Patents

Literature

64results about How to "Achieve oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for pressurized oxidative coupling of methane to prepare ethylene and its prepn.

InactiveCN1389293AHigh content of active ingredientsNo diluent requiredHydrocarbon by hydrocarbon condensationMetal/metal-oxides/metal-hydroxide catalystsActive componentSpace velocity

The present invention discloses a catalyst for methane oxidative coupling polymerization to prepare ethylene under the condition of pressurization, and said catalyst uses SiO2 as support, and its active component is formed from Mn2O3, Na2WO4 and SnO2, and its active component content is 10 wt%-20 wt%. Under the condition of no dilution gas, 0.6 MPa and high space velocity it can obtain 33.0% of methane conversion rate and 24.1% of C2 hydrocarbon yield.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

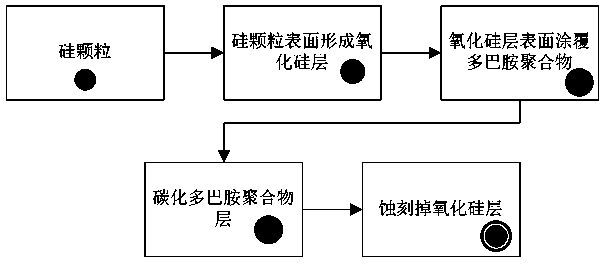

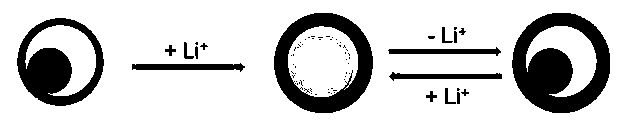

Hollow structure material as well as preparation method and use thereof

InactiveCN103779546AImprove electronic conductivityImprove ionic conductivityMaterial nanotechnologyCell electrodesComposite materialSilicon particle

The invention discloses a hollow structure material. The hollow structure material comprises silicon particles and an amorphous carbon shell, wherein the silicon particles are arranged in the amorphous carbon shell. The hollow structure material has the advantages that a hollow part between a silicon kernel and the carbon shell can be used for volume expansion of silicon; direct contact between the silicon and an electrolyte solution is blocked by a carbon shell membrane of a surface layer, so that a steady solid-state electrolyte solution interface can be formed on the surface of the carbon shell; and amorphous carbon is high in electronic conductivity and high in ionic conductivity, so that lithium ions and electrons can be freely transported through the amorphous carbon. A carbon-coated hollow material is applied to an existing slurry coating method electrode preparation technology and lays a foundation for industrial application. The invention also discloses a preparation method of the hollow structure material. The preparation method does not relate to dangerous gas such as silicane or similar expensive instruments for chemical vapor deposition. The large-scale production manufacturing of the hollow structure material is easily realized. A production condition control requirement is not strict, so that the hollow structure material is high in repeatability.

Owner:NANJING AMPRIUS

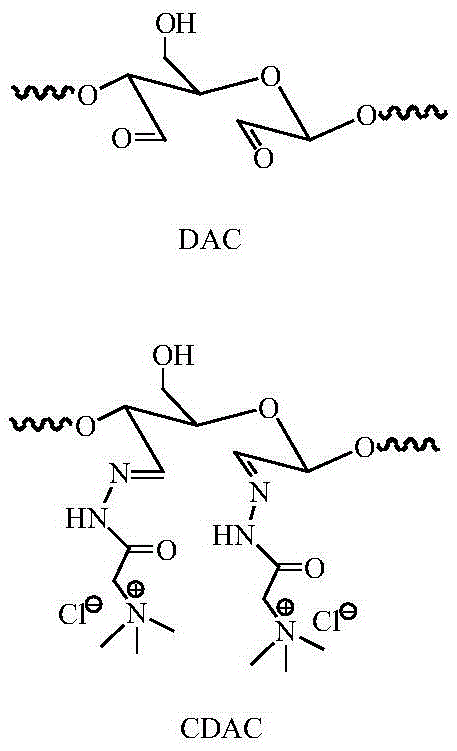

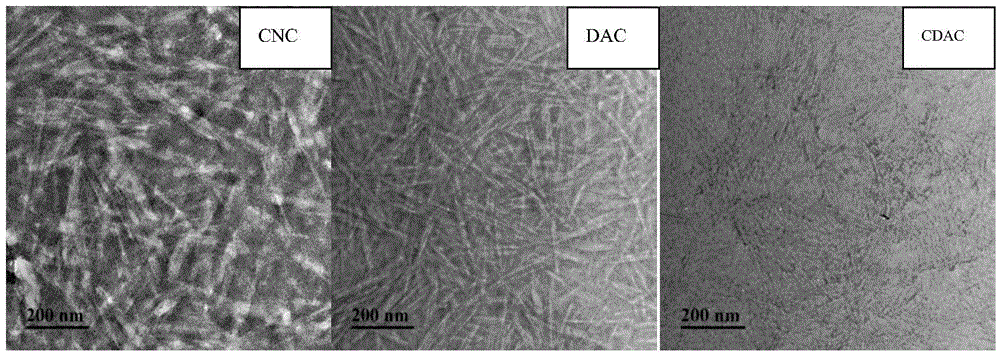

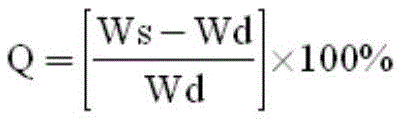

Preparation method of cellulose nanocrystal and chitosan composite membrane

The invention discloses a preparation method of a cellulose nanocrystal and chitosan composite membrane, and belongs to the field of modification of natural polymers. The method comprises the steps that cellulose nanocrystal (CNC) sol is prepared by conducting concentrated sulfuric acid hydrolysis on microcrystalline cellulose; the cellulose nanocrystal (CNC) sol is reacted with sodium periodate to prepare dialdehyde cellulose nanocrystal (DAC) sol and the cellulose nanocrystal (CNC) sol is reacted with a Girard's reagent T to prepare cationic cellulose nanocrystal (CDAC) sol. The CDAC sol is directly mixed with a chitosan-acetic acid solution, vacuum defoamation tape casting is conducted in a polytetrafluoroethylene mold, drying at room temperature is conducted, and the membrane is obtained. Compared with a pure chitosan membrane, the mechanical property of the prepared cellulose nanocrystal and chitosan composite membrane can be obviously improved, and the swelling degree in water is obviously reduced.

Owner:JIANGNAN UNIV

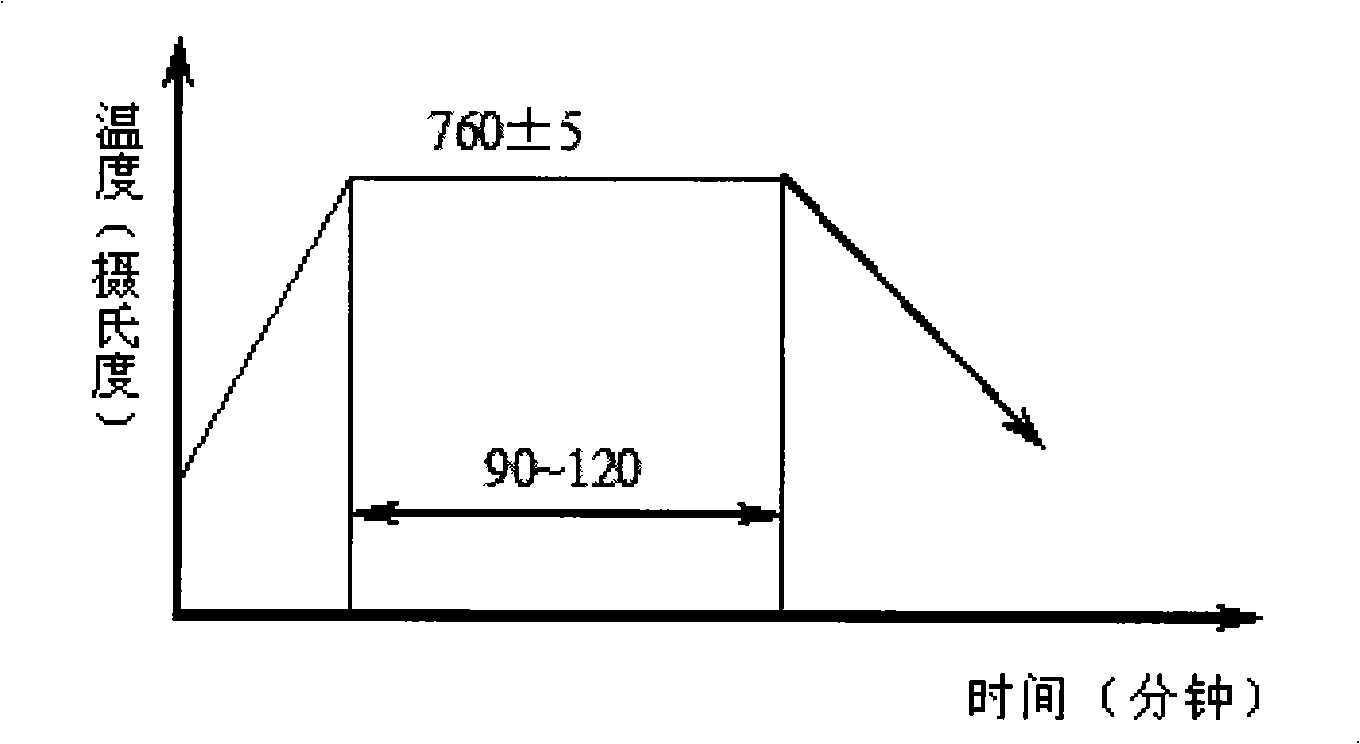

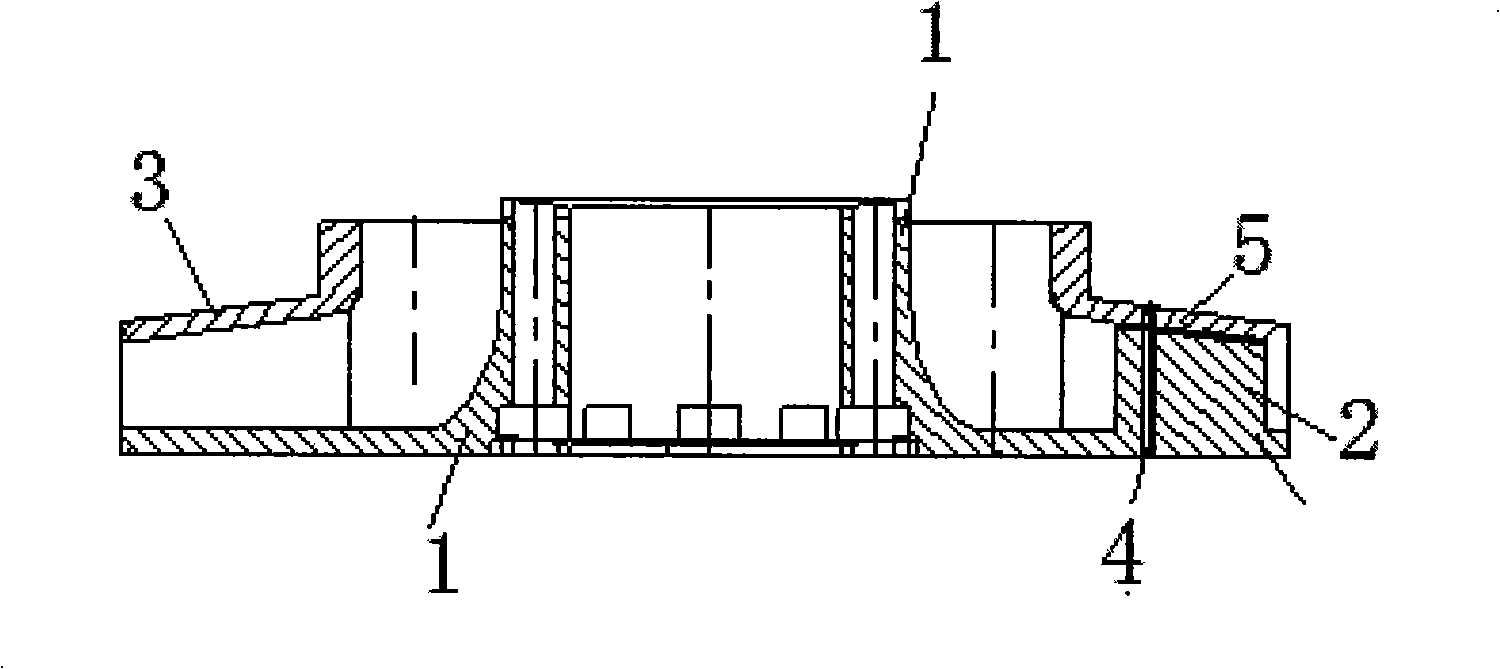

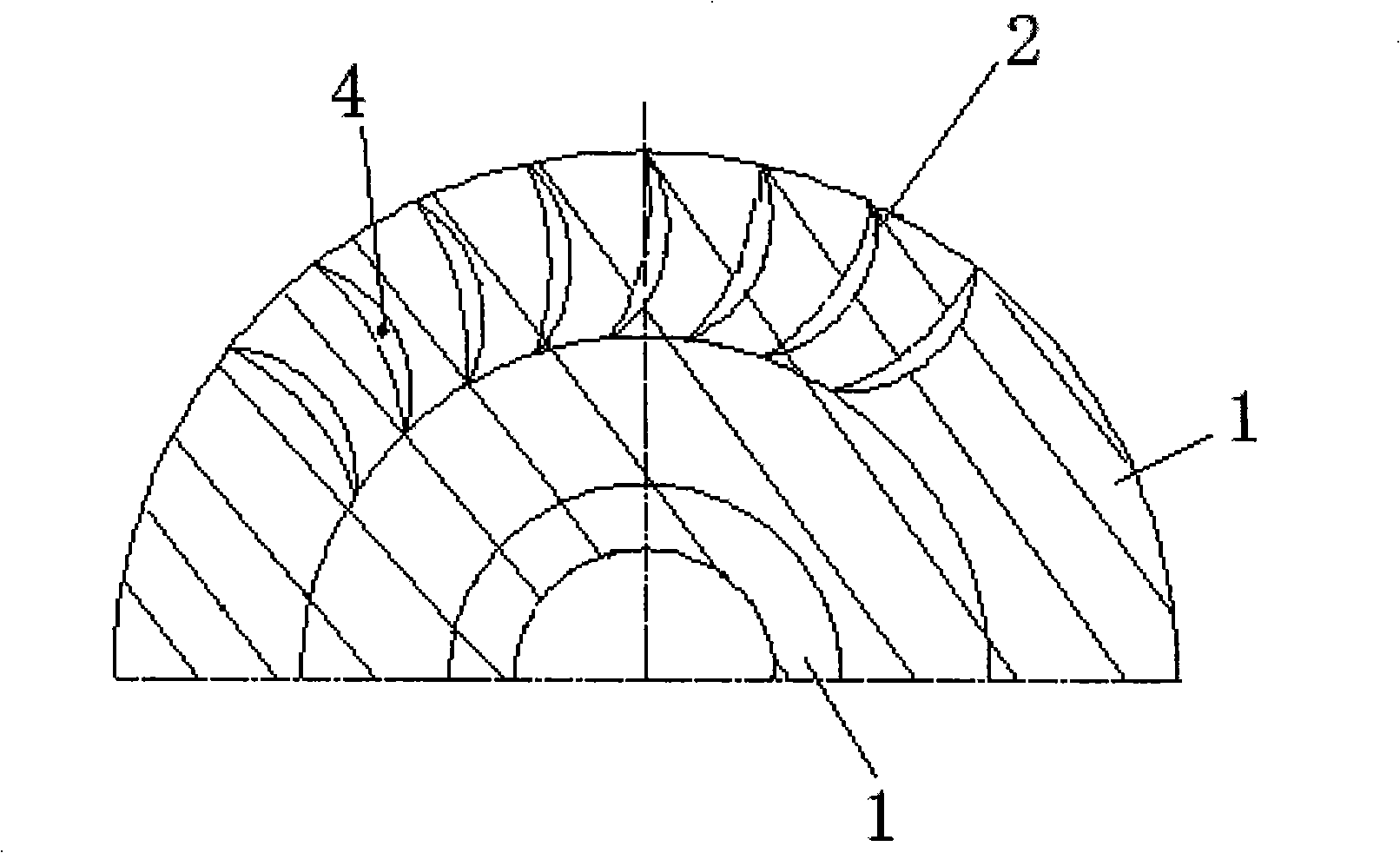

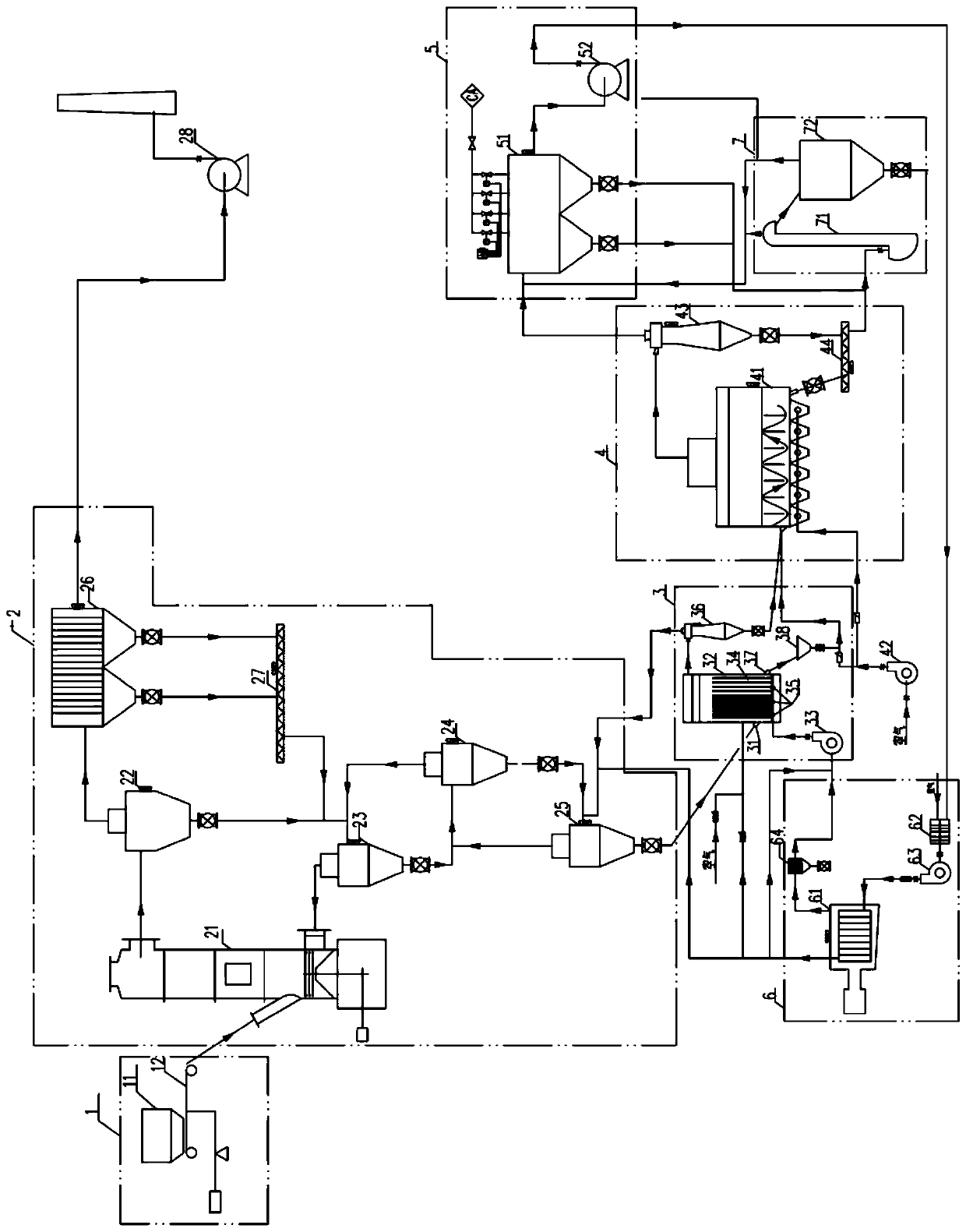

Vacuum brazing method for pump impeller

The invention relates to a vacuum brazing method for a pump impeller, which comprises the following steps: 1) cutting soldering terminals into shapes corresponding to those of the cross sections of blades on an impeller, and punching positioning holes on the 2 to 3 soldering terminals; 2) cleaning a pump impeller to be welded and the soldering terminals, and checking the smoothness of welding surfaces of the blades; 3) preheating the pump impeller to be welded; 4) coating the welding surfaces of the blades to be welded with welding flux, placing the soldering terminals on the welding surfaces of the blades, and then coating the welding flux on the upper surfaces of the soldering terminals; 5) using a pump cover to cover the upper surfaces of the soldering terminals, and using positioning pins to fix the pump cover on the soldering terminals; 6) assembling an upper pressed tyre and a lower pressed tyre together by the pump impeller to be welded; 7) sending an assembly into a heating chamber in a vacuum furnace for heating; and 8) taking out a workpiece after the temperature reduction. The pump impeller brazed by the method has uniform and full welding seams, apparent circular arcs at interfaces, compactly combined welding surfaces, no air holes, high welding strength, and longer service life.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

