An ink production device

A production device and ink technology, applied in the field of ink, can solve the problems of affecting performance, different ink colors, non-uniformity, etc., to ensure uniformity and detail, achieve uniformity and stability, and improve performance and pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

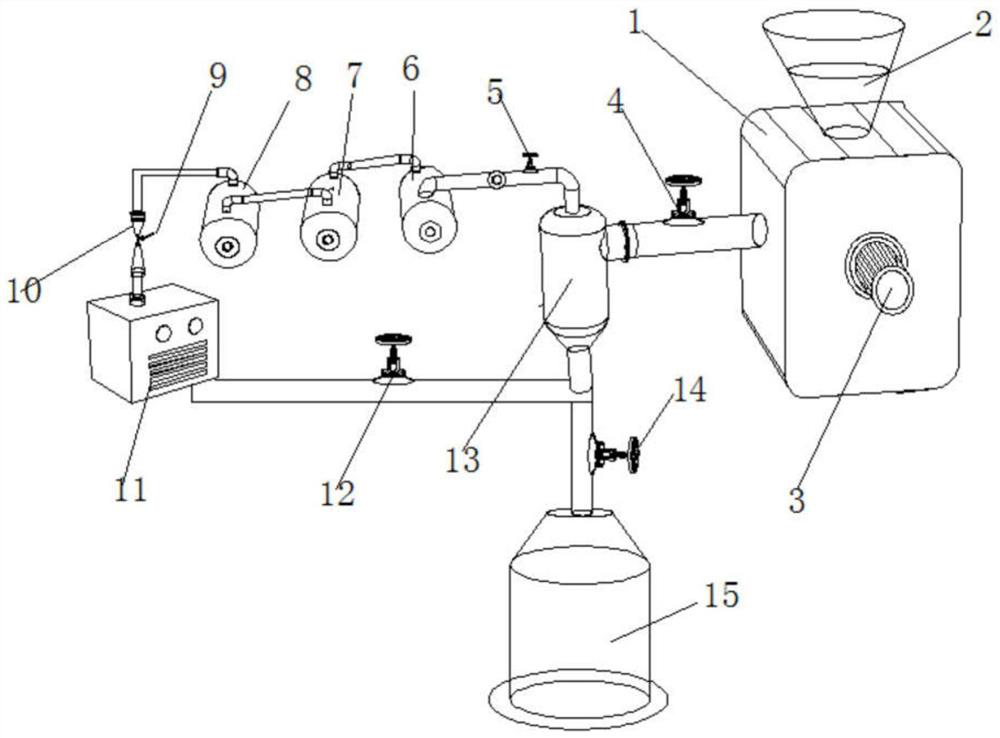

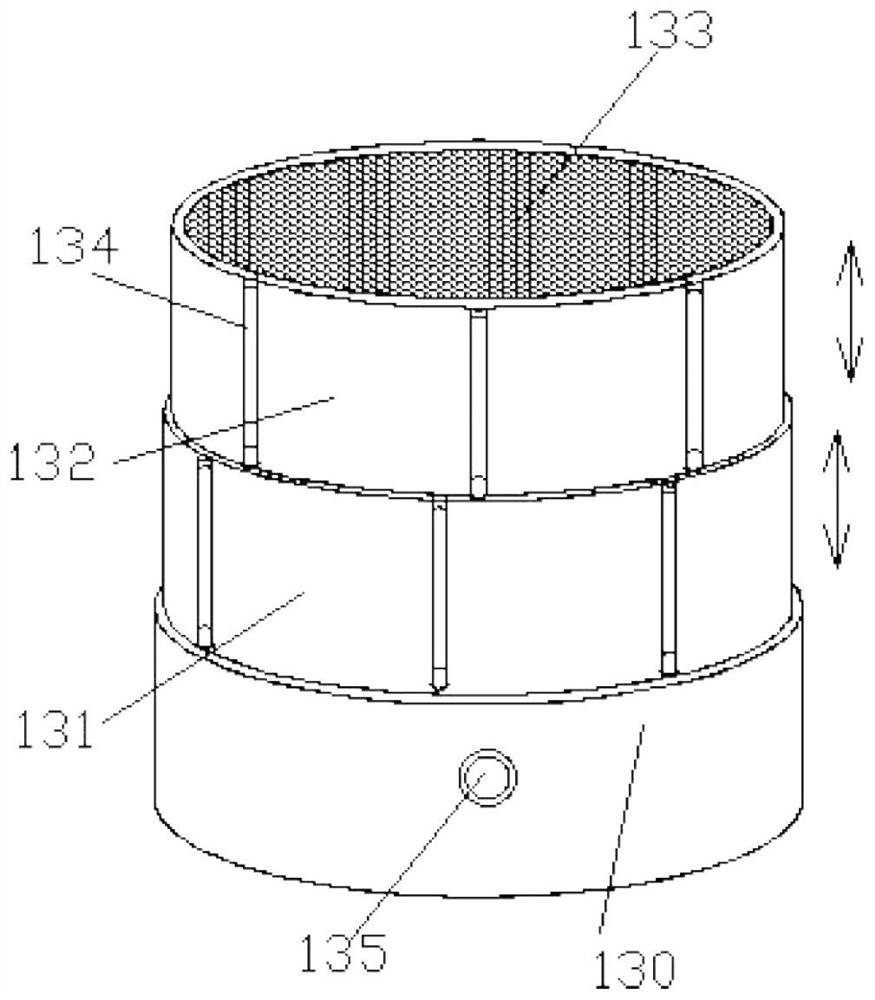

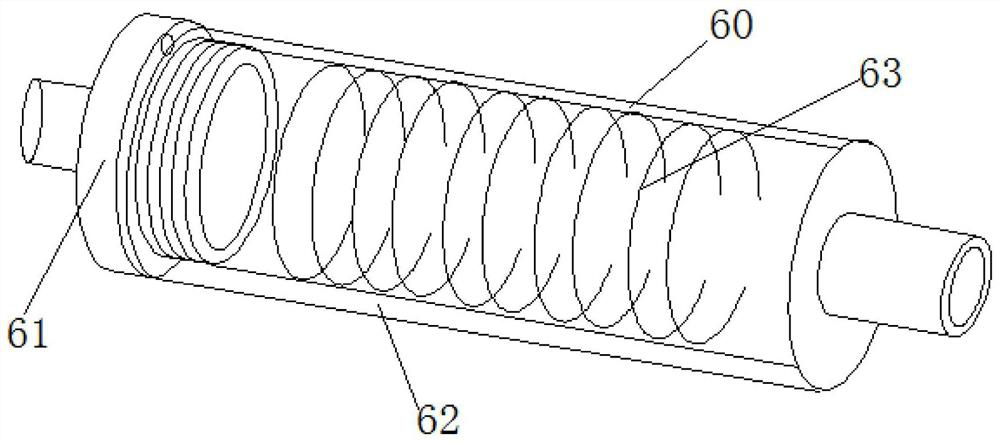

[0031] See Figure 1 ~ 4 In the embodiment of the present invention, an ink production device includes a batch tank 1, a circulating mixing assembly, a canned tank 15, and a controller, and the upper end of the material tank 1 is provided with a feed strip 2, the flavor tank The output terminal is connected to the circulating mix assembly, and the canned tube connection is provided on the circulating mix assembly, which is characterized in that the main pipe is provided with a control valve one. 4. The control valve two 14 is provided on the canned pipe;

[0032] When the circulating mixing assembly is circulated by the ink flowing out of the batch tank 1, the controller controls the control valve one and the control valve two all in the closed state; when the circulating mixing operation is completed, the ink is carried out. When the canned operation, the controller controls the control valve two 14 to open and control the control valve one 4 close; when the canned tank 15 dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com