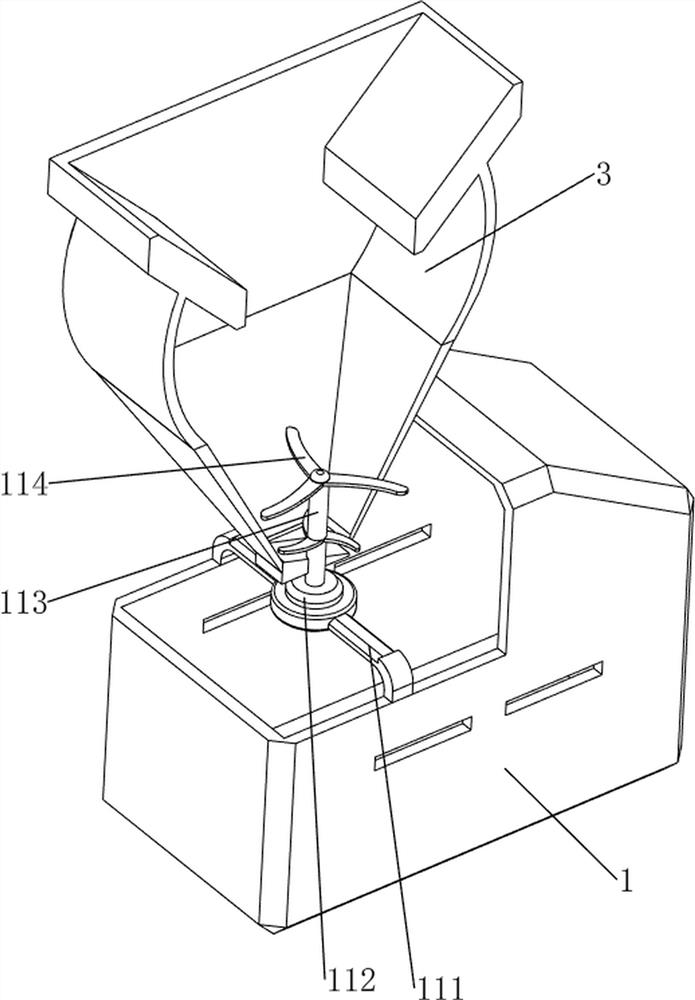

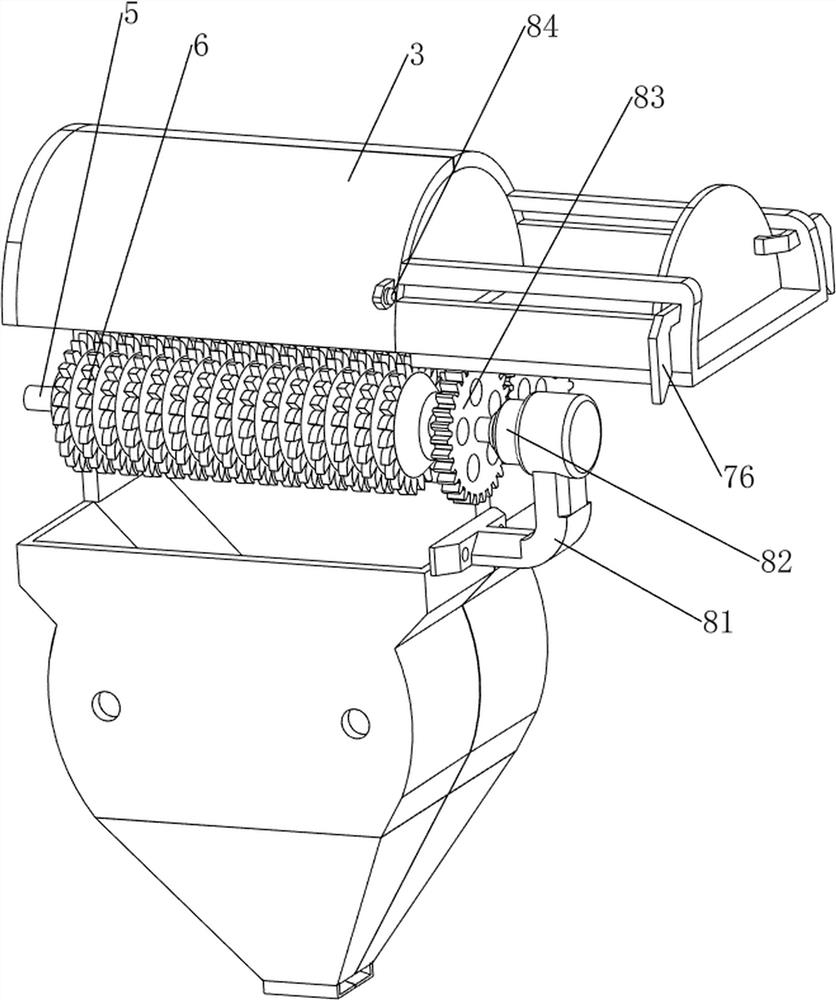

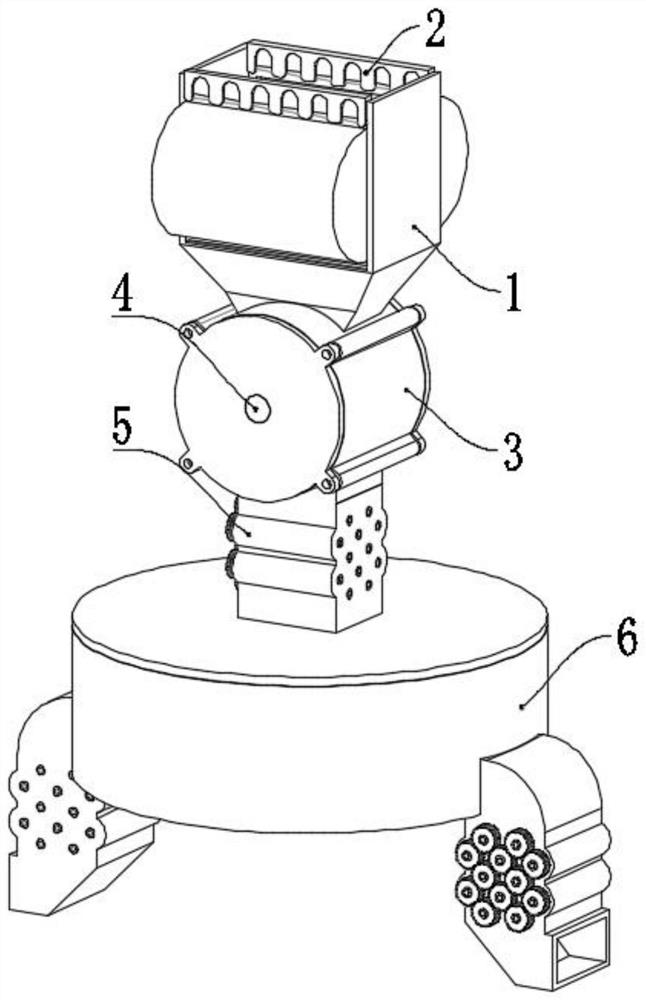

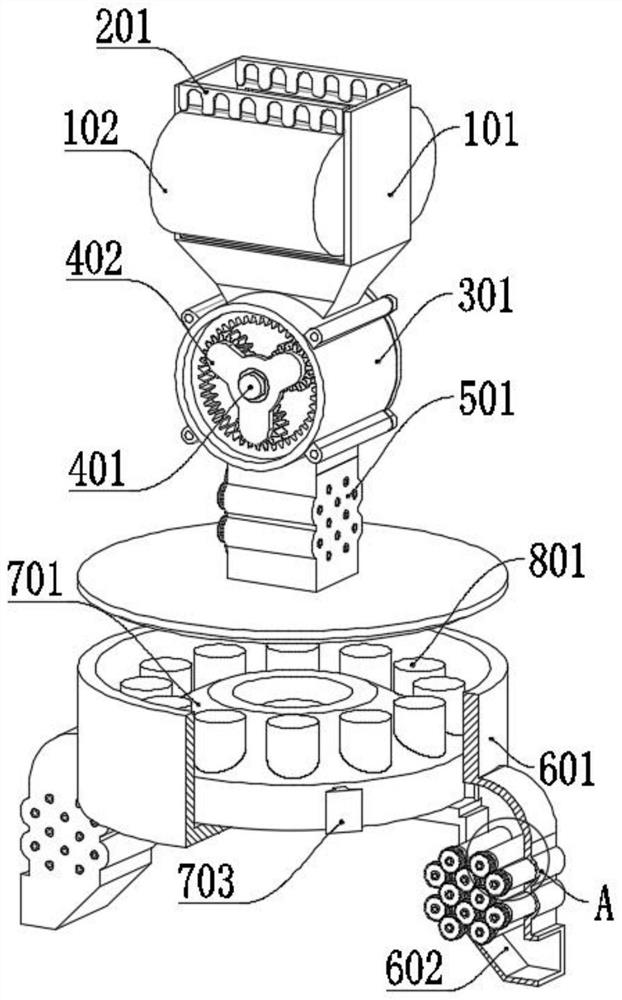

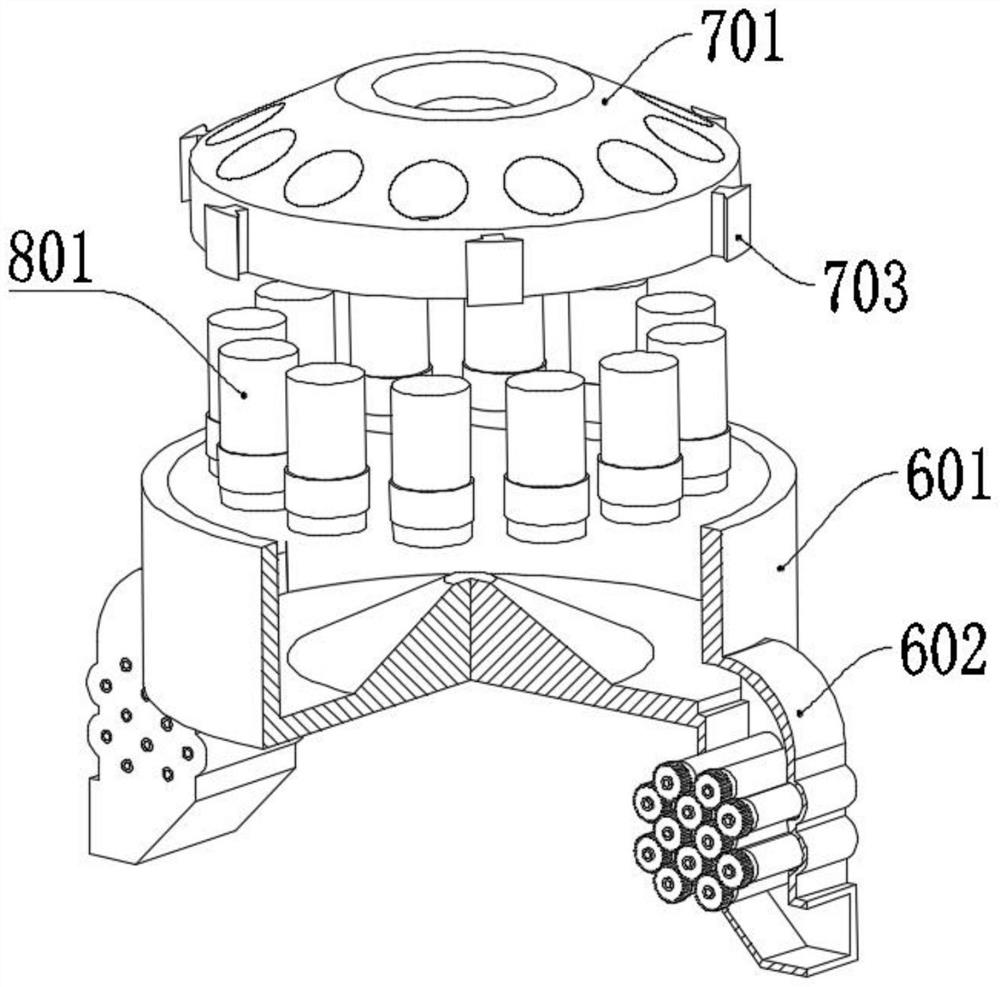

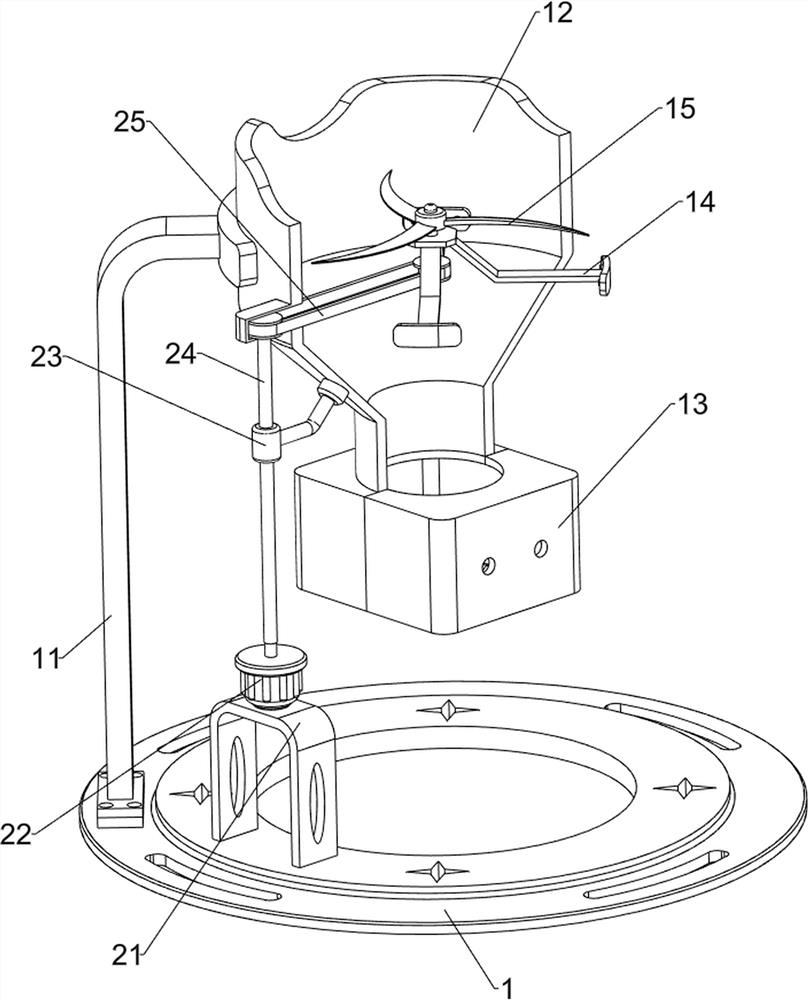

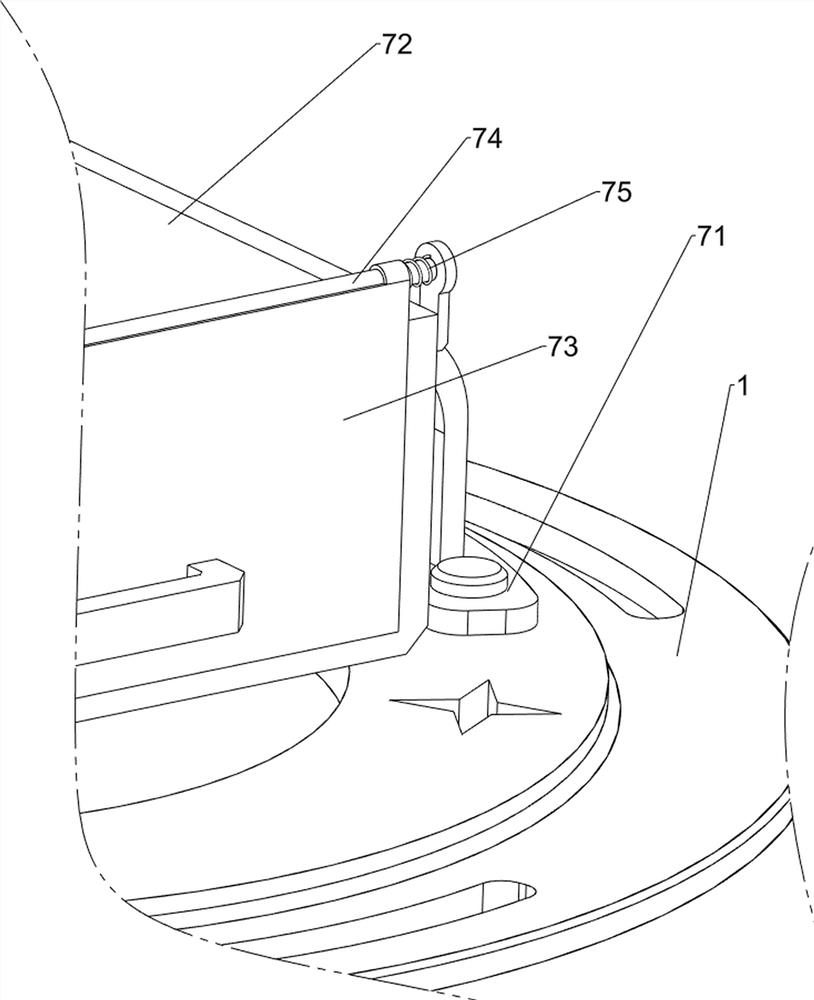

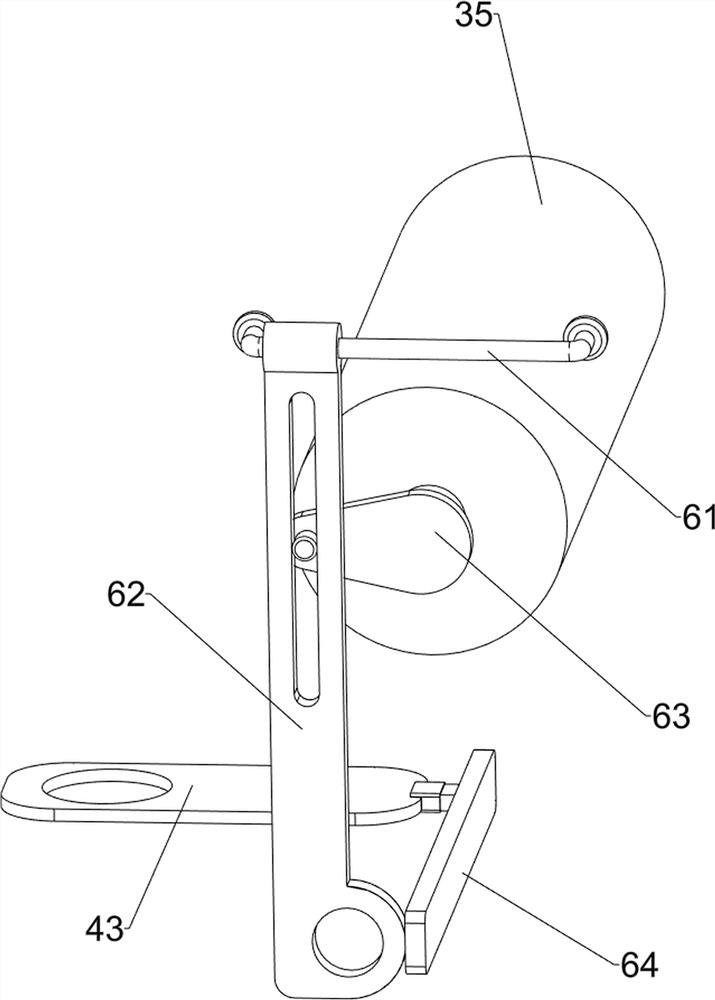

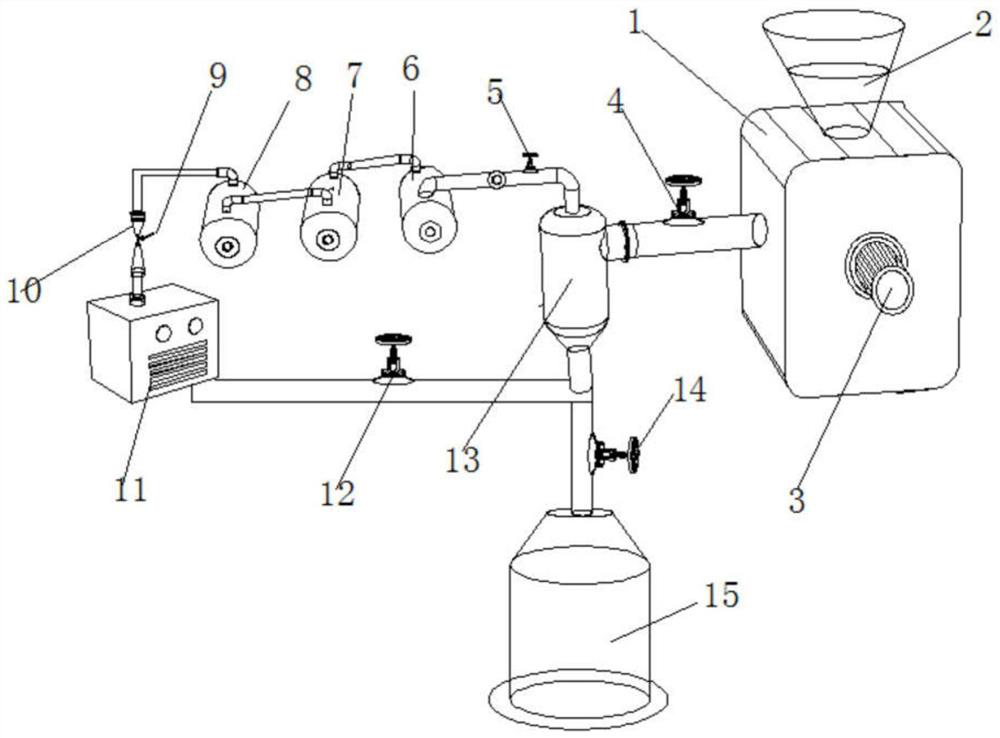

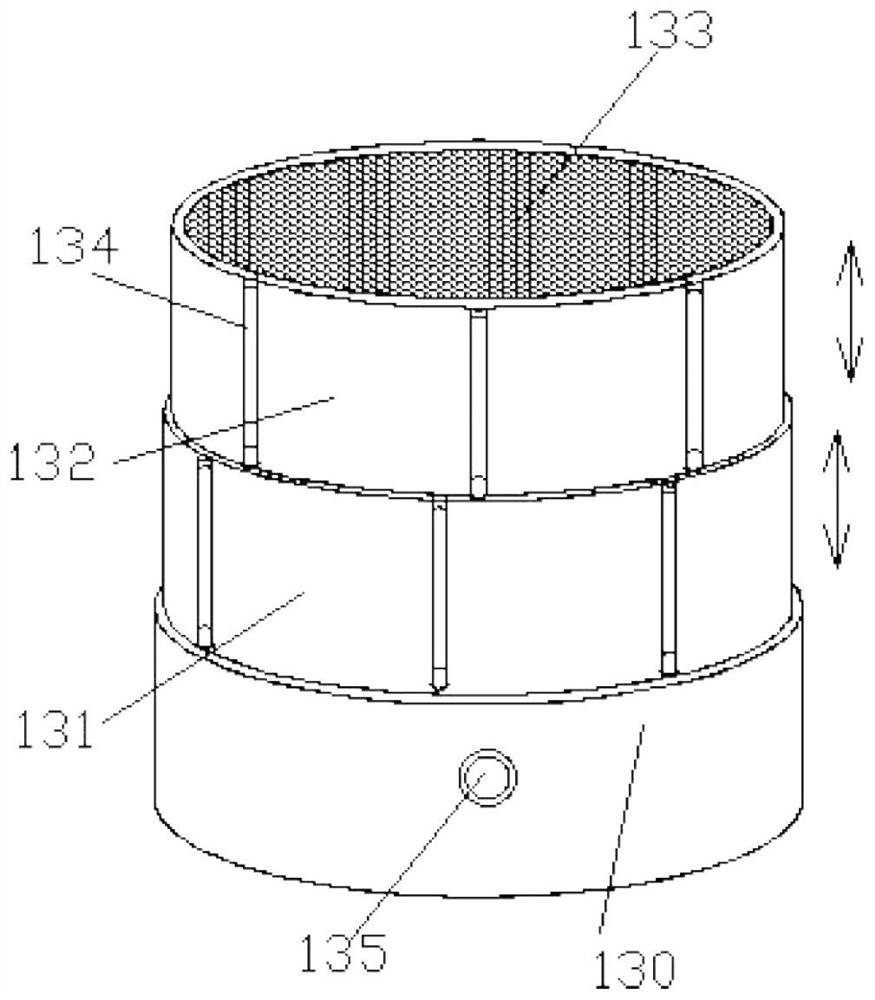

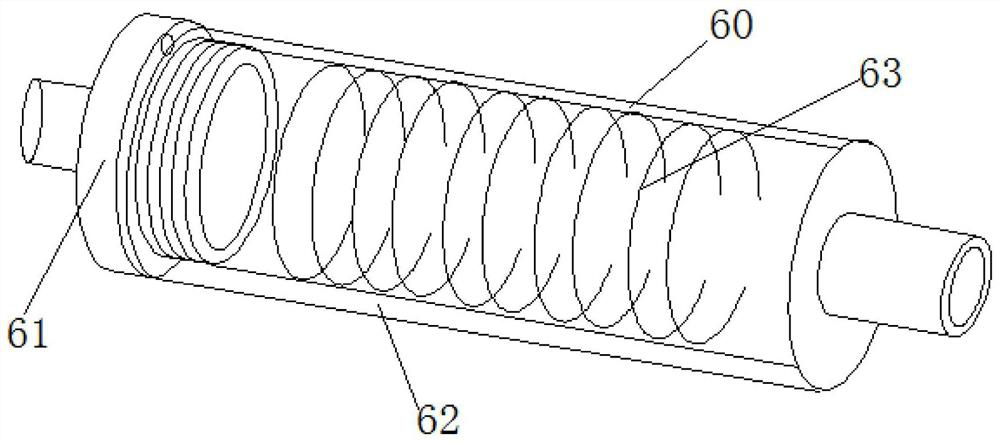

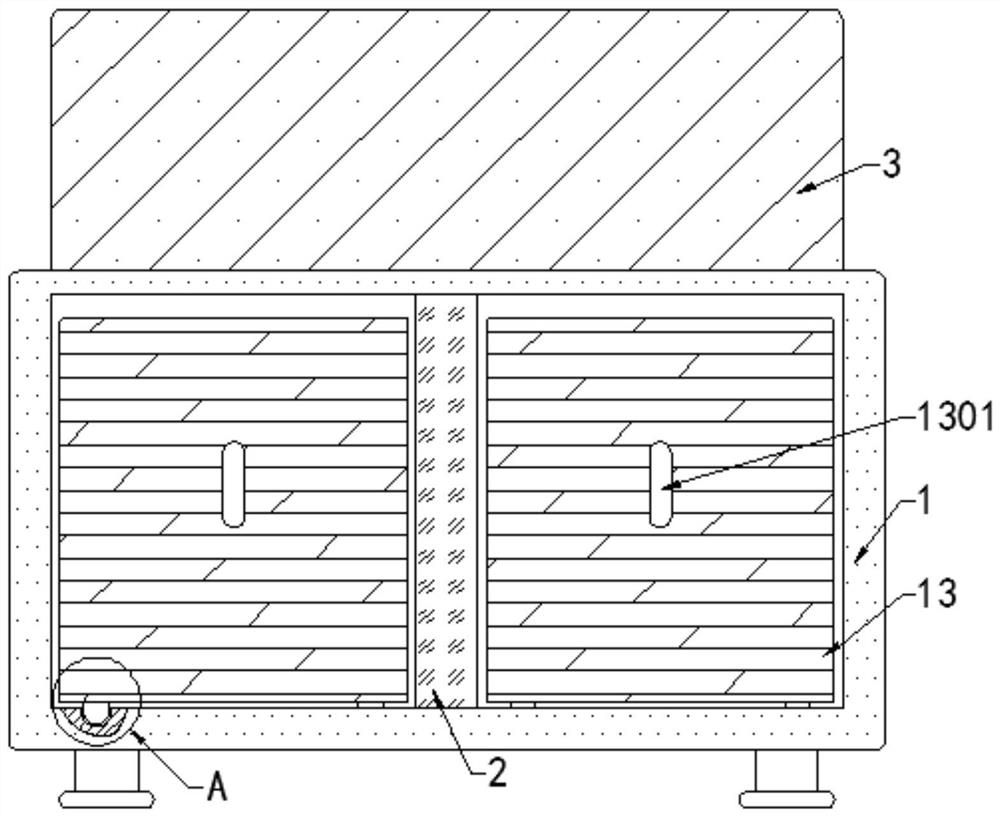

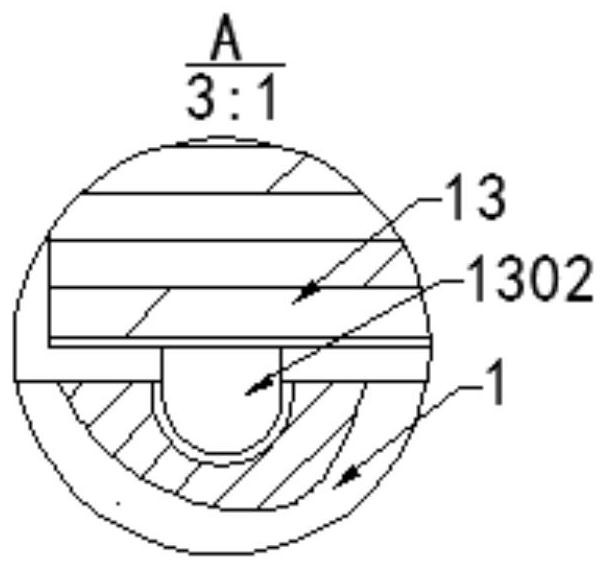

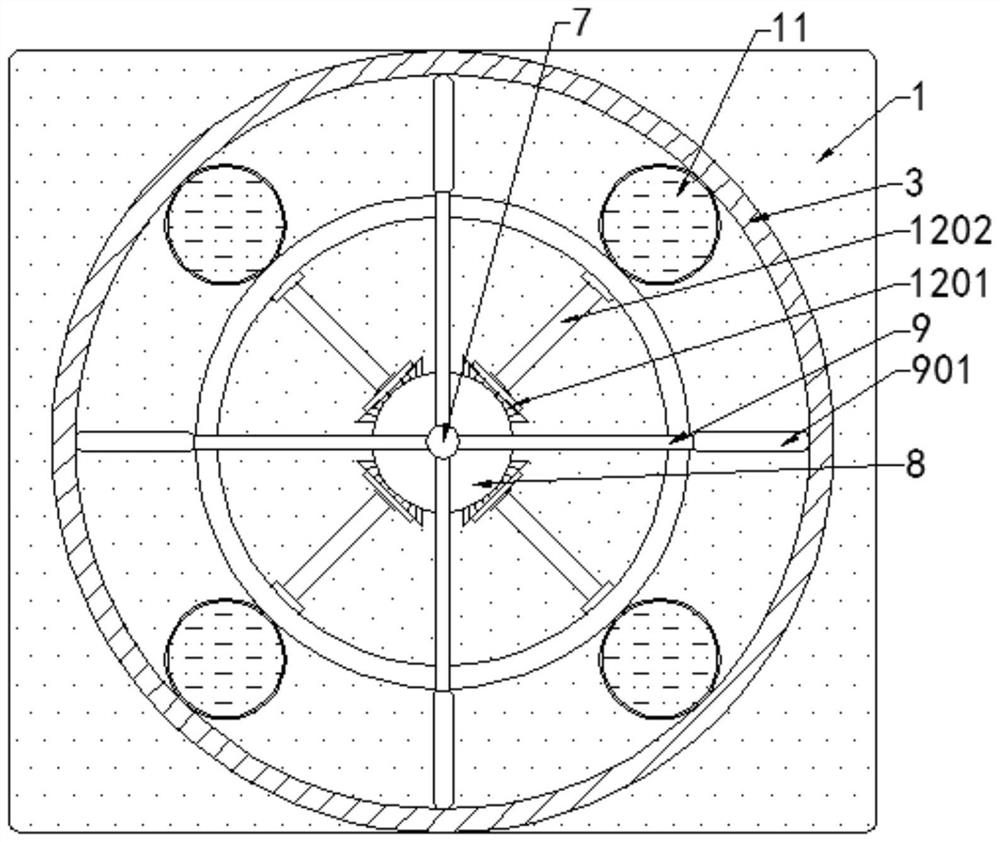

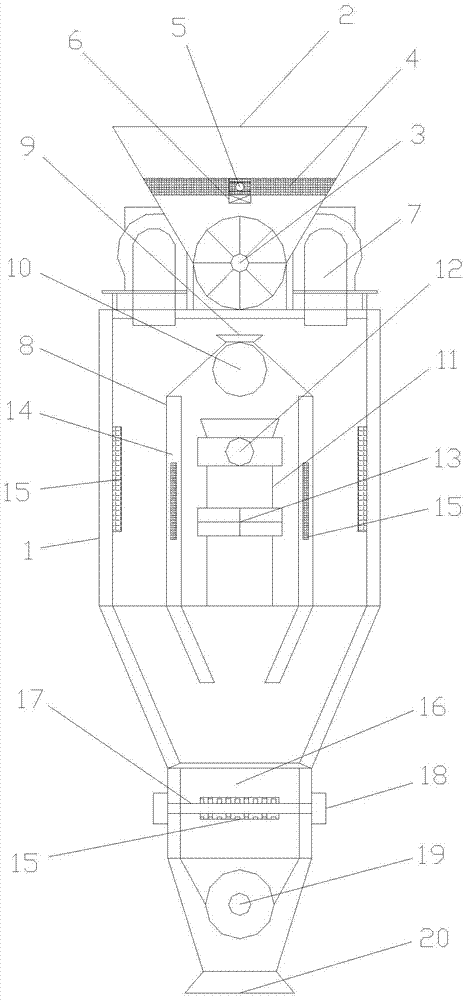

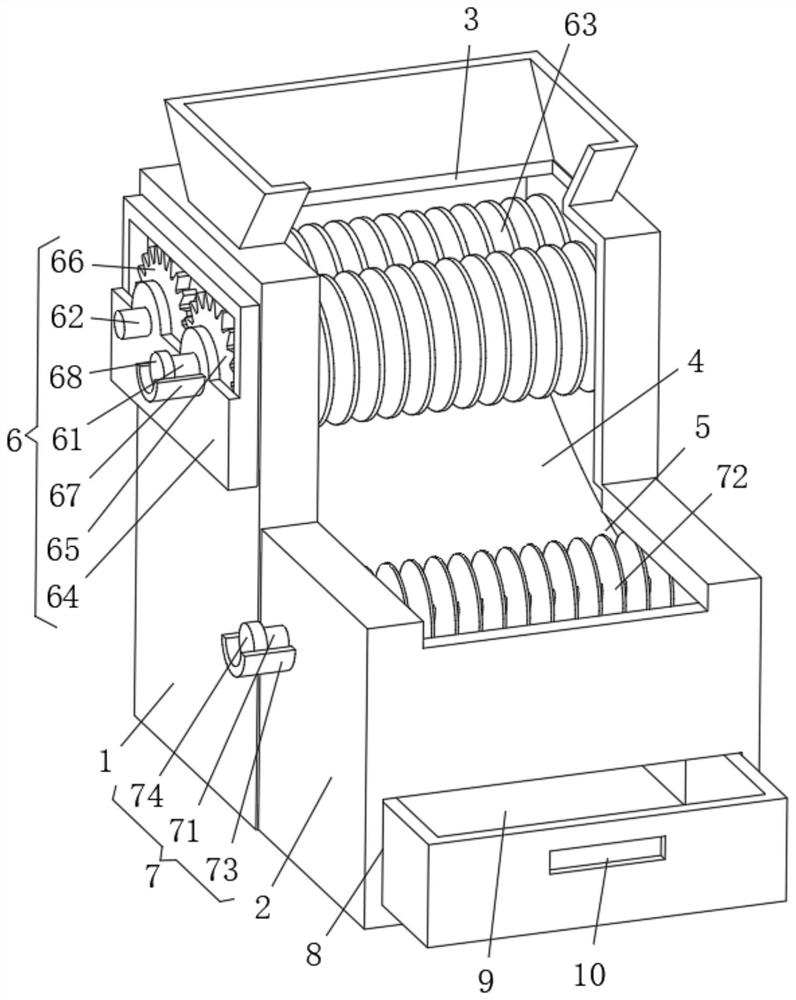

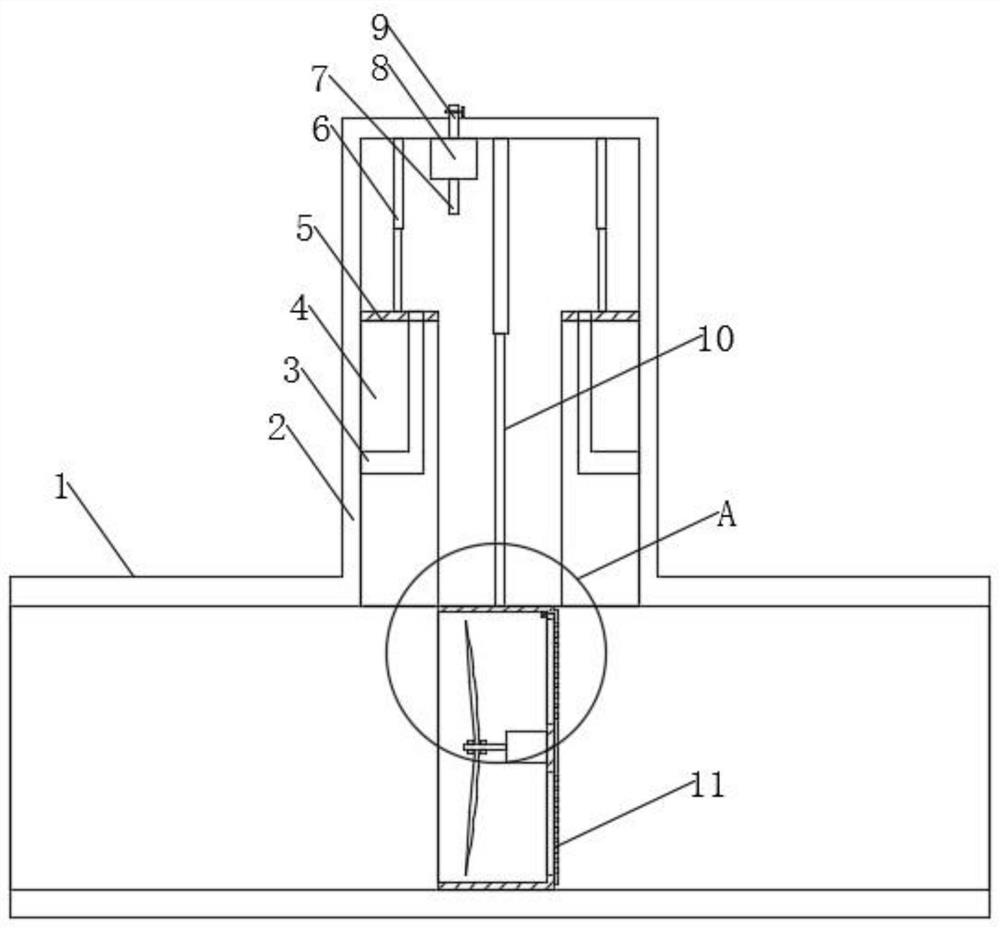

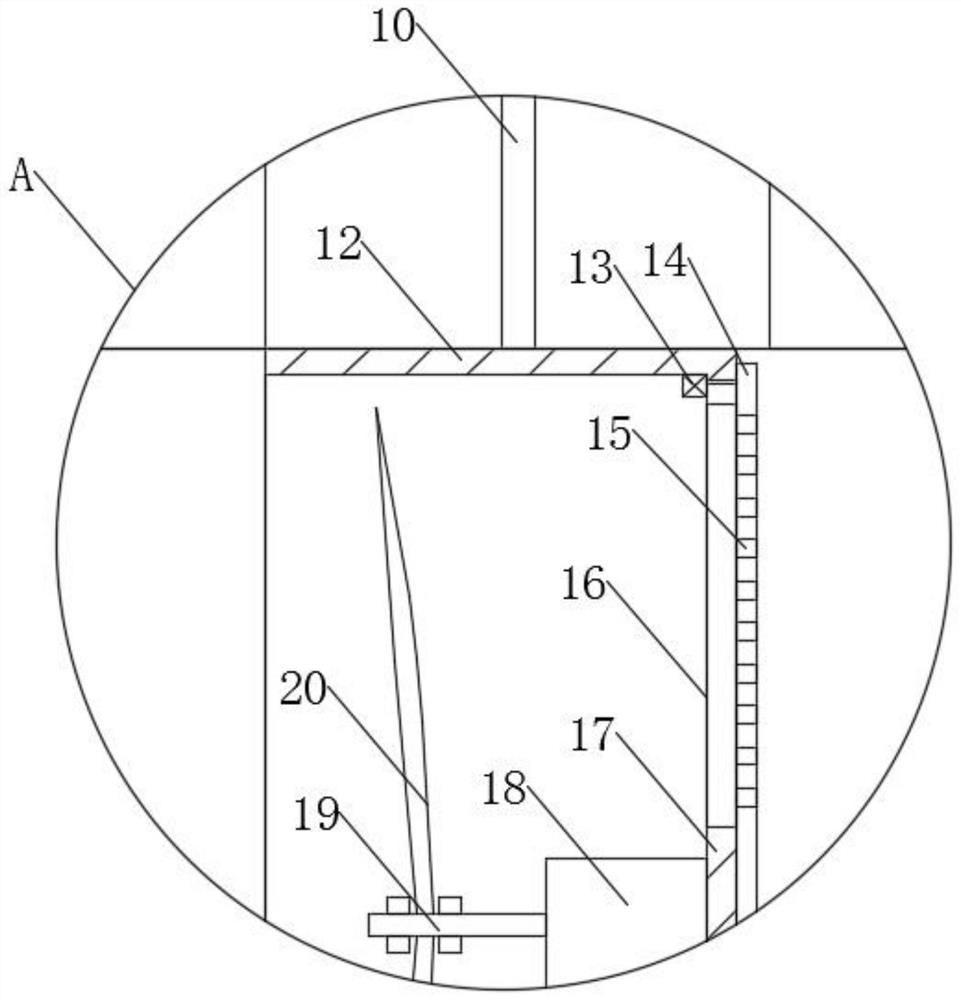

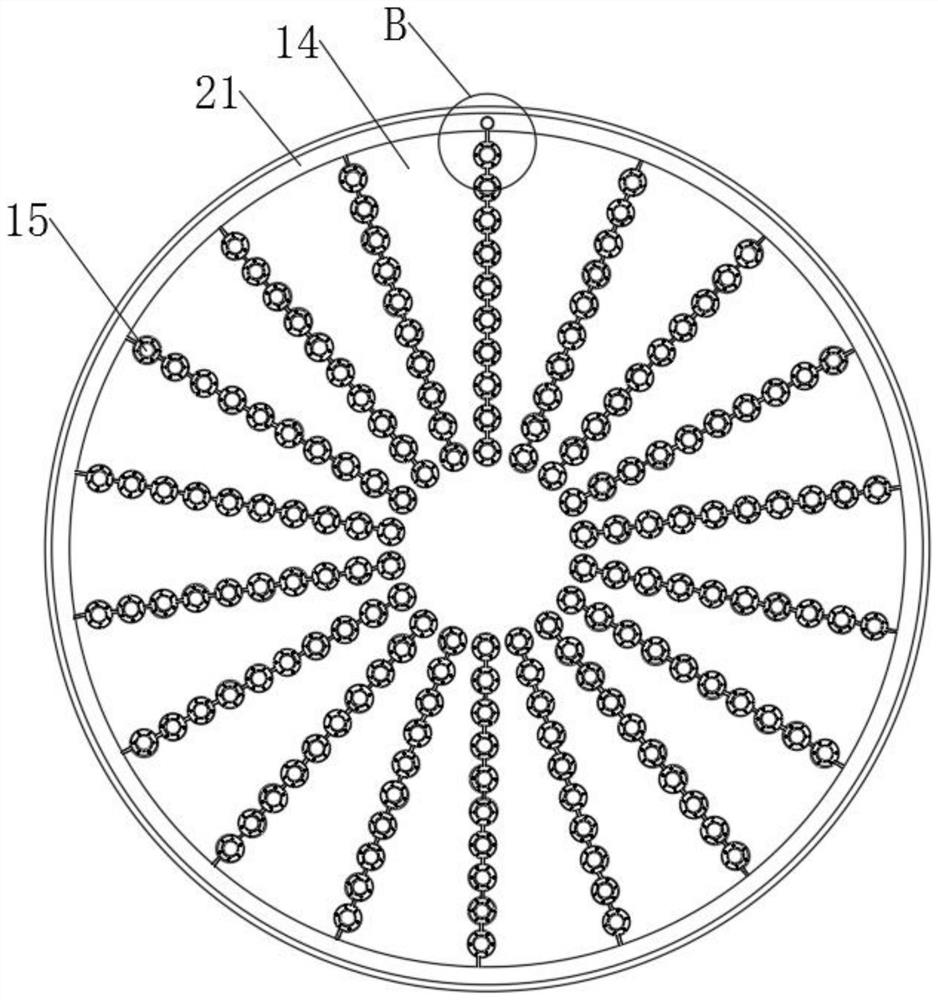

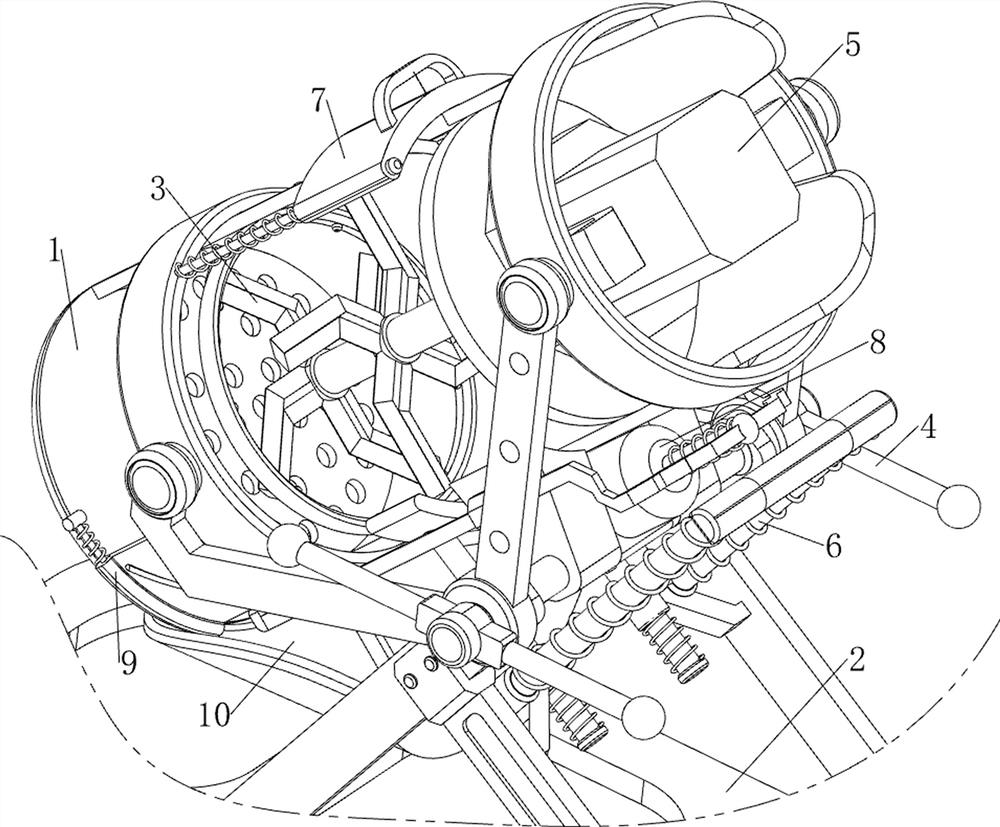

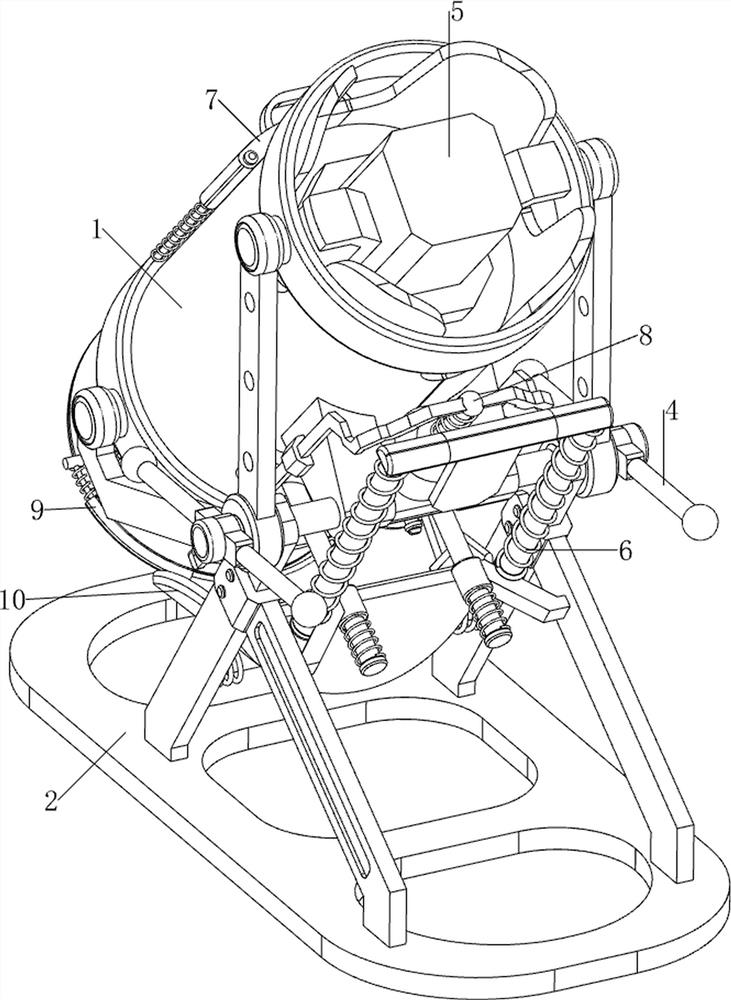

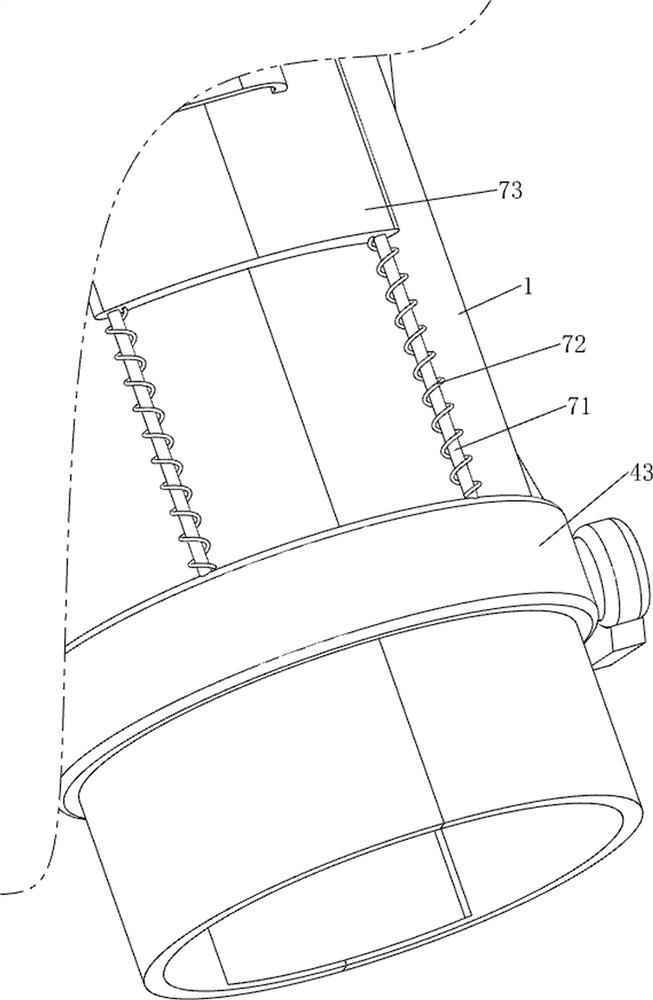

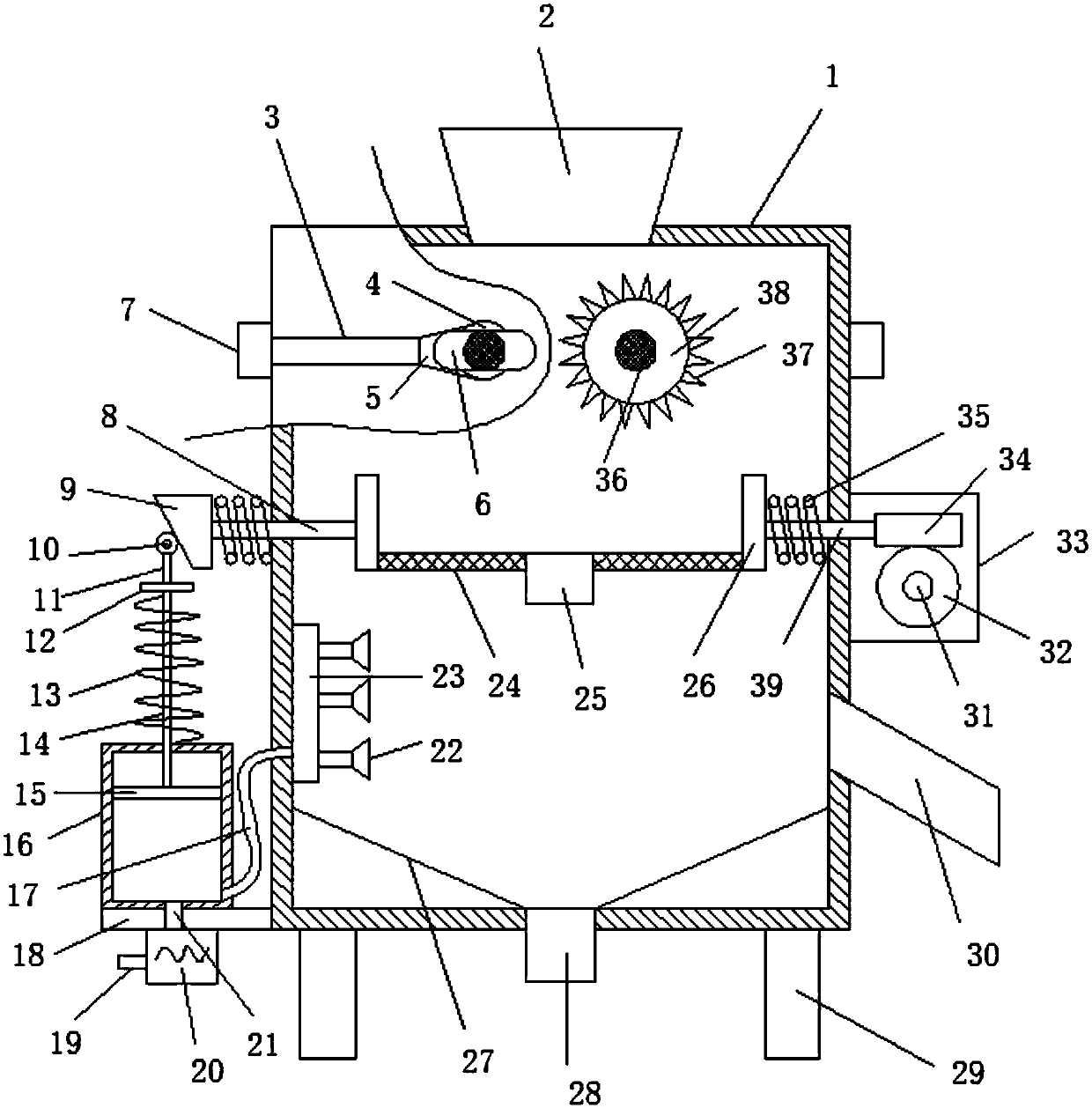

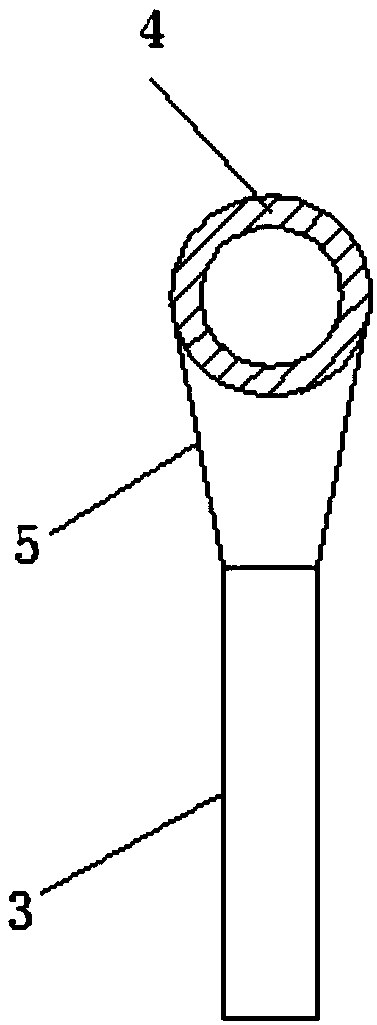

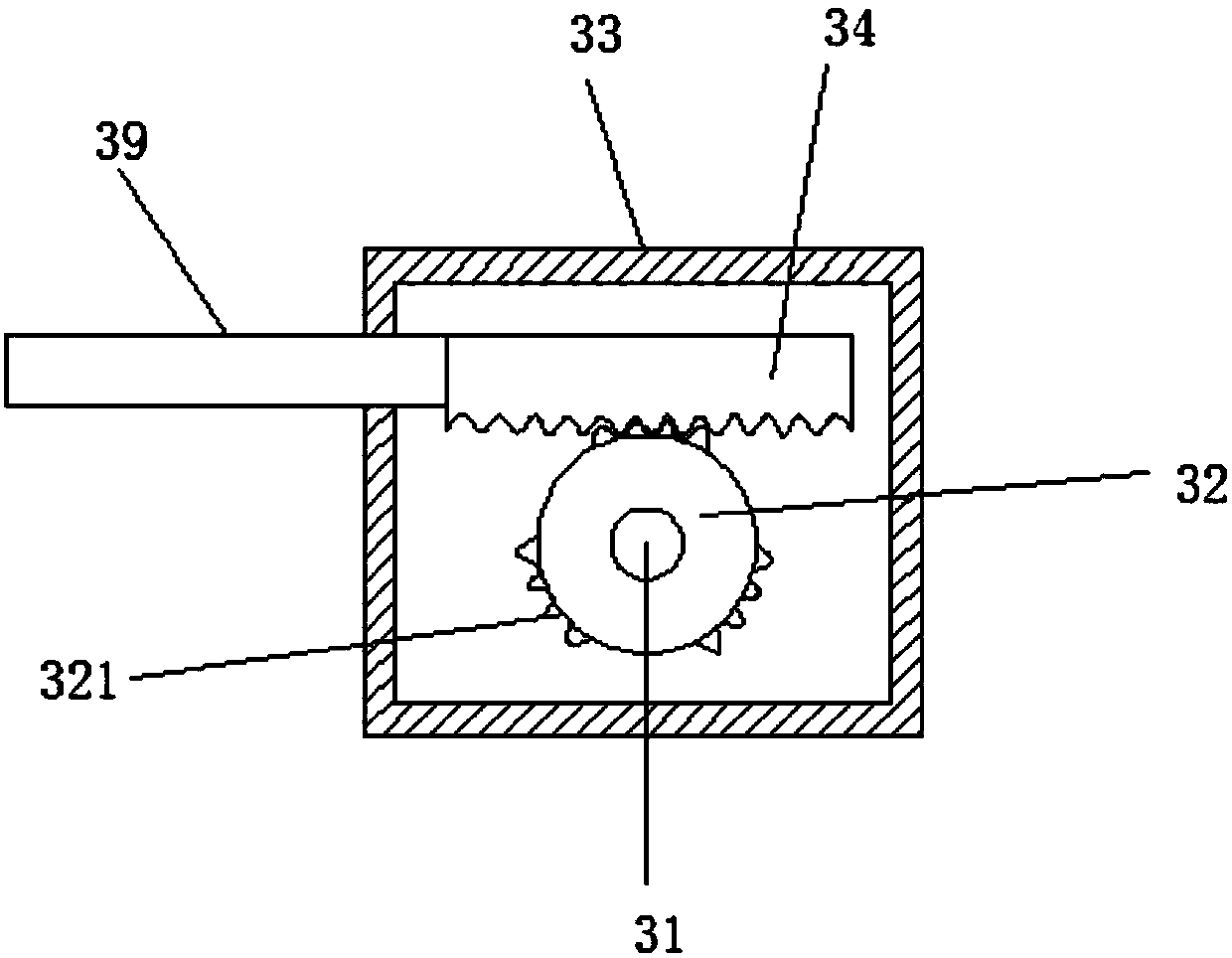

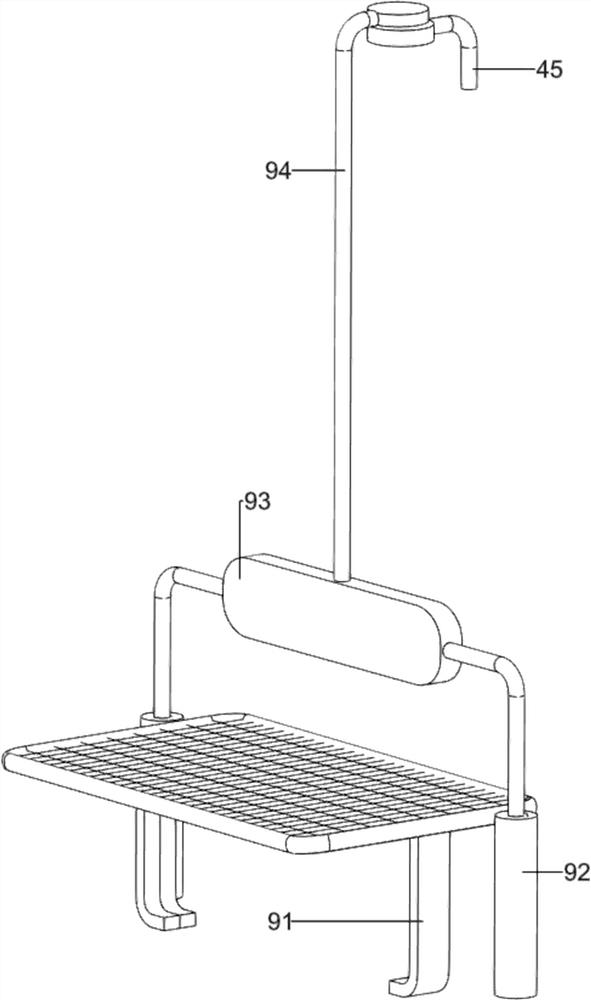

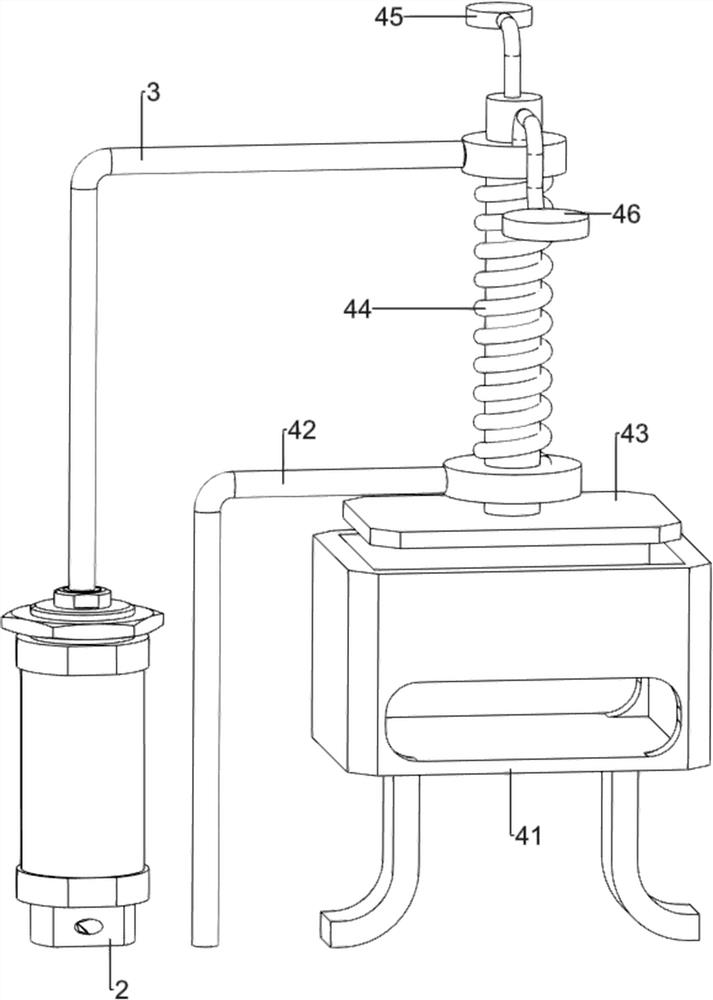

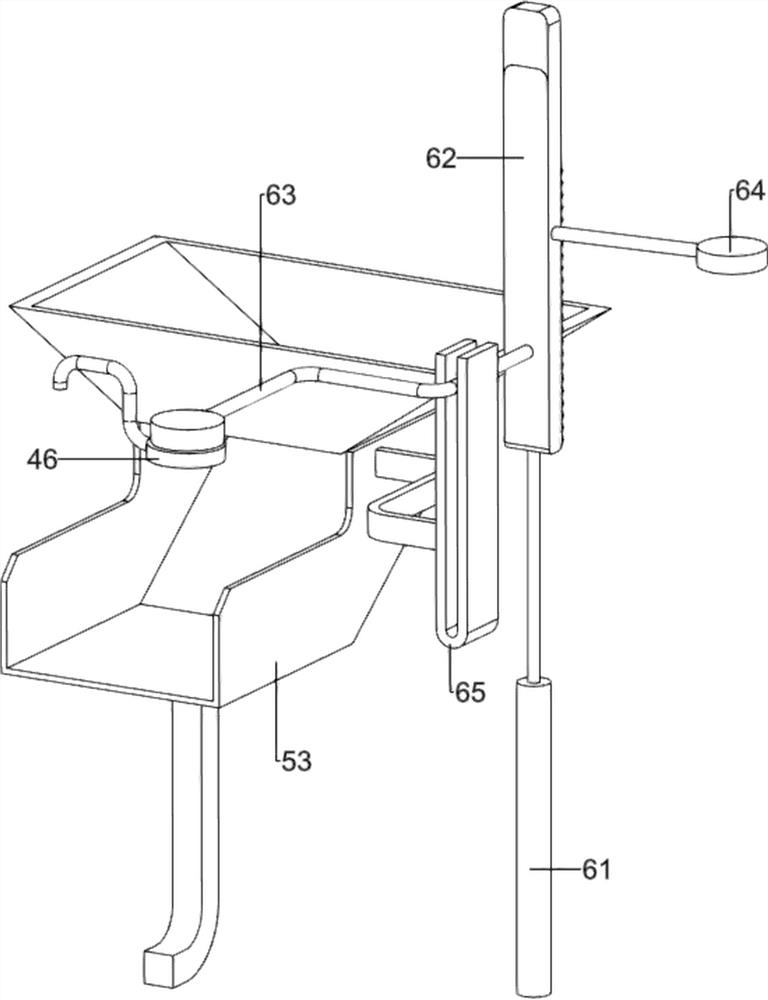

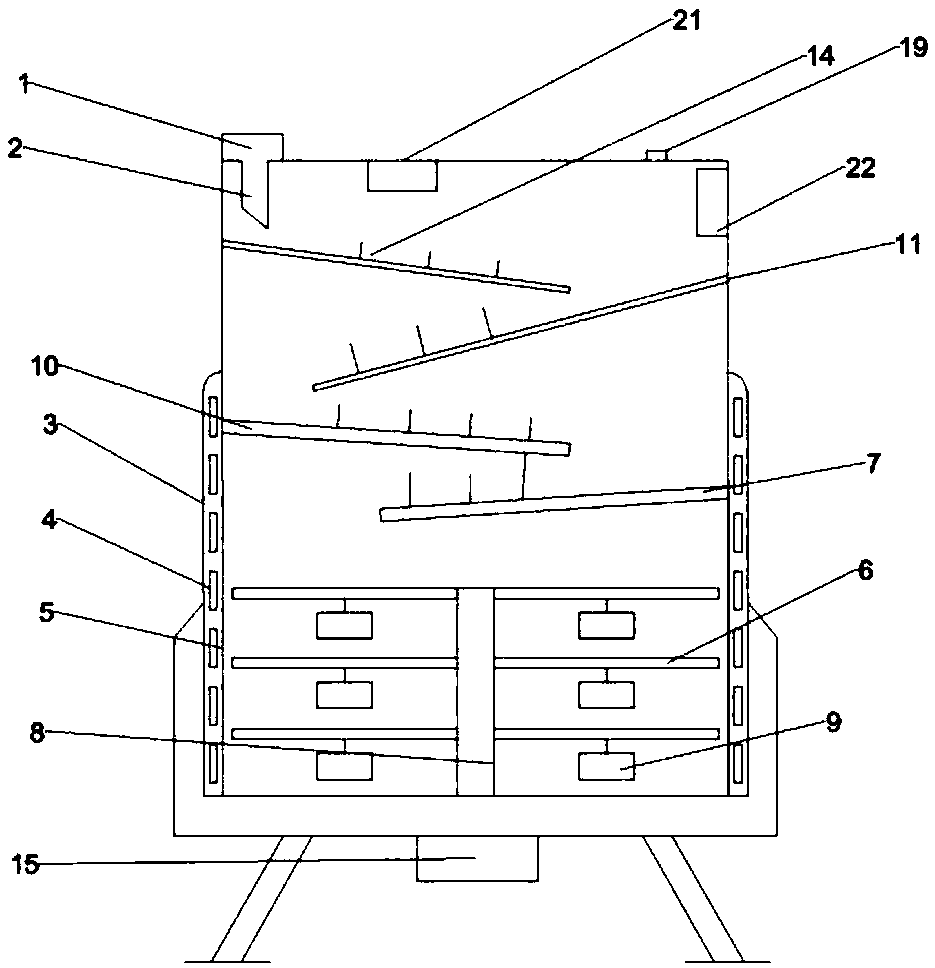

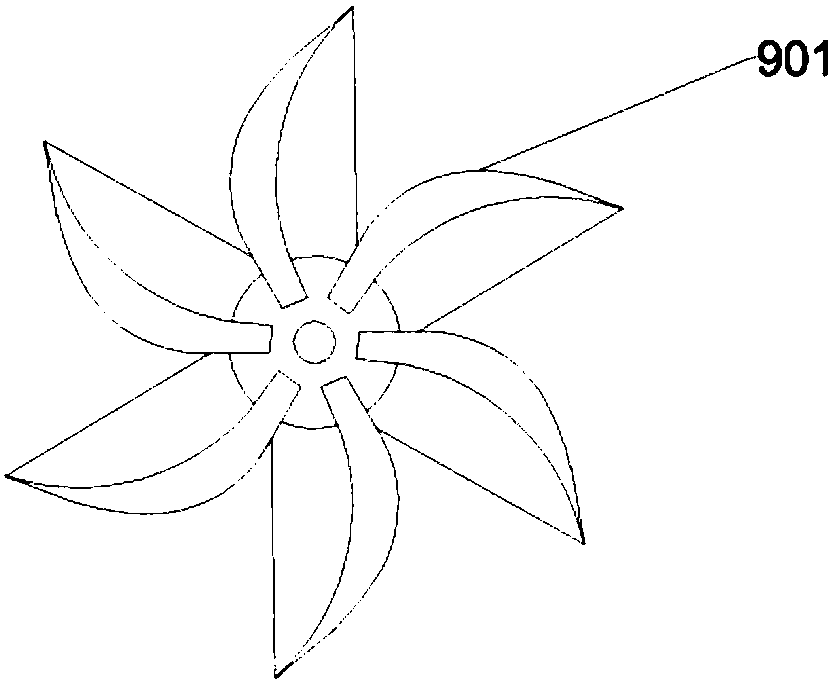

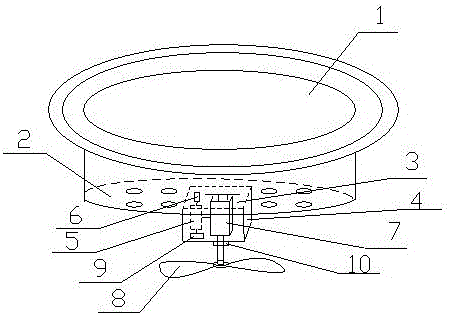

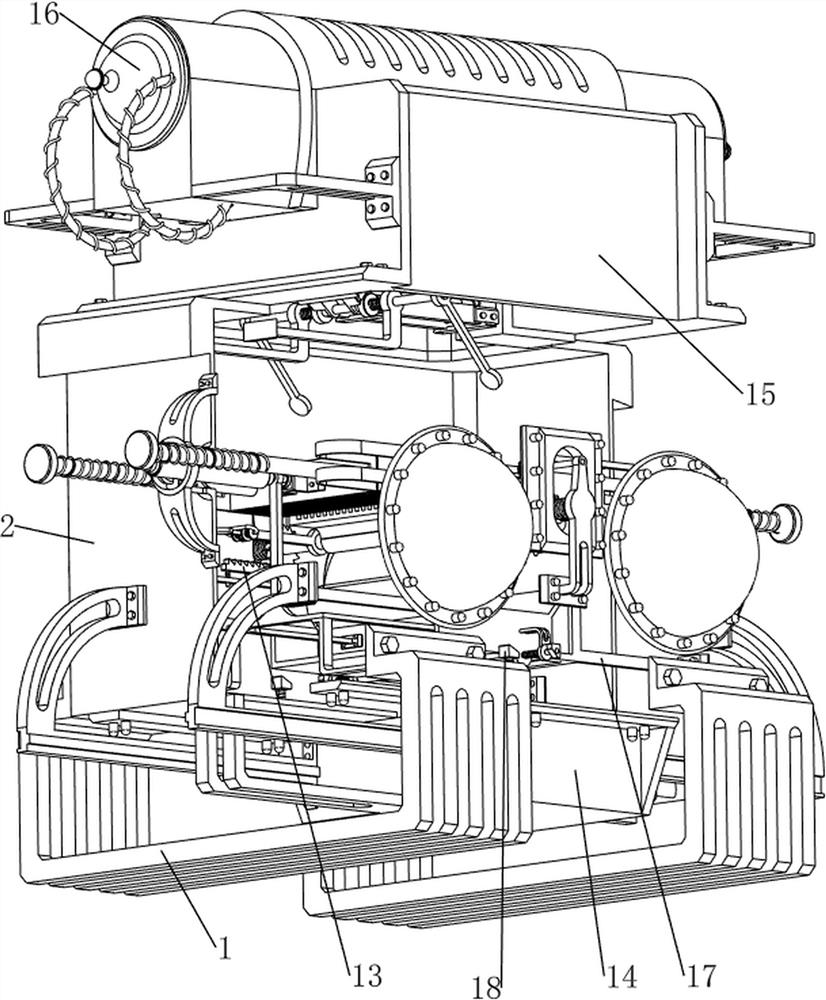

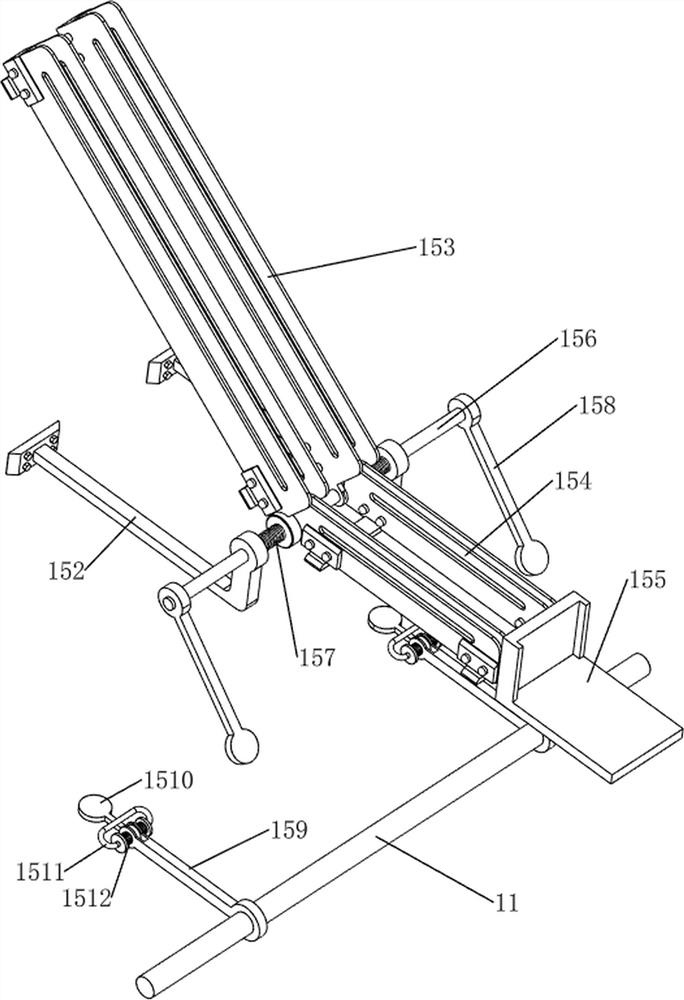

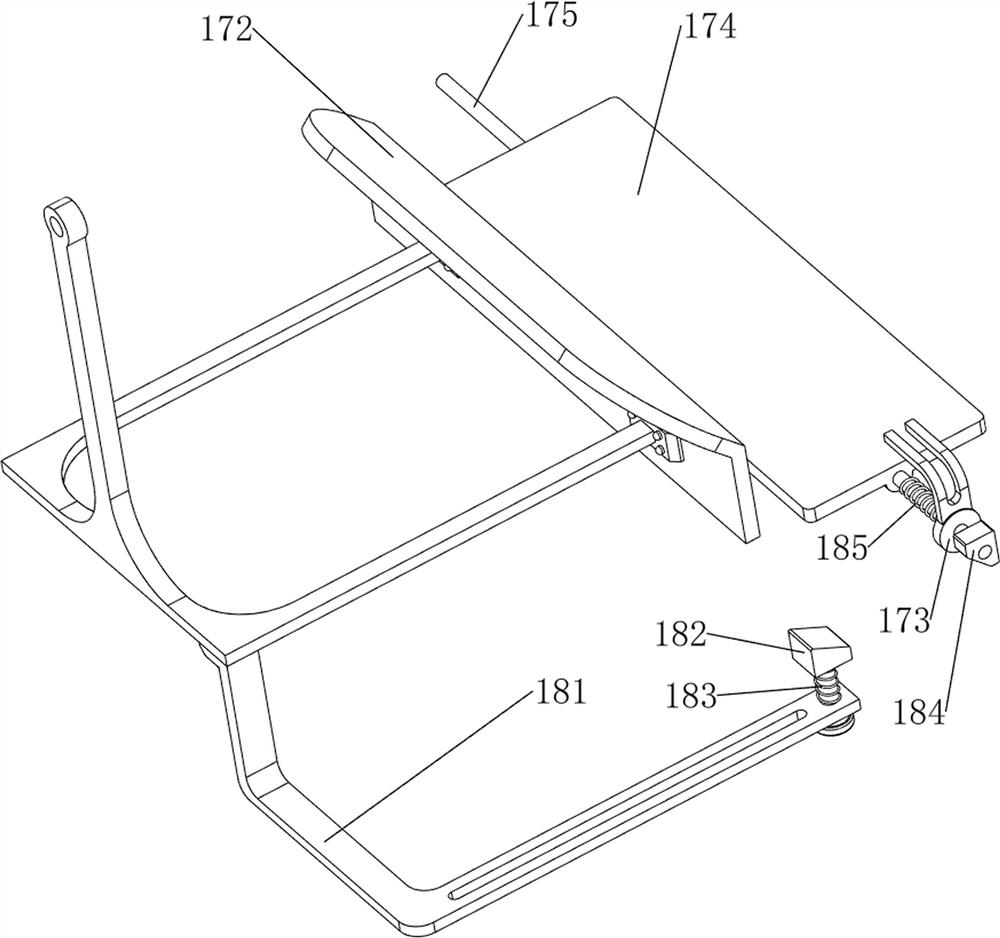

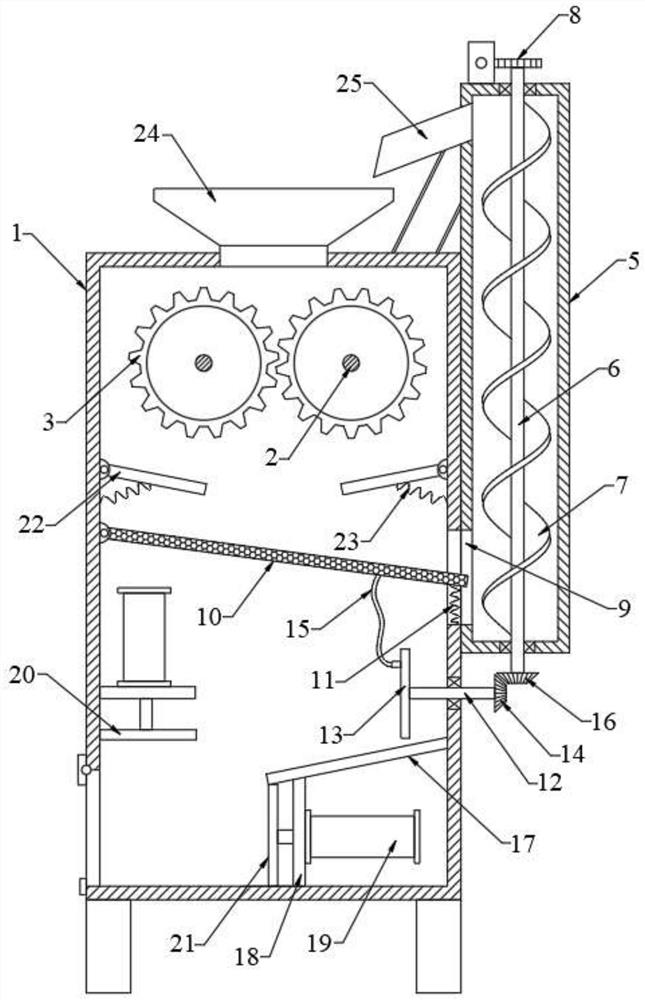

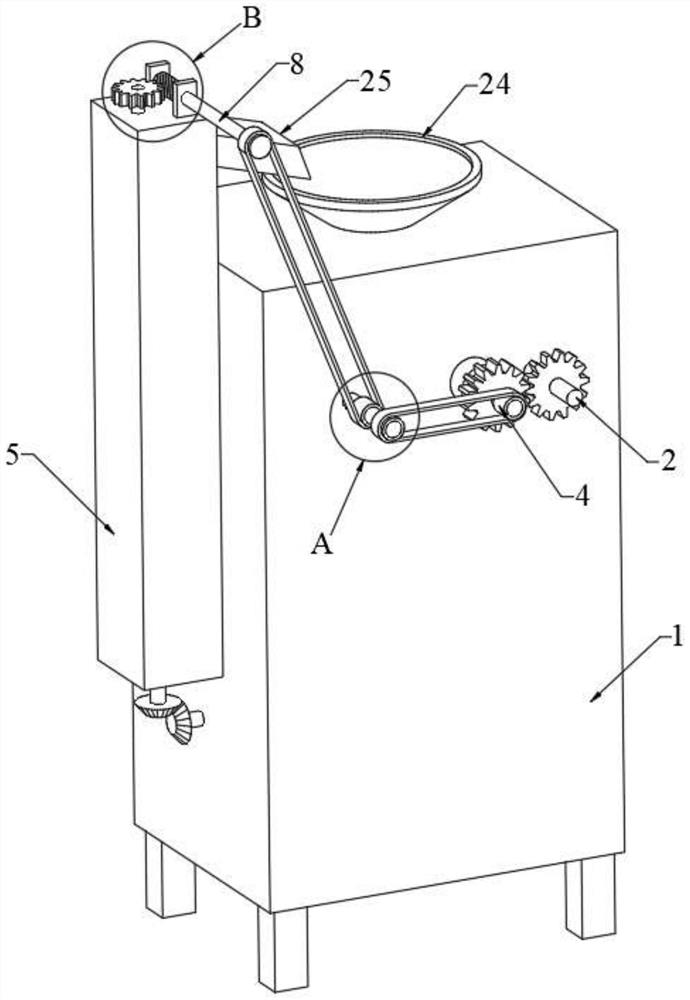

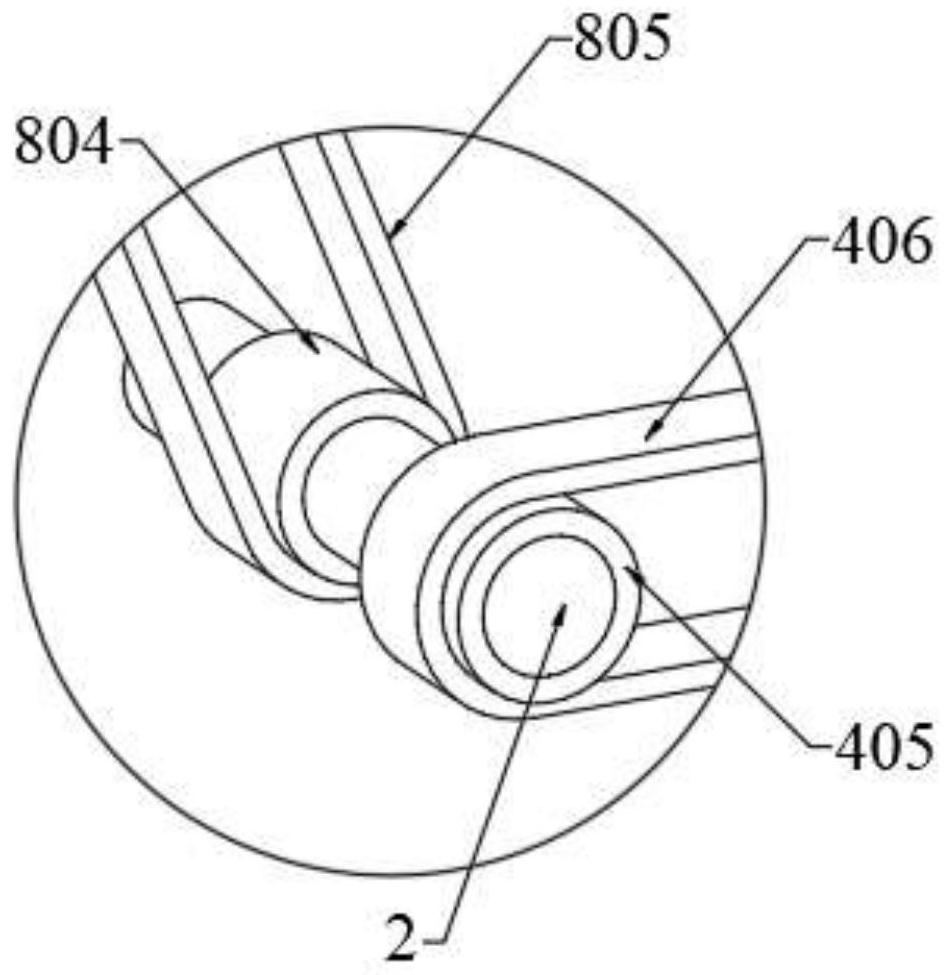

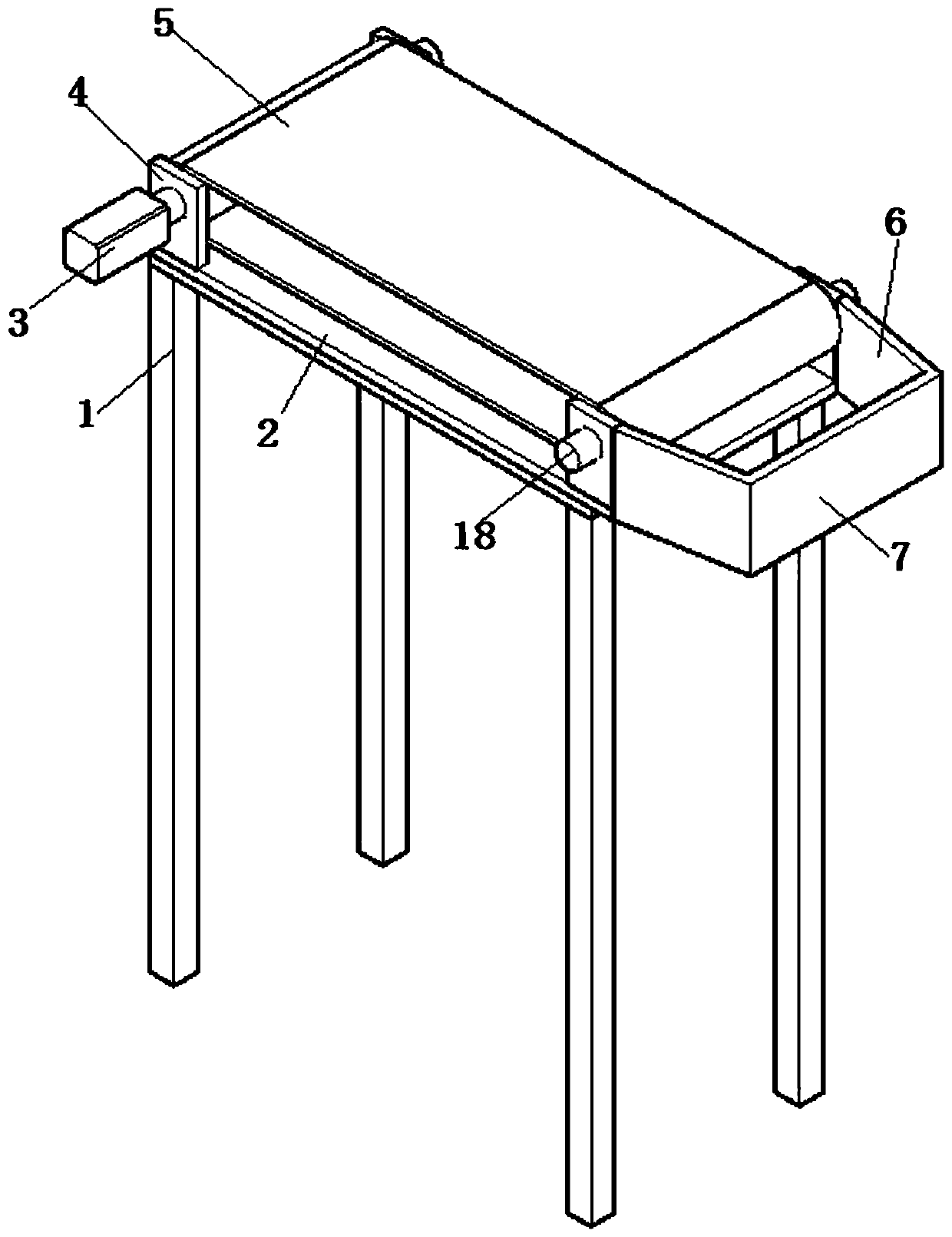

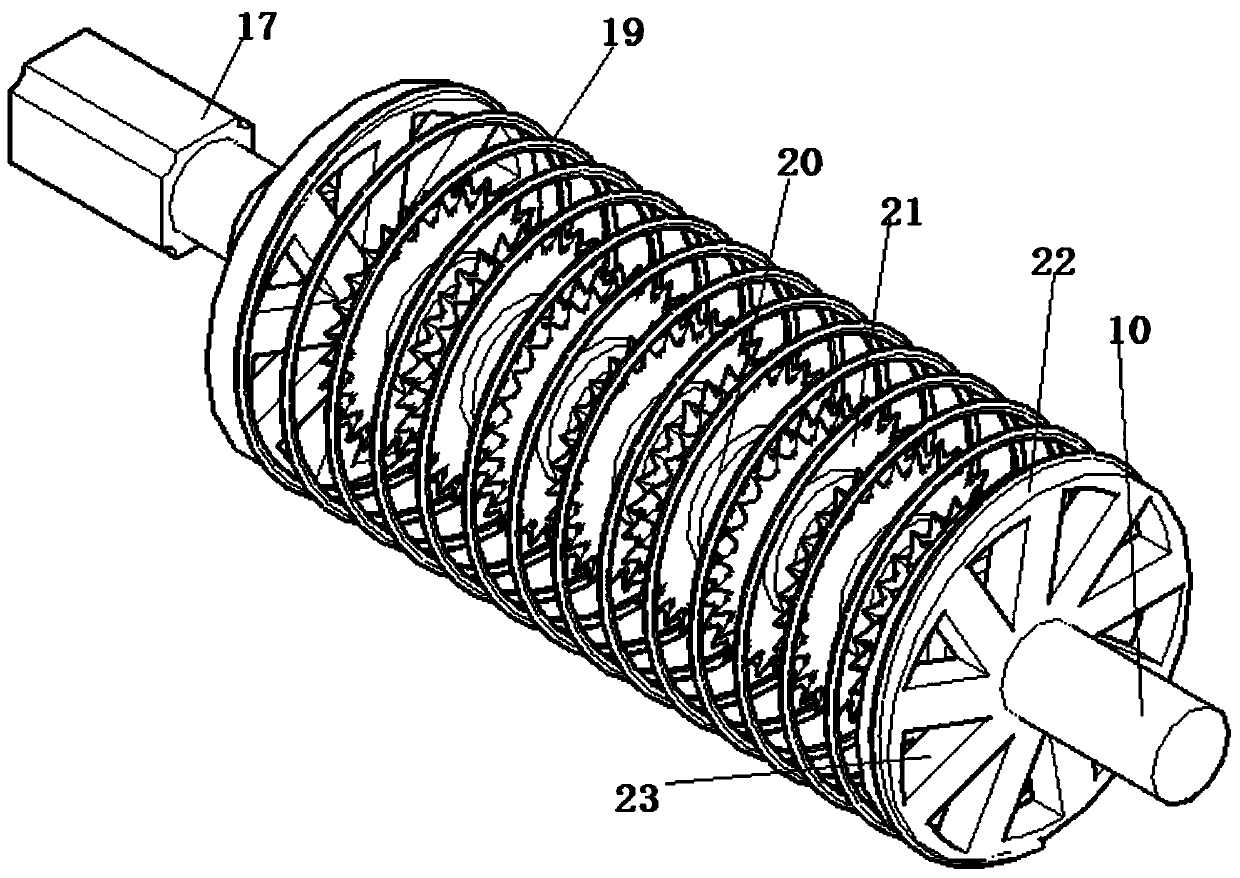

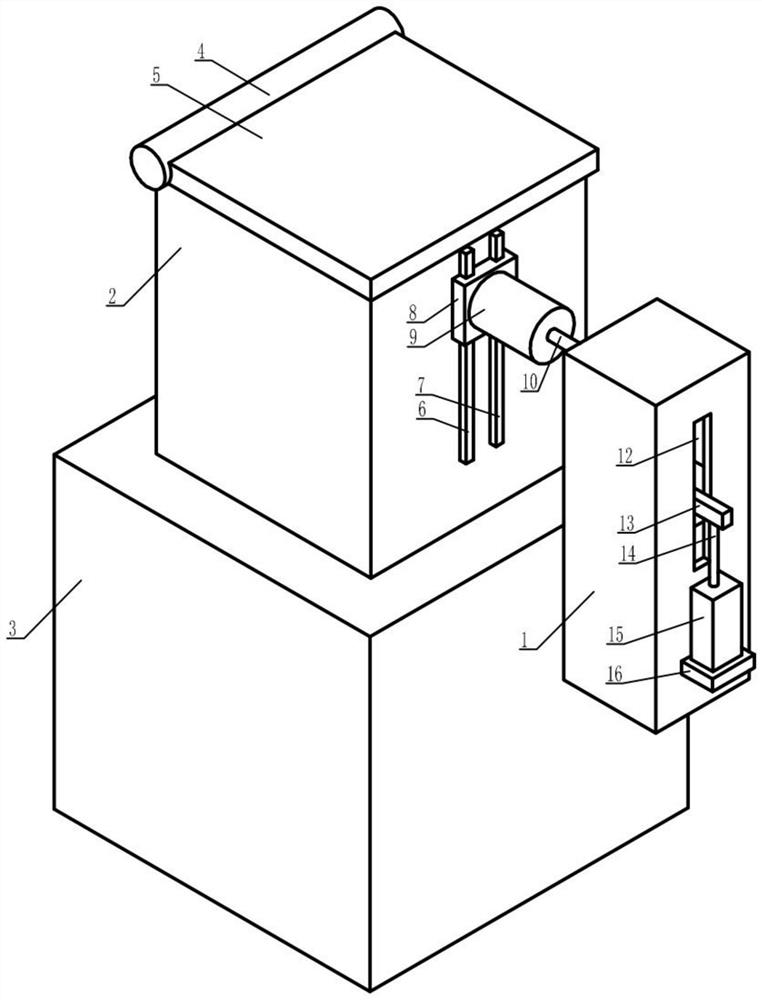

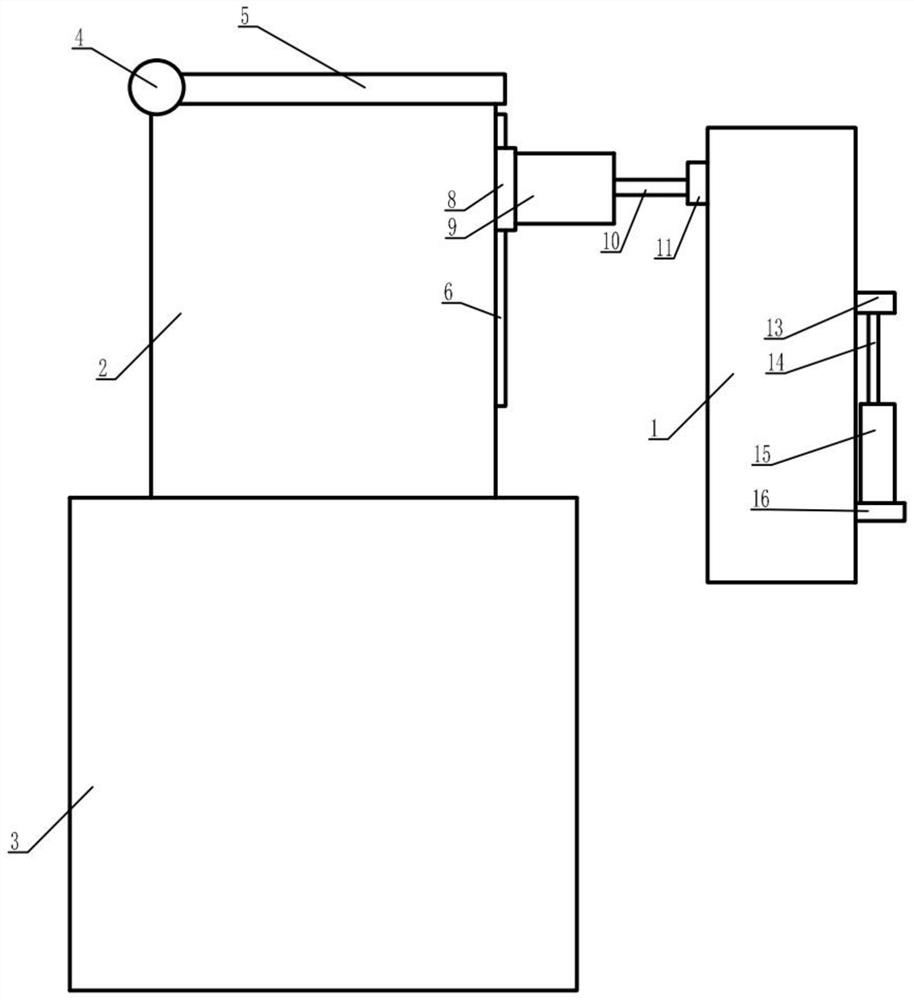

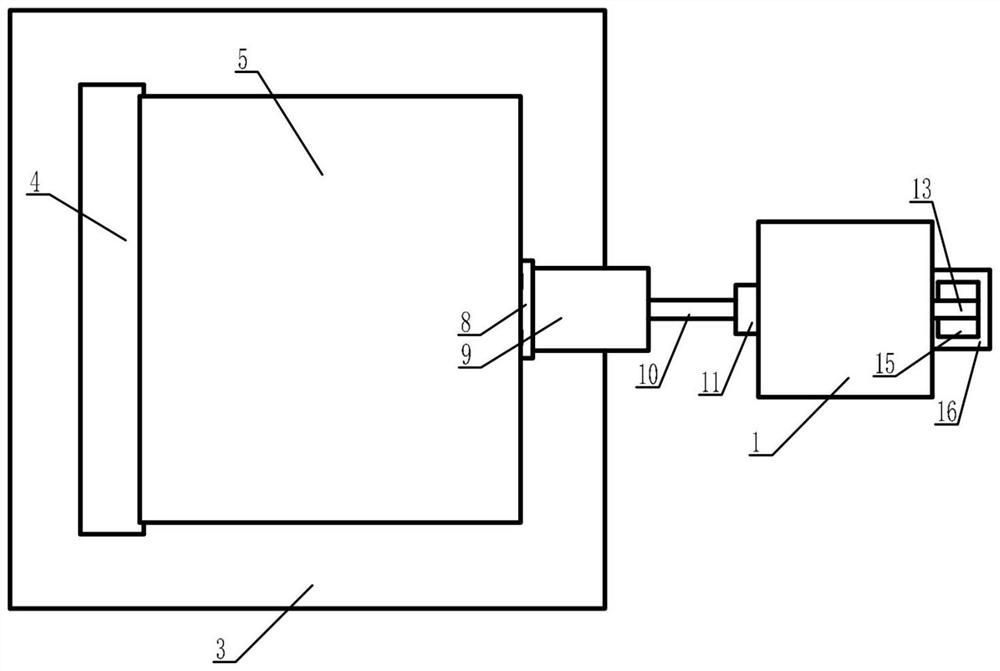

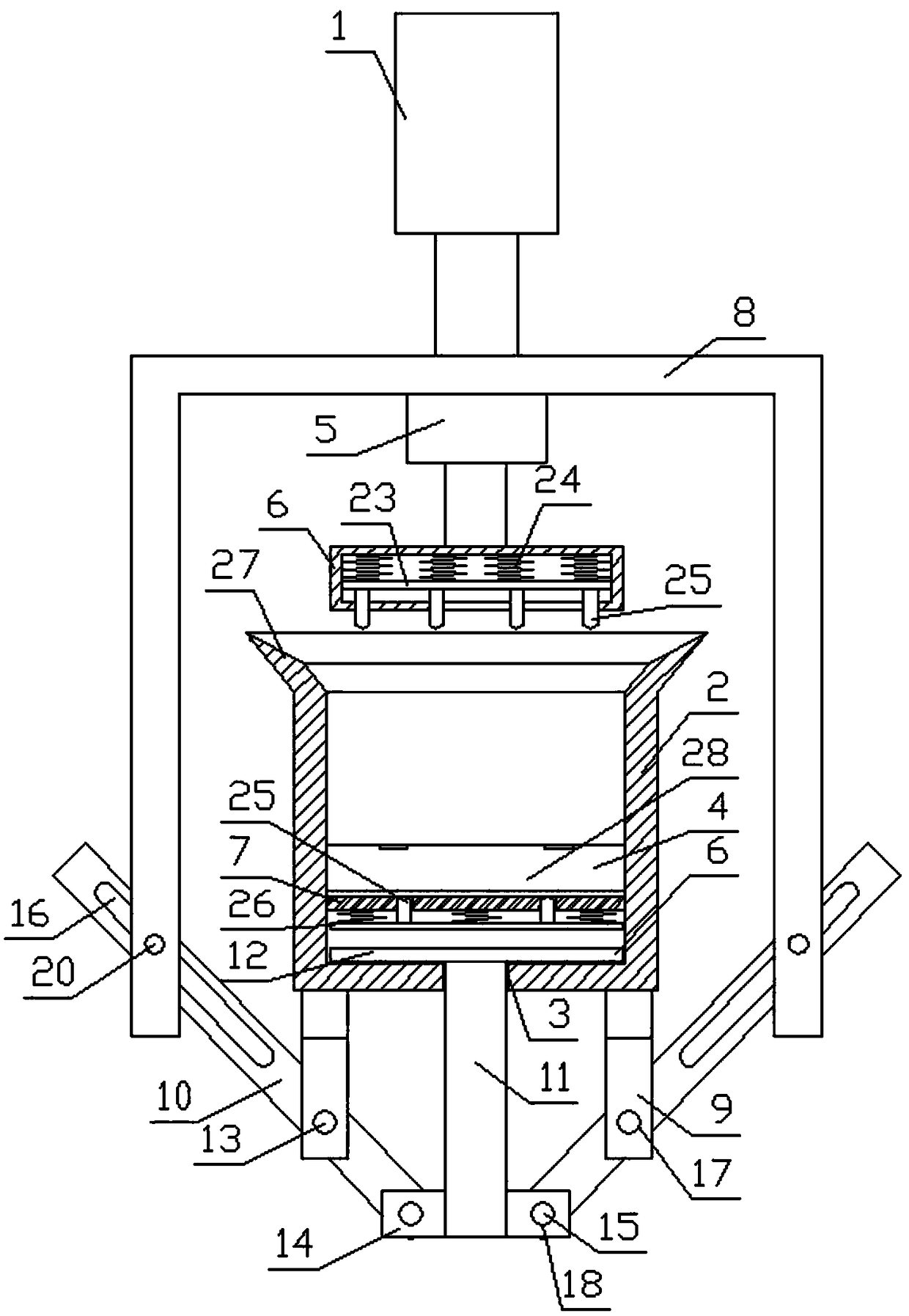

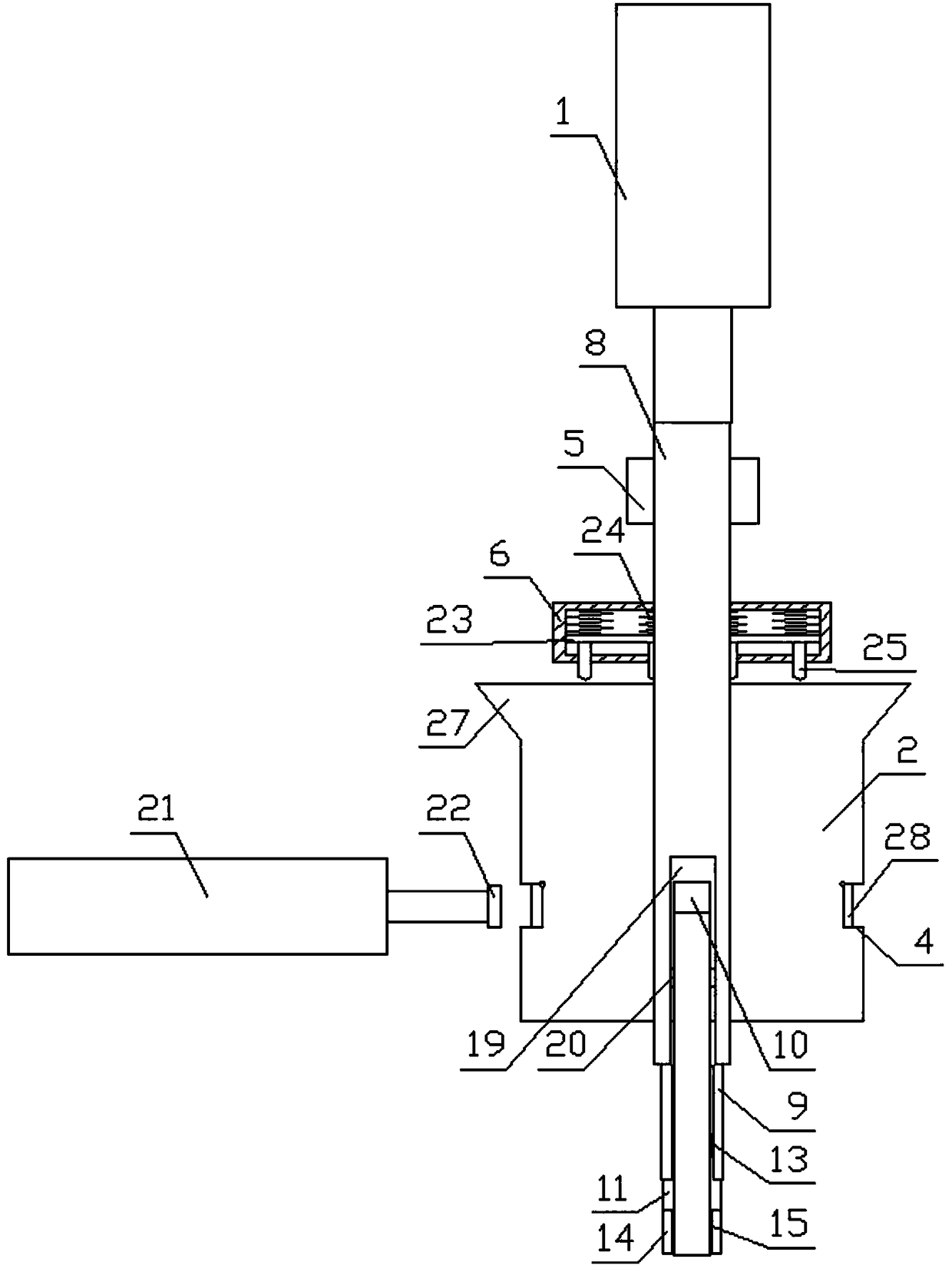

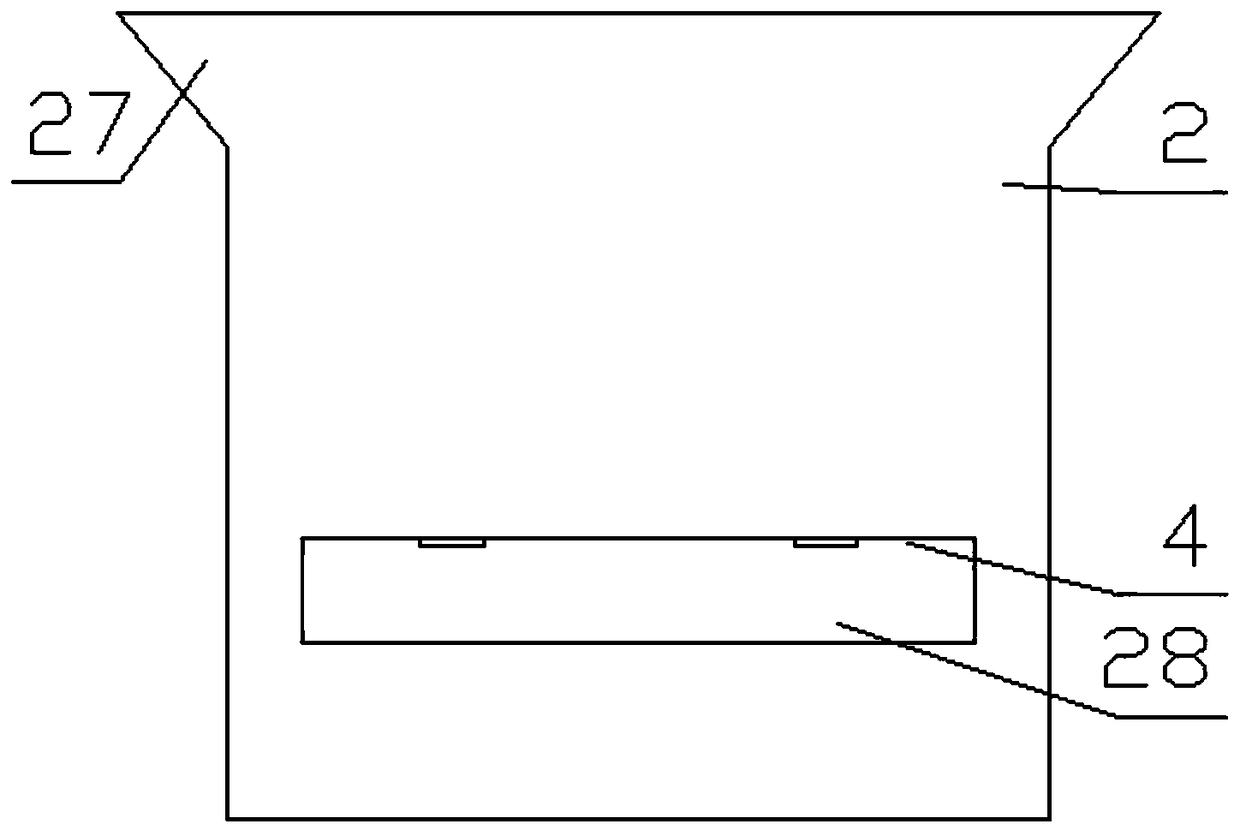

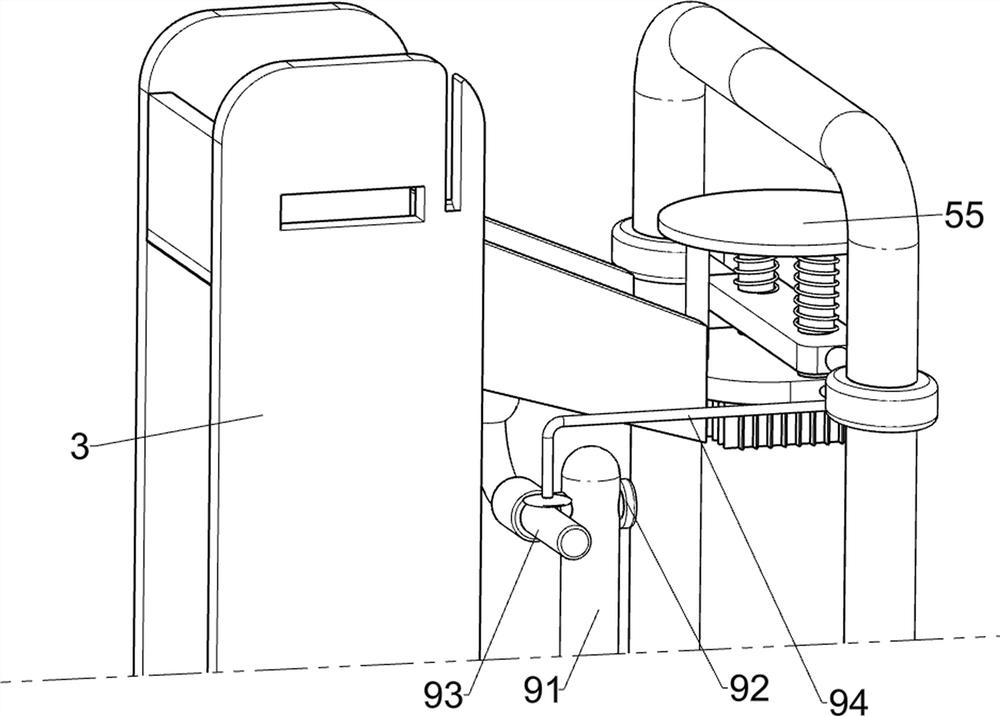

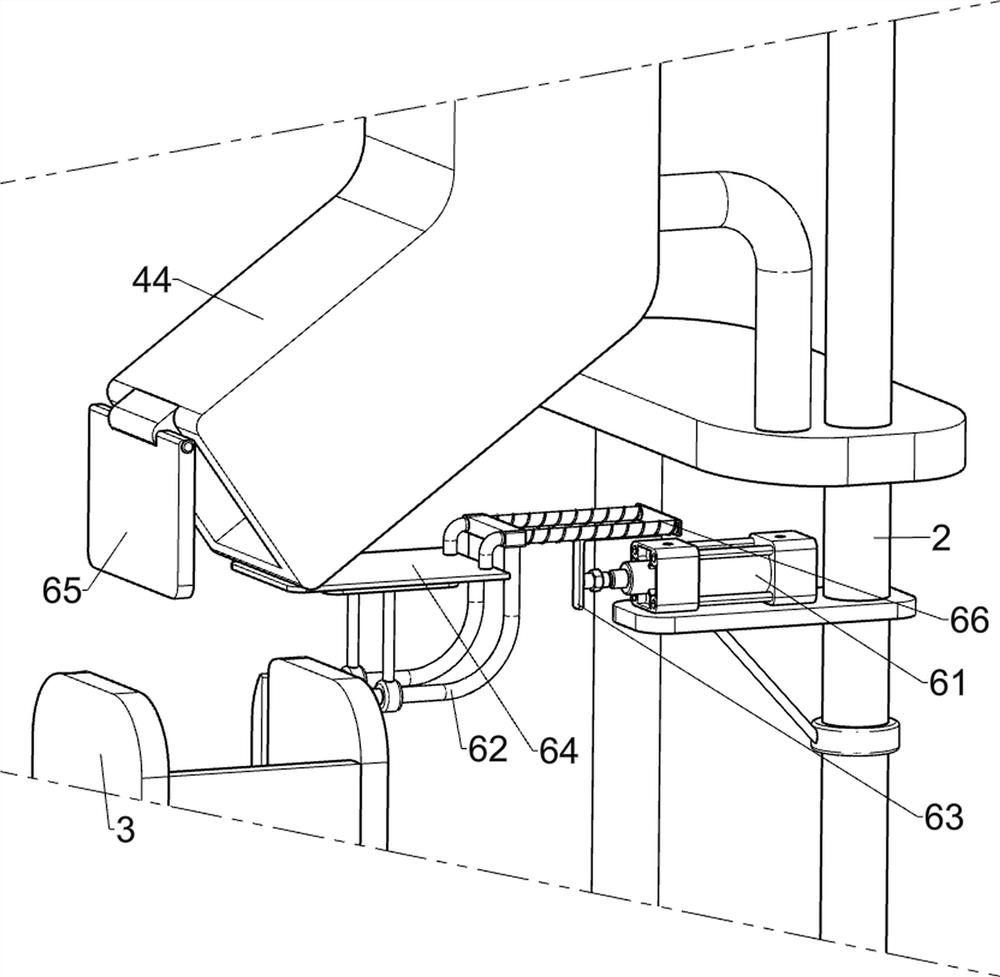

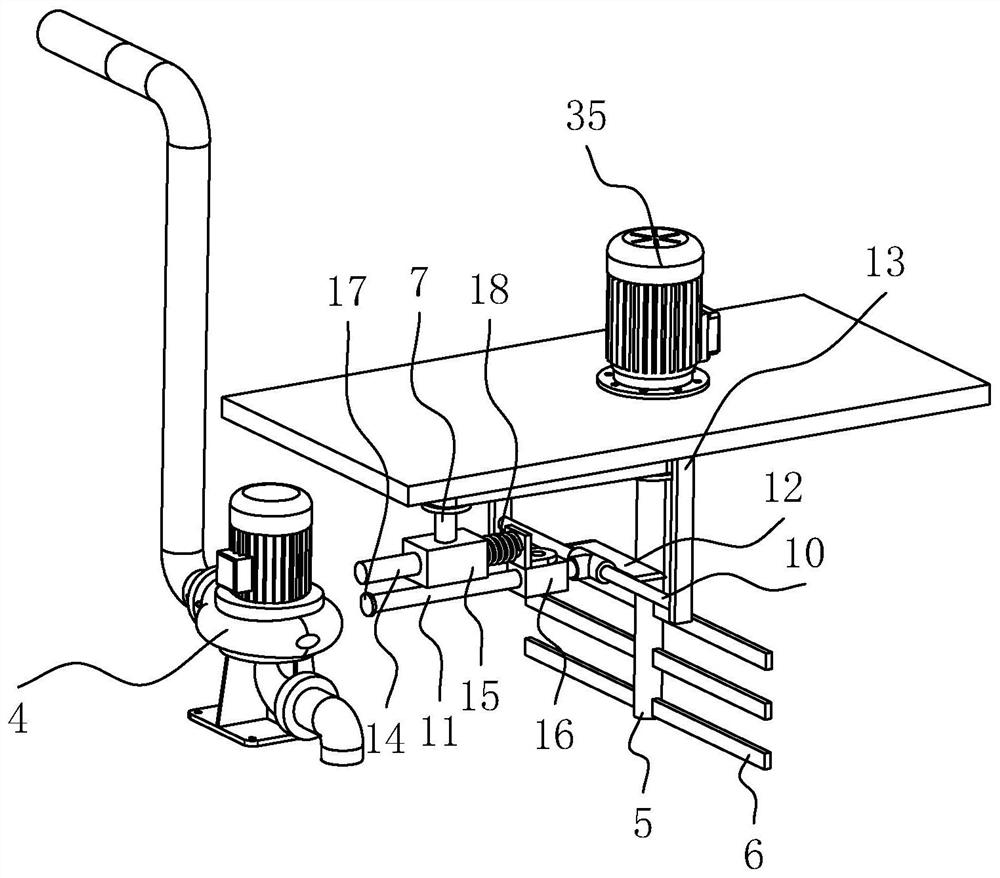

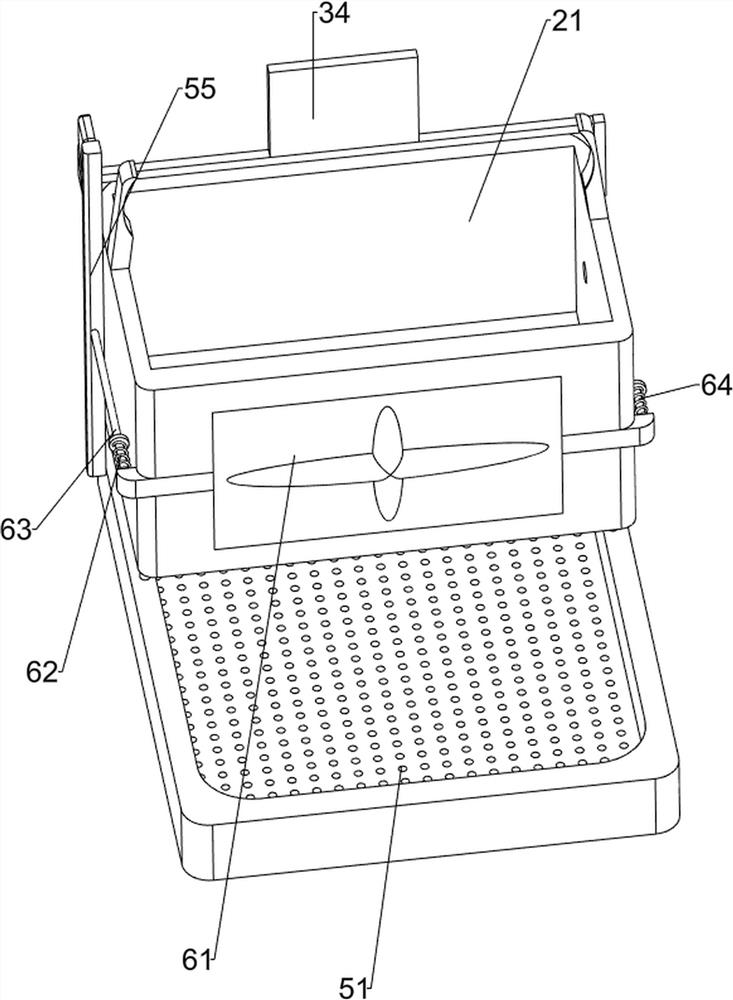