Method for comprehensively recovering valuable metal from copper tellurium slag

InactiveCN102994766AReduce the impactReduce pollutionProcess efficiency improvementBinary selenium/tellurium compoundsFractional PrecipitationSlag

The invention discloses a method for comprehensively recovering valuable metal from copper tellurium slag. The copper tellurium slag is dissolved by using nitric acid, so that silver, copper and bismuth in the copper tellurium slag are basically dissolved in a solution; tellurium is oxidized into tellurium oxide, thereby entering undissolved slag. Silver, copper and bismuth are separated and recovered via fractional precipitation of the solution; and tellurium is separated and recovered via alkaline leaching of the undissolved slag. The method solves the problems that cost of a conventional process is high, copper recovery rate and tellurium recovery rate are not high, and that silver and bismuth cannot be recovered in the conventional process; influences on the environment of the production process are reduced; a whole process is simple; and pollutions toward the environment is small. The method is simple in the whole production process, low in cost and small pollutions toward the environment, has high comprehensive recovery rate, and realizes complete separation of silver, copper, bismuth and tellurium. The obtained products have high purity; and the recovery rate of silver, copper, bismuth and tellurium is higher than 99%.

Owner:SIHUI CITY HONGMING PRECIOUS METALS

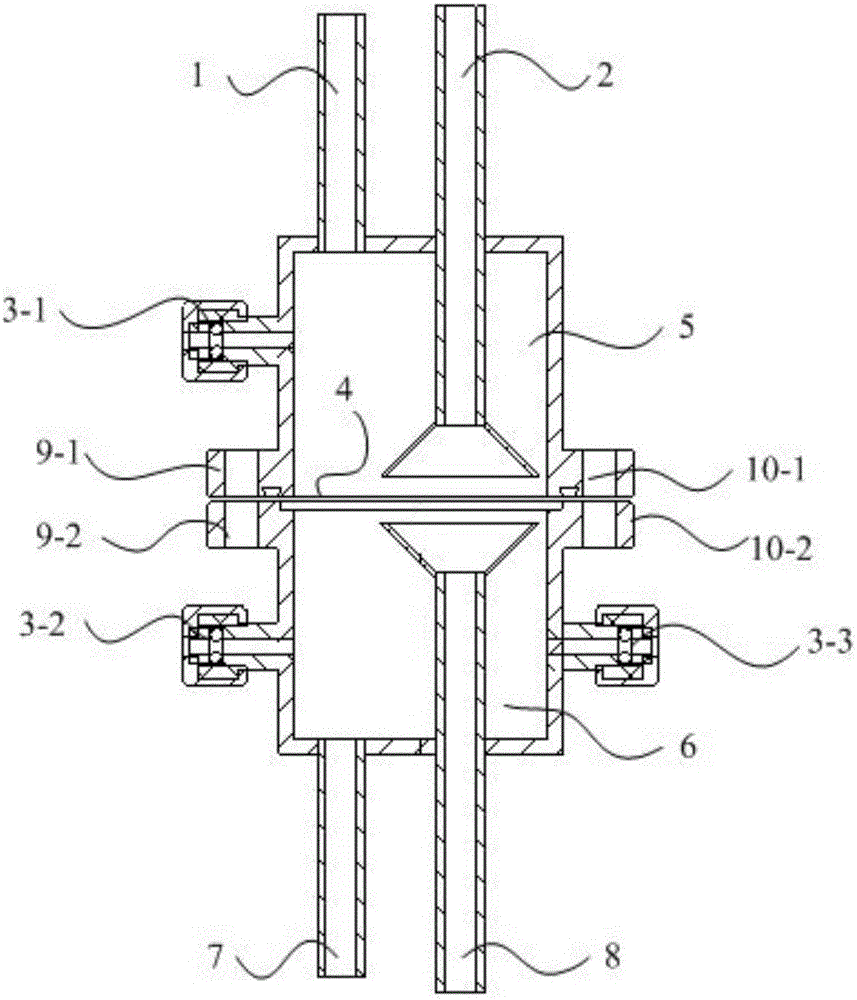

Reactor for gas-solid phase electro-catalytic reaction, and method for eliminating VOCs by using reactor

ActiveCN106732238ASimple structureGood for non-distractionGas treatmentDispersed particle separationElectricityGas solid

The invention provides a reactor for gas-solid phase electro-catalytic reaction, and a method for eliminating VOCs (volatile organic contaminants) by using the reactor. The reactor comprises an anode gas chamber, a cathode gas chamber, an electrocatalytic anode, a diaphragm and an electrocatalytic cathode, wherein both of the electrocatalytic anode and the electrocatalytic cathode are air-permeable; the diaphragm is placed between the electrocatalytic anode and the electrocatalytic cathode; the disphragm, the electrocatalytic anode and the electrocatalytic cathode form an integrated body, so as to form an integrated structure; the anode gas chamber and the cathode gas chamber are independently cavities with through holes; and the integrated structure is placed between the through hole of the anode gas chamber and the through hole of the cathode gas chamber, and covers the through hole of the anode gas chamber and the through hole of the cathode gas chamber. An electrolytic tank can eliminate the indoor VOCs at room temperature, and most of the products are CO2; in addition, the electrolytic tank for eliminating the indoor VOCs is safe, convenient and small in energy consumption, and oxidative degradation of the VOCs can be realized only by 2-V additional direct-current voltage.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

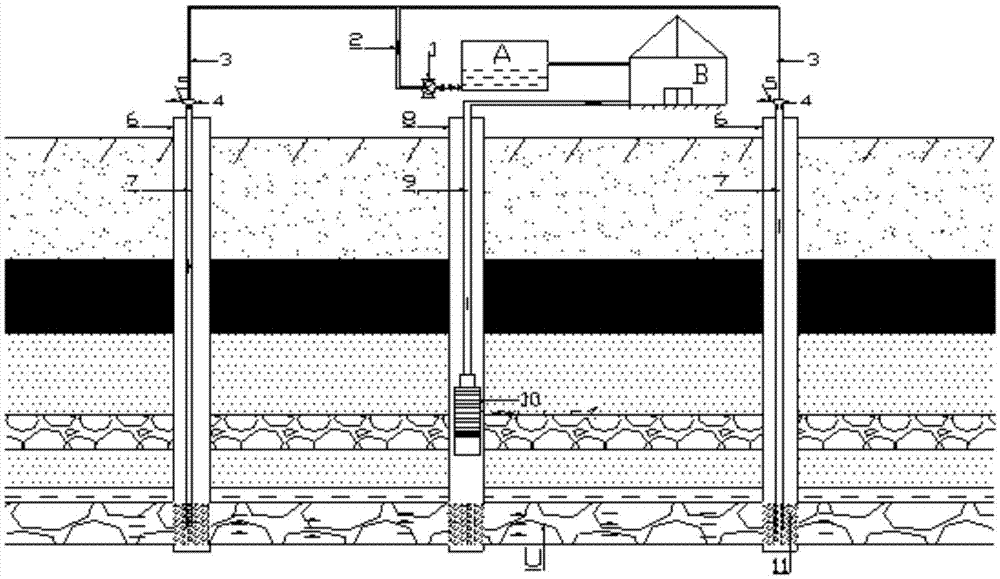

Permeable in-situ leaching uranium mining leaching process for hydrochloric acid modified sand layer

ActiveCN106930738AStable controlImprove the ability of pumping and injecting fluidFluid removalPregnant leach solutionResource quality

The invention belongs to the technical field of in-situ leaching uranium mining and particularly relates to a permeable in-situ leaching uranium mining leaching process for a hydrochloric acid modified sand layer. The purpose is to solve the technical problem that traditional mining processes of sulfuric acid in-situ leaching and alkaline in-situ leaching cannot meet mining requirements under the condition of decreasing of the uranium resource quality. In practical use, the leaching process is stable in control and compact in joining, liquid extracting and injecting capacity is improved, oxidation of uranium minerals is accelerated and achieved, uranium-containing leachate is obtained, and the condition of production concentration treatment in later period can be met. In the leaching mining process at a Shihongtan 1# mining area, by adopting the leaching process, the liquid injecting capacity is increased from 108 m<3> / h to 132 m<3> / h; oxygen is dissolved effectively and injected into the ore-containing sand layer, the oxygen content in the leachate is 18 mg / l, the average peak value of the uranium concentration of the leachate is 27.8 mg / l, and the uranium concentration peak value of a single well is 64 mg / l; and accordingly the effects that the uranium resource of the mining area is exploited, and the recovery rate of the uranium resource of the mining area reaches 76.5% are achieved.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

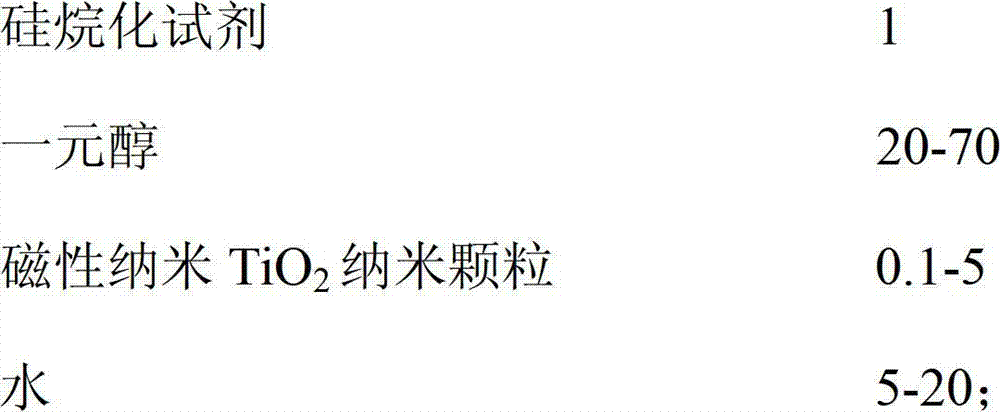

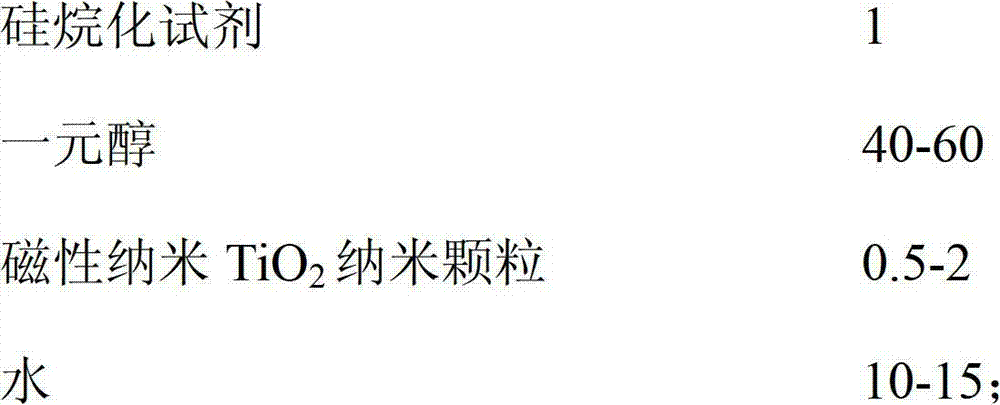

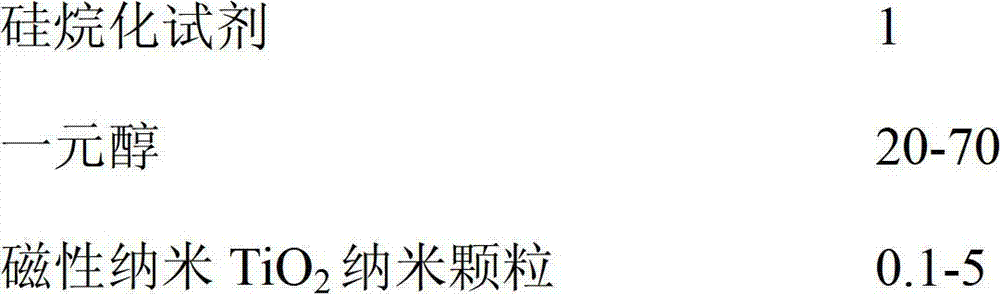

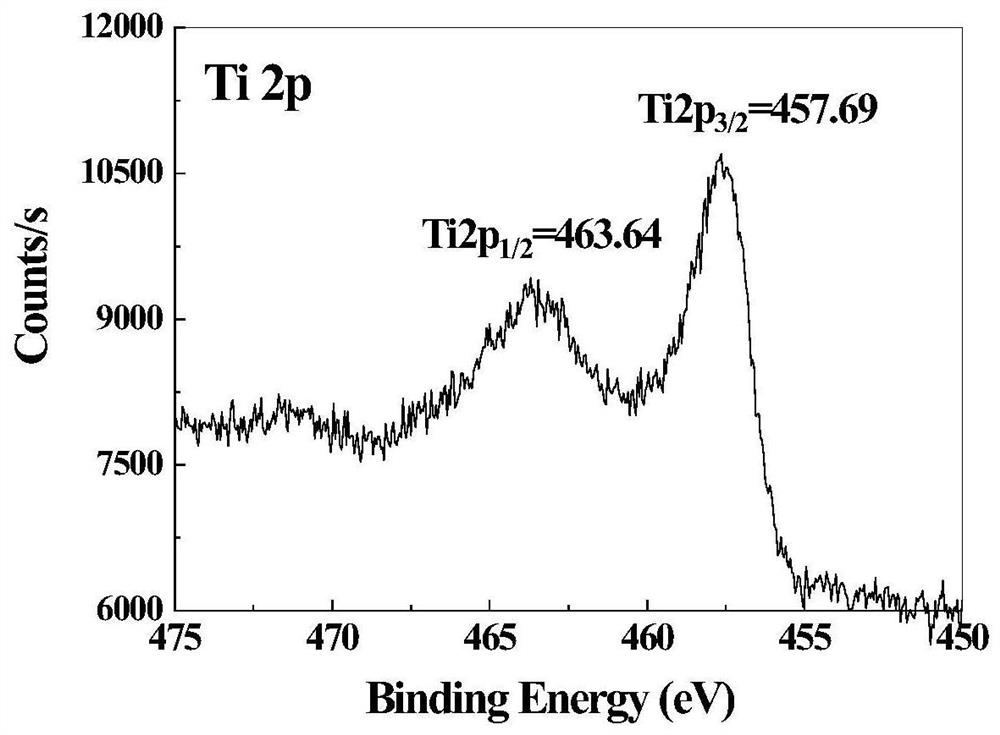

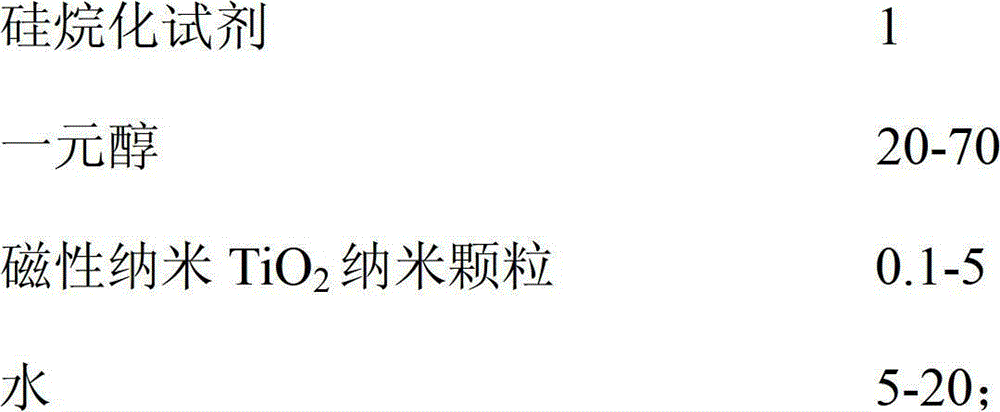

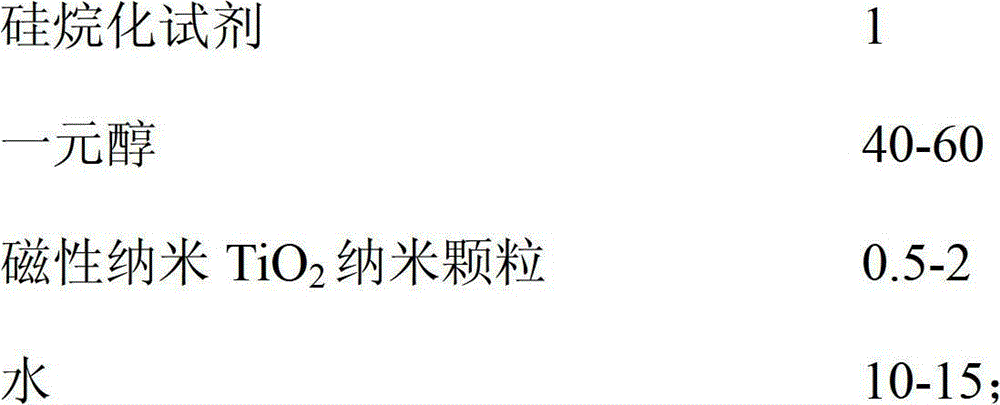

Magnetic light-enzyme composite catalyst and preparation method thereof

InactiveCN102728410AAchieve deliverySteps to lift the transfer rate limitOrganic-compounds/hydrides/coordination-complexes catalystsSurface functionIon

