Nano-electromechanical structure and method for the production thereof

A mechanical and microelectronic technology, applied in the direction of nanostructure manufacturing, microelectronic microstructure devices, nanotechnology, etc., can solve problems such as aggravation, unresolved devices, and reduced time stability of memory components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

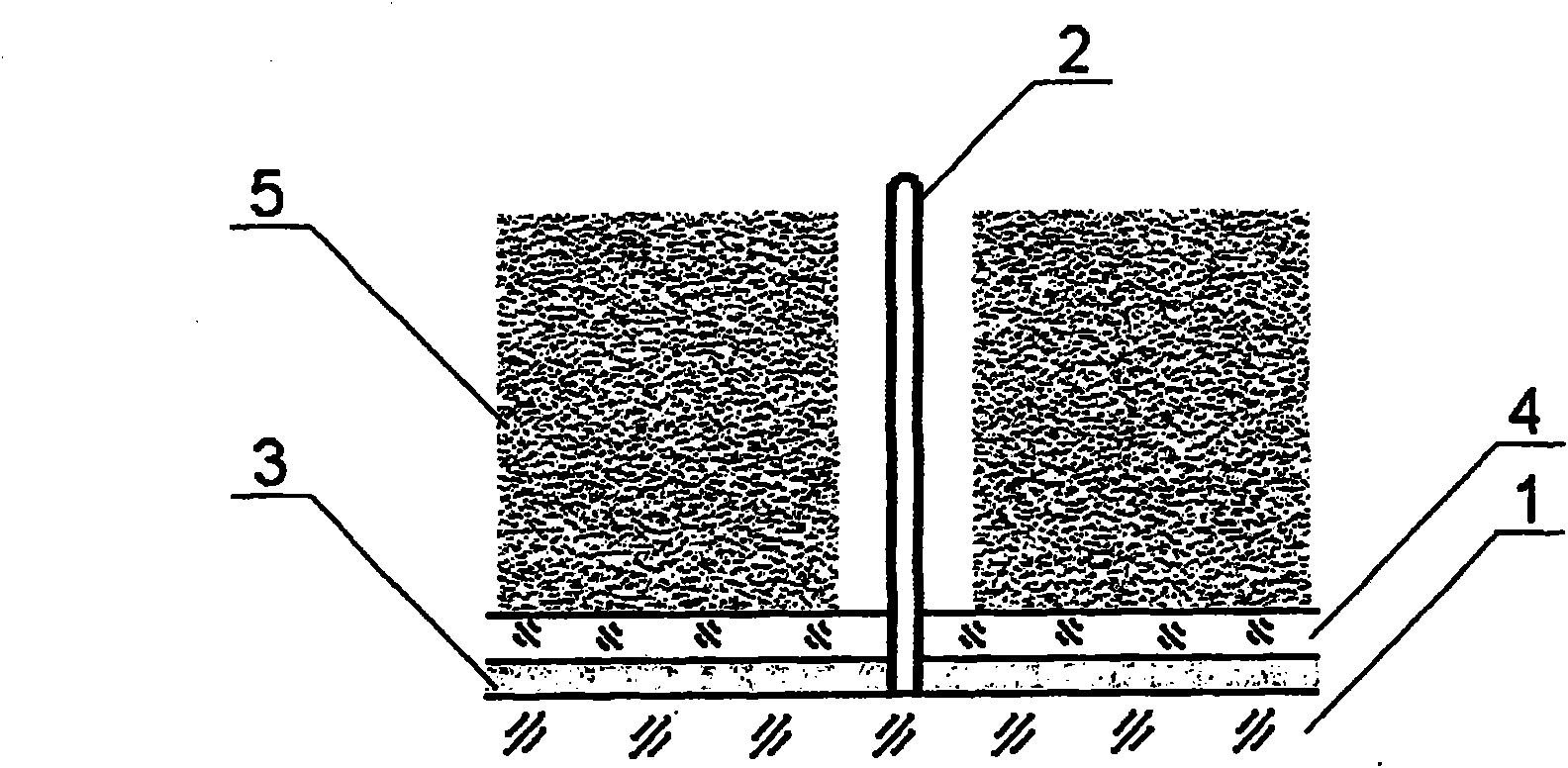

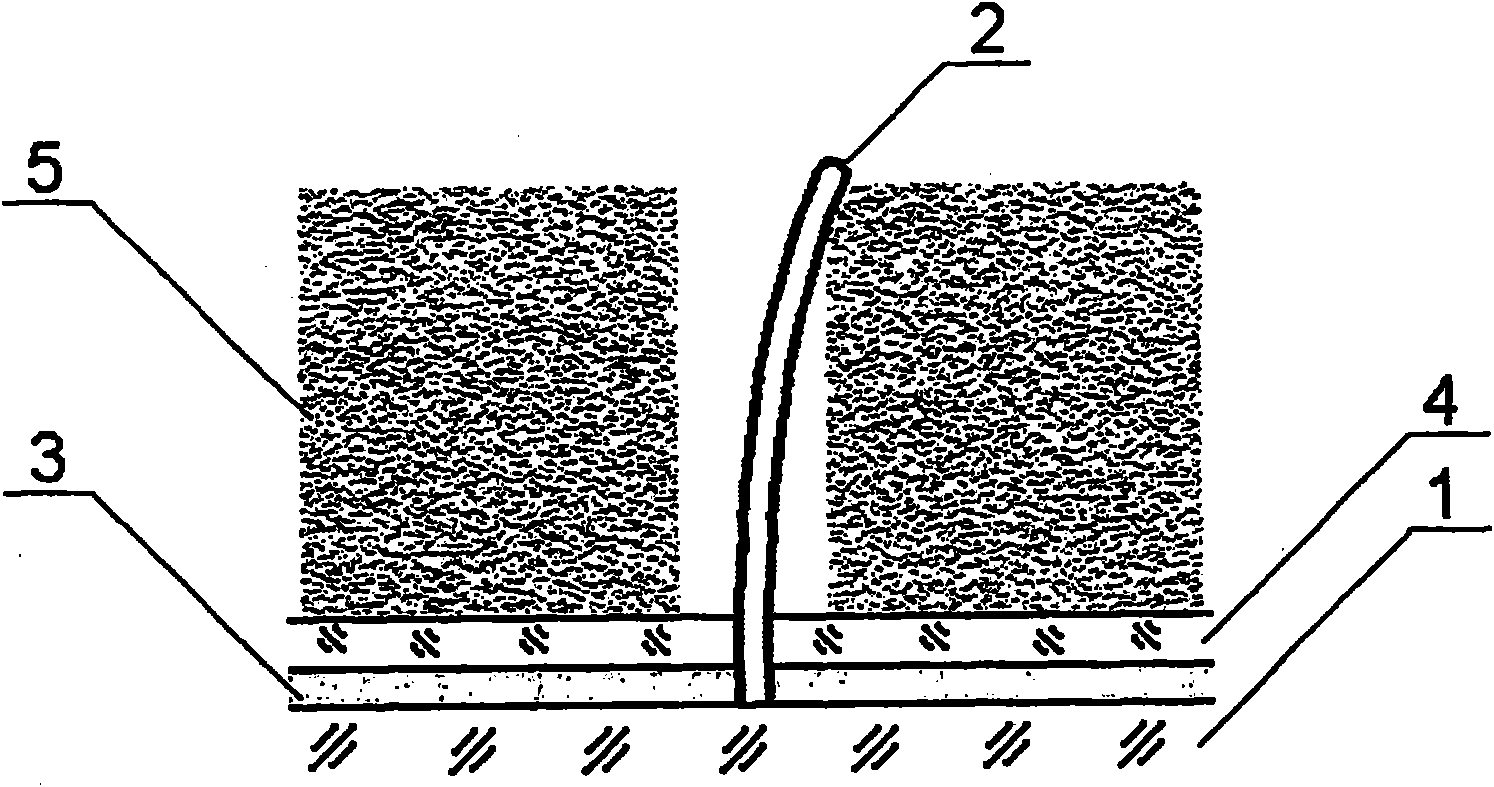

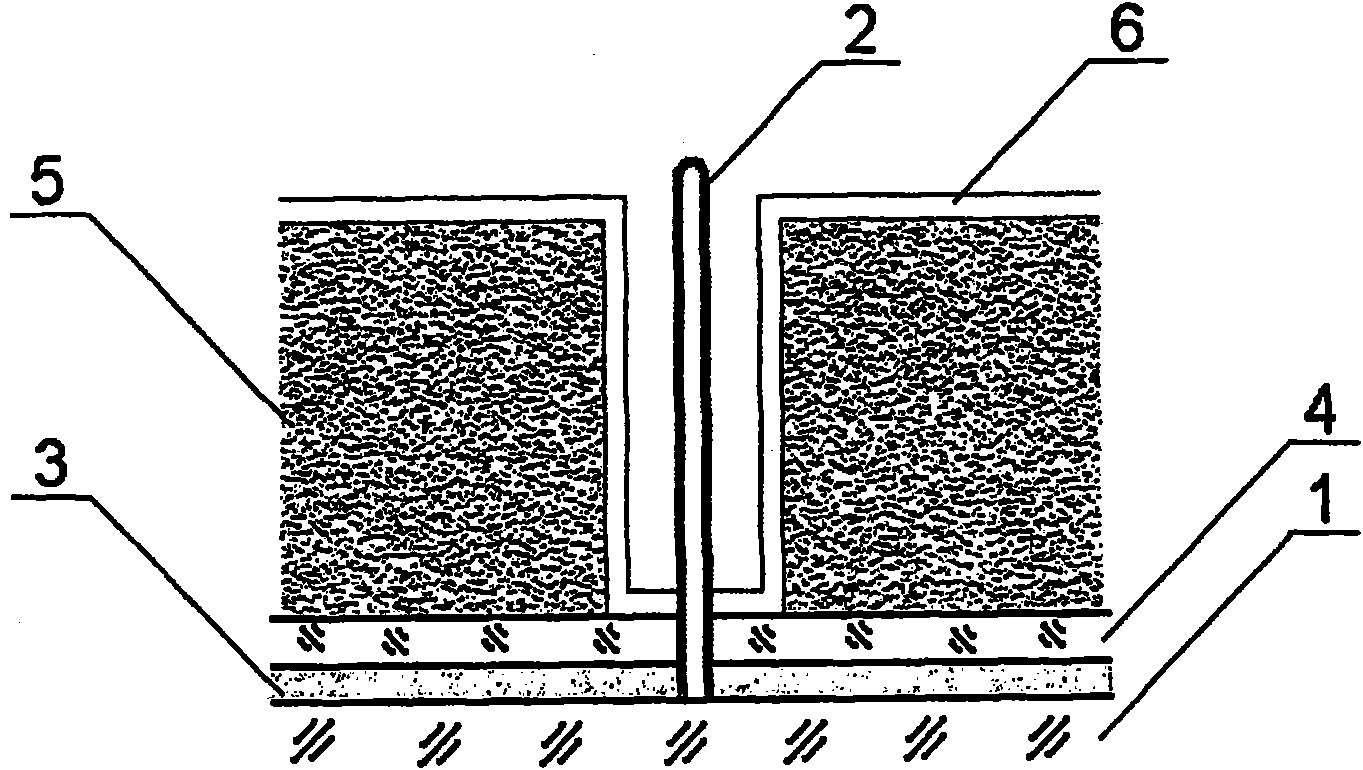

[0107] By using the sol technique, it is possible to build on a dielectric substrate 1( Figure 6) formed on the surface of nickel nanoparticles. The process of producing carbon nanotubes in an electric field is accomplished by catalytic cracking of vapors of carbon-carrying gases such as butane-propane mixtures. As a result of the process described, a large number of vertically oriented carbon nanotubes 2 is produced. The metal layer 3 (eg tantalum layer) is applied by laser ablation or sputtering. The layer performs the function of the input electrode, which also provides additional support for the nanotubes in vertical position. A dielectric layer 4 (eg aluminum oxide layer) is applied by magnetron sputtering. The amorphous carbon layer 5 is applied by sputtering, said layer performing the function of the output electrode. The electrical conductivity of the amorphous carbon layer 5 is increased by means of thermal annealing. A voltage difference of at least 3 V is appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com