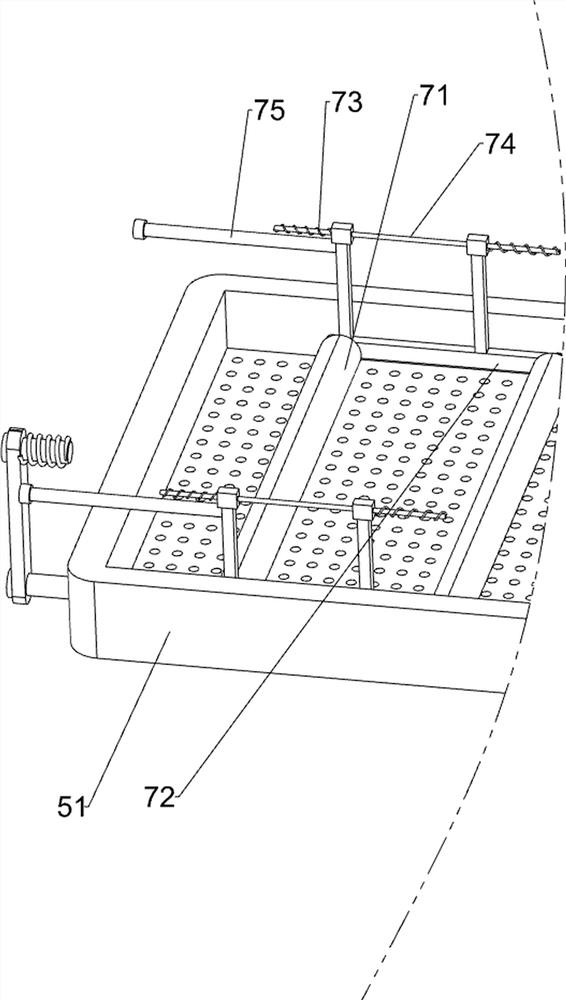

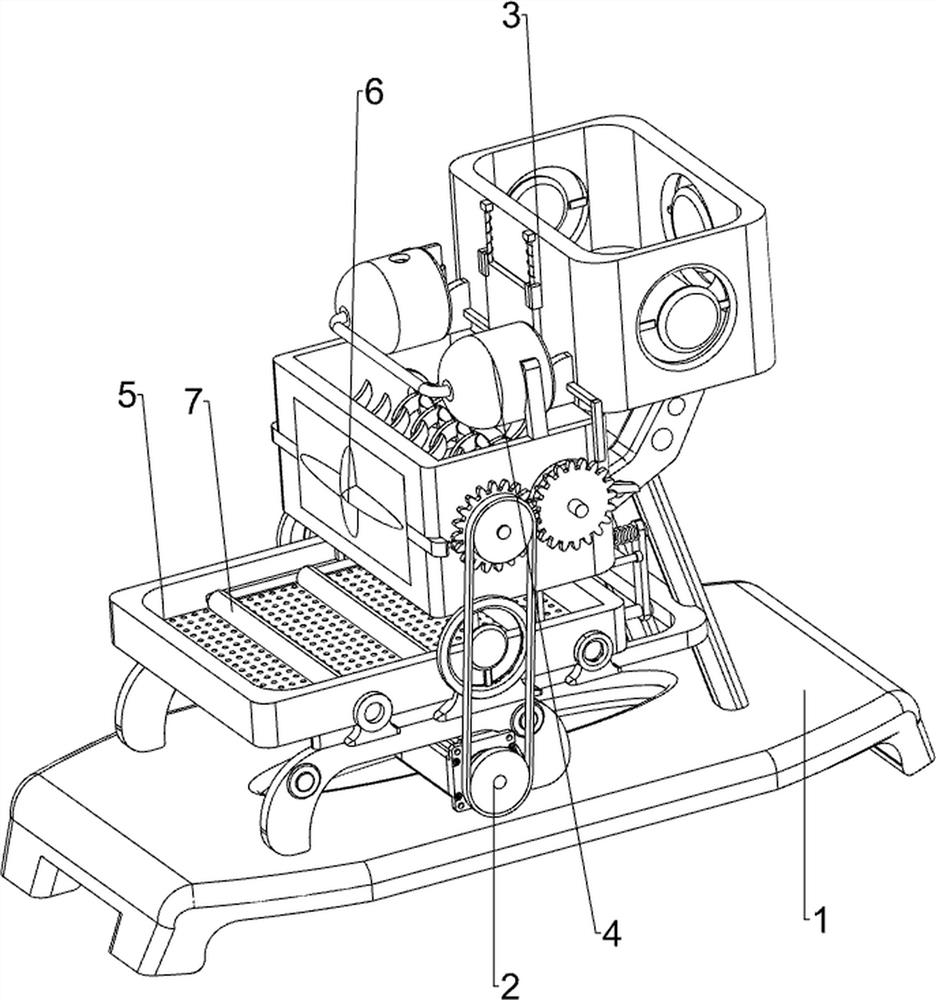

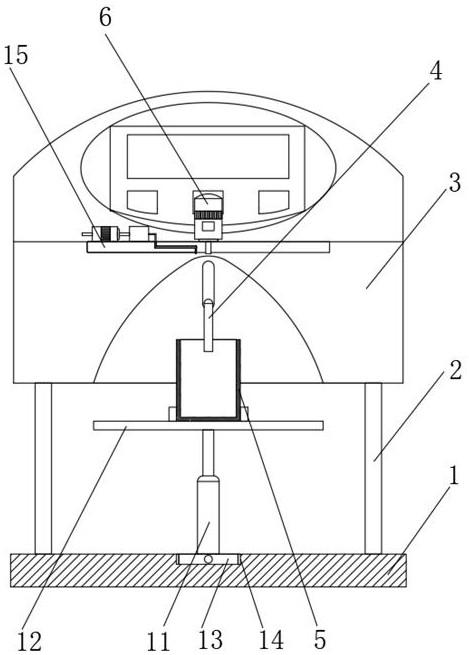

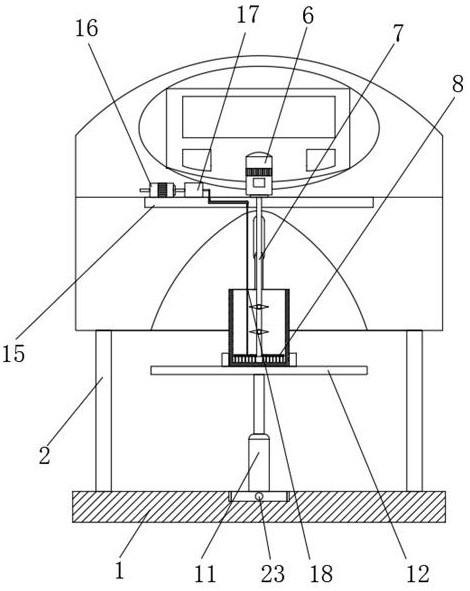

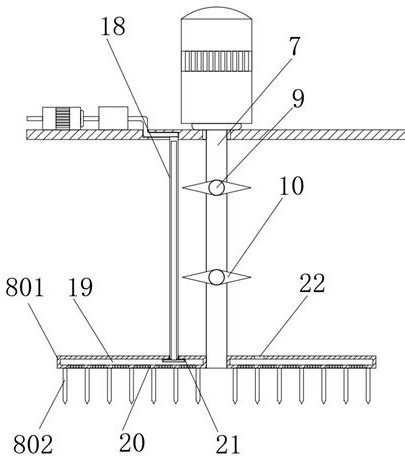

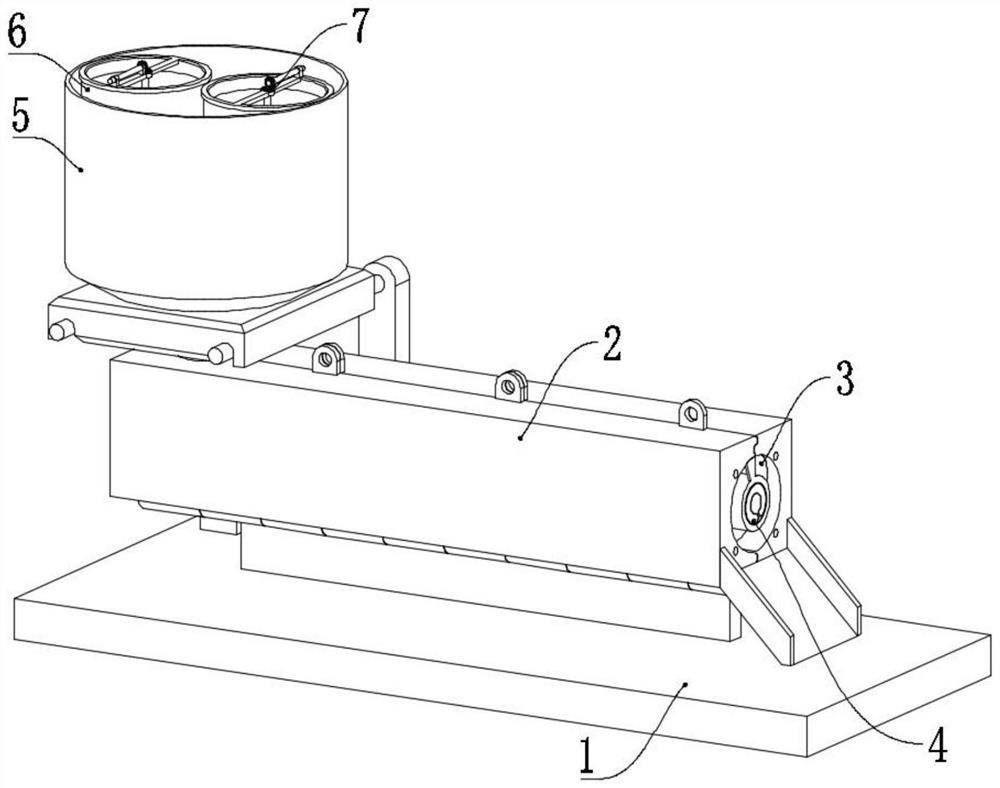

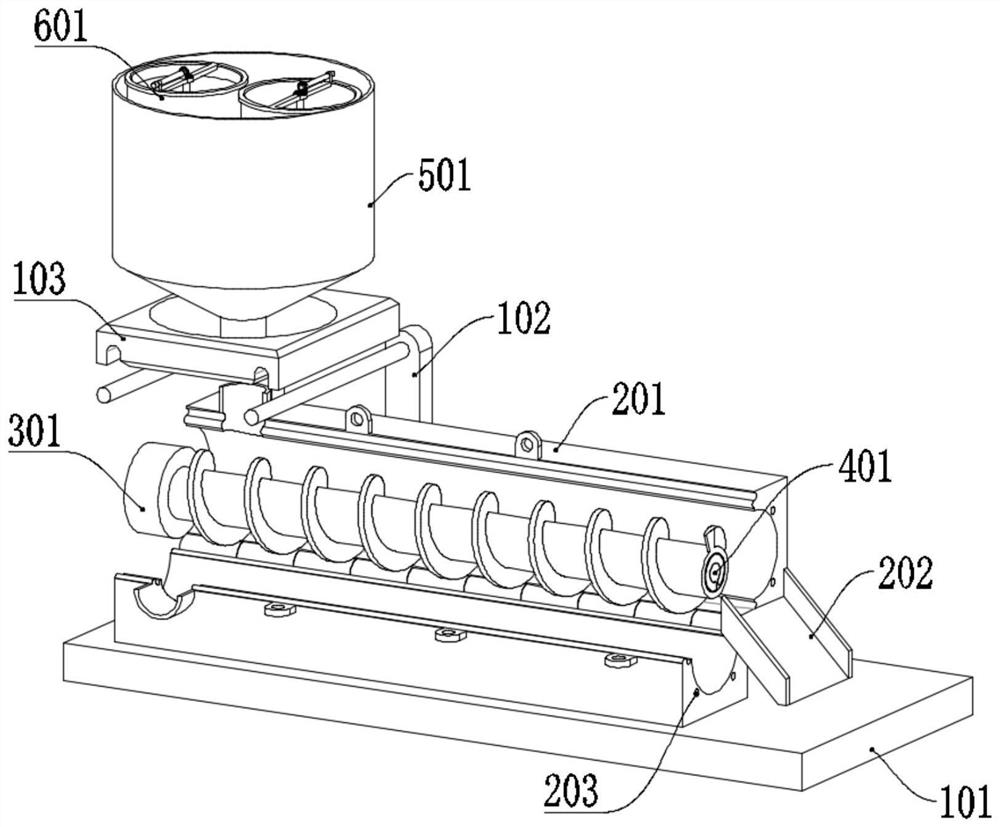

Soil remediation agent spraying device for soil remediation[v]

InactiveCN111229816AAchieving a shattering effectIncrease contact areaSoil lifting machinesTransportation and packagingSoil scienceSoil remediation

The invention discloses a soil remediation agent spraying device for soil remediation. The device comprises a shell, a smashing mechanism is fixedly connected to the back face of the inner wall of theshell, a spraying mechanism is fixedly connected to the front face of the smashing mechanism, the smashing mechanism is in transmission connection with the spraying mechanism, a discharging pipe communicated with the spraying mechanism is fixedly connected to the lower portion of the spraying mechanism, and a driving mechanism is fixedly connected to the bottom end of the front face of the smashing mechanism. The invention relates to the field of garden cultivation. According to the soil remediation agent spraying device for soil remediation, the crushing effect on a solid soil remediation agent is achieved through the crushing mechanism; the problem of caking caused by long-time stacking, extrusion and the like is avoided, in the real-time proportioning process, the powder is crushed into powder, the contact area between the powder and a solvent in unit mass is increased, dissolution is more complete, the dissolution effect is better, and blockage is not likely to be caused during spraying. The problem that an existing spraying device is not ideal in solid-liquid repairing agent mixing effect is solved.

Owner:苏州晨霞美合智能科技有限公司

Orthopedic gypsum recycling and crushing equipment

InactiveCN114011556AAvoid spillingPlay a dust-proof effectGrain treatmentsGypsum recyclingEnvironmental geology