The invention relates to a magnetic light-enzyme composite catalyst and a preparation method thereof. The magnetic light-enzyme composite catalyst is laccase immobilized on magnetic nano TiO2 processed by surface functionalization, particularly laccase immobilized on magnetic nano TiO2 particles modified by copper ion chelating. According to the invention, the magnetic light-enzyme composite catalyst provided by the invention realizes the transmission of electrons between laccase and TiO2 in the catalytic oxidation process, solves the problems of slow speed of receiving electrons by laccase from the substrate and slow combination between photoinduced electrons and O2; by using the synergism of enzyme catalysis and photocatalysis to raise catalytic oxidation efficiency, the oxidation of substrates with high oxidation-reduction potential and macromolecule substrates can be realized; the catalyst has superparamagnetism, can be conveniently and effectively controlled and separated under the effect of external magnetic field, the preparation process is simple, and the catalyst is suitable for large scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

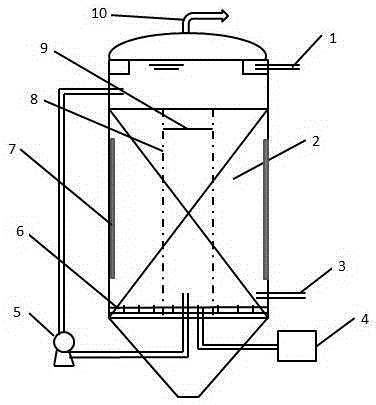

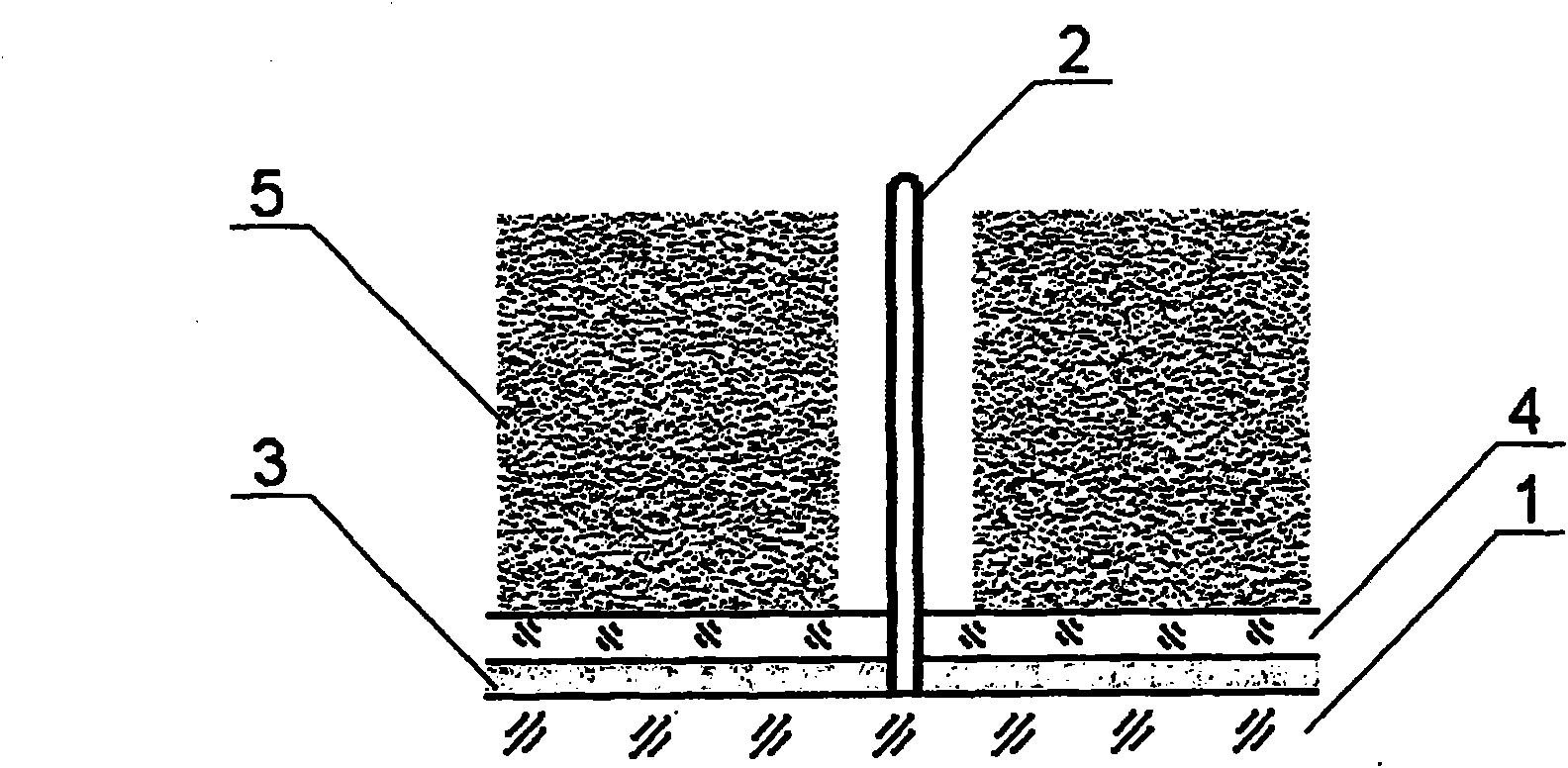

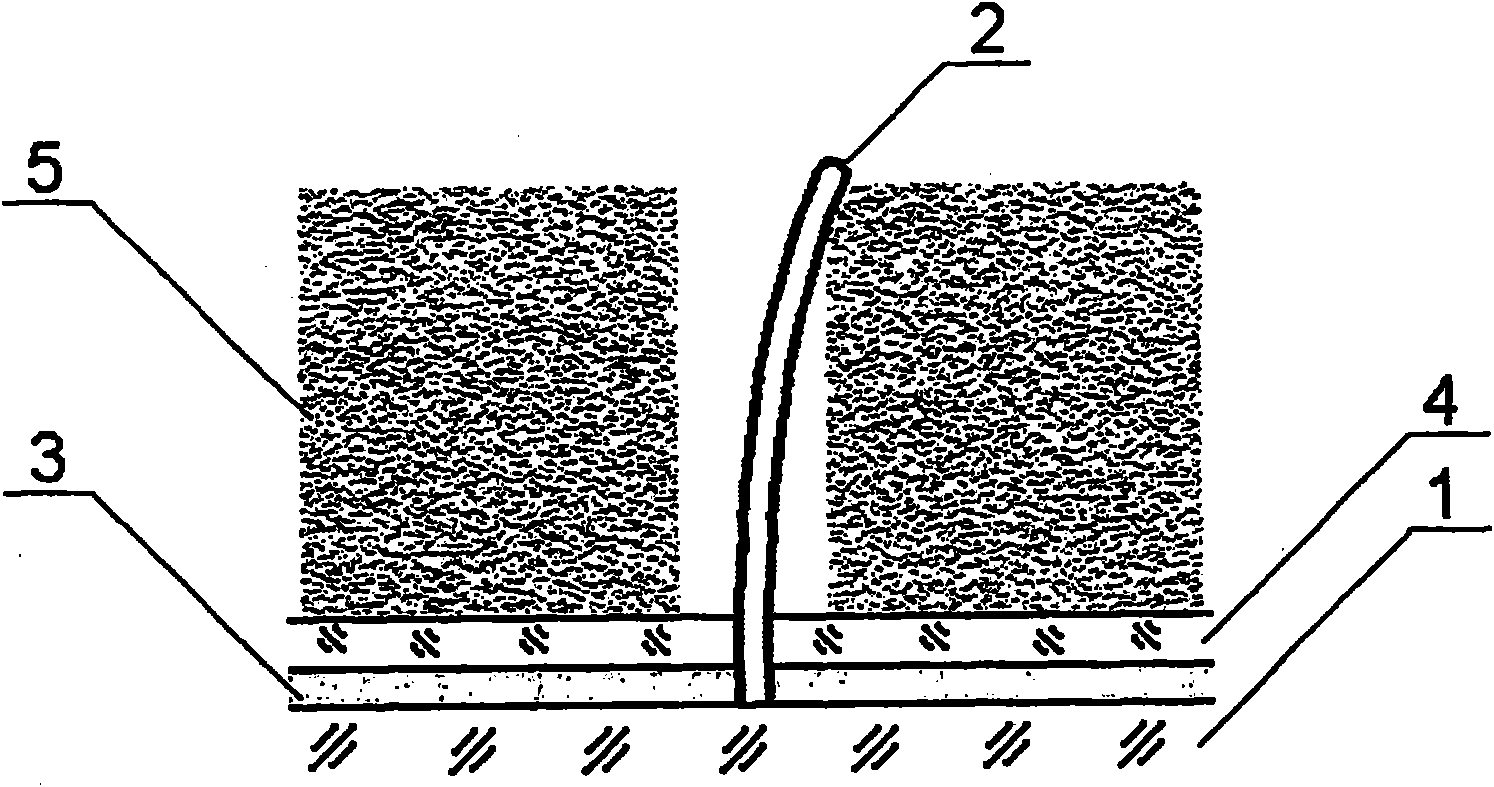

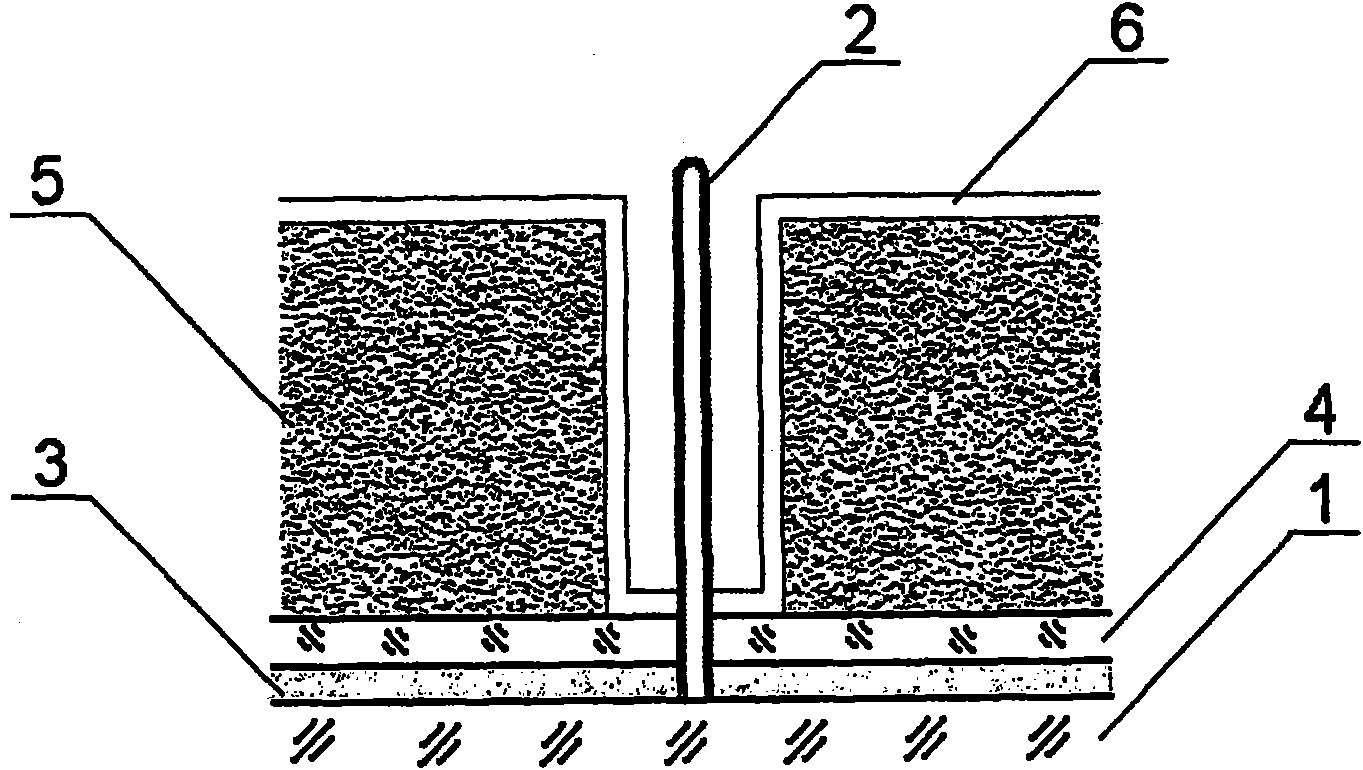

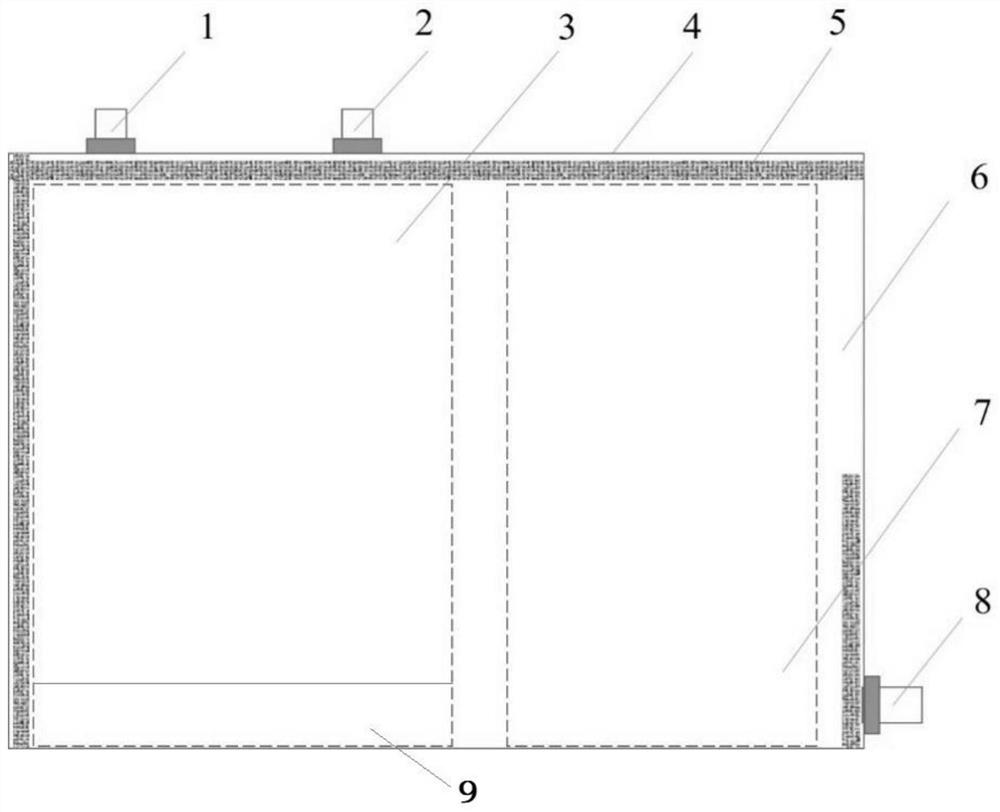

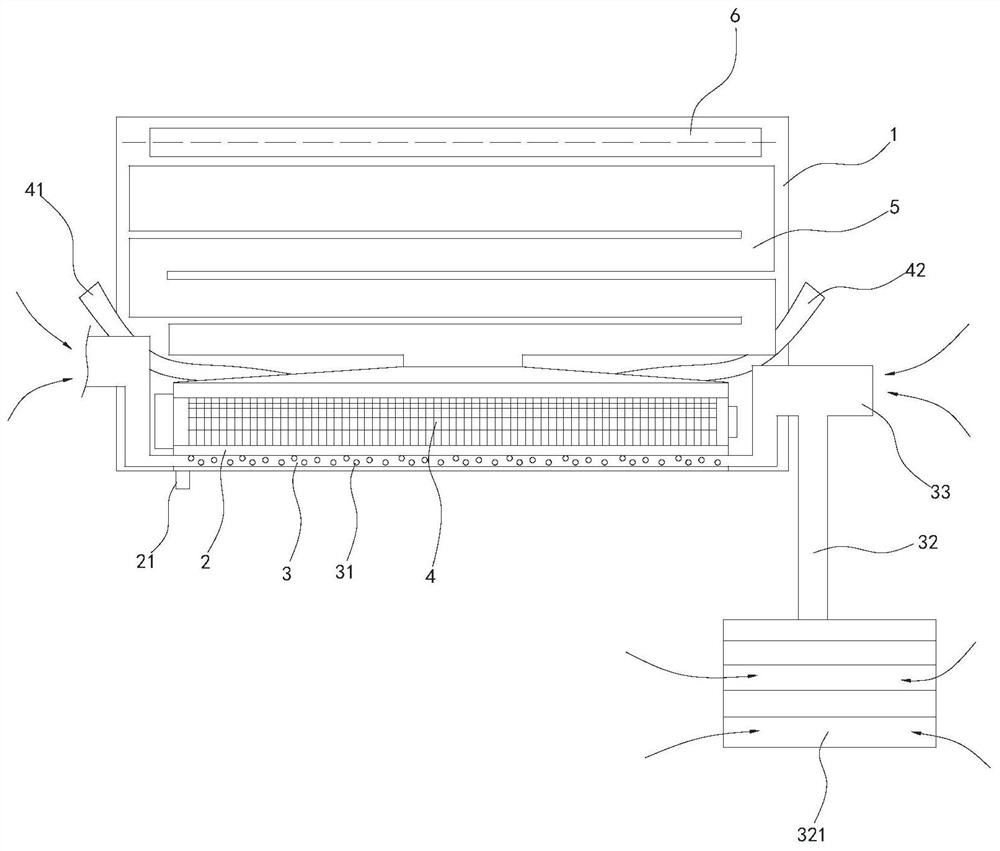

Oxidation and reduction double-effect micro electrolysis combined reactor and application thereof

InactiveCN105417643AAchieve oxidationAchieve restorationWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment apparatusElectrolysisPhysical chemistry

The invention provides a double-effect micro electrolysis combined reactor which comprises a cylinder body and special iron carbon catalytic packing. The center of the cylinder is provided with a channel baffle, the channel baffle is a cylindrical baffle provided with sieve holes, and the special iron carbon catalytic packing is arranged in a packing area formed between the channel baffle and the cylinder body in a filled mode; the channel baffle is internally provided with a circulating pipe, and the circulating pipe is connected with the upper end of the cylinder body through a pump; the bottom of the packing area is provided with a microporous aeration plate, and the microporous aeration plate is connected with an aeration generator; the bottom end of the cylinder body is provided with a water inlet, and the top of the cylinder body is provided with a water outlet; the water inlet is higher than the bottom of the packing area, and the water outlet is higher than the whole circulating pipe. By means of the oxidation and reduction double-effect micro electrolysis combined reactor, an oxidation and reduction integrated reaction can be achieved.

Owner:NANJING GW ENVIRONMENT ENG

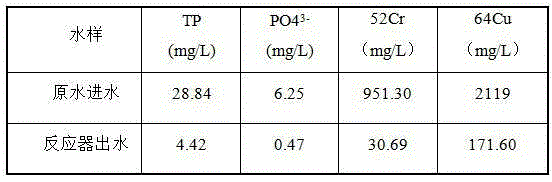

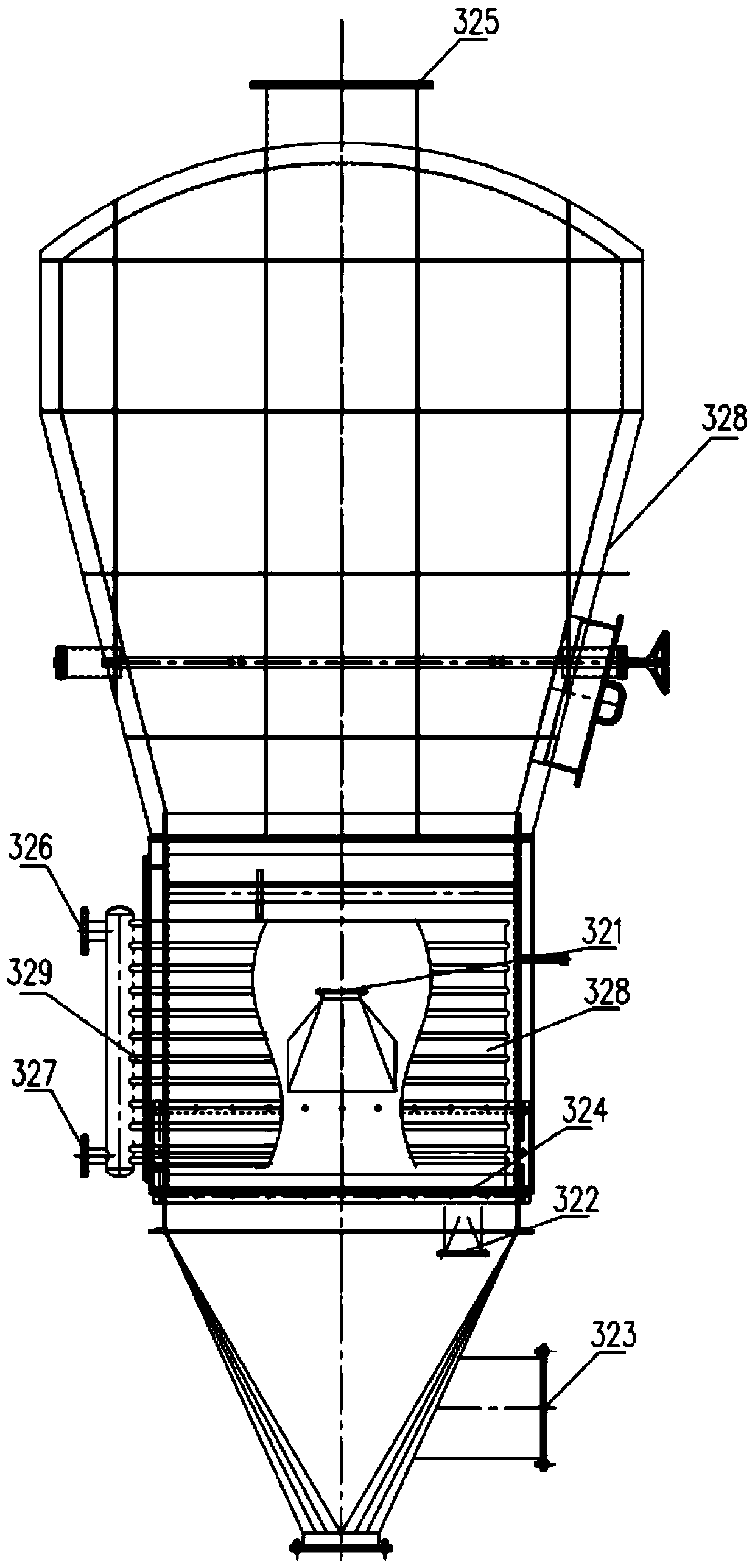

Device and method for producing type II anhydrous gypsum from desulfurized gypsum

PendingCN110803877AImprove resource utilizationReduce water consumptionCalcium/strontium/barium sulfatesSulfatePhysical chemistry

The invention provides a device and a method for producing type II anhydrous gypsum from desulfurized gypsum. The device comprises a drying unit, a calcining unit and a product collecting unit which are sequentially connected, wherein the drying unit comprises a crushing device and at least one-stage drying device, and the calcining unit comprises a fluidized calcining device. According to the device disclosed by the invention, the desulfurized gypsum is accurately converted into the II-type anhydrous gypsum through the combination of drying and calcining processes, oxidation of calcium sulfite and decomposition of organic matters in the desulfurized gypsum can be realized, the impurity removal rate reaches more than 99%, and the influence of harmful impurities on gypsum products is greatly reduced; according to the method, when super sulfate cement is taken as a target product, the lowest limit value of chloride ions in desulfurized gypsum raw materials is increased, and the pretreated water consumption and secondary water pollution are indirectly reduced; according to the invention, the comprehensive utilization efficiency of the desulfurized gypsum is improved, the super sulfatecement is further compounded, the product has stable performance and high strength, and the application way of the desulfurized gypsum is expanded.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

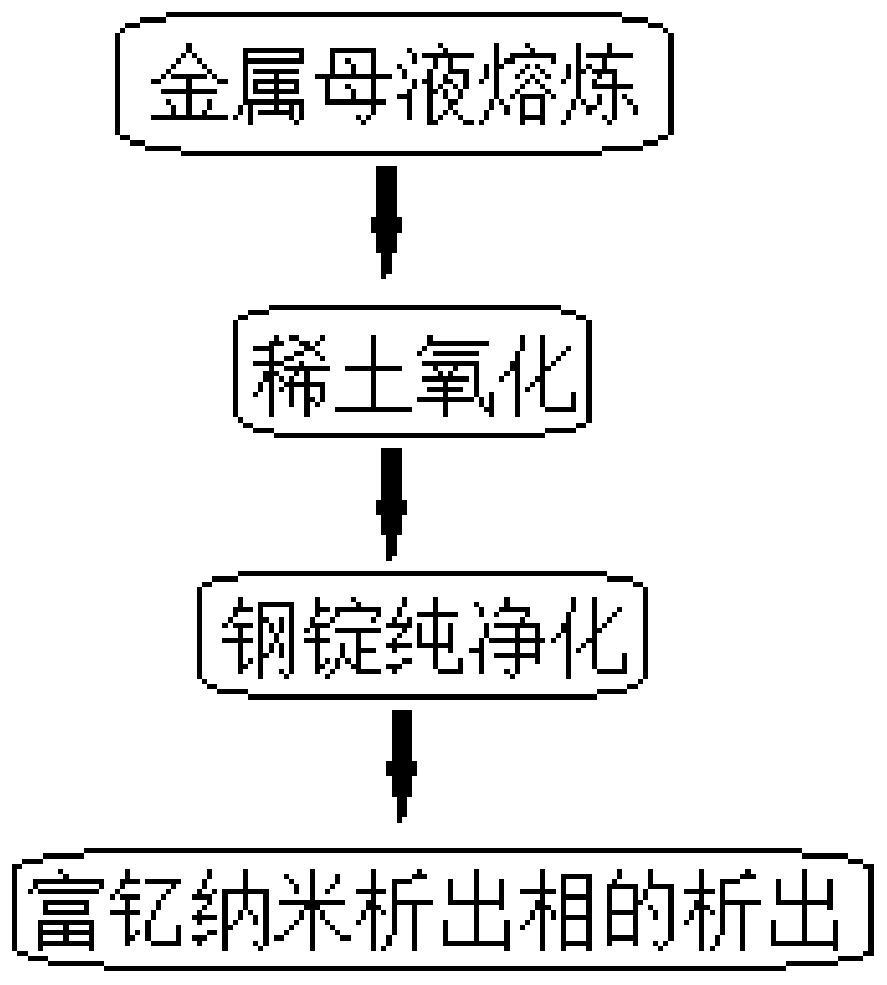

Rare earth steel and preparation method thereof

ActiveCN111705264AImprove high temperature mechanical propertiesSimple processYttriumOxidizing agent

The invention discloses rare earth steel and a preparation method of the rare earth steel. The rare earth steel comprises the following components of, in percentage by weight, 0.01%-0.05% of C, 0.15%-0.3% of Si, 0.4%-0.5% of Mn, 8%-10% of Cr, 2%-2.5% of W, 0.2%-0.25% of V, 0.05%-0.1% of Ta, 0.001%-0.01% of Zr, 0.3%-0.6% of Y<2>O<3> and the balance Fe; during preparation, Cr, W, Ta, Fe, Si, Mn andY are smelted into metal mother liquor, then mixed gas of CO<2> and Ar serving as an oxidizing agent is introduced into the alloy mother liquor, Y is oxidized into Y<2>O<3>, Zr, V and C are added, casting is performed after melting down; electroslag remelting is carried out on a cast ingot in a protective atmosphere, purifying is carried out; austenitizing is carried out on a purified steel ingot,then the steel ingot is subjected to pressure machining to form a steel plate, water cooling is carried out after pressure machining; and heat treatment is carried out on the steel plate obtained through pressure machining, a yttrium nanometer precipitated phase is precipitated from the steel plate, and the rare earth steel is obtained. According to the rare earth steel and the preparation methodof the rare earth steel, RAFM ( Reduced Activation Ferritic / Martensitic ) steel can be produced in a smelting and casting mode, the yield of the RAFM steel can be increased, and meanwhile the high-temperature mechanical property of the RAFM steel is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

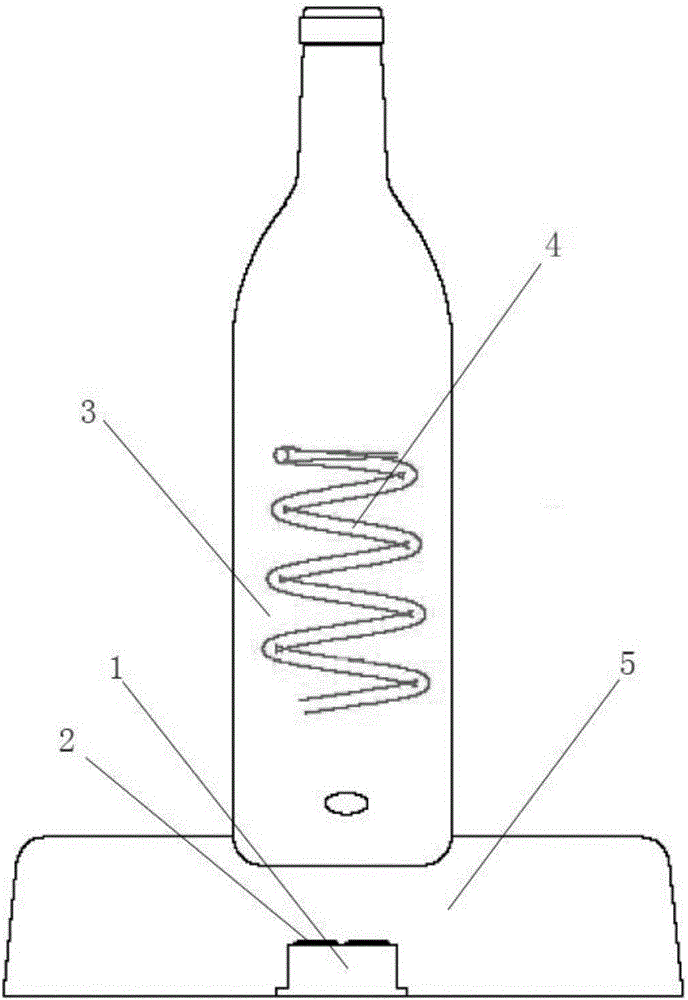

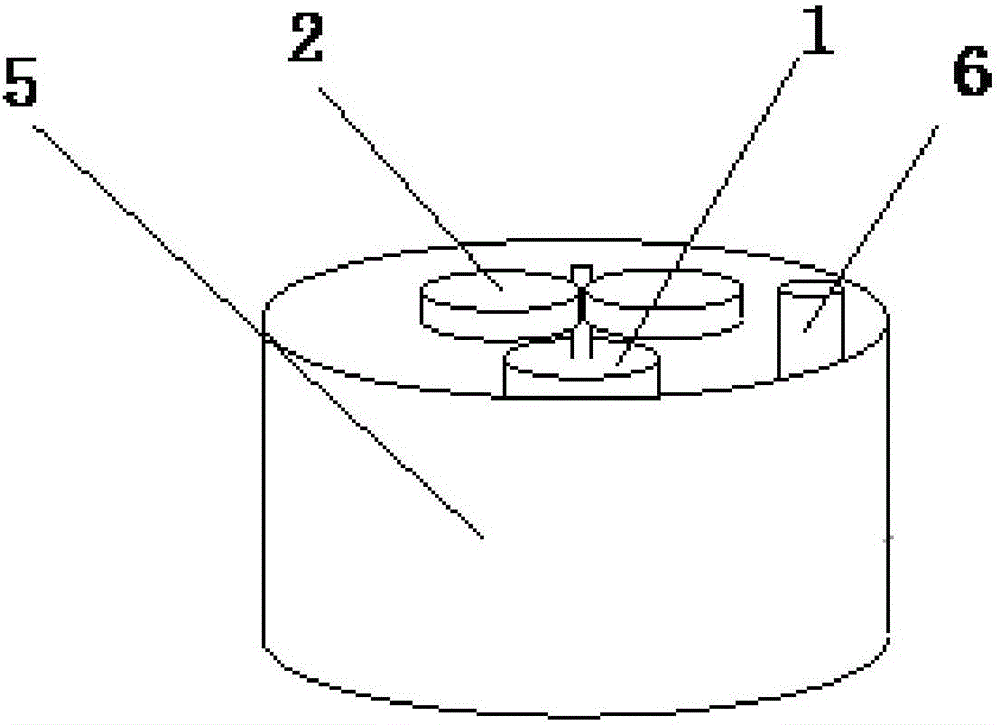

Novel automatic rotating type wine decanter

InactiveCN105747918AGreat tasteAchieve oxidationKitchen equipmentDrive shaftArchitectural engineering

The invention provides a novel automatic rotating type wine decanter.The novel automatic rotating type wine decanter comprises a motor, at least one magnet, a bottle body, a magnet rod and a base.The motor is installed in the base, a transmission shaft of the motor is located in the center of the base, the magnets are connected with the transmission shaft of the motor and located at non-central positions, the bottle body is installed on the base, and the magnet rod is placed in the bottle body.The magnet rod is a magnetic soft rod made of edible gum.The magnet rod is provided with a fluorescence coating.The two magnets are located on the two sides of the transmission shaft and are kept in central symmetry.An LED spotlight is arranged on the base, and the magnet rod is spiral.When the motor rotates, the magnet rod rotates along with the bottom motor, the speed of the magnet rod is consistent with that of the motor, under stirring of the magnet rod, wine rotates at a constant speed, and a liquid flow visual effect is generated through irradiation of the LED spotlight on the base.After a bottle stopper is opened, the wine makes full contact with air to be oxidized, the fragrance of the wine rapidly volatiles, and the taste of the wine can be improved within a short time.