The invention relates to crushing equipment, in particular to orthopedic gypsum recycling and crushing equipment. The orthopedic gypsum recycling and crushing equipment is good in crushing effect, small in environmental pollution and convenient to use. The orthopedic gypsum recycling and crushing equipment comprises a base and first supporting frames, wherein the first supporting frames are arranged on the two sides of the base; a crushing box which is arranged between the two first supporting frames; first rotating shafts rotationally arranged on the two sides of the crushing box; crushing wheels arranged on the two first rotating shafts; a dustproof mechanism which is arranged on the crushing box; and a crushing mechanism arranged between the crushing box and the two first rotating shafts. A first sliding rod is driven to move downwards through resetting of a first spring, so that a first wedge-shaped block is driven to move downwards, a second wedge-shaped block can clamp the first wedge-shaped block, a large amount of dust can be prevented from being scattered in the gypsum crushing process, and the dustproof effect is achieved.

Owner:杨策

Grinding device for producing medicine for treating gastroesophageal reflux disease of old people

The invention provides a grinding device for producing a medicine for treating the gastroesophageal reflux disease of old people, and relates to the technical field of medical production equipment. A fixing assembly is fixedly mounted at the top of the feeding assembly; a smashing assembly is arranged at the bottom of the feeding assembly, a blocking wheel is installed at the top of the feeding assembly, medicine particles entering the feeding assembly cannot be splashed and popped out of the feeding assembly due to the smashing assembly, the structure in the smashing assembly is of a left-right overturning structure through a transmission assembly, medicine smashing is better, and the medicine particle smashing effect is better. A cooling assembly is arranged at the discharging position of the lower end