Owner:ZHEJIANG LUCKY FAITH DIGITAL TECH

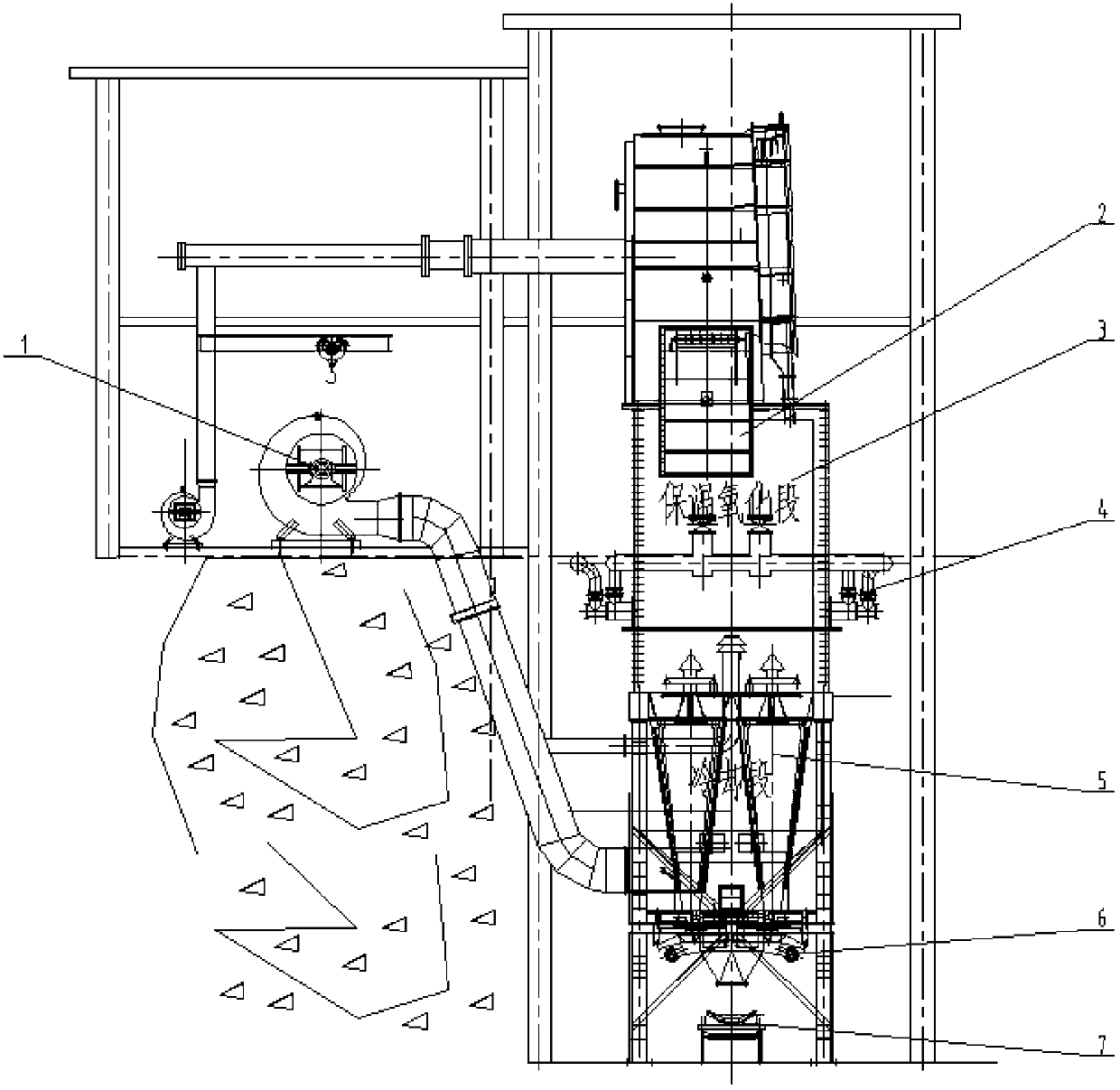

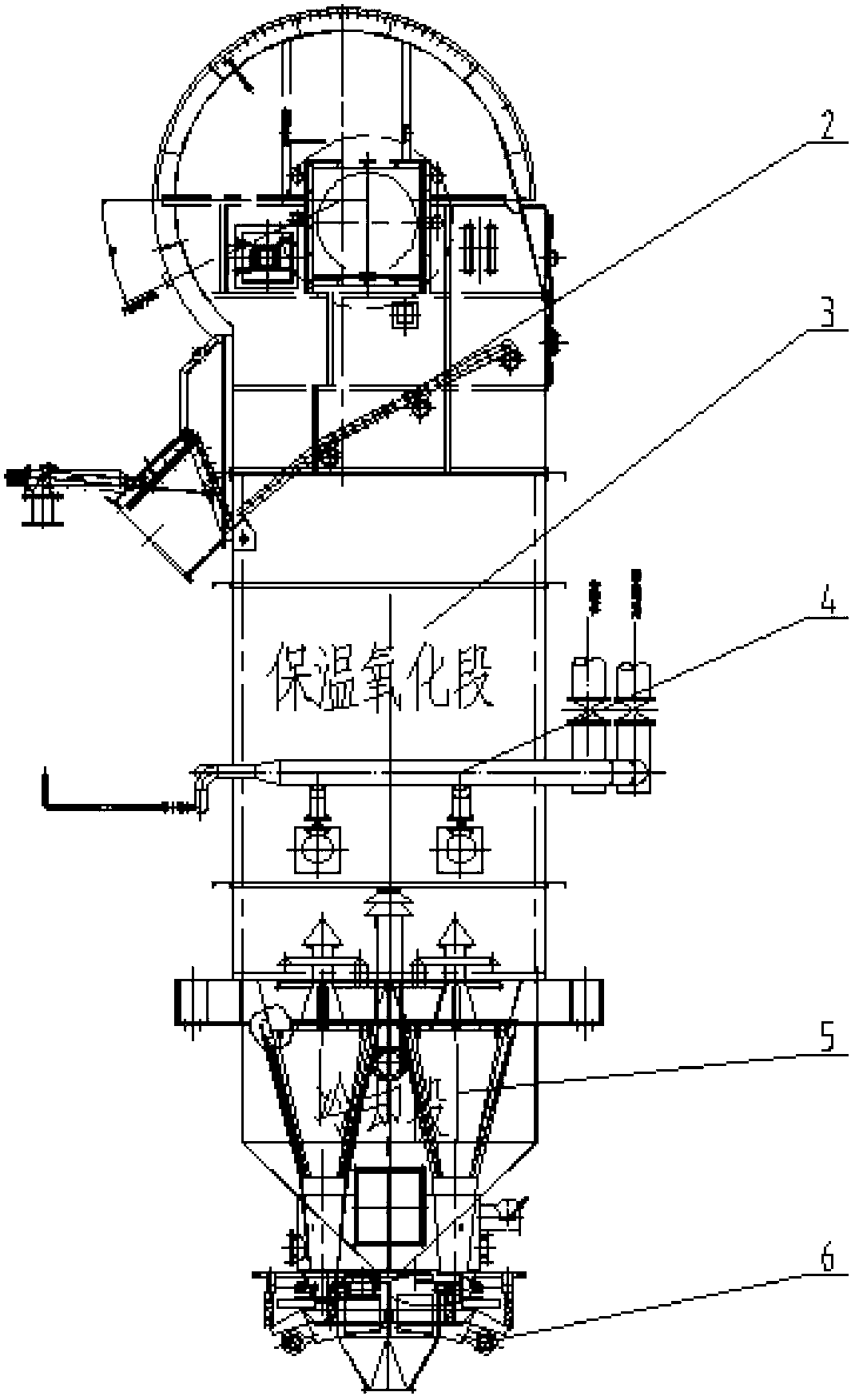

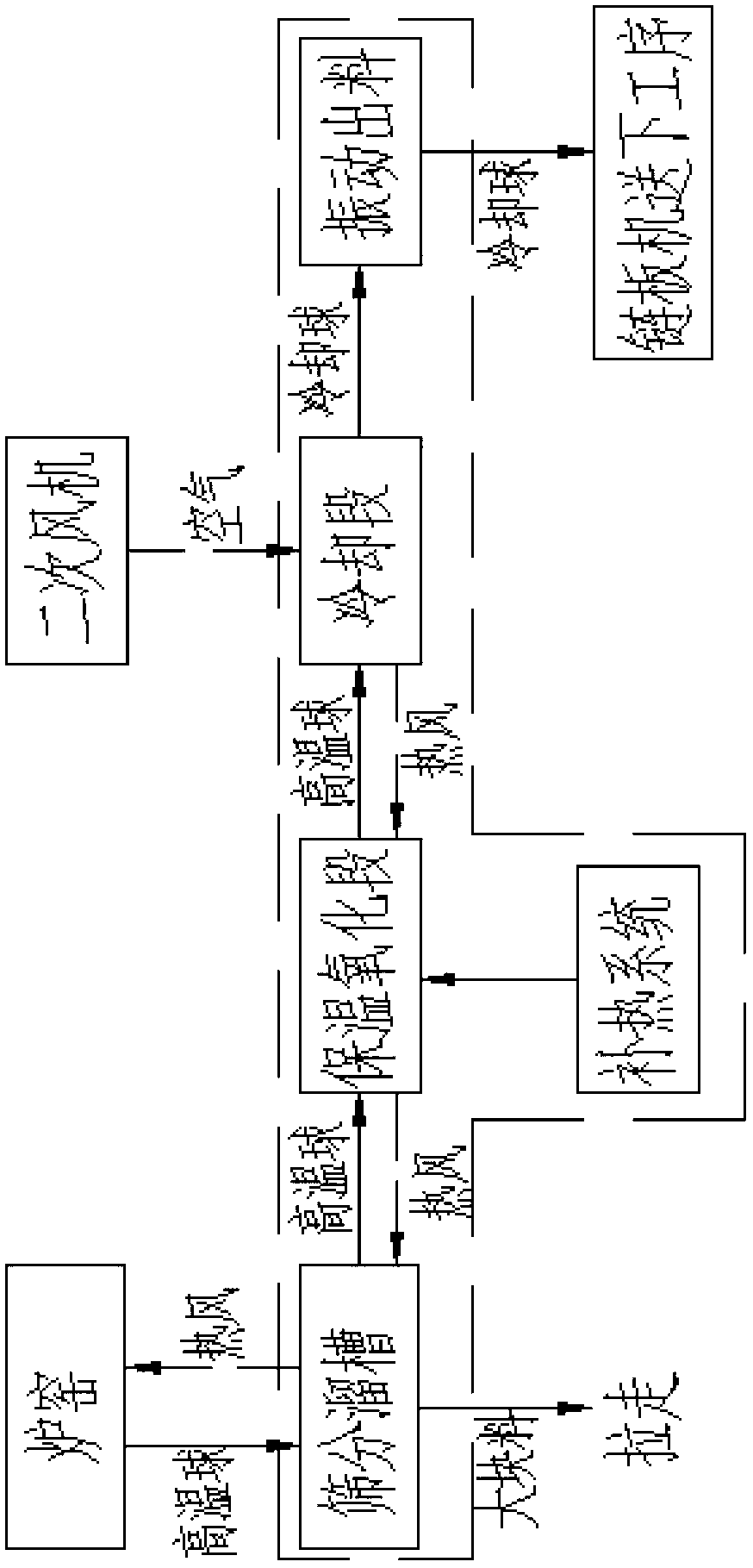

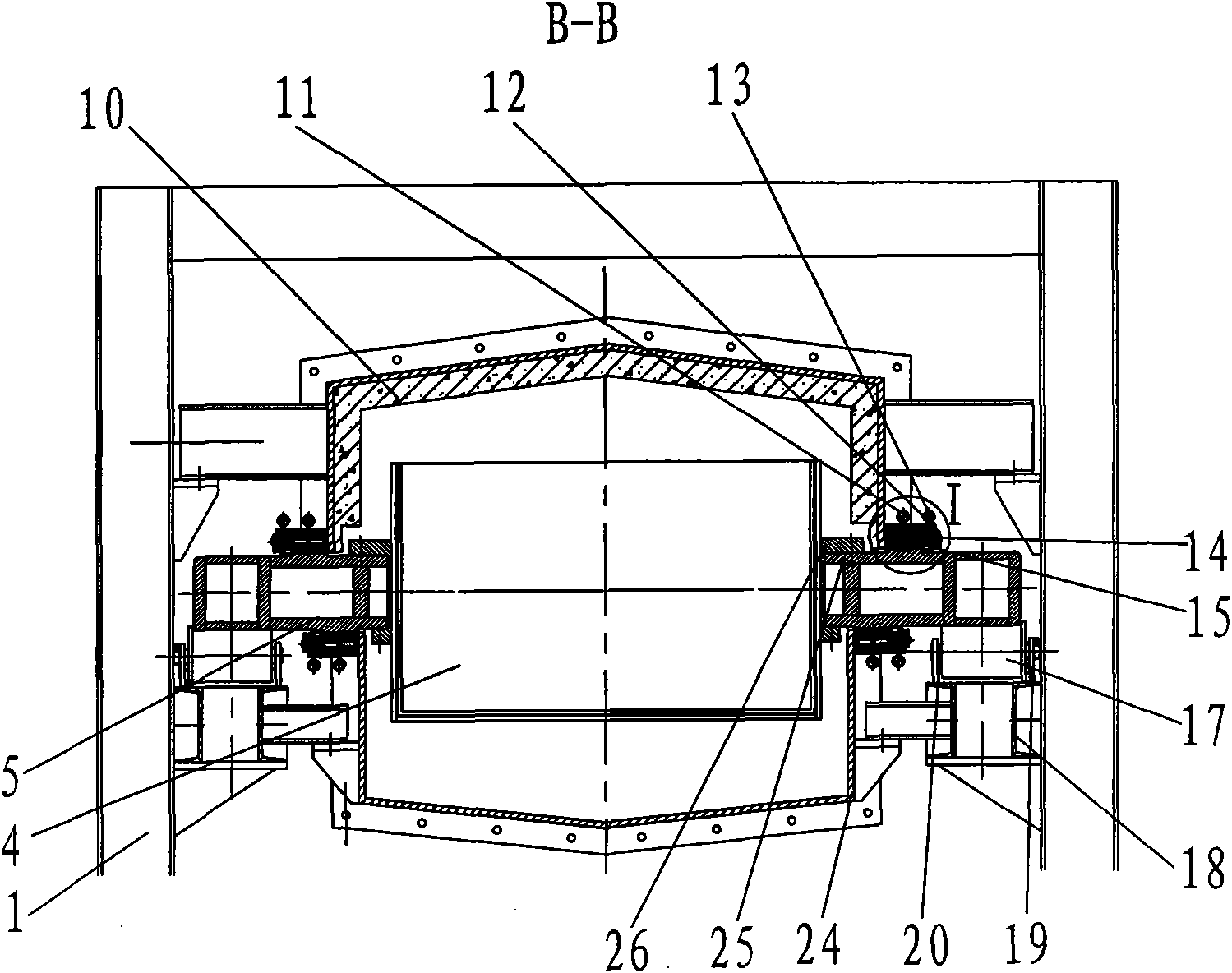

Thermal-insulating, oxidizing and cooling device used in vanadium extraction from stone coal and using method of device

The invention relates to a thermal-insulating, oxidizing and cooling device used in vanadium extraction from stone coal and a using method of the device, and the device belongs to the technical field of vanadium extraction. The thermal-insulating, oxidizing and cooling device comprises a secondary air fan, a screening chute, a thermal-insulating and oxidizing segment, a heat compensation system, a cooling segment, a vibrating discharge device and a chain-slat conveyor, wherein the screening chute is supported on a beam at the upper part of the thermal-insulating and oxidizing segment in an inclined way and an angle of 25 degrees is formed between the screening chute and the horizontal surface, the thermal-insulating and oxidizing segment is arranged under the screening chute, the cooling segment is arranged below the thermal-insulating and oxidizing segment; the cooling segment is directly communicated with the thermal-insulating and oxidizing segment in a welded way, the lower end of the cooling segment is connected with the vibrating discharge device through bolts; conveying equipment, namely the chain-slat conveyor is arranged at a 350mm part below the vibrating discharge device; the heat compensation system is arranged 300mm above the connection part of the thermal-insulating and oxidizing segment and the cooling segment; the heat compensation system is connected with the thermal-insulating and oxidizing segment through flange bolts; the secondary air fan is introduced into the cooling segment (5) through an air pipeline; and the air pipeline of the secondary air fan (1) is connected with the cooling segment (5) through flange bolts. The thermal-insulating, oxidizing and cooling device and the using method of the device have the advantages of solving the problems such as insufficient oxidizing atmosphere and short thermal insulation time in stone mine calcination.

Owner:XINXING ENERGY EQUIP

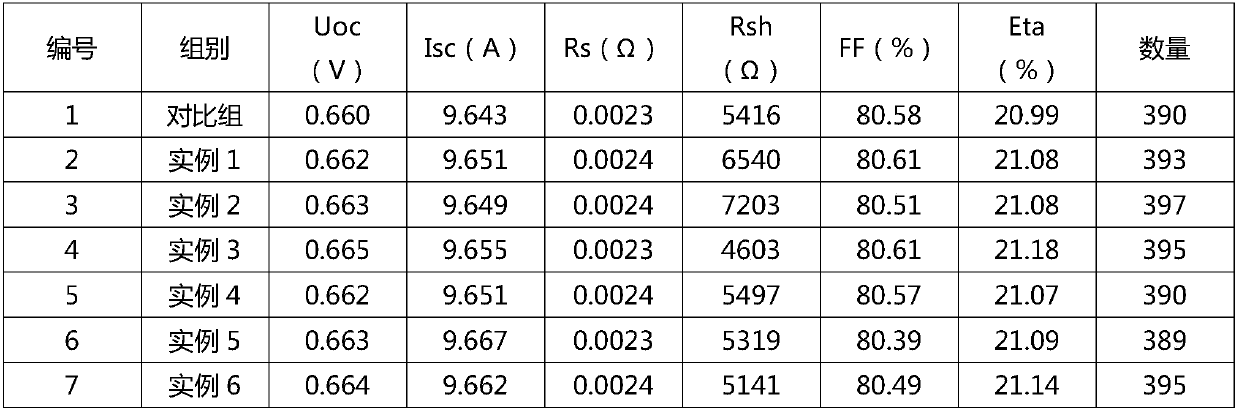

Method for optimizing monocrystalline-silicon pyramid-structured textured face

InactiveCN107675263AControl flowControl contentPolycrystalline material growthAfter-treatment detailsSingle crystalOrganic matter

The invention discloses a method for optimizing a monocrystalline-silicon pyramid-structured textured face. The method is characterized in that ozone gas is introduced into a pickling acid mixing tankof alkali texturing equipment, thus, the flow rate of ozone can be controlled in an ozone introducing manner so as to effectively control the content of ozone in the tank and better achieve an oxidation action, and meanwhile, the acid mixing tank plays a role in neutralizing residual alkali and removing metal ions. According to the method, the ozone of certain concentration is introduced into thepickling acid mixing tank of the alkali texturing equipment, thus, the action of neutralizing the residual alkali and removing the metal ions of the traditional pickling tank can be exerted, and a microstructure of a monocrystalline pyramid textured face can be optimized. Thus, the uniformity of a diffused PN junction and the uniformity of sheet resistance can be effectively improved, the effectof cleaning organic matters and metal ions from surfaces of silicon wafers is improved, the front face passivating effect is improved, and thus, the conversion efficiency of cell sheets is increased.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