of the bottom box assembly, the cooling assembly has the effect of dissipating heat of the passing medicine powder, a cooling assembly is also arranged at the discharging position of the lower end of the bottom box assembly, the effect of further cooling the medicine powder is achieved, and the problems that before existing granular medicine is ground, splashing occurs at an inlet of a smashing structure, certain heat is generated during grinding of the medicine, and the medicine powder is wasted are solved. And the quality of medicines in subsequent production is not good.

Owner:中国人民解放军联勤保障部队第九二〇医院

Environment-friendly straw recycling device

ActiveCN113711782ARealize automatic cuttingRealize the effect of automatic rice straw cuttingCuttersProcess engineeringWaste management

The invention relates to a recycling device, in particular to an environment-friendly straw recycling device. The invention provides an environment-friendly straw recycling device which is reliable, simple to operate and convenient. The environment-friendly straw recycling device comprises a base, supporting columns, a discharging box, a smashing box, a first support, a cutting tool, a rotating mechanism, a smashing mechanism and the like, the supporting columns are arranged on the front portion and the rear portion of the left side of the base, the discharging box is arranged between the tops of the two supporting columns, the smashing box is arranged at the bottom of the discharging box, and the first support is arranged in the discharging box; the cutting tool is rotationally arranged at the top of the first support, the rotating mechanism is arranged on the left side of the base, and the smashing mechanism is arranged in the smashing box. According to the device, by arranging the rotating mechanism, the rotating mechanism can drive the cutting tool to rotate, and the effect that the cutting tool rotates to automatically cut rice straw is achieved.

Owner:南京多昇智能科技有限公司

An ink production device

InactiveCN109758933BImprove production efficiencyAchieve uniformityFlow mixersMixing materials pretreatmentProcess engineeringIndustrial engineering

The invention discloses an ink production device. The invention uses a batching tank for batching, and then uses a circulating mixing component to carry out circulating mixing. During the batching process, the previous batch of feed liquid is mixed repeatedly to improve the ink production efficiency. The preparation efficiency can also achieve the uniformity and stability of the mixing; the circulating mixing component can not only realize the mixing, but also grind the particles or flocs in the ink, and use the high-frequency oscillation of the filter to achieve further The crushing effect ensures the uniformity and fineness of the ink; the transfer control tank can control the amount of liquid mixed in the circulation to ensure the synchronization of mixing and batching; there is also a Venturi tube between the crushing filter tank assembly and the transfer control tank, The air inflow pipe of the Venturi tube utilizes the negative pressure of the Venturi tube to realize the inhalation of air, realize the oxidation of part of the material liquid that has not exerted oxidation resistance, ensure that the subsequent ink does not change color, cause color problems, and improve the color of the ink. performance and yield.

Owner:汕尾职业技术学院

Classified storage automatic sealing type garbage can for operating room nursing

PendingCN114803195AImprove space utilizationRealize the sealing effectRefuse receptaclesStructural engineeringMechanical engineering

The automatic sealing type garbage can comprises a main box body, a partition plate is fixed to the inner side of the main box body, a screening box is fixed to the upper end face of the main box body, rotatable cover plates are symmetrically connected to the screening box through columnar shafts, and meanwhile detection probes are symmetrically arranged on the side edges of the cover plates; the detection probe is fixed to the upper end of the inner side of the