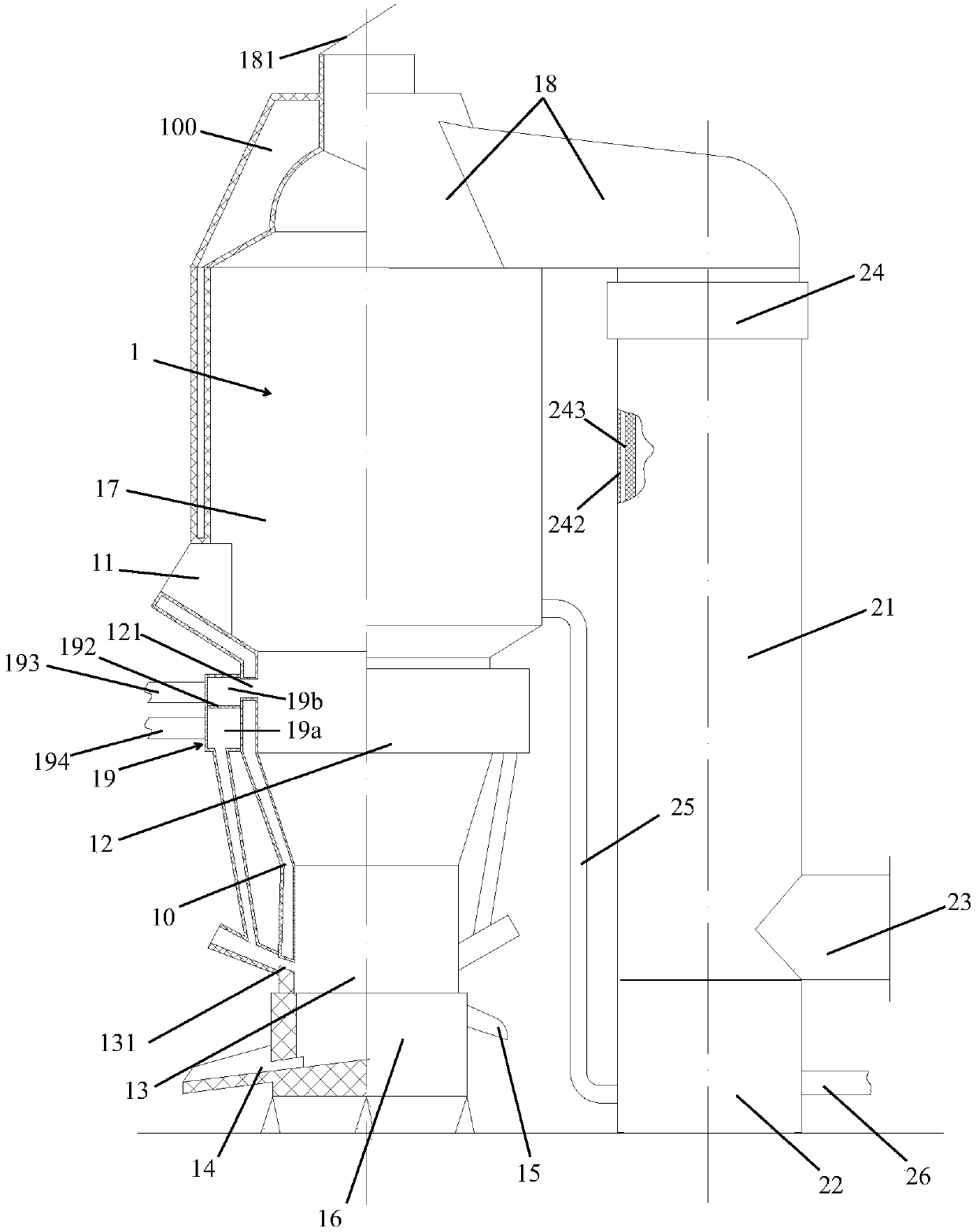

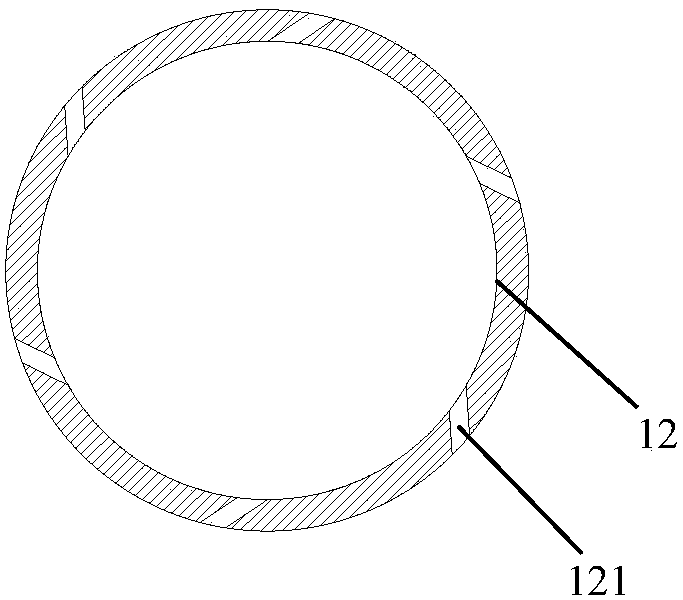

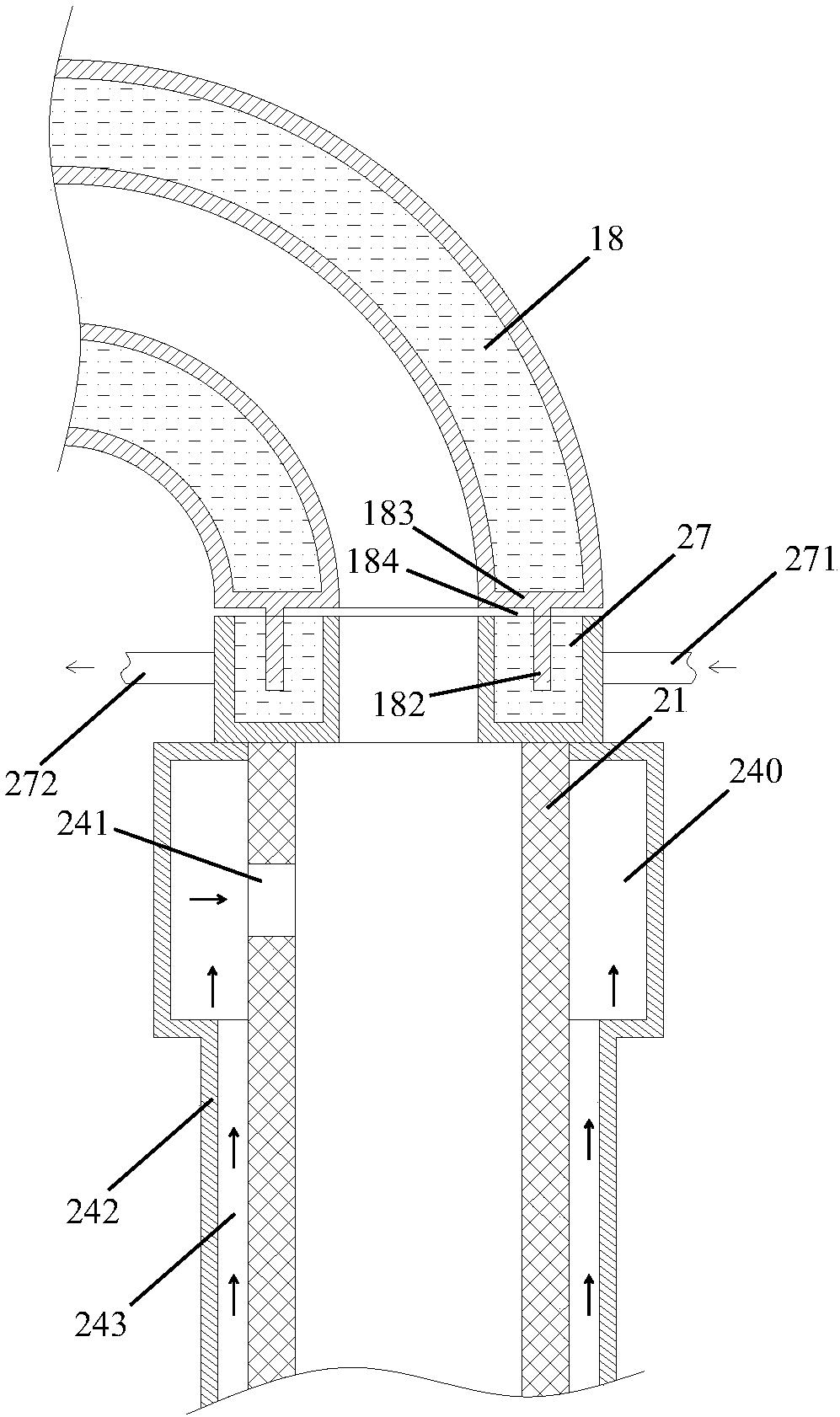

Circuit board incineration smelting furnace and circuit board incineration smelting method

ActiveCN107726331AEmission reductionIncrease profitEmission preventionIncinerator apparatusThermal energyBrick

The invention discloses a circuit board incineration smelting furnace and a circuit board incineration smelting method adopting the circuit board incineration smelting furnace. The circuit board incineration smelting furnace comprises a main furnace body arranged vertically and a reversal combustion tower. The main furnace body is provided with a charging port, a waste material combustion chambercommunicating with the charging port, a smelting chamber located below the waste material combustion chamber, a boiling combustion chamber located above the waste material combustion chamber and a smoke collection hood located above the boiling combustion chamber. The reversal combustion tower communicates with the smoke collection hood. A smoke dust settling chamber is arranged below the reversalcombustion tower. A pneumatic carrier pipe communicates between the boiling combustion chamber and the smoke dust settling chamber. The lower side of the smoke dust settling chamber is further provided with a Venturi feed pipe. By means of the technical scheme, the utilization rate of thermal energy is increased, emissions of poisonous and harmful gas are reduced, and the combustion efficiency ishigh; the early-period treatment cost is reduced, energy is saved by 50%, consumption of refractory materials such as refractory bricks is reduced, and the service cycle of the furnace is prolonged.

Owner:邹资生

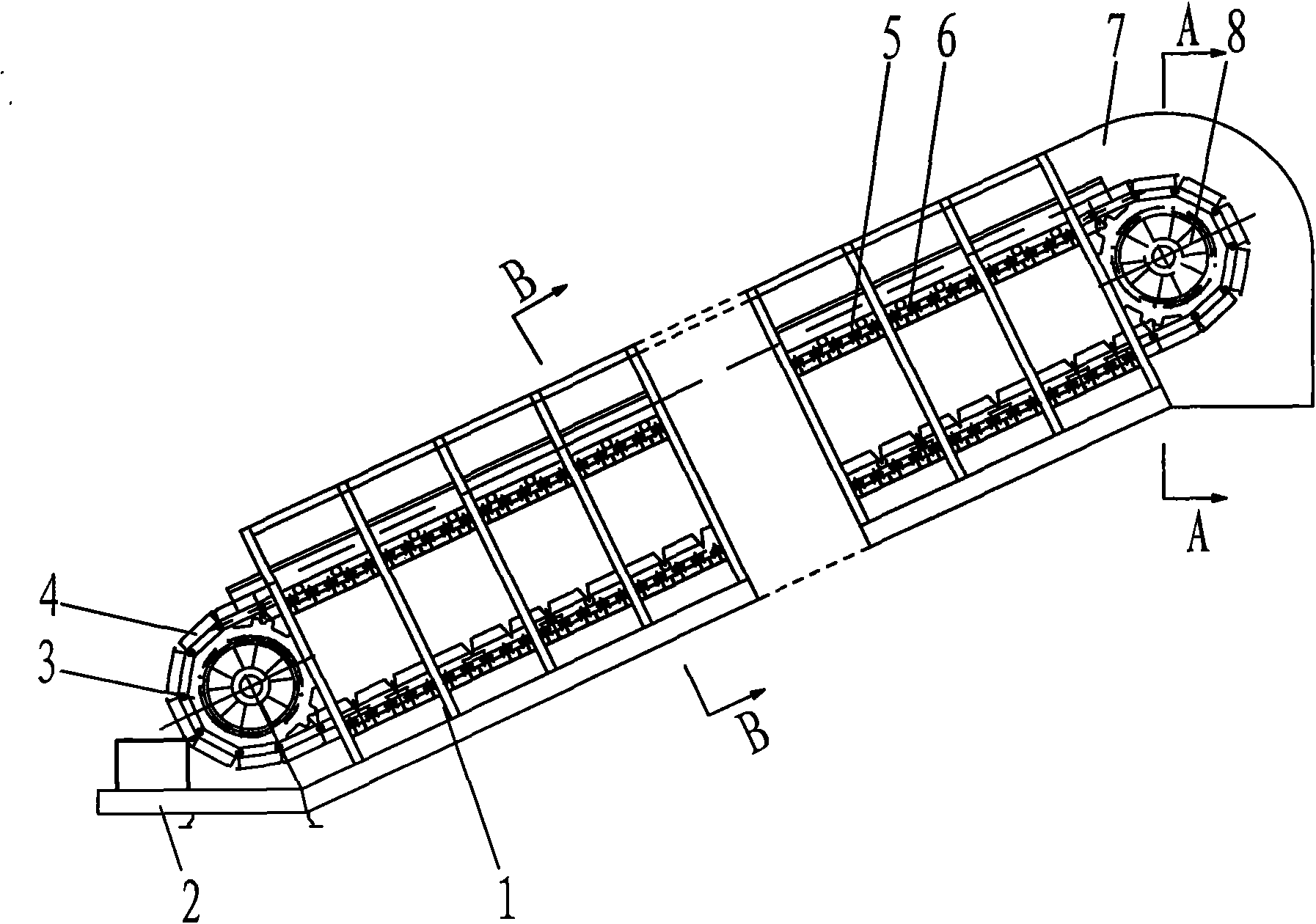

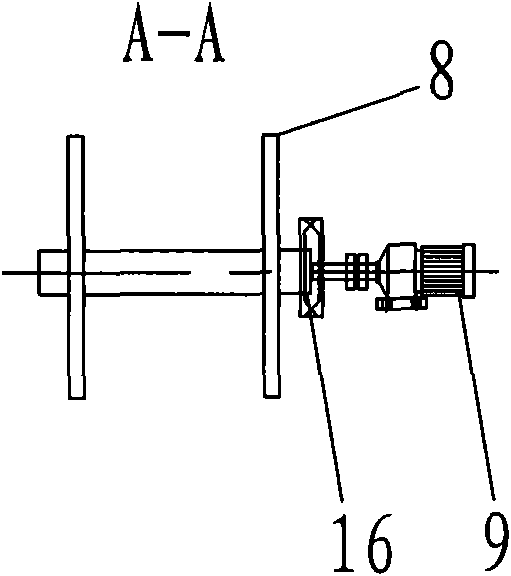

Heat direct reduced iron conveyor

InactiveCN102161423AAchieve oxidationRealize the insulation effectConveyorsCharge manipulationEngineeringSprocket

The invention discloses a heat direct reduced iron conveyor which is characterized in that: a driven sprocket (3) is arranged at the front of a conveyor rack (1), and a driving sprocket (8) is arranged at the back of the conveyor rack (1); a roller track (6) is arranged between the driven sprocket (3) and the driving sprocket (8), and the two sides of a material conveying carriage (4) are respectively connected with chain links (5); a chain formed by the chain links (5) runs on the roller track (6), and upper and lower heat insulation sealing covers (10,17) are fixed on the rack (1); and spring slide block slideway devices are used for sealing edges of the two sides of the upper and lower heat insulation sealing covers (10,17) and the chain links (5) at the two sides. In the heat direct reduced iron conveyor, the heat direct reduced iron is conveyed, and simultaneously, heat direct reduced iron can be insulated from heat and oxygen so as to avoid oxidation, so that the conditions are created for sending the heat direct reduced iron into an electric furnace at a high temperature; and the production cycle is shortened, the productivity is improved, and the energy loss is reduced.

Owner:秦皇岛西重所燕大重型机械研究院有限公司

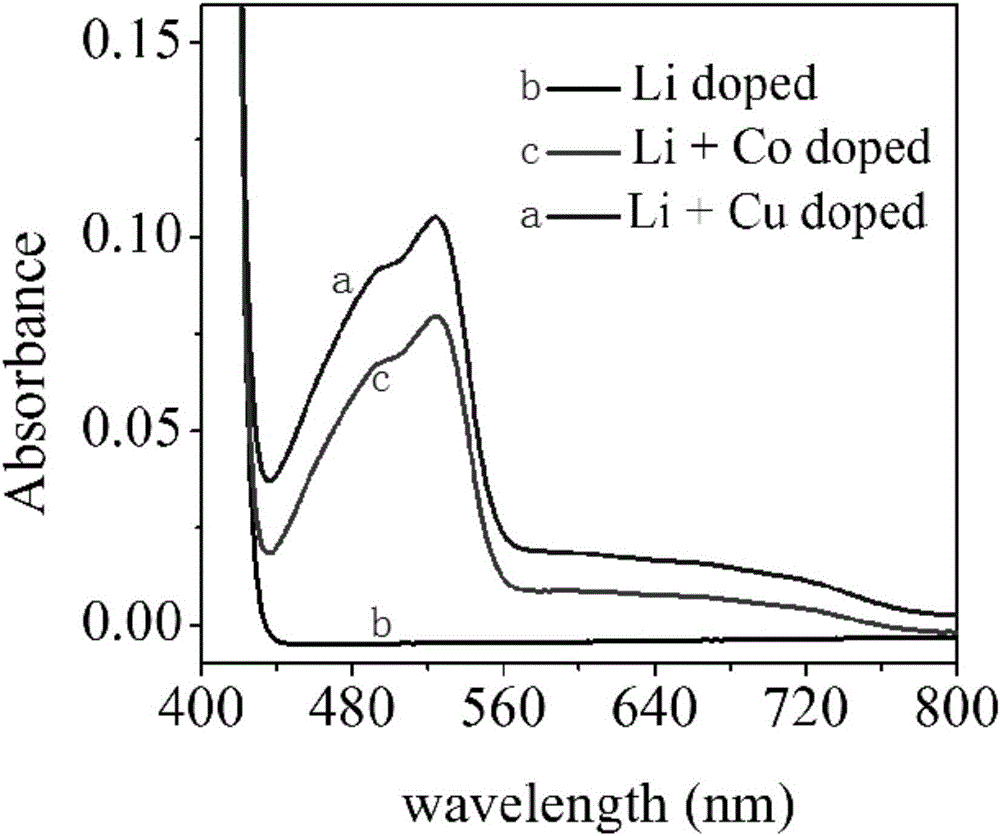

Hole transmission material and manufacturing method for perovskite solar energy cell containing hole transmission material

ActiveCN105789454ASimple preparation stepsImprove pass rateFinal product manufactureSolid-state devicesLithiumPerovskite solar cell

The invention relates to a hole transmission material and a manufacturing method for a perovskite solar energy cell containing the hole transmission material. The hole transmission material comprises a solvent, a spiro-MeOTAD, an inorganic oxidizing agent containing cuprous ions, tetrabutyl pyridine and lithium trifluoromethane sulfonamide, wherein the mole ratio of the spiro-MeOTAD, the inorganic oxidizing agent, the tetrabutyl pyridine and the lithium trifluoromethane sulfonamide is 1:(0.1-4):(0.7-0.9):(0.2-0.4). The hole transmission material employs inorganic micromolecules as an additive of the hole transmission material spiro-MeOTAD of the perovskite solar energy cell, the inorganic oxidizing agent has relatively good oxidation effect on the spiro-MeOTA, so hole transmission performance of the spiro-MeOTA is improved, the inorganic oxidizing agent has relatively low price, so manufacturing cost of the hole transmission material can be greatly reduced, moreover, manufacturing steps of the perovskite solar energy cell are simple, no acetonitrile is taken as a solvent in the manufacturing process, no damage to the perovskite crystal structure occurs, and the qualified rate of cells is improved to a great degree.

Owner:NINGBO UNIV

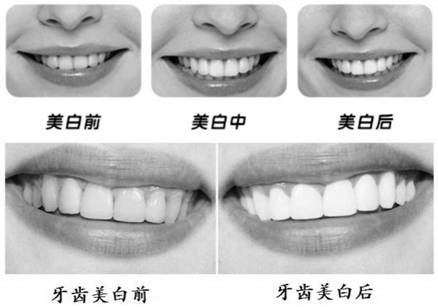

Visible light catalytic modified titanium dioxide and preparation method and application thereof

PendingCN113499767AAchieve oxidationAchieve whitening effectCosmetic preparationsToilet preparationsTooth whiteningTitanium oxide

The invention relates to a tooth whitening technology, in particular to visible light catalytic modified titanium dioxide and a preparation method and application thereof. Butyl titanate and bismuth nitrate are subjected to a sol-gel reaction in a low-boiling-point organic solvent, and then high-temperature calcination is performed to obtain the bismuth-doped titanium dioxide with the spherical structure. The nano modified titanium dioxide is applied to tooth whitening gel. According to the tooth whitening gel, the photocatalytic activity of the nano-modified titanium dioxide is utilized, electron holes with strong oxidizing property are generated by assisting visible light illumination, and the electron holes can also synergistically catalyze and decompose hydrogen peroxide to generate hydroxyl radicals (. OH), so that the catalytic activity of the hydrogen peroxide is improved, and the whitening effect on teeth can be remarkably improved through electron holes and .OH.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

Method for efficiently repairing petroleum hydrocarbon pollution of soil

PendingCN113305142APromote degradationStrong oxidation abilityContaminated soil reclamationCalcium hydroxideSoil science

The invention discloses a method for efficiently repairing petroleum hydrocarbon pollution of soil. The method comprises the following steps of cleaning, mixing and maintaining. Calcium oxide reacts with water to generate calcium hydroxide, and a large amount of heat is released in the reaction process; due to the fact that calcium hydroxide is strongly alkaline, sodium persulfate activated by quick lime can provide the complementary activation effect of alkali activation and thermal activation at the same time; Na2S2O8 reacts with OH <-> in a liquid phase to generate OH<2->, then Na2S2O8 reacts with S2O8<2-> to cause-O-O-bond breakage to generate SO4 <->.; SO4 <-> is mainly produced under acidic and neutral conditions (pH = 2-7) and is relatively stable in a solution; in a solution having a pH greater than 8.5, SO4 <-> oxidizes water or OH <-> to gradually produce OH. with an increase in proportion, while in an alkaline solution (pH greater than 12), OH. is mainly produced; and because the oxidizability of OH. is stronger than that of SO4 <->, the-O-O-bond is broken to cause the production of SO4<->., and the oxidation of pollutants is realized.