screening box, and the detection probe is connected with the controller to achieve the regulation and control effect. According to the automatic sealing type garbage can with the classified storage function for operating room nursing, the automatic classification mechanism with the cleaning function is adopted to achieve the classification function on garbage, so that the garbage can be conveniently classified and treated in the later period, and the crushing function on the garbage can be achieved in cooperation with the linked crushing mechanism; therefore, a large gap can be effectively avoided when garbage is stacked, the space utilization rate is improved, the sealing effect can be achieved when the garbage bag is taken out through the automatic sealing mechanism, and therefore the garbage is prevented from falling off.

Owner:申海洋

A powder-spraying three-return dryer lowering hopper

ActiveCN105466203BEasy to controlImprove drying efficiencyDrying solid materialsDrying goods handlingThermal insulationEngineering

The invention discloses a powder spraying three-return dryer unloading hopper. The unloading hopper comprises a hopper body; a feed hopper is arranged at the top end of the hopper body, and is communicated with the hopper body; an impeller distributor is arranged in the connected place of the feed hopper and the hopper body; a heating rod is arranged on the side wall of the hopper body; an embedder is arranged in the hopper body; a material receiving port is formed in the top end of the embedder; a hot air connecting pipe is arranged in the material receiving port; an inner cylinder is arranged below the hot air connecting pipe; a cyclone separator is arranged at the top end; an ultrafine crusher is arranged on the inner cylinder below the cyclone separator; a thermal insulation layer is arranged on the side wall of the embedder; the heating rod is arranged in the thermal insulation layer; a material chamber is formed in the bottom end of the hopper body; a material transmission port is formed in the