Owner:广州穗土环保工程有限公司

Nano-electromechanical structure and method for the production thereof

InactiveCN101795962AAchieve oxidationAct as a cathodeMaterial nanotechnologyMaterial analysis using sonic/ultrasonic/infrasonic wavesResonanceInterconnection

The invention relates to micro- and nano-electromechanical devices and to a method for the production thereof. One of the variants of the inventive method for producing a nano-electromechanical structure is based on the use of self-organising and self-alignment mechanisms, thereby unlimiting the substantial geometrical parameters thereof with respect to possibilities of traditional lithography, which makes it possible to achieve an integration degree equal to 1016 m-2 and greater. Moreover, one of the inventive aspects uses the resonance frequency of the elements in the form of an independentaddressing co-ordinate thereof,thereby making it possible to reduce the density of the required interconnections. The other aspect of the invention provides a gas sensor exhibiting a high sensitivityof the measurement of given gases or particles in the atmosphere, having multipurpose and flexible selectivity mechanisms and a controllable process of sensory ability regeneration. The inventive structure provides a simple method for measuring the resonance frequency of an oscillating element, which does not require high-frequency signal analysis.

Owner:S·V·哈特夫 +1

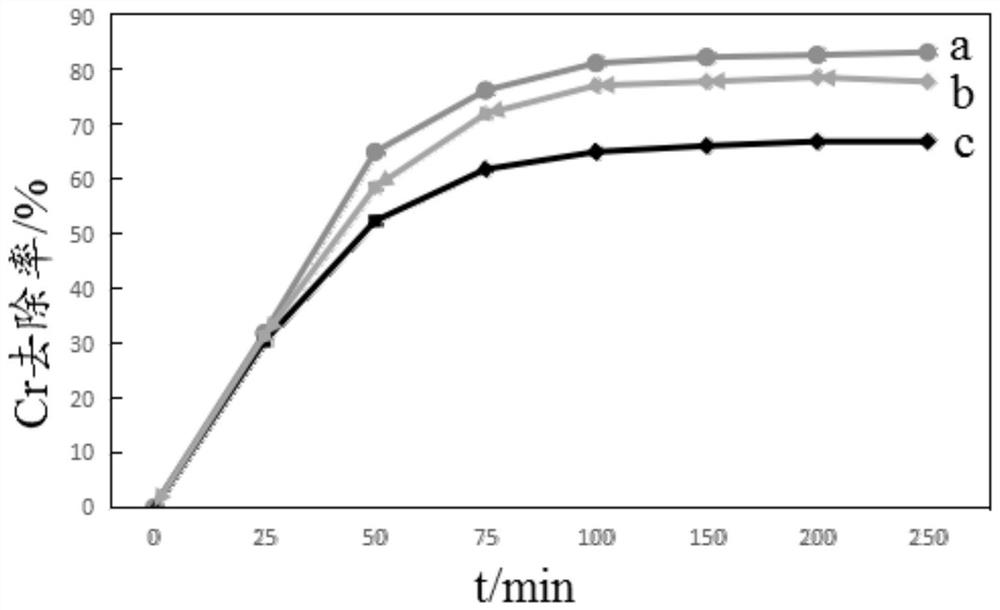

Graphene modified material, and preparation method and application thereof

PendingCN112850691AAchieve oxidationWith adsorptionIon-exchange process apparatusOther chemical processesRare-earth elementGraphite oxide

The invention relates to the technical field of graphene modified materials, and concretely relates to a graphene modified material, and a preparation method and application thereof. The preparation method comprises the following steps: firstly, preparing a graphene oxide@Fe3O4 material, then performing reduction treatment on the surface of graphene oxide to obtain modified graphene, and finally under the action of an activating agent , grafting weakly acidic polyacrylic resin to obtain the graphene modified material. The prepared graphene modified material can be applied to medicine extraction and purification, rare earth element separation and purification and heavy metal treatment of sewage.

Owner:JIAOZUO UNIV

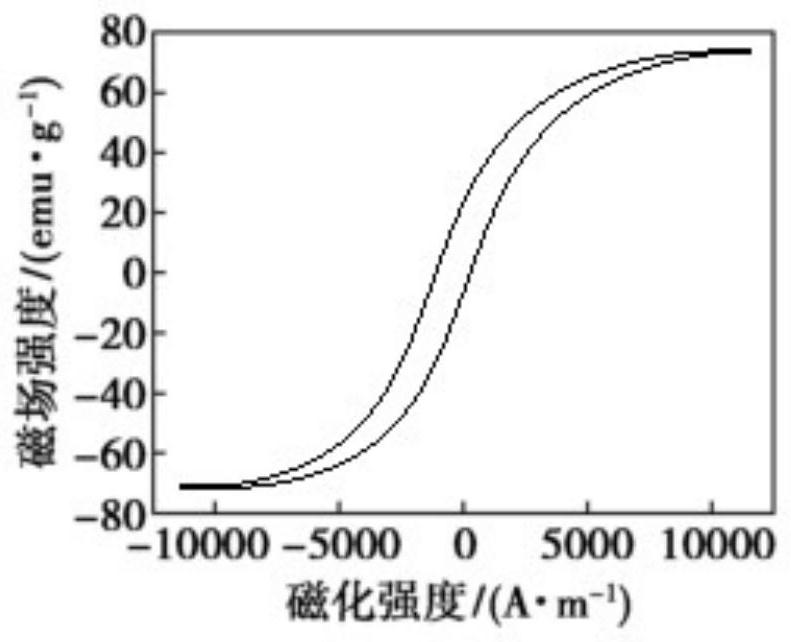

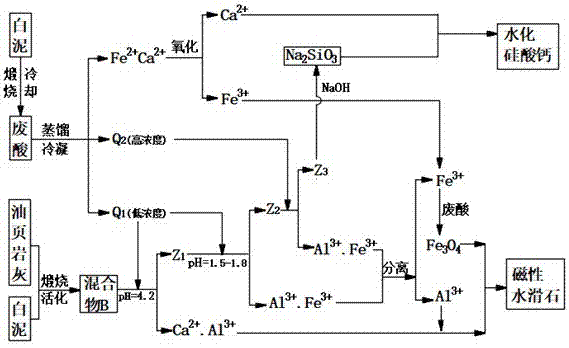

Treatment method of waste acid, oil shale ash and white mud

InactiveCN107570108AReduce generationContinuous and stable productionOther chemical processesAlkali metal oxides/hydroxidesLiquid wasteCalcium silicate

The invention provides a treatment method of waste acid, oil shale ash and white mud, relates to a treatment method of industrial wastes and in particular relates to the technical field of comprehensive utilization of industrial wastes including the oil shale ash, the white mud and the waste acid and preparation of a heavy metal sewage and waste liquid treatment material. The white mud is added and is used as an additive so that the waste acid recycling effect is improved; the recycled acid is extracted through a gradient extraction method to separate a mixture of the oil shale ash and the white mud; metal ions in an extracting solution are combined to prepare magnetic hydrotalcite and hydrated calcium silicate. According to the treatment method provided by the invention, the industrial wastes are used as raw materials to prepare a high-performance adsorbent and an adsorption material can be recycled.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

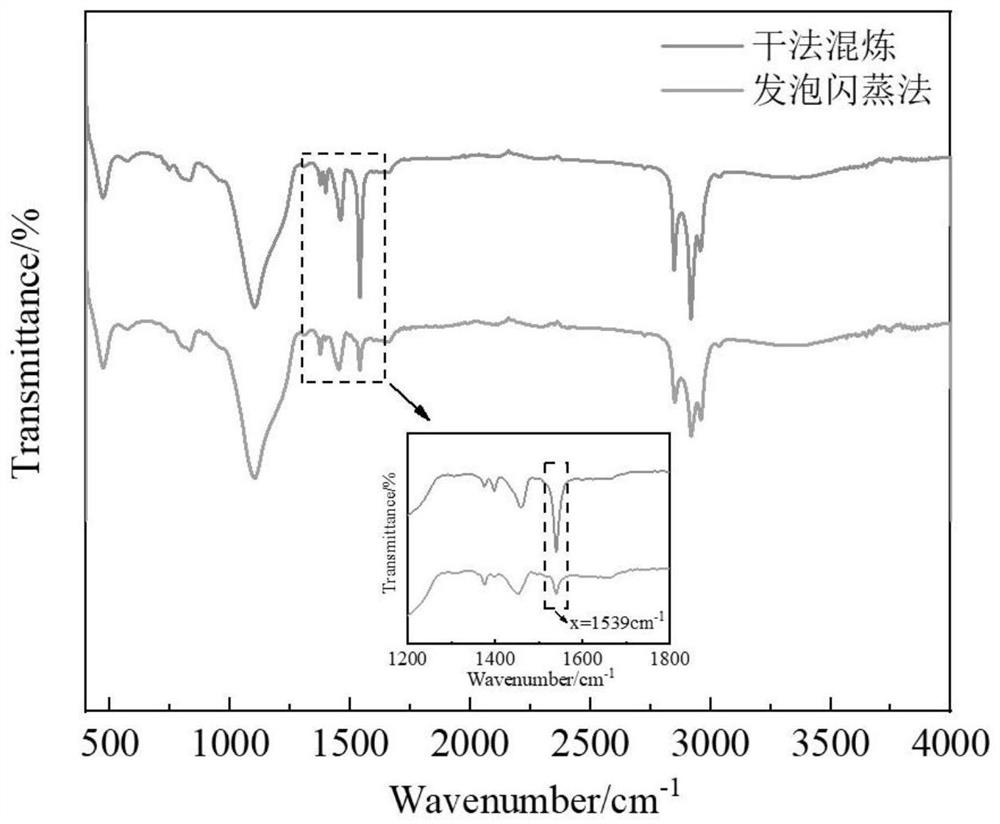

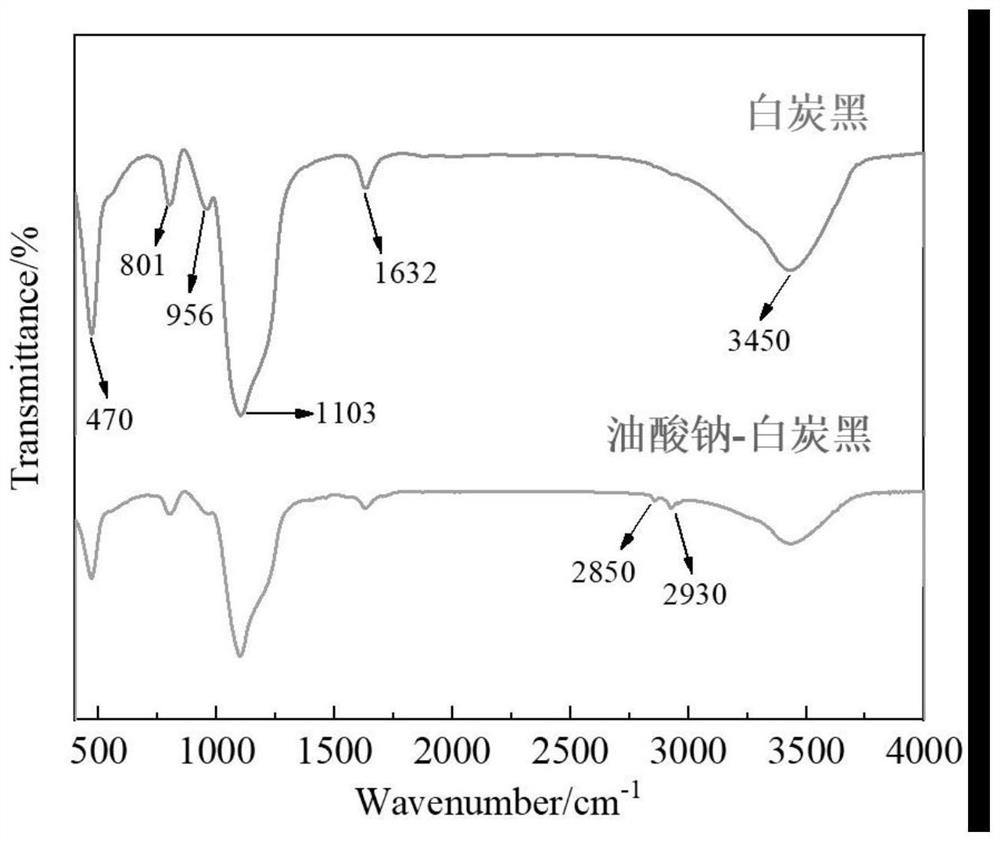

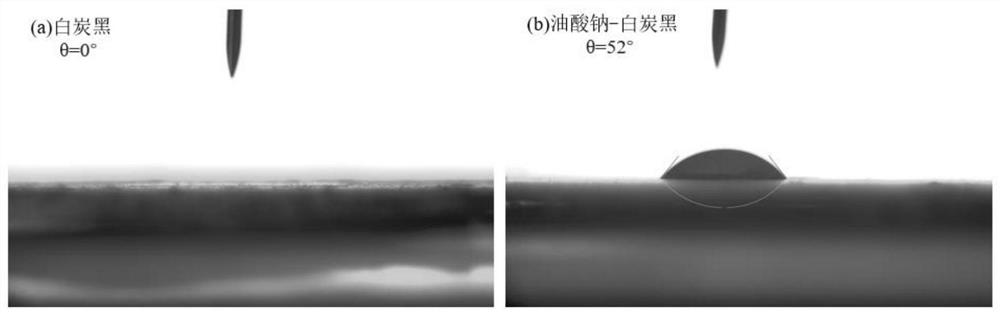

Preparation method of inorganic filler/rubber composite material

ActiveCN114381049AImprove foaming efficiencyImprove stabilityRolling resistance optimizationRubber materialPolymer science

The invention belongs to the technical field of wet mixing, and relates to a preparation method of an inorganic filler / rubber composite material, which comprises the following steps: adding a foaming agent into a pre-dispersion of an inorganic filler and latex, and breaking a filler aggregate by using volume expansion power formed by breaking and expanding bubbles generated by the foaming agent to prepare the inorganic filler / rubber composite material. Due to the foaming uniformity, the rubber and the inorganic filler are in full contact under the liquid phase condition, the interface phase structures of the inorganic filler and the rubber are increased, the mixed emulsion is instantly solidified and dried after being deposited on the wall surface of a high-temperature roller, and the oxidation chain scission degree of the rubber and the loss of non-rubber components such as protein and phospholipid are reduced; a foaming pre-dispersion technology and a flash drying technology are combined, so that the problems that polar filler is easy to agglomerate and difficult to disperse in the mixing process, the compatibility of inorganic filler and rubber is poor, the rubber material performance is poor due to acid flocculant coagulated latex, the environment is polluted by discharged acid gas and the like are solved, and the preparation efficiency and the comprehensive performance of wet-process mixed rubber are improved; and a basis is provided for preparation of high-end rubber products.

Owner:QINGDAO UNIV OF SCI & TECH

Copper matte desulfurization and deoxidation gas switching control method

A copper matte desulfurization and deoxidation gas switching control method comprises the following control steps that (1) when it is detected that the sulfur content in a melt in a fire refining furnace is more than 0.3%, oxygen-enriched gas is sprayed into the fire refining furnace through a bottom blowing spray gun, wherein the volume content of O2 in the oxygen-enriched gas is 20.5-60%; (2) when it is detected that the sulfur content in the melt in the fire refining furnace is less than 0.3%, reducing gas is gradually sprayed into the fire refining furnace through the bottom blowing spraygun, wherein when the reducing gas is natural gas, the volume ratio of the O2 in the oxygen-containing gas sprayed by the bottom blowing spray gun to the reducing gas is 2.8-3.2; and (3) when it is detected that the oxygen content in the melt in the fire refining furnace is greater than or equal to 0.6%, the bottom blowing spray gun starts to spray more reducing gas into the fire refining furnace,and when the reducing gas is the natural gas, the volume ratio of the O2 in the oxygen-containing gas sprayed by the bottom blowing spray gun to the reducing gas is 1.1-1.3. With the method, anode copper is directly produced, the process is simplified, the cost is reduced, and the grade of the produced anode copper is high.

Owner:DONGYING FANGYUAN NONFERROUS METALS +2

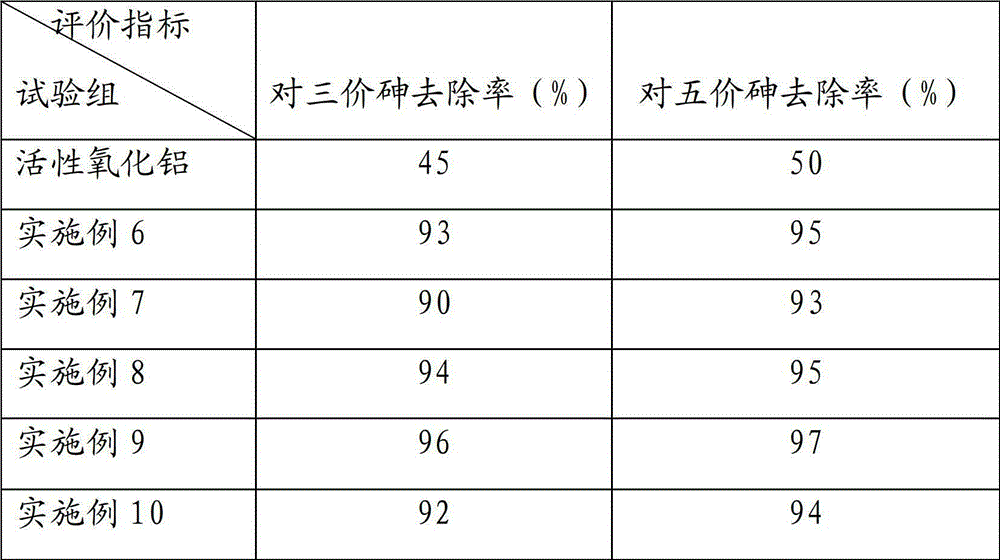

Composite material for removing arsenic in water and preparation method thereof

ActiveCN103084140BMagneticAchieve separationOther chemical processesAluminium silicatesTitaniumArsenic

The invention relates to a composite capable of removing arsenic in water, and a preparation method thereof. The composite comprises the following ingredients in parts by weight: 100 parts of bentonite, 1-6 parts of polymerized ferric salt, 0.8-4.8 parts of hydrolyzed titanium salt, wherein the quantity of the polymerized ferric salt is determined by the mass of ferrum element; and the quantity of the hydrolyzed titanium salt is determined by the mass of titanium element. A ferrum-titanium bioxide intercalated modified composite is formed by intercalating the polymerized ferric salt and the hydrolyzed titanium salt into bentonite and drying and calcining, and the composite can realize the oxidization on trivalent arsenic and the synchronous and efficient removal on the trivalent arsenic and pentavalent arsenic under the illumination action.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

A kind of manufacturing method of high energy density pouch battery

ActiveCN113097567BCompensation for irreversible capacity lossAchieve oxidationFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentHigh energy

The invention provides a method for manufacturing a high-energy-density pouch battery, which includes the following steps: Step 1: Wrap the bottom of the lithium battery core with an auxiliary electrode of aluminum foil, and use a separator to isolate and insulate the battery core and the auxiliary electrode of the aluminum foil , to obtain a pouch battery after assembly; step 2: inject electrolyte 1 into the pouch battery obtained in step 1, and use the aluminum foil auxiliary electrode for pre-charging after sealing; step 3: take out the aluminum foil auxiliary electrode after pre-charging, and remove free Electrolyte 1 is injected into electrolyte 2, and after post-treatment, a high-energy-density pouch battery is obtained. In the present invention, an aluminum foil auxiliary electrode is preset at the bottom of the lithium ion battery core, and through the synergistic effect of the aluminum foil auxiliary electrode and the electrolyte solution 1 containing additives, the pre-embedded lithium on the negative electrode of the lithium ion battery is realized during the small current precharging process, solving the problem of Or improve the problem of low charging and discharging efficiency of lithium-ion batteries for the first time, thereby increasing the capacity and energy density of lithium-ion batteries.