bottom end of the material chamber; and a conveyor is arranged in the material chamber. The device realizes a preheating effect and a crushing effect of fine particles in the material unloading process, guarantees the unloading progress of wet wood powder materials, prevents the waste, and improves the drying quality of the wet wood powder materials.

Owner:ANHUI DING BEAM BIO ENERGY TECH DEV CO LTD

Mulberry leaf crusher

PendingCN113953069ARealize the collection effectIncrease mobilityGrain treatmentsSpiral bladeStructural engineering

The invention discloses a mulberry leaf crusher. The mulberry leaf crusher comprises a first box body and a crushing unit, a second box body is arranged at the lower end of the front side of the first box body, a feeding port is formed in the middle of the upper side of the first box body, a connecting port is formed between the front side in the first box body and the upper end of the rear side in the second box body, an inclined plate is arranged in the first box body, and the front end of the inclined plate is connected with the connecting port in a matched mode. A cutting unit is arranged at the upper end in the first box body; the crushing unit comprises a rotating shaft, a spiral blade and a power assembly, the side faces of the left end and the right end of the rotating shaft are rotationally connected with the left side and the right side of the interior of the second box body correspondingly, the rotating shaft is driven to rotate under the action of the power assembly, and the spiral blade is driven to rotate through rotation of the rotating shaft; and under the matched connection effect between the outer side of the spiral blade and the front side of the connecting port, the effect of crushing cut mulberry leaves is achieved.

Owner:DONGTAI HONGRI ELECTRONICS +2

A transmission pipeline of a pulverized coal adsorption device

ActiveCN112610802BAchieving a shattering effectImprove efficiencyDispersed particle filtrationPipe elementsThermodynamicsProcess engineering

Owner:淮南矿业集团兴科计量技术服务有限责任公司

Respiratory surgery nasal oxygen cannula smashing and recycling device

PendingCN114074009ARealize the rotation effectAchieving a shattering effectGrain treatmentsPlastic recyclingRespiratory surgeryBiomedical engineering

The invention relates to a recycling device, in particular to a respiratory surgery nasal oxygen cannula smashing and recycling device. The respiratory surgery nasal oxygen cannula smashing and recycling device can conduct smashing automatically, reduces the transportation cost and is easy to operate. A respiratory surgery nasal oxygen cannula smashing and recycling device comprises a bottom plate and a rotating mechanism arranged on the bottom plate; a smashing barrel arranged on the rotating mechanism; a smashing mechanism arranged on the smashing barrel; a first blade arranged on the smashing mechanism; and a buffering mechanism arranged on the rotating mechanism. A second supporting frame swings forwards, so that a first fixing sleeve swings forwards, the smashing barrel is driven to swing forwards, the smashing mechanism is driven to swing forwards, the first blade swings forwards, a nasal oxygen cannula can make contact with the first blade and the smashing mechanism, and a rotating effect can be achieved.

Owner:杨红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Soil remediation agent spraying device for soil remediation[v] Soil remediation agent spraying device for soil remediation[v]](https://images-eureka.patsnap.com/patent_img/b445a3c1-41ff-4469-a0f8-89724b59da13/HDA0002386899850000011.png)

![Soil remediation agent spraying device for soil remediation[v] Soil remediation agent spraying device for soil remediation[v]](https://images-eureka.patsnap.com/patent_img/b445a3c1-41ff-4469-a0f8-89724b59da13/HDA0002386899850000012.png)

![Soil remediation agent spraying device for soil remediation[v] Soil remediation agent spraying device for soil remediation[v]](https://images-eureka.patsnap.com/patent_img/b445a3c1-41ff-4469-a0f8-89724b59da13/HDA0002386899850000021.png)