Owner:HUNAN GAOYUAN BATTERY

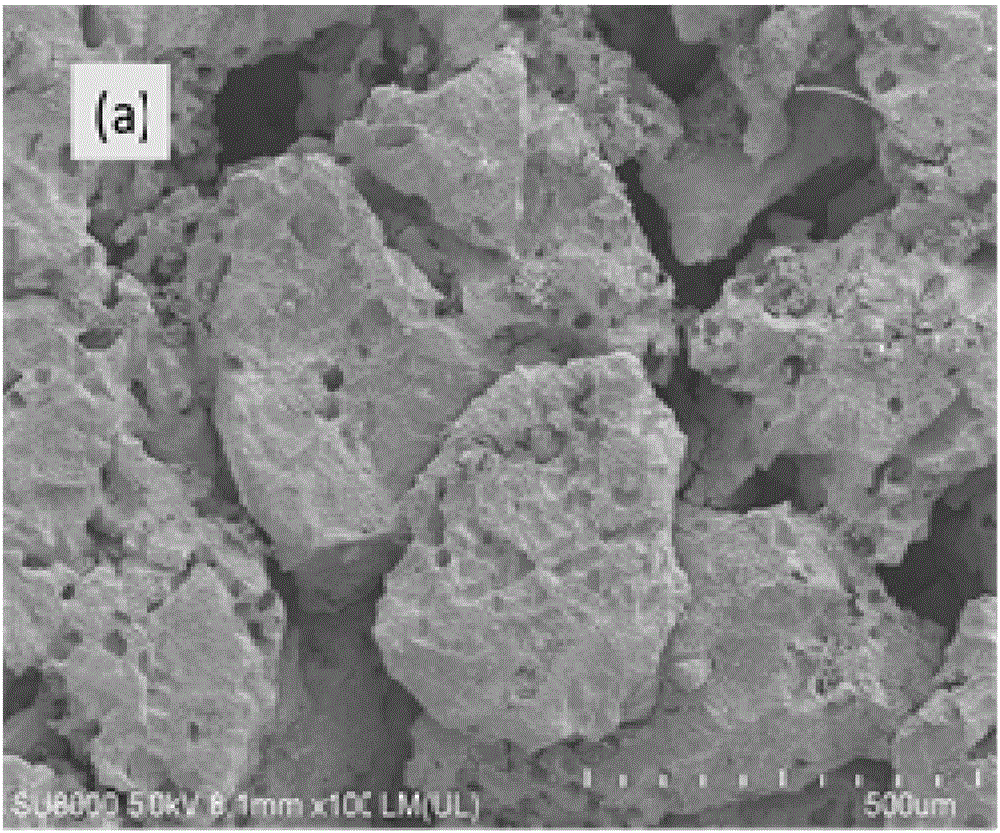

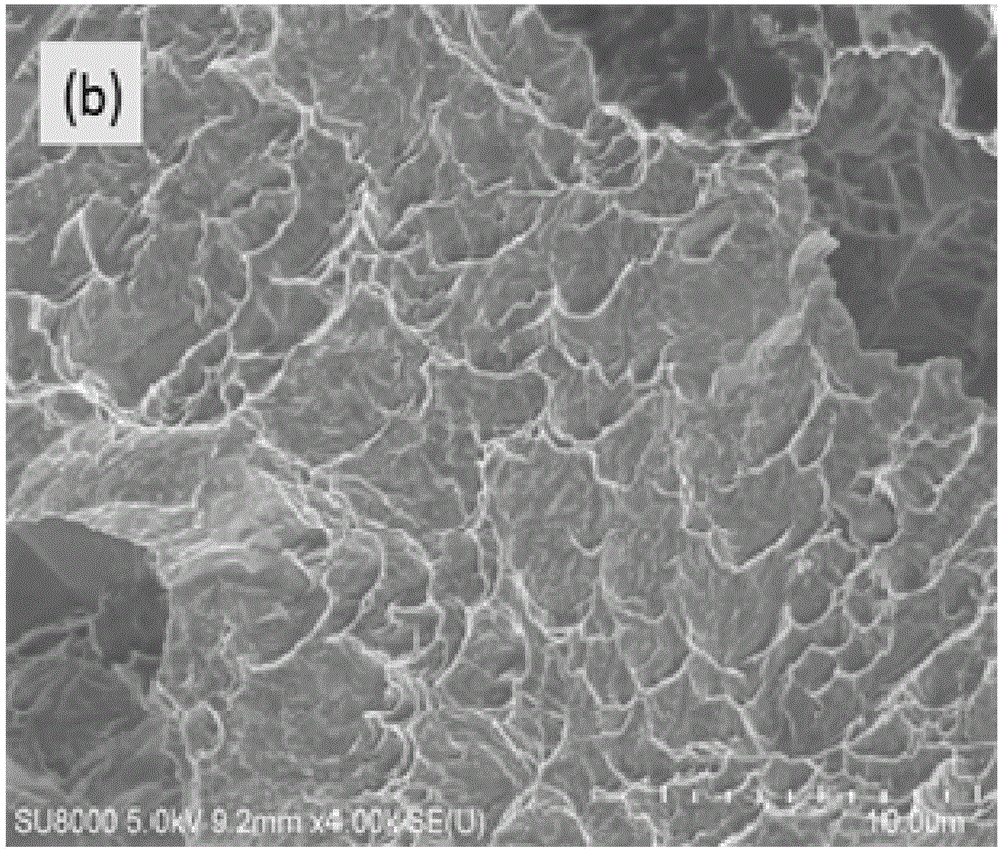

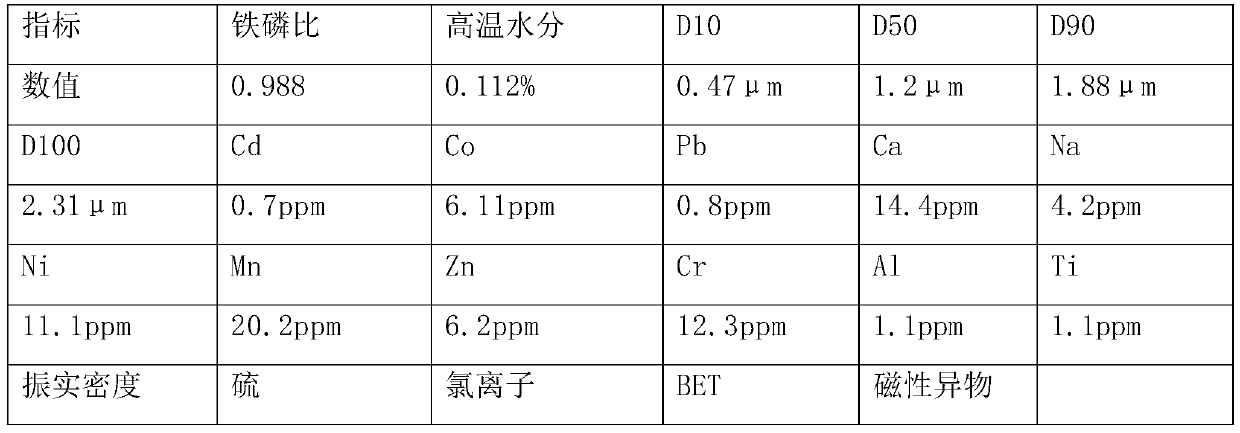

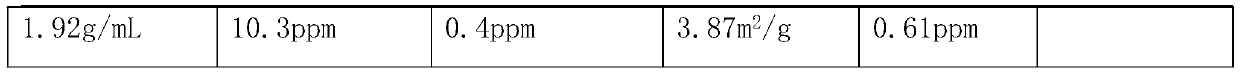

Preparation method of iron phosphate with high tap density

The invention discloses a preparation method of iron phosphate with a high tap density. The preparation method comprises the following steps: red phosphorus and iron powder are mixed in an inert atmosphere, then alcohol is added, the obtained mixture is placed in a ball mill and is ball-milled, and the ball-milled mixture is calcined at a high temperature in an inert atmosphere in an atmosphere furnace to obtain a ferrophosphorus alloy; the ferrophosphorus alloy is placed in a rotary furnace, and is oxidatively calcined by an oxygen-rich gas at 500-650 DEG C for 4-5 h to obtain a calcined powder; and the calcined powder undergoes jet milling to obtain a powder with a particle size of 0.5-2 [mu]m, and the powder is screened, and undergoes electromagnetic iron removal to obtain anhydrous iron phosphate. The preparation method has the advantages of simple process and low cost, and the obtained iron phosphate has the advantages of high tap density, good sphericity and large particle size,and is suitable for preparing high-compactness lithium iron phosphate.

Owner:王东升

Clean wall-mounted air sterilizer

ActiveCN113566360AAchieving Collaborative DisinfectionAchieve oxidationMechanical apparatusLighting and heating apparatusSodium chlorateUltraviolet lights

The invention discloses a clean wall-mounted air sterilizer which comprises a shell and is characterized in that a closed box is arranged in the shell, a filter layer which is sparse at the lower part and dense at the upper part is arranged in the closed box, a sodium chlorate aqueous solution bin and a hydrochloric acid aqueous solution bin are arranged outside the shell, and an air inlet pipe is arranged in the closed box. The air inlet is detachably connected with at least one air conveying pipe, the end of the air conveying pipe is connected with an air inlet grille used for being installed at the bottom of a room, the top of the closed box is connected with at least one concentric-square-shaped pipe, a light touch film is arranged on the inner wall of the concentric-square-shaped pipe, an ultraviolet lamp tube is arranged in the concentric-square-shaped pipe, and an exhaust cavity is formed in the shell. An air outlet is formed in the top surface and / or the bottom surface and / or the side surface of the shell. According to the clean wall-mounted air sterilizer provided by the invention, a personnel activity area at the bottom of a room is taken as a high-purification area, so that dust is prevented from appearing in the sterilizer shell, and all parts in the sterilizer are always kept clean.

Owner:CIXI BEILIAN ELECTRICAL APPLIANCE CO LTD

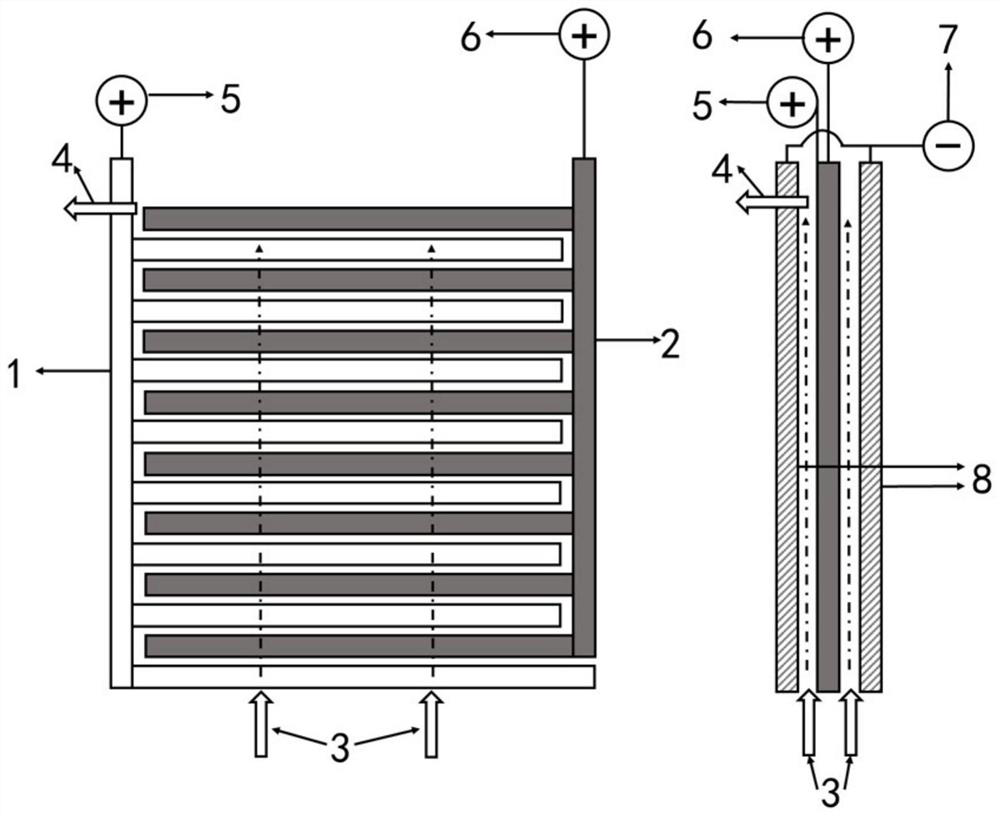

Double-potential anode electrolysis device and method

InactiveCN112830555AAchieve oxidationImprove current efficiencyWater contaminantsWater/sewage treatmentOrganic synthesisElectrochemical anodization

The invention discloses a double-potential anode electrolysis device and method, and relates to the field of electrochemical anodic oxidation and water treatment. Double-potential anodes in an electrolytic cell comprise two sets of anodes which are arranged in a staggered manner and do not communicate with each other, and the potential applied to an anode 1 is lower than that of an anode 2. A catalyst layer of the anode 1 is made of an electrode material with lower oxygen evolution overpotential (less than 600mV at 10 mA*cm<-2>). A catalyst layer of the anode 2 is made of an electrode material with relatively high oxygen evolution overpotential (greater than 600mV at 10 mA*cm<-2>). The anode 1 and the anode 2 share one set of cathode. Wastewater flows through the anode 1 and the anode 2 which are alternately arranged, organic substance functional groups which are easy to oxidize in the wastewater are oxidized on the anode 1, and organic substances difficult to oxidize and stable chemical bonds are oxidized and broken on the anode 2 to form micromolecules which are easy to oxidize, so that the wastewater sequentially passes through the anode 1 and the anode 2 which are alternately arranged to be subjected to electrochemical synergistic deep oxidation. The invention has the beneficial effects that through synergistic oxidation of the double-potential anodes which are arranged in a staggered manner, the current efficiency is high, the energy consumption is low, and the device has a remarkable application value in the fields of electrochemical water treatment and electrochemical organic synthesis.

Owner:BEIJING UNIV OF CHEM TECH

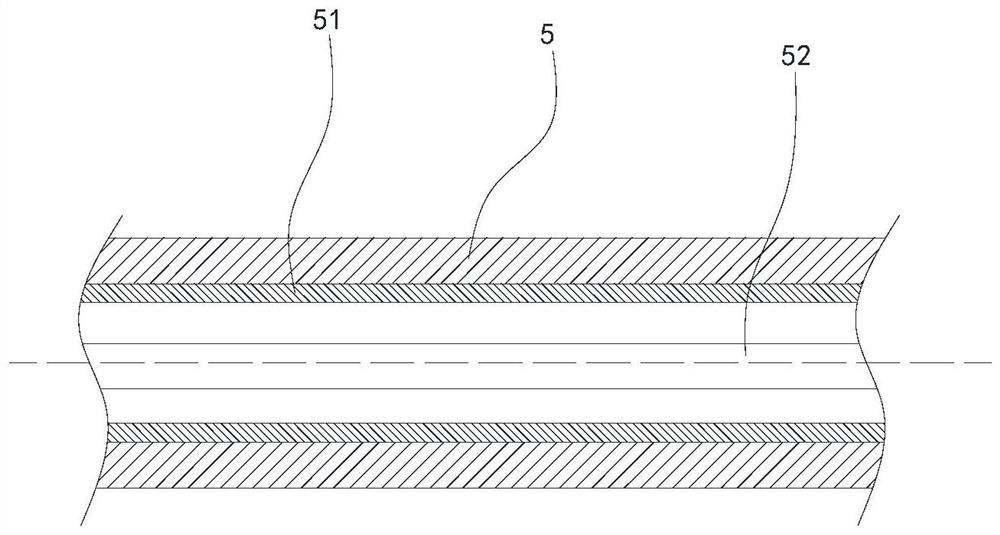

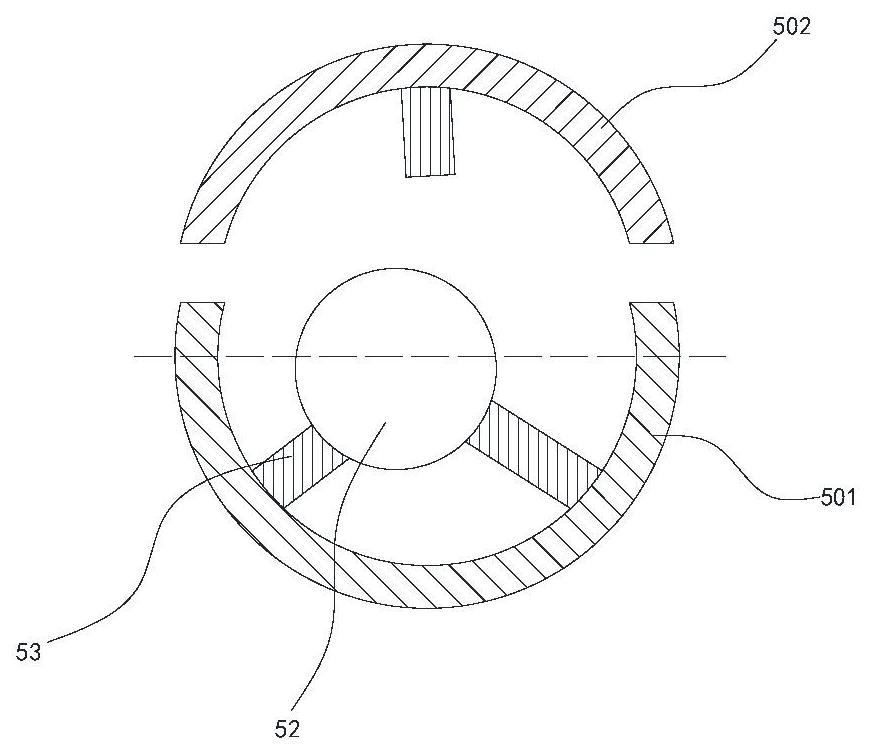

Magnetic light-enzyme composite catalyst and preparation method thereof

InactiveCN102728410BAchieve deliverySteps to lift the transfer rate limitOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic oxidationSuperparamagnetism

The invention relates to a magnetic light-enzyme composite catalyst and a preparation method thereof. The magnetic light-enzyme composite catalyst is laccase immobilized on magnetic nano TiO2 processed by surface functionalization, particularly laccase immobilized on magnetic nano TiO2 particles modified by copper ion chelating. According to the invention, the magnetic light-enzyme composite catalyst provided by the invention realizes the transmission of electrons between laccase and TiO2 in the catalytic oxidation process, solves the problems of slow speed of receiving electrons by laccase from the substrate and slow combination between photoinduced electrons and O2; by using the synergism of enzyme catalysis and photocatalysis to raise catalytic oxidation efficiency, the oxidation of substrates with high oxidation-reduction potential and macromolecule substrates can be realized; the catalyst has superparamagnetism, can be conveniently and effectively controlled and separated under the effect of external magnetic field, the preparation process is simple, and the catalyst is suitable